Enhanced Thermal and Dielectric Properties of Polyarylene Ether Nitrile Nanocomposites Incorporated with BN/TiO2-Based Hybrids for Flexible Dielectrics

Abstract

:1. Introduction

2. Experimental Methods

2.1. Materials

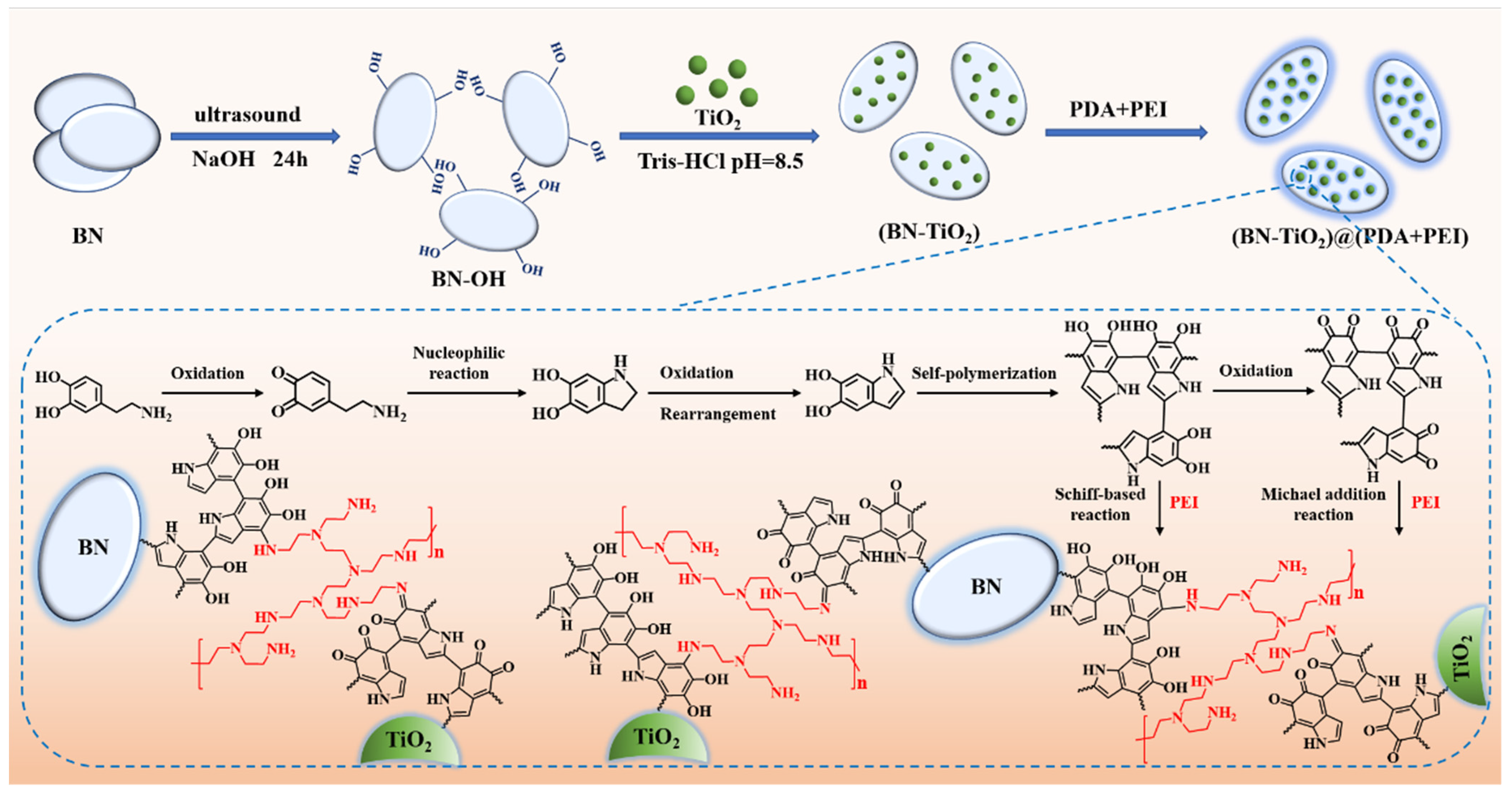

2.2. Preparation of (BN-TiO2)@(PDA + PEI) Nanohybrids

2.3. Preparation of PEN Nanocomposite Films

2.4. Characterization

3. Results and Discussion

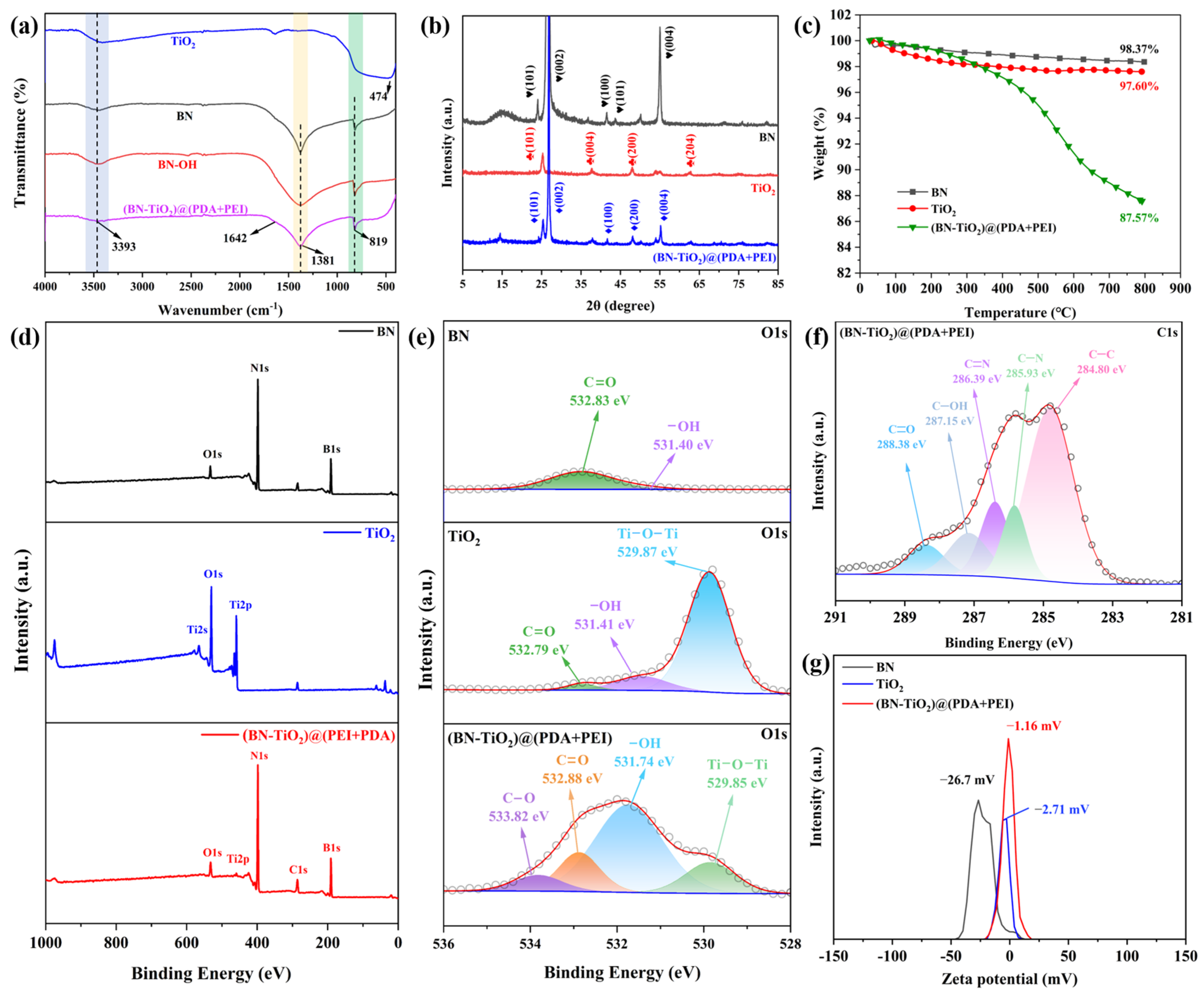

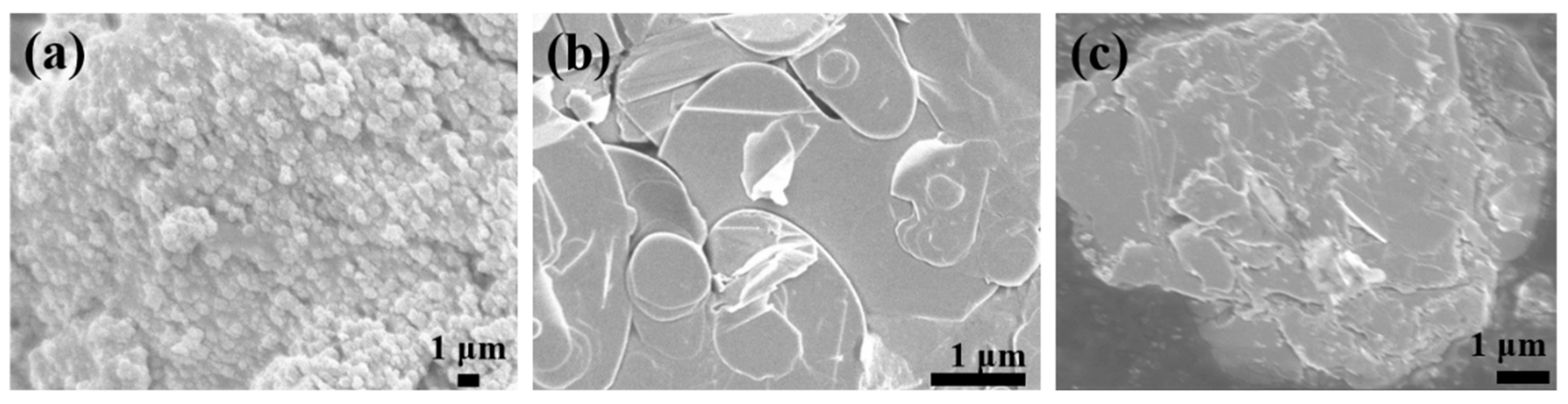

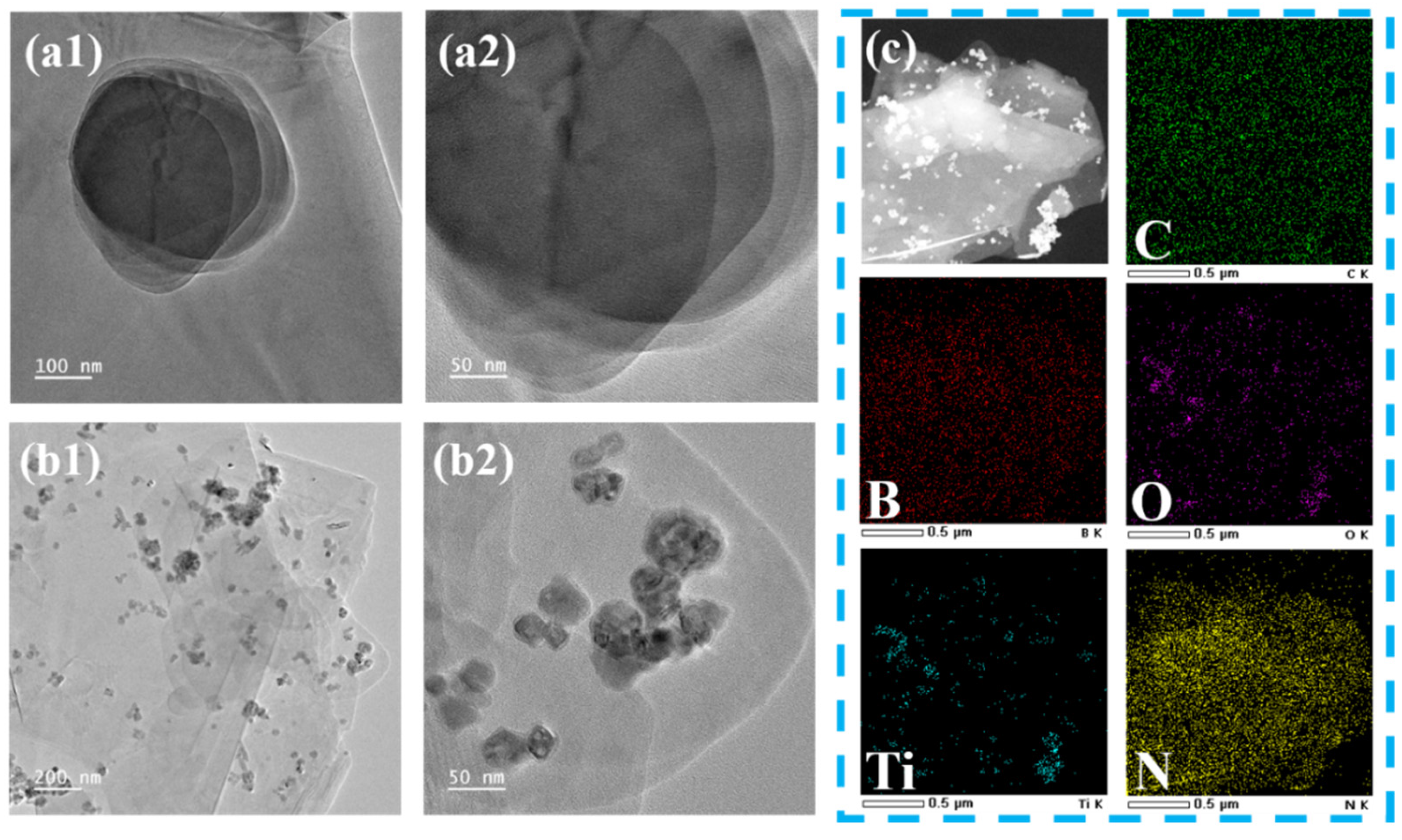

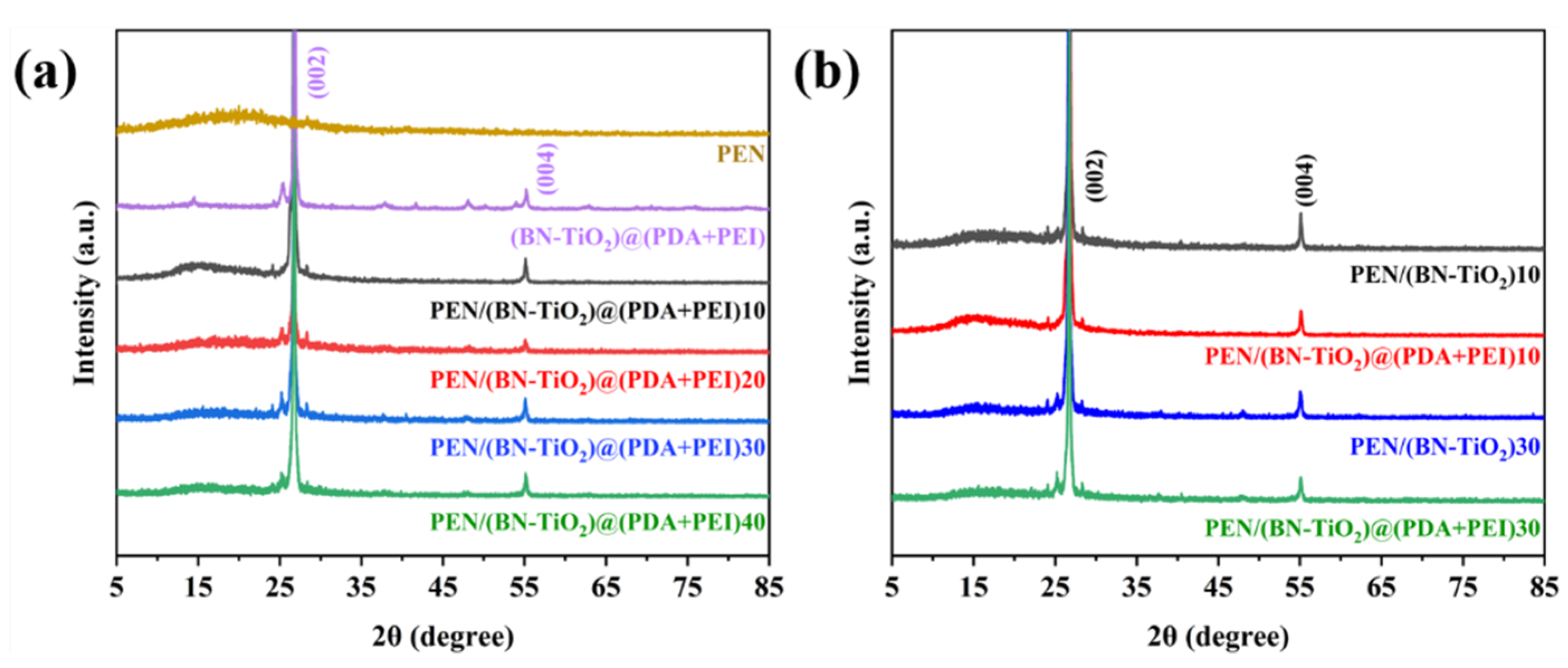

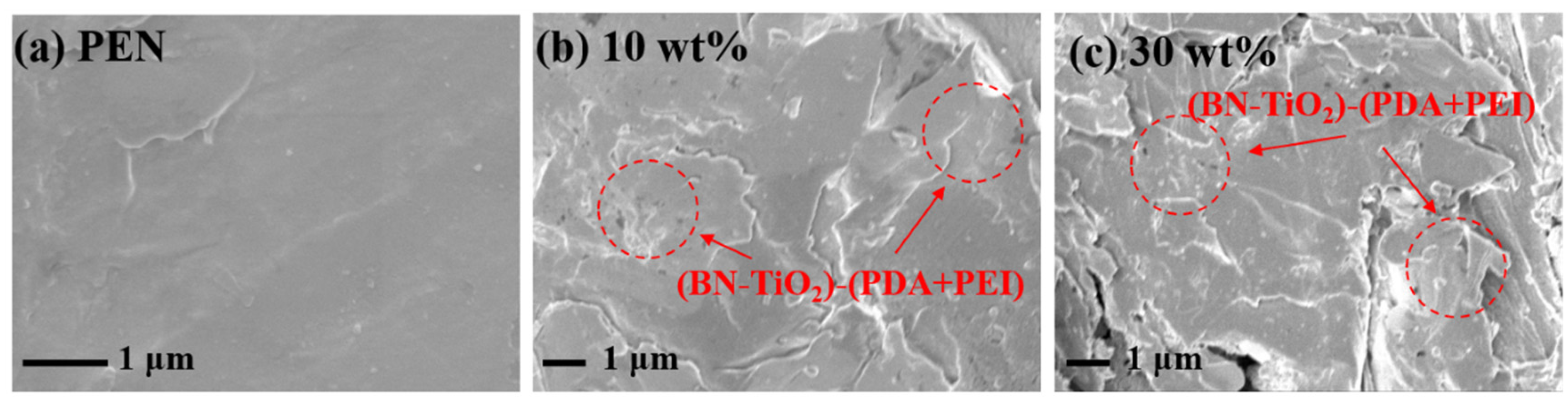

3.1. Characterization of (BN-TiO2)@(PDA + PEI) Nanohybrids

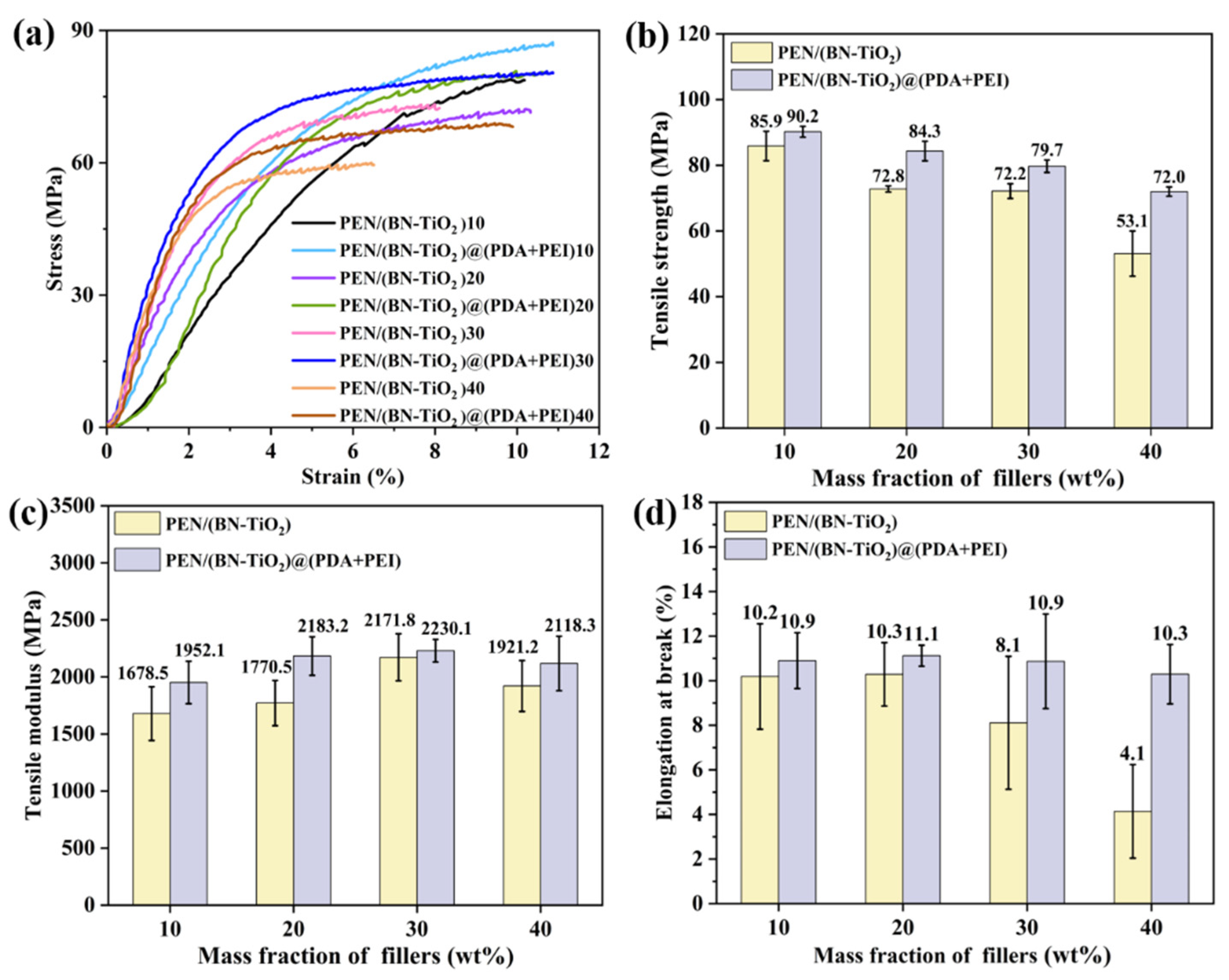

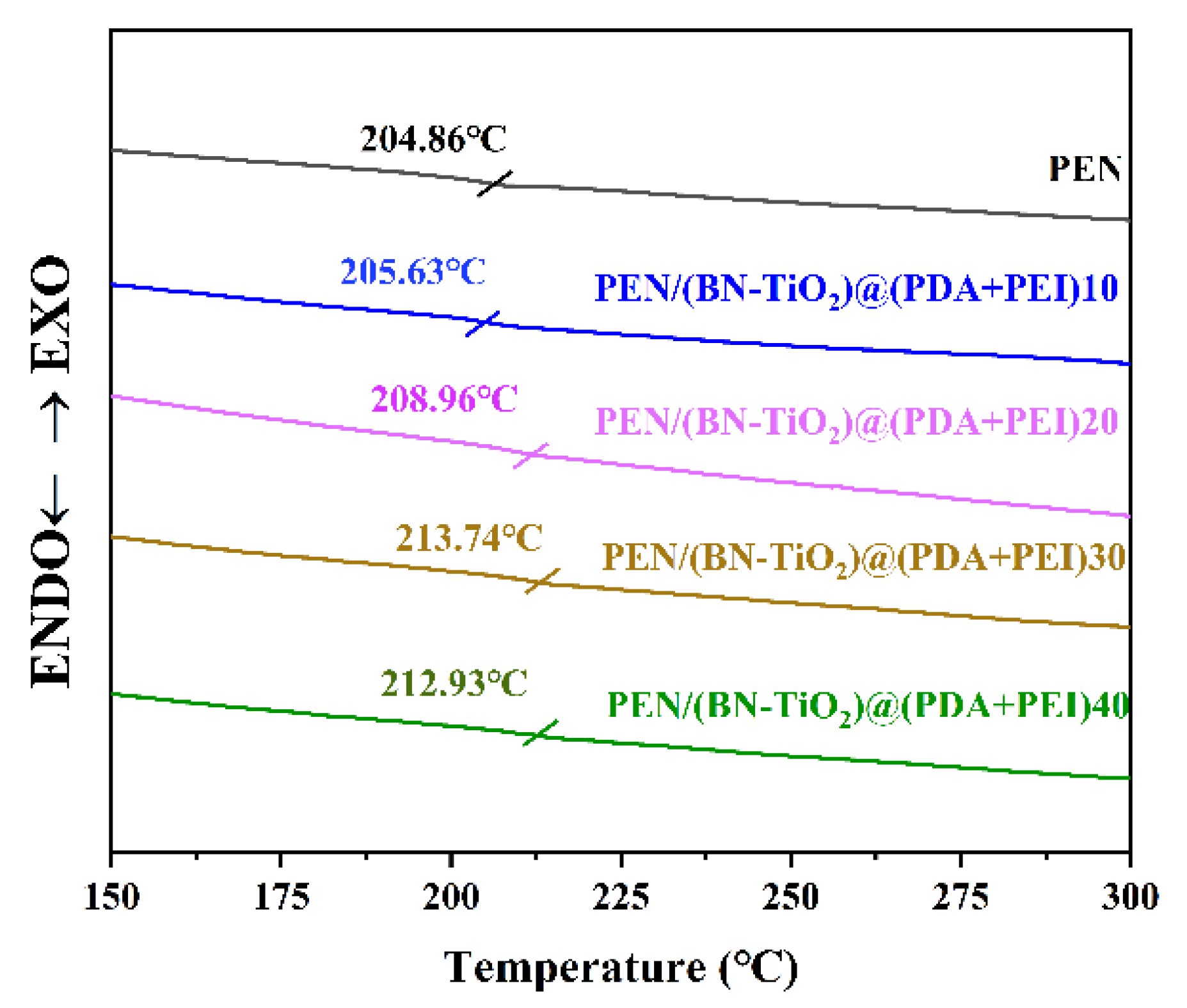

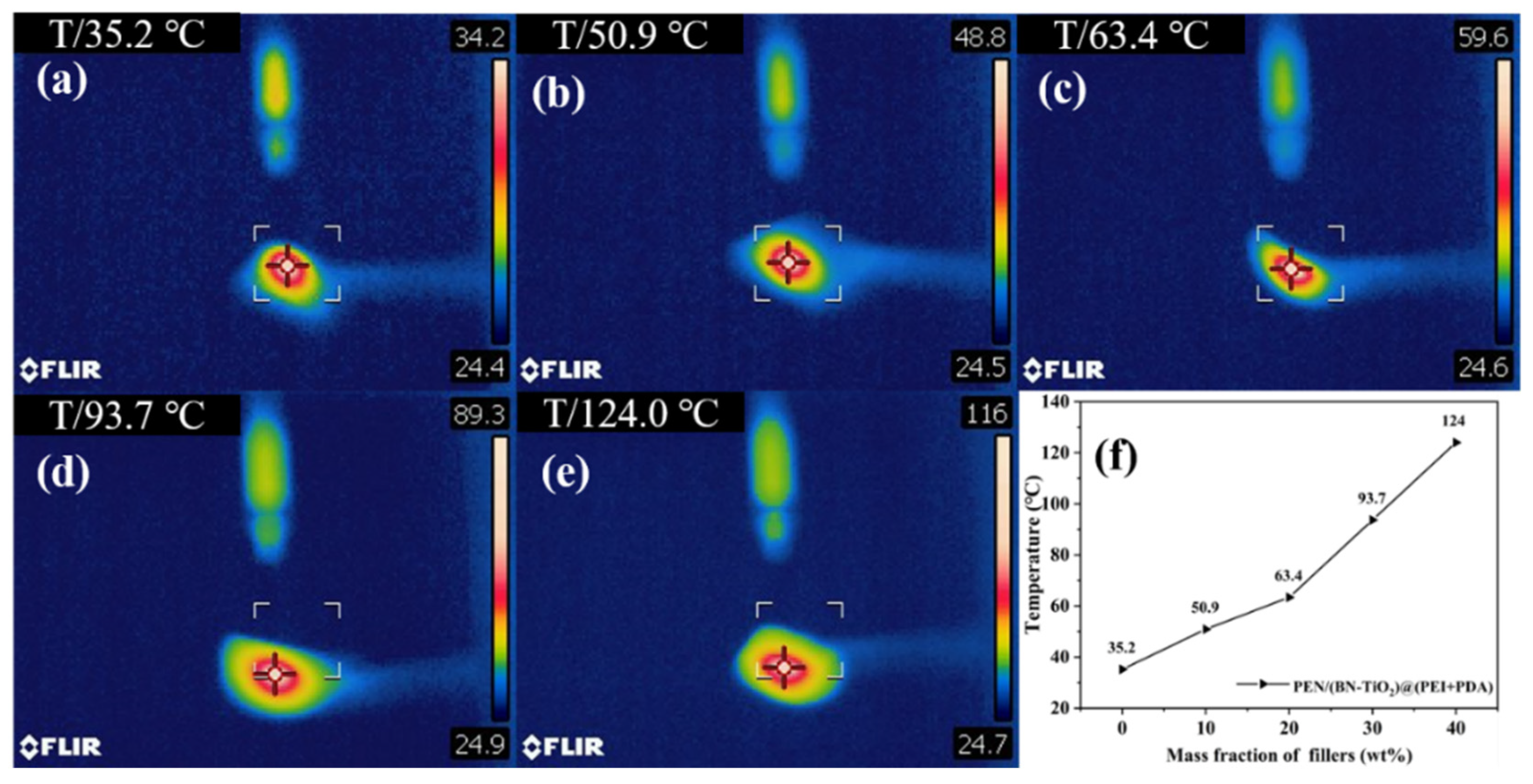

