Assessing the Long-Term Creep Behaviour of Hydrothermally Treated Japanese Cedar Wood Using the Short-Term Accelerated Stepped Isostress Method

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Hydrothermal Treatment of Japanese Cedar Timber

2.3. Characterization of Wood Properties

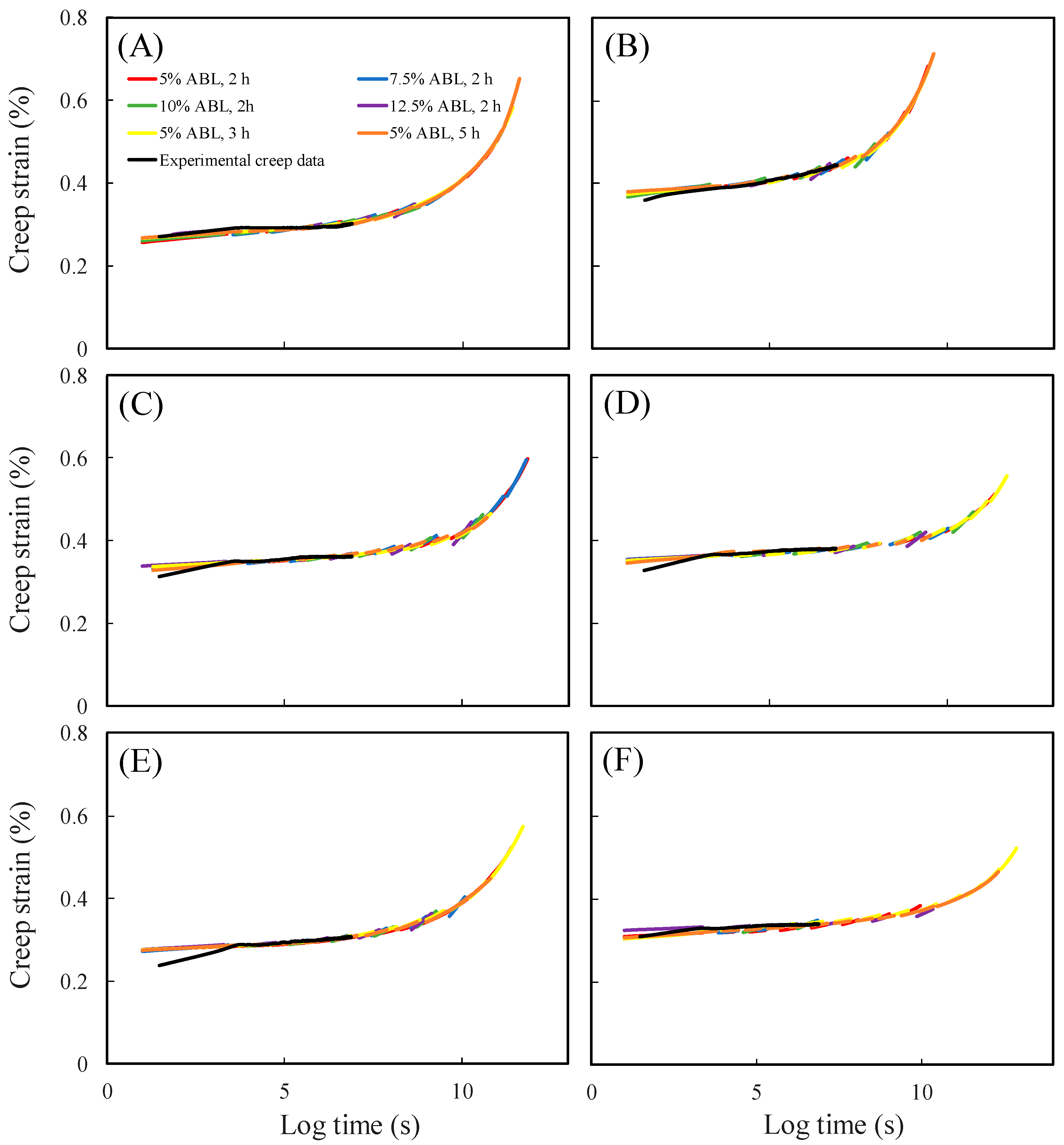

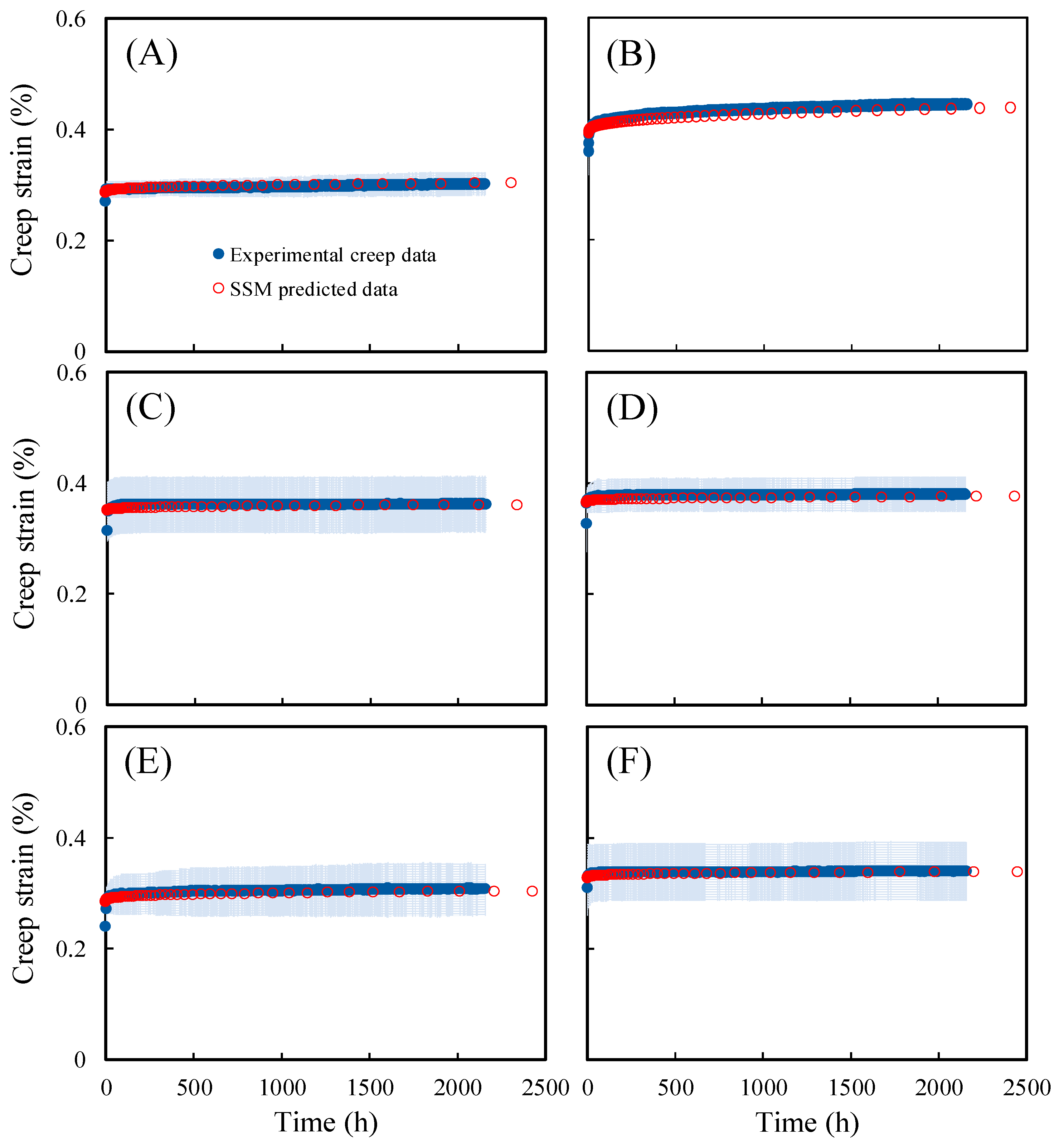

2.4. Creep Behaviour Analysis

2.5. Analysis of Variance

3. Results and Discussion

3.1. Impact of Different Hydrothermal Treatment Conditions on the Physicomechanical Properties of Japanese Cedar Wood

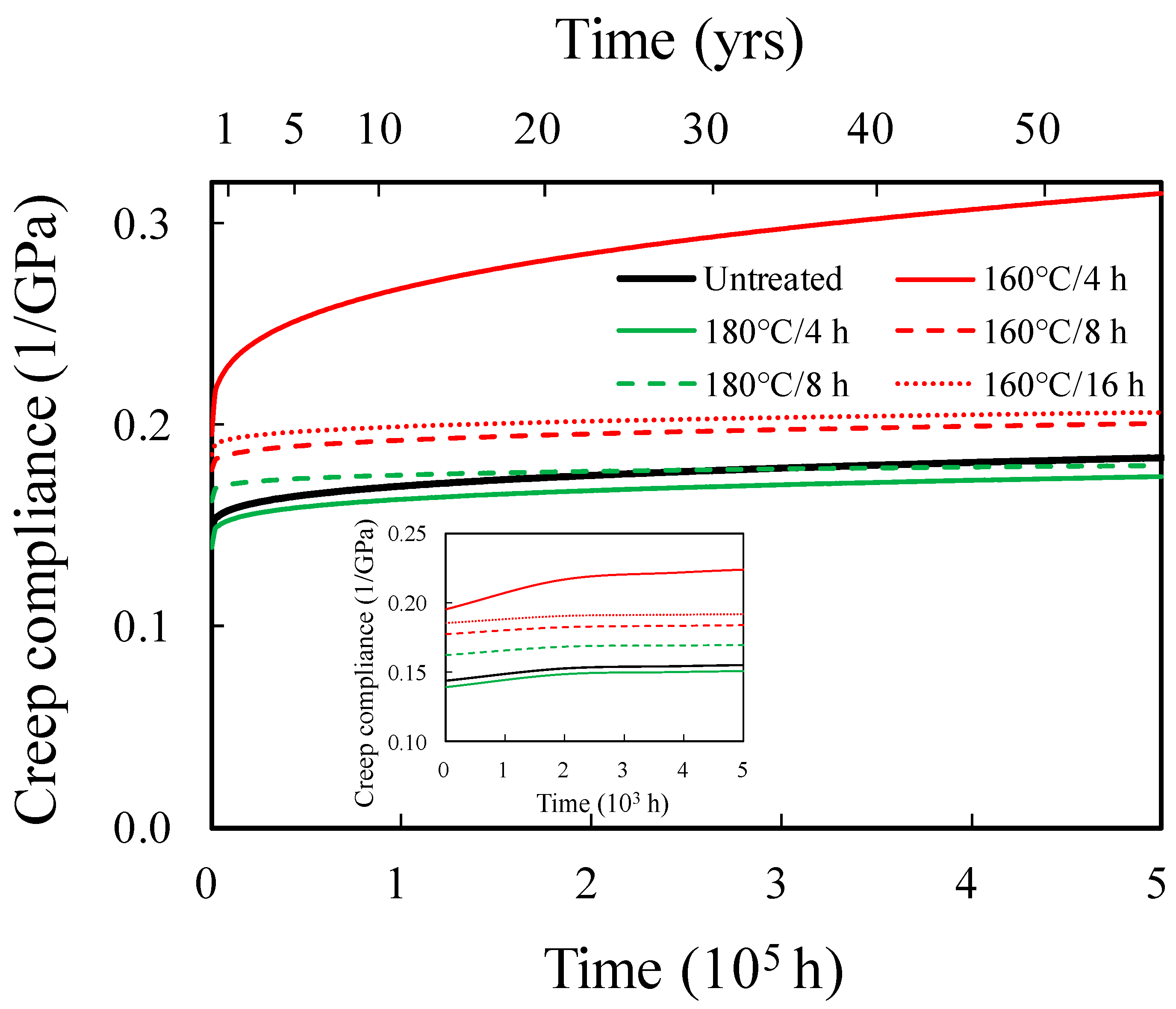

3.2. Impact of Different Hydrothermal Treatment Conditions on the Creep Properties of Japanese Cedar Wood

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Nikko, M.; Malekabadi, R.A.; Hafeez, G. Estimating the mechanical properties of Heat-Treated woods using Optimization Algorithms-Based ANN. Measurement 2023, 207, 112354. [Google Scholar] [CrossRef]

