Tensile Properties of Four Types of ABS Lattice Structures—A Comparative Study

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

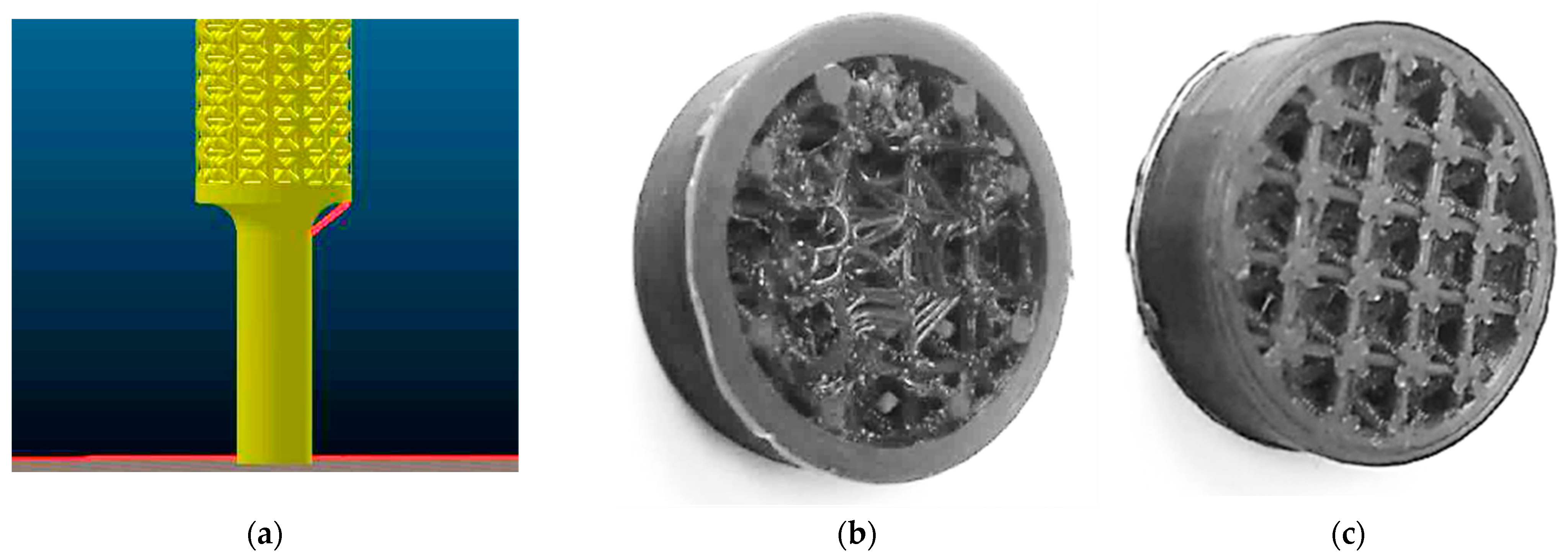

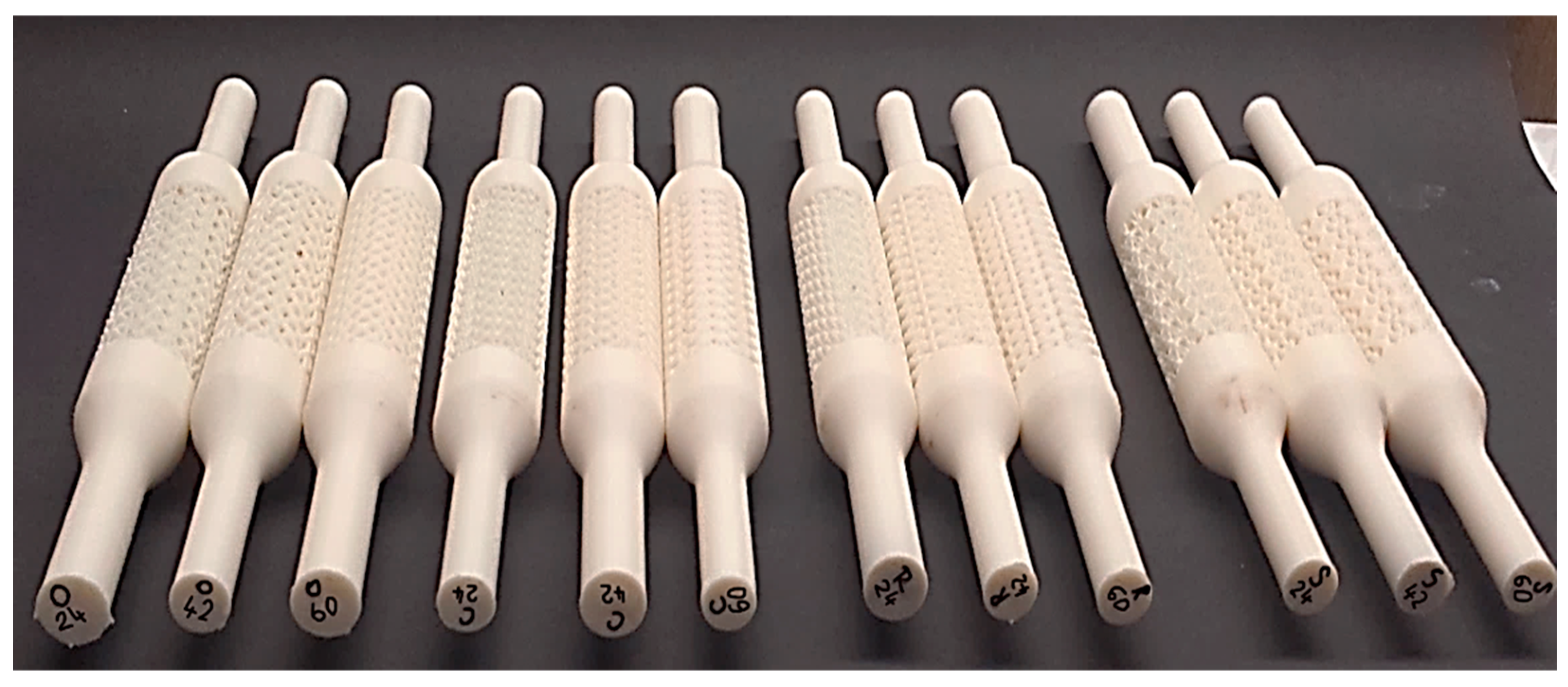

2.2. Preparation and Production of Samples

2.3. Methods

2.3.1. Testing

2.3.2. Evaluation

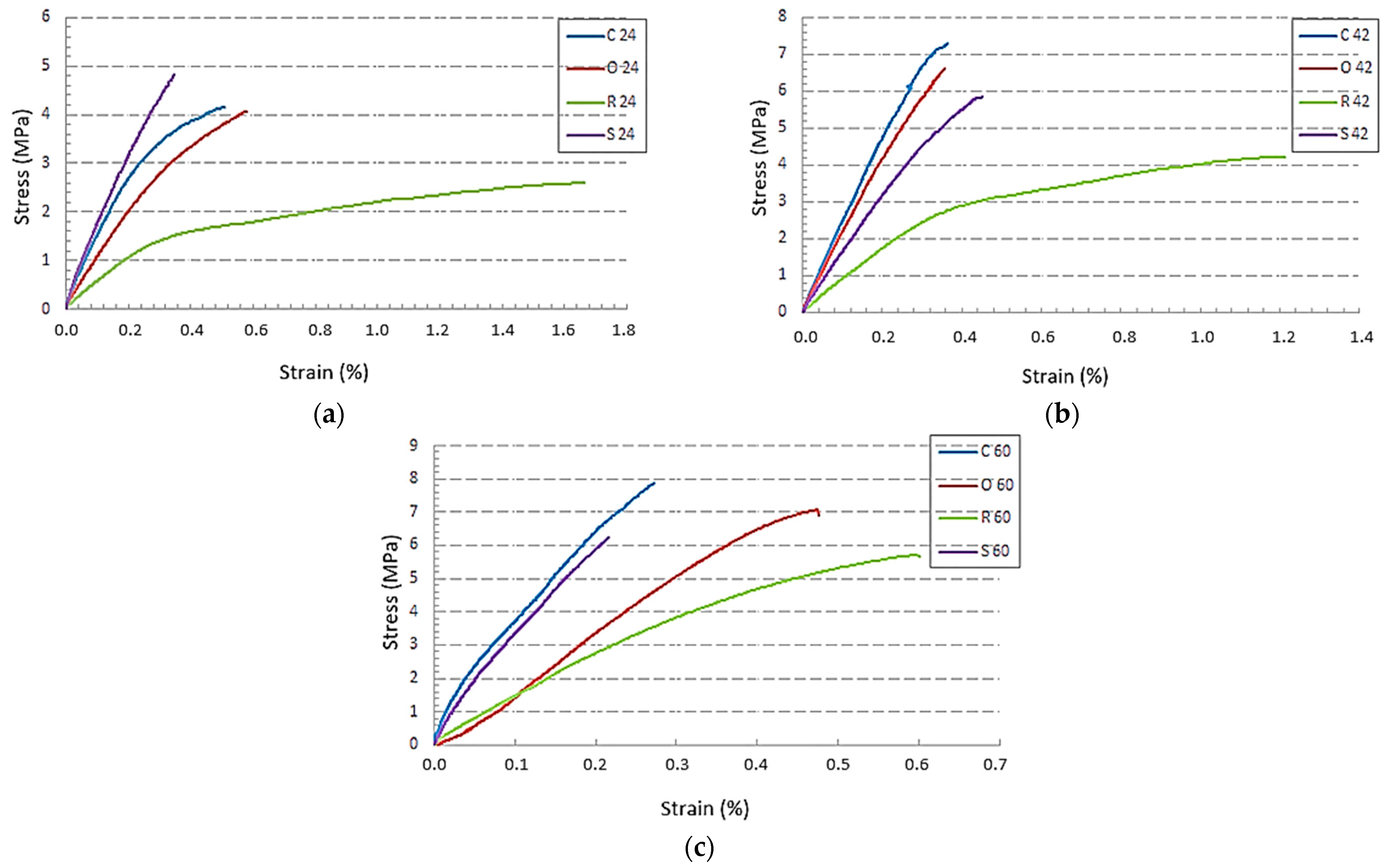

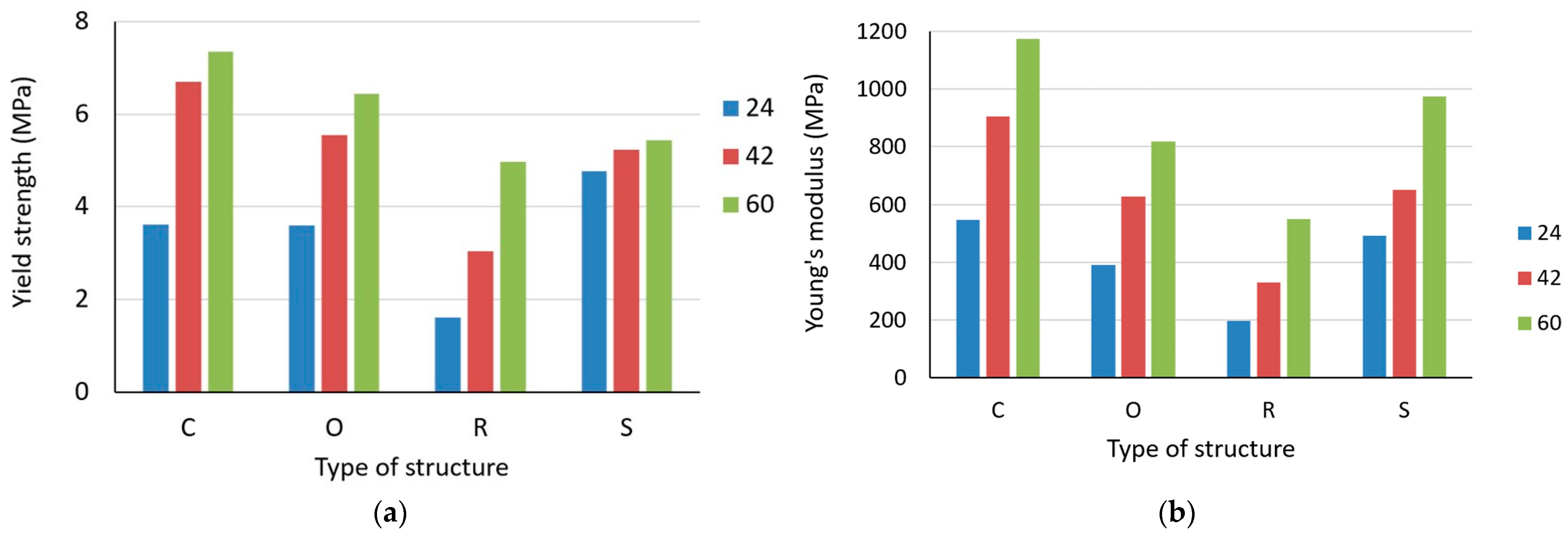

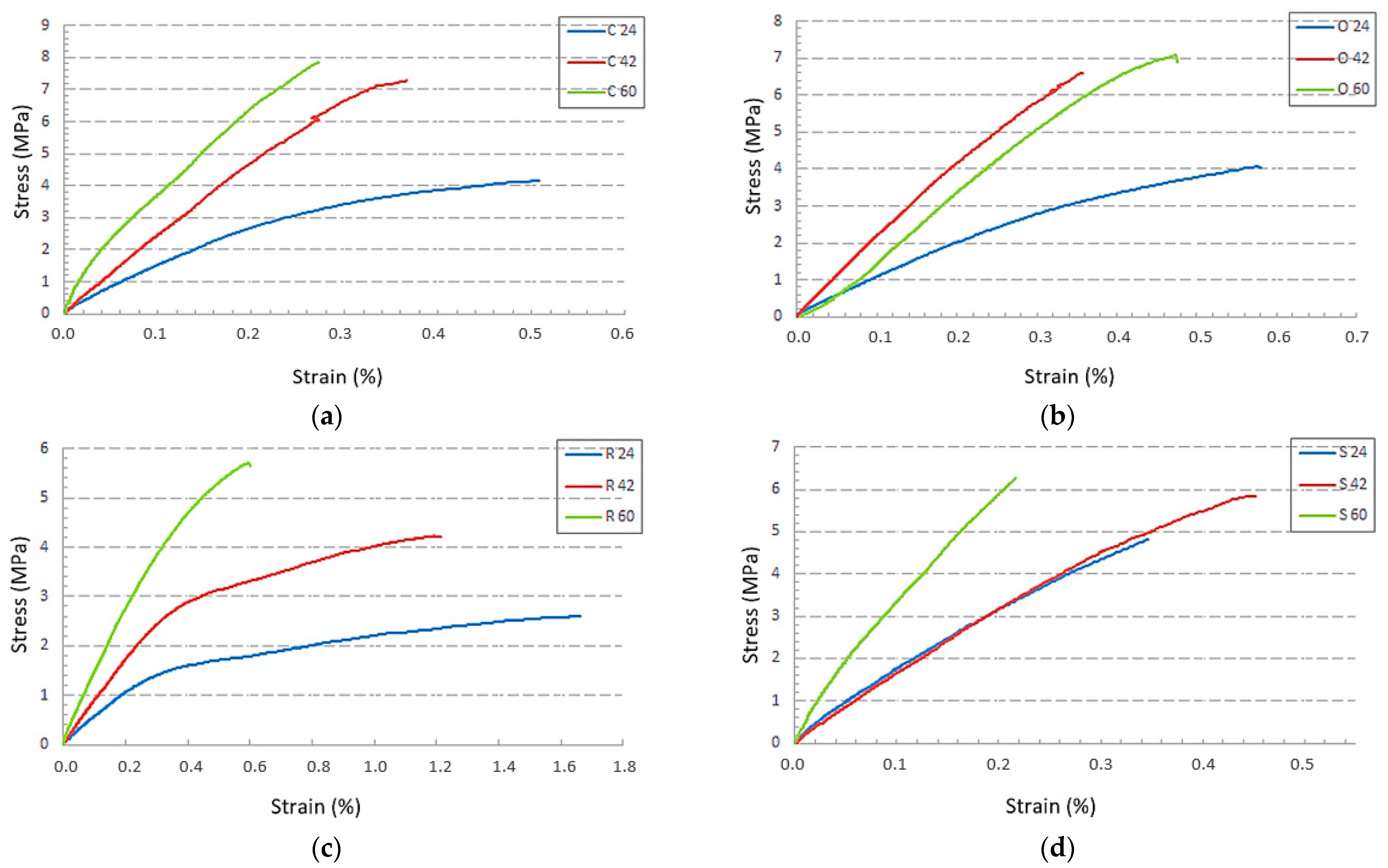

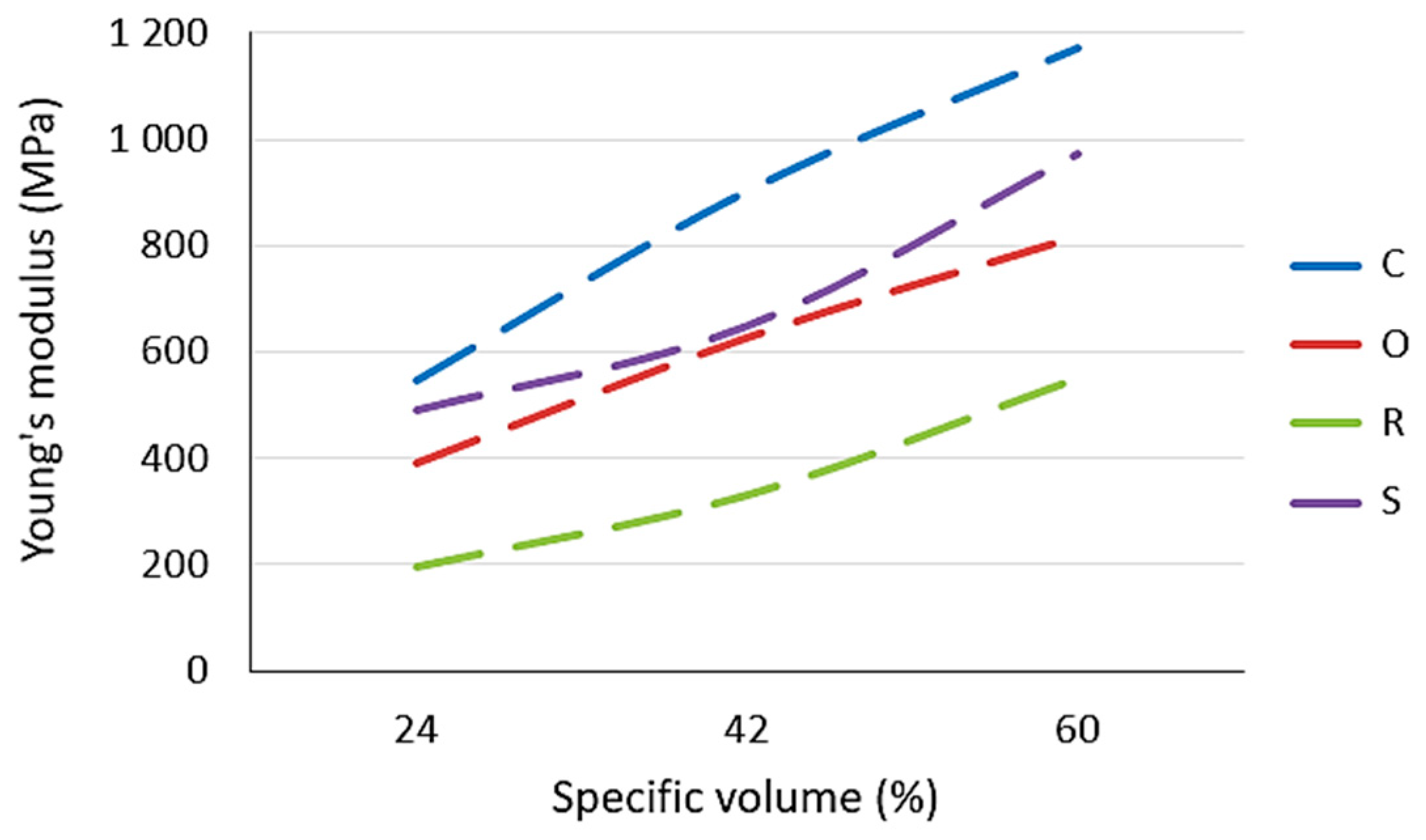

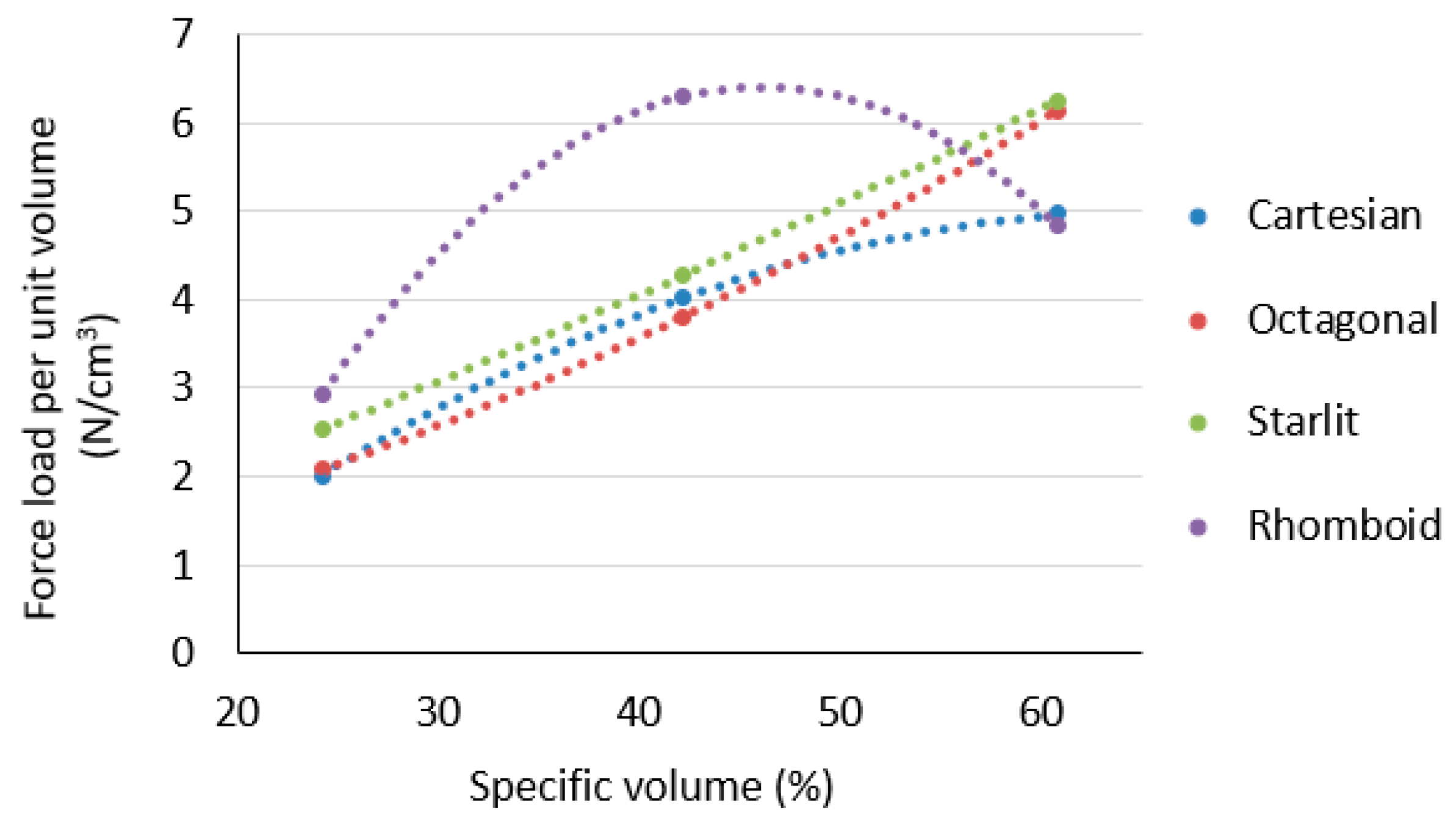

