Improved Heat Dissipation of NR/SBR-Based Tire Tread Compounds via Hybrid Fillers of Multi-Walled Carbon Nanotube and Carbon Black

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

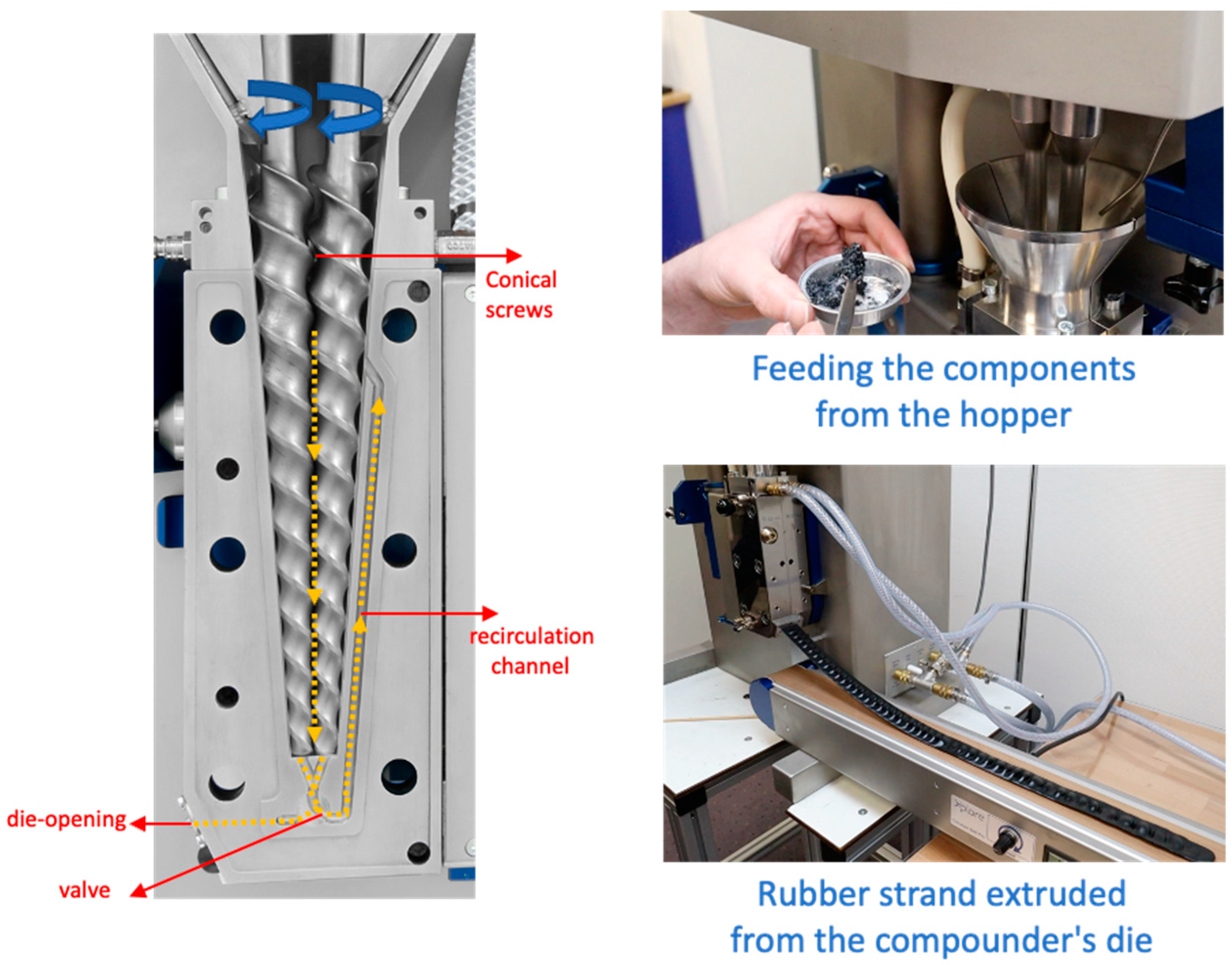

2.2. Processing

2.3. Characterization

3. Results and Discussions

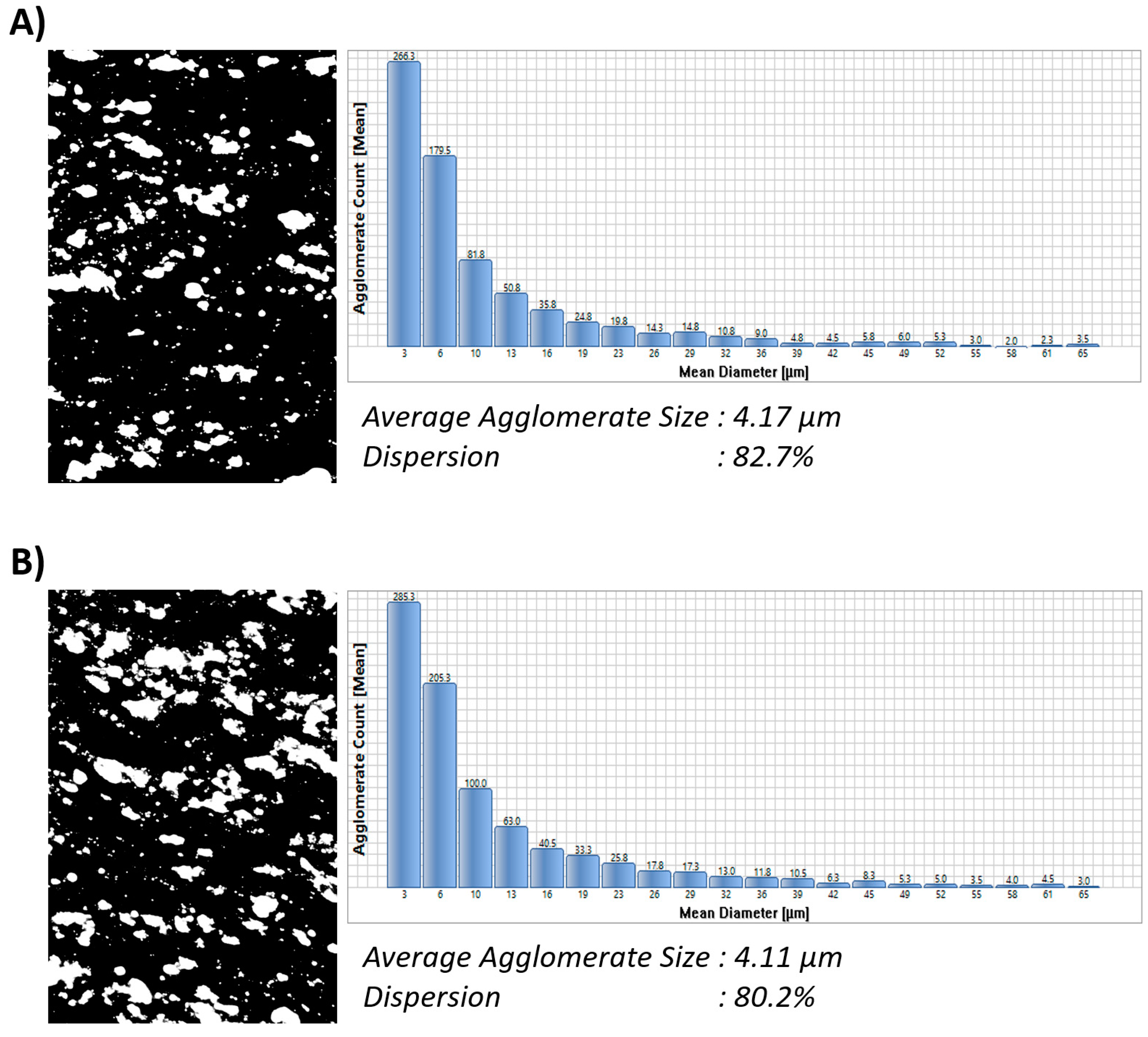

3.1. Morphological Analyses of Samples via Scanning Electron Microscopy (SEM) and DisperGrader

3.2. Curing and Rheological Properties of Compounds

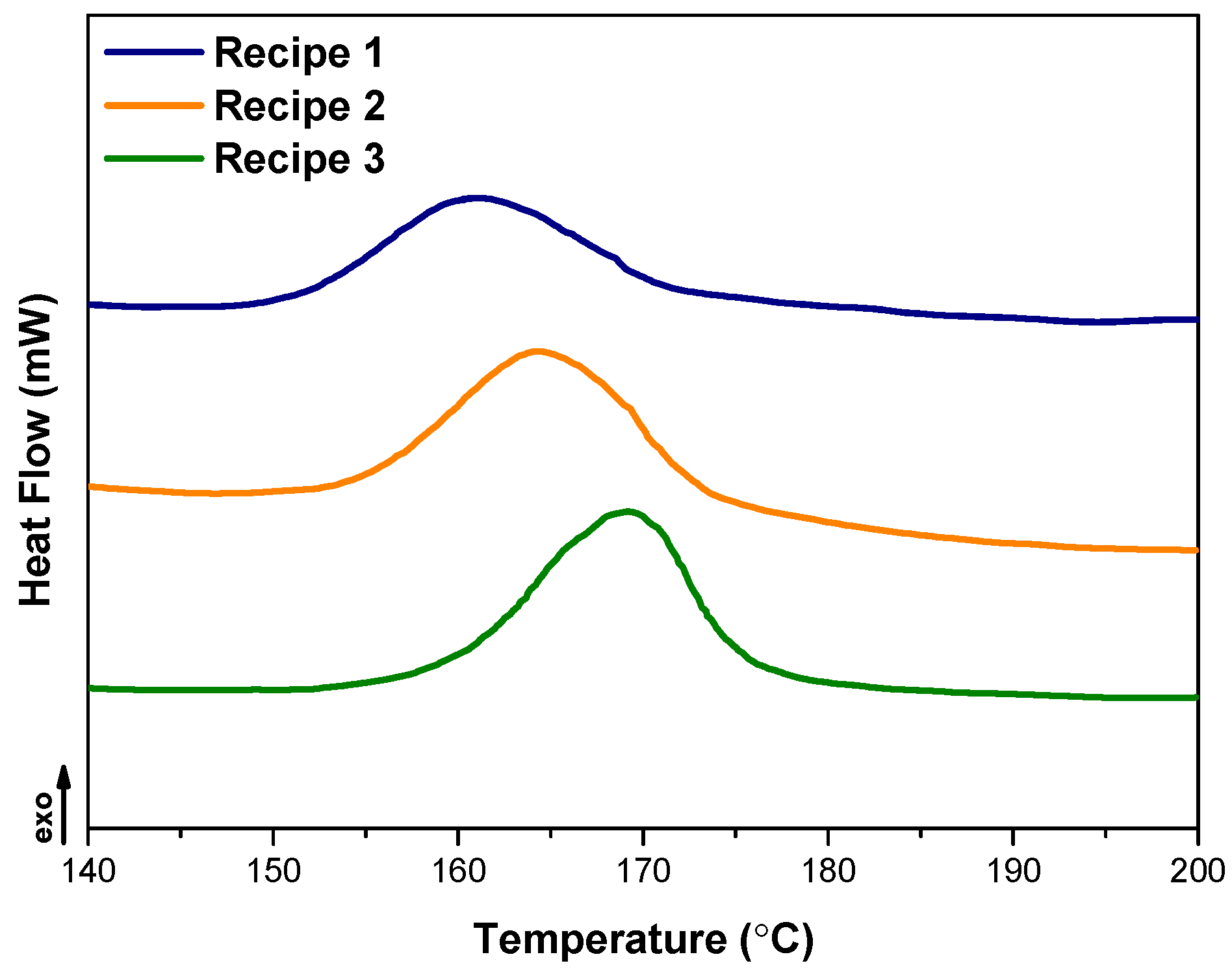

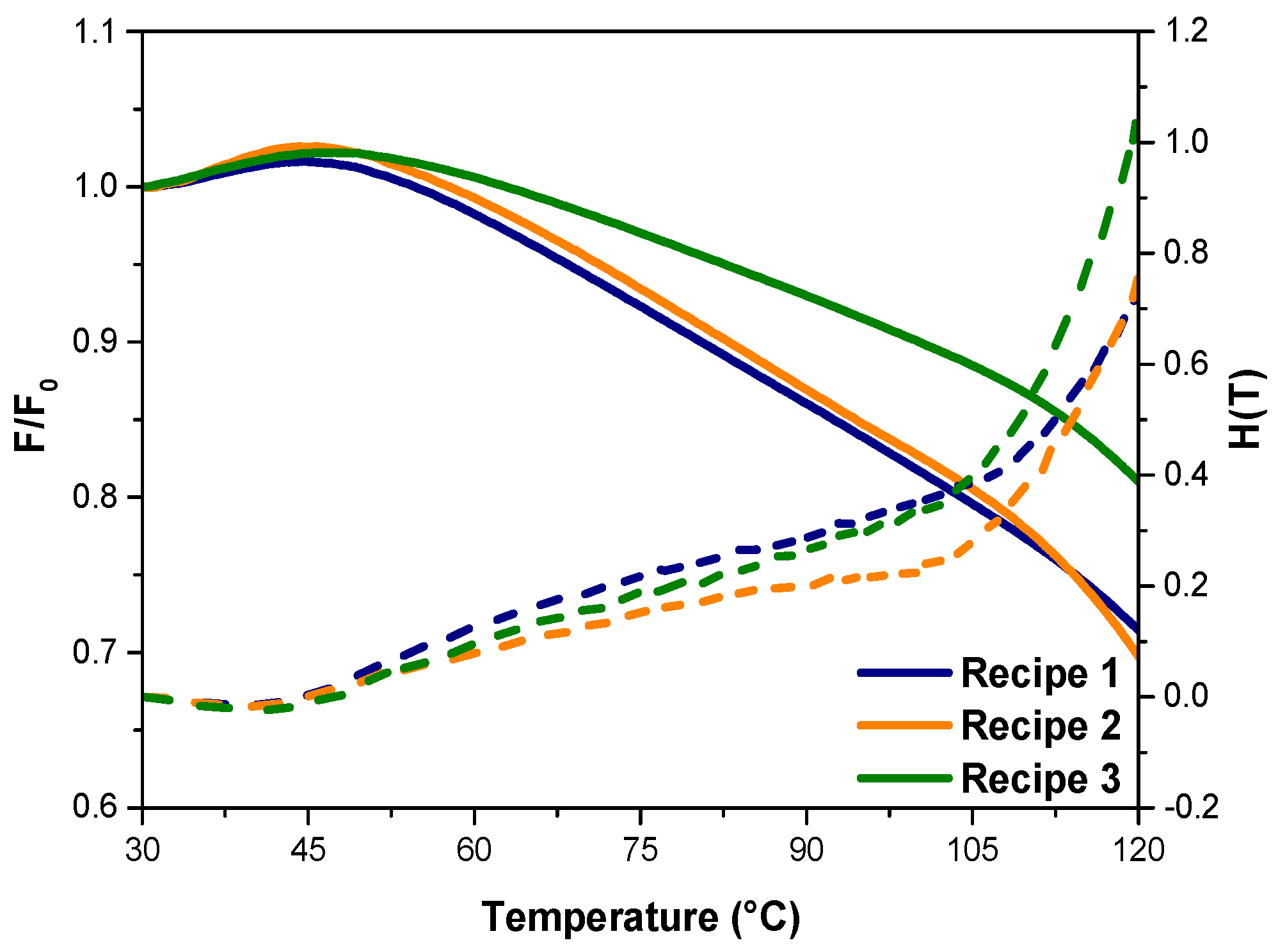

3.3. Cross-Link Density Measurements and Stress Relaxation Behaviors of Samples

3.4. Mechanical Properties