- Mori, Y.; Suzuki, R.; Yamashita, K.; Katayama, Y.; Kiguchi, M. Influence of hydrothermal treatment on hemicellulose structure in Cryptomeria japonica. BioResources 2023, 18, 3254. [Google Scholar] [CrossRef]

- Hoseinzadeh, M.; Zabihzadeh, S.M.; Dastoorian, F. Creep behavior of heat treated beech wood and the relation to its chemical structure. Constr. Build. Mater. 2019, 226, 220–226. [Google Scholar] [CrossRef]

- Xu, J.-W.; Li, C.-C.; Hung, K.-C.; Chang, W.-S.; Wu, J.-H. Physicomechanical properties of hydrothermally treated Japanese cedar timber and their relationships with chemical compositions. J. Mater. Res. Technol. 2022, 21, 4982–4993. [Google Scholar] [CrossRef]

- Jeong, S.Y.; Lee, J.W. Hydrothermal Treatment. In Pretreatment of Biomass: Processes and Technologies; Pandy, A., Negi, S., Binod, P., Larroche, C., Eds.; Elsevier: Amsterdam, The Netherlands, 2015; pp. 61–74. [Google Scholar]

- Hsu, F.-Y.; Hung, K.-C.; Xu, J.-W.; Wu, T.-L.; Wu, J.-H. Physicomechanical properties and creep behavior of plywood composed of fully and partially heat-treated veneers. Wood Sci. Technol. 2021, 55, 445–460. [Google Scholar] [CrossRef]

- Hung, K.-C.; Wu, T.-L.; Wu, J.-H. Long-term creep behavior prediction of sol-gel derived SiO2-and TiO2-wood composites using the stepped isostress method. Polymers 2019, 11, 1215. [Google Scholar] [CrossRef] [PubMed]

- Kijidani, Y.; Morita, H.; Aratake, S.; Tsuyama, T.; Arima, T. Partial compression strength of sugi (Japanese cedar, Cryptomeria japonica) wood near the pith perpendicular to the grain. J. Wood Sci. 2019, 65, 16. [Google Scholar] [CrossRef]

- Ando, K.; Nakamura, R.; Kushino, T. Variation of shear creep properties of wood within a stem: Effects of macro-and microstructural variability. Wood Sci. Technol. 2023, 57, 93–110. [Google Scholar] [CrossRef]

- Zhou, Y.; Fushitani, M.; Kubo, T. Effect of stress level on bending creep behavior of wood during cyclic moisture changes. Wood Fiber Sci. 2000, 32, 20–28. [Google Scholar]

- Anshari, B.; Guan, Z.W.; Kitamori, A.; Jung, K.; Hassel, I.; Komatsu, K. Mechanical and moisture-dependent swelling properties of compressed Japanese cedar. Constr. Build. Mater. 2011, 25, 1718–1725. [Google Scholar] [CrossRef]

- CNS 452; Wood—Determination of Moisture Content for Physical and Mechanical Tests. Bureau of Standards, Metrology and Inspection: Taipei, Taiwan, 2013.

- ASTM D1037; Standard Test Methods for Evaluating Properties of Wood-Base Fiber and Particle Panel Materials. ASTM Standards International: West Conshohocken, PA, USA, 2012. [CrossRef]

- CNS 454; Wood—Determination of Static Bending Properties. Bureau of Standards, Metrology and Inspection: Taipei, Taiwan, 2013.

