Characterization of PS/PP/HDPE/LDPE Polymer Blend Obtained from Plastic Waste Collected on Beaches in Ilhéus-Bahia, Brazil

Abstract

1. Introduction

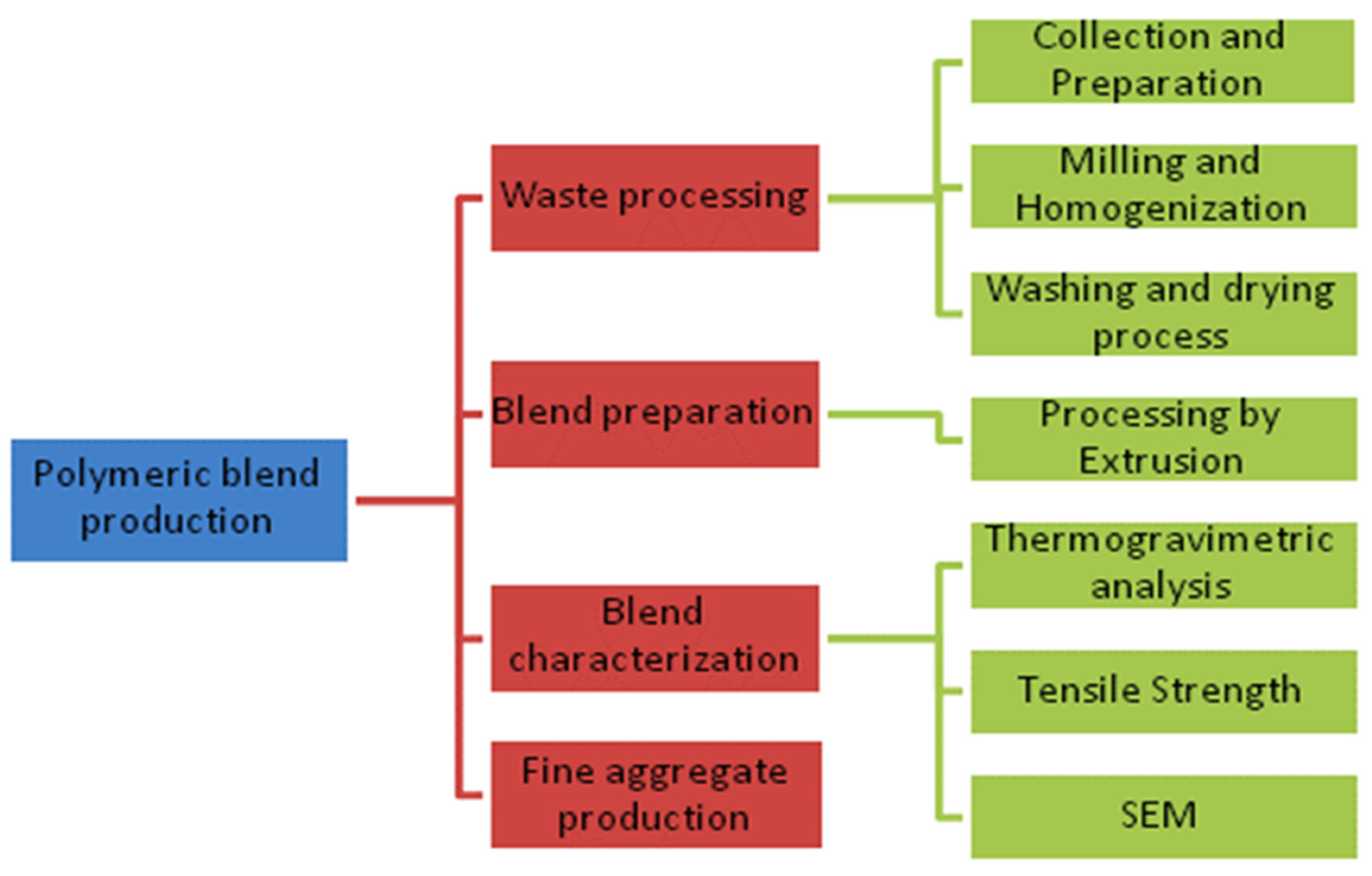

2. Materials and Methods

2.1. Waste Collection and Preparation

2.2. Milling and Homogenization

2.3. Washing and Drying

2.4. Preparation of Blends

2.5. Characterization of Blends Polymeric

2.5.1. Thermogravimetric Analysis (TGA)

2.5.2. Tensile Test

2.5.3. Scanning Electronic Microscopy (SEM)

2.5.4. Production of Fine Aggregate

3. Results and Discussion

3.1. Polymeric Waste Collection and Characterization

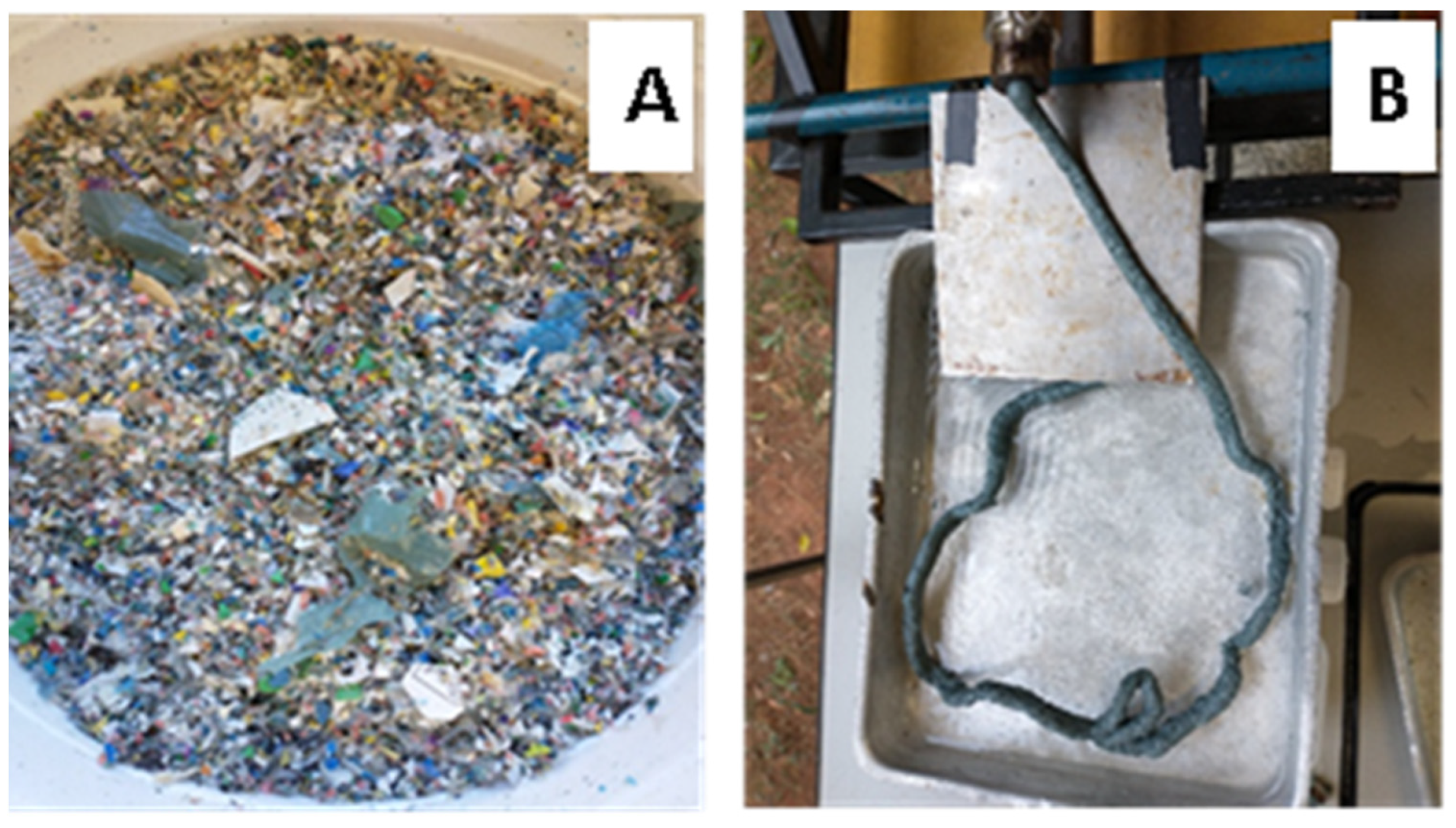

