Recycled PET Composites Reinforced with Stainless Steel Lattice Structures Made by AM

Abstract

:1. Introduction

2. Materials and Methods

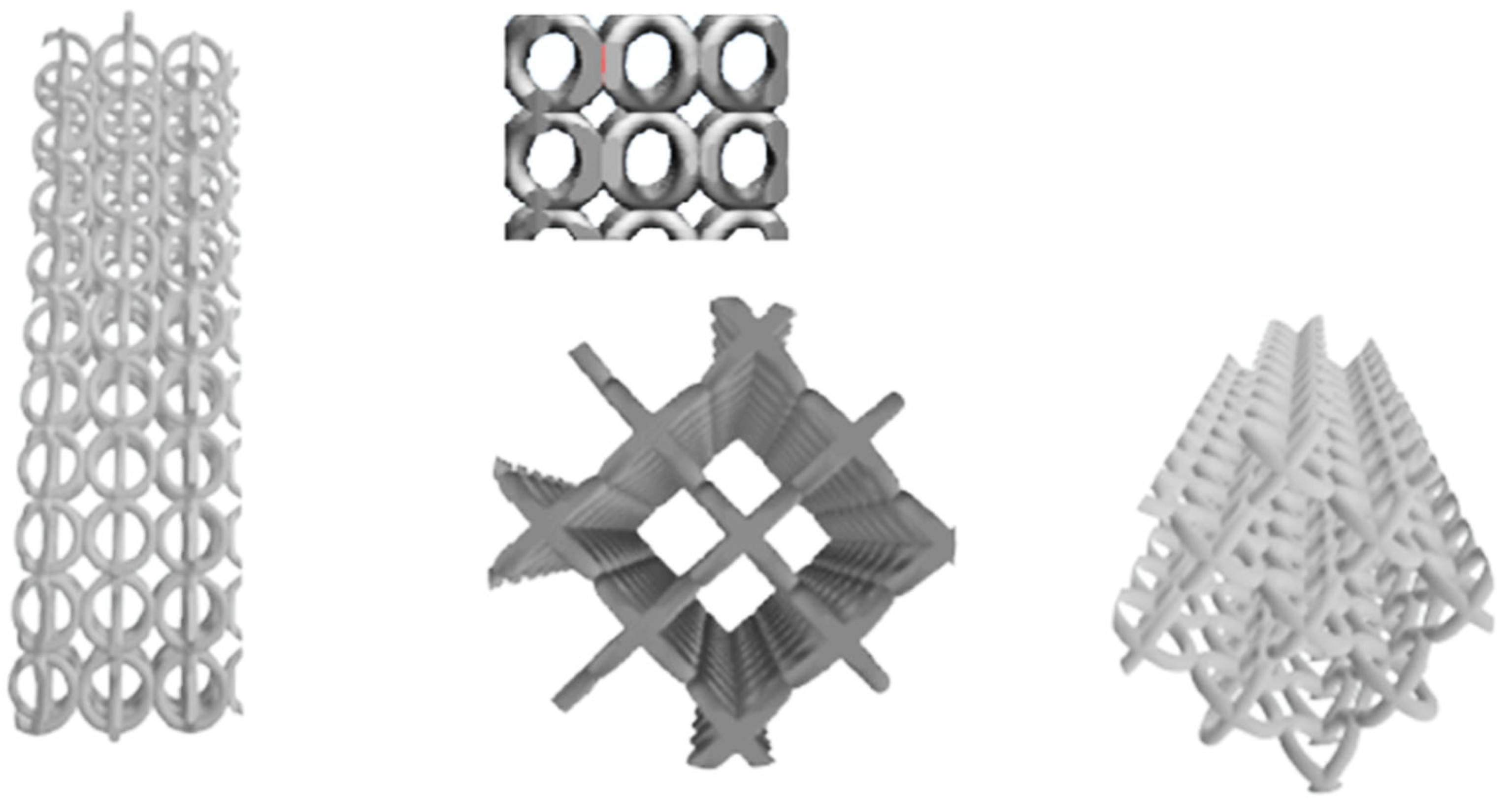