- ASTM D2990; Standard Test Methods for Tensile, Compressive, and Flexural Creep and Creep-Rupture of Plastics. ASTM Standards International: West Conshohocken, PA, USA, 2009. [CrossRef]

- Hadid, M.; Guerira, B.; Bahri, M.; Zouani, A. Assessment of the stepped isostress method in the prediction of long term creep of thermoplastics. Polym. Test. 2014, 34, 113–119. [Google Scholar] [CrossRef]

- Giannopoulos, I.; Burgoyne, C.J. Prediction of the long-term behaviour of high modulus fibres using the stepped isostress method (SSM). J. Mater. Sci. 2011, 46, 7660–7672. [Google Scholar] [CrossRef]

- Chevali, V.S.; Dean, D.R.; Janowski, G.M. Flexural creep behavior of discontinuous thermoplastic composites: Non-linear viscoelastic modeling and time–temperature–stress superposition. Compos. Part A Appl. Sci. Manuf. 2009, 40, 870–877. [Google Scholar] [CrossRef]

- Findley, W.N.; Lai, J.S.; Onaran, K. Creep and Relaxation of Nonlinear Viscoelastic Materials with an Introduction to Linear Viscoelasticity; Dover Publications: New York, NY, USA, 1976; p. 380. [Google Scholar]

- Kutnar, A.; Kamke, F.A. Compression of wood under saturated steam, superheated steam, and transient conditions at 150 °C, 160 °C, and 170 °C. Wood Sci. Technol. 2012, 46, 73–88. [Google Scholar] [CrossRef]

- Kifani-Sahban, F.; Kifani, A.; Belkbir, L.; Belkbir, A.; Zoulalian, A.; Arauzo, J.; Cardero, T. A physical approach in the understanding of the phenomena accompanying the thermal treatment of lignin. Thermochim. Acta 1997, 298, 199–204. [Google Scholar] [CrossRef]

- Altgen, M.; Willems, W.; Militz, H. Wood degradation affected by process conditions during thermal modification of European beech in a high-pressure reactor system. Eur. J. Wood Prod. 2016, 74, 653–662. [Google Scholar] [CrossRef]

- Gawron, J.; Grzeskiewicz, M.; Zawadzki, J.; Zielenkiewicz, T.; Radomski, A. The influence of time and temperature of beech wood (Fagus sylvatica L.) heat treatment in superheated steam on the carbohydrates content. Wood Res. 2011, 56, 213–220. [Google Scholar]

- Xing, D.; Wang, X.; Wang, S. Temperature-dependent creep behavior and quasi-static mechanical properties of heat-treated wood. Forests 2021, 12, 968. [Google Scholar] [CrossRef]

- Gao, J.; Kim, J.S.; Terziev, N.; Daniel, G. Decay resistance of softwoods and hardwoods thermally modified by the Thermovuoto type thermo-vacuum process to brown rot and white rot fungi. Holzforschung 2016, 70, 877–884. [Google Scholar] [CrossRef]

