Recycling as a Key Enabler for Sustainable Additive Manufacturing of Polymer Composites: A Critical Perspective on Fused Filament Fabrication

Abstract

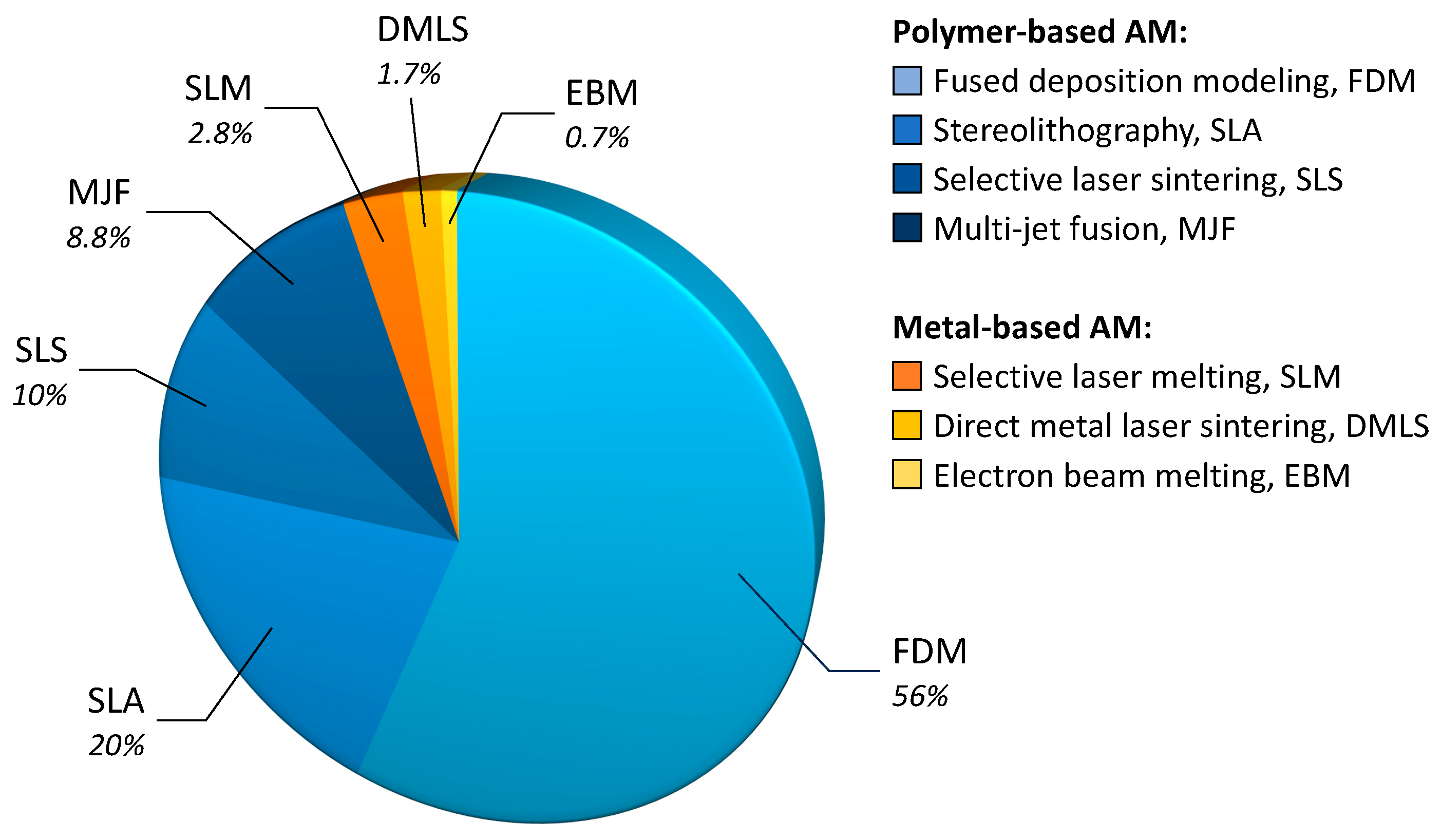

:1. Introduction

2. The AM—Composite Materials—Sustainability Triangle

3. Critical Considerations about “Sustainability” and “Sustainable Materials”

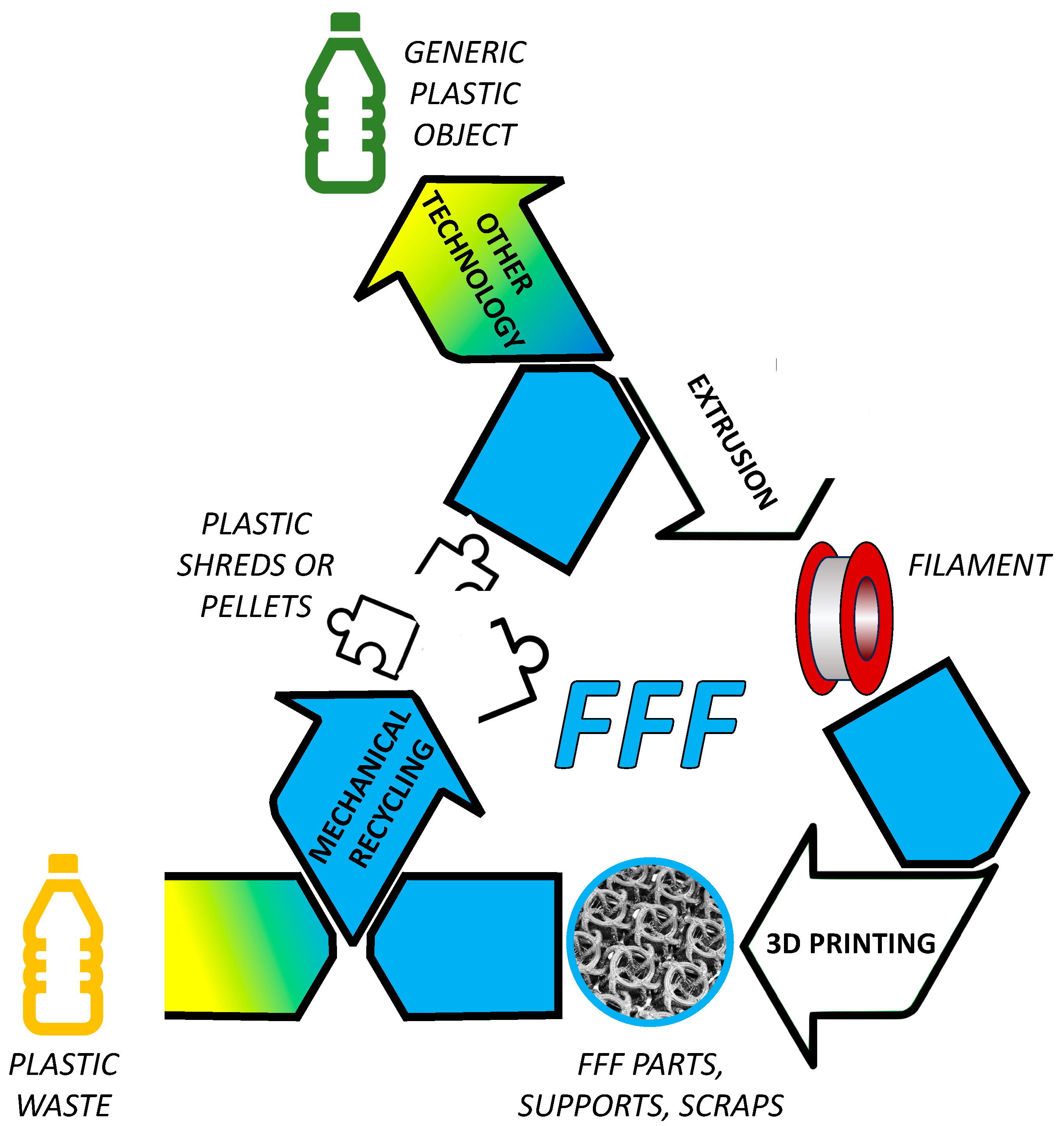

4. Recycling as a Key Enabler for Sustainable FFF of Polymer Composites

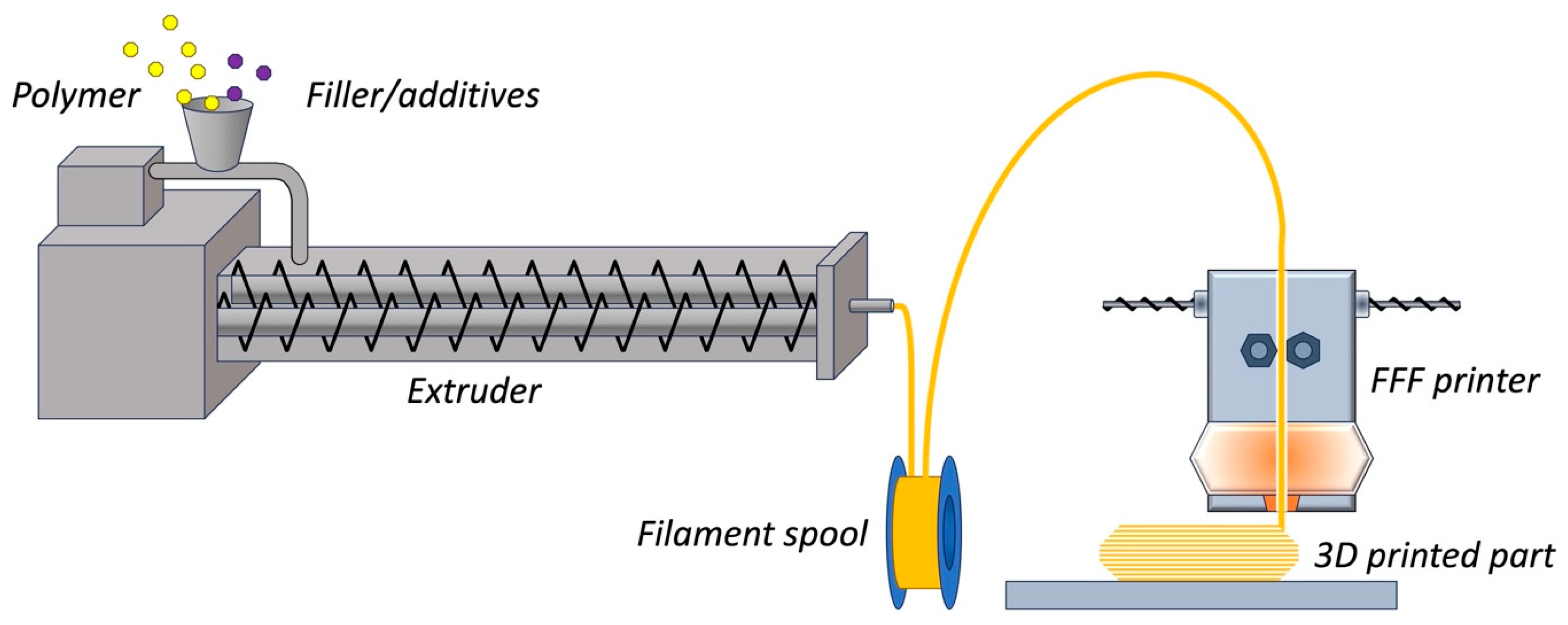

5. Recycling for Producing Composite Feedstock for FFF

5.1. Thermoplastic Matrix

5.2. Fillers

6. Recycling and FFF of Composite Materials: New Trends and Future Opportunities

7. Conclusions

- Being based on thermoplastic filaments, FFF may receive mechanically recycled plastics as the input material. Likewise, fillers can be recycled from other industrial activities, or sourced from agri-food waste. This will reduce the dependency on petrochemical products, and reduce the volume of landfilled materials;

