Weld Line Strength of Polyamide Fiberglass Composite at Different Processing Parameters in Injection Molding Technique

Abstract

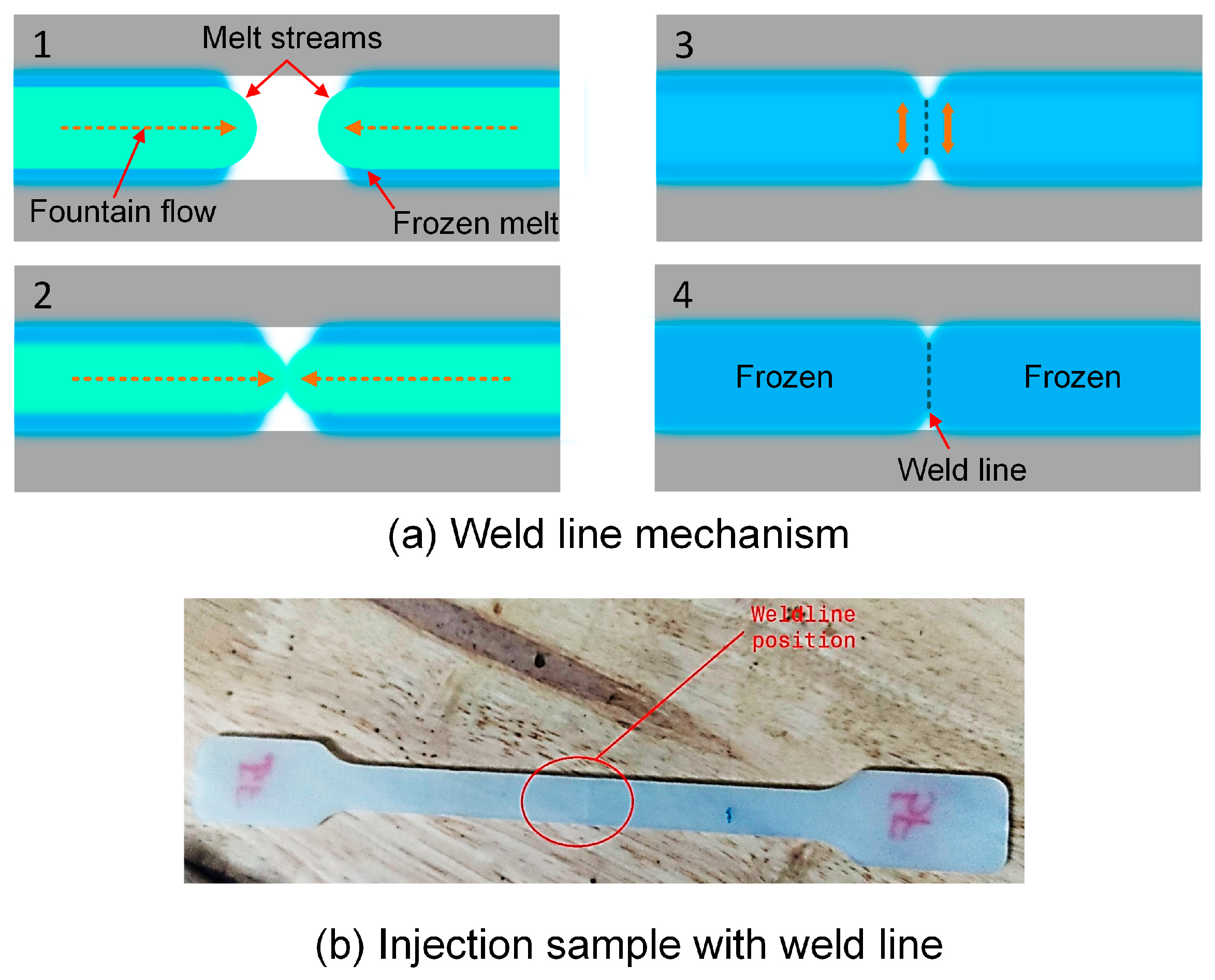