3.5. TGA Results

3.6. Electrical and Thermal Conductivity Test Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Roberts, A.D. Natural Rubber Science and Technology; Oxford University Press: Oxford, UK, 1988; ISBN 0198552254. [Google Scholar]

- Wei, L.; Fu, X.; Luo, M.; Xie, Z.; Huang, C.; Zhou, J.; Zhu, Y.; Huang, G.; Wu, J. Synergistic Effect of CB and GO/CNT Hybrid Fillers on the Mechanical Properties and Fatigue Behavior of NR Composites. RSC Adv. 2018, 8, 10573–10581. [Google Scholar] [CrossRef]

- Trabelsi, S.; Albouy, P.A.; Rault, J. Stress-Induced Crystallization around a Crack Tip in Natural Rubber. Macromolecules 2002, 35, 10054–10061. [Google Scholar] [CrossRef]

- Ismail, M.N.; El-Sabbagh, S.H.; Yehia, A.A. Fatigue and Mechanical Properties of NR/SBR and NR/NBR Blend Vulcanizates. J. Elastomers Plast. 1999, 31, 255–270. [Google Scholar] [CrossRef]

- Joseph, R.; George, K.E.; Francis, D.J. Studies on the Cure Characteristics and Vulcanizate Properties of 50/50 NR/SBR Blend. J. Appl. Polym. Sci. 1988, 35, 1003–1017. [Google Scholar] [CrossRef]

- Parameswaran, S.K.; Bhattacharya, S.; Mukhopadhyay, R.; Naskar, K.; Bhowmick, A.K. Excavating the Unique Synergism of Nanofibers and Carbon Black in Natural Rubber Based Tire Tread Composition. J. Appl. Polym. Sci. 2021, 138, 49682. [Google Scholar] [CrossRef]