- In spite of comprising heterogeneous phases, FFF composite parts can also be mechanically recycled like any other thermoplastic-matrix composites, which can be completed either through FFF (closed-loop recycling) or through other thermoplastic-based technologies (open-loop recycling). This will valorise end-of-life composite parts;

- While some challenges remain, such as the progressive degradation of the polymer matrix occurring upon thermo-mechanical (re-)processing, new strategies are emerging that will mitigate the functionality loss, such as the design of dedicated chain extenders that help restore the molecular weight of the polymer matrix;

- Research is being geared towards the development of new materials, like nanocomposites with minimal filler loading, that hold the promise to facilitate recycling and further lessen the environmental load of composite materials in FFF. A very promising area for future growth is represented by self-reinforced polymer composites, where the fibres and matrix have different structural organisation, but the same chemical composition. Although widening the processibility window of these materials represents a challenge in thermal processing methods like melt extrusion and FFF printing, the chemical homogeneity of self-reinforced polymer composites is a fundamental advantage for recycling over conventional multi-material composites.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dilberoglu, U.M.; Gharehpapagh, B.; Yaman, U.; Dolen, M. The Role of Additive Manufacturing in the Era of Industry 4.0. Procedia Manuf. 2017, 11, 545–554. [Google Scholar] [CrossRef]

- Maddikunta, P.K.; Pham, Q.V.; Prabadevi, B.; Deepa, N.; Dev, K.; Gadekallu, T.R.; Ruby, R.; Liyanage, M. Industry 5.0: A Survey on Enabling Technologies and Potential Applications. J. Ind. Inf. Integr. 2022, 26, 100257. [Google Scholar] [CrossRef]

- Trinchi, A.; Sola, A. Embedding Function within Additively Manufactured Parts: Materials Challenges and Opportunities. Adv. Eng. Mater. 2023, 25, 2300395. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive Manufacturing (3D Printing): A Review of Materials, Methods, Applications and Challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Chen, Z.; Li, Z.; Li, J.; Liu, C.; Lao, C.; Fu, Y.; Liu, C.; Li, Y.; Wang, P.; He, Y. 3D Printing of Ceramics: A Review. J. Eur. Ceram. Soc. 2019, 39, 661–687. [Google Scholar] [CrossRef]

- Sun, J.; Ye, D.; Zou, J.; Chen, X.; Wang, Y.; Yuan, J.; Liang, H.; Qu, H.; Binner, J.; Bai, J. A Review on Additive Manufacturing of Ceramic Matrix Composites. J. Mater. Sci. Technol. 2023, 138, 1–16. [Google Scholar] [CrossRef]

- Reichardt, A.; Shapiro, A.A.; Otis, R.; Dillon, R.P.; Borgonia, J.P.; McEnerney, B.W.; Hosemann, P.; Beese, A.M. Advances in Additive Manufacturing of Metal-Based Functionally Graded Materials. Int. Mater. Rev. 2021, 66, 1–29. [Google Scholar] [CrossRef]

- Ostolaza, M.; Arrizubieta, J.I.; Lamikiz, A.; Plaza, S.; Ortega, N. Latest Developments to Manufacture Metal Matrix Composites and Functionally Graded Materials through AM: A State-of-the-Art Review. Materials 2023, 16, 1746. [Google Scholar] [CrossRef] [PubMed]

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mülhaupt, R. Polymers for 3D Printing and Customized Additive Manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef]

- Sam-Daliri, O.; Ghabezi, P.; Steinbach, J.; Flanagan, T.; Finnegan, W.; Mitchell, S.; Harrison, N. Experimental Study on Mechanical Properties of Material Extrusion Additive Manufactured Parts from Recycled Glass Fibre-Reinforced Polypropylene Composite. Compos. Sci. Technol. 2023, 241, 110125. [Google Scholar] [CrossRef]

- ISO/ASTM 52900:2021; Additive Manufacturing—General Principles—Fundamentals and Vocabulary. ISO: Geneva, Switzerland, 2021.

- Sola, A. Materials Requirements in Fused Filament Fabrication: A Framework for the Design of Next-generation 3D Printable Thermoplastics and Composites. Macromol. Mater. Eng. 2022, 307, 2200197. [Google Scholar] [CrossRef]

- Saadi, M.A.S.R.; Maguire, A.; Pottackal, N.T.; Thakur, M.S.H.; Ikram, M.M.; Hart, A.J.; Ajayan, P.M.; Rahman, M.M. Direct Ink Writing: A 3D Printing Technology for Diverse Materials. Adv. Mater. 2022, 34, 2108855. [Google Scholar] [CrossRef]

- Vanaei, S.; Parizi, M.S.; Vanaei, S.; Salemizadehparizi, F.; Vanaei, H.R. An Overview on Materials and Techniques in 3D Bioprinting toward Biomedical Application. Eng. Regen. 2021, 2, 1–18. [Google Scholar] [CrossRef]

- Hubs 3D Printing Trend Report. Available online: https://www.hubs.com/get/trends/ (accessed on 10 August 2023).

- Rahimizadeh, A.; Kalman, J.; Fayazbakhsh, K.; Lessard, L. Recycling of Fiberglass Wind Turbine Blades into Reinforced Filaments for Use in Additive Manufacturing. Compos. Part B Eng. 2019, 175, 107101. [Google Scholar] [CrossRef]

- Rahimizadeh, A.; Kalman, J.; Fayazbakhsh, K.; Lessard, L. Mechanical and Thermal Study of 3D Printing Composite Filaments from Wind Turbine Waste. Polym. Compos. 2021, 42, 2305–2316. [Google Scholar] [CrossRef]

- Bharti, N.; Singh, S. Three-Dimensional (3D) Printers in Libraries: Perspective and Preliminary Safety Analysis. J. Chem. Educ. 2017, 94, 879–885. [Google Scholar] [CrossRef]

- Diep, T.T.; Ray, P.P.; Edwards, A.D. Methods for Rapid Prototyping Novel Labware: Using CAD and Desktop 3D Printing in the Microbiology Laboratory. Lett. Appl. Microbiol. 2022, 74, 247–257. [Google Scholar] [CrossRef]

- Ford, S.; Minshall, T. Invited Review Article: Where and How 3D Printing Is Used in Teaching and Education. Addit. Manuf. 2019, 25, 131–150. [Google Scholar] [CrossRef]

- Ong, T.K.; Choo, H.L.; Choo, W.J.; Koay, S.C.; Pang, M.M. Recycling of Polylactic Acid (PLA) Wastes from 3D Printing Laboratory. In Advances in Manufacturing Engineering; Emamian, S.S., Awang, M., Yusof, F., Eds.; Lecture Notes in Mechanical Engineering; Springer: Singapore, 2020; pp. 725–732. ISBN 9789811557521. [Google Scholar]

- Stefaniak, A.B.; Bowers, L.N.; Cottrell, G.; Erdem, E.; Knepp, A.K.; Martin, S.; Pretty, J.; Duling, M.G.; Arnold, E.D.; Wilson, Z.; et al. Use of 3-Dimensional Printers in Educational Settings: The Need for Awareness of the Effects of Printer Temperature and Filament Type on Contaminant Releases. ACS Chem. Health Saf. 2021, 28, 444–456. [Google Scholar] [CrossRef]

- Sule, S.S.; Petsiuk, A.L.; Pearce, J.M. Open Source Completely 3-D Printable Centrifuge. Instruments 2019, 3, 30. [Google Scholar] [CrossRef]

- Widden, M.; Gunn, K.; Rennie, A. Use of FDM in an Undergraduate Student Project: Design, Build and Test a Model Wind Turbine. In Annals of DAAAM for 2010 and Proceedings of the 21st International DAAAM Symposium “Intelligent Manufacturing and Automation: Focus on Interdisciplinary Solutions”; DAAAM International: Vienna, Austria, 2010; pp. 1583–1584. [Google Scholar]

- Portolés, L.; Jordá, O.; Jordá, L.; Uriondo, A.; Esperon-Miguez, M.; Perinpanayagam, S. A Qualification Procedure to Manufacture and Repair Aerospace Parts with Electron Beam Melting. J. Manuf. Syst. 2016, 41, 65–75. [Google Scholar] [CrossRef]

- Ulkir, O. Energy-Consumption-Based Life Cycle Assessment of Additive-Manufactured Product with Different Types of Materials. Polymers 2023, 15, 1466. [Google Scholar] [CrossRef] [PubMed]

- Gopal, M.; Lemu, H.G.; Gutema, E.M. Sustainable Additive Manufacturing and Environmental Implications: Literature Review. Sustainability 2023, 15, 504. [Google Scholar] [CrossRef]

- Czerwinski, F. Current Trends in Automotive Lightweighting Strategies and Materials. Materials 2021, 14, 6631. [Google Scholar] [CrossRef]

- Fan, J.; Njuguna, J. 1—An Introduction to Lightweight Composite Materials and Their Use in Transport Structures. In Lightweight Composite Structures in Transport; Njuguna, J., Ed.; Woodhead Publishing: Duxford, UK; Cambridge, MA, USA; Kidlington, UK, 2016; pp. 3–34. ISBN 978-1-78242-325-6. [Google Scholar]

- Morris, H. Airline Weight Reduction to Save Fuel: The Crazy Ways Airlines Save Weight on Planes. Available online: https://www.smh.com.au/traveller/reviews-and-advice/airline-weight-reduction-to-save-fuel-the-crazy-ways-airlines-save-weight-on-planes-20180903-h14vlh.html (accessed on 30 September 2023).

- Durach, C.F.; Kurpjuweit, S.; Wagner, S.M. The Impact of Additive Manufacturing on Supply Chains. Int. J. Phys. Distrib. Logist. Manag. 2017, 47, 954–971. [Google Scholar] [CrossRef]

- Nugraha, A.D.; Ruli; Supriyanto, E.; Rasgianti; Prawara, B.; Martides, E.; Junianto, E.; Wibowo, A.; Sentanuhady, J.; Muflikhun, M.A. First-Rate Manufacturing Process of Primary Air Fan (PAF) Coal Power Plant in Indonesia Using Laser Powder Bed Fusion (LPBF) Technology. J. Mater. Res. Technol. 2022, 18, 4075–4088. [Google Scholar] [CrossRef]

- McCarthy, E.; Brabazon, D. Additive Manufacturing for Sustainability of Composite Materials Production. In Encyclopedia of Materials: Composites; Brabazon, D., Ed.; Elsevier: Amsterdam, The Netherlands; Oxford, UK; Cambridge, MA, USA, 2021; pp. 263–275. ISBN 978-0-12-819731-8. [Google Scholar]

- Sola, A.; Trinchi, A.; Hill, A.J. Self-Assembly Meets Additive Manufacturing: Bridging the Gap between Nanoscale Arrangement of Matter and Macroscale Fabrication. Smart Mater. Manuf. 2023, 1, 100013. [Google Scholar] [CrossRef]

- Fan, Z.; Yan, X.; Fu, Z.; Niu, B.; Chen, J.; Hu, Y.; Chang, C.; Yi, J. In Situ Formation of D022-Al3Ti during Selective Laser Melting of Nano-TiC/AlSi10Mg Alloy Prepared by Electrostatic Self-Assembly. Vacuum 2021, 188, 110179. [Google Scholar] [CrossRef]

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of Selective Laser Melting: Materials and Applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef]

- Martin, J.H.; Yahata, B.D.; Hundley, J.M.; Mayer, J.A.; Schaedler, T.A.; Pollock, T.M. 3D Printing of High-Strength Aluminium Alloys. Nature 2017, 549, 365–369. [Google Scholar] [CrossRef]

- Sola, A.; Trinchi, A. Chapter 11—Open Challenges and Future Opportunities in Fused Deposition Modeling of Composite Materials. In Fused Deposition Modeling of Composite Materials; Sola, A., Trinchi, A., Eds.; Woodhead Publishing Series in Composites Science and Engineering; Woodhead Publishing, Elsevier: Cambridge, MA, USA; Kidlington, UK, 2023; pp. 289–329. ISBN 978-0-323-98823-0. [Google Scholar]

- Sola, A.; Trinchi, A. Chapter 3—The Need for Fused Deposition Modeling of Composite Materials. In Fused Deposition Modeling of Composite Materials; Sola, A., Trinchi, A., Eds.; Woodhead Publishing Series in Composites Science and Engineering; Woodhead Publishing, Elsevier: Cambridge, MA, USA; Kidlington, UK, 2023; pp. 39–89. ISBN 978-0-323-98823-0. [Google Scholar]

- Alfarisi, N.A.S.; Santos, G.N.C.; Norcahyo, R.; Sentanuhady, J.; Azizah, N.; Muflikhun, M.A. Model Optimization and Performance Evaluation of Hand Cranked Music Box Base Structure Manufactured via 3D Printing. Heliyon 2021, 7, e08432. [Google Scholar] [CrossRef] [PubMed]

- Protopasta Hardanger Fiddle Uses HTPLA-CF for Stiffness and Style. Available online: https://www.proto-pasta.com/blogs/applications/hardanger-fiddle-uses-htpla-cf-for-stiffness-and-good-looks (accessed on 11 August 2023).