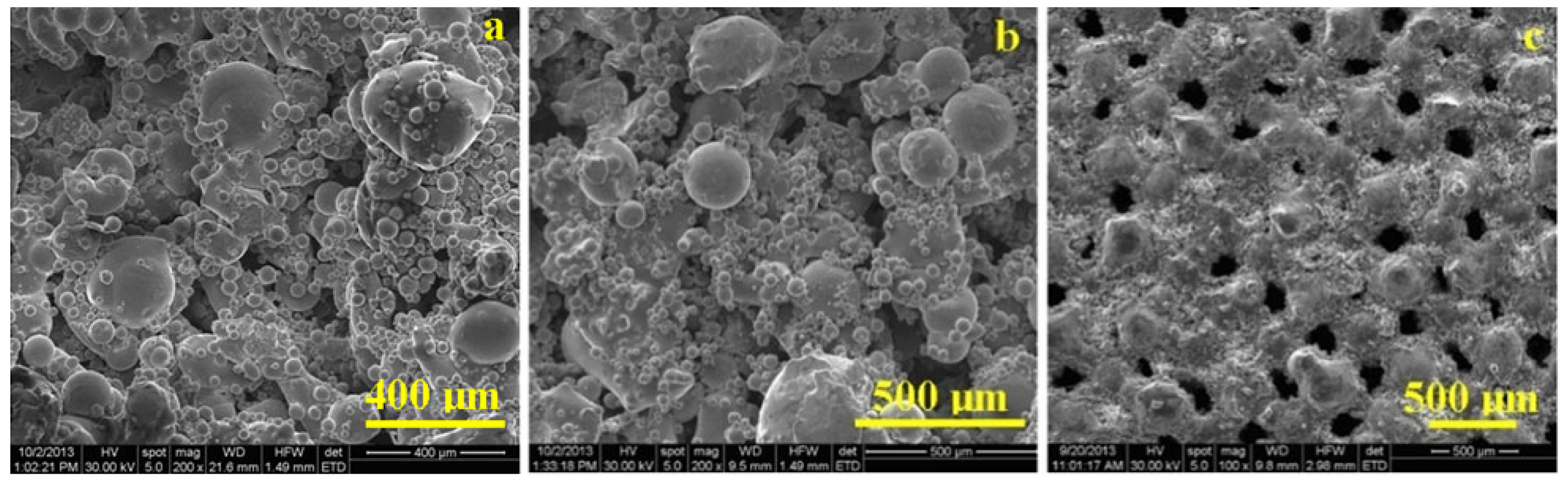

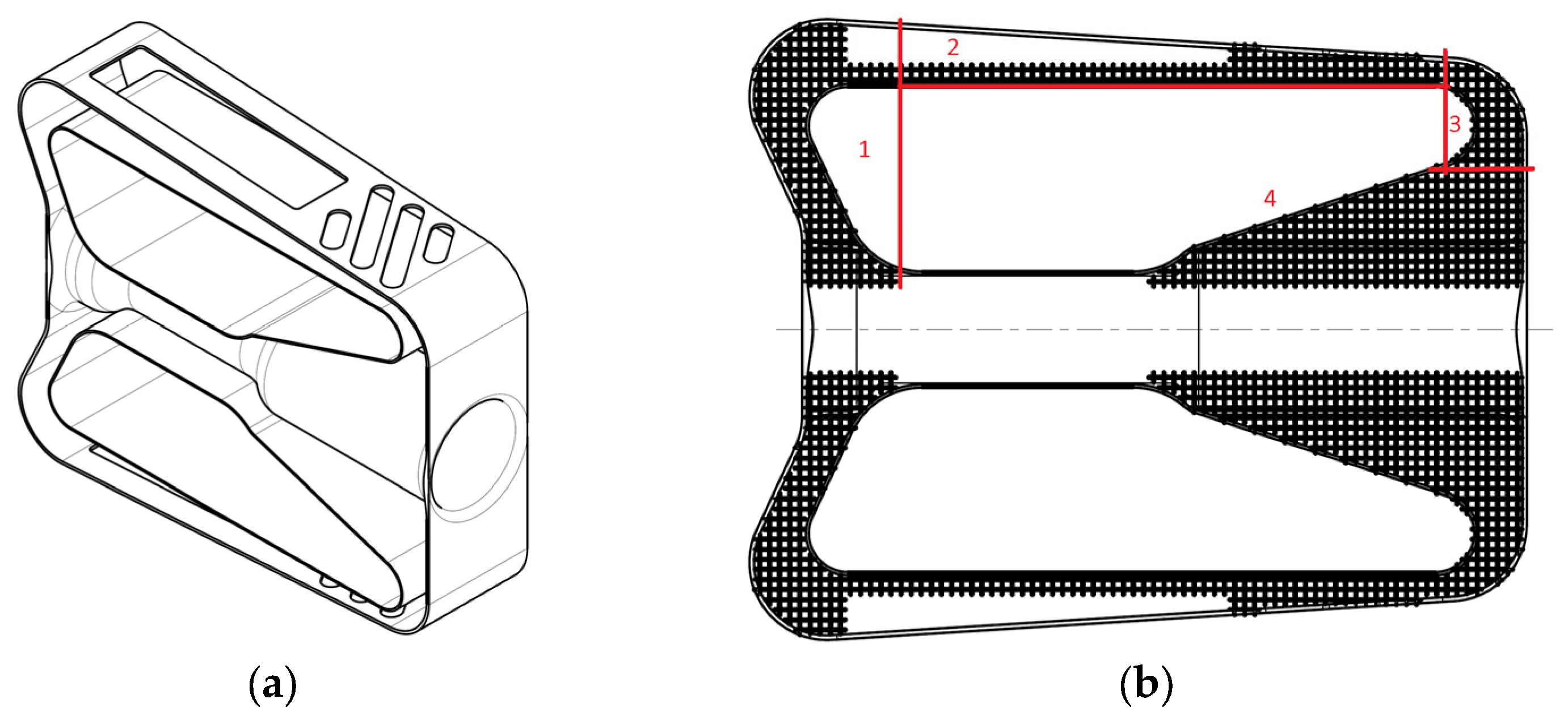

2.1. Lattice Structures’ Design and Manufacturing