:1. Introduction

2. Experimental Methods

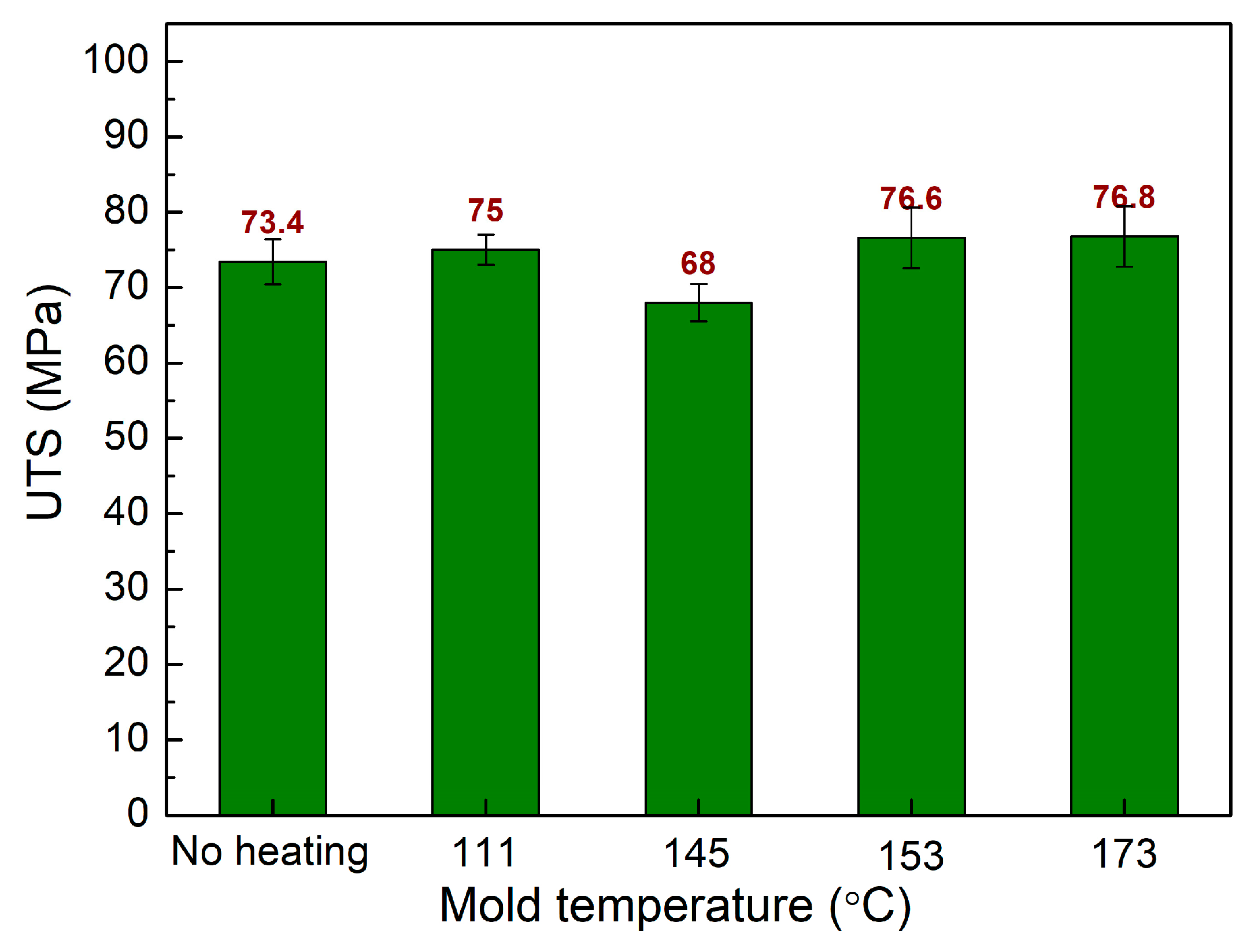

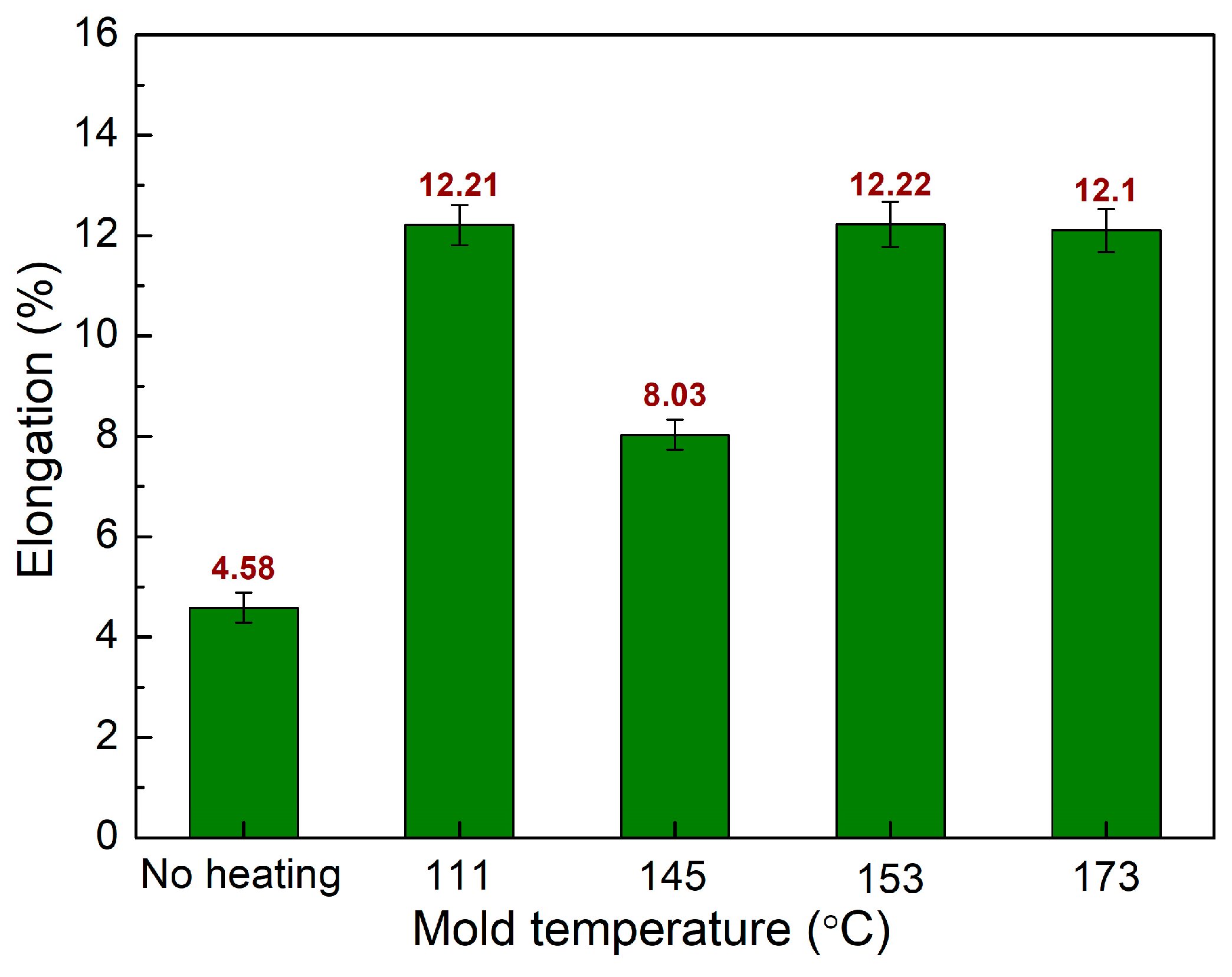