- Stratasys East West Industries: 3D Printing Metal Forming Dies. Available online: https://www.stratasys.com/en/resources/case-studies/east-west-industries-metal-forming-use-case/ (accessed on 11 August 2023).

- Stratasys Graco Engineers 3D Printed Forming Dies Using FDM Technology. Available online: https://www.stratasys.com/en/resources/case-studies/graco-metal-forming-use-case/ (accessed on 11 August 2023).

- Markforged End-of-Arm Tooling. Available online: https://markforged.com/resources/manufacturing-applications/end-of-arm-tooling (accessed on 11 August 2023).

- Sola, A.; Trinchi, A. Chapter 4—Production of Composite Filaments for Fused Deposition Modeling. In Fused Deposition Modeling of Composite Materials; Sola, A., Trinchi, A., Eds.; Woodhead Publishing Series in Composites Science and Engineering; Woodhead Publishing, Elsevier: Cambridge, MA, USA; Kidlington, UK, 2023; pp. 89–108. ISBN 978-0-323-98823-0. [Google Scholar]

- Al-Mazrouei, N.; Al-Marzouqi, A.H.; Ahmed, W. Characterization and Sustainability Potential of Recycling 3D-Printed Nylon Composite Wastes. Sustainability 2022, 14, 10458. [Google Scholar] [CrossRef]

- Fico, D.; Rizzo, D.; Casciaro, R.; Esposito Corcione, C. A Review of Polymer-Based Materials for Fused Filament Fabrication (FFF): Focus on Sustainability and Recycled Materials. Polymers 2022, 14, 465. [Google Scholar] [CrossRef] [PubMed]

- Fico, D.; Rizzo, D.; De Carolis, V.; Montagna, F.; Palumbo, E.; Corcione, C.E. Development and Characterization of Sustainable PLA/Olive Wood Waste Composites for Rehabilitation Applications Using Fused Filament Fabrication (FFF). J. Build. Eng. 2022, 56, 104673. [Google Scholar] [CrossRef]

- Bianchi, I.; Forcellese, A.; Mancia, T.; Simoncini, M.; Vita, A. Process Parameters Effect on Environmental Sustainability of Composites FFF Technology. Mater. Manuf. Process. 2022, 37, 591–601. [Google Scholar] [CrossRef]

- Chatzipanagiotou, K.-R.; Antypa, D.; Petrakli, F.; Karatza, A.; Pikoń, K.; Bogacka, M.; Poranek, N.; Werle, S.; Amanatides, E.; Mataras, D.; et al. Life Cycle Assessment of Composites Additive Manufacturing Using Recycled Materials. Sustainability 2023, 15, 12843. [Google Scholar] [CrossRef]

- United Nations Sustainability. Available online: http://www.un-documents.net/our-common-future.pdf (accessed on 19 October 2023).

- Rutgers What Are Sustainable Materials? Center for Sustainable Materials. Available online: http://sustain.rutgers.edu/what_are_sustainable_materials (accessed on 10 August 2023).

- Merrington, A. 11—Recycling of Plastics. In Applied Plastics Engineering Handbook; Kutz, M., Ed.; William Andrew Publishing, Elsevier: Kidlington, Oxford, UK; Cambridge, MA, USA, 2011; pp. 177–192. ISBN 978-1-4377-3514-7. [Google Scholar]

- Wilson, M. When Creative Consumers Go Green: Understanding Consumer Upcycling. J. Prod. Brand Manag. 2016, 25, 394–399. [Google Scholar] [CrossRef]

- Murali Krishna, I.V.; Manickam, V. Chapter 5—Life Cycle Assessment. In Environmental Management; Muralikrishna, I.V., Manickam, V., Eds.; Butterworth-Heinemann, Elsevier: Oxford, UK, 2017; pp. 57–75. ISBN 978-0-12-811989-1. [Google Scholar]

- Ragaert, K.; Delva, L.; Van Geem, K. Mechanical and Chemical Recycling of Solid Plastic Waste. Waste Manag. 2017, 69, 24–58. [Google Scholar] [CrossRef]

- Bracquené, E.; Dewulf, W.; Duflou, J.R. Measuring the Performance of More Circular Complex Product Supply Chains. Resour. Conserv. Recycl. 2020, 154, 104608. [Google Scholar] [CrossRef]

- Circularity Indicators Project Overview. Available online: https://emf.thirdlight.com/link/yybss1obhtdv-ub419h/@/preview/1?o (accessed on 22 August 2023).

- Material Circularity Indicator (MCI). Available online: https://ellenmacarthurfoundation.org/material-circularity-indicator (accessed on 22 August 2023).

- Zobel, G. Alfredo Moser: Bottle Light Inventor Proud to Be Poor. BBC News, 13 August 2013. [Google Scholar]

- Pérez-Fonseca, A.A.; González-López, M.E.; Robledo-Ortíz, J.R. Reprocessing and Recycling of Poly(Lactic Acid): A Review. J. Polym. Environ. 2023, 31, 4143–4159. [Google Scholar] [CrossRef]

- Oberoi, P. Recycling of Materials for Sustainable Development: Reasons, Approaches, Economics, and Stakeholders of Recycling. In Responsible Consumption and Production; Leal Filho, W., Azul, A.M., Brandli, L., Özuyar, P.G., Wall, T., Eds.; Encyclopedia of the UN Sustainable Development Goals; Springer International Publishing: Cham, Switzerland, 2020; pp. 581–591. ISBN 978-3-319-95726-5. [Google Scholar]

- Farjana, S.H.; Mahmud, M.A.P.; Huda, N. Chapter 1—Introduction to Life Cycle Assessment. In Life Cycle Assessment for Sustainable Mining; Farjana, S.H., Mahmud, M.A.P., Huda, N., Eds.; Elsevier: Amsterdam, The Netherlands; Kidlington, Oxford, UK; Cambridge, MA, USA, 2021; pp. 1–13. ISBN 978-0-323-85451-1. [Google Scholar]

- Dastjerdi, B.; Strezov, V.; Rajaeifar, M.A.; Kumar, R.; Behnia, M. Waste to Energy Technologies. In Reference Module in Earth Systems and Environmental Sciences; Elsevier: Amsterdam, The Netherlands, 2022; ISBN 978-0-12-409548-9. [Google Scholar]

- Mohan, M.K.; Rahul, A.V.; van Dam, B.; Zeidan, T.; De Schutter, G.; Van Tittelboom, K. Performance Criteria, Environmental Impact and Cost Assessment for 3D Printable Concrete Mixtures. Resour. Conserv. Recycl. 2022, 181, 106255. [Google Scholar] [CrossRef]

- Song, Y.S.; Youn, J.R.; Gutowski, T.G. Life Cycle Energy Analysis of Fiber-Reinforced Composites. Compos. Part Appl. Sci. Manuf. 2009, 40, 1257–1265. [Google Scholar] [CrossRef]

- Valente, M.; Rossitti, I.; Sambucci, M. Different Production Processes for Thermoplastic Composite Materials: Sustainability versus Mechanical Properties and Processes Parameter. Polymers 2023, 15, 242. [Google Scholar] [CrossRef] [PubMed]

- Pawar, S.S.; Hutchinson, S.A.; Eyckens, D.J.; Stojcevski, F.; Hayne, D.J.; Gengenbach, T.R.; Razal, J.M.; Henderson, L.C. Carbon Fiber Sizing Agents Based on Renewable Terpenes. Compos. Sci. Technol. 2022, 220, 109280. [Google Scholar] [CrossRef]

- Krauklis, A.E.; Karl, C.W.; Gagani, A.I.; Jørgensen, J.K. Composite Material Recycling Technology—State-of-the-Art and Sustainable Development for the 2020s. J. Compos. Sci. 2021, 5, 28. [Google Scholar] [CrossRef]

- Ahmad, H.; Markina, A.A.; Porotnikov, M.V.; Ahmad, F. A Review of Carbon Fiber Materials in Automotive Industry. IOP Conf. Ser. Mater. Sci. Eng. 2020, 971, 032011. [Google Scholar] [CrossRef]

- Isaiah, D. Carbon Fibre: The Fabric of the Future? Automotive World, 20 May 2014. [Google Scholar]

- Peças, P.; Carvalho, H.; Salman, H.; Leite, M. Natural Fibre Composites and Their Applications: A Review. J. Compos. Sci. 2018, 2, 66. [Google Scholar] [CrossRef]

- Balla, E.; Daniilidis, V.; Karlioti, G.; Kalamas, T.; Stefanidou, M.; Bikiaris, N.D.; Vlachopoulos, A.; Koumentakou, I.; Bikiaris, D.N. Poly(Lactic Acid): A Versatile Biobased Polymer for the Future with Multifunctional Properties—From Monomer Synthesis, Polymerization Techniques and Molecular Weight Increase to PLA Applications. Polymers 2021, 13, 1822. [Google Scholar] [CrossRef]

- Rajeshkumar, G.; Arvindh Seshadri, S.; Devnani, G.L.; Sanjay, M.R.; Siengchin, S.; Prakash Maran, J.; Al-Dhabi, N.A.; Karuppiah, P.; Mariadhas, V.A.; Sivarajasekar, N.; et al. Environment Friendly, Renewable and Sustainable Poly Lactic Acid (PLA) Based Natural Fiber Reinforced Composites—A Comprehensive Review. J. Clean. Prod. 2021, 310, 127483. [Google Scholar] [CrossRef]

- International Energy Agency. The Future of Petrochemicals—Analysis. Available online: https://www.iea.org/reports/the-future-of-petrochemicals (accessed on 15 August 2023).

- Petroleum. Available online: https://education.nationalgeographic.org/resource/petroleum (accessed on 15 August 2023).