3. Results and Discussion

3.1. Effect of Structure Type

3.2. Effect of Specific Volume

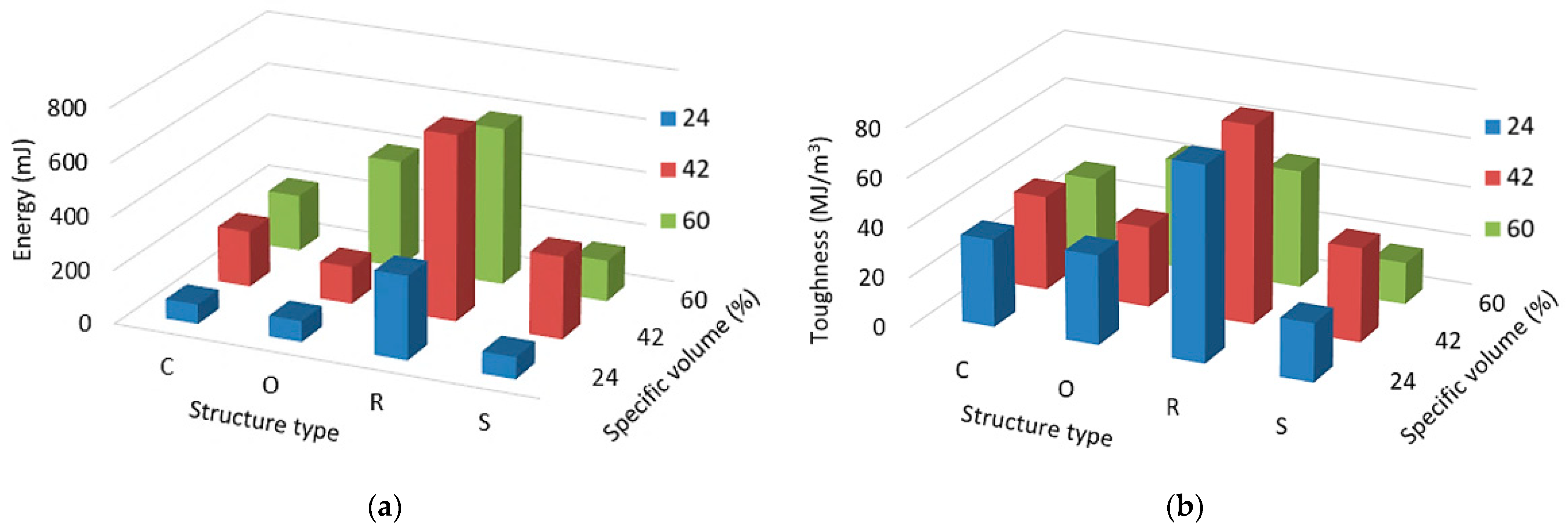

3.3. Energy Absorption and Toughness

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Scott, J.; Gupta, N.; Weber, C.; Newsome, S.; Wohlers, T.; Caffrey, T. Additive Manufacturing: Status and Opportunities; Science and Technology Policy Institute: Washington, DC, USA, 2012. [Google Scholar]

