Optimization of Piezoresistive Response of Elastomeric Porous Structures Based on Carbon-Based Hybrid Fillers Created by Selective Laser Sintering

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Design and Creation of the TPU/(GE-MWCNTs) Porous Structures

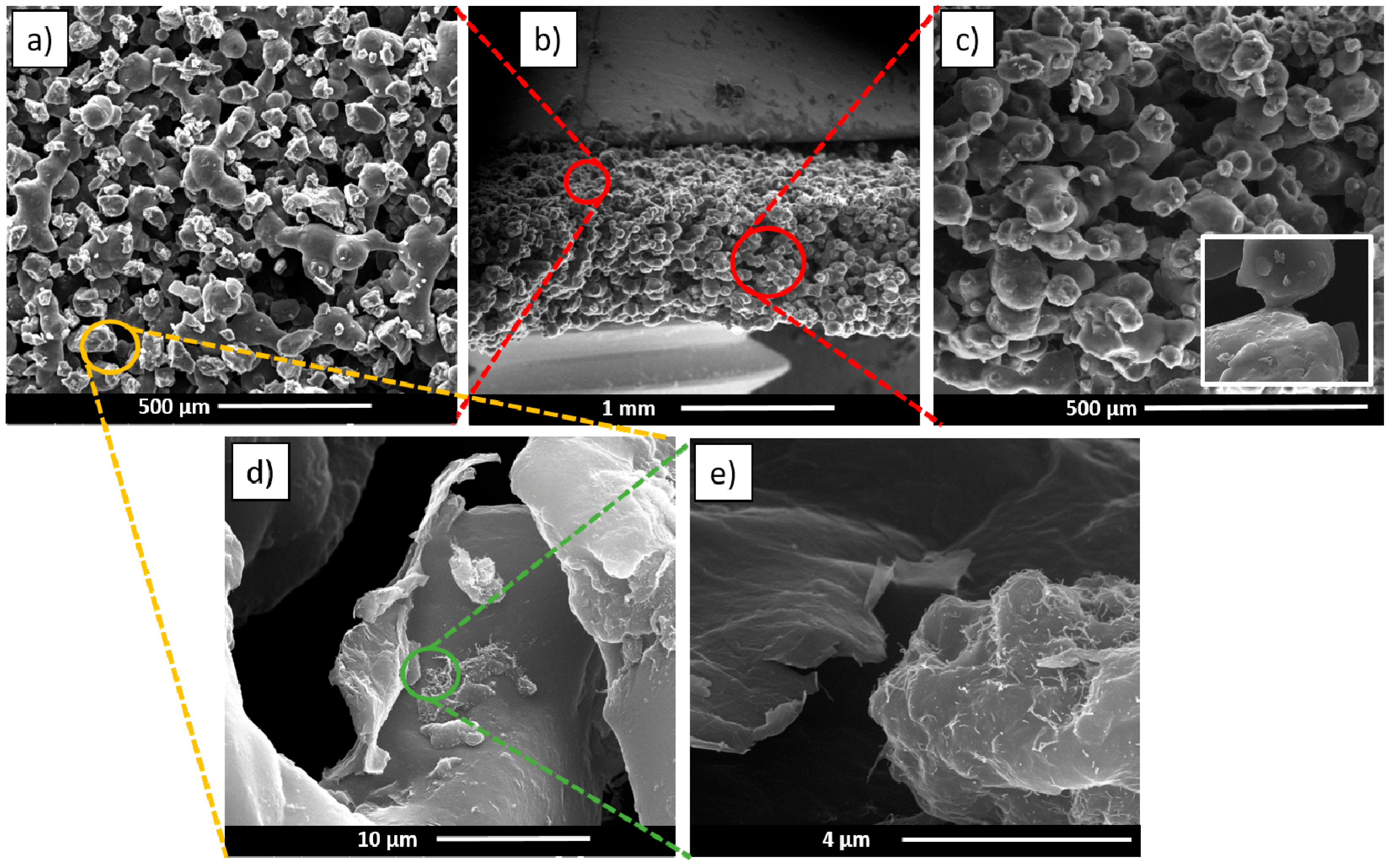

3.2. Morphological Characterization of the SLS-Manufactured Porous Structures

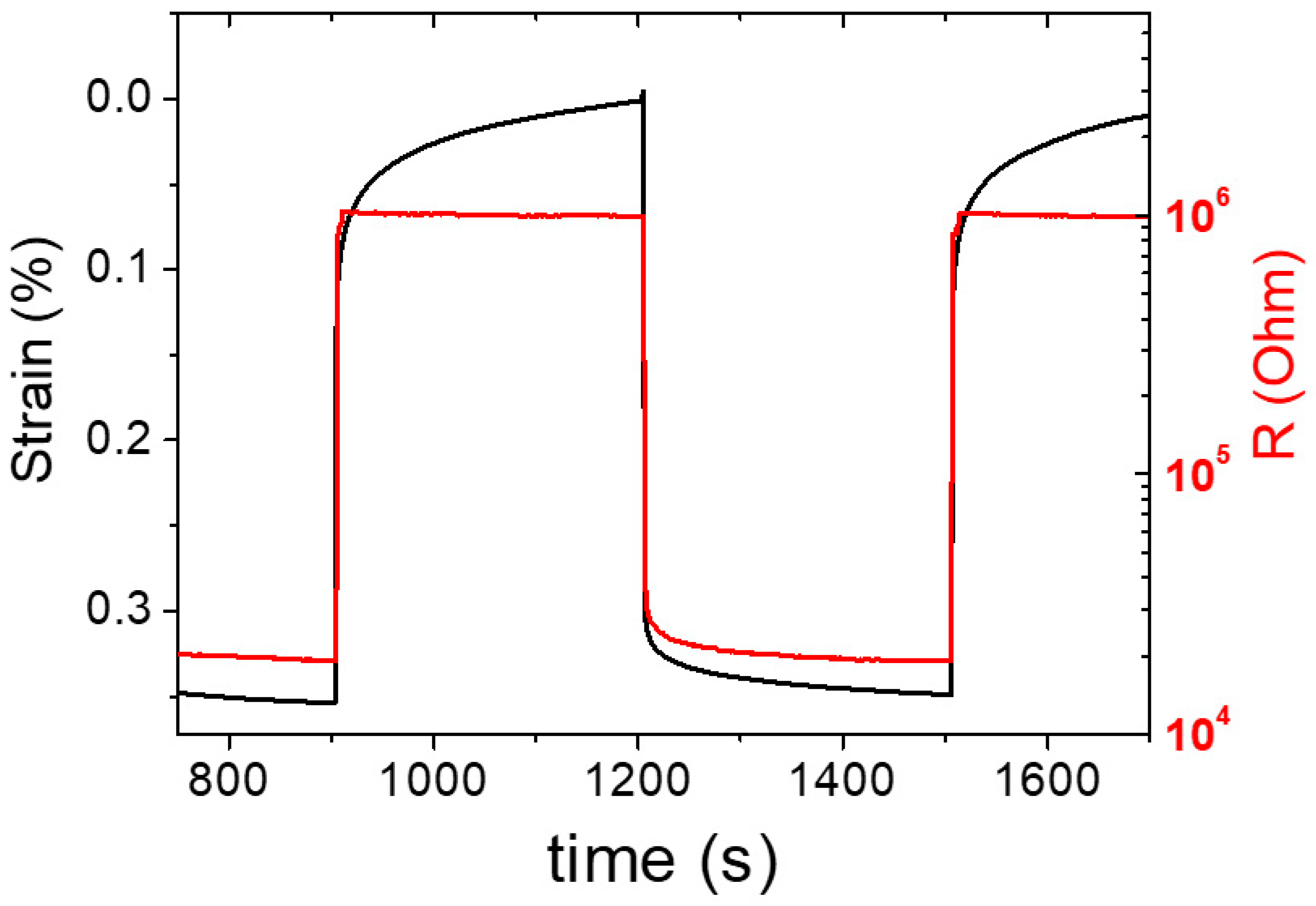

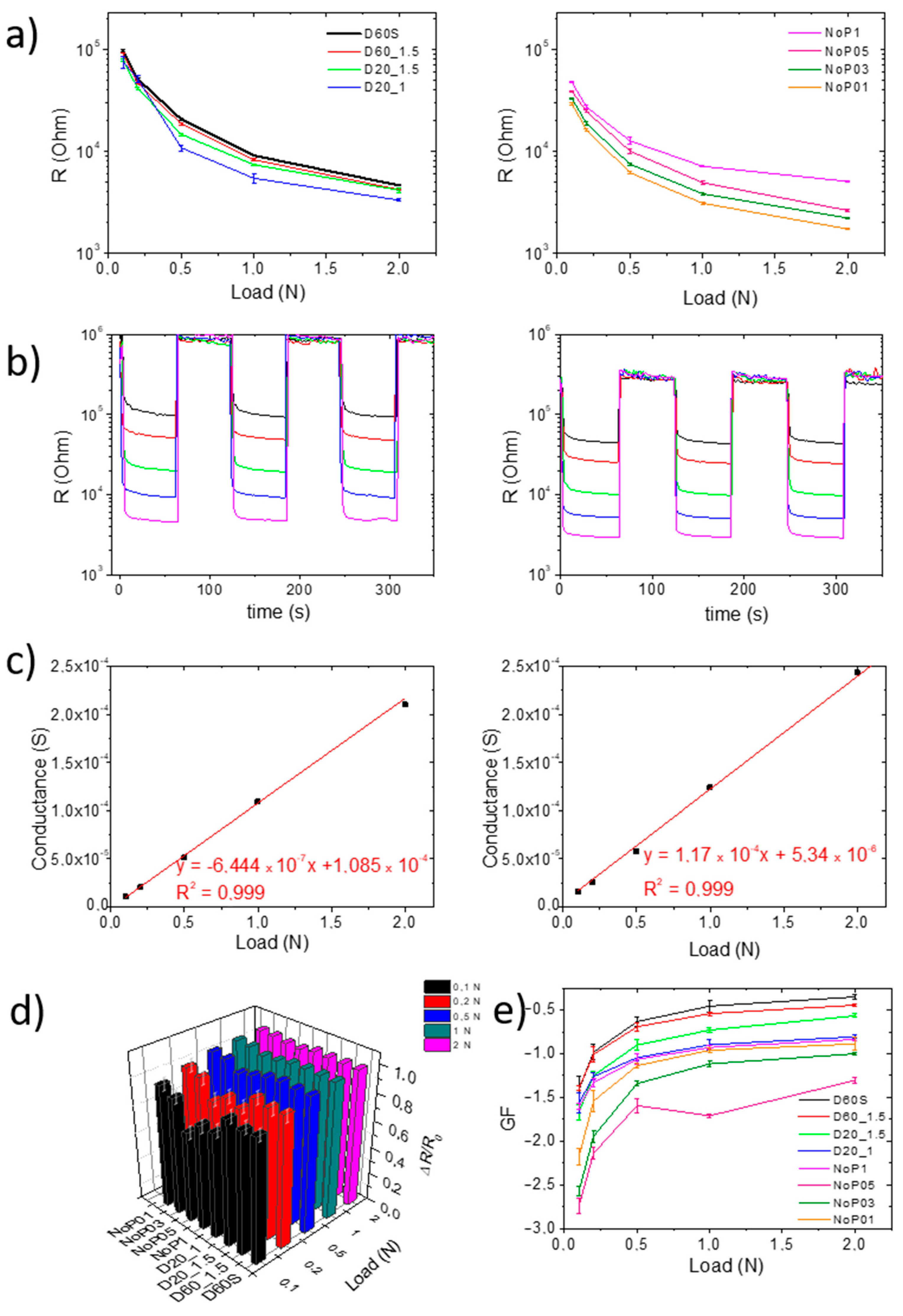

3.3. Electromechanical Characterization

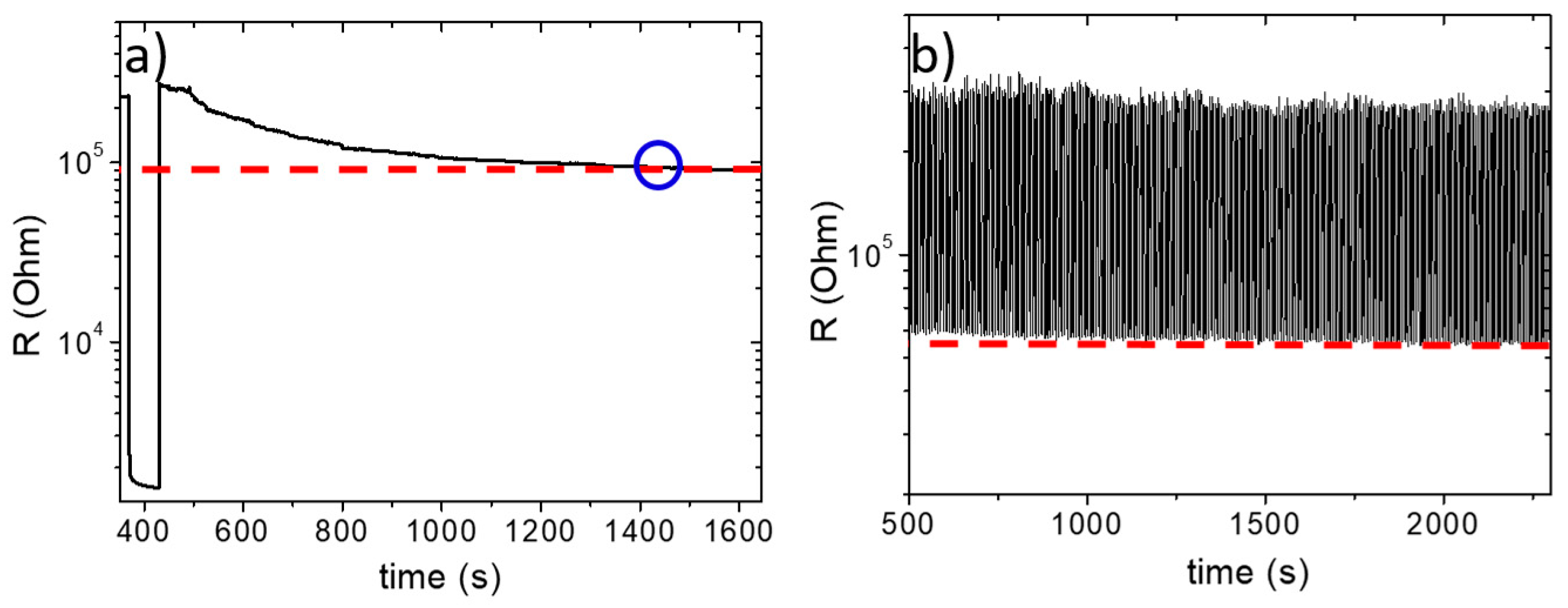