| Sample Code | EMC (%) | MEE (%) | MOE (GPa) | MOR (MPa) |

|---|---|---|---|---|

| Untreated | 13.9 ± 0.3 A | – | 6.8 ± 0.8 A | 59.7 ± 9.6 A |

| 160 °C/4 h | 7.8 ± 0.5 B | 44.4 ± 3.4 C | 6.4 ± 1.1 A | 53.1 ± 6.6 A |

| 160 °C/8 h | 7.4 ± 0.5 B | 47.1 ± 3.5 C | 5.8 ± 0.8 A | 55.7 ± 8.2 A |

| 160 °C/16 h | 7.3 ± 0.3 B | 47.9 ± 2.2 C | 6.8 ± 1.0 A | 58.7 ± 11.6 A |

| 180 °C/4 h | 7.8 ± 0.3 B | 43.6 ± 1.8 C | 6.8 ± 0.6 A | 54.3 ± 7.0 A |

| 180 °C/8 h | 7.2 ± 0.6 B | 48.6 ± 4.0 B | 6.2 ± 0.9 A | 57.4 ± 7.8 A |

| 180 °C/16 h | 6.4 ± 0.3 B | 54.6 ± 2.2 B | 6.2 ± 1.1 A | 50.5 ± 9.8 B |

| 200 °C/4 h | 7.9 ± 0.3 B | 44.0 ± 2.3 C | 6.0 ± 0.8 A | 49.7 ± 8.8 B |

| 200 °C/8 h | 6.9 ± 1.2 B | 50.7 ± 8.7 B | 6.5 ± 0.7 A | 43.3 ± 8.4 B |

| 200 °C/16 h | 5.4 ± 0.4 C | 61.5 ± 2.5 A | 4.9 ± 0.7 B | 29.1 ± 6.4 C |

| Specimen | S0 (GPa−1) | a | b | S(t) (GPa−1) | ICR (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Time (Years) | Time (Years) | ||||||||||||

| 1 | 5 | 10 | 20 | 50 | 1 | 5 | 10 | 20 | 50 | ||||

| Untreated | 0.144 | 0.0011 | 0.27 | 0.16 | 0.16 | 0.17 | 0.17 | 0.18 | – | – | – | – | – |

| 160 °C/4 h | 0.195 | 0.0020 | 0.31 | 0.23 | 0.25 | 0.27 | 0.28 | 0.31 | −46 | −53 | −57 | −62 | −70 |

| 160 °C/8 h | 0.177 | 0.0006 | 0.28 | 0.18 | 0.19 | 0.19 | 0.19 | 0.20 | −18 | −15 | −14 | −12 | −10 |

| 160 °C/16 h | 0.185 | 0.0007 | 0.26 | 0.19 | 0.20 | 0.20 | 0.20 | 0.21 | −23 | −20 | −18 | −16 | −13 |

| 180 °C/4 h | 0.139 | 0.0015 | 0.15 | 0.15 | 0.16 | 0.16 | 0.17 | 0.17 | 3 | 3 | 4 | 4 | 5 |

| 180 °C/8 h | 0.162 | 0.0014 | 0.14 | 0.17 | 0.17 | 0.17 | 0.18 | 0.18 | −9 | −6 | −4 | −2 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, J.-W.; Li, C.-C.; Liu, J.-W.; Chang, W.-C.; Chang, W.-S.; Wu, J.-H. Assessing the Long-Term Creep Behaviour of Hydrothermally Treated Japanese Cedar Wood Using the Short-Term Accelerated Stepped Isostress Method. Polymers 2023, 15, 4149. https://doi.org/10.3390/polym15204149

Xu J-W, Li C-C, Liu J-W, Chang W-C, Chang W-S, Wu J-H. Assessing the Long-Term Creep Behaviour of Hydrothermally Treated Japanese Cedar Wood Using the Short-Term Accelerated Stepped Isostress Method. Polymers. 2023; 15(20):4149. https://doi.org/10.3390/polym15204149

Chicago/Turabian StyleXu, Jin-Wei, Cheng-Chun Li, Jian-Wei Liu, Wen-Chao Chang, Wen-Shao Chang, and Jyh-Horng Wu. 2023. "Assessing the Long-Term Creep Behaviour of Hydrothermally Treated Japanese Cedar Wood Using the Short-Term Accelerated Stepped Isostress Method" Polymers 15, no. 20: 4149. https://doi.org/10.3390/polym15204149

APA StyleXu, J.-W., Li, C.-C., Liu, J.-W., Chang, W.-C., Chang, W.-S., & Wu, J.-H. (2023). Assessing the Long-Term Creep Behaviour of Hydrothermally Treated Japanese Cedar Wood Using the Short-Term Accelerated Stepped Isostress Method. Polymers, 15(20), 4149. https://doi.org/10.3390/polym15204149