- Sudarmadji, N.; Tan, J.Y.; Leong, K.F.; Chua, C.K.; Loh, Y.T. Investigation of the mechanical properties and porosity relationships in selective laser-sintered polyhedral for functionally graded scaffolds. Acta Biomater. 2011, 7, 530–537. [Google Scholar] [CrossRef] [PubMed]

- Stojadinovic, S.M.; Majstorovic, V.D. Developing engineering ontology for domain coordinate metrology. FME Trans. 2014, 42, 249–255. [Google Scholar] [CrossRef]

- Vychytil, J.; Holeček, M. The simple model of cell prestress maintained by cell incompressibility. Math. Comput. Simul. 2010, 80, 1337–1344. [Google Scholar] [CrossRef]

- Trišović, N.; Maneski, T.; Kozak, D. Developed procedure for dynamic reanalysis of structures. Strojarstvo 2010, 52, 147–158. [Google Scholar]

- Baron, P.; Dobránsky, J.; Pollák, M.; Cmorej, T.; Kočiško, M. Proposal of the Knowledge Application Environment of Calculating Operational Parameters for Conventional Machining Technology. Key Eng. Mater. 2016, 669, 95–102. [Google Scholar] [CrossRef]

- Messner, M.C. Optimal lattice-structured materials. J. Mech. Phys. Solids 2016, 96, 162–183. [Google Scholar] [CrossRef]

- Ozcelik, B.; Ozbay, A.; Demirbas, E. Influence of injection parameters and mold materials on mechanical properties of ABS in plastic injection molding. Int. Commun. Heat Mass Transf. 2010, 37, 1359–1365. [Google Scholar] [CrossRef]

- Jiang, B.; Wang, Z.J.; Zhao, N.Q. Effect of pore size and relative density on the mechanical properties of open cell aluminum foams. Scr. Mater. 2007, 56, 169–172. [Google Scholar] [CrossRef]

- Kadkhodapour, J.; Montazerian, H.; Darabi, A.C.; Anaraki, A.P.; Ahmadi, S.M.; Zadpoor, A.A.; Schmauder, S. Failure mechanisms of additively manufactured porous biomaterials. J. Mech. Behav. Biomed. Mater. 2015, 50, 180–191. [Google Scholar] [CrossRef]

- Gorguluarslan, R.M.; Park, S.-I.; Rosen, D.W.; Choi, S.-K. A Multilevel Upscaling Method for Material Characterization of Additively Manufactured Part Under Uncertainties. J. Mech. Des. 2015, 137, 111408. [Google Scholar] [CrossRef]