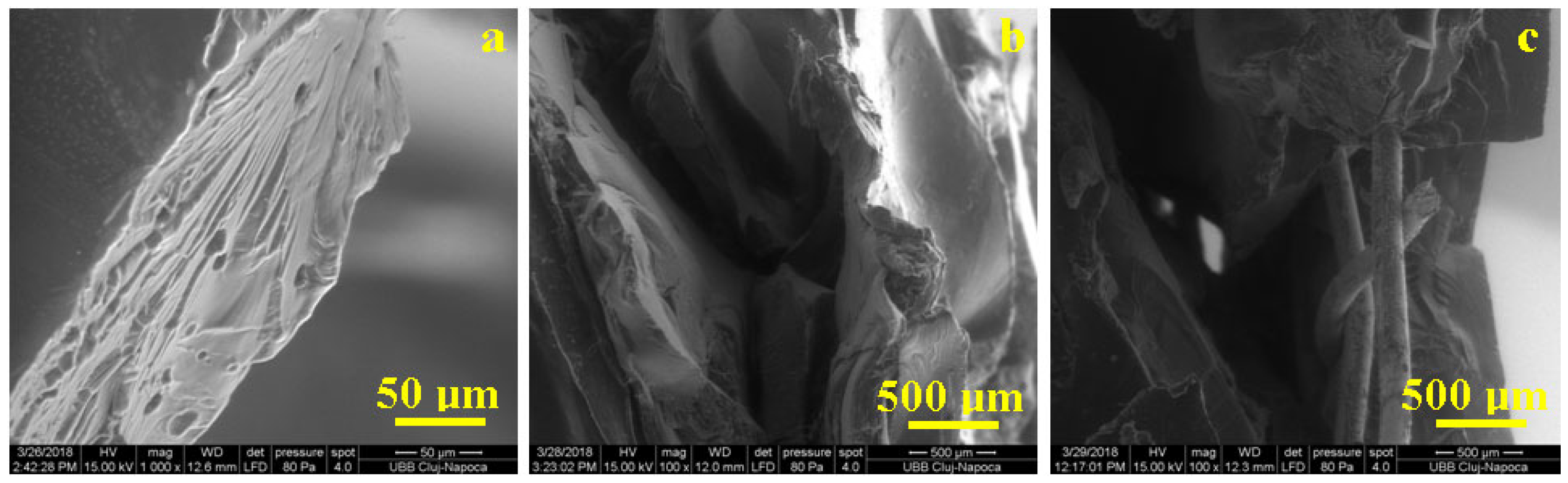

2.2. Composite Samples’ Preparation

2.3. Investigation Methods

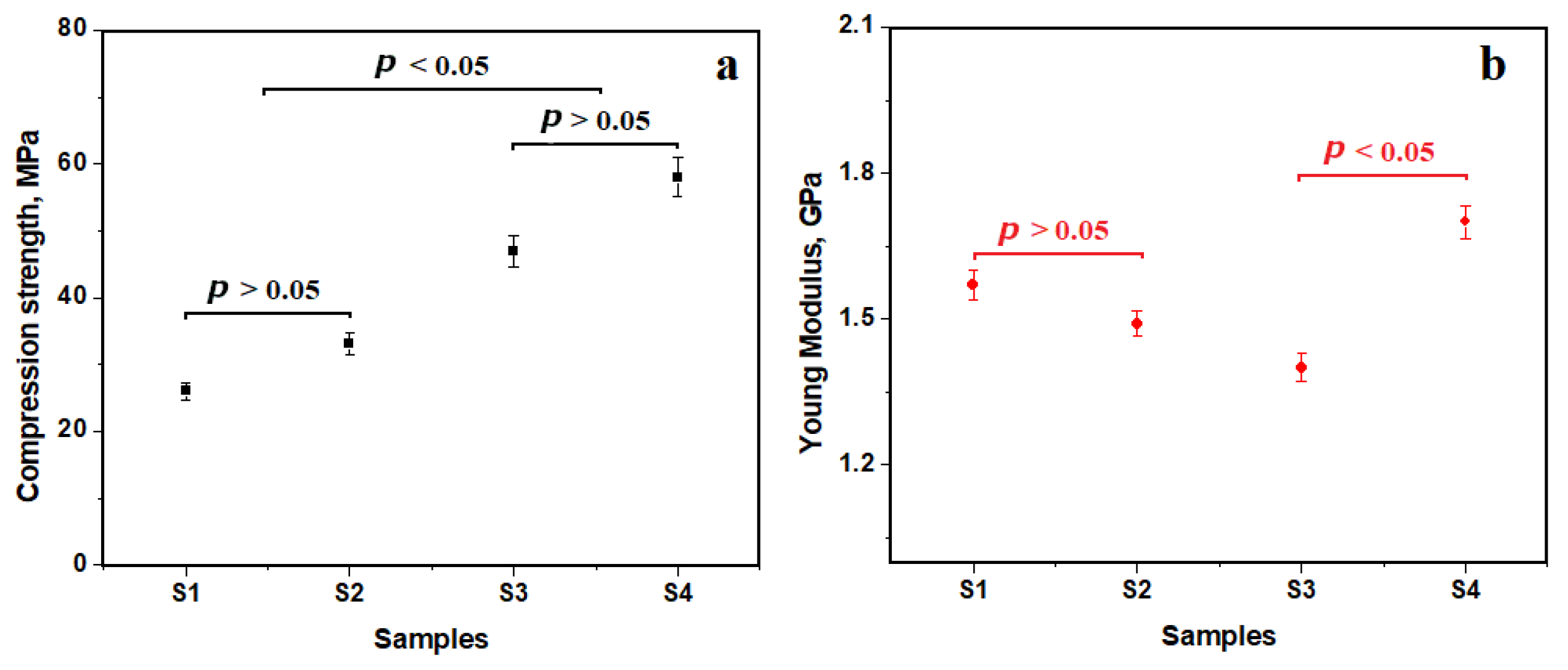

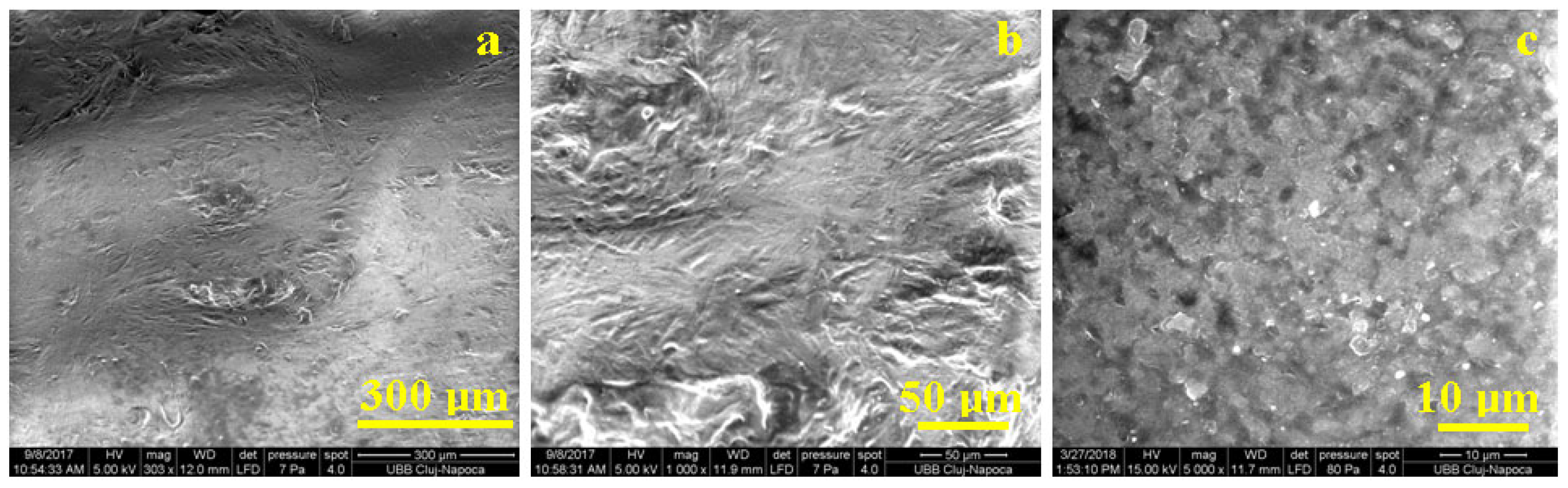

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Setter, R.; Hafenecker, J.; Rothfelder, R.; Kopp, S.-P.; Roth, S.; Schmidt, M.; Merklein, M.; Wudy, K. Innovative Process Strategies in Powder-Based Multi-Material Additive Manufacturing. J. Manuf. Mater. Process. 2023, 7, 133. [Google Scholar] [CrossRef]