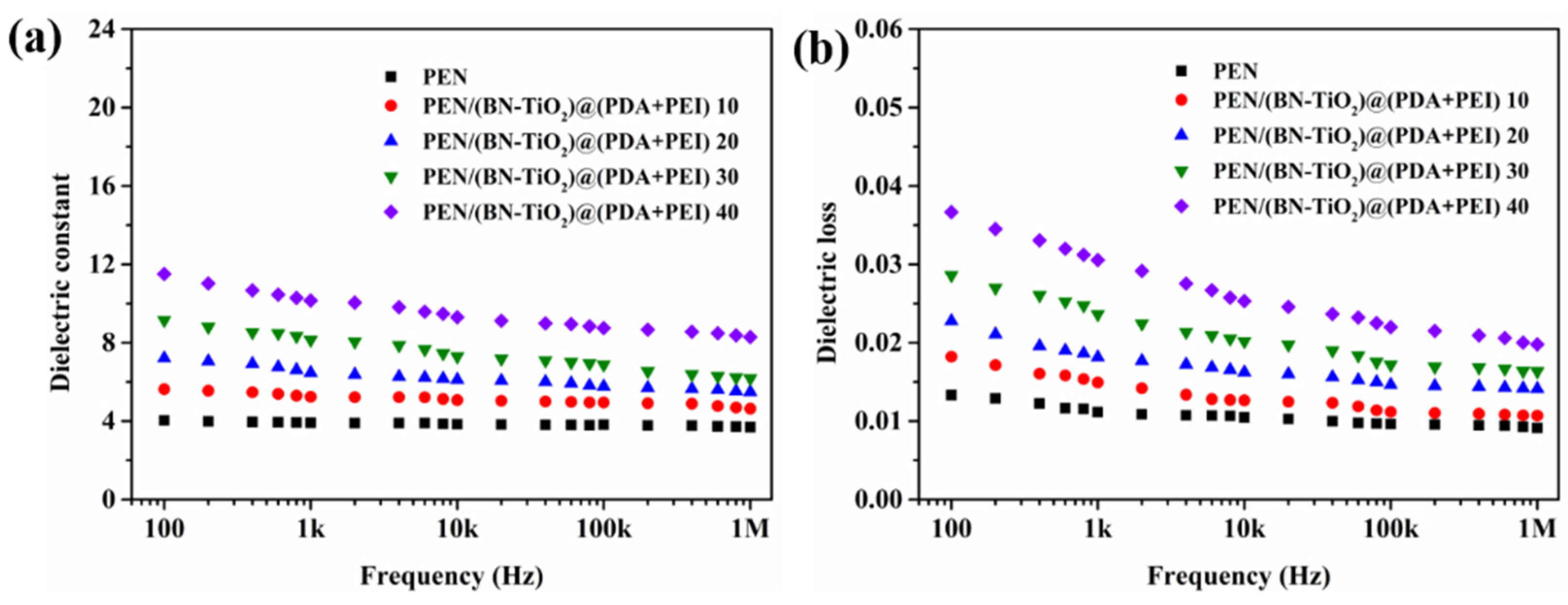

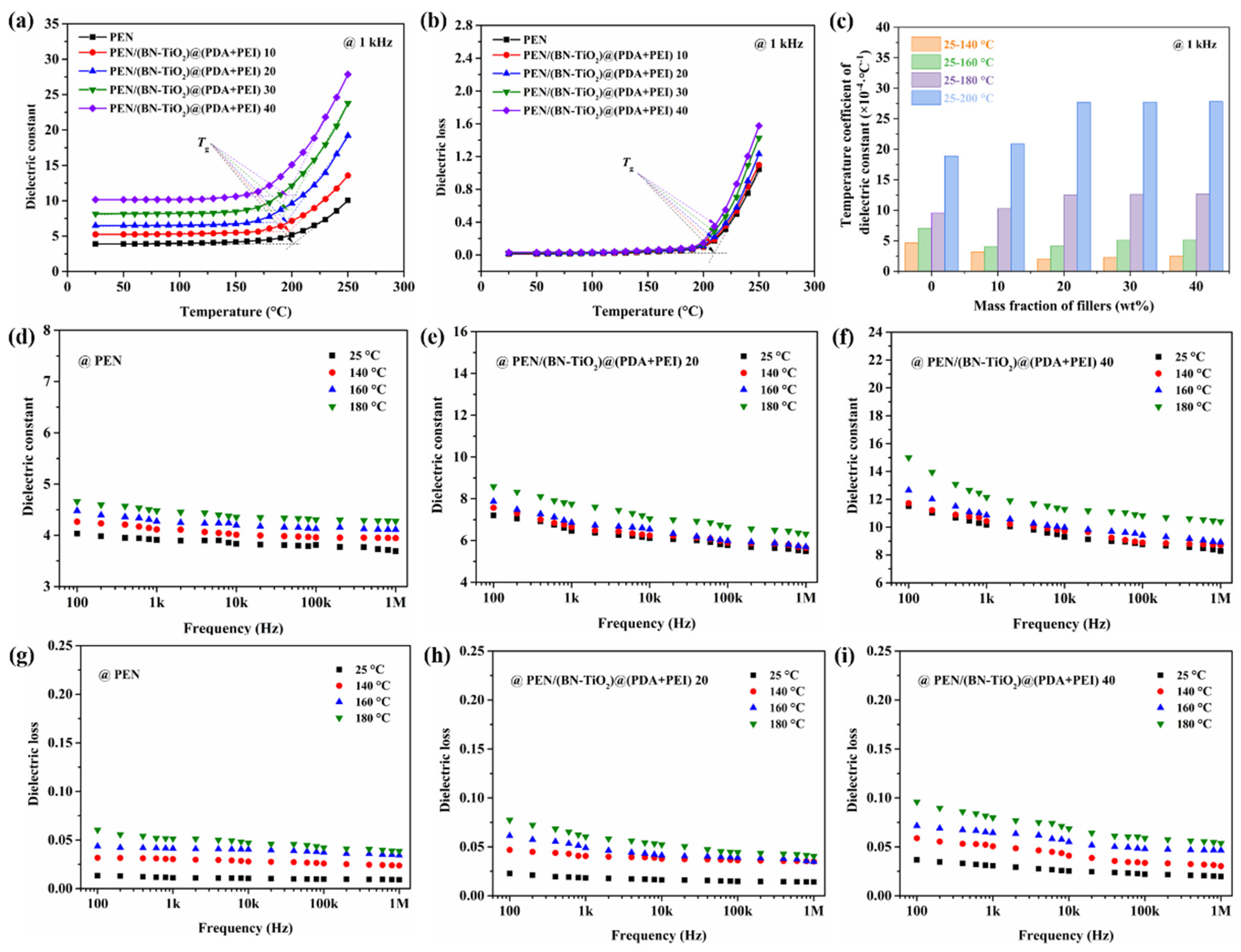

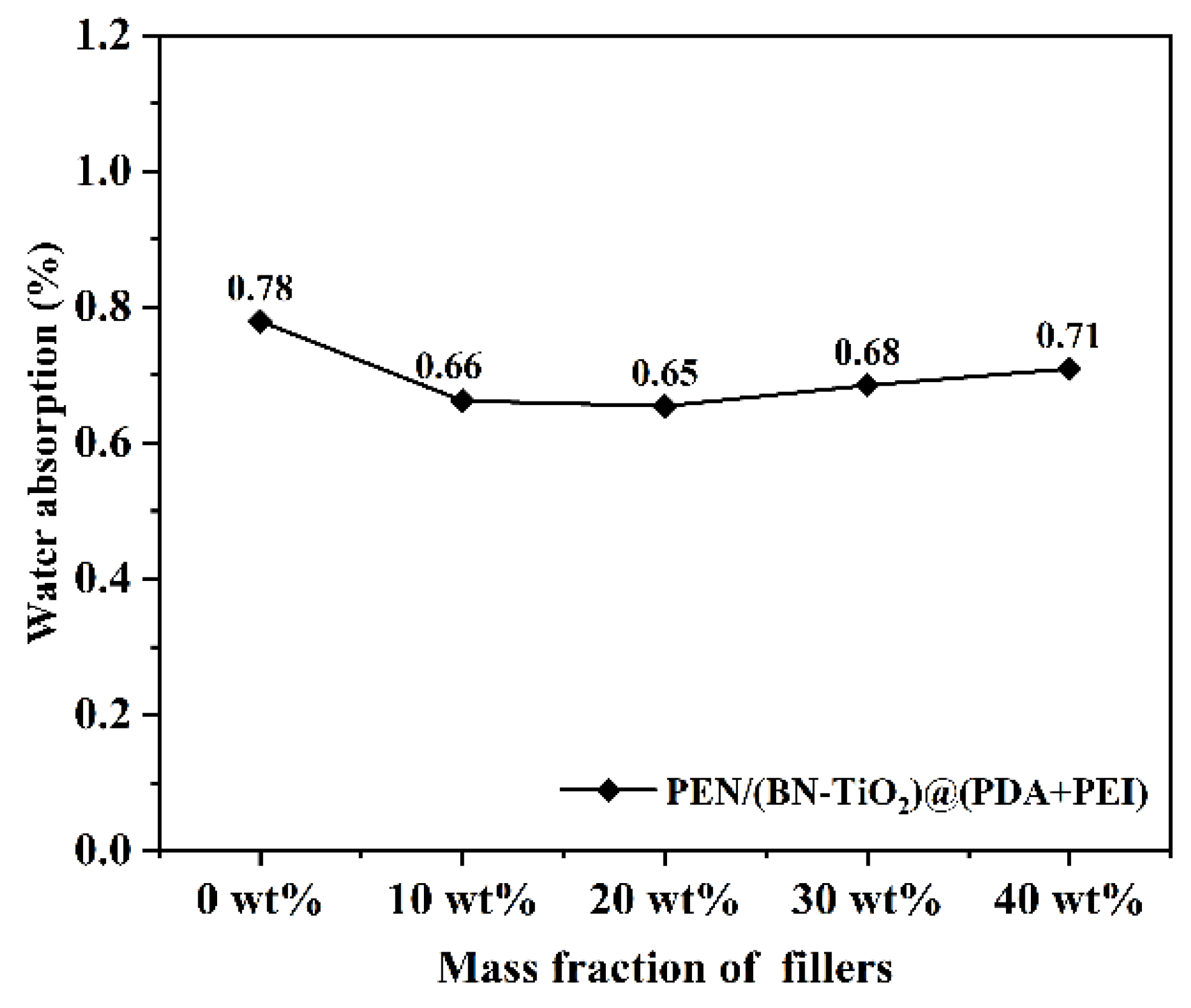

3.2. The Properties of Nanocomposites

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, Y.; Qian, C.; Qu, L.; Wu, Y.; Zhang, Y.; Wu, X.; Zou, B.; Chen, W.; Chen, Z.; Chi, Z.; et al. A bulk dielectric polymer film with intrinsic ultralow dielectric constant and outstanding comprehensive properties. Chem. Mater. 2015, 27, 6543–6549. [Google Scholar] [CrossRef]

- Qiu, J.; Gu, Q.; Sha, Y.; Huang, Y.; Zhang, M.; Luo, Z.Y. Preparation and application of dielectric polymers with high permittivity and low energy loss: A mini review. J. Appl. Polym. Sci. 2022, 139, e52367. [Google Scholar] [CrossRef]