- Tkac, J.; Samborski, S.; Monkova, K.; Debski, H. Analysis of mechanical properties of a lattice structure produced with the additive technology. Compos. Struct. 2020, 242, 112138. [Google Scholar] [CrossRef]

- Jimbo, K.; Tateno, T. Design of isotropic-tensile-strength lattice structure fabricated by AM. J. Soc. Mech. Eng. 2019, 85, 871. [Google Scholar] [CrossRef]

- Durbaca, A.C.; Iatan, R.; Durbaca, I.; Dinita, A.; Vasilescu, M. Experimental Research on the Triangular Lattice Type Polymer Based Composites Structures for Sandwich Panels Construction. Mater. Plast. 2017, 54, 639–644. [Google Scholar] [CrossRef]

- Sadali, M.F.; Hassan, M.Z.; Ahmad, N.H. Modelling of Printed Polylactide Lattice Structure and its Tensile Behaviour. In Proceedings of the International Graduate Conference on Engineering, Science and Humanities, Jahor Bahru, Malaysia, 13–15 August 2018. [Google Scholar]

- ISO 527-1:2019; Plastics—Determination of Tensile Properties. International Organization for Standardization: Geneva, Switzerland, 2019.

- An, D.S.; Kim, T.H.; Lee, E.H. Analytical and Experimental Investigation into the Relative influence of Core and Side Parts on Structures Laminated by Fused Deposition Modeling. Int. J. Precis. Eng. Manuf.-Green Technol. 2020, 8, 13–27. [Google Scholar] [CrossRef]

- Farbman, D.; McCoy, C. Materials Testing of 3D Printed ABS and PLA Samples to Guide Mechanical Design. In Proceedings of the ASME 2016 International Manufacturing Science and Engineering Conference, Blacksburg, VA, USA, 27 June–1 July 2016. [Google Scholar]

- Wu, Y.; Yang, L. The Effect of Unit Cell Size and Topology on Tensile Failure Behavior of 2D Lattice Structures. Int. J. Mech. Sci. 2019, 170, 105342. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, H.; Šavija, B.; Figueiredo, S.C.; Schlangen, E. Deformation and fracture of 3D printed disordered lattice materials: Experiments and modeling. Mater. Des. 2019, 162, 143–153. [Google Scholar] [CrossRef]

- Raghavendra, S.; Molinari, A.; Fontanari, V.; Dallago, M.; Luchin, V.; Zappini, G.; Benedetti, M. Tension-compression asymmetric mechanical behavior of lattice cellular structures produced by selective laser melting. J. Mech. Eng. Sci. 2020, 234, 3241–3256. [Google Scholar] [CrossRef]

- Seiler, P.E.; Tankasala, H.C.; Fleck, N.A. The role of defects in dictating the strength of brittle honeycombs made by rapid prototyping. Acta Mater. 2019, 171, 190–200. [Google Scholar] [CrossRef]

- Hasan, R.; Shamsudin, Z.; Muslim, M.F.; Yusof, A.M. Study on modulus of ABS single strut and reclaimed carbon fibre. In Proceedings of the Mechanical Engineering Research Day 2019, Melaka, Malaysia, 31 July 2019. [Google Scholar]

- Bhate, D.; Van Soest, J.; Reeher, J.; Patel, D.; Gibson, D.; Gerbasi, J.; Finfrock, M. A Validated Methodology for Predicting the Mechanical Behavior of ULTEM-9085 Honeycomb Structures Manufactured by Fused Deposition Modeling. In Proceedings of the Solid Freeform Fabrication 2016: Proceedings of the 27th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, SFF 2016, Austin, TX, USA, 8–10 August 2016. [Google Scholar]

- Kessler, J.; Balc, N.; Gebhardt, A. Basic research on lattice structures focused on the reliance of the cross sectional area and additional coatings. MATEC Web. Conf. 2017, 94, 03008. [Google Scholar] [CrossRef][Green Version]

- Bauer, J.; Schroer, A.; Schwaiger, R. The Impact of Size and Loading Direction on the Strength of Architected Lattice Materials. Adv. Eng. Mater. 2016, 18, 1537–1543. [Google Scholar] [CrossRef]

- Monkova, K.; Vasina, M.; Zaludek, M.; Monka, P.P.; Tkac, J. Mechanical Vibration Damping and Compression Properties of a Lattice Structure. Materials 2021, 14, 1502. [Google Scholar] [CrossRef] [PubMed]

- Rybachuk, M.; Alice Mauger, C.; Fiedler, T.; Öchsner, A. Anisotropic mechanical properties of fused deposition modeled parts fabricated by using Acrylonitrile Butadiene Styrene polymer. J. Polym. Eng. 2017, 37, 699–706. [Google Scholar] [CrossRef]

- Azmi, M.S.; Ismail, R.; Hasan, R.; Alkahari, M.R. Vibration Analysis of Fused Deposition Modelling Printed Lattice Structure Bar for Application in Automated Device. Int. J. Eng. Technol. 2018, 7, 21–24. [Google Scholar] [CrossRef]

- Kessler, J.; Balc, N.; Gebhardt, A. Basic Research on Lattice Structures Focused on the Tensile Strength. Appl. Mech. Mater. 2015, 808, 193–198. [Google Scholar] [CrossRef]

- Tahseen, A.; Mian, A. Developing and Equivalent Solid Material Model for BCC Lattice Cell Structures Involving Vertical and Horizontal Struts. J. Compos. Sci. 2020, 4, 74. [Google Scholar]

- ISO 527-1:2012; Plastics—Determination of Tensile Properties, General Principles. International Organization for Standardization: Geneva, Switzerland, 2012.