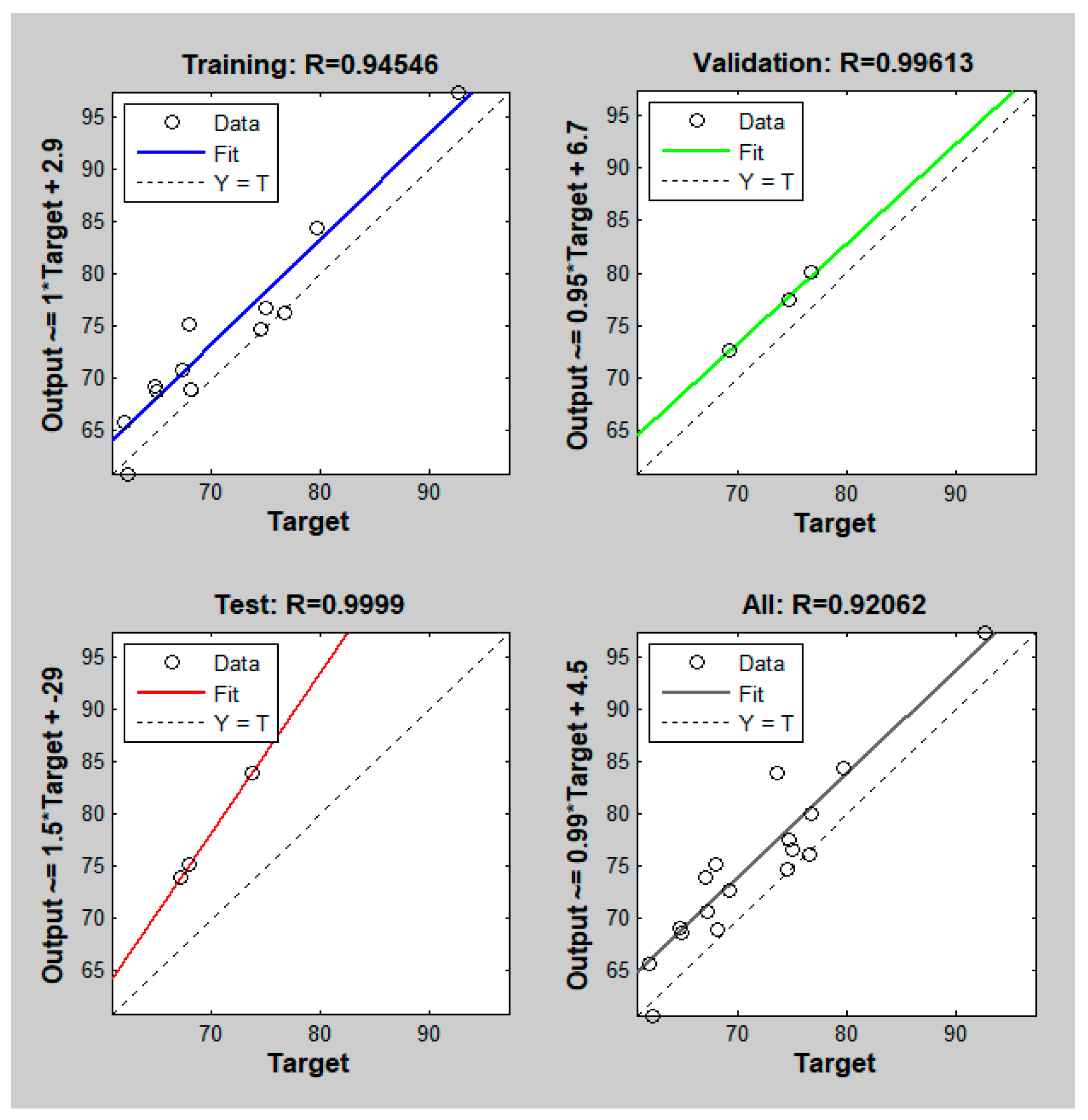

3. Results and Discussion

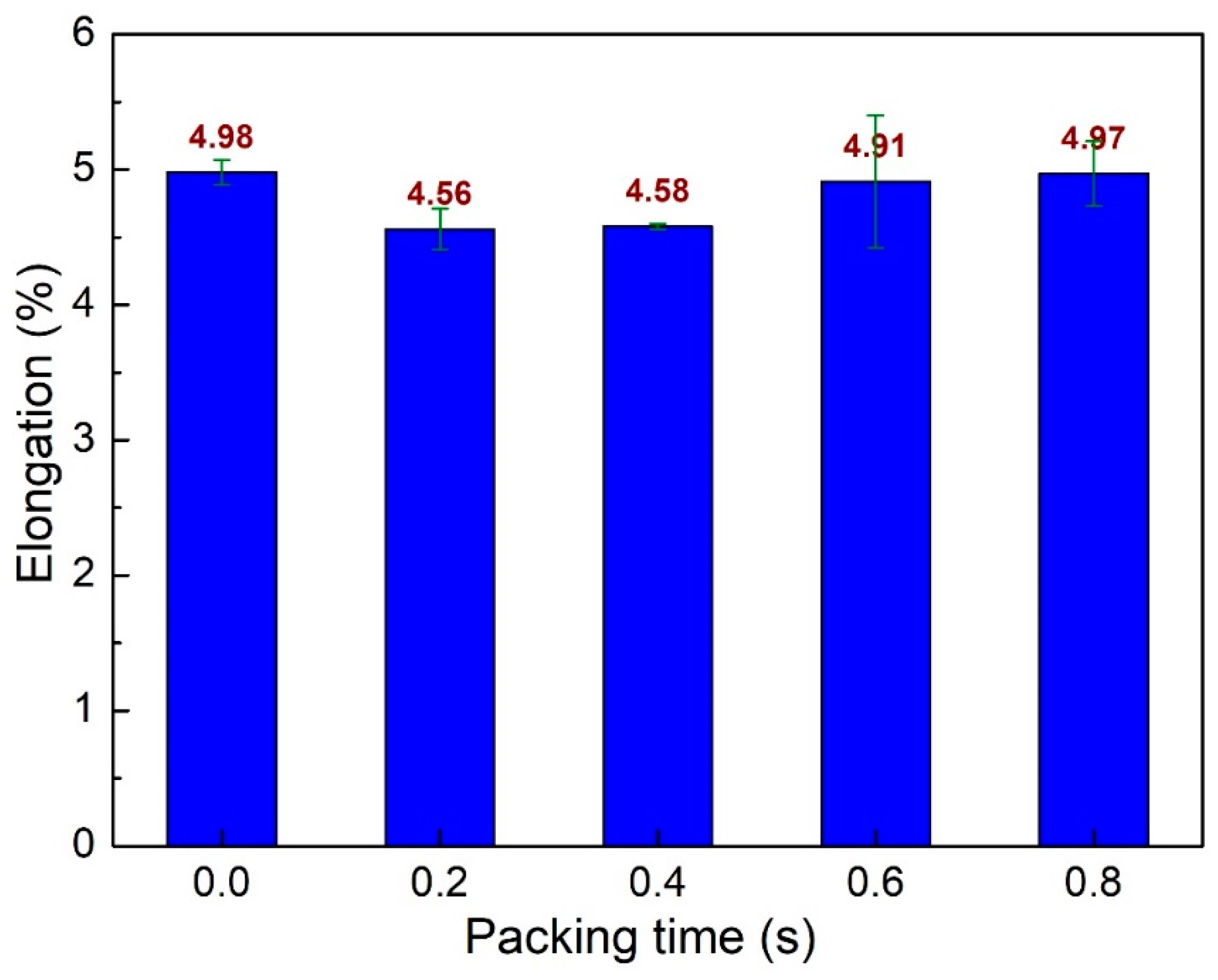

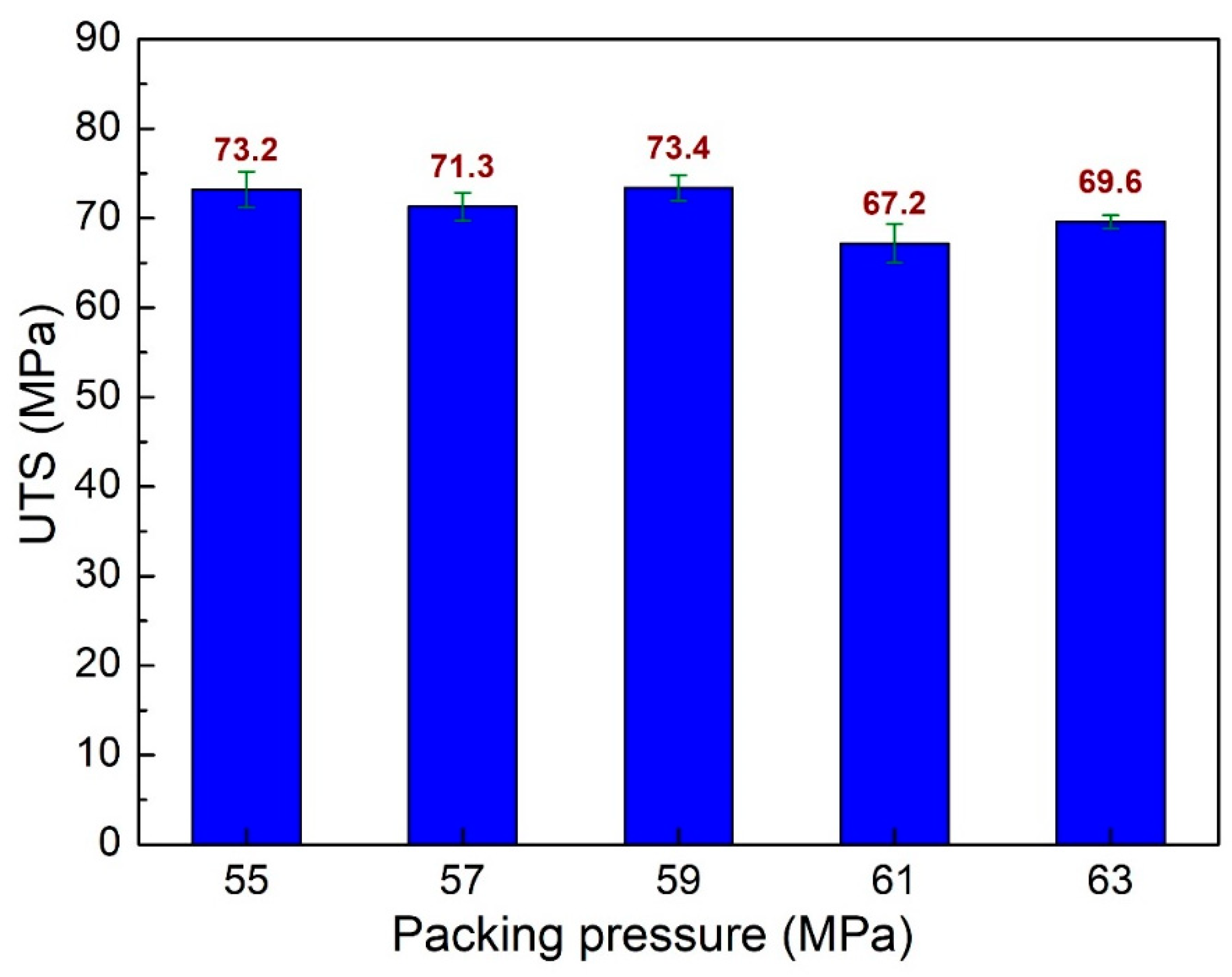

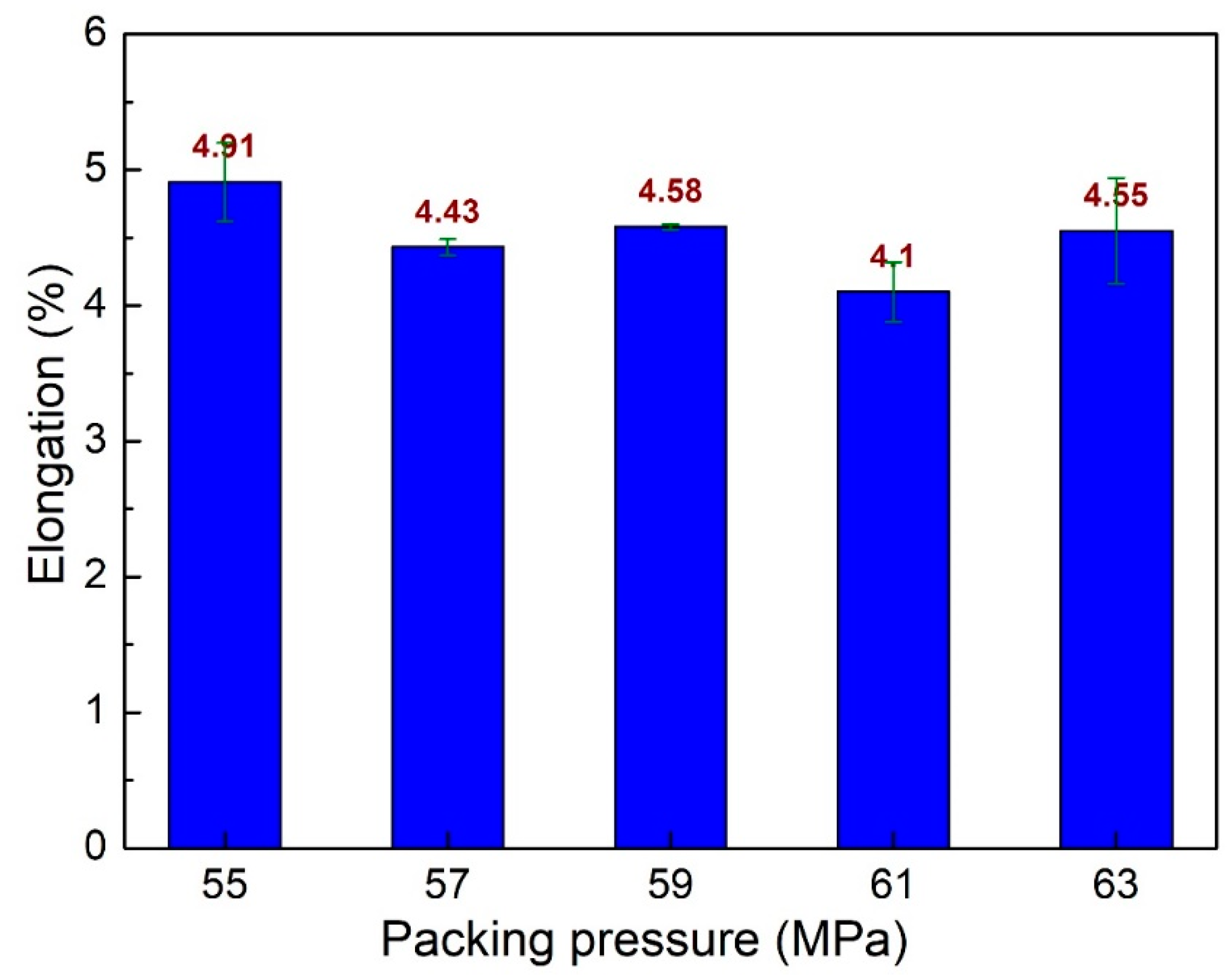

3.1. Effects of Injection Parameters

3.2. SEM Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, S.C.; Lin, C.Y.; Chang, J.A.; Minh, P.S. Gas-assisted heating technology for high aspect ratio microstructure injection molding. Adv. Mech. Eng. 2013, 5, 282906. [Google Scholar] [CrossRef]

