Mechanical and Wear Studies of Boron Nitride-Reinforced Polymer Composites Developed via 3D Printing Technology

Abstract

:1. Introduction

2. Materials and Methods

2.1. Polylactic Acid (PLA)

2.2. Boron Nitride

2.3. Blending and Extrusion

2.4. Fused Deposition Modeling (FDM)

2.5. Testing and Characterization

3. Results and Discussion

3.1. Microstructure Studies

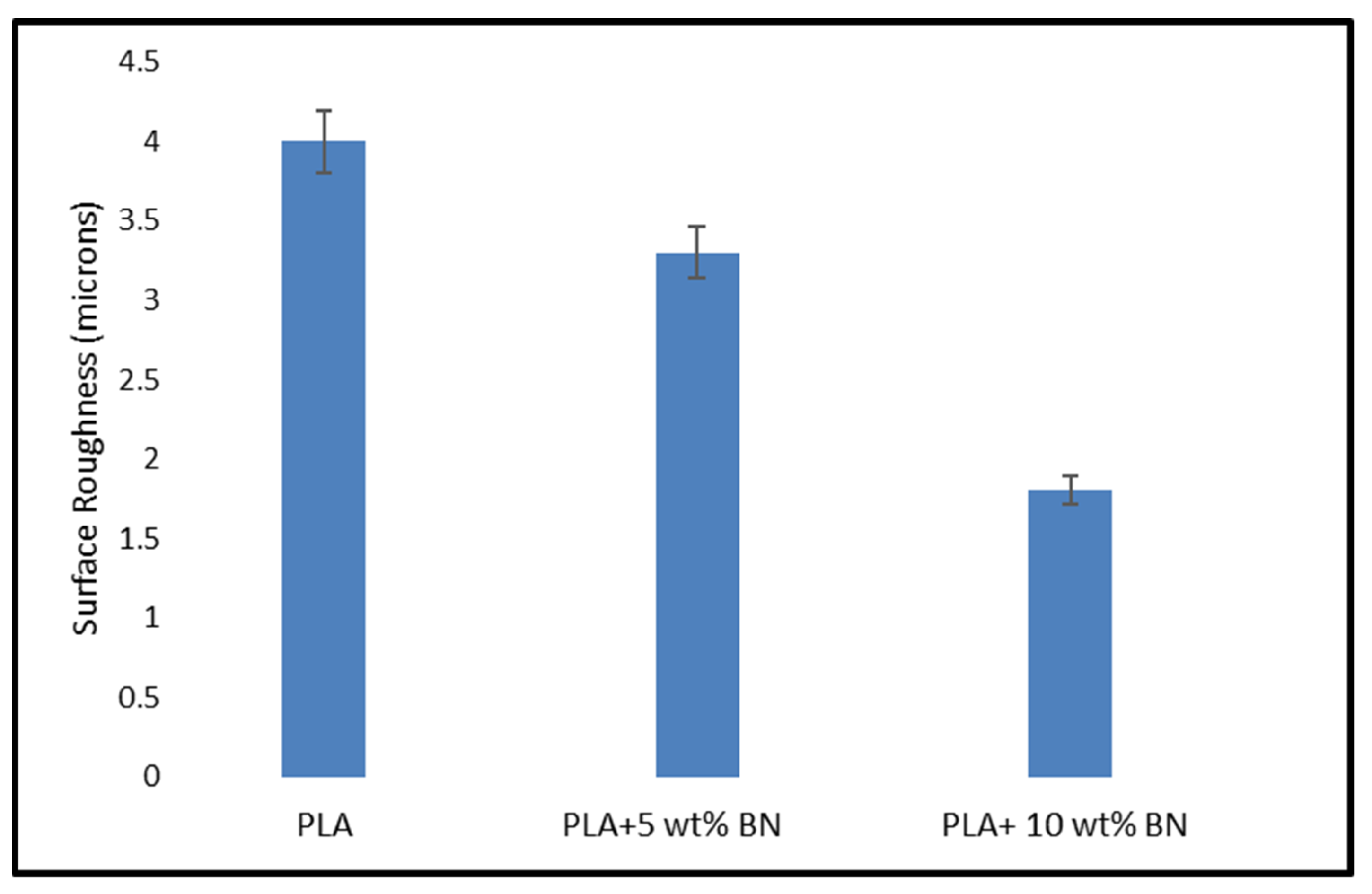

3.2. Surface Roughness

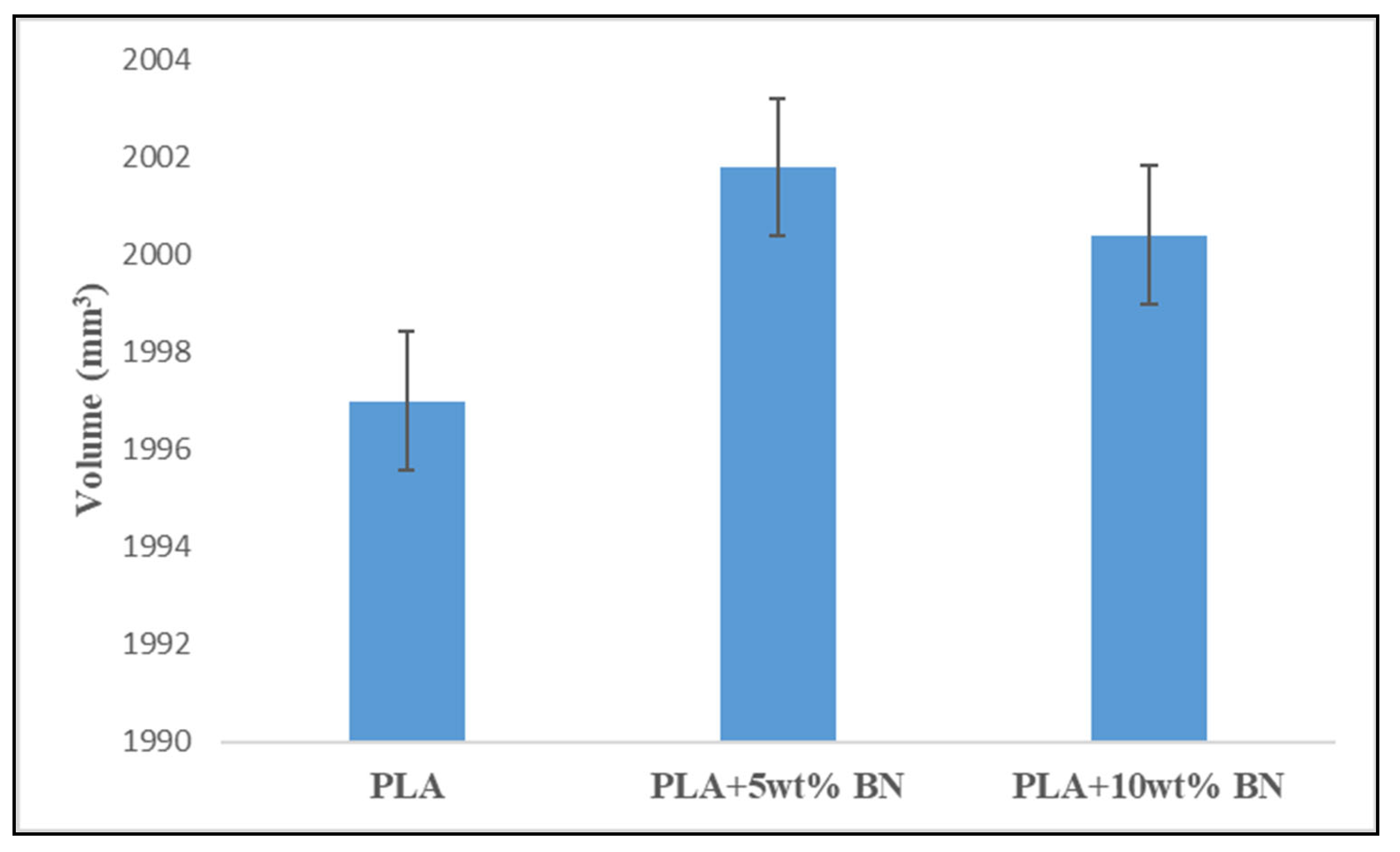

3.3. Dimensional Accuracy

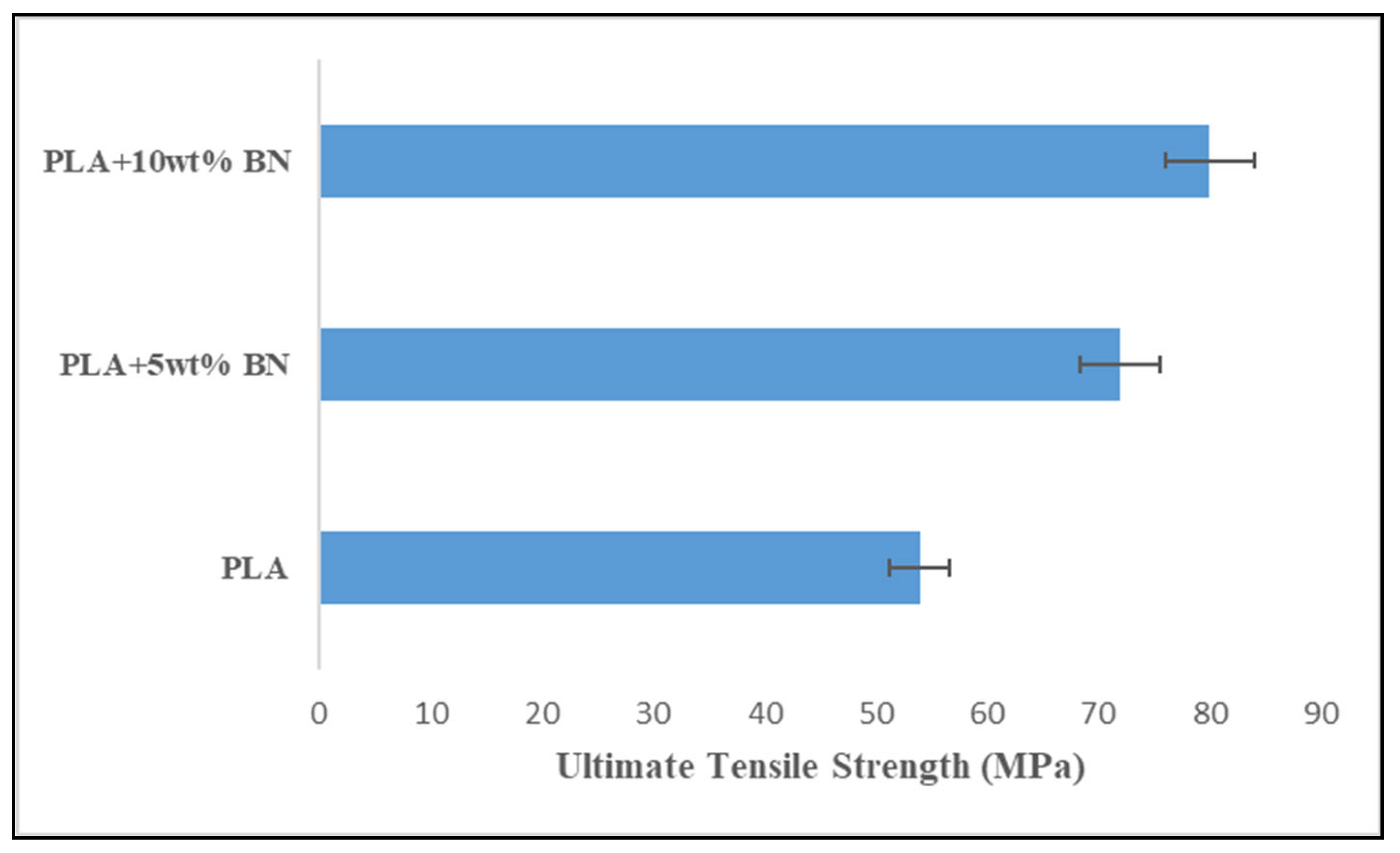

3.4. Ultimate Tensile Strength

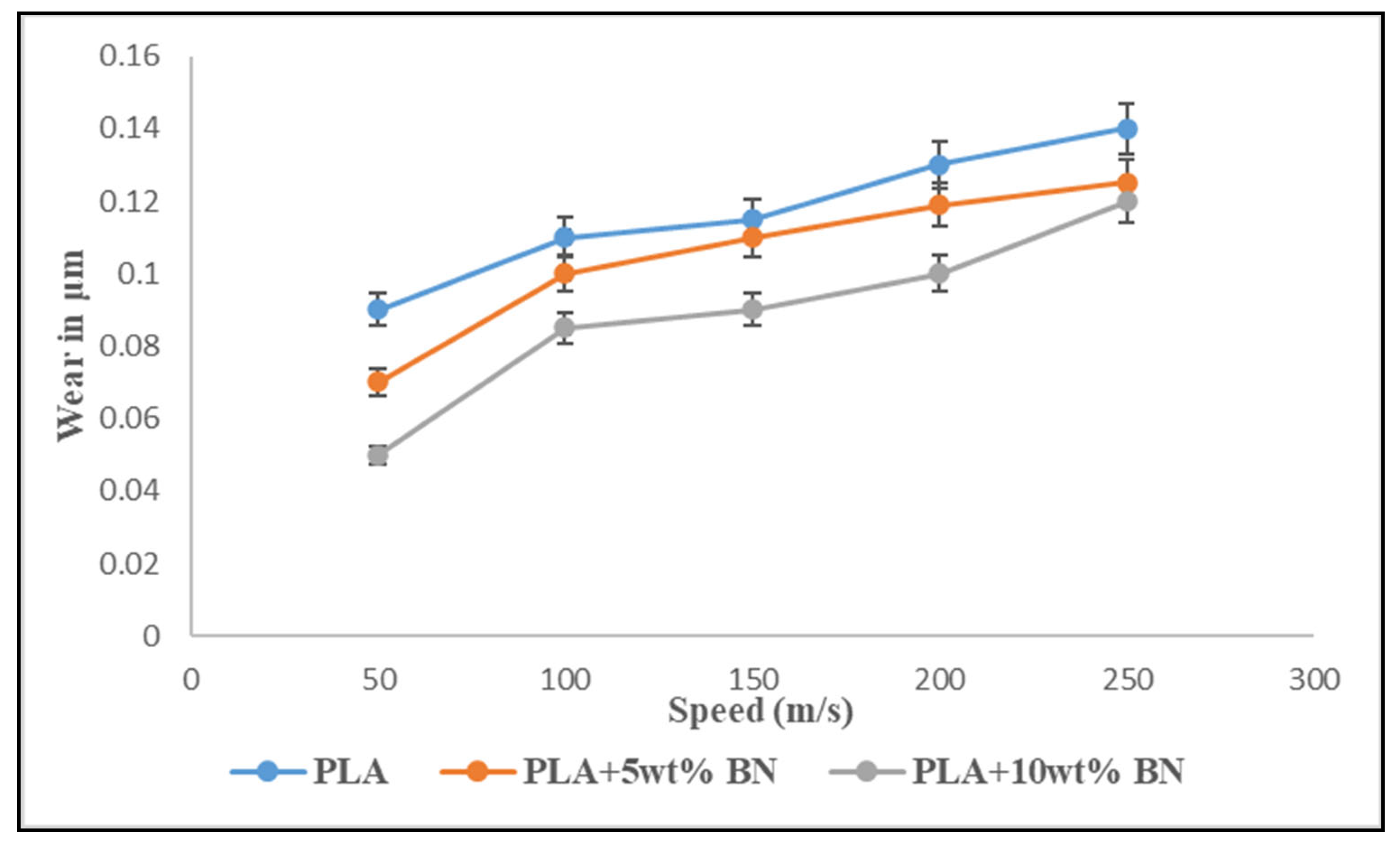

3.5. Wear Test

3.5.1. Constant Load