- Seok, W.; Jeon, E.; Kim, Y. Effects of Annealing for Strength Enhancement of FDM 3D-Printed ABS Reinforced with Recycled Carbon Fiber. Polymers 2023, 15, 3110. [Google Scholar] [CrossRef] [PubMed]

- Basar, O.; Veliyath, V.P.; Tarak, F.; Sabet, E. A Systematic Study on Impact of Binder Formulation on Green Body Strength of Vat-Photopolymerisation 3D Printed Silica Ceramics Used in Investment Casting. Polymers 2023, 15, 3141. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Ma, M.; Chang, Z.; Yan, P.; Li, F. Advances in crack formation mechanism and inhibition strategy for ceramic additive manufacturing. J. Eur. Ceram. Soc. 2023, 43, 5078–5098. [Google Scholar] [CrossRef]

- Liu, L.; Xu, W.; Zhao, Y.; Lin, Z.; Liu, Z.; Dong, Y.; Dong, C. Tailoring the microstructure and mechanical properties of wire and arc additive manufactured Al–Mg alloy via interlayer friction stir processing. J. Mater. Res. Technol. 2023, 25, 1055–1068. [Google Scholar] [CrossRef]

- Thoma, D.J.; Spethson, J.T.; Francis, C.S.; Voyles, P.M.; Perepezko, J.H. High-Throughput Synthesis and Characterization Screening of Mg-Cu-Y Metallic Glass. Metals 2023, 13, 1317. [Google Scholar] [CrossRef]

- Tofail, S.A.M.; Koumoulos, E.P.; Bandyopadhyay, A.; Bose, S.; O’Donoghue, L.; Charitidis, C. Additive manufacturing: Scientific and technological challenges, market uptake and opportunities. Mater. Today 2018, 21, 22–37. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part. B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Yuan, L.; Ding, S.; Wen, C. Additive manufacturing technology for porous metal implant applications and triple minimal surface structures: A review. Bioact. Mater. 2019, 4, 56–70. [Google Scholar] [CrossRef]

- Obaton, A.-F.; Fain, J.; Meinel, D.; Tsamos, A.; Léonard, F.; Lécuelle, B.; Djemaï, M. In Vivo Bone Progression in and around Lattice Implants Additively Manufactured with a New Titanium Alloy. Appl. Sci. 2023, 13, 7282. [Google Scholar] [CrossRef]

- He, G.; Peng, X.; Zhou, H.; Huang, G.; Xie, Y.; He, Y.; Liu, H.; Huang, K. Superior Mechanical Properties of Invar36 Alloy Lattices Structures Manufactured by Laser Powder Bed Fusion. Materials 2023, 16, 4433. [Google Scholar] [CrossRef] [PubMed]

- Mager, V.; Balc, N.; Leordean, D.; Dudescu, M.C.; Fockele, M. Research on Producing Complex Metal Parts with Lattice Structure, by Selective Laser Melting. Appl. Mech. Mater. 2013, 371, 280–284. [Google Scholar] [CrossRef]

- Alabi, O.A.; Ologbonjaye, K.; Awosolu, O.; Alalade, O. Public and environmental health effects of plastic wastes disposal: A review. J. Toxicol. Risk Assess. 2019, 5, 021. [Google Scholar] [CrossRef]

- Reis, J.; Chianelli-Junior, R.; Cardoso, J.; Marinho, F. Effect of recycled PET in the fracture mechanics of polymer mortar. Constr. Build. Mater. 2011, 25, 2799–2804. [Google Scholar] [CrossRef]

- Belioka, M.-P.; Markozanne, G.; Chrissopoulou, K.; Achilias, D.S. Advanced Plastic Waste Recycling—The Effect of Clay on the Morphological and Thermal Behavior of Recycled PET/PLA Sustainable Blends. Polymers 2023, 15, 3145. [Google Scholar] [CrossRef]