- Chen, H.L.; Chien, R.D.; Chen, S.C. Using thermally insulated polymer film for mold temperature control to improve surface quality of microcellular injection molded parts. Int. Commun. Heat Mass Transf. 2008, 35, 991–994. [Google Scholar] [CrossRef]

- Lucchetta, G.; Masato, D.; Sorgato, M. Optimization of mold thermal control for minimum energy consumption in injection molding of polypropylene parts. J. Clean. Prod. 2018, 182, 217–226. [Google Scholar] [CrossRef]

- Kulkarni, S.; Sreedhara, V.S.M.; Mocko, G. Heat Assisted Single Point Incremental Forming of Polymer Sheets. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Charlotte, NC, USA, 21–24 August 2016; American Society of Mechanical Engineers: New York, NY, USA; Volume 50145, p. V004T05A006. [Google Scholar]

- Saito, T.; Satoh, I.; Kurosaki, Y. A new concept of active temperature control for an injection molding process using infrared radiation heating. Polym. Eng. Sci. 2002, 42, 2418–2429. [Google Scholar] [CrossRef]

- Minh, P.S.; Do, T.T.; Uyen, T.M.T. The feasibility of external gas-assisted mold-temperature control for thin-wall injection molding. Adv. Mech. Eng. 2018, 10, 1687814018806102. [Google Scholar] [CrossRef]

- Wang, G.; Zhao, G.; Li, H.; Guan, Y. Research of thermal response simulation and mold structure optimization for rapid heat cycle molding processes, respectively, with steam heating and electric heating. Mater. Des. 2010, 31, 382–395. [Google Scholar] [CrossRef]

- Yang, B.; Fu, X.R.; Yang, W.; Liang, S.P.; Sun, N.; Hu, S.; Yang, M.B. Effect of melt and mold temperatures on the solidification behavior of HDPE during gas-assisted injection molding: An enthalpy transformation approach. Macromol. Mater. Eng. 2009, 294, 336–344. [Google Scholar] [CrossRef]

- García, J.M.; García, F.C.; Serna, F.; de la Peña, J.L. High-performance aromatic polyamides. Prog. Polym. Sci. 2010, 35, 623–686. [Google Scholar] [CrossRef]

- Venoor, V.; Park, J.H.; Kazmer, D.O.; Sobkowicz, M.J. Understanding the effect of water in polyamides: A review. Polym. Rev. 2021, 61, 598–645. [Google Scholar] [CrossRef]

- Khorshidi, B.; Thundat, T.; Fleck, B.A.; Sadrzadeh, M. A novel approach toward fabrication of high performance thin film composite polyamide membranes. Sci. Rep. 2016, 6, 22069. [Google Scholar] [CrossRef]

- Millet, H.; Vangheluwe, P.; Block, C.; Sevenster, A.; Garcia, L.; Antonopoulos, R. The Nature of Plastics and Their Societal Usage; Royal Society of Chemistry: Cambridge, UK, 2018. [Google Scholar]

- Fan, J.; Njuguna, J. An introduction to lightweight composite materials and their use in transport structures. In Lightweight Composite Structures in Transport; Woodhead Publishing: Sawston, UK, 2016; pp. 3–34. [Google Scholar]

- Kausar, A.; Rafique, I.; Muhammad, B. Aerospace application of polymer nanocomposite with carbon nanotube, graphite, graphene oxide, and nanoclay. Polym.-Plast. Technol. Eng. 2017, 56, 1438–1456. [Google Scholar] [CrossRef]

- Luo, W.; Liu, Q.; Li, Y.; Zhou, S.; Zou, H.; Liang, M. Enhanced mechanical and tribological properties in polyphenylene sulfide/polytetrafluoroethylene composites reinforced by short carbon fiber. Compos. Part B Eng. 2016, 91, 579–588. [Google Scholar] [CrossRef]

- Rajesh, J.J.; Bijwe, J.; Tewari, U.S. Influence of fillers on abrasive wear of short glass fibre reinforced polyamide composites. J. Mater. Sci. 2001, 36, 351–356. [Google Scholar] [CrossRef]

- Yousfi, M.; Livi, S.; Dumas, A.; Le Roux, C.; Crépin-Leblond, J.; Greenhill-Hooper, M.; Duchet-Rumeau, J. Use of new synthetic talc as reinforcing nanofillers for polypropylene and polyamide 6 systems: Thermal and mechanical properties. J. Colloid Interface Sci. 2013, 403, 29–42. [Google Scholar] [CrossRef]

- Botelho, E.C.; Rezende, M.C.; Lauke, B. Mechanical behavior of carbon fiber reinforced polyamide composites. Compos. Sci. Technol. 2003, 63, 1843–1855. [Google Scholar] [CrossRef]

- Peng, X.; Zhang, M.; Guo, Z.; Sang, L.; Hou, W. Investigation of processing parameters on tensile performance for FDM-printed carbon fiber reinforced polyamide 6 composites. Compos. Commun. 2020, 22, 100478. [Google Scholar] [CrossRef]

- Eriksson, P.A.; Albertsson, A.C.; Boydell, P.; Prautzsch, G.; Månson, J.A. Prediction of mechanical properties of recycled fiberglass reinforced polyamide 66. Polym. Compos. 1996, 17, 830–839. [Google Scholar] [CrossRef]

- Pinto, C.; e Silva, L.G.A. Study of ionizing radiation on the properties of polyamide 6 with fiberglass reinforcement. Radiat. Phys. Chem. 2007, 76, 1708–1710. [Google Scholar] [CrossRef]