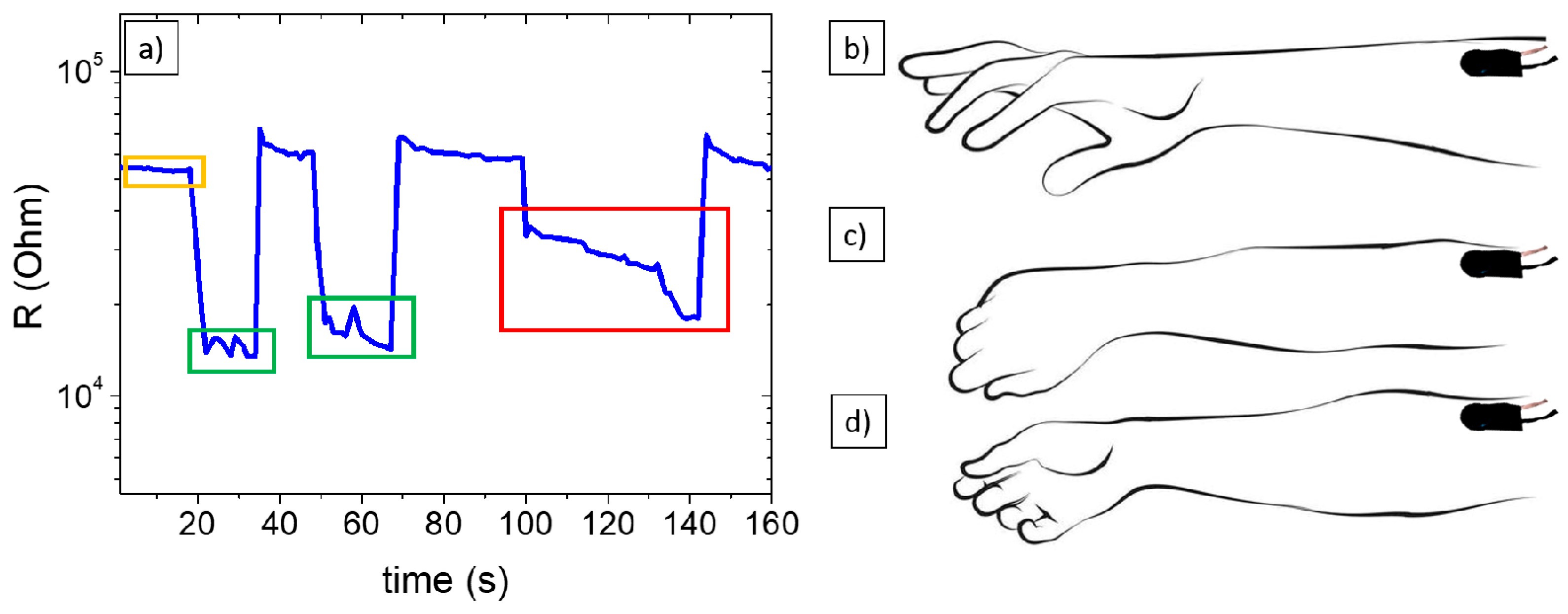

3.4. Application Test

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Duan, Y.; He, S.; Wu, J.; Su, B.; Wang, Y. Recent Progress in Flexible Pressure Sensor Arrays. Nanomaterials 2022, 12, 2495. [Google Scholar] [CrossRef] [PubMed]

- Hu, X.; Yang, F.; Wu, M.; Sui, Y.; Guo, D.; Li, M.; Kang, Z.; Sun, J.; Liu, J. A Super-Stretchable and Highly Sensitive Carbon Nanotube Capacitive Strain Sensor for Wearable Applications and Soft Robotics. Adv. Mater. Technol. 2022, 7, 2100769. [Google Scholar] [CrossRef]