3.5.2. Constant Speed

3.5.3. SEM of Worn-Out Surface

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tambrallimath, V.; Keshavamurthy, R. Glimpses of 3D printing in 21st Century. In Development, Properties, and Industrial Applications of 3D Printed Polymer Composites; IGI Global: Hershey, PA, USA, 2023. [Google Scholar] [CrossRef]

- Blanco, I.; Cicala, G.; Recca, G.; Tosto, C. Specific Heat Capacity and Thermal Conductivity Measurements of PLA-Based 3D-Printed Parts with Milled Carbon Fiber Reinforcement. Entropy 2022, 24, 654. [Google Scholar] [CrossRef] [PubMed]

- Singh, S.; Ghosh, A.K.; Maiti, S.N.; Raha, S.; Gupta, R.K.; Bhattacharya, S. Morphology and rheological behavior of polylactic acid/clay nanocomposites. Polym. Eng. Sci. 2011, 52, 225–232. [Google Scholar] [CrossRef]

- Pracella, M.; Haque, M.-U.; Puglia, D. Morphology and properties tuning of PLA/cellulose nanocrystals bio-nanocomposites by means of reactive functionalization and blending with PVAc. Polymer 2014, 55, 3720–3728. [Google Scholar] [CrossRef]

- Serizawa, S.; Inoue, K.; Iji, M. Kenaf-fiber-reinforced poly(lactic acid) used for electronic products. J. Appl. Polym. Sci. 2006, 100, 618–624. [Google Scholar] [CrossRef]