- Hardy, C.; Kociok-Köhn, G.; Buchard, A. UV Degradation of Poly(Lactic Acid) Materials through Copolymerisation with a Sugar-Derived Cyclic Xanthate. Chem. Commun. 2022, 58, 5463–5466. [Google Scholar] [CrossRef] [PubMed]

- McKeown, P.; Jones, M.D. The Chemical Recycling of PLA: A Review. Sustain. Chem. 2020, 1, 1–22. [Google Scholar] [CrossRef]

- Kucherov, F.A.; Gordeev, E.G.; Kashin, A.S.; Ananikov, V.P. Three-Dimensional Printing with Biomass-Derived PEF for Carbon-Neutral Manufacturing. Angew. Chem. Int. Ed. 2017, 56, 15931–15935. [Google Scholar] [CrossRef]

- Mehrpouya, M.; Vahabi, H.; Barletta, M.; Laheurte, P.; Langlois, V. Additive Manufacturing of Polyhydroxyalkanoates (PHAs) Biopolymers: Materials, Printing Techniques, and Applications. Mater. Sci. Eng. C 2021, 127, 112216. [Google Scholar] [CrossRef] [PubMed]

- Choe, S.; Kim, Y.; Park, G.; Lee, D.H.; Park, J.; Mossisa, A.T.; Lee, S.; Myung, J. Biodegradation of 3D-Printed Biodegradable/Non-Biodegradable Plastic Blends. ACS Appl. Polym. Mater. 2022, 4, 5077–5090. [Google Scholar] [CrossRef]

- Muthe, L.P.; Pickering, K.; Gauss, C. A Review of 3D/4D Printing of Poly-Lactic Acid Composites with Bio-Derived Reinforcements. Compos. Part C Open Access 2022, 8, 100271. [Google Scholar] [CrossRef]

- Zgodavová, K.; Lengyelová, K.; Bober, P.; Eguren, J.A.; Moreno, A. 3D Printing Optimization for Environmental Sustainability: Experimenting with Materials of Protective Face Shield Frames. Materials 2021, 14, 6595. [Google Scholar] [CrossRef]

- Rett, J.P.; Traore, Y.L.; Ho, E.A. Sustainable Materials for Fused Deposition Modeling 3D Printing Applications. Adv. Eng. Mater. 2021, 23, 2001472. [Google Scholar] [CrossRef]

- Farzi, A.; Dehnad, A.; Fotouhi, A. Biodegradation of Polyethylene Terephthalate Waste Using Streptomyces Species and Kinetic Modeling of the Process. Biocatal. Agric. Biotechnol. 2019, 17, 25–31. [Google Scholar] [CrossRef]

- Chiellini, E.; Corti, A.; D’Antone, S.; Solaro, R. Biodegradation of Poly (Vinyl Alcohol) Based Materials. Prog. Polym. Sci. 2003, 28, 963–1014. [Google Scholar] [CrossRef]

- Le Duigou, A.; Barbé, A.; Guillou, E.; Castro, M. 3D Printing of Continuous Flax Fibre Reinforced Biocomposites for Structural Applications. Mater. Des. 2019, 180, 107884. [Google Scholar] [CrossRef]

- Matsuzaki, R.; Ueda, M.; Namiki, M.; Jeong, T.-K.; Asahara, H.; Horiguchi, K.; Nakamura, T.; Todoroki, A.; Hirano, Y. Three-Dimensional Printing of Continuous-Fiber Composites by in-Nozzle Impregnation. Sci. Rep. 2016, 6, 23058. [Google Scholar] [CrossRef]

- Tao, Y.; Li, P.; Zhang, J.; Wang, S.; Shi, S.Q.; Kong, F. A Review of Fused Filament Fabrication of Continuous Natural Fiber Reinforced Thermoplastic Composites: Techniques and Materials. Polym. Compos. 2023. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, D.; Huang, T.; Hu, Q.; Lammer, H. Three-Dimensional Printing of Continuous Flax Fiber-Reinforced Thermoplastic Composites by Five-Axis Machine. Materials 2020, 13, 1678. [Google Scholar] [CrossRef] [PubMed]

- Das, A.K.; Agar, D.A.; Rudolfsson, M.; Larsson, S.H. A Review on Wood Powders in 3D Printing: Processes, Properties and Potential Applications. J. Mater. Res. Technol. 2021, 15, 241–255. [Google Scholar] [CrossRef]

- Bardot, M.; Schulz, M.D. Biodegradable Poly(Lactic Acid) Nanocomposites for Fused Deposition Modeling 3D Printing. Nanomaterials 2020, 10, 2567. [Google Scholar] [CrossRef]

- Valentini, F.; Dorigato, A.; Rigotti, D.; Pegoretti, A. Polyhydroxyalkanoates/Fibrillated Nanocellulose Composites for Additive Manufacturing. J. Polym. Environ. 2019, 27, 1333–1341. [Google Scholar] [CrossRef]

- Torrado, A.R.; Shemelya, C.M.; English, J.D.; Lin, Y.; Wicker, R.B.; Roberson, D.A. Characterizing the Effect of Additives to ABS on the Mechanical Property Anisotropy of Specimens Fabricated by Material Extrusion 3D Printing. Addit. Manuf. 2015, 6, 16–29. [Google Scholar] [CrossRef]

- Torrado Perez, A.R.; Roberson, D.A.; Wicker, R.B. Fracture Surface Analysis of 3D-Printed Tensile Specimens of Novel ABS-Based Materials. J. Fail. Anal. Prev. 2014, 14, 343–353. [Google Scholar] [CrossRef]

- Jamadi, A.H.; Razali, N.; Petrů, M.; Taha, M.M.; Muhammad, N.; Ilyas, R.A. Effect of Chemically Treated Kenaf Fibre on Mechanical and Thermal Properties of PLA Composites Prepared through Fused Deposition Modeling (FDM). Polymers 2021, 13, 3299. [Google Scholar] [CrossRef]

- Depuydt, D.; Balthazar, M.; Hendrickx, K.; Six, W.; Ferraris, E.; Desplentere, F.; Ivens, J.; Van Vuure, A.W. Production and Characterization of Bamboo and Flax Fiber Reinforced Polylactic Acid Filaments for Fused Deposition Modeling (FDM). Polym. Compos. 2019, 40, 1951–1963. [Google Scholar] [CrossRef]

- Taborda-Ríos, J.A.; López-Botello, O.; Zambrano-Robledo, P.; Reyes-Osorio, L.A.; Garza, C. Mechanical Characterisation of a Bamboo Fibre/Polylactic Acid Composite Produced by Fused Deposition Modelling. J. Reinf. Plast. Compos. 2020, 39, 932–944. [Google Scholar] [CrossRef]

- Stoof, D.; Pickering, K.L. 3D Printing of Natural Fibre Reinforced Recycled Polypropylene; Bickerton, S., Lin, R.J.-T., Somashekar, A.A., Singh, I., Srivatsan, T.S., Eds.; University of Auckland: Auckland, New Zealand, 2017; pp. 668–691. [Google Scholar]

- Stoof, D.; Pickering, K.; Zhang, Y. Fused Deposition Modelling of Natural Fibre/Polylactic Acid Composites. J. Compos. Sci. 2017, 1, 8. [Google Scholar] [CrossRef]

- Patel, R.; Dhimmar, V.; Kagzi, S.; Patel, M. Investigation of Fused Deposition Modelling Process Parameters in 3D Printing for Composite Material (Poly Lactic Acid and Banana Fibre). Int. J. Automot. Mech. Eng. 2022, 19, 10028–10038. [Google Scholar] [CrossRef]

- Porras, A.; Maranon, A.; Ashcroft, I.A. Characterization of a Novel Natural Cellulose Fabric from Manicaria Saccifera Palm as Possible Reinforcement of Composite Materials. Compos. Part B Eng. 2015, 74, 66–73. [Google Scholar] [CrossRef]

- Figueroa-Velarde, V.; Diaz-Vidal, T.; Cisneros-López, E.O.; Robledo-Ortiz, J.R.; López-Naranjo, E.J.; Ortega-Gudiño, P.; Rosales-Rivera, L.C. Mechanical and Physicochemical Properties of 3d-Printed Agave Fibers/Poly(Lactic) Acid Biocomposites. Materials 2021, 14, 3111. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; He, H.; Peng, X.; Huang, B.; Li, J. Three-Dimensional Printing of Poly(Lactic Acid) Bio-Based Composites with Sugarcane Bagasse Fiber: Effect of Printing Orientation on Tensile Performance. Polym. Adv. Technol. 2019, 30, 910–922. [Google Scholar] [CrossRef]

- Aida, H.J.; Nadlene, R.; Mastura, M.T.; Yusriah, L.; Sivakumar, D.; Ilyas, R.A. Natural Fibre Filament for Fused Deposition Modelling (FDM): A Review. Int. J. Sustain. Eng. 2021, 14, 1988–2008. [Google Scholar] [CrossRef]

- Periyasamy, R.; Hemanth Kumar, M.; Rangappa, S.M.; Siengchin, S. A Comprehensive Review on Natural Fillers Reinforced Polymer Composites Using Fused Deposition Modeling. Polym. Compos. 2023, 44, 3715–3747. [Google Scholar] [CrossRef]

- Sabbatini, B.; Cambriani, A.; Cespi, M.; Palmieri, G.F.; Perinelli, D.R.; Bonacucina, G. An Overview of Natural Polymers as Reinforcing Agents for 3D Printing. ChemEngineering 2021, 5, 78. [Google Scholar] [CrossRef]

- Pringle, A.M.; Rudnicki, M.; Pearce, J.M. Wood Furniture Waste-Based Recycled 3-D Printing Filament. For. Prod. J. 2018, 68, 86–95. [Google Scholar] [CrossRef]

- Mazzanti, V.; Malagutti, L.; Mollica, F. FDM 3D Printing of Polymers Containing Natural Fillers: A Review of Their Mechanical Properties. Polymers 2019, 11, 1094. [Google Scholar] [CrossRef]

- Azwa, Z.N.; Yousif, B.F.; Manalo, A.C.; Karunasena, W. A Review on the Degradability of Polymeric Composites Based on Natural Fibres. Mater. Des. 2013, 47, 424–442. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Biocomposites Reinforced with Natural Fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Dogru, A.; Sozen, A.; Neser, G.; Seydibeyoglu, M.O. Effects of Aging and Infill Pattern on Mechanical Properties of Hemp Reinforced PLA Composite Produced by Fused Filament Fabrication (FFF). Appl. Sci. Eng. Prog. 2021, 14, 651–660. [Google Scholar] [CrossRef]

- Sola, A.; Trinchi, A. Chapter 8—Fused Deposition Modeling of Polymer-Matrix Composites with Natural Fibers. In Fused Deposition Modeling of Composite Materials; Sola, A., Trinchi, A., Eds.; Woodhead Publishing Series in Composites Science and Engineering; Woodhead Publishing, Elsevier: Cambridge, MA, USA; Kidlington, UK, 2023; pp. 189–210. ISBN 978-0-323-98823-0. [Google Scholar]

- Scaffaro, R.; Citarrella, M.C.; Catania, A.; Settanni, L. Green Composites Based on Biodegradable Polymers and Anchovy (Engraulis encrasicolus) Waste Suitable for 3D Printing Applications. Compos. Sci. Technol. 2022, 230, 109768. [Google Scholar] [CrossRef]

- Singh, S.; Ramakrishna, S.; Singh, R. Material Issues in Additive Manufacturing: A Review. J. Manuf. Process. 2017, 25, 185–200. [Google Scholar] [CrossRef]

- Soykan, U. Development of Turkey Feather Fiber-Filled Thermoplastic Polyurethane Composites: Thermal, Mechanical, Water-Uptake, and Morphological Characterizations. J. Compos. Mater. 2022, 56, 339–355. [Google Scholar] [CrossRef]

- Weng, Z.; Wang, J.; Senthil, T.; Wu, L. Mechanical and Thermal Properties of ABS/Montmorillonite Nanocomposites for Fused Deposition Modeling 3D Printing. Mater. Des. 2016, 102, 276–283. [Google Scholar] [CrossRef]

- Bertolino, M.; Battegazzore, D.; Arrigo, R.; Frache, A. Designing 3D Printable Polypropylene: Material and Process Optimisation through Rheology. Addit. Manuf. 2021, 40, 101944. [Google Scholar] [CrossRef]

- Stoof, D.; Pickering, K. Sustainable Composite Fused Deposition Modelling Filament Using Recycled Pre-Consumer Polypropylene. Compos. Part B Eng. 2018, 135, 110–118. [Google Scholar] [CrossRef]

- Dunham, S.K. Non-Renewable Mineral Resources. Resour. Policy 1974, 1, 3–13. [Google Scholar] [CrossRef]