- Jeun, J.P.; Shin, B.S.; Kim, H.B.; Nho, Y.C.; Kang, P.H. Effects of electron beam irradiation on polyamide 12 with fiberglass reinforcement. In AIP Conference Proceedings; American Institute of Physics: College Park, MD, USA, 2010; Volume 1255, pp. 281–283. [Google Scholar]

- Farias-Aguilar, J.C.; Ramírez-Moreno, M.J.; Gonzalez-García, D.M.; Téllez-Jurado, L.; Balmori-Ramirez, H. Evaluation of the ballistic protection level of (glass-fiber reinforced polyamide 6)-aramid fabric sandwich composite panels. J. Mater. Res. Technol. 2021, 12, 1606–1614. [Google Scholar] [CrossRef]

- Bernasconi, A.; Davoli, P.; Basile, A.; Filippi, A. Effect of fibre orientation on the fatigue behaviour of a short glass fibre reinforced polyamide-6. Int. J. Fatigue 2007, 29, 199–208. [Google Scholar] [CrossRef]

- Wu, C.H.; Liang, W.J. Effects of geometry and injection-molding parameters on weld-line strength. Polym. Eng. Sci. 2005, 45, 1021–1030. [Google Scholar] [CrossRef]

- Li, X.; Wang, D.; Saeed, T. Multi-scale numerical approach to the polymer filling process in the weld line region. Facta Univ. Ser. Mech. Eng. 2022, 20, 363–380. [Google Scholar] [CrossRef]

- Ersoy, O.G.; Nugay, N. A new approach to increase weld line strength of incompatible polymer blend composites: Selective filler addition. Polymer 2004, 45, 1243–1252. [Google Scholar] [CrossRef]

- Kagitci, Y.C.; Tarakcioglu, N. The effect of weld line on tensile strength in a polymer composite part. Int. J. Adv. Manuf. Technol. 2016, 85, 1125–1135. [Google Scholar] [CrossRef]

- Koponen, M.; Enqvist, J.; Nguyen-Chung, T.; Mennig, G. Advanced injection molding mold and molding process for improvement of weld line strengths and isotropy of glass fiber filled aromatic polyester LCP. Polym. Eng. Sci. 2008, 48, 711–716. [Google Scholar] [CrossRef]

- Munankar, A.B.; Sitap, N.A.; Tembhurkar, A.A.; Thakur, M.B.; Kanse, S.S. Simulation for optimum gate location in plastic injection moulding for spanner. Int. Res. J. Eng. Technol. 2019, 6, 1228–1234. [Google Scholar]

- Huang, M.S.; Lin, C.Y. A novel clamping force searching method based on sensing tie-bar elongation for injection molding. Int. J. Heat Mass Transf. 2017, 109, 223–230. [Google Scholar] [CrossRef]

- Xu, Y.; Liu, G.; Dang, K.; Fu, N.; Jiao, X.; Wang, J.; Xie, P.; Yang, W. A novel strategy to determine the optimal clamping force based on the clamping force change during injection molding. Polym. Eng. Sci. 2021, 61, 3170–3178. [Google Scholar] [CrossRef]

- Dairanieh, I.S.; Haufe, A.; Wolf, H.J.; Mennig, G. Computer simulation of weld lines in injection molded poly (methyl methacrylate). Polym. Eng. Sci. 1996, 36, 2050–2057. [Google Scholar] [CrossRef]

- Michaeli, W.; Ziegmann, C. Micro assembly injection moulding for the generation of hybrid microstructures. Microsyst. Technol. 2003, 9, 427–430. [Google Scholar] [CrossRef]

- Liu, S.J.; Wu, J.Y.; Chang, J.H.; Hung, S.W. An experimental matrix design to optimize the weldline strength in injection molded parts. Polym. Eng. Sci. 2000, 40, 1256–1262. [Google Scholar] [CrossRef]

- ASTM D638-14; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2014.

- Selden, R. Effect of processing on weld line strength in five thermoplastics. Polym. Eng. Sci. 1997, 37, 205–218. [Google Scholar] [CrossRef]

- Chen, C.S.; Chen, T.J.; Chien, R.D.; Chen, S.C. Investigation on the weldline strength of thin-wall injection molded ABS parts. Int. Commun. Heat Mass Transf. 2007, 34, 448–455. [Google Scholar] [CrossRef]

- Gohn, A.M.; Brown, D.; Mendis, G.; Forster, S.; Rudd, N.; Giles, M. Mold inserts for injection molding prototype applications fabricated via material extrusion additive manufacturing. Addit. Manuf. 2022, 51, 102595. [Google Scholar] [CrossRef]

- Davis, C.S.; Hillgartner, K.E.; Han, S.H.; Seppala, J.E. Mechanical strength of welding zones produced by polymer extrusion additive manufacturing. Addit. Manuf. 2017, 16, 162–166. [Google Scholar] [CrossRef] [PubMed]

- Seppala, J.E.; Migler, K.D. Infrared thermography of welding zones produced by polymer extrusion additive manufacturing. Addit. Manuf. 2016, 12, 71–76. [Google Scholar] [CrossRef] [PubMed]

- Cox, H.W.; Mentzer, C.C. Injection molding: The effect of fill time on properties. Polym. Eng. Sci. 1986, 26, 488–498. [Google Scholar] [CrossRef]

- Kitayama, S.; Tsurita, S.; Takano, M.; Yamazaki, Y.; Kubo, Y.; Aiba, S. Multi-objective process parameters optimization in rapid heat cycle molding incorporating variable packing pressure profile for improving weldline, clamping force, and cycle time. Int. J. Adv. Manuf. Technol. 2022, 120, 3669–3681. [Google Scholar] [CrossRef]