- Liu, X.; Wei, Y.; Qiu, Y. Advanced Flexible Skin-like Pressure and Strain Sensors for Human Health Monitoring. Micromachines 2021, 12, 695. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Li, R.; González, O.G.; Chen, T.; Xiao, X. Highly Sensitive and Flexible Piezoresistive Sensor Based on C-MWCNTs Decorated TPU Electrospun Fibrous Network for Human Motion Detection. Compos. Sci. Technol. 2021, 203, 108617. [Google Scholar] [CrossRef]

- Pierre Claver, U.; Zhao, G. Recent Progress in Flexible Pressure Sensors Based Electronic Skin. Adv. Eng. Mater. 2021, 23, 2001187. [Google Scholar] [CrossRef]

- Zhao, Y.; Huang, Y.; Hu, W.; Guo, X.; Wang, Y.; Liu, P.; Liu, C.; Zhang, Y. Highly Sensitive Flexible Strain Sensor Based on Threadlike Spandex Substrate Coating with Conductive Nanocomposites for Wearable Electronic Skin. Smart Mater. Struct. 2019, 28, 35004. [Google Scholar] [CrossRef]

- Tian, Y.; He, P.; Yang, B.; Yi, Z.; Lu, L.; Liu, J. A Flexible Piezoelectric Strain Sensor Array with Laser-Patterned Serpentine Interconnects. IEEE Sens. J. 2020, 20, 8463–8468. [Google Scholar] [CrossRef]

- Xu, H.; Lv, Y.; Qiu, D.; Zhou, Y.; Zeng, H.; Chu, Y. An Ultra-Stretchable, Highly Sensitive and Biocompatible Capacitive Strain Sensor from an Ionic Nanocomposite for on-Skin Monitoring. Nanoscale 2019, 11, 1570–1578. [Google Scholar] [CrossRef]

- Iqra, M.; Anwar, F.; Jan, R.; Mohammad, M.A. A Flexible Piezoresistive Strain Sensor Based on Laser Scribed Graphene Oxide on Polydimethylsiloxane. Sci. Rep. 2022, 12, 4882. [Google Scholar] [CrossRef]