- Gumede, J.I.; Carson, J.; Hlangothi, S.P.; Bolo, L.L. Effect of Single-Walled Carbon Nanotubes on the Cure and Mechanical Properties of Reclaimed Rubber/Natural Rubber Blends. Mater. Today Commun. 2020, 23, 100852. [Google Scholar] [CrossRef]

- Farahani, T.D.; Bakhshandeh, G.R.; Abtahi, M. Mechanical and Viscoelastic Properties of Natural Rubber/ Reclaimed Rubber Blends. Polym. Bull. 2006, 56, 495–505. [Google Scholar] [CrossRef]

- Boonmahitthisud, A.; Chuayjuljit, S. NR/XSBR Nanocomposites with Carbon Black and Carbon Nanotube Prepared by Latex Compounding. J. Met. Mater. Miner. 2012, 22, 77–85. [Google Scholar]

- Dong, B.; Liu, C.; Lu, Y.; Wu, Y. Synergistic Effects of Carbon Nanotubes and Carbon Black on the Fracture and Fatigue Resistance of Natural Rubber Composites. J. Appl. Polym. Sci. 2015, 132, 42075. [Google Scholar] [CrossRef]

- Chen, L.; Yu, G.; Zhuang, T.; Pang, X. Reinforcing Effects of Carbon Nanotubes on Graphene/Trans-1,4-Polyisoprene/Natural Rubber Composites. J. Polym. Res. 2022, 29, 387. [Google Scholar] [CrossRef]

- Sattayanurak, S.; Noordermeer, J.W.M.; Sahakaro, K.; Kaewsakul, W.; Dierkes, W.K.; Blume, A. Silica-Reinforced Natural Rubber: Synergistic Effects by Addition of Small Amounts of Secondary Fillers to Silica-Reinforced Natural Rubber Tire Tread Compounds. Adv. Mater. Sci. Eng. 2019, 2019, 5891051. [Google Scholar] [CrossRef]

- Cao, L.; Sinha, T.K.; Tao, L.; Li, H.; Zong, C.; Kim, J.K. Synergistic Reinforcement of Silanized Silica-Graphene Oxide Hybrid in Natural Rubber for Tire-Tread Fabrication: A Latex Based Facile Approach. Compos. Part B Eng. 2019, 161, 667–676. [Google Scholar] [CrossRef]

- Kong, L.; Li, F.; Wang, F.; Miao, Y.; Huang, X.; Zhu, H.; Lu, Y. High-Performing Multi-Walled Carbon Nanotubes/Silica Nanocomposites for Elastomer Application. Compos. Sci. Technol. 2018, 162, 23–32. [Google Scholar] [CrossRef]

- Junkong, P.; Kueseng, P.; Wirasate, S.; Huynh, C.; Rattanasom, N. Cut Growth and Abrasion Behaviour, and Morphology of Natural Rubber Filled with MWCNT and MWCNT/Carbon Black. Polym. Test. 2015, 41, 172–183. [Google Scholar] [CrossRef]

- Kaushik, B.K.; Majumder, M.K. Carbon Nanotube: Properties and Applications. In Carbon Nanotube Based VLSI Interconnects: Analysis and Design; Kaushik, B.K., Majumder, M.K., Eds.; Springer: New Delhi, India, 2015; pp. 17–37. ISBN 9788132220466. [Google Scholar]

- Jogi, B.F.; Sawant, M.; Kulkarni, M.; Brahmankar, P.K. Dispersion and Performance Properties of Carbon Nanotubes (CNTs) Based Polymer Composites: A Review. J. Encapsulation Adsorpt. Sci. 2012, 2012, 69–78. [Google Scholar] [CrossRef]

- Kummerlowe, C.; Vennemann, N.; Pieper, S.; Siebert, A.; Nakaramontri, Y. Preparation and Properties of Carbon-Nanotube Composites with Natural Rubber and Epoxidized Natural Rubber. Polimery 2014, 59, 811–818. [Google Scholar] [CrossRef]

- Bernal-Ortega, P.; Bernal, M.M.; Blume, A.; González-Jiménez, A.; Posadas, P.; Navarro, R.; Valentín, J.L. Sulfur-Modified Carbon Nanotubes for the Development of Advanced Elastomeric Materials. Polymers 2021, 13, 821. [Google Scholar] [CrossRef]

- Bokobza, L. Natural Rubber Nanocomposites: A Review. Nanomaterials 2018, 9, 12. [Google Scholar] [CrossRef]

- Rafiee, R. Carbon Nanotube-Reinforced Polymers: From Nanoscale to Macroscale; Elsevier: Amsterdam, The Netherlands, 2018; ISBN 9780323482219. [Google Scholar]

- Sethulekshmi, A.S.; Saritha, A.; Joseph, K. A Comprehensive Review on the Recent Advancements in Natural Rubber Nanocomposites. Int. J. Biol. Macromol. 2022, 194, 819–842. [Google Scholar] [CrossRef]

- Fawaz, J.; Mittal, V. Synthesis of Polymer Nanocomposites: Review of Various Techniques. In Synthesis Techniques for Polymer Nanocomposites; Mittal, V., Ed.; John Wiley & Sons: Hoboken, NJ, USA, 2014; pp. 1–30. ISBN 9783527670307. [Google Scholar]

- Fakhru’l-Razi, A.; Atieh, M.A.; Girun, N.; Chuah, T.G.; El-Sadig, M.; Biak, D.R.A. Effect of Multi-Wall Carbon Nanotubes on the Mechanical Properties of Natural Rubber. Compos. Struct. 2006, 75, 496–500. [Google Scholar] [CrossRef]

- Ismail, H.; Ramly, F.; Othman, N. Multiwall Carbon Nanotube-Filled Natural Rubber: The Effects of Filler Loading and Mixing Method. Polym. Plast. Technol. Eng. 2010, 49, 260–266. [Google Scholar] [CrossRef]