- Minh, P.S.; Dang, H.S.; Ha, N.C. Optimization of 3D cooling channels in plastic injection molds by Taguchi-integrated principal component analysis (PCA). Polymers 2023, 15, 1080. [Google Scholar] [CrossRef]

- Uyen, T.M.T.; Do, T.T.; Minh, P.S. Internal Gas-Assisted Mold Temperature Control for Improving the Filling Ability of Polyamide 6+ 30% Glass Fiber in the Micro-Injection Molding Process. Polymers 2022, 14, 2218. [Google Scholar] [CrossRef]

- Horst, J.J.; Spoormaker, J.L. Mechanisms of fatigue in short glass fiber reinforced polyamide 6. Polym. Eng. Sci. 1996, 36, 2718–2726. [Google Scholar] [CrossRef]

| No. | Filling Time (s) | Packing Time (s) | Packing Pressure (MPa) | Melt Temperature (°C) |

|---|---|---|---|---|

| 1 | 3.0 | 0.4 | 59 | 269 |

| 2 | 3.2 | |||

| 3 | 3.4 | |||

| 4 | 3.6 | |||

| 5 | 3.8 | |||

| 6 | 3.4 | 0 | 59 | 269 |

| 7 | 0.2 | |||

| 8 | 0.4 | |||

| 9 | 0.6 | |||

| 10 | 0.8 | |||

| 11 | 3.4 | 0.4 | 55 | 269 |

| 12 | 57 | |||

| 13 | 59 | |||

| 14 | 61 | |||

| 15 | 63 | |||

| 16 | 3.4 | 0.4 | 59 | 265 |

| 17 | 267 | |||

| 18 | 269 | |||

| 19 | 271 | |||

| 20 | 273 |

| Factors | Average UTS (MPa) | UTS Standard Deviation (MPa) | Average Elongation (%) | Elongation Standard Deviation (%) |

|---|---|---|---|---|

| Filling time | 73.36 | 0.70 | 4.65 | 0.14 |

| Packing time | 70.80 | 1.54 | 4.80 | 0.19 |

| Packing pressure | 70.94 | 2.33 | 4.51 | 0.23 |

| Melt temperature | 70.82 | 2.08 | 4.30 | 0.39 |

| No. | Experiment (MPa) | Network Output (MPa) | Relative Deviation (%) |

|---|---|---|---|

| 1 | 73.6 | 74.1 | 0.7 |

| 2 | 72.1 | 73.8 | 2.4 |

| 3 | 73.4 | 72.5 | 1.2 |

| 4 | 74.0 | 73.1 | 1.2 |

| 5 | 73.7 | 73.8 | 0.1 |

| 6 | 71.3 | 72.6 | 1.8 |

| 7 | 69.7 | 70.8 | 1.6 |

| 8 | 73.4 | 70.5 | 4.0 |

| 9 | 68.9 | 74.7 | 8.4 |

| 10 | 70.6 | 73.4 | 4.0 |

| 11 | 73.2 | 72.5 | 1.0 |

| 12 | 71.3 | 68.4 | 4.1 |

| 13 | 73.4 | 67.3 | 8.3 |

| 14 | 67.2 | 71.6 | 6.5 |

| 15 | 69.6 | 73.5 | 5.6 |

| 16 | 69.7 | 72.5 | 4.0 |

| 17 | 67.4 | 71.1 | 5.5 |

| 18 | 73.4 | 72.1 | 1.8 |

| 19 | 71.9 | 76.8 | 6.8 |

| 20 | 71.7 | 74.3 | 3.6 |

| PA6 30% GF | Filling Time (s) | Packing Time (s) | Packing Pressure (MPa) | Melt Temperature (°C) | Mold Temperature (°C) |

|---|---|---|---|---|---|

| ANN + GA | 3.0 | 0.312 | 55.45 | 265.74 | 97.74 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, V.-T.; Uyen, T.M.T.; Minh, P.S.; Do, T.T.; Huynh, T.H.; Nguyen, T.; Nguyen, V.T.; Nguyen, V.T.T. Weld Line Strength of Polyamide Fiberglass Composite at Different Processing Parameters in Injection Molding Technique. Polymers 2023, 15, 4102. https://doi.org/10.3390/polym15204102

Nguyen V-T, Uyen TMT, Minh PS, Do TT, Huynh TH, Nguyen T, Nguyen VT, Nguyen VTT. Weld Line Strength of Polyamide Fiberglass Composite at Different Processing Parameters in Injection Molding Technique. Polymers. 2023; 15(20):4102. https://doi.org/10.3390/polym15204102

Chicago/Turabian StyleNguyen, Van-Thuc, Tran Minh The Uyen, Pham Son Minh, Thanh Trung Do, Trung H. Huynh, Tronghieu Nguyen, Vinh Tien Nguyen, and Van Thanh Tien Nguyen. 2023. "Weld Line Strength of Polyamide Fiberglass Composite at Different Processing Parameters in Injection Molding Technique" Polymers 15, no. 20: 4102. https://doi.org/10.3390/polym15204102

APA StyleNguyen, V.-T., Uyen, T. M. T., Minh, P. S., Do, T. T., Huynh, T. H., Nguyen, T., Nguyen, V. T., & Nguyen, V. T. T. (2023). Weld Line Strength of Polyamide Fiberglass Composite at Different Processing Parameters in Injection Molding Technique. Polymers, 15(20), 4102. https://doi.org/10.3390/polym15204102