- Esposito Corcione, C.; Palumbo, E.; Masciullo, A.; Montagna, F.; Torricelli, M.C. Fused Deposition Modeling (FDM): An Innovative Technique Aimed at Reusing Lecce Stone Waste for Industrial Design and Building Applications. Constr. Build. Mater. 2018, 158, 276–284. [Google Scholar] [CrossRef]

- Lendvai, L.; Singh, T.; Fekete, G.; Patnaik, A.; Dogossy, G. Utilization of Waste Marble Dust in Poly(Lactic Acid)-Based Biocomposites: Mechanical, Thermal and Wear Properties. J. Polym. Environ. 2021, 29, 2952–2963. [Google Scholar] [CrossRef]

- Tan, L.J.; Zhu, W.; Zhou, K. Recent Progress on Polymer Materials for Additive Manufacturing. Adv. Funct. Mater. 2020, 30, 2003062. [Google Scholar] [CrossRef]

- Guo, A.; Kong, D.; Zhou, X.; Qu, P.; Wang, S.; Li, J.; Li, F.; Wang, L.; Hu, Y. Evaluation of Material Reuse Degree in Additive Manufacturing by the Improved Resolution Coefficient Grey Correlation Method. Process Saf. Environ. Prot. 2022, 166, 451–460. [Google Scholar] [CrossRef]

- Mikula, K.; Skrzypczak, D.; Izydorczyk, G.; Warchoł, J.; Moustakas, K.; Chojnacka, K.; Witek-Krowiak, A. 3D Printing Filament as a Second Life of Waste Plastics—A Review. Environ. Sci. Pollut. Res. 2021, 28, 12321–12333. [Google Scholar] [CrossRef]

- Hunt, E.J.; Zhang, C.; Anzalone, N.; Pearce, J.M. Polymer Recycling Codes for Distributed Manufacturing with 3-D Printers. Resour. Conserv. Recycl. 2015, 97, 24–30. [Google Scholar] [CrossRef]

- De-la-Cruz-Diaz, M.; Alvarez-Risco, A.; Jaramillo-Arévalo, M.; de las Mercedes Anderson-Seminario, M.; Del-Aguila-Arcentales, S. 3D Print, Circularity, and Footprints. In Circular Economy: Impact on Carbon and Water Footprint; Alvarez-Risco, A., Muthu, S.S., Del-Aguila-Arcentales, S., Eds.; Environmental Footprints and Eco-Design of Products and Processes; Springer: Singapore, 2022; pp. 93–112. ISBN 978-981-19054-9-0. [Google Scholar]

- Gil Muñoz, V.; Muneta, L.M.; Carrasco-Gallego, R.; de Juanes Marquez, J.; Hidalgo-Carvajal, D. Evaluation of the Circularity of Recycled PLA Filaments for 3D Printers. Appl. Sci. 2020, 10, 8967. [Google Scholar] [CrossRef]

- Hong, J.-H.; Yu, T.; Park, S.-J.; Kim, Y.-H. Repetitive Recycling of 3D Printing PLA Filament as Renewable Resources on Mechanical and Thermal Loads. Int. J. Mod. Phys. B 2020, 34, 2040147. [Google Scholar] [CrossRef]

- Lanzotti, A.; Martorelli, M.; Maietta, S.; Gerbino, S.; Penta, F.; Gloria, A. A Comparison between Mechanical Properties of Specimens 3D Printed with Virgin and Recycled PLA. Procedia CIRP 2019, 79, 143–146. [Google Scholar] [CrossRef]

- Morsidi, M.; Mativenga, P.T.; Fahad, M. Fused Deposition Modelling Filament with Recyclate Fibre Reinforcement. Procedia CIRP 2019, 85, 353–358. [Google Scholar] [CrossRef]

- Pegoretti, A. Recycling Concepts for Short-Fiber-Reinforced and Particle-Filled Thermoplastic Composites: A Review. Adv. Ind. Eng. Polym. Res. 2021, 4, 93–104. [Google Scholar] [CrossRef]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, Use, and Fate of All Plastics Ever Made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef]

- Lee, A.; Liew, M.S. Tertiary Recycling of Plastics Waste: An Analysis of Feedstock, Chemical and Biological Degradation Methods. J. Mater. Cycles Waste Manag. 2021, 23, 32–43. [Google Scholar] [CrossRef]

- Zhao, P.; Rao, C.; Gu, F.; Sharmin, N.; Fu, J. Close-Looped Recycling of Polylactic Acid Used in 3D Printing: An Experimental Investigation and Life Cycle Assessment. J. Clean. Prod. 2018, 197, 1046–1055. [Google Scholar] [CrossRef]

- Madhu, N.R.; Erfani, H.; Jadoun, S.; Amir, M.; Thiagarajan, Y.; Chauhan, N.P.S. Fused Deposition Modelling Approach Using 3D Printing and Recycled Industrial Materials for a Sustainable Environment: A Review. Int. J. Adv. Manuf. Technol. 2022, 122, 2125–2138. [Google Scholar] [CrossRef]

- Burnett, M.J.; Wilson, M.A.; Filoso, A. The Practicality and Scalability of Respooling 3-D Printing Thermoplastics a Multidisciplinary Research Project by the Canino School of Engineering Technology at SUNY Canton (WIP). In Proceedings of the 2020 ASEE Virtual Annual Conference Content Access, Online, 22–26 June 2020; Volume 2020. [Google Scholar]

- Cruz Sanchez, F.A.; Boudaoud, H.; Camargo, M.; Pearce, J.M. Plastic Recycling in Additive Manufacturing: A Systematic Literature Review and Opportunities for the Circular Economy. J. Clean. Prod. 2020, 264, 121602. [Google Scholar] [CrossRef]

- Nagengast, N.; Bay, C.; Döpper, F.; Schmidt, H.-W.; Neuber, C. Thermo-Mechanical Recyclability of Additively Manufactured Polypropylene and Polylactic Acid Parts and Polypropylene Support Structures. Polymers 2023, 15, 2291. [Google Scholar] [CrossRef]

- Zheng, J.; Arifuzzaman, M.; Tang, X.; Chen, X.C.; Saito, T. Recent Development of End-of-Life Strategies for Plastic in Industry and Academia: Bridging Their Gap for Future Deployment. Mater. Horiz. 2023, 10, 1608–1624. [Google Scholar] [CrossRef]

- Rigotti, D.; Armoni, D.; Dul, S.; Pegoretti, A. From Nautical Waste to Additive Manufacturing: Sustainable Recycling of High-Density Polyethylene for 3D Printing Applications. J. Compos. Sci. 2023, 7, 320. [Google Scholar] [CrossRef]

- Lange, J.-P. Managing Plastic waste—Sorting, Recycling, Disposal, and Product Redesign. ACS Sustain. Chem. Eng. 2021, 9, 15722–15738. [Google Scholar] [CrossRef]

- Zander, N.E.; Gillan, M.; Burckhard, Z.; Gardea, F. Recycled Polypropylene Blends as Novel 3D Printing Materials. Addit. Manuf. 2019, 25, 122–130. [Google Scholar] [CrossRef]

- Mishra, V.; Negi, S.; Kar, S. FDM-Based Additive Manufacturing of Recycled Thermoplastics and Associated Composites. J. Mater. Cycles Waste Manag. 2023, 25, 758–784. [Google Scholar] [CrossRef] [PubMed]

- Andrady, A.L.; Neal, M.A. Applications and Societal Benefits of Plastics. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 1977–1984. [Google Scholar] [CrossRef] [PubMed]

- Vaucher, J.; Demongeot, A.; Michaud, V.; Leterrier, Y. Recycling of Bottle Grade PET: Influence of HDPE Contamination on the Microstructure and Mechanical Performance of 3D Printed Parts. Polymers 2022, 14, 5507. [Google Scholar] [CrossRef] [PubMed]

- Ng, T.Y.; Koay, S.C.; Chan, M.Y.; Choo, H.L.; Ong, T.K. Preparation and Characterisation of 3D Printer Filament from Post-Used Styrofoam. AIP Conf. Proc. 2020, 2233, 020022. [Google Scholar] [CrossRef]

- Correia, C.; Gomes, T.E.P.; Gonçalves, I.; Neto, V. Reprocessability of PLA through Chain Extension for Fused Filament Fabrication. J. Manuf. Mater. Process. 2022, 6, 26. [Google Scholar] [CrossRef]

- Katalagarianakis, A.; Van de Voorde, B.; Pien, N.; Polyzos, E.; Duretek, I.; Holzer, C.; Cardon, L.; Bernaerts, K.V.; Van Hemelrijck, D.; Van Vlierberghe, S.; et al. The Effect of Carbon Fiber Content on Physico-Mechanical Properties of Recycled Poly(Ethylene Terephthalate) Composites Additively Manufactured with Fused Filament Fabrication. Addit. Manuf. 2022, 60, 103246. [Google Scholar] [CrossRef]

- Pinho, A.C.; Amaro, A.M.; Piedade, A.P. 3D Printing Goes Greener: Study of the Properties of Post-Consumer Recycled Polymers for the Manufacturing of Engineering Components. Waste Manag. 2020, 118, 426–434. [Google Scholar] [CrossRef]

- Wu, M.Y.T.; Tang, W.F.; Li, C.H.; Chan, T.W.; Mak, S.L. A Review on Melt Flow Index Characteristics of Polylactide (PLA) for Recycle Use in 3-D Printing. J. Test. Eval. 2022, 50, 2260–2267. [Google Scholar] [CrossRef]

- Nagata, K.; Inaba, K.; Kimoto, K.; Kawana, H. Accuracy of Dental Models Fabricated Using Recycled Poly-Lactic Acid. Materials 2023, 16, 2620. [Google Scholar] [CrossRef]

- Patti, A.; Acierno, S.; Cicala, G.; Acierno, D. Changes in Chemical and Physical Properties of Bio-Based Thermoplastics during Fused Deposition Modelling (FDM) Process. Chem. Eng. Trans. 2023, 100, 439–444. [Google Scholar] [CrossRef]

- Kuclourya, T.; Monroy, R.; Ahmad, R. Design of Experiments to Compare the Reprocessing Effect with Fused Deposition Modeling Printing Parameters on Mechanical Properties of Polylactic Acid Specimens towards Circular Economy. Prog. Rubber Plast. Recycl. Technol. 2023, 39, 111–140. [Google Scholar] [CrossRef]

- Dal Fabbro, P.; La Gala, A.; Van De Steene, W.; D’hooge, D.R.; Lucchetta, G.; Cardon, L.; Fiorio, R. Influence of Machine Type and Consecutive Closed-Loop Recycling on Macroscopic Properties for Fused Filament Fabrication of Acrylonitrile-Butadiene-Styrene Parts. Rapid Prototyp. J. 2021, 27, 268–277. [Google Scholar] [CrossRef]

- Mohammed, M.I.; Wilson, D.; Gomez-Kervin, E.; Tang, B.; Wang, J. Investigation of Closed-Loop Manufacturing with Acrylonitrile Butadiene Styrene over Multiple Generations Using Additive Manufacturing. ACS Sustain. Chem. Eng. 2019, 7, 13955–13969. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Maniadi, A.; Koudoumas, E.; Vairis, A.; Kechagias, J. Sustainable Additive Manufacturing: Mechanical Response of Acrylonitrile-Butadiene-Styrene over Multiple Recycling Processes. Sustainability 2020, 12, 3568. [Google Scholar] [CrossRef]

- Fukushima, K.; Tabuani, D.; Dottori, M.; Armentano, I.; Kenny, J.M.; Camino, G. Effect of Temperature and Nanoparticle Type on Hydrolytic Degradation of Poly(Lactic Acid) Nanocomposites. Polym. Degrad. Stab. 2011, 96, 2120–2129. [Google Scholar] [CrossRef]