- Andrzejewski, J. The Use of Recycled Polymers for the Preparation of Self-Reinforced Composites by the Overmolding Technique: Materials Performance Evaluation. Sustainability 2023, 15, 11318. [Google Scholar] [CrossRef]

- Hu, Z. Biomimetic Design and Topology Optimization of Discontinuous Carbon Fiber-Reinforced Composite Lattice Structures. Biomimetics 2023, 8, 148. [Google Scholar] [CrossRef]

- Saleh, M.; Anwar, S.; Al-Ahmari, A.M.; AlFaify, A.Y. Prediction of Mechanical Properties for Carbon fiber/PLA Composite Lattice Structures Using Mathematical and ANFIS Models. Polymers 2023, 15, 1720. [Google Scholar] [CrossRef] [PubMed]

- Cao, X.; Li, X.; Tang, B. Test and Numerical Simulation Investigation on Seismic Performance of Different Types of Expansive Polystyrene Granule Cement Latticed Concrete Walls. Materials 2021, 14, 3082. [Google Scholar] [CrossRef] [PubMed]

- Tang, B.Z.; Xiong, L.H.; Li, X.J.; Chen, S.; Chen, H.P.; Huang, D.W. Experimental study on seismic behavior of full-scale reinforced concrete frame with EPSC latticed concrete infill wall. J. Build. Struct. 2020, 41, 13–23. [Google Scholar]

- Marković, M.-P.; Cingesar, I.K.; Keran, L.; Prlić, D.; Grčić, I.; Vrsaljko, D. Thermal and Mechanical Characterization of the New Functional Composites Used for 3D Printing of Static Mixers. Materials 2022, 15, 6713. [Google Scholar] [CrossRef]

- Candal, M.V.; Safari, M.; Fernández, M.; Otaegi, I.; Múgica, A.; Zubitur, M.; Gerrica-echevarria, G.; Sebastián, V.; Irusta, S.; Loaeza, D.; et al. Structure and Properties of Reactively Extruded Opaque Post-Consumer Recycled PET. Polymers 2021, 13, 3531. [Google Scholar] [CrossRef]

- Wu, J.; Ma, J.; Niu, X.; Shen, M.; Wei, T.; Li, W. Numerical Simulation of Selective Laser Melting of 304 L Stainless Steel. Metals 2023, 13, 1212. [Google Scholar] [CrossRef]

- Wang, W.-Y.; Godfrey, A.; Liu, W. Effect of Heat Treatment on Microstructural Evolution in Additively Manufactured 316L Stainless Steel. Metals 2023, 13, 1062. [Google Scholar] [CrossRef]

- Liu, J.; Yang, H.; Meng, L.; Liu, D.; Xu, T.; Xu, D.; Shao, X.; Shao, C.; Li, S.; Zhang, P.; et al. Significance of Melt Pool Structure on the Hydrogen Embrittlement Behavior of a Selective Laser-Melted 316L Austenitic Stainless Steel. Materials 2023, 16, 1741. [Google Scholar] [CrossRef] [PubMed]

- Xu, S.; Ma, H.; Song, X.; Zhang, S.; Hu, X.; Meng, Z. Finite Element Simulation of Stainless Steel Porous Scaffolds for Selective Laser Melting (SLM) and Its Experimental Investigation. Coatings 2023, 13, 134. [Google Scholar] [CrossRef]

- Ciobanu, R.C.; Aradoaei, M.; Caramitu, A.R.; Ion, I.; Schreiner, C.M.; Tsakiris, V.; Marinescu, V.; Hitruc, E.G.; Aflori, M. Special Packaging Materials from Recycled PET and Metallic Nano-Powders. Polymers 2023, 15, 3161. [Google Scholar] [CrossRef] [PubMed]

- Almahri, G.; Madi, K.; Alkaabi, F.; Badran, Y.; Shehadeh, K.; ElHassan, A.; Ahmed, W.; Alzahmi, S. Characterization of Hybrid FRP Composite Produced from Recycled PET and CFRP. Polymers 2023, 15, 2946. [Google Scholar] [CrossRef] [PubMed]