- Zhou, L.; Jiang, Y.F. Recent progress in dielectric nanocomposites. Mater. Sci. Technol. 2020, 36, 1–16. [Google Scholar] [CrossRef]

- Hikosaka, S.; Ohki, Y. Dielectric properties of poly(phenylene sulfide) as a function of temperature and frequency. IEEJ Trans. Electr. Electron. Eng. 2012, 7, 116–120. [Google Scholar] [CrossRef]

- Dang, Z.M.; Zhou, T.; Yao, S.H.; Yuan, J.K.; Zha, J.W.; Song, H.T.; Li, J.Y.; Chen, Q.; Yang, W.T.; Bai, J. Advanced calcium copper titanate/polyimide functional hybrid films with high dielectric permittivity. Adv. Mater. 2009, 21, 2077–2082. [Google Scholar] [CrossRef]

- Liu, Y.W.; Tang, L.S.; Qu, L.J.; Liu, S.W.; Chi, Z.G.; Zhang, Y.; Xu, J.R. Synthesis and properties of high performance functional polyimides containing rigid nonplanar conjugated fluorene moieties. Chin. J. Polym. Sci. 2019, 37, 416–427. [Google Scholar] [CrossRef]

- You, Y.; Zhan, C.; Tu, L.; Wang, Y.; Hu, W.; Wei, R.; Liu, X. Polyarylene ether nitrile-based high-composites for dielectric applications. Int. J. Polym. Sci. 2018, 2018, 5161908. [Google Scholar] [CrossRef]

- Yao, Z.; Song, Z.; Hao, H.; Yu, Z.; Cao, M.; Zhang, S.; Lanagan, M.T.; Liu, H. Homogeneous/inhomogeneous-structured dielectrics and their energy-storage performances. Adv. Mater. 2017, 29, 1601727. [Google Scholar] [CrossRef] [PubMed]

- Zhan, J.Y.; Tian, G.F.; Wu, Z.P.; Qi, S.L.; Wu, D.Z. Preparation of polyimide/BaTiO3/Ag nanocomposite films via in situ technique and study of their dielectric behavior. Chin. J. Polym. Sci. 2014, 32, 424–431. [Google Scholar] [CrossRef]