- Huang, K.; Jiang, L.; Du, Y.; Wang, J.; Zheng, X.; Jiang, X.; Sui, Y.; Che, M.; Xu, Q.; Li, L.; et al. Multifunctional NR/MWCNTs Nanocomposites Constructed via Combining Volume Exclusion of SiO2 Microspheres with Interface Reinforcement of Tannic Acid. Eur. Polym. J. 2021, 151, 110424. [Google Scholar] [CrossRef]

- Malas, A. Rubber Nanocomposites with Graphene as the Nanofiller. In Progress in Rubber Nanocomposites; Thomas, S., Maria, H.J., Eds.; Woodhead Publishing: Cambridge, UK, 2017; pp. 179–229. ISBN 9780081004289. [Google Scholar]

- Guo, X.; Guo, S.; Liu, G.; Bai, L.; Liu, H.; Xu, Y.; Zhao, J.; Chai, H.; Jian, X.; Guo, L.; et al. Improving Dispersion of Carbon Nanotubes in Natural Rubber by Using Waterjet-Produced Rubber Powder as a Carrier. Polymers 2023, 15, 477. [Google Scholar] [CrossRef] [PubMed]

- Bian, H.; Xue, J.; Hao, G.; Hao, Y.; Xie, M.; Wang, C.; Wang, Z.; Zhu, L.; Xiao, Y. High Thermal Conductivity Graphene Oxide/Carbon Nanotubes/Butyl Rubber Composites Prepared by a Dry Ice Expansion Pre-Dispersion Flocculation Method. J. Appl. Polym. Sci. 2022, 139, 51897. [Google Scholar] [CrossRef]

- Anand, K.A.; Jose, T.S.; Alex, R.; Joseph, R. Natural Rubber-Carbon Nanotube Composites through Latex Compounding. Int. J. Polym. Mater. 2009, 59, 33–44. [Google Scholar] [CrossRef]

- Xiao, W.; Yu, S.; Cao, X.; Su, K.; Qu, Q.; Tan, Y.; Zhao, F.; Zhao, S.; Zhang, G.; Gao, A.; et al. High-Speed Shear Dispersion of MWCNTs Assisted by PVP in Water and Its Effective Combination with Wet-Mixing Technology for NR/MWCNTs Nanocomposites. Polym. Compos. 2022, 43, 3858–3870. [Google Scholar] [CrossRef]

- Song, S.H. Effect of Surfactants on MWNT Filled Elastomer Composites by Latex Mixing. Polym. Eng. Sci. 2018, 58, 1843–1848. [Google Scholar] [CrossRef]

- ASTM D3184; Standard Practice for Rubber—Evaluation of NR (Natural Rubber). ASTM International: West Conshohocken, PA, USA, 2022.

- ISO 11345; Assessment of Carbon Black and Carbon Black/Silica Dispersion. Rapid Comparative Methods. ISO: Geneva, Switzerland, 2006.

- ASTM D-5289; Standard Test Method for Rubber Property—Vulcanization Using Rotorless Cure Meters. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM D8363-20; Standard Test Method for Rubber—Stress Relaxation in Tension Under Non-Isothermal Conditions. ASTM International: West Conshohocken, PA, USA, 2020.

- Vennemann, N.; Schwarze, C.; Kummerlöwe, C. Determination of Crosslink Density and Network Structure of NR Vulcanizates by Means of TSSR. Adv. Mater. Res. 2014, 844, 482–485. [Google Scholar] [CrossRef]

- ISO 527; Plastics—Determination of tensile properties. ISO: Geneva, Switzerland, 2012.

- ASTM D412; Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D2240; Standard Test Method for Rubber Property—Durometer Hardness. ASTM International: West Conshohocken, PA, USA, 2021.

- ISO 4649; Rubber, Vulcanized or Thermoplastic—Determination of Abrasion Resistance Using a Rotating Cylindrical Drum Device. ISO: Geneva, Switzerland, 2017.

- ASTM E1530; Standard Test Method for Evaluating the Resistance to Thermal Transmission by the Guarded Heat Flow Meter Technique. ASTM International: West Conshohocken, PA, USA, 2019.

- Lu, Y.; Liu, J.; Hou, G.; Ma, J.; Wang, W.; Wei, F.; Zhang, L. From Nano to Giant? Designing Carbon Nanotubes for Rubber Reinforcement and Their Applications for High Performance Tires. Compos. Sci. Technol. 2016, 137, 94–101. [Google Scholar] [CrossRef]

- Abdelsalam, A.A.; Araby, S.; El-Sabbagh, S.H.; Abdelmoneim, A.; Hassan, M.A. A Comparative Study on Mechanical and Rheological Properties of Ternary Rubber Blends. Polym. Polym. Compos. 2021, 29, 15–28. [Google Scholar] [CrossRef]

- Yang, H.-H.; Manas-Zloczower, I. Flow Field Analysis of the Kneading Disc Region in a Co-Rotating Twin Screw Extruder. Polym. Eng. Sci. 1992, 32, 1411–1417. [Google Scholar] [CrossRef]

- Yazıcı, N.; Kodal, M.; Özkoç, G. Lab-Scale Twin-Screw Micro-Compounders as a New Rubber-Mixing Tool: ‘A Comparison on EPDM/Carbon Black and EPDM/Silica Composites’. Polymers 2021, 13, 4391. [Google Scholar] [CrossRef] [PubMed]

- Yang, G.; Liao, Z.; Yang, Z.; Tang, Z.; Guo, B. Effects of Substitution for Carbon Black with Graphene Oxide or Graphene on the Morphology and Performance of Natural Rubber/Carbon Black Composites. J. Appl. Polym. Sci. 2015, 132, 41832. [Google Scholar] [CrossRef]

- Strommer, B.; Schulze, D.; Schartel, B.; Böhning, M. Networking Skills: The Effect of Graphene on the Crosslinking of Natural Rubber Nanocomposites with Sulfur and Peroxide Systems. Polymers 2022, 14, 4363. [Google Scholar] [CrossRef]