- Cao, Y.; Feng, J.; Wu, P. Preparation of organically dispersible graphene nanosheet powders through a lyophilization method and their poly(lactic acid) composites. Carbon 2010, 48, 3834–3839. [Google Scholar] [CrossRef]

- Bindhu, B.; Renisha, R.; Roberts, L.; Varghese, T. Boron Nitride reinforced polylactic acid composites film for packaging: Preparation and properties. Polym. Test. 2018, 66, 172–177. [Google Scholar] [CrossRef]

- Guo, H.; Niu, H.; Zhao, H.; Kang, L.; Ren, Y.; Lv, R.; Ren, L.; Maqbool, M.; Bashir, A.; Bai, S. Highly Anisotropic Thermal Conductivity of Three-Dimensional Printed Boron Nitride-Filled Thermoplastic Polyurethane Composites: Effects of Size, Orientation, Viscosity, and Voids. ACS Appl. Mater. Interfaces 2022, 14, 14568–14578. [Google Scholar] [CrossRef] [PubMed]

- Nagarajan, V.; Mohanty, A.K.; Misra, M. Perspective on Polylactic Acid (PLA) based Sustainable Materials for Durable Applications: Focus on Toughness and Heat Resistance. ACS Sustain. Chem. Eng. 2016, 4, 2899–2916. [Google Scholar] [CrossRef]

- Tambrallimath, V.; Keshavamurthy, R.; Patil, A.; Adarsha, H. Mechanical and Tribological Characteristics of Polymer Composites Developed by Fused Deposition Modelling. In Fused Deposition Modeling Based 3D Printing, Materials Forming, Machining and Tribology; Dave, H.K., Davim, J.P., Eds.; Springer: Berlin, Germany, 2021. [Google Scholar] [CrossRef]