- Dang, Z.M.; Yuan, J.K.; Zha, J.W.; Zhou, T.; Li, S.T.; Hu, G.H. Fundamentals, processes and applications of high-permittivity polymer-matrix composites. Prog. Mater. Sci. 2012, 57, 660–723. [Google Scholar] [CrossRef]

- Wang, P.; Wang, M.; Song, T.; Chen, J.; Liu, X.; Liu, X.; You, Y.; Song, H.; Li, K.; Li, Y.; et al. Anti-bacterial robust Ag@PDA/PEN electrospinning nanofibrous membrane for oil-water separation. J. Water Process Eng. 2023, 51, 103358. [Google Scholar] [CrossRef]

- Chen, S.Y.; Yang, S.; Chen, S.S.; Zuo, F.; Wang, P.; Li, Y.; You, Y. Polyarylene ether nitrile dielectric films modified by HNTs@PDA hybrids for high-temperature resistant organic electronics field. Nanotechnol. Rev. 2023, 12, 20230117. [Google Scholar] [CrossRef]

- Yang, M.; Zhao, H.; He, D.; Bai, J. Constructing a continuous amorphous carbon interlayer to enhance dielectric performance of carbon nanotubes/polyvinylidene fluoride nanocomposites. Carbon 2017, 116, 94–102. [Google Scholar] [CrossRef]

- Chen, J.J.; Li, Y.; Zheng, X.M.; He, F.A.; Lam, K.H. Enhancement in electroactive crystalline phase and dielectric performance of novel PEG-graphene/PVDF composites. Appl. Surf. Sci. 2018, 448, 320–330. [Google Scholar] [CrossRef]

- Sun, L.L.; Li, B.; Zhao, Y.; Mitchell, G.; Zhong, W.H. Structure-induced high dielectric constant and low loss of CNF/PVDF composites with heterogeneous CNF distribution. Nanotechnology 2010, 21, 305702. [Google Scholar] [CrossRef] [PubMed]

- Dang, Z.M.; Peng, B.; Xie, D.; Yao, S.H.; Jiang, M.J.; Bai, J. High dielectric permittivity silver/polyimide composite films with excellent thermal stability. Appl. Phys. Lett. 2008, 92, 112910. [Google Scholar] [CrossRef]