- Sui, G.; Zhong, W.H.; Yang, X.P.; Yu, Y.H.; Zhao, S.H. Preparation and Properties of Natural Rubber Composites Reinforced with Pretreated Carbon Nanotubes. Polym. Adv. Technol. 2008, 19, 1543–1549. [Google Scholar] [CrossRef]

- Shanmugharaj, A.M.; Bae, J.H.; Lee, K.Y.; Noh, W.H.; Lee, S.H.; Ryu, S.H. Physical and Chemical Characteristics of Multiwalled Carbon Nanotubes Functionalized with Aminosilane and Its Influence on the Properties of Natural Rubber Composites. Compos. Sci. Technol. 2007, 67, 1813–1822. [Google Scholar] [CrossRef]

- Yan, N.; Wu, J.K.; Zhan, Y.H.; Xia, H.S. Carbon Nanotubes/Carbon Black Synergistic Reinforced Natural Rubber Composites. Plast. Rubber Compos. 2009, 38, 290–296. [Google Scholar] [CrossRef]

- Kueseng, K.; Jacob, K.I. Natural Rubber Nanocomposites with SiC Nanoparticles and Carbon Nanotubes. Eur. Polym. J. 2006, 42, 220–227. [Google Scholar] [CrossRef]

- Shao, H.Q.; Wei, H.; He, J.H. DYNAMIC PROPERTIES AND TIRE PERFORMANCES OF COMPOSITES FILLED WITH CARBON NANOTUBES. Rubber Chem. Technol. 2018, 91, 609–620. [Google Scholar] [CrossRef]

- Valentini, L.; Bittolo Bon, S.; Hernández, M.; Lopez-Manchado, M.A.; Pugno, N.M. Nitrile Butadiene Rubber Composites Reinforced with Reduced Graphene Oxide and Carbon Nanotubes Show Superior Mechanical, Electrical and Icephobic Properties. Compos. Sci. Technol. 2018, 166, 109–114. [Google Scholar] [CrossRef]

- Zhang, H.; Zheng, S.; Zheng, L.; Wang, M.J. Silica Masterbatches Produced with Liquid Phase Mixing Part IV. Volume Variation and SEM Observations upon Stretching. Polym. Eng. Sci. 2021, 61, 1368–1378. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, J.; Jia, H.; You, S.; Xiong, X.; Ding, L.; Xu, Z. Multifunctional Nanocomposites between Natural Rubber and Polyvinyl Pyrrolidone Modified Graphene. Compos. Part B Eng. 2016, 84, 121–129. [Google Scholar] [CrossRef]

- Le, H.H.; Pham, T.; Henning, S.; Klehm, J.; Wießner, S.; Stöckelhuber, K.W.; Das, A.; Hoang, X.T.; Do, Q.K.; Wu, M.; et al. Formation and Stability of Carbon Nanotube Network in Natural Rubber: Effect of Non-Rubber Components. Polymer 2015, 73, 111–121. [Google Scholar] [CrossRef]

- Le, H.H.; Abhijeet, S.; Ilisch, S.; Klehm, J.; Henning, S.; Beiner, M.; Sarkawi, S.S.; Dierkes, W.; Das, A.; Fischer, D.; et al. The Role of Linked Phospholipids in the Rubber-Filler Interaction in Carbon Nanotube (CNT) Filled Natural Rubber (NR) Composites. Polymer 2014, 55, 4738–4747. [Google Scholar] [CrossRef]

- Vennemann, N.; Wu, M.; Heinz, M. Experimentelle Untersuchungen Und Entwicklung Eines Modells Der Thermoelastischen Eigenschaften Russgefüllter SBR-Vulkanisate. KGK 2011, 64, 40–46. [Google Scholar]

- Vennemann, N.; Wu, M.; Heinz, M. Thermoelastic Properties and Relaxation Behavior of S-SBR/Silica Vulcanizates. Rubber World 2012, 246, 18–23. [Google Scholar]

- Damampai, K.; Pichaiyut, S.; Das, A.; Nakason, C. Internal Polymerization of Epoxy Group of Epoxidized Natural Rubber by Ferric Chloride Filled with Carbon Nanotubes: Mechanical, Morphological, Thermal and Electrical Properties of Rubber Vulcanizates. Express Polym. Lett. 2022, 16, 812–826. [Google Scholar] [CrossRef]

- Kitisavetjit, W.; Nakaramontri, Y.; Pichaiyut, S.; Wisunthorn, S.; Nakason, C.; Kiatkamjornwong, S. Influences of Carbon Nanotubes and Graphite Hybrid Filler on Properties of Natural Rubber Nanocomposites. Polym. Test. 2021, 93, 106981. [Google Scholar] [CrossRef]

- Nakaramontri, Y.; Kummerlöwe, C.; Vennemann, N.; Wisunthorn, S.; Pichaiyut, S. Effect of Bis(Triethoxysilylpropyl) Tetrasulfide (TESPT) on Properties of Carbon Nanotubes and Conductive Carbon Black Hybrid Filler Filled Natural Rubber Nanocomposites. Express Polym. Lett. 2018, 12, 867–884. [Google Scholar] [CrossRef]

- Yazıcı, N.; Opar, E.; Kodal, M.; Tanören, B.; Sezen, M.; Özkoç, G. A Novel Practical Approach for Monitoring the Crosslink Density of an Ethylene Propylene Diene Monomer Compound: Complementary Scanning Acoustic Microscopy and FIB-SEM-EDS Analyses. Polym. Polym. Compos. 2022, 30, doi. [Google Scholar] [CrossRef]

- Karaağaç, B.; Cengiz, S.C.; Bayram, T.; Şen, M. Identification of Temperature Scanning Stress Relaxation Behaviors of New Grade Ethylene Propylene Diene Elastomers. Adv. Polym. Technol. 2018, 37, 3027–3037. [Google Scholar] [CrossRef]