- GrayIv, R.W.; Baird, D.G.; Bøhn, J.H. Effects of processing conditions on short TLCP fiber reinforced FDM parts. Rapid Prototype J. 1998, 4, 14–25. [Google Scholar]

- Zhong, W.; Li, F.; Zhang, Z.; Song, L.; Li, Z. Short fiber reinforced composites for fused deposition modeling. Mater. Sci. Eng. A 2001, 301, 125–130. [Google Scholar] [CrossRef]

- Shofner, M.L.; Lozano, K.; Rodríguez-Macías, F.J.; Barrera, E.V. Nanofiber-reinforced polymers prepared by fused deposition modeling. J. Appl. Polym. Sci. 2003, 89, 3081–3090. [Google Scholar] [CrossRef]

- Melenka, G.W.; Cheung, B.K.O.; Schofield, J.S.; Dawson, M.R.; Carey, J.P. Evaluation and prediction of the tensile properties of continuous fiber-reinforced 3D printed structures. Compos. Struct. 2016, 153, 866–875. [Google Scholar] [CrossRef]

- Perez, A.R.T.; Roberson, D.A.; Wicker, R.B. Fracture Surface Analysis of 3D-Printed Tensile Specimens of Novel ABS-Based Materials. J. Fail. Anal. Prev. 2014, 14, 343–353. [Google Scholar] [CrossRef]

- Francis, V.; Jain, P.K. A filament modification approach for in situ ABS/OMMT nanocomposite development in extrusion-based 3D printing. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 361. [Google Scholar] [CrossRef]

- Domingo-Espin, M.; Puigoriol-Forcada, J.M.; Garcia-Granada, A.-A.; Llumà, J.; Borros, S.; Reyes, G. Mechanical property characterization and simulation of fused deposition modeling Polycarbonate parts. Mater. Des. 2015, 83, 670–677. [Google Scholar] [CrossRef]

- Quill, T.J.; Smith, M.K.; Zhou, T.; Baioumy, M.G.S.; Berenguer, J.P.; Cola, B.A.; Kalaitzidou, K.; Bougher, T.L. Thermal and mechanical properties of 3D printed boron nitride—ABS composites. Appl. Compos. Mater. 2017, 25, 1205–1217. [Google Scholar] [CrossRef]

- Jiang, N.; Yu, T.; Li, Y.; Pirzada, T.J.; Marrow, T.J. Hygrothermal aging and structural damage of a jute/poly (lactic acid) (PLA) composite observed by X-ray tomography. Compos. Sci. Technol. 2019, 173, 15–23. [Google Scholar] [CrossRef]

- Tambrallimath, V.; Keshavamurthy, R.; Saravanbavan, D.; Pradeepkumar, G.S.; Harish Kumar, M. Synthesis and Characterization of Graphene Filled PC-ABS Filament for FDM Applications. In Proceedings of the Advances in Polymer Composites: Mechanics, Characterization and Applications, AIP Second International Conference on Polymer Composites (ICPC 2018), Surathkal, India, 15–16 December 2018. [Google Scholar]

- Vishal, K.; Rajkumar, K.; Sabarinathan, P.; Dhinakaran, V. Mechanical and Wear Characteristics Investigation on 3D Printed Silicon Filled Poly (Lactic Acid) Biopolymer Composite Fabricated by Fused Deposition Modeling. Silicon 2022, 14, 9379–9391. [Google Scholar] [CrossRef]

- Pant, M.; Singari, R.M.; Arora, P.K.; Moona, G.; Kumar, H. Wear assessment of 3–D printed parts of PLA (polylactic acid) using Taguchi design and Artificial Neural Network (ANN) technique. Mater. Res. Express 2020, 7, 115307. [Google Scholar] [CrossRef]