- Vaes, D.; Van Puyvelde, P. Semi-Crystalline Feedstock for Filament-Based 3D Printing of Polymers. Prog. Polym. Sci. 2021, 118, 101411. [Google Scholar] [CrossRef]

- Singh, R.; Kumar, R.; Singh, I. Investigations on 3D Printed Thermosetting and Ceramic-Reinforced Recycled Thermoplastic-Based Functional Prototypes. J. Thermoplast. Compos. Mater. 2021, 34, 1103–1122. [Google Scholar] [CrossRef]

- Singh, R.; Singh, I.; Kumar, R. Mechanical and Morphological Investigations of 3D Printed Recycled ABS Reinforced with Bakelite–SiC–Al2O3. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 5933–5944. [Google Scholar] [CrossRef]

- Ragab, A.; Elazhary, R.; Schmauder, S.; Ramzy, A. Plastic Waste Valorization for Fused Deposition Modeling Feedstock: A Case Study on Recycled Polyethylene Terephthalate/High-Density Polyethylene Sustainability. Sustainability 2023, 15, 13291. [Google Scholar] [CrossRef]

- Zhang, W.; Cotton, C.; Sun, J.; Heider, D.; Gu, B.; Sun, B.; Chou, T.-W. Interfacial Bonding Strength of Short Carbon Fiber/Acrylonitrile-Butadiene-Styrene Composites Fabricated by Fused Deposition Modeling. Compos. Part B Eng. 2018, 137, 51–59. [Google Scholar] [CrossRef]

- Gao, X.; Zhang, D.; Qi, S.; Wen, X.; Su, Y. Mechanical Properties of 3D Parts Fabricated by Fused Deposition Modeling: Effect of Various Fillers in Polylactide. J. Appl. Polym. Sci. 2019, 136, 47824. [Google Scholar] [CrossRef]

- Yu, W.; Wang, X.; Ferraris, E.; Zhang, J. Melt Crystallization of PLA/Talc in Fused Filament Fabrication. Mater. Des. 2019, 182, 108013. [Google Scholar] [CrossRef]

- Mazzanti, V.; Salzano de Luna, M.; Pariante, R.; Mollica, F.; Filippone, G. Natural Fiber-Induced Degradation in PLA-Hemp Biocomposites in the Molten State. Compos. Part Appl. Sci. Manuf. 2020, 137, 105990. [Google Scholar] [CrossRef]

- Chong, W.J.; Shen, S.; Li, Y.; Trinchi, A.; Pejak, D.; Kyratzis, I.; Sola, A.; Wen, C. Additive Manufacturing of Antibacterial PLA-ZnO Nanocomposites: Benefits, Limitations and Open Challenges. J. Mater. Sci. Technol. 2022, 111, 120–151. [Google Scholar] [CrossRef]

- Duty, C.; Ajinjeru, C.; Kishore, V.; Compton, B.; Hmeidat, N.; Chen, X.; Liu, P.; Hassen, A.A.; Lindahl, J.; Kunc, V. What Makes a Material Printable? A Viscoelastic Model for Extrusion-Based 3D Printing of Polymers. J. Manuf. Process. 2018, 35, 526–537. [Google Scholar] [CrossRef]

- Fico, D.; Rizzo, D.; De Carolis, V.; Montagna, F.; Esposito Corcione, C. Sustainable Polymer Composites Manufacturing through 3D Printing Technologies by Using Recycled Polymer and Filler. Polymers 2022, 14, 3756. [Google Scholar] [CrossRef]

- Laoutid, F.; Lafqir, S.; Toncheva, A.; Dubois, P. Valorization of Recycled Tire Rubber for 3D Printing of ABS- and TPO-Based Composites. Materials 2021, 14, 5889. [Google Scholar] [CrossRef]

- Nguyen, H.T.; Crittenden, K.; Weiss, L.; Bardaweel, H. Recycle of Waste Tire Rubber in a 3D Printed Composite with Enhanced Damping Properties. J. Clean. Prod. 2022, 368, 133085. [Google Scholar] [CrossRef]

- Jacobs, J.; Pejak, D.; Ebdon, N.; Sola, A. Polymer/Metal Composite Filaments for Fused Filament Fabrication (FFF). In Proceedings of the APICAM 2023, Sydney, NSW, Australia, 21–23 June 2023. [Google Scholar]

- Tao, Y.; Liu, M.; Han, W.; Li, P. Waste Office Paper Filled Polylactic Acid Composite Filaments for 3D Printing. Compos. Part B Eng. 2021, 221, 108998. [Google Scholar] [CrossRef]

- Zander, N.E.; Park, J.; Boelter, Z.; Gillan, M. Recycled Cellulose Polypropylene Composite Feedstocks for Polymer Additive Manufacturing. ACS Omega 2019, 4, 13879–13888. [Google Scholar] [CrossRef] [PubMed]

- Carrete, I.A.; Quiñonez, P.A.; Bermudez, D.; Roberson, D.A. Incorporating Textile-Derived Cellulose Fibers for the Strengthening of Recycled Polyethylene Terephthalate for 3D Printing Feedstock Materials. J. Polym. Environ. 2021, 29, 662–671. [Google Scholar] [CrossRef]

- Palaniyappan, S.; Sivakumar, N.K.; Sekar, V. Sustainable Approach to the Revalorization of Crab Shell Waste in Polymeric Filament Extrusion for 3D Printing Applications. Biomass Convers. Biorefinery 2023. [Google Scholar] [CrossRef]

- Yang, F.; Ye, X.; Zhong, J.; Lin, Z.; Wu, S.; Hu, Y.; Zheng, W.; Zhou, W.; Wei, Y.; Dong, X. Recycling of Waste Crab Shells into Reinforced Poly (Lactic Acid) Biocomposites for 3D Printing. Int. J. Biol. Macromol. 2023, 234, 122974. [Google Scholar] [CrossRef]

- Mankotia, K.; Chohan, J.S.; Singh, R. On Almond Skin Powder Reinforced PA6 Composite for 3D Printing Applications. Proc. Natl. Acad. Sci. India Sect. Phys. Sci. 2022, 92, 467–478. [Google Scholar] [CrossRef]

- Singh, R.; Kumar, R.; Pawanpreet; Singh, M.; Singh, J. On Mechanical, Thermal and Morphological Investigations of Almond Skin Powder-Reinforced Polylactic Acid Feedstock Filament. J. Thermoplast. Compos. Mater. 2022, 35, 230–248. [Google Scholar] [CrossRef]

- Mathiazhagan, N.; Sivakumar, N.K.; Palaniyappan, S.; Rahaman, M. Influence of Printing-Based Factors on the Mechanical Properties of Hexagonal Lattice-Structured 3D Printed Novel Walnut Shell/Polylactic Acid Composite. J. Thermoplast. Compos. Mater. 2023. [Google Scholar] [CrossRef]

- Palaniyappan, S.; Veeman, D.; Sivakumar, N.K.; Natrayan, L. Development and Optimization of Lattice Structure on the Walnut Shell Reinforced PLA Composite for the Tensile Strength and Dimensional Error Properties. Structures 2022, 45, 163–178. [Google Scholar] [CrossRef]

- Morales, M.A.; Maranon, A.; Hernandez, C.; Porras, A. Development and Characterization of a 3D Printed Cocoa Bean Shell Filled Recycled Polypropylene for Sustainable Composites. Polymers 2021, 13, 3162. [Google Scholar] [CrossRef]

- Jerman, M.; Krinke, S.; Kühnel, L.; Müller, M.; Valentinčič, J.; Zeidler, H. Additive Manufacturing Using Renewable Materials: Concept of Upcycling Peach Kernels for Use in Binder Jetting and FFF. In Proceedings of the Euspen’s 20th International Conference & Exhibition, Geneva, Switzerland, 8–12 June 2020; pp. 123–124. [Google Scholar]

- Ariel Leong, J.J.; Koay, S.C.; Chan, M.Y.; Choo, H.L.; Tshai, K.Y.; Ong, T.K. Composite Filament Made from Post-Used Styrofoam and Corn Husk Fiber for Fuse Deposition Modeling. J. Nat. Fibers 2022, 19, 7033–7048. [Google Scholar] [CrossRef]

- Morales, M.A.; Atencio Martinez, C.L.; Maranon, A.; Hernandez, C.; Michaud, V.; Porras, A. Development and Characterization of Rice Husk and Recycled Polypropylene Composite Filaments for 3D Printing. Polymers 2021, 13, 1067. [Google Scholar] [CrossRef]

- Maldonado-García, B.; Pal, A.K.; Misra, M.; Gregori, S.; Mohanty, A.K. Sustainable 3D Printed Composites from Recycled Ocean Plastics and Pyrolyzed Soy-Hulls: Optimization of Printing Parameters, Performance Studies and Prototypes Development. Compos. Part C Open Access 2021, 6, 100197. [Google Scholar] [CrossRef]

- Su, N.; Pierce, R.S.; Rudd, C.; Liu, X. Comprehensive Investigation of Reclaimed Carbon Fibre Reinforced Polyamide (rCF/PA) Filaments and FDM Printed Composites. Compos. Part B Eng. 2022, 233, 109646. [Google Scholar] [CrossRef]

- Giani, N.; Ortolani, J.; Mazzocchetti, L.; Benelli, T.; Picchioni, F.; Giorgini, L. Production of Thermoplastic Composite Filaments for Additive Manufacturing Using Recycled Carbon Fibers. Macromol. Symp. 2022, 405, 2100249. [Google Scholar] [CrossRef]

- Seok, W.; Jeon, E.; Kim, Y. Effects of Annealing for Strength Enhancement of FDM 3D-Printed ABS Reinforced with Recycled Carbon Fiber. Polymers 2023, 15, 3110. [Google Scholar] [CrossRef] [PubMed]

- Tosto, C.; Pergolizzi, E.; Vitiello, L.; Filippone, G.; Cicala, G. Production of PLA-Milled Carbon Fibers (MCF) Filled Filaments for Fused Filament Fabrication (FFF) Printing. Macromol. Symp. 2022, 404, 2100417. [Google Scholar] [CrossRef]

- Liu, W.; Huang, H.; Zhu, L.; Liu, Z. Integrating Carbon Fiber Reclamation and Additive Manufacturing for Recycling CFRP Waste. Compos. Part B Eng. 2021, 215, 108808. [Google Scholar] [CrossRef]

- Omar, N.W.; Shuaib, N.A.; Hadi, M.H.; Azmi, A.I.; Misbah, M.N. Mechanical and Physical Properties of Recycled-Carbon-Fiber-Reinforced Polylactide Fused Deposition Modelling Filament. Materials 2022, 15, 190. [Google Scholar] [CrossRef]

- Cheng, H.; Guo, L.; Qian, Z.; Sun, R.; Zhang, J. Remanufacturing of Recycled Carbon Fiber-Reinforced Composites Based on Fused Deposition Modeling Processes. Int. J. Adv. Manuf. Technol. 2021, 116, 1609–1619. [Google Scholar] [CrossRef]

- Huang, H.; Liu, W.; Liu, Z. An Additive Manufacturing-Based Approach for Carbon Fiber Reinforced Polymer Recycling. CIRP Ann. 2020, 69, 33–36. [Google Scholar] [CrossRef]

- Giani, N.; Mazzocchetti, L.; Benelli, T.; Picchioni, F.; Giorgini, L. Towards Sustainability in 3D Printing of Thermoplastic Composites: Evaluation of Recycled Carbon Fibers as Reinforcing Agent for FDM Filament Production and 3D Printing. Compos. Part Appl. Sci. Manuf. 2022, 159, 107002. [Google Scholar] [CrossRef]

- Mohammed, L.; Ansari, M.N.M.; Pua, G.; Jawaid, M.; Islam, M.S. A Review on Natural Fiber Reinforced Polymer Composite and Its Applications. Int. J. Polym. Sci. 2015, 2015, e243947. [Google Scholar] [CrossRef]