3.2. Milling, Washing, and Drying Polymeric Waste

3.3. Characterization of the Processed Polymeric Material

3.3.1. Extrusion Processing

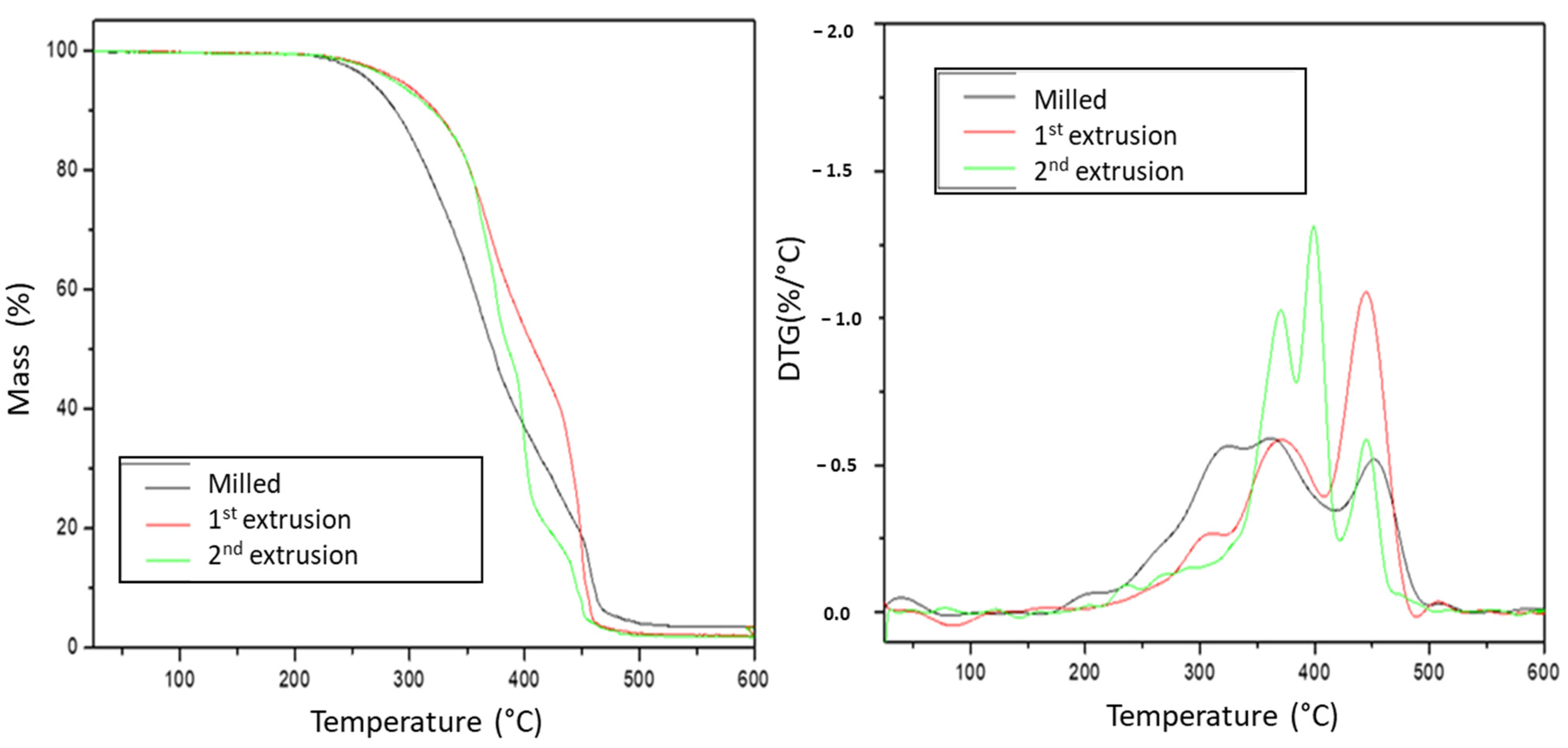

3.3.2. Thermogravimetric Analysis

3.3.3. Evaluation of the Mechanical Properties of the Polymer Blend

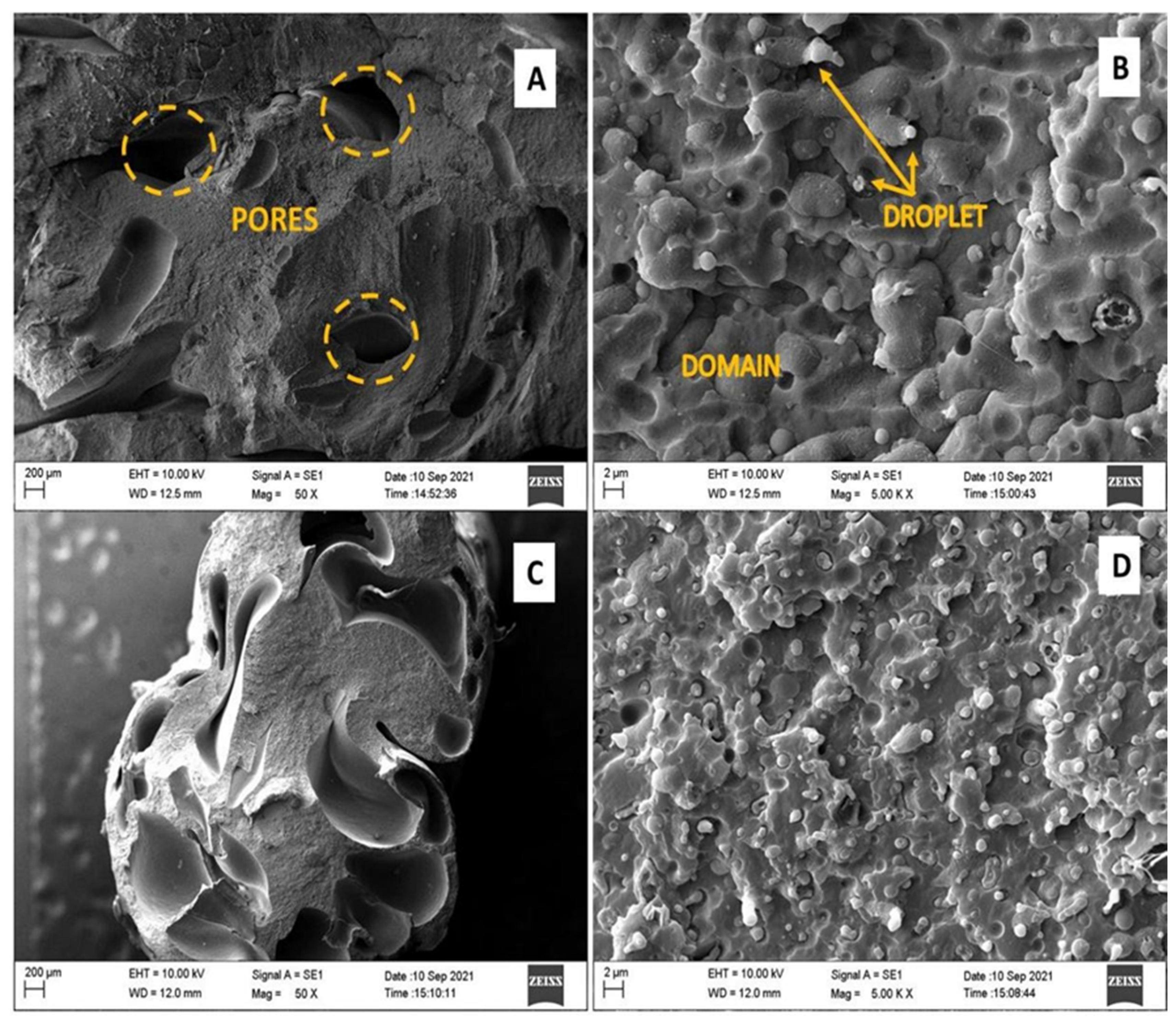

3.3.4. Morphological Evaluation of the Polymer Blend

3.3.5. Production of Recycled Aggregate

4. Conclusions

- The washing, drying, and milling steps proved to be efficient. The most recurrent residues in the collections were the pots and lids of margarine/cream foods, disposable cups, EPS packages for meals, and cleaning products such as alcohol and bleach (provided by the pandemic);

- The sample collected, separated for analysis, was composed of 54% PP, 39% HDPE, 6% LDPE, and 1% PS;

- Through extrusion processing, a polymeric blend of PS/PP/HDPE/LDPE was obtained, with homogeneous characteristics, rough surface, uniform in color, and having voids;

- Regarding the morphology of the polymer blend, all samples presented a multiphase character with a regular-looking surface, continuous and rough;

- The results for elastic modulus, deformation, and resistance to tensile strength at rupture showed that the extruded material only presented better performance to be used as aggregate fine (sand) in concrete mixes once.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Awoyera, P.O.; Adesina, A. Plastic wastes to construction products: Status, limitations and future perspective. Case Stud. Constr. Mater. 2020, 12, e00330. [Google Scholar] [CrossRef]

- Dorigato, A. Recycling of polymer blends. Adv. Ind. Eng. Polym. Res. 2021, 4, 53–69. [Google Scholar] [CrossRef]

- ABIPLAST. Perfil 2021: As Indústrias de Transformação e Reciclagem de Plástico no Brasil; ABIPLAST: São Paulo, Brazil, 2021; p. 6. Available online: http://www.abiplast.org.br/publicacoes/perfil-2021/ (accessed on 17 May 2022).