- Keshavamurthy, R.; Tambrallimath, V.; Rajhi, A.A.; Ahmed R.M., S.; Patil, A.Y.; Khan, T.M.Y.; Makannavar, R. Influence of Solid Lubricant Addition on Friction and Wear Response of 3D Printed Polymer Composites. Polymers 2021, 13, 2905. [Google Scholar] [CrossRef]

- Keshavamurthy, R.; Tambrallimath, V.; Badari, A.; Krishna, R.A.; Kumar, G.P.; Jeevan, M. Friction and wear behaviour of copper reinforced acrylonitrile butadiene styrene based polymer composite developed by fused deposition modelling process. FME Trans. 2020, 48, 543–550. [Google Scholar] [CrossRef]

- Pan, D.; Li, Q.; Zhang, W.; Dong, J.; Su, F.; Murugadoss, V.; Liu, Y.; Liu, C.; Naik, N.; Guo, Z. Highly thermal conductive epoxy nanocomposites filled with 3D BN/C spatial network prepared by salt template assisted method. Compos. Part B Eng. 2021, 209, 108609. [Google Scholar] [CrossRef]

- Joy, J.; George, E.; Haritha, P.; Thomas, S.; Anas, S. An overview of boron nitride based polymer nanocomposites. J. Polym. Sci. 2020, 58, 3115–3141. [Google Scholar] [CrossRef]

- Su, K.-H.; Su, C.-Y.; Shih, W.-L.; Lee, F.-T. Improvement of the Thermal Conductivity and Mechanical Properties of 3D-Printed Polyurethane Composites by Incorporating Hydroxylated Boron Nitride Functional Fillers. Materials 2022, 16, 356. [Google Scholar] [CrossRef] [PubMed]

- Bashir, A.; Maqbool, M.; Lv, R.; Usman, A.; Guo, H.; Aftab, W.; Niu, H.; Liu, M.; Bai, S.-L. Surface modified boron nitride towards enhanced thermal and mechanical performance of thermoplastic polyurethane composite. Compos. Part B Eng. 2021, 218, 108871. [Google Scholar] [CrossRef]

- Otsuki, M.; Matsukawa, H. Systematic Breakdown of Amontons′ Law of Friction for an Elastic Object Locally. Sci. Rep. 2013, 3, 1586. [Google Scholar] [CrossRef] [PubMed]

- Alem, S.; Latifi, R.; Angizi, S.; Mohamadbeigi, N.; Rajabi, M.; Ghasali, E.; Orooji, Y. Development of Metal Matrix Composites and Nanocomposites Via Double-Pressing Double-Sintering (DPDS) Method. Mater. Today Commun. 2020, 25, 101245. [Google Scholar] [CrossRef]

- Anitha, R.; Arunachalam, S.; Radhakrishnan, P. Critical parameters influencing the quality of prototypes in fused deposition modelling. J. Am. Acad. Dermatol. 2001, 118, 385–388. [Google Scholar] [CrossRef]

- Chohan, J.S.; Singh, R. Pre and post processing techniques to improve surface characteristics of FDM parts: A state of art review and future applications. Rapid Prototyp. J. 2017, 23, 495–513. [Google Scholar] [CrossRef]

- Zhao, L.-H.; Wang, L.; Jin, Y.-F.; Ren, J.-W.; Wang, Z.; Jia, L.-C. Simultaneously improved thermal conductivity and mechanical properties of boron nitride nanosheets/aramid nanofiber films by constructing multilayer gradient structure. Compos. Part B Eng. 2021, 229, 109454. [Google Scholar] [CrossRef]

- Kumar, H.R.M.; Benal, M.G.M.; Kumar, G.S.P.; Tambrallimath, V.H.R.G.; Khan, T.M.Y.; Rajhi, A.A.; Baig, M.A.A. Influence of Short Glass Fibre Reinforcement on Mechanical Properties of 3D Printed ABS-Based Polymer Composites. Polymers 2022, 14, 1182. [Google Scholar] [CrossRef]