- Marotta, A.; Causa, A.; Salzano de Luna, M.; Ambrogi, V.; Filippone, G. Tuning the Morphology of HDPE/PP/PET Ternary Blends by Nanoparticles: A Simple Way to Improve the Performance of Mixed Recycled Plastics. Polymers 2022, 14, 5390. [Google Scholar] [CrossRef] [PubMed]

- Rubio Arias, J.J.; Thielemans, W. Efficient Depolymerization of Glass Fiber Reinforced PET Composites. Polymers 2022, 14, 5171. [Google Scholar] [CrossRef] [PubMed]

- Ortego, A.; Russo, S.; Iglesias-Émbil, M.; Valero, A.; Magdalena, R. Exergy Assessment of Plastic Car Parts. Vehicles 2023, 5, 1211–1226. [Google Scholar] [CrossRef]

- Okoruwa, L.; Sameni, F.; Borisov, P.; Sabet, E. 3D Printing Soft Magnet: Binder Study for Vat Photopolymerization of Ferrosilicon Magnetic Composites. Polymers 2023, 15, 3482. [Google Scholar] [CrossRef] [PubMed]

- Bertagna, S.; Braidotti, L.; Laurini, E.; Marinò, A.; Pricl, S.; Bucci, V. Thermoplastic Materials for the Metal Replacement of Non-Structural Components in Marine Engines. Appl. Sci. 2022, 12, 8766. [Google Scholar] [CrossRef]

- Matúš, M.; Križan, P.; Kijovský, J.; Strigáč, S.; Beniak, J.; Šooš, Ľ. Implementation of Finite Element Method Simulation in Control of Additive Manufacturing to Increase Component Strength and Productivity. Symmetry 2023, 15, 2036. [Google Scholar] [CrossRef]

- Bere, P.; Dudescu, M.; Neamțu, C.; Cocian, C. Design, Manufacturing and Test of CFRP Front Hood Concepts for a Light-Weight Vehicle. Polymers 2021, 13, 1374. [Google Scholar] [CrossRef]

| Chemical Element | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| Wt.% | 0.03 | 2 | 0.75 | 0.045 | 0.03 | 18 | 3 | 14 | 0.1 | 66 |

| Samples | Composition |

|---|---|

| S1 | Recycled PET |

| S2 | Recycled PET + 5.5% PEG + 8% TiO2 |

| S3 | SLM cylinder |

| S4 | SLM cylinder filled with Recycled PET + 5.5% PEG + 8% TiO2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rusu, M.; Balc, N.; Moldovan, M.; Cuc, S.; Petean, I.; Cosma, C.; Leordean, D. Recycled PET Composites Reinforced with Stainless Steel Lattice Structures Made by AM. Polymers 2023, 15, 4591. https://doi.org/10.3390/polym15234591

Rusu M, Balc N, Moldovan M, Cuc S, Petean I, Cosma C, Leordean D. Recycled PET Composites Reinforced with Stainless Steel Lattice Structures Made by AM. Polymers. 2023; 15(23):4591. https://doi.org/10.3390/polym15234591

Chicago/Turabian StyleRusu, Mircea, Nicolae Balc, Marioara Moldovan, Stanca Cuc, Ioan Petean, Cosmin Cosma, and Dan Leordean. 2023. "Recycled PET Composites Reinforced with Stainless Steel Lattice Structures Made by AM" Polymers 15, no. 23: 4591. https://doi.org/10.3390/polym15234591

APA StyleRusu, M., Balc, N., Moldovan, M., Cuc, S., Petean, I., Cosma, C., & Leordean, D. (2023). Recycled PET Composites Reinforced with Stainless Steel Lattice Structures Made by AM. Polymers, 15(23), 4591. https://doi.org/10.3390/polym15234591