- Chen, W.; Yan, X. Progress in Achieving High-Performance Piezoresistive and Capacitive Flexible Pressure Sensors: A Review. J. Mater. Sci. Technol. 2020, 43, 175–188. [Google Scholar] [CrossRef]

- Homayounfar, S.Z.; Andrew, T.L. Wearable Sensors for Monitoring Human Motion: A Review on Mechanisms, Materials, and Challenges. SLAS Technol. Transl. Life Sci. Innov. 2020, 25, 9–24. [Google Scholar] [CrossRef]

- Cao, M.; Su, J.; Fan, S.; Qiu, H.; Su, D.; Li, L. Wearable Piezoresistive Pressure Sensors Based on 3D Graphene. Chem. Eng. J. 2021, 406, 126777. [Google Scholar] [CrossRef]

- Zhu, Y.; Hartel, M.C.; Yu, N.; Garrido, P.R.; Kim, S.; Lee, J.; Bandaru, P.; Guan, S.; Lin, H.; Emaminejad, S. Epidermis-inspired Wearable Piezoresistive Pressure Sensors Using Reduced Graphene Oxide Self-wrapped Copper Nanowire Networks. Small Methods 2022, 6, 2100900. [Google Scholar] [CrossRef] [PubMed]

- Ma, Z.; Xiang, X.; Shao, L.; Zhang, Y.; Gu, J. Multifunctional Wearable Silver Nanowire Decorated Leather Nanocomposites for Joule Heating, Electromagnetic Interference Shielding and Piezoresistive Sensing. Angew. Chem. Int. Ed. 2022, 61, e202200705. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Z.; Li, Q.; Dong, Y.; Gong, J.; Li, Z.; Zhang, J. Washable Patches with Gold Nanowires/Textiles in Wearable Sensors for Health Monitoring. ACS Appl. Mater. Interfaces 2022, 14, 18884–18900. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, T.; Dinh, T.; Phan, H.-P.; Pham, T.A.; Nguyen, N.-T.; Dao, D.V. Advances in Ultrasensitive Piezoresistive Sensors: From Conventional to Flexible and Stretchable Applications. Mater. Horiz. 2021, 8, 2123–2150. [Google Scholar] [CrossRef]

- Nag, A.; Mukhopadhyay, S.C. Fabrication and Implementation of Carbon Nanotubes for Piezoresistive-Sensing Applications: A Review. J. Sci. Adv. Mater. Devices 2021, 7, 100416. [Google Scholar] [CrossRef]

- Zheng, Q.; Lee, J.; Shen, X.; Chen, X.; Kim, J.-K. Graphene-Based Wearable Piezoresistive Physical Sensors. Mater. Today 2020, 36, 158–179. [Google Scholar] [CrossRef]

- Zhai, Y.; Yu, Y.; Zhou, K.; Yun, Z.; Huang, W.; Liu, H.; Xia, Q.; Dai, K.; Zheng, G.; Liu, C. Flexible and Wearable Carbon Black/Thermoplastic Polyurethane Foam with a Pinnate-Veined Aligned Porous Structure for Multifunctional Piezoresistive Sensors. Chem. Eng. J. 2020, 382, 122985. [Google Scholar] [CrossRef]

- Kwon, Y.J.; Kim, Y.; Jeon, H.; Cho, S.; Lee, W.; Lee, J.U. Graphene/Carbon Nanotube Hybrid as a Multi-Functional Interfacial Reinforcement for Carbon Fiber-Reinforced Composites. Compos. Part B Eng. 2017, 122, 23–30. [Google Scholar] [CrossRef]

- Ruoff, R.S.; Qian, D.; Liu, W.K. Mechanical Properties of Carbon Nanotubes: Theoretical Predictions and Experimental Measurements. Comptes Rendus Phys. 2003, 4, 993–1008. [Google Scholar] [CrossRef]

- Hong, W.-T.; Tai, N.-H. Investigations on the Thermal Conductivity of Composites Reinforced with Carbon Nanotubes. Diam. Relat. Mater. 2008, 17, 1577–1581. [Google Scholar] [CrossRef]