- Li, S.; Wang, K.; Zhu, W.; Peng, Y.; Ahzi, S.; Chinesta, F. Investigation on the mechanical properties of 3D printed hybrid continuous fiber-filled composite considering influence of interfaces. Int. J. Adv. Manuf. Technol. 2022, 123, 3147–3158. [Google Scholar] [CrossRef]

- Tronvoll, S.A.; Welo, T.; Elverum, C.W. The effects of voids on structural properties of fused deposition modelled parts: A probabilistic approach. Int. J. Adv. Manuf. Technol. 2018, 97, 3607–3618. [Google Scholar] [CrossRef]

- Shaikh, M.; Singh, P.; Kate, K.; Freese, M.; Atre, S. Finite element-based simulation of metal fused filament fab-rication process: Distortion prediction and experimental verification. J. Mater. Eng. Perform. 2021, 30, 5135–5149. [Google Scholar] [CrossRef]

- Kumar, M.S.; Mangalaraja, R.V.; Kumar, R.S.; Natrayan, L. Processing and Characterization of AA2024/Al2O3/SiC Reinforces Hybrid Composites Using Squeeze Casting Technique. Iran. J. Mater. Sci. Eng. 2019, 16, 55–67. [Google Scholar]

- Sarmah, A.; Kar, S.; Patowari, P.K.; Sarmah, A. Surface modification of aluminum with green compact powder met-allurgy Inconel-aluminum tool in EDM. Mater. Manuf. Process. 2020, 35, 1104–1112. [Google Scholar] [CrossRef]

- Tyagi, R.; Pandey, K.; Das, A.K.; Mandal, A. Deposition of hBN + Cu layer through electrical discharge process using green compact electrode. Mater. Manuf. Process. 2019, 34, 1035–1048. [Google Scholar] [CrossRef]

- Huang, T.; Xin, Y.; Li, T.; Nutt, S.; Su, C.; Chen, H.; Liu, P.; Lai, Z. Modified graphene/polyimide nanocomposites: Reinforcing and tribological effects. ACS Appl. Mater. Interfaces 2013, 5, 4878–4891. [Google Scholar] [CrossRef]

- Friedrich, K.; Flöck, J.; Váradi, K.; Néder, Z. Experimental and numerical evaluation of the mechanical properties of compacted wear debris layers formed between composite and steel surfaces in sliding contact. Wear 2001, 251, 1202–1212. [Google Scholar] [CrossRef]

- ASTM G99; Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM-D638; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2012.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Keshavamurthy, R.; Tambrallimath, V.; Patil, S.; Rajhi, A.A.; Duhduh, A.A.; Khan, T.M.Y. Mechanical and Wear Studies of Boron Nitride-Reinforced Polymer Composites Developed via 3D Printing Technology. Polymers 2023, 15, 4368. https://doi.org/10.3390/polym15224368

Keshavamurthy R, Tambrallimath V, Patil S, Rajhi AA, Duhduh AA, Khan TMY. Mechanical and Wear Studies of Boron Nitride-Reinforced Polymer Composites Developed via 3D Printing Technology. Polymers. 2023; 15(22):4368. https://doi.org/10.3390/polym15224368

Chicago/Turabian StyleKeshavamurthy, Ramaiah, Vijay Tambrallimath, Swetha Patil, Ali A. Rajhi, Alaauldeen A. Duhduh, and T. M. Yunus Khan. 2023. "Mechanical and Wear Studies of Boron Nitride-Reinforced Polymer Composites Developed via 3D Printing Technology" Polymers 15, no. 22: 4368. https://doi.org/10.3390/polym15224368

APA StyleKeshavamurthy, R., Tambrallimath, V., Patil, S., Rajhi, A. A., Duhduh, A. A., & Khan, T. M. Y. (2023). Mechanical and Wear Studies of Boron Nitride-Reinforced Polymer Composites Developed via 3D Printing Technology. Polymers, 15(22), 4368. https://doi.org/10.3390/polym15224368