- Lacerda, A.L.F. Plásticos na Superfície Oceânica do sul do Brasil e Antártica: Concentrações, Características e Comunidades Epiplásticas. Ph.D. Thesis, Universidade Federal do Rio Grande, Rio Grande, Brazil, 2019; p. 41. Available online: https://ppgocbio.furg.br/dissertacoes-e-teses/72-publicacoes-de-2019/587-12521tese-ana-luzia-de-figueiredo-lacerda (accessed on 17 May 2022).

- Madureira, E.A.L.; da Silva, A.L.C.; Macedo, A.V.; Gralato, J.D.C.A. Análise da composição, distribuição e origem do lixo nas praias oceânicas de dois rios e Lopes Mendes na Ilha Grande (Angra dos Reis, RJ). Congr. Nac. Geogr. Física 2017, 1, 3015–3020. [Google Scholar] [CrossRef][Green Version]

- Nunes, Y.B.S.; Silva, L.R.; Mendes, E.d.S.; Araújo, N.B.; Bezerra, M. Composição e abundância de resíduos sólidos em praias urbanas da região metropolitana da Ilha de São Luís (MA), Brasil. Rev. Bras. Eng. Pesca 2018, 11, 1–12. [Google Scholar] [CrossRef]

- De Souza, J.L.; Silva, I.R. Avaliação da qualidade ambiental das praias da Ilha de Itaparica, Baía de Todos os Santos, Bahia. Soc. Nat. 2015, 27, 469–483. [Google Scholar] [CrossRef][Green Version]

- Rosa, C.; Widmer, W.M. Diagnóstico do lixo marinho na Praia de Navegantes/SC em períodos de baixa e alta vazão do Rio Itajaí-Açu. Desenvolv. Meio Ambient. 2021, 58, 126–146. [Google Scholar] [CrossRef]

- Grigore, M.E. Methods of Recycling, Properties and Applications of Recycled Thermoplastic Polymers. Recycling 2017, 2, 24. [Google Scholar] [CrossRef]

- Ragaert, K.; Delva, L.; Van Geem, K. Mechanical and chemical recycling of solid plastic waste. Waste Manag. 2017, 69, 24–58. [Google Scholar] [CrossRef] [PubMed]

- Azeez, T.O. Thermoplastic Recycling: Properties, Modifications, and Applications. In Thermosoftening Plastics; IntechOpen: Rijeka, Croatia, 2019. [Google Scholar] [CrossRef]

- Ajitha, A.R.; Sabu, T. Introduction: Polymer blends, thermodynamics, miscibility, phase separation, and compatibilization. In Compatibilization of Polymer Blends; Elsevier: Amsterdam, The Netherlands, 2020; pp. 1–29. [Google Scholar] [CrossRef]

- Vuksanović, M.M.; Heinemann, R.J. Micro and nanoscale morphology characterization of compatibilized polymer blends by microscopy. In Compatibilization of Polymer Blends; Elsevier: Amsterdam, The Netherlands, 2020; pp. 299–330. [Google Scholar] [CrossRef]

- Macosko, C.W. Morphology Development and Control in Immiscible Polymer Blends. In Macromolecular Symposia; Wiley: Weinheim, Germany, 2000; Volume 149, pp. 171–184. [Google Scholar] [CrossRef]

- Chanda, M. Plastics Tecnology Handbook, 5th ed.; CRC Press, Taylor & Francis Group: Abingdon, UK, 2018; p. 1012. [Google Scholar]

- Harper, C.A. Handbook of Plastics, Elastomers and Composites, 4th ed.; McGraw-Hill Professional: New York, NY, USA, 2004; p. 884. [Google Scholar]

- He, J.; Bu, W.; Zeng, J. Co-phase continuity in immiscible binary polymer blends. Polymer 1997, 38, 6347–6353. [Google Scholar] [CrossRef]

- Pötschke, P.; Paul, D.R. Formation of Co-continuous Structures in Melt-Mixed Immiscible Polymer Blends. J. Macromol. Sci. Part C Polym. Rev. 2003, 43, 87–141. [Google Scholar] [CrossRef]

- Spinacé, M.A.D.S.; De Paoli, M.A. A tecnologia da reciclagem de polímeros. Química Nova 2005, 28, 65–72. [Google Scholar] [CrossRef]

- ABNT. Associação Brasileira de Normas Técnicas, NBR 13230: Symbology Indicative of Recyclability and Identification of Plastic Materials (Simbologia Indicativa de Reciclabilidade e Identificação de Materiais Plásticos); ABNT: Rio de Janeiro, Brasil, 2008; p. 6. Available online: https://www.normas.com.br/visualizar/abnt-nbr-nm/7929/nbr13230-embalagens-e-acondicionamento-plasticos-reciclaveis-identificacao-e-simbologia (accessed on 18 April 2023).

- ASTM D882-10; Standard Test Methods for Tensile Properties of Thin Plastic Sheeting Annual Book of ASTM Standards. ASTM International: West Conshohocken, PA, USA, 2010. Available online: https://www.astm.org/standards/d882 (accessed on 18 April 2023).

- Waldman, W.R. Interação Entre Processos Degradativos na Blenda de Polipropileno E Poliestireno Compatibilizados Com SBS. Doctoral Dissertation, Universidade Estadual de Campinas, Campinas, Brazil, 2006. [Google Scholar] [CrossRef]

- Sharuddin, S.D.A.; Abnisa, F.; Daud, W.M.A.W.; Aroua, M.K. Energy recovery from pyrolysis of plastic waste: Study on non-recycled plastics (NRP) data as the real measure of plastic waste. Energy Convers. Manag. 2017, 148, 925–934. [Google Scholar] [CrossRef]

- Anuar Sharuddin, S.D.; Abnisa, F.; Wan Daud, W.M.A.; Aroua, M.K. A review on pyrolysis of plastic wastes. Energy Convers. Manag. 2016, 115, 308–326. [Google Scholar] [CrossRef]

- Singh, R.; Ruj, B.; Sadhukhan, A.; Gupta, P. A TG-FTIR investigation on the co-pyrolysis of the waste HDPE, PP, PS and PET under high heating conditions. J. Energy Inst. 2019, 93, 1020–1035. [Google Scholar] [CrossRef]

- Saikrishnan, S.; Jubinville, D.; Tzoganakis, C.; Mekonnen, T.H. Thermo-mechanical degradation of polypropylene (PP) and low-density polyethylene (LDPE) blends exposed to simulated recycling. Polym. Degrad. Stab. 2020, 182, 109390. [Google Scholar] [CrossRef]

- Perondi, D.; Restelatto, D.; Manera, C.; Tonello, A.P.; Godinho, M.; Vilela, A.C.F. Características do resíduo do triturador de sucatas (RTS) de uma siderúrgica brasileira (Characteristics of scrap shredder waste (RTS) from a Brazilian steel plant). In 48° Seminário de Aciaria, Fundição e Metalurgia de Não-Ferrosos; Blucher Proceeding: São Paulo, Brazil, 2017; Volume 48, pp. 563–573. ISSN 2594-5300. [Google Scholar] [CrossRef]

- Salih, S.E.; Oleiwi, J.K.; Ameer, R.A.A. Comparing effect of adding LDPE, PP, PMMA on the mechanical properties of polystyrene (PS). Eng. Technol. J. 2015, 33, 1450–1461. [Google Scholar]

- Bertin, S.; Robin, J.-J. Study and characterization of virgin and recycled LDPE/PP blends. Eur. Polym. J. 2002, 38, 2255–2264. [Google Scholar] [CrossRef]

- Deka, B.K.; Maji, T. Effect of coupling agent and nanoclay on properties of HDPE, LDPE, PP, PVC blend and Phargamites karka nanocomposite. Compos. Sci. Technol. 2010, 70, 1755–1761. [Google Scholar] [CrossRef]

- Callister, W.D.; Rethwisch, D.G. Ciência e Engenharia de Materiais: Uma Introdução, 8th ed.; LTC: Rio de Janeiro, Brazil, 2012. [Google Scholar]