- Zhan, Y.H.; Liu, G.Q.; Xia, H.S.; Yan, N. Natural Rubber/Carbon Black/Carbon Nanotubes Composites Prepared through Ultrasonic Assisted Latex Mixing Process. Plast. Rubber Compos. 2011, 40, 32–39. [Google Scholar] [CrossRef]

- Pojanavaraphan, T.; Magaraphan, R. Prevulcanized Natural Rubber Latex/Clay Aerogel Nanocomposites. Eur. Polym. J. 2008, 44, 1968–1977. [Google Scholar] [CrossRef]

- Kader, M.A.; Kim, K.; Lee, Y.S.; Nah, C. Preparation and Properties of Nitrile Rubber/Montmorillonite Nanocomposites via Latex Blending. J. Mater. Sci. 2006, 41, 7341–7352. [Google Scholar] [CrossRef]

- Payne, A.R. The Dynamic Properties of Carbon Black Loaded Natural Rubber Vulcanizates. Part II. J. Appl. Polym. Sci. 1962, 6, 368–372. [Google Scholar] [CrossRef]

- Payne, A.R. The Dynamic Properties of Carbon Black-Loaded Natural Rubber Vulcanizates. Part I. J. Appl. Polym. Sci. 1962, 6, 57–63. [Google Scholar] [CrossRef]

- Payne, A.R.; Whittaker, R.E. Low Strain Dynamic Properties of Filled Rubbers. Rubber Chem. Technol. 1971, 44, 440–478. [Google Scholar] [CrossRef]

- Shanmugharaj, A.M.; Hun Ryu, S. Influence of Aminosilane-Functionalized Carbon Nanotubes on the Rheometric, Mechanical, Electrical and Thermal Degradation Properties of Epoxidized Natural Rubber Nanocomposites. Polym. Int. 2013, 62, 1433–1441. [Google Scholar] [CrossRef]

- Zainal Abidin, Z.; Mamauod, S.N.L.; Romli, A.Z.; Sarkawi, S.S.; Zainal, N.H. Synergistic Effect of Partial Replacement of Carbon Black by Palm Kernel Shell Biochar in Carboxylated Nitrile Butadiene Rubber Composites. Polymers 2023, 15, 943. [Google Scholar] [CrossRef]

- Shahamatifard, F.; Rodrigue, D.; Mighri, F. Thermal and Mechanical Properties of Carbon-Based Rubber Nanocomposites: A Review. Plast. Rubber Compos. 2023, 52, 483–505. [Google Scholar] [CrossRef]

- Shahamatifard, F.; Rodrigue, D.; Park, K.W.; Frikha, S.; Mighri, F. Natural Rubber Nanocomposites: Effect of Carbon Black/Multi-Walled Carbon Nanotubes Hybrid Fillers on the Mechanical Properties and Thermal Conductivity. Polym. Technol. Mater. 2021, 60, 1686–1696. [Google Scholar] [CrossRef]

- Wang, H.; Li, L.; Chen, Y.; Li, M.; Fu, H.; Hou, X.; Wu, X.; Lin, C.T.; Jiang, N.; Yu, J. Efficient Thermal Transport Highway Construction within Epoxy Matrix via Hybrid Carbon Fibers and Alumina Particles. ACS Omega 2020, 5, 1170–1177. [Google Scholar] [CrossRef]

- Song, J.; Li, X.; Tian, K.; Ma, L.; Li, W.; Yao, S. Thermal Conductivity of Natural Rubber Nanocomposites with Hybrid Fillers. Chin. J. Chem. Eng. 2019, 27, 928–934. [Google Scholar] [CrossRef]

- Ismail, H.; Ramly, A.F.; Othman, N. The Effect of Carbon Black/Multiwall Carbon Nanotube Hybrid Fillers on the Properties of Natural Rubber Nanocomposites. Polym. Plast. Technol. Eng. 2011, 50, 660–666. [Google Scholar] [CrossRef]

- Yuan, W.; Xiao, Q.; Li, L.; Xu, T. Thermal Conductivity of Epoxy Adhesive Enhanced by Hybrid Graphene Oxide/AlN Particles. Appl. Therm. Eng. 2016, 106, 1067–1074. [Google Scholar] [CrossRef]

- Rattanasom, N.; Saowapark, T.; Deeprasertkul, C. Reinforcement of Natural Rubber with Silica/Carbon Black Hybrid Filler. Polym. Test. 2007, 26, 369–377. [Google Scholar] [CrossRef]

- Sae-Oui, P.; Thepsuwan, U.; Thaptong, P.; Sirisinha, C. Comparison of Reinforcing Efficiency of Carbon Black, Conductive Carbon Black, and Carbon Nanotube in Natural Rubber. Adv. Polym. Technol. 2014, 33, 21422. [Google Scholar] [CrossRef]

- Bokobza, L.; El Bounia, N.E. Reinforcement Effects of Multiwall Carbon Nanotubes in Elastomeric Matrices: Comparison with Other Types of Fillers. Compos. Interfaces 2008, 15, 9–17. [Google Scholar] [CrossRef]

- Bokobza, L.; Rahmani, M.; Belin, C.; Bruneel, J.L.; El Bounia, N.E. Blends of Carbon Blacks and Multiwall Carbon Nanotubes as Reinforcing Fillers for Hydrocarbon Rubbers. J. Polym. Sci. Part B Polym. Phys. 2008, 46, 1939–1951. [Google Scholar] [CrossRef]

- Gojny, F.H.; Schulte, K. Functionalisation Effect on the Thermo-Mechanical Behaviour of Multi-Wall Carbon Nanotube/Epoxy-Composites. Compos. Sci. Technol. 2004, 64, 2303–2308. [Google Scholar] [CrossRef]