- ISO 527-2:2012; Plastics—Determination of Tensile Properties, Test Conditions for Molding and Extrusion Plastics. International Organization for Standardization: Geneva, Switzerland, 2012.

- Ozdemir, Z.; Hernandez-Nava, E.; Tyas, A.; Warren, J.A.; Fay, S.D.; Goodall, R.; Todd, I.; Askes, H. Energy absorption in lattice structures in dynamics: Experiments. Int. J. Impact Eng. 2016, 89, 49–61. [Google Scholar] [CrossRef]

- Ahmad, Y.A.l.-M.; Sandeep, P.P.; Bernd, M. Effects of porosity on the mechanical properties of additively manufactured components: A critical review. Mater. Res. Express 2020, 7, 122001. [Google Scholar] [CrossRef]

- Monkova, K.; Monka, P.P.; Žaludek, M.; Beňo, P.; Hricová, R.; Šmeringaiová, A. Experimental Study of the Bending Behaviour of the Neovius Porous Structure Made Additively from Aluminium Alloy. Aerospace 2023, 10, 361. [Google Scholar] [CrossRef]

- Carmona, S.; Molins, C. Equivalence Between Flexural Toughness Energy Absorption Capacity of FRC. In Fibre Reinforced Concrete: Improvements and Innovations; BEFIB 2020; RILEM Bookseries; Serna, P., Llano-Torre, A., Martí-Vargas, J.R., Navarro-Gregori, J., Eds.; Springer: Berlin/Heidelberg, Germany, 2021; Volume 30. [Google Scholar] [CrossRef]

- Chen, D.; Kitipornchai, S.; Yang, J. Dynamic response and energy absorption of functionally graded porous structures. Mater. Des. 2018, 140, 473–487. [Google Scholar] [CrossRef]

- Yang, P.; Yue, W.; Li, J.; Bin, G.; Li, C. Review of damage mechanism and protection of aero-engine blades based on impact properties. Eng. Fail. Anal. 2022, 140, 106570. [Google Scholar] [CrossRef]

- Gibson, L.J.; Ashby, M.F. Cellular Solids, Structure and Properties, 2nd ed.; Cambridge University Press: Cambridge, UK, 1999. [Google Scholar]

- Cantrell, J.T.; Rohde, S.; Damiani, D.; Gurnani, R.; DiSandro, L.; Anton, J.; Young, A.; Jerez, A.; Steinbach, D.; Kroese, C.; et al. Experimental characterization of the mechanical properties of 3D-printed ABS and polycarbonate parts. Rapid Prototyp. J. 2017, 23, 811–824. [Google Scholar] [CrossRef]

- Muminović, A.J.; Braut, S.; Božić, Ž.; Pervan, N.; Skoblar., A. Experimental failure analysis of polylactic acid gears made by additive manufacturing. Procedia Struct. Integr. 2023, 46, 125–130. [Google Scholar] [CrossRef]

- Pantazopoulos, G.A. A Short Review on Fracture Mechanisms of Mechanical Components Operated under Industrial Process Conditions: Fractographic Analysis and Selected Prevention Strategies. Metals 2019, 9, 148. [Google Scholar] [CrossRef]

- Liović, D.; Franulović, M.; Kozak, D. The effect of process parameters on mechanical behavior of selective laser melted Ti6Al4V alloy. Procedia Struct. Integr. 2023, 46, 42–48. [Google Scholar] [CrossRef]

- Braut, S. Fatigue strength analysis of an axial compressor blade using the modified Locati method. Eng. Fail. Anal. 2022, 141, 106655. [Google Scholar] [CrossRef]

- Mahshid, R.; Hansen, H.N.; Hojbjerre, L.K.L.K. Strength analysis and modeling of cellular lattice structures manufactured using selective laser melting for tooling applications. Mater. Des. 2016, 104, 276–283. [Google Scholar] [CrossRef]

- Monkova, K.; Pantazopoulos, G.; Toulfatzis, A.; Papadopoulou, S.; Monka, P.P.; Vanca, J. Tensile fracture analysis of 3D printed Inconel 718. Procedia Struct. Integr. 2023, 46, 30–34. [Google Scholar] [CrossRef]

- Iyibilgin, O.; Yigit, C. Experimental investigation of different cellular lattice structures manufactured by fused deposition modeling. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 12–14 August 2013; pp. 895–907. [Google Scholar]

- Naghieh, S.; Karamooz Ravari, M.R.; Badrossamay, M.; Foroozmehr, E.; Kadkhodaei, M. Numