Circular Economy Insights on the Suitability of New Tri-Layer Compostable Packaging Films after Degradation in Storage Conditions

Abstract

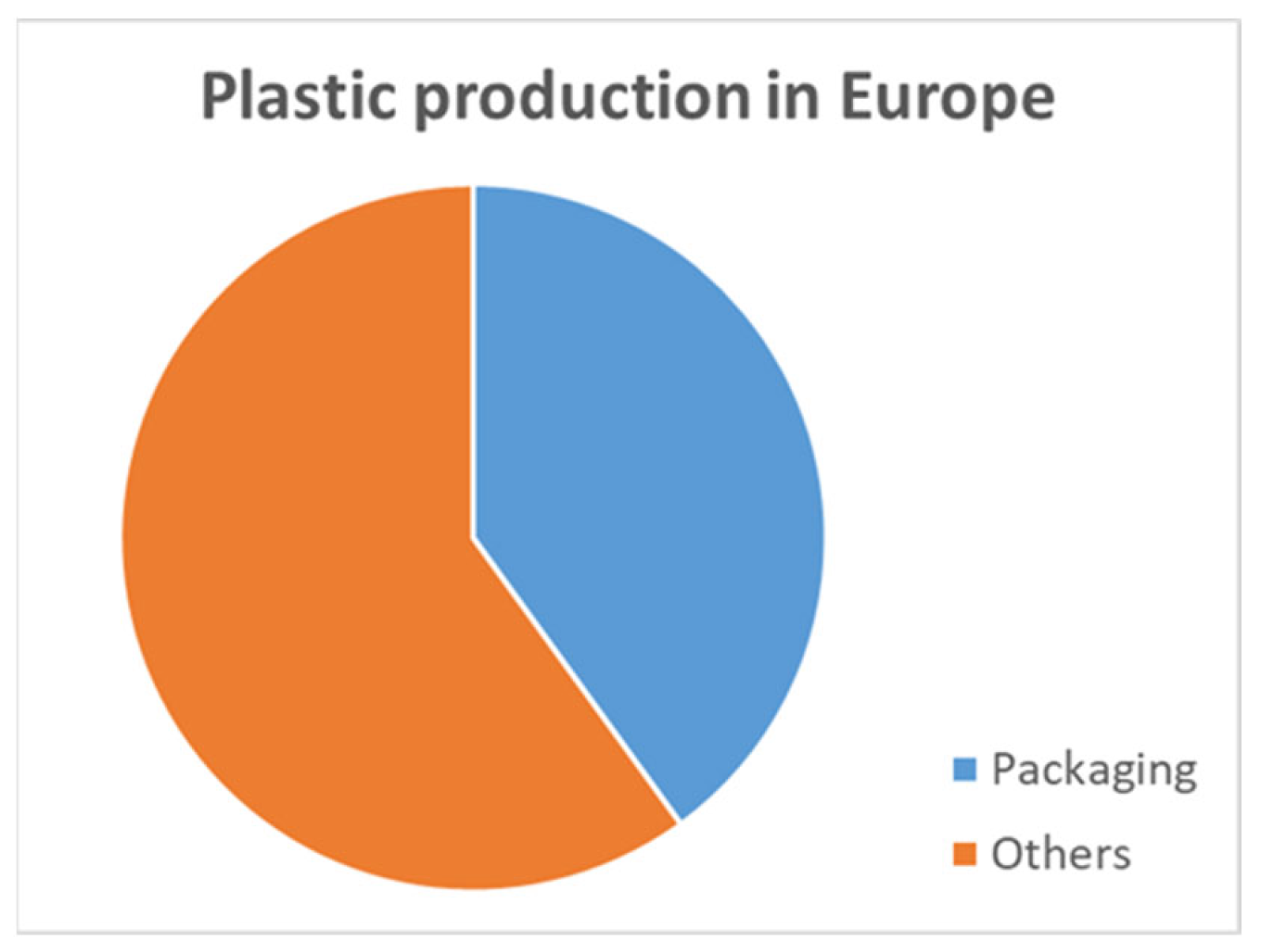

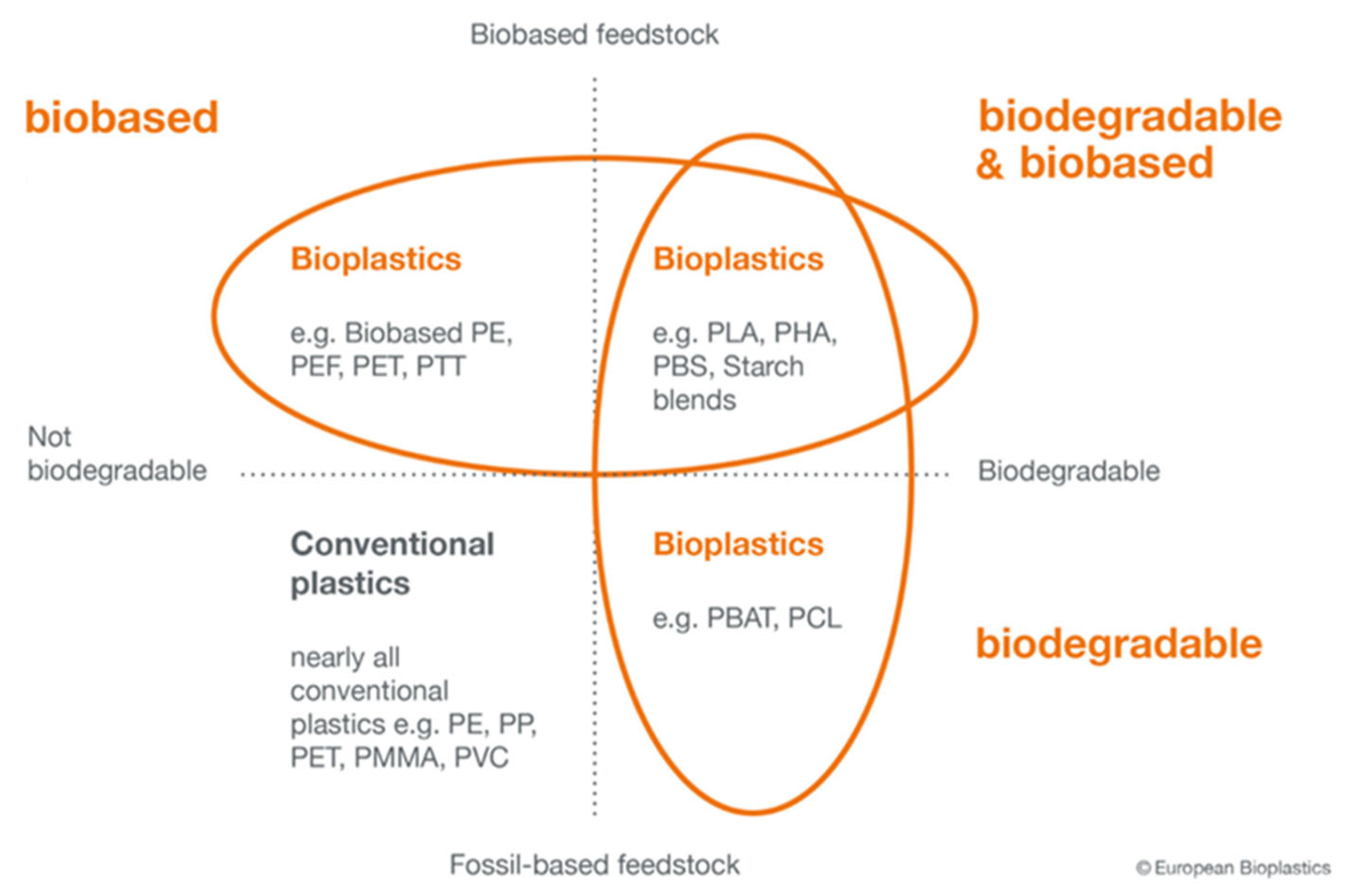

:1. Introduction

2. Materials and Methods

2.1. Film Composition

2.2. Film Degradation

2.3. Film Characterization

3. Results

3.1. Technical Requirements of Films

3.2. Mechanical properties

3.2.1. Impact Resistance

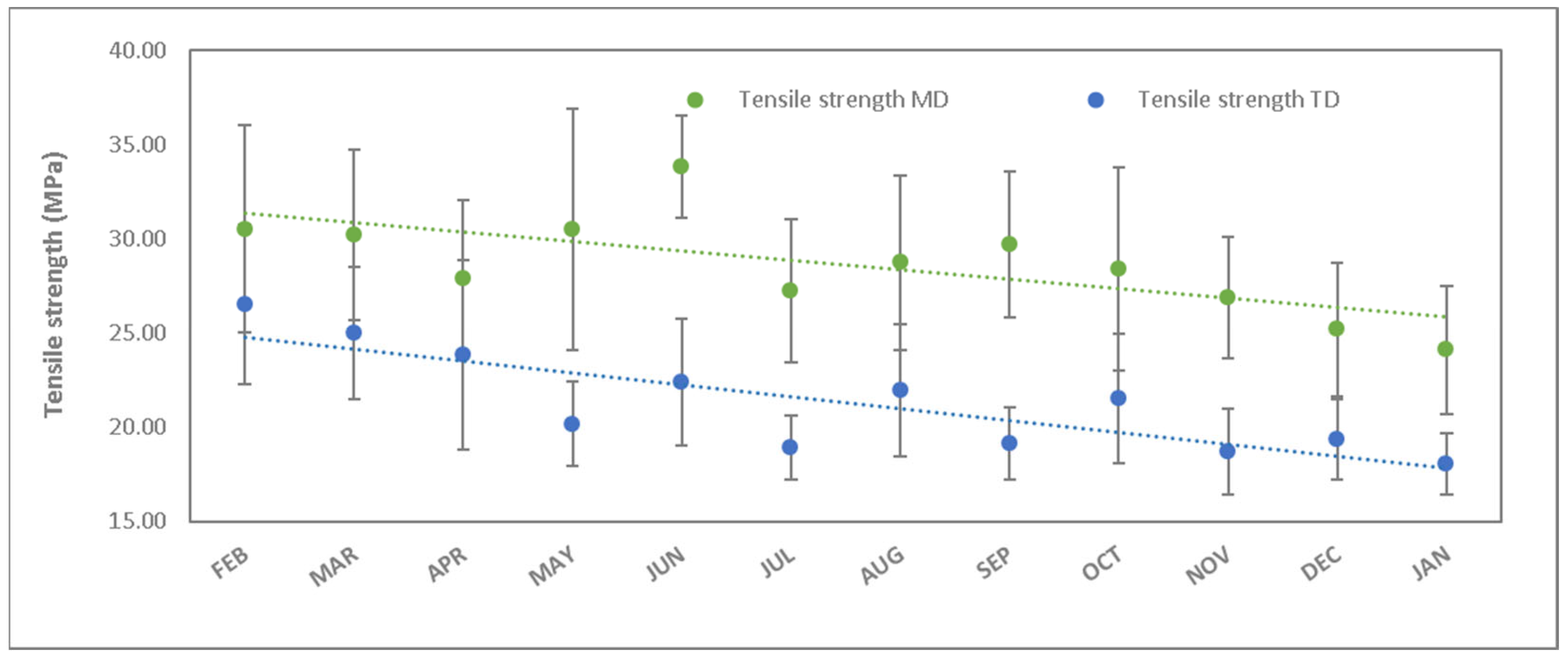

3.2.2. Tensile Strength

3.2.3. Tear Resistance

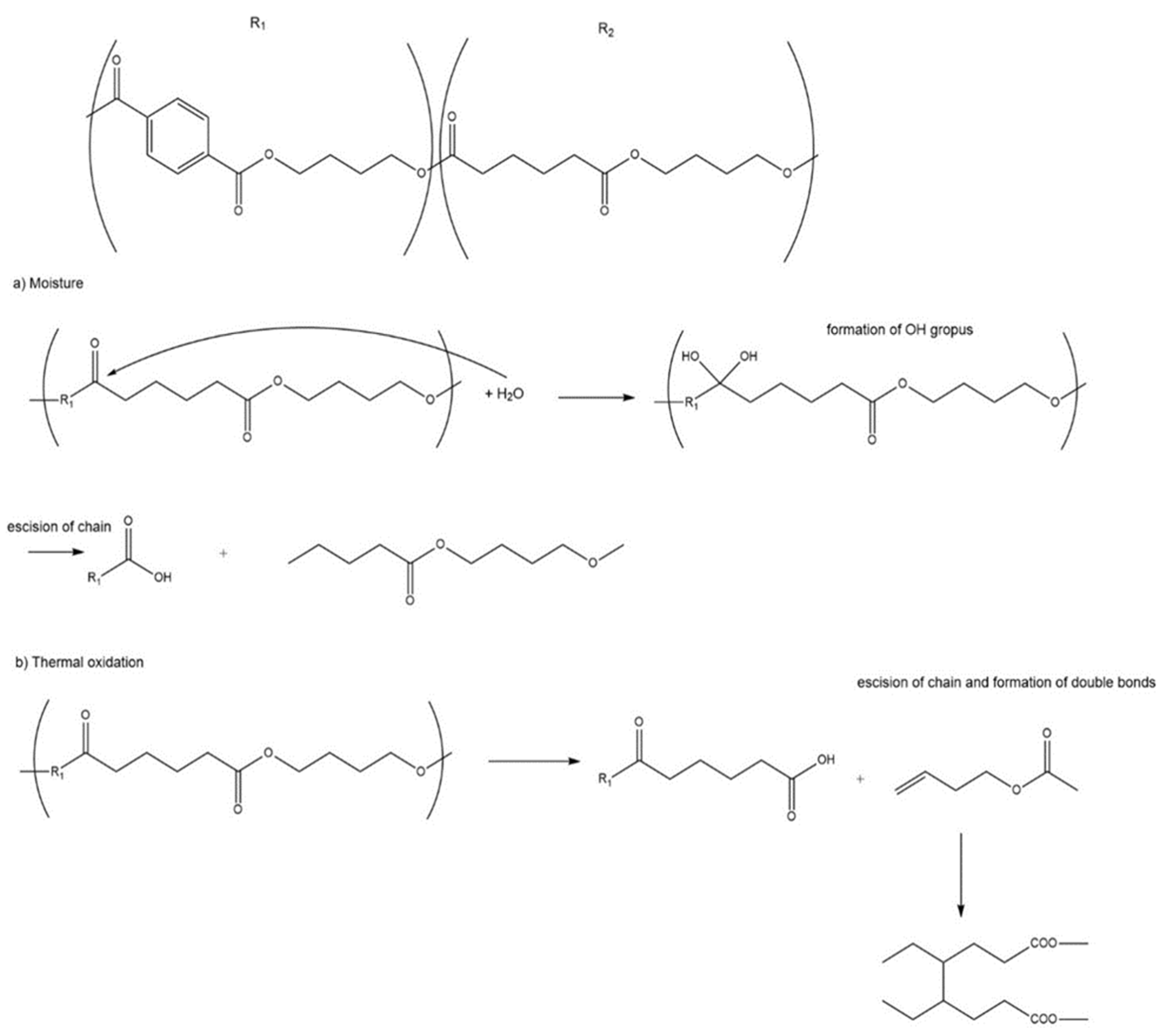

3.3. Structural Characterization with FTIR

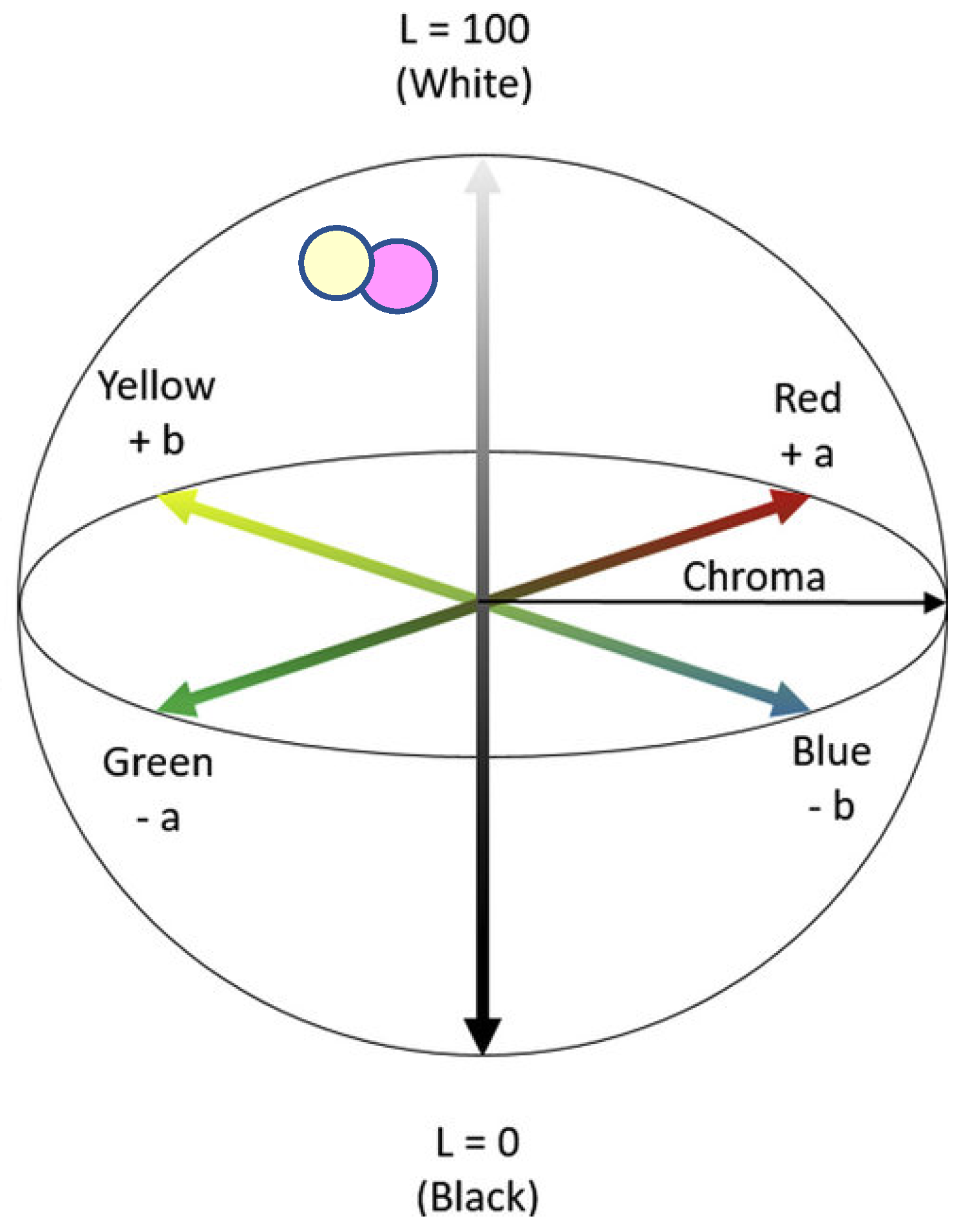

3.4. Colorimetry

3.5. Thermal Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Beckman, E. The World’s Plastic Problem in Numbers; The Conversation: London, UK, 2018; Available online: https://www.weforum.org/agenda/2018/08/the-world-of-plastics-in-numbers (accessed on 28 February 2022).

- PlasticEurope. Plastics–The Facts 2020. 2020. Available online: https://plasticseurope.org/knowledge-hub/plastics-the-facts-2020/ (accessed on 11 April 2022).

- Filiciotto, L.; Rothenberg, G. Biodegradable plastics: Standards, policies, and impacts. ChemSusChem 2021, 14, 56–72. [Google Scholar] [CrossRef] [PubMed]

- Stiftung, H.B. Plastic Atlas: Facts and Figures about the World of Synthetic Polymers. Berlin. 2019. Available online: https://za.boell.org/en/2019/11/06/plastic-atlas-facts-and-figures-about-world-synthetic-polymers (accessed on 11 April 2022).

- Ballestar, R.; Pradas, C.; Puig Bosch, P.; Cañavate, F.J.; Colom, X. Physical-Thermal characterization of the degradation process during the manufacturing of an LLDPE film to produce bags. AFINIDAD 2021, 58, 177. [Google Scholar]

- Maione, C.; Lapko, Y.; Trucco, P. Towards a circular economy for the plastic packaging sector: Insights from the Italian case. Sustain. Prod. Consum. 2022, 34, 78–89. [Google Scholar] [CrossRef]

- Clark, W.W., II; Bonato, D. Circular Economy: The Strategies to Global Business Economics. In Innovation in Global Green Technologies; IntechOpen: London, UK, 2020. [Google Scholar]

- Pilz, H.; Brandt, B.; Fehringer, R. The Impact of Plastics on Life Cycle Energy Consumption and Greenhouse Gas Emissions in Europe; Summary Report; June 2010. Available online: https://plasticseurope.org/wp-content/uploads/2021/10/201009-Denkstatt-Report.pdf (accessed on 1 June 2022).

- Ballestar, R.; Pradas, C.; Carrillo-Navarrete, F.; Cañavate, J.; Colom, X. Circular Economy Assessment in Recycling of LLDPE Bags According to European Resolution, Thermal and Structural Characterization. Polymers 2022, 14, 754. [Google Scholar] [CrossRef]

- Chrispim, M.C.; Mattsson, M.; Ulvenblad, P. The underrepresented key elements of Circular Economy: A critical review of assessment tools and a guide for action. Sustain. Prod. Consum. 2022, 35, 539–558. [Google Scholar] [CrossRef]

- Juikar, S.K.; Warkar, S.G. Biopolymers for packaging applications: An overview. Packag. Technol. Sci. 2023, 36, 229. [Google Scholar] [CrossRef]

- La Fuente, C.I.A.; Maniglia, B.C.; Tadini, C.C. Biodegradable polymers: A review about biodegradation and its implications and applications. Packag. Technol. Sci. 2023, 36, 81–95. [Google Scholar] [CrossRef]

- Varela-Alende, J.L.; de Justicia, L.D.L.A.; de España, P. Análisis de la nueva ley de residuos, 7/2022, de 8 de abril y sus implicaciones en la corresponsabilidad de la gestión de residuos en la industria textil. Actual. Jurídica Ambient. 2022, 129. [Google Scholar] [CrossRef]

- Desole, M.P.; Aversa, C.; Barletta, M.; Gisario, A.; Vosooghnia, A. Life cycle assessment (LCA) of PET and PLA bottles for the packaging of fresh pasteurised milk: The role of the manufacturing process and the disposal scenario. Packag. Technol. Sci. 2022, 35, 135–152. [Google Scholar] [CrossRef]

- Vikhareva, I.N.; Buylova, E.A.; Yarmuhametova, G.U.; Aminova, G.K.; Mazitova, A.K. An Overview of the Main Trends in the Creation of Biodegradable Polymer Materials. J. Chem. 2021, 2021, 5099705. [Google Scholar] [CrossRef]

- Giri, N.C.; Verma, V.; Patro, B.P. Development of Bioplastic and Biodegradable Plastics. In Assessing the Effects of Emerging Plastics on the Environment and Public Health; IGI Global: Hershey, PA, USA, 2022; pp. 249–283. [Google Scholar]

- Aponte, G.; Soledad, B. Bioplásticos: Sustentabilidad Ambiental y Principales Tendencias: Bioplastics: Environmental Sustainability and Main Trends. Tekhné 2022, 25, 45–60. [Google Scholar]

- Guo, J.J.; Huang, X.P.; Xiang, L.; Wang, Y.Z.; Li, Y.W.; Li, H.; Wong, M.H. Source, migration and toxicology of microplastics in soil. Environ. Int. 2020, 137, 105263. [Google Scholar] [CrossRef] [PubMed]

- Schmitt, H.; Guidez, A.; Prashantha, K.; Soulestin, J.; Lacrampe, M.F.; Krawczak, P. Studies on the effect of storage time and plasticizers on the structural variations in thermoplastic starch. Carbohydr. Polym. 2015, 115, 364–372. [Google Scholar] [CrossRef] [PubMed]

- Thoden van Velzen, E.U.; Chu, S.; Molenveld, K.; Jašo, V. Effect of poly lactic acid trays on the optical and thermal properties of recycled poly (ethylene terephthalate). Packag. Technol. Sci. 2022, 35, 351–360. [Google Scholar] [CrossRef]

- Frojan, J.; Bisquert, P.; Buche, P.; Gontard, N.; Boone, L.; Nhu Thuy, T.; Vermeulen, A.; Ragaert, P.; Dewulf, J.; Guillard, V. Scoring methodology for comparing the environmental performance of food packaging. Packag. Technol. Sci. 2023, 36, 439–463. [Google Scholar] [CrossRef]

- Liu, W.; Wang, Z.; Liu, J.; Dai, B.; Hu, S.; Hong, R.; Zeng, G. Preparation, reinforcement and properties of thermoplastic starch film by film blowing. Food Hydrocoll. 2020, 108, 106006. [Google Scholar] [CrossRef]

- Witt, U.; Einig, T.; Yamamoto, M.; Kleeberg, I.; Deckwer, W.D.; Müller, R.J. Biodegradation of aliphatic-aromatic copolyesters: Evaluation of the final biodegradability and ecotoxicological impact of degradation intermediates. Chemosphere 2001, 44, 289–299. [Google Scholar] [CrossRef] [PubMed]

- Someya, Y.; Sugahara, Y.; Shibata, M. Nanocomposites based on poly (butylene adipate-co-terephthalate) and montmorillonite. J. Appl. Polym. Sci. 2005, 95, 386–392. [Google Scholar] [CrossRef]

- Jiang, L.; Wolcott, M.P.; Zhang, J. Study of biodegradable polylactide/poly (butylene adipate-co-terephthalate) blends. Biomacromolecules 2006, 7, 199–207. [Google Scholar] [CrossRef]

- Yeh, J.T.; Tsou, C.H.; Huang, C.Y.; Chen, K.N.; Wu, C.S.; Chai, W.L. Compatible and crystallization properties of poly (lactic acid)/poly (butylene adipate-co-terephthalate) blends. J. Appl. Polym. Sci. 2010, 116, 680–687. [Google Scholar] [CrossRef]

- Yeh, J.T.; Tsou, C.H.; Lu, W.; Li, Y.M.; Xiao, H.W.; Huang, C.Y.; Chai, W.L. Compatible and tearing properties of poly (lactic acid)/poly (ethylene glutaric-co-terephthalate) copolyester blends. J. Polym. Sci. Part B Polym. Phys. 2010, 48, 913–920. [Google Scholar] [CrossRef]

- Weng, Y.X.; Jin, Y.J.; Meng, Q.Y.; Wang, L.; Zhang, M.; Wang, Y.Z. Biodegradation behavior of poly(butylene adipate-co-terephthalate) (PBAT), poly(lactic acid) (PLA), and their blend under soil conditions. Polym. Test. 2013, 32, 918–926. [Google Scholar] [CrossRef]

- ISO 527; Plastics—Determination of Tensile Properties—Part 1: General Principles. ISO: Geneva, Switzerland, 2019.

- ISO 7765-1; Plastics—Film and Sheeting—Determination of Impact Resistance by the Free-Falling Dart Method—Part 1: Staircase Methods. ISO: Geneva, Switzerland, 1988.

- ISO 6383-2; Plastics—Film and Sheeting—Determination of Tear Resistance. ISO: Geneva, Switzerland, 1983.

- EN 13432; Certified Bioplastics Performance in Industrial Composting. European Standards: Brussels, Belgium, 2015.

- Li, X.Q.; Scanlon, M.G.; Liu, Q.; Coleman, W.K. Processing and value addition. In Handbook of Potato Production, Improvement, and Postharvest Management; CRC Press: Boca Raton, FL, USA, 2006; pp. 523–556. [Google Scholar]

- Cortez, R.; Luna-Vital, D.A.; Margulis, D.; Gonzalez de Mejia, E. Natural pigments: Stabilization methods of anthocyanins for food applications. Compr. Rev. Food Sci. Food Saf. 2017, 16, 180–198. [Google Scholar] [CrossRef] [PubMed]

- Schnabel, W. Polymer Degradation. Principles and Practical Applications; Hanser Publishers: Munchen, Germany, 1992. [Google Scholar]

- Colom, X.; Cañavate, J.; Suñol, J.J.; Pagès, P.; Saurina, J.; Carrasco, F. Natural and Artificial Aging of Polypropylene–Polyethylene Copolymers. J. Appl. Polym. Sci. 2003, 87, 1685–1692. [Google Scholar] [CrossRef]

- Pagès, P.; Carrasco, F.; Saurina, J.; Colom, X. FTIR and DSC Study of HDPE Structural Changes and Mechanical Properties Variation When Exposed to Weathering Aging During Canadian Winter. J. Appl. Polym. Sci. 1996, 60, 153–159. [Google Scholar] [CrossRef]

- Dordevic, S.; Dordevic, D.; Sedlacek, P.; Kalina, M.; Tesikova, K.; Antonic, B.; Tremlova, B.; Treml, J.; Nejezchlebova, M.; Vapenka, L.; et al. Incorporation of Natural Blueberry, Red Grapes and Parsley Extract ByProducts into the Production of Chitosan Edible Films. Polymers 2021, 13, 3388. [Google Scholar] [CrossRef] [PubMed]

- Kochanska, E.; Wozniak, K.; Nowaczyk, A.; Piedade, P.J.; de Almeida Lavorato, M.L.; Almeida, A.M.; Lukasik, R.M. Global Ban on Plastic and What Next? Are Consumers Ready to Replace Plastic with the Second-Generation Bioplastic? Results of the Snowball Sample Consumer Research in China, Western and Eastern Europe, North America and Brazil. Int. J. Environ. Res. Public Health 2022, 19, 13970. [Google Scholar] [CrossRef]

| Distribution of Layers | Layer A | Layer B | Layer C |

|---|---|---|---|

| Percentage of total thickness | 30% | 40% | 30% |

| PBAT | 65% | 10% | 55% |

| Starch compound | 75% | ||

| PLA compound | 25% | 5% | 35% |

| Mineral charge | 10% | 10% | 10% |

| Feb. | Mar. | Apr. | May | Jun. | Jul. | Aug. | Sep. | Oct. | Nov. | Dec. | Jan. | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| T. average (°C) | 9.4 | 8.4 | 10.8 | 15.4 | 19.8 | 22.7 | 23.1 | 18.8 | 13.3 | 6.1 | 7.0 | 2.0 |

| T. average max (°C) | 15.3 | 15.3 | 16.9 | 22.2 | 26.7 | 31.2 | 31.3 | 25.1 | 21.3 | 11.1 | 12.5 | 7.3 |

| T. average min (°C) | 3.6 | 1.4 | 4.6 | 8.5 | 12.9 | 14.2 | 14.8 | 12.4 | 5.3 | 1.1 | 1.4 | −3.2 |

| Average rainfall (mm) | 26.0 | 2.4 | 64.8 | 70.8 | 50.0 | 19.0 | 15.6 | 114.4 | 31.8 | 91.2 | 13.4 | 48.0 |

| Relative humidity average (%) | 65 | 59 | 63 | 53 | 55 | 42 | 46 | 64 | 63 | 74 | 76 | 77 |

| Mechanical Property | Technical Specification—Minimum Value |

|---|---|

| Impact (g/µm) | 10 |

| Tensile strength LD (MPa) | 9.6 |

| Tensile strength TD (MPa) | 7.89 |

| Elongation LD (%) | 250 |

| Elongation TD (%) | 400 |

| Tearing LD (mN) | 1200 |

| Tearing TD (mN) | 4000 |

| Month | Feb. | Mar. | Apr. | May | Jun. | Jul. |

| Impact (g/µm) | 19.0 ± 0.52 | 19.0 ± 0.59 | 19.0 ± 0.63 | 18.0 ± 0.44 | 19.0 ± 0.47 | 19.0 ± 0.63 |

| Tensile strength LD (MPa) | 30.52 ± 0.41 | 30.24 ± 0.46 | 27.9 ±0.50 | 30.48 ± 0.58 | 33.83 ± 0.47 | 27.24 ± 0.42 |

| Tensile strength TD (MPa) | 26.53 ± 0.40 | 25.04 ± 0.42 | 23.84 ± 0.47 | 20.19 ± 0.50 | 22.4 ± 0.47 | 18.93 ± 0.41 |

| Elongation LD (%) | 588 ± 34.60 | 544 ± 41.84 | 525 ± 39.22 | 547 ± 36.78 | 515 ± 37.79 | 508 ± 39.12 |

| Elongation TD (%) | 733 ± 46.94 | 783 ± 49.16 | 693 ± 50.76 | 655 ± 43.66 | 624 ± 40.97 | 678 ± 49.95 |

| Tearing LD (mN) | 1799 ± 199 | 1695 ± 185 | 1582 ± 176 | 1595 ± 201 | 1718 ± 183 | 1707 ± 168 |

| Tearing TD (mN) | 4897 ± 242 | 4907 ± 216 | 4660 ± 267 | 4907 ± 230 | 4908 ± 236 | 4523 ± 233 |

| Month | Aug. | Sep. | Oct. | Nov. | Dec. | Jan. |

| Impact (g/µm) | 19.0 ± 0.52 | 19.0 ± 0.42 | 17.0 ± 0.78 | 17.0 ± 0.69 | 16.0 ± 0.67 | 14.0 ± 0.55 |

| Tensile strength LD (MPa) | 28.74 ± 0.43 | 29.71 ± 0.51 | 28.43 ± 0.37 | 26.91 ± 0.31 | 25.2 ± 0.30 | 24.12 ± 0.30 |

| Tensile strength TD (MPa) | 21.99 ± 0.40 | 19.17 ± 0.49 | 21.56 ± 0.30 | 18.73 ± 0.28 | 19.36 ± 0.32 | 18.07 ± 0.30 |

| Elongation LD (%) | 542 ± 32.97 | 530 ± 34.85 | 558 ± 31.11 | 507 ± 28.15 | 519 ± 32.78 | 447 ± 26.70 |

| Elongation TD (%) | 687 ± 45.13 | 618 ± 44.55 | 693 ± 39.16 | 539 ± 37.94 | 632 ± 41.93 | 629 ± 40.15 |

| Tearing LD (mN) | 1704 ± 200 | 1686 ± 186 | 1745 ± 182 | 1794 ± 195 | 1824 ± 207 | 1879 ± 182 |

| Tearing TD (mN) | 4816 ± 219 | 4836 ± 228 | 5288 ± 297 | 5234 ± 235 | 5227 ± 232 | 5297 ± 245 |

| Month | Feb. | Mar. | Apr. | May | Jun. | Jul. | Aug. | Sep. | Oct. | Nov. | Dec. | Jan. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L | 92.72 | 92.54 | 92.80 | 92.71 | 92.21 | 92.48 | 93.14 | 93.93 | 93.31 | 93.06 | 93.17 | 93.21 |

| a | −1.92 | −1.98 | −1.98 | −1.93 | −2.01 | −1.98 | −2.03 | −1.95 | −1.97 | −2.01 | −2.06 | −2.12 |

| b | 1.38 | 1.36 | 1.42 | 1.69 | 1.31 | 1.33 | 1.46 | 1.44 | 1.22 | 1.10 | 1.30 | 1.15 |

| ∆E | 0.00 | 0.19 | 0.11 | 0.32 | 0.36 | 0.25 | 0.44 | 1.21 | 0.61 | 0.45 | 0.48 | 0.58 |

| Month | Initial | Final | Variation |

|---|---|---|---|

| L | 92.72 | 93.21 | 1% |

| a | −1.92 | −2.12 | 10% |

| b | 1.38 | 1.15 | −17% |

| ∆E | 0 | 0.58 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

de las Heras, R.B.; Ayala, S.F.; Salazar, E.M.; Carrillo, F.; Cañavate, J.; Colom, X. Circular Economy Insights on the Suitability of New Tri-Layer Compostable Packaging Films after Degradation in Storage Conditions. Polymers 2023, 15, 4154. https://doi.org/10.3390/polym15204154

de las Heras RB, Ayala SF, Salazar EM, Carrillo F, Cañavate J, Colom X. Circular Economy Insights on the Suitability of New Tri-Layer Compostable Packaging Films after Degradation in Storage Conditions. Polymers. 2023; 15(20):4154. https://doi.org/10.3390/polym15204154

Chicago/Turabian Stylede las Heras, Ricardo Ballestar, Sergio Fernández Ayala, Estefanía Molina Salazar, Fernando Carrillo, Javier Cañavate, and Xavier Colom. 2023. "Circular Economy Insights on the Suitability of New Tri-Layer Compostable Packaging Films after Degradation in Storage Conditions" Polymers 15, no. 20: 4154. https://doi.org/10.3390/polym15204154

APA Stylede las Heras, R. B., Ayala, S. F., Salazar, E. M., Carrillo, F., Cañavate, J., & Colom, X. (2023). Circular Economy Insights on the Suitability of New Tri-Layer Compostable Packaging Films after Degradation in Storage Conditions. Polymers, 15(20), 4154. https://doi.org/10.3390/polym15204154