- Willemse, R.; de Boer, A.P.; van Dam, J.; Gotsis, A. Co-continuous morphologies in polymer blends: The influence of the interfacial tension. Polymer 1999, 40, 827–834. [Google Scholar] [CrossRef]

| POLYMER | FEATURES | MASS (kg) |

|---|---|---|

| HDPE (High-Density Polyethylene) | Packages of cleaning and beauty products, alcohol, and bleach. Yogurt pots, buckets, bowls, and PET bottle caps. Bottles and reagents. | 1.86 |

| LDPE (Low-Density Polyethylene) | Plastic bags | 0.30 |

| PP (Polypropylene) | Plastic cups, margarine jars, plastic straws, lollipop sticks, flexible plastic rods, kitchen pots and lids, and CD packaging | 2.60 |

| PS (Polystyrene) | Plastic cups and straws | 0.06 |

| OTHERS | Toothpaste tubes, refrigerator shelves, cue cone pieces; Tupperware® jars (has bisphenol A); Unidentified polymer fragments | 2.02 |

| TOTAL | 6.84 | |

| SAMPLE | Ti (°C) | Tf (°C) | Tmax (°C) | ∆T (°C) = Tmax − Ti | Mass (%) |

|---|---|---|---|---|---|

| Milled residue | 239 | 510 | 362 | 123 | 96 |

| Blend after the first extrusion | 247 | 500 | 444 | 197 | 97 |

| Blend after the second extrusion | 250 | 490 | 398 | 148 | 98 |

| Evaluated Properties | Processing Cycle | |

|---|---|---|

| First Extrusion | Second Extrusion | |

| Tensile strength (MPa) | 10.57 ± 0.68 | 9.37 ± 0.20 |

| Elastic Modulus (MPa) | 1831.98 ± 227.52 | 2272.62 ± 427.78 |

| Deformation (mm/mm) | 1.53 ± 0.02 | 1.63 ± 0.11 |

| DF | SS | SM | F | p | |

|---|---|---|---|---|---|

| Constant | 1 | 994.2968 | 994.2968 | 2965.054 | 0.000000 |

| Processing cycle | 1 | 3.5458 | 3.5458 | 10.574 | 0.011671 |

| Error | 8 | 2.6827 | 0.3353 | ||

| Total | 9 | 6.2285 |

| Polymer | Tensile Strength (MPa) | Elastic Modulus (MPa) | Deformation at Rupture (%) |

|---|---|---|---|

| PP (Polypropylene) # | 31–41.4 | 1140–1550 | 100–600 |

| PS (Polystyrene) # | 35.9–51.7 | 2280–3280 | 1.2–2.5 |

| HDPE (High-Density Polyethylene) # | 22.1–31.0 | 1060–1090 | 10–1200 |

| LDPE (Low-Density Polyethylene) # | 8.3–31.4 | 170–280 | 100–650 |

| Blend after first extrusion * | 10.57 ± 0.68 | 1831.98 ± 227.52 | 1.53 ± 0.02 |

| Blend after second extrusion * | 9.37 ± 0.2 | 2272.62 ± 427.78 | 1.63 ± 0.11 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

de Jesus, T.W.S.; Pasquini, D.; Benvenuti, T. Characterization of PS/PP/HDPE/LDPE Polymer Blend Obtained from Plastic Waste Collected on Beaches in Ilhéus-Bahia, Brazil. Polymers 2023, 15, 4155. https://doi.org/10.3390/polym15204155

de Jesus TWS, Pasquini D, Benvenuti T. Characterization of PS/PP/HDPE/LDPE Polymer Blend Obtained from Plastic Waste Collected on Beaches in Ilhéus-Bahia, Brazil. Polymers. 2023; 15(20):4155. https://doi.org/10.3390/polym15204155

Chicago/Turabian Stylede Jesus, Tauane Winny Silva, Daniel Pasquini, and Tatiane Benvenuti. 2023. "Characterization of PS/PP/HDPE/LDPE Polymer Blend Obtained from Plastic Waste Collected on Beaches in Ilhéus-Bahia, Brazil" Polymers 15, no. 20: 4155. https://doi.org/10.3390/polym15204155

APA Stylede Jesus, T. W. S., Pasquini, D., & Benvenuti, T. (2023). Characterization of PS/PP/HDPE/LDPE Polymer Blend Obtained from Plastic Waste Collected on Beaches in Ilhéus-Bahia, Brazil. Polymers, 15(20), 4155. https://doi.org/10.3390/polym15204155