- Isa, A.; Nosbi, N.; Che Ismail, M.; Md Akil, H.; Wan Ali, W.F.; Omar, M.F. A Review on Recycling of Carbon Fibres: Methods to Reinforce and Expected Fibre Composite Degradations. Materials 2022, 15, 4991. [Google Scholar] [CrossRef]

- Tan, Y.A.; Chan, M.Y.; Koay, S.C.; Ong, T.K. 3D Polymer Composite Filament Development from Post-Consumer Polypropylene and Disposable Chopstick Fillers. J. Vinyl Addit. Technol. 2023, 29, 909–922. [Google Scholar] [CrossRef]

- Yu, I.K.M.; Wong, K.-H. Food Waste-Derived 3D Printable Materials: A Carbon Neutral Solution to Global Foodloss. Trends Food Sci. Technol. 2023, 137, 156–166. [Google Scholar] [CrossRef]

- Díaz-Rodríguez, J.G.; Pertúz-Comas, A.D.; González-Estrada, O.A. Mechanical Properties for Long Fibre Reinforced Fused Deposition Manufactured Composites. Compos. Part B Eng. 2021, 211, 108657. [Google Scholar] [CrossRef]

- Ismail, K.I.; Yap, T.C.; Ahmed, R. 3D-Printed Fiber-Reinforced Polymer Composites by Fused Deposition Modelling (FDM): Fiber Length and Fiber Implementation Techniques. Polymers 2022, 14, 4659. [Google Scholar] [CrossRef]

- Sola, A.; Trinchi, A. Chapter 9—Fused Deposition Modeling of Continuous Fiber-Reinforced Composites and Sandwich Structures. In Fused Deposition Modeling of Composite Materials; Sola, A., Trinchi, A., Eds.; Woodhead Publishing Series in Composites Science and Engineering; Woodhead Publishing, Elsevier: Cambridge, MA, USA; Kidlington, UK, 2023; pp. 211–248. ISBN 978-0-323-98823-0. [Google Scholar]

- Zare, Y. Study of Nanoparticles Aggregation/Agglomeration in Polymer Particulate Nanocomposites by Mechanical Properties. Compos. Part Appl. Sci. Manuf. 2016, 84, 158–164. [Google Scholar] [CrossRef]

- Hanif, A.; Usman, M. 3—Fly Ash Cenosphere: Characterization, Processing, and Properties. In Handbook of Fly Ash; Kar, K.K., Ed.; Butterworth-Heinemann, Elsevier: Kidlington, Oxford, UK; Cambridge, MA, USA, 2022; pp. 57–75. ISBN 978-0-12-817686-3. [Google Scholar]

- Doddamani, M.; Gupta, N. 26—3D Printing of Fly Ash-Based Syntactic Foams. In Handbook of Fly Ash; Kar, K.K., Ed.; Butterworth-Heinemann, Elsevier: Kidlington, Oxford, UK; Cambridge, MA, USA, 2022; pp. 793–818. ISBN 978-0-12-817686-3. [Google Scholar]

- Singh, A.K.; Patil, B.; Hoffmann, N.; Saltonstall, B.; Doddamani, M.; Gupta, N. Additive Manufacturing of Syntactic Foams: Part 1: Development, Properties, and Recycling Potential of Filaments. JOM 2018, 70, 303–309. [Google Scholar] [CrossRef]

- Blok, L.G.; Yu, H.; Longana, M.L.; Woods, B.K.S. Development of Discontinuous Fibre Reinforced Thermoplastic Feedstocks for High Performance 3D Printing. In Proceedings of the ECCM 2018—18th European Conference on Composite Materials, Athens, Greece, 25–28 June 2018. [Google Scholar]

- Jiang, D.; Smith, D.E. Anisotropic Mechanical Properties of Oriented Carbon Fiber Filled Polymer Composites Produced with Fused Filament Fabrication. Addit. Manuf. 2017, 18, 84–94. [Google Scholar] [CrossRef]

- Shah, A.K.; Jain, A. Microstructure and Mechanical Properties of Filament and Fused Deposition Modelling Printed Polylactic-Acid and Carbon-Fiber Reinforced Polylactic-Acid. J. Reinf. Plast. Compos. 2023. [Google Scholar] [CrossRef]

- Vaxman, A.; Narkis, M.; Siegmann, A.; Kenig, S. Short-Fiber Thermoplastics Composites: Fiber Fracture during Melt Processing. In Wiley Encyclopedia of Composites; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2012; pp. 1–19. ISBN 978-1-118-09729-8. [Google Scholar]

- Yang, D.; Zhang, H.; Wu, J.; McCarthy, E.D. Fibre Flow and Void Formation in 3D Printing of Short-Fibre Reinforced Thermoplastic Composites: An Experimental Benchmark Exercise. Addit. Manuf. 2021, 37, 101686. [Google Scholar] [CrossRef]

- Fallon, J.J.; McKnight, S.H.; Bortner, M.J. Highly Loaded Fiber Filled Polymers for Material Extrusion: A Review of Current Understanding. Addit. Manuf. 2019, 30, 100810. [Google Scholar] [CrossRef]

- Gupta, A.; Fidan, I.; Hasanov, S.; Nasirov, A. Processing, Mechanical Characterization, and Micrography of 3D-Printed Short Carbon Fiber Reinforced Polycarbonate Polymer Matrix Composite Material. Int. J. Adv. Manuf. Technol. 2020, 107, 3185–3205. [Google Scholar] [CrossRef]

- Fu, S.-Y.; Lauke, B. Effects of Fiber Length and Fiber Orientation Distributions on the Tensile Strength of Short-Fiber-Reinforced Polymers. Compos. Sci. Technol. 1996, 56, 1179–1190. [Google Scholar] [CrossRef]

- Monette, L.; Anderson, M.P.; Grest, G.S. The Meaning of the Critical Length Concept in Composites: Study of Matrix Viscosity and Strain Rate on the Average Fiber Fragmentation Length in Short-Fiber Polymer Composites. Polym. Compos. 1993, 14, 101–115. [Google Scholar] [CrossRef]

- Slapnik, J.; Lucyshyn, T.; Pinter, G. Relationships between the Decomposition Behaviour of Renewable Fibres and Their Reinforcing Effect in Composites Processed at High Temperatures. Polymers 2021, 13, 4448. [Google Scholar] [CrossRef]

- Thomason, J.L.; Yang, L.; Meier, R. The Properties of Glass Fibres after Conditioning at Composite Recycling Temperatures. Compos. Part Appl. Sci. Manuf. 2014, 61, 201–208. [Google Scholar] [CrossRef]

- Feih, S.; Boiocchi, E.; Kandare, E.; Mathys, Z.; Gibson, A.; Mouritz, A.P. Strength Degradation of Glass and Carbon Fibres at High Temperature. In Proceedings of the ICCM-17—17th International Conference on Composite Materials, Edinburgh, UK, 27–31 July 2009. [Google Scholar]

- Jenkins, P.G. Understanding Physical Changes and Strength Loss of E-Glass Fibres Following Exposure to Elevated Temperatures. Mater. Sci. Technol. 2017, 33, 255–264. [Google Scholar] [CrossRef]

- Proctor, B.A.; Whitney, I.; Johnson, J.W. The Strength of Fused Silica. Proc. R. Soc. Lond. Ser. Math. Phys. Sci. 1967, 297, 534–557. [Google Scholar]

- Militký, J.; Kovačič, V.; Rubnerová, J. Influence of Thermal Treatment on Tensile Failure of Basalt Fibers. Eng. Fract. Mech. 2002, 69, 1025–1033. [Google Scholar] [CrossRef]

- Yin, Y.; Binner, J.G.P.; Cross, T.E.; Marshall, S.J. The Oxidation Behaviour of Carbon Fibres. J. Mater. Sci. 1994, 29, 2250–2254. [Google Scholar] [CrossRef]

- Yang, G.; Wang, W.; Peng, S.; Huang, Z. The Research on Oxidation Resistance Ability and Mechanical Properties of Carbon Fiber Reinforced Phenolic Resin Composites. Mater. Res. Express 2020, 7, 065604. [Google Scholar] [CrossRef]

- Yip, H.L.H.; Pickering, S.J.; Rudd, C.D. Characterisation of Carbon Fibres Recycled from Scrap Composites Using Fluidised Bed Process. Plast. Rubber Compos. 2002, 31, 278–282. [Google Scholar] [CrossRef]

- Burn, D.T.; Harper, L.T.; Johnson, M.; Warrior, N.A.; Nagel, U.; Yang, L.; Thomason, J. The Usability of Recycled Carbon Fibres in Short Fibre Thermoplastics: Interfacial Properties. J. Mater. Sci. 2016, 51, 7699–7715. [Google Scholar] [CrossRef]

- Távora de Mello Soares, C.; Ek, M.; Östmark, E.; Gällstedt, M.; Karlsson, S. Recycling of Multi-Material Multilayer Plastic Packaging: Current Trends and Future Scenarios. Resour. Conserv. Recycl. 2022, 176, 105905. [Google Scholar] [CrossRef]

- Schmidt, J.; Grau, L.; Auer, M.; Maletz, R.; Woidasky, J. Multilayer Packaging in a Circular Economy. Polymers 2022, 14, 1825. [Google Scholar] [CrossRef]

- Wei, B.; Yang, S.; Wang, Q. Green Recycling of Aluminum Plastic Packaging Waste by Solid-State Shear Milling and 3D Printing for Thermal Conductive Composites. Polym. Adv. Technol. 2021, 32, 2576–2587. [Google Scholar] [CrossRef]

- Hart, K.R.; Frketic, J.B.; Brown, J.R. Recycling Meal-Ready-to-Eat (MRE) Pouches into Polymer Filament for Material Extrusion Additive Manufacturing. Addit. Manuf. 2018, 21, 536–543. [Google Scholar] [CrossRef]

- Singh, J.; Chawla, K.; Singh, R. Mechanical and Rheological Investigations of Bakelite Reinforced ABS. In Encyclopedia of Materials: Plastics and Polymers; Hashmi, M.S.J., Ed.; Elsevier: Amsterdam, The Netherlands; Kidlington, Oxford, UK; Cambridge, MA, USA, 2022; pp. 253–264. ISBN 978-0-12-823291-0. [Google Scholar]

- Singh, R.; Kumar, S.; Singh, A.P.; Wei, Y. On Comparison of Recycled LDPE and LDPE–Bakelite Composite Based 3D Printed Patch Antenna. Proc. Inst. Mech. Eng. Part J. Mater. Des. Appl. 2022, 236, 842–856. [Google Scholar] [CrossRef]

- Waheed, S.; Cabot, J.M.; Smejkal, P.; Farajikhah, S.; Sayyar, S.; Innis, P.C.; Beirne, S.; Barnsley, G.; Lewis, T.W.; Breadmore, M.C.; et al. Three-Dimensional Printing of Abrasive, Hard, and Thermally Conductive Synthetic Microdiamond–Polymer Composite Using Low-Cost Fused Deposition Modeling Printer. ACS Appl. Mater. Interfaces 2019, 11, 4353–4363. [Google Scholar] [CrossRef] [PubMed]

- Pal, A.K.; Cisneros-López, E.O.; U-Rodriguez, A.; Wu, F.; Misra, M.; Mielewski, D.F.; Kiziltas, A.; Mohanty, A.K. 3d Printing Sustainable Biocomposites from Recycled PLA and Micro-Crystalline Cellulose. In Proceedings of the Annual Technical Conference—ANTEC 2021, Conference Proceedings, Online, 10–21 May 2021. [Google Scholar]

- Peterson, A.M. Review of Acrylonitrile Butadiene Styrene in Fused Filament Fabrication: A Plastics Engineering-Focused Perspective. Addit. Manuf. 2019, 27, 363–371. [Google Scholar] [CrossRef]

- Materials in LEGO® Elements. Available online: https://www.lego.com/ms-my/sustainability/product-safety/materials (accessed on 31 August 2023).