- Nakaramontri, Y.; Nakason, C.; Kummerlöwe, C.; Vennemann, N. Enhancement of Electrical Conductivity and Other Related Properties of Epoxidized Natural Rubber/Carbon Nanotube Composites by Optimizing Concentration of 3-Aminopropyltriethoxy Silane. Polym. Eng. Sci. 2017, 57, 381–391. [Google Scholar] [CrossRef]

| Materials | Suppliers |

|---|---|

| NR | Baria Rubber Co., Ho Chi Minh City, Vietnam |

| SBR | Baria Rubber Co., Ho Chi Minh City, Vietnam |

| CB | Elkim/N330, Istanbul, Türkiye |

| MWCNT | Nanografi, Ankara, Türkiye |

| Naphthenic Oil | Petro Yağ, Kocaeli, Türkiye |

| Zinc Oxide | RubberChem, Istanbul, Türkiye |

| Stearic Acid | RubberChem, Istanbul, Türkiye |

| IPPD | RubberChem, Istanbul, Türkiye |

| TMQ | RubberChem, Istanbul, Türkiye |

| MBT | RubberChem, Istanbul, Türkiye |

| CBS | RubberChem, Istanbul, Türkiye |

| PVI | RubberChem, Istanbul, Türkiye |

| Sulfur | RubberChem, Istanbul, Türkiye |

| Components | Recipe 1 | Recipe 2 | Recipe 3 |

|---|---|---|---|

| NR | 70 | 70 | 70 |

| SBR | 30 | 30 | 30 |

| CB | 30 | 27 | 23 |

| MWCNT | 0 | 3 | 7 |

| Oil | 10 | 10 | 10 |

| ZnO | 3 | 3 | 3 |

| Stearic Acid | 2 | 2 | 2 |

| IPPD | 2 | 2 | 2 |

| TMQ | 1 | 1 | 1 |

| MBTS | 0.4 | 0.4 | 0.4 |

| CBS | 1 | 1 | 1 |

| PVI | 0.2 | 0.2 | 0.2 |

| Sulfur | 2.0 | 2.0 | 2.0 |

| Compounds | Tx-link,onset (°C) | Tx-link,peak (°C) |

|---|---|---|

| Recipe 1 | 148.6 | 161.3 |

| Recipe 2 | 151.3 | 164.5 |

| Recipe 3 | 154.1 | 169.5 |

| Compounds | ML (dNm) | MH (dNm) | ts2 (min) | t90 (min) | Cure Extent (dNm) | Cure Rate Index (CRI) |

|---|---|---|---|---|---|---|

| Recipe 1 | 1.25 | 7.41 | 1.27 | 2.78 | 6.16 | 66.22 |

| Recipe 2 | 1.43 | 7.88 | 1.34 | 3.00 | 6.45 | 60.24 |

| Recipe 3 | 1.63 | 8.72 | 1.35 | 3.19 | 7.09 | 54.34 |

| Compounds | T10 (°C) * | Initial Stress, σ0 (MPa) | TSSR (mol/m3) | Flory–Rehner (mol/m3) |

|---|---|---|---|---|

| Recipe 1 | 80.5 | 0.58 | 97.8 | 231.8 |

| Recipe 2 | 83.0 | 0.40 | 117.9 | 304.3 |

| Recipe 3 | 100.2 | 0.79 | 132.9 | 383.7 |

| Compounds | Tensile Strength (MPa) | Elongation at Break (%) | Young Modulus (MPa) | Shore D | Abrasion Loss (%) | Abrasion Loss (mm3) |

|---|---|---|---|---|---|---|

| Recipe 1 | 8.2 ± 1.1 | 548 ± 20 | 6.0 ± 0.5 | 69 ± 3 | 19.8 | 191.1 |

| Recipe 2 | 12.7 ± 1.5 | 543 ± 26 | 8.7 ± 1.5 | 72 ± 2 | 19.4 | 188.5 |

| Recipe 3 | 16.5 ± 1.1 | 536 ± 16 | 10.5 ± 0.8 | 76 ± 6 | 10.4 | 131.3 |

| Compounds | Td5 (°C) | Td10 (°C) | Tdmax (°C) | Char Yield (%) |

|---|---|---|---|---|

| Recipe 1 | 301.0 | 339.1 | 376.0 | 19.3 |

| Recipe 2 | 282.9 | 328.5 | 377.3 | 20.3 |

| Recipe 3 | 286.4 | 329.0 | 377.0 | 23.2 |

| Compounds | Surface Resistivity (Ohm/cm2) | Thermal Conductivity (W/m·K) |

|---|---|---|

| Recipe 1 | 4.5 × 107 | 0.56 |

| Recipe 2 | 6.5 × 106 | 0.58 |

| Recipe 3 | 1.4 × 106 | 0.91 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kodal, M.; Yazıcı Çakır, N.; Yıldırım, R.; Karakaya, N.; Özkoç, G. Improved Heat Dissipation of NR/SBR-Based Tire Tread Compounds via Hybrid Fillers of Multi-Walled Carbon Nanotube and Carbon Black. Polymers 2023, 15, 4503. https://doi.org/10.3390/polym15234503

Kodal M, Yazıcı Çakır N, Yıldırım R, Karakaya N, Özkoç G. Improved Heat Dissipation of NR/SBR-Based Tire Tread Compounds via Hybrid Fillers of Multi-Walled Carbon Nanotube and Carbon Black. Polymers. 2023; 15(23):4503. https://doi.org/10.3390/polym15234503

Chicago/Turabian StyleKodal, Mehmet, Nazlı Yazıcı Çakır, Rumeysa Yıldırım, Nursel Karakaya, and Güralp Özkoç. 2023. "Improved Heat Dissipation of NR/SBR-Based Tire Tread Compounds via Hybrid Fillers of Multi-Walled Carbon Nanotube and Carbon Black" Polymers 15, no. 23: 4503. https://doi.org/10.3390/polym15234503

APA StyleKodal, M., Yazıcı Çakır, N., Yıldırım, R., Karakaya, N., & Özkoç, G. (2023). Improved Heat Dissipation of NR/SBR-Based Tire Tread Compounds via Hybrid Fillers of Multi-Walled Carbon Nanotube and Carbon Black. Polymers, 15(23), 4503. https://doi.org/10.3390/polym15234503