- De Volder, M.F.L.; Tawfick, S.H.; Baughman, R.H.; Hart, A.J. Carbon Nanotubes: Present and Future Commercial Applications. Science 2013, 339, 535–539. [Google Scholar] [CrossRef] [PubMed]

- Goh, G.D.; Yap, Y.L.; Agarwala, S.; Yeong, W.Y. Recent Progress in Additive Manufacturing of Fiber Reinforced Polymer Composite. Adv. Mater. Technol. 2019, 4, 1800271. [Google Scholar] [CrossRef]

- Phiri, J.; Johansson, L.-S.; Gane, P.; Maloney, T. A Comparative Study of Mechanical, Thermal and Electrical Properties of Graphene-, Graphene Oxide-and Reduced Graphene Oxide-Doped Microfibrillated Cellulose Nanocomposites. Compos. Part B Eng. 2018, 147, 104–113. [Google Scholar] [CrossRef]

- Sang, M.; Shin, J.; Kim, K.; Yu, K.J. Electronic and Thermal Properties of Graphene and Recent Advances in Graphene Based Electronics Applications. Nanomaterials 2019, 9, 374. [Google Scholar] [CrossRef] [PubMed]

- Yi, Y.; Samara, A.; Wang, B. A New Approach for an Ultra-Thin Piezoresistive Sensor Based on Solidified Carbon Ink Film. J. Mater. Sci. 2021, 56, 607–614. [Google Scholar] [CrossRef]

- Mannsfeld, S.C.B.; Tee, B.C.K.; Stoltenberg, R.M.; Chen, C.V.H.H.; Barman, S.; Muir, B.V.O.; Sokolov, A.N.; Reese, C.; Bao, Z. Highly Sensitive Flexible Pressure Sensors with Microstructured Rubber Dielectric Layers. Nat. Mater. 2010, 9, 859–864. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive Manufacturing (3D Printing): A Review of Materials, Methods, Applications and Challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Tsolakis, I.A.; Gizani, S.; Tsolakis, A.I.; Panayi, N. Three-Dimensional-Printed Customized Orthodontic and Pedodontic Appliances: A Critical Review of a New Era for Treatment. Children 2022, 9, 1107. [Google Scholar] [CrossRef]

- Schmid, M.; Wegener, K. Additive Manufacturing: Polymers Applicable for Laser Sintering (LS). Procedia Eng. 2016, 149, 457–464. [Google Scholar] [CrossRef]

- Yuan, S.; Shen, F.; Chua, C.K.; Zhou, K. Polymeric Composites for Powder-Based Additive Manufacturing: Materials and Applications. Prog. Polym. Sci. 2019, 91, 141–168. [Google Scholar] [CrossRef]

- Li, X.; Ouyang, H.; Sun, S.; Wang, J.; Fei, G.; Xia, H. Selective Laser Sintering for Electrically Conductive Poly (Dimethylsiloxane) Composites with Self-Healing Lattice Structures. ACS Appl. Polym. Mater. 2023, 5, 2944–2955. [Google Scholar] [CrossRef]

- Zhuang, Y.; Guo, Y.; Li, J.; Jiang, K.; Yu, Y.; Zhang, H.; Liu, D. Preparation and Laser Sintering of a Thermoplastic Polyurethane Carbon Nanotube Composite-Based Pressure Sensor. RSC Adv. 2020, 10, 23644–23652. [Google Scholar] [CrossRef] [PubMed]

- Ronca, A.; Rollo, G.; Cerruti, P.; Fei, G.; Gan, X.; Buonocore, G.G.; Lavorgna, M.; Xia, H.; Silvestre, C.; Ambrosio, L. Selective Laser Sintering Fabricated Thermoplastic Polyurethane/Graphene Cellular Structures with Tailorable Properties and High Strain Sensitivity. Appl. Sci. 2019, 9, 864. [Google Scholar] [CrossRef]

- Rollo, G.; Ronca, A.; Cerruti, P.; Gan, X.P.; Fei, G.; Xia, H.; Gorokhov, G.; Bychanok, D.; Kuzhir, P.; Lavorgna, M. On the Synergistic Effect of Multi-Walled Carbon Nanotubes and Graphene Nanoplatelets to Enhance the Functional Properties of SLS 3D-Printed Elastomeric Structures. Polymers 2020, 12, 1841. [Google Scholar] [CrossRef] [PubMed]