- Kim, S.; Rahman, M.A.; Arifuzzaman, M.; Gilmer, D.B.; Li, B.; Wilt, J.K.; Lara-Curzio, E.; Saito, T. Closed-Loop Additive Manufacturing of Upcycled Commodity Plastic through Dynamic Cross-Linking. Sci. Adv. 2022, 8, eabn6006. [Google Scholar] [CrossRef] [PubMed]

- Tian, X.; Liu, T.; Wang, Q.; Dilmurat, A.; Li, D.; Ziegmann, G. Recycling and Remanufacturing of 3D Printed Continuous Carbon Fiber Reinforced PLA Composites. J. Clean. Prod. 2017, 142, 1609–1618. [Google Scholar] [CrossRef]

- Al Rashid, A.; Khan, S.A.; Al-Ghamdi, S.G.; Koç, M. Additive Manufacturing of Polymer Nanocomposites: Needs and Challenges in Materials, Processes, and Applications. J. Mater. Res. Technol. 2021, 14, 910–941. [Google Scholar] [CrossRef]

- Nanotechnology. Available online: https://education.nationalgeographic.org/resource/nanotechnology (accessed on 28 August 2023).

- Wu, H.; Fahy, W.P.; Kim, S.; Kim, H.; Zhao, N.; Pilato, L.; Kafi, A.; Bateman, S.; Koo, J.H. Recent Developments in Polymers/Polymer Nanocomposites for Additive Manufacturing. Prog. Mater. Sci. 2020, 111, 100638. [Google Scholar] [CrossRef]

- Paul, D.R.; Robeson, L.M. Polymer Nanotechnology: Nanocomposites. Polymer 2008, 49, 3187–3204. [Google Scholar] [CrossRef]

- Kong, K.T.S.; Mariatti, M.; Rashid, A.A.; Busfield, J.J.C. Effect of Processing Methods and Functional Groups on the Properties of Multi-Walled Carbon Nanotube Filled Poly(Dimethyl Siloxane) Composites. Polym. Bull. 2012, 69, 937–953. [Google Scholar] [CrossRef]

- Borm, P.J.; Robbins, D.; Haubold, S.; Kuhlbusch, T.; Fissan, H.; Donaldson, K.; Schins, R.; Stone, V.; Kreyling, W.; Lademann, J.; et al. The Potential Risks of Nanomaterials: A Review Carried out for ECETOC. Part. Fibre Toxicol. 2006, 3, 11. [Google Scholar] [CrossRef] [PubMed]

- Pacheco, I.; Buzea, C. Nanomaterials and Nanocomposites: Classification and Toxicity. In Handbook of Nanomaterials and Nanocomposites for Energy and Environmental Applications; Kharissova, O.V., Torres-Martínez, L.M., Kharisov, B.I., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 3–39. ISBN 978-3-030-36268-3. [Google Scholar]

- Ging, J.; Tejerina-Anton, R.; Ramakrishnan, G.; Nielsen, M.; Murphy, K.; Gorham, J.M.; Nguyen, T.; Orlov, A. Development of a Conceptual Framework for Evaluation of Nanomaterials Release from Nanocomposites: Environmental and Toxicological Implications. Sci. Total Environ. 2014, 473–474, 9–19. [Google Scholar] [CrossRef]

- Raynor, P.C.; Cebula, J.I.; Spangenberger, J.S.; Olson, B.A.; Dasch, J.M.; D’Arcy, J.B. Assessing Potential Nanoparticle Release During Nanocomposite Shredding Using Direct-Reading Instruments. J. Occup. Environ. Hyg. 2012, 9, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Kozlowski, M.A.; Macyszyn, J. Recycling of Nanocomposites. In Ecosustainable Polymer Nanomaterials for Food Packaging: Innovative Solutions, Characterization Needs, Safety and Environmental Issues; Routledge: Abingdon, UK, 2013; pp. 313–336. ISBN 978-90-04-20738-7. [Google Scholar]

- Morgan, L.M.; Weager, B.M.; Hare, C.M.; Bishop, G.R.; Smith, G.M. Self Reinforced Polymer Composites: Coming of Age. In Proceedings of the 17th International Conference on Composite Materials, Edinburgh, UK, 27–31 July 2009. [Google Scholar]

- Babu, N.K.; Mensah, R.A.; Shanmugam, V.; Rashedi, A.; Athimoolam, P.; Aseer, J.R.; Das, O. Self-Reinforced Polymer Composites: An Opportunity to Recycle Plastic Wastes and Their Future Trends. J. Appl. Polym. Sci. 2022, 139, e53143. [Google Scholar] [CrossRef]

- Mai, F.; Tu, W.; Bilotti, E.; Peijs, T. Preparation and Properties of Self-Reinforced Poly(Lactic Acid) Composites Based on Oriented Tapes. Compos. Part Appl. Sci. Manuf. 2015, 76, 145–153. [Google Scholar] [CrossRef]

- Zhang, M.; Tian, X.; Cao, H.; Liu, T.; Akmal Zia, A.; Li, D. 3D Printing of Fully Recyclable Continuous Fiber Self-Reinforced Composites Utilizing Supercooled Polymer Melts. Compos. Part Appl. Sci. Manuf. 2023, 169, 107513. [Google Scholar] [CrossRef]

- Gantenbein, S.; Masania, K.; Woigk, W.; Sesseg, J.P.W.; Tervoort, T.A.; Studart, A.R. Three-Dimensional Printing of Hierarchical Liquid-Crystal-Polymer Structures. Nature 2018, 561, 226–230. [Google Scholar] [CrossRef]

- Gantenbein, S.; Mascolo, C.; Houriet, C.; Zboray, R.; Neels, A.; Masania, K.; Studart, A.R. Spin-printing of Liquid Crystal Polymer into Recyclable and Strong All-fiber Materials. Adv. Funct. Mater. 2021, 31, 2104574. [Google Scholar] [CrossRef]

- Wypych, G. 8—The Effect of Fillers on the Mechanical Properties of Filled Materials. In Handbook of Fillers, 4th ed.; Wypych, G., Ed.; ChemTec Publishing: Scarborough, ON, Canada, 2016; pp. 467–531. ISBN 978-1-895198-91-1. [Google Scholar]

- Ma, H.; Zhang, Y.; Jiao, Z.; Yang, W.; He, X.; Xie, G.; Li, H. Comprehensive Assessment of the Environmental Impact of Fused Filament Fabrication Products Produced under Various Performance Requirements. J. Inst. Eng. India Ser. C 2021, 102, 59–73. [Google Scholar] [CrossRef]

- Chong, S.; Chiu, H.-L.; Liao, Y.-C.; Hung, S.-T.; Pan, G.-T. Cradle to Cradle® Design for 3D Printing. Chem. Eng. Trans. 2015, 45, 1669–1674. [Google Scholar] [CrossRef]

- Kuijer, L. Implications of Social Practice Theory for Sustainable Design. Ph.D. Thesis, Technische Universiteit Delft, Delft, The Netherlands, 2014. [Google Scholar]

- Muflikhun, M.A.; Sentanu, D.A. Characteristics and Performance of Carabiner Remodeling Using 3D Printing with Graded Filler and Different Orientation Methods. Eng. Fail. Anal. 2021, 130, 105795. [Google Scholar] [CrossRef]

- Shan, H.; Yang, J. Promoting the Implementation of Extended Producer Responsibility Systems in China: A Behavioral Game Perspective. J. Clean. Prod. 2020, 250, 119446. [Google Scholar] [CrossRef]

- COM (2019) 190 Final. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX%3A52019DC0190 (accessed on 17 October 2023).

- Calisto Friant, M.; Vermeulen, W.J.V.; Salomone, R. Analysing European Union Circular Economy Policies: Words versus Actions. Sustain. Prod. Consum. 2021, 27, 337–353. [Google Scholar] [CrossRef]

- Mhatre, P.; Panchal, R.; Singh, A.; Bibyan, S. A Systematic Literature Review on the Circular Economy Initiatives in the European Union. Sustain. Prod. Consum. 2021, 26, 187–202. [Google Scholar] [CrossRef]

| Keyword | Definition | Ref. |

|---|---|---|

| Chemical recycling | Conversion from waste to new raw material through chemical means that convert the material (typically, a polymer) into smaller molecules to produce fuels and virgin plastic or plastic compounds. | [56] |

| Downcycling | The practice of downgrading the original material into a material of lesser quality. For example, producing rags from old clothing. | [54] |

| Life cycle assessment | Standardised analysis technique to assess environmental impacts associated with all the stages of a product’s life. | [55] |

| Material circularity indicator | For a given product, parameter measuring the extent to which the linear flow of material has been minimized and restorative flow maximized. | [57,58,59] |

| Mechanical recycling | Conversion from waste to new raw material through mechanical means like collection, sorting, washing, and grinding, which have minimal consequences to the material’s chemical composition. Steps may occur in a different order, repeatedly, or not at all. | [56] |

| Primary recycling | The recovered plastic is used in a new item having performance characteristics that are equivalent to virgin plastic. For example, PET recovered from post-consumer bottles being reused for producing new bottles. OR | [53] |

| Primary recycling | Recycling of post-industrial polymer waste (for example, obtained during injection or extrusion processes) to generate new products. | [61] |

| Quaternary recycling | Waste plastic is incinerated for producing (thermal) energy, and possibly sourcing residues as by-products. For example, tire-derived fuel. | [53] |

| Secondary recycling | The recovered plastic is used in a new item having inferior performance characteristics than virgin plastic. For example, PET recovered from post-consumer bottles being used for fibre spinning in textiles. OR | [53] |

| Secondary recycling | Recycling of post-consumer materials that are reprocessed into new products, which can be either higher-value products (upcycling) or lower-value products (downcycling). | [61] |

| Sustainability | Meeting the needs of the present without compromising the ability of future generations to meet their own needs. | [51] |

| Sustainability | The potential for something to continue indefinitely. | [33] |

| Sustainable materials | Materials used throughout our consumer and industrial economy that can be produced in required volumes without depleting non-renewable resources and without disrupting the established steady-state equilibrium of the environment and key natural resource systems. | [52] |

| Tertiary recycling | Waste plastic is used as the feedstock in a process that generates chemicals and fuels. For example, waste PET can be returned to diols and dimethyl terephthalate by chemical methods (glycolysis). Raw chemicals can then be used for making virgin PET. | [53] |

| Upcycling | The practice of refashioning something to a higher value. For example, a used plastic bottle is reinvented as a Moser light bulb [60]. | [54] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sola, A.; Trinchi, A. Recycling as a Key Enabler for Sustainable Additive Manufacturing of Polymer Composites: A Critical Perspective on Fused Filament Fabrication. Polymers 2023, 15, 4219. https://doi.org/10.3390/polym15214219

Sola A, Trinchi A. Recycling as a Key Enabler for Sustainable Additive Manufacturing of Polymer Composites: A Critical Perspective on Fused Filament Fabrication. Polymers. 2023; 15(21):4219. https://doi.org/10.3390/polym15214219

Chicago/Turabian StyleSola, Antonella, and Adrian Trinchi. 2023. "Recycling as a Key Enabler for Sustainable Additive Manufacturing of Polymer Composites: A Critical Perspective on Fused Filament Fabrication" Polymers 15, no. 21: 4219. https://doi.org/10.3390/polym15214219

APA StyleSola, A., & Trinchi, A. (2023). Recycling as a Key Enabler for Sustainable Additive Manufacturing of Polymer Composites: A Critical Perspective on Fused Filament Fabrication. Polymers, 15(21), 4219. https://doi.org/10.3390/polym15214219