- Luo, S.; Shen, Y.; Yu, S.; Wan, Y.; Liao, W.H.; Sun, R.; Wong, C.P. Construction of a 3D-BaTiO3 network leading to significantly enhanced dielectric permittivity and energy storage density of polymer composites. Energy Environ. Sci. 2017, 10, 137–144. [Google Scholar] [CrossRef]

- Yao, L.; Pan, Z.; Zhai, J.; Zhang, G.; Liu, Z.; Liu, Y. High-energy-density with polymer nanocomposites containing of SrTiO3 nanofibers for capacitor application. Compos. Part A 2018, 109, 48–54. [Google Scholar] [CrossRef]

- Wu, C.; Huang, X.; Xie, L.; Wu, X.; Yu, J.; Jiang, P. Morphology-controllable graphene-TiO2 nanorod hybrid nanostructures for polymer composites with high dielectric performance. J. Mater. Chem. 2011, 21, 17729–17736. [Google Scholar] [CrossRef]

- Chen, S.; Xu, R.; Liu, J.; Zou, X.; Qiu, L.; Kang, F.; Liu, B.; Cheng, H.M. Simultaneous production and functionalization of boron nitride nanosheets by sugar-assisted mechanochemical exfoliation. Adv. Mater. 2019, 31, 1804810. [Google Scholar] [CrossRef] [PubMed]

- Zhi, C.; Bando, Y.; Tang, C.; Kuwahara, H.; Golberg, D. Large-scale fabrication of boron nitride nanosheets and their utilization in polymeric composites with improved thermal and mechanical properties. Adv. Mater. 2009, 21, 2889–2893. [Google Scholar] [CrossRef]

- Bai, H.; Ge, G.; He, X.; Shen, B.; Zhai, J.; Pan, H. Ultrahigh breakdown strength and energy density of polymer nanocomposite containing surface insulated BCZT@BN nanofibers. Compos. Sci. Technol. 2020, 195, 108209. [Google Scholar] [CrossRef]

- Li, Q.; Chen, L.; Gadinski, M.R.; Zhang, S.; Zhang, G.; Li, H.U.; Iagodkine, E.; Haque, A.; Chen, L.Q.; Jackson, T.N.; et al. Flexible high-temperature dielectric materials from polymer nanocomposites. Nature 2015, 523, 576–579. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Liu, W.; Li, S.; Jiang, P.; Tanaka, T. Boron nitride based poly(phenylene sulfide) composites with enhanced thermal conductivity and breakdown strength. IEEJ Trans. Fundam. Mater. 2013, 133, 66–70. [Google Scholar] [CrossRef]

- You, Y.; Wang, Y.; Tu, L.; Tong, L.; Wei, R.; Liu, X. Interface modulation of core-shell structured BaTiO3@polyaniline for novel dielectric materials from its nanocomposite with polyarylene ether nitrile. Polymers 2018, 10, 1378. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Liu, C.; Liu, C.; Tu, L.; You, Y.; Wei, R.; Liu, X. Polyarylene ether nitrile and barium titanate nanocomposite plasticized by carboxylated zinc phthalocyanine buffer. Polymers 2019, 11, 418. [Google Scholar] [CrossRef] [PubMed]

- Yang, R.; Xiao, Q.; You, Y.; Wei, R.; Liu, X. In situ catalyzed and reinforced high-temperature flexible crosslinked ZnO nano-whisker/polyarylene ether nitriles composite dielectric films. Polym. Compos. 2018, 39, 2801–2811. [Google Scholar] [CrossRef]

- Cai, W.; Guo, W.; Pan, Y.; Wang, J.; Mu, X.; Feng, X.; Yuan, B.; Wang, B.; Hu, Y. Polydopamine-bridged synthesis of ternary h-BN@PDA@SnO2 as nanoenhancers for flame retardant and smoke suppression of epoxy composites. Compos. Part A 2018, 111, 94–105. [Google Scholar] [CrossRef]

- Ren, H.; Kulkarni, D.D.; Kodiyath, R.; Xu, W.; Choi, I.; Tsukruk, V.V. Competitive adsorption of dopamine and rhodamine 6G on the surface of graphene oxide. ACS Appl. Mater. Interfaces 2014, 6, 2459–2470. [Google Scholar] [CrossRef]

- Yang, D.; Ruan, M.; Huang, S.; Wu, Y.; Li, S.; Wang, H.; Shang, Y.; Li, B.; Guo, W.; Zhang, L. Improved electromechanical properties of NBR dielectric composites by poly(dopamine) and silane surface functionalized TiO2 nanoparticles. J. Mater. Chem. C 2016, 4, 7724–7734. [Google Scholar] [CrossRef]

- Bhattacharyya, P.; Sahoo, S.; Seikh, A.H.; Mohammed, S.K.; Sarkar, A.; Alharthi, N. Synthesis, characterization and optical property study of BCNO and BCN related nanopowder. Diamond Relat. Mater. 2019, 92, 235–241. [Google Scholar] [CrossRef]

- Tang, C.; Bando, Y.; Huang, Y.; Zhi, C.; Golberg, D. Synthetic routes and formation mechanisms of spherical boron nitride nanoparticles. Adv. Funct. Mater. 2008, 18, 3653–3661. [Google Scholar] [CrossRef]

- Yang, W.; Xu, W.; Wang, Y.; Chen, D.; Wang, X.; Cao, Y.; Wu, Q.; Tu, J.; Zhen, C. Photoelectrochemical glucose biosensor based on the heterogeneous facets of nanocrystalline TiO2/Au/glucose oxidase films. ACS Appl. Nano Mater. 2020, 3, 2723–2732. [Google Scholar] [CrossRef]

- Cui, Z.; Marcelle, S.; Zhao, M.; Wu, J.; Liu, X.; Si, J.; Wang, Q. Thermoplastic polyurethane/titania/polydopamine (TPU/TiO2/PDA) 3-D porous composite foam with outstanding oil/water separation performance and photocatalytic dye degradation. Adv. Compos. Hybrid Mater. 2022, 5, 2801–2816. [Google Scholar] [CrossRef]

- Dong, S.; Xiao, G.; Chen, C.; Yang, Z.; Chen, C.; Wang, Q.; Lin, L. Polydopamine enwrapped titanium dioxide-assisted dispersion of graphene to strength fire resistance of intumescent waterborne epoxy coating. Prog. Org. Coat. 2021, 157, 106291. [Google Scholar] [CrossRef]

- Wang, Y.; Kai, Y.; Tong, L.; You, Y.; Huang, Y.; Liu, X. The frequency independent functionalized MoS2 nanosheet/poly(arylene ether nitrile) composites with improved dielectric and thermal properties via mussel inspired surface chemistry. Appl. Surf. Sci. 2019, 481, 1239–1248. [Google Scholar] [CrossRef]

- Zhang, J.X.; Ma, J.C.; Zhang, L.Q.; Zong, C.Y.; Xu, A.H.; Zhang, Y.B.; Geng, B.; Zhang, S.X. Enhanced breakdown strength and suppressed dielectric loss of polymer nanocomposites with BaTiO3 fillers modified by fluoropolymer. RSC Adv. 2020, 10, 7065–7072. [Google Scholar] [CrossRef]

- Feng, M.N.; Ma, D.Y.; Chen, X.R.; Wang, P.; Lin, J. Enhanced dielectric properties of poly(arylene ether nitrile) composite films employing MoS2-based semiconductors for organic film capacitor applications. Mater. Sci. Semicond. Process. 2021, 136, 106127. [Google Scholar] [CrossRef]

- Pu, Z.; Tang, H.; Huang, X.; Yang, J.; Zhan, Y.; Zhao, R.; Liu, X. Effect of surface functionalization of SiO2 particles on the interfacial and mechanical properties of PEN composite films. Colloids Surf. A. 2012, 415, 125–133. [Google Scholar] [CrossRef]