- Gan, X.; Wang, J.; Wang, Z.; Zheng, Z.; Lavorgna, M.; Ronca, A.; Fei, G.; Xia, H. Simultaneous Realization of Conductive Segregation Network Microstructure and Minimal Surface Porous Macrostructure by SLS 3D Printing. Mater. Des. 2019, 178, 107874. [Google Scholar] [CrossRef]

- Haghgoo, M.; Ansari, R.; Hassanzadeh-Aghdam, M.K. Synergic Effect of Graphene Nanoplatelets and Carbon Nanotubes on the Electrical Resistivity and Percolation Threshold of Polymer Hybrid Nanocomposites. Eur. Phys. J. Plus 2021, 136, 768. [Google Scholar] [CrossRef]

- Tang, Z.-H.; Wang, D.-Y.; Li, Y.-Q.; Huang, P.; Fu, S.-Y. Modeling the Synergistic Electrical Percolation Effect of Carbon Nanotube/Graphene/Polymer Composites. Compos. Sci. Technol. 2022, 225, 109496. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, S.; Li, M.; Gu, Y.; Zhang, Z. Piezoresistive Response of Carbon Nanotube Composite Film under Laterally Compressive Strain. Sens. Actuators A Phys. 2018, 273, 140–146. [Google Scholar] [CrossRef]

- Lu, J.; Lu, M.; Bermak, A.; Lee, Y.-K. Study of Piezoresistance Effect of Carbon Nanotube-PDMS Composite Materials for Nanosensors. In Proceedings of the 2007 7th IEEE Conference on Nanotechnology (IEEE NANO), Hong Kong, China, 2–5 August 2007; pp. 1240–1243. [Google Scholar]

| Sample | Dimension (d × h) (mm·mm) | Porosity (%) | Bulk Volume (Vb) (mm3) | Real Volume (Vr) (mm3) |

|---|---|---|---|---|

| D60S | 20 × 2 | 60 | 628.00 | 345.4 |

| D60_1.5 | 20 × 1.5 | 60 | 471.00 | 188.40 |

| D20_1.5 | 13 × 1.5 | 20 | 198.99 | 159.19 |

| D20_1 | 13 × 1.0 | 20 | 132.66 | 106.13 |

| NoP1 | 13 × 1.0 | 0 | 132.66 | 132.66 |

| NoP05 | 13 × 0.5 | 0 | 66.33 | 66.33 |

| NoP03 | 13 × 0.3 | 0 | 39.79 | 39.79 |

| NoP01 | 13 × 0.1 | 0 | 13.26 | 13.26 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rollo, G.; Ronca, A.; Cerruti, P.; Xia, H.; Gruppioni, E.; Lavorgna, M. Optimization of Piezoresistive Response of Elastomeric Porous Structures Based on Carbon-Based Hybrid Fillers Created by Selective Laser Sintering. Polymers 2023, 15, 4404. https://doi.org/10.3390/polym15224404

Rollo G, Ronca A, Cerruti P, Xia H, Gruppioni E, Lavorgna M. Optimization of Piezoresistive Response of Elastomeric Porous Structures Based on Carbon-Based Hybrid Fillers Created by Selective Laser Sintering. Polymers. 2023; 15(22):4404. https://doi.org/10.3390/polym15224404

Chicago/Turabian StyleRollo, Gennaro, Alfredo Ronca, Pierfrancesco Cerruti, Hesheng Xia, Emanuele Gruppioni, and Marino Lavorgna. 2023. "Optimization of Piezoresistive Response of Elastomeric Porous Structures Based on Carbon-Based Hybrid Fillers Created by Selective Laser Sintering" Polymers 15, no. 22: 4404. https://doi.org/10.3390/polym15224404

APA StyleRollo, G., Ronca, A., Cerruti, P., Xia, H., Gruppioni, E., & Lavorgna, M. (2023). Optimization of Piezoresistive Response of Elastomeric Porous Structures Based on Carbon-Based Hybrid Fillers Created by Selective Laser Sintering. Polymers, 15(22), 4404. https://doi.org/10.3390/polym15224404