- Tong, L.F.; He, L.; Zhan, C.H.; Xia, Y.Q.; Liu, X.B. Poly(arylene ether nitrile) dielectric film modified by Bi2S3/rGO-CN fillers for high temperature resistant electronics fields. Chin. J. Polym. Sci. 2022, 40, 1441–1450. [Google Scholar] [CrossRef]

- Zhou, S.; Xu, T.; Jiang, F.; Song, N.; Shi, L.; Ding, P. High thermal conductivity property of polyamide-imide/boron nitride composite films by doping boron nitride quantum dots. J. Mater. Chem. C. 2019, 7, 13896–13903. [Google Scholar] [CrossRef]

- Tu, L.; Xiao, Q.; Wei, R.; Liu, X. Fabrication and enhanced thermal conductivity of boron nitride and polyarylene ether nitrile hybrids. Polymers 2019, 11, 1340. [Google Scholar] [CrossRef]

- You, Y.; Liu, S.; Tu, L.; Wang, Y.; Zhan, C.; Du, X.; Wei, R.; Liu, X. Controllable fabrication of poly(arylene ether nitrile) dielectrics for thermal-resistant film capacitors. Macromolecules 2019, 52, 5850–5859. [Google Scholar] [CrossRef]

- Wang, J.; Chen, H.; Li, X.; Zhang, C.; Yu, W.; Zhou, L.; Yang, Q.; Shi, Z.; Xiong, C. Flexible dielectric film with high energy density based on chitin/boron nitride nanosheets. Chem. Eng. J. 2020, 383, 123147. [Google Scholar] [CrossRef]

- Kushwaha, A.D.; Patel, B.; Khan, I.A.; Agrawal, A. Fabrication and characterization of hexagonal boron nitride/polyester composites to study the effect of filler loading and surface modification for microelectronic applications. Polym. Compos. 2023, 44, 4579–4593. [Google Scholar] [CrossRef]

- Sun, J.; Wang, D.; Yao, Y.; Zeng, X.; Pan, G.; Huang, Y.; Hu, J.; Sun, R.; Xu, J.B.; Wong, C.P. Boron nitride microsphere/epoxy composites with enhanced thermal conductivity. High Volt. 2017, 2, 147–153. [Google Scholar] [CrossRef]

- Ge, M.; Zhang, J.; Zhao, C.; Lu, C.; Du, G. Effect of hexagonal boron nitride on the thermal and dielectric properties of polyphenylene ether resin for high-frequency copper clad laminates. Mater. Des. 2019, 182, 108028. [Google Scholar] [CrossRef]

- Zazoum, B.; Frechette, M.; David, E. LDPE/TiO2 nanocomposites: Effect of poss on structure and dielectric properties. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 2505–2507. [Google Scholar] [CrossRef]

- Jia, Y.; Yang, J.; Dong, W.; Li, B.; Liu, Z. The dielectric properties and thermal conductivities of epoxy composites reinforced by titanium dioxide. J. Inorg. Organomet. Polym. Mater. 2022, 32, 1206–1212. [Google Scholar] [CrossRef]

- Choudhary, S.; Sengwa, R.J. Anomalous behavior of the dielectric and electrical properties of polymeric nanodielectric poly(vinyl alcohol)-titanium dioxide films. J. Appl. Polym. Sci. 2017, 134, 44568. [Google Scholar] [CrossRef]

- Xiao, Q.; Han, W.H.; Yang, R.Q.; You, Y.; Wei, R.B.; Liu, X.B. Mechanical, dielectric, and thermal properties of polyarylene ether nitrile and boron nitride nanosheets composites. Polym. Compos. 2018, 39, E1598–E1605. [Google Scholar] [CrossRef]

- He, L.; Zhang, W.; Li, J.; Liu, X.; Tong, L. Preparation and performance of PEN-OH@BNNS-OH/PEN interlayer dielectric films with superior interfacial compatibility. Mater. Today Commun. 2023, 37, 106996. [Google Scholar] [CrossRef]

- Liu, S.; Liu, C.; Feng, X.; Lin, G.; Bai, Z.; Liu, X. Dielectric properties of polyarylene ether nitrile composites based on modified boron nitride. J. Phys. Conf. Ser. 2022, 2338, 012035. [Google Scholar] [CrossRef]

- Huang, X.; Pu, Z.; Tong, L.; Wang, Z.; Liu, X. Preparation and dielectric properties of surface modified TiO2/PEN composite films with high thermal stability and flexibility. J. Mater. Sci. Mater. Electron. 2012, 23, 2089–2097. [Google Scholar] [CrossRef]

- Wei, R.B.; Zhan, C.H.; Yang, Y.; He, P.L.; Liu, X.B. Polyarylene ether nitrile and titanium dioxide hybrids as thermal resistant dielectrics. Chin. J. Polym. Sci. 2021, 39, 211–218. [Google Scholar] [CrossRef]

| Samples | Content | Dielectric Constant (1 kHz) | Dielectric Loss (1 kHz) | Working Temperature (°C) | Ref. |

|---|---|---|---|---|---|

| RCH-BN | 10% | 6.78 | ~0.018 | - | [44] |

| Polyester/surface-modified hBN | 10% | ~3.70 | - | ~100 | [45] |

| Epoxy/h-BN | 10% | ~5.60 | ~0.090 | <146 | [46] |

| PPER/h-BN@SiO2 | 20% | ~3.57 | ~0.006 | - | [47] |

| LDPE/tr-TiO2 | 3% | ~2.28 | ~0.0005 | - | [48] |

| EP/S-TiO2 | 5% | ~3.70 | ~0.018 | - | [49] |

| PVA/TiO2 | 5% | 3.55 | - | - | [50] |

| PEN/BNNS | 5% | ~3.60 | ~0.020 | ~160 | [51] |

| PEN/P@B PEN/CuPc-BN | 10% 10% | ~4.50 ~5.00 | ~0.010 ~0.013 | <180 - | [52] [53] |

| PEN/TiO2 | 10% | ~4.70 | ~0.013 | <180 | [54] |

| PEN/TiO2-CN | 10% | 4.02 | ~0.010 | <180 | [55] |

| PEN/(BN-TiO2)@(PDA + PEI) | 10% | ~5.20 | ~0.015 | ~160 | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

You, Y.; Chen, S.; Yang, S.; Li, L.; Wang, P. Enhanced Thermal and Dielectric Properties of Polyarylene Ether Nitrile Nanocomposites Incorporated with BN/TiO2-Based Hybrids for Flexible Dielectrics. Polymers 2023, 15, 4279. https://doi.org/10.3390/polym15214279

You Y, Chen S, Yang S, Li L, Wang P. Enhanced Thermal and Dielectric Properties of Polyarylene Ether Nitrile Nanocomposites Incorporated with BN/TiO2-Based Hybrids for Flexible Dielectrics. Polymers. 2023; 15(21):4279. https://doi.org/10.3390/polym15214279

Chicago/Turabian StyleYou, Yong, Siyi Chen, Shuang Yang, Lianjun Li, and Pan Wang. 2023. "Enhanced Thermal and Dielectric Properties of Polyarylene Ether Nitrile Nanocomposites Incorporated with BN/TiO2-Based Hybrids for Flexible Dielectrics" Polymers 15, no. 21: 4279. https://doi.org/10.3390/polym15214279

APA StyleYou, Y., Chen, S., Yang, S., Li, L., & Wang, P. (2023). Enhanced Thermal and Dielectric Properties of Polyarylene Ether Nitrile Nanocomposites Incorporated with BN/TiO2-Based Hybrids for Flexible Dielectrics. Polymers, 15(21), 4279. https://doi.org/10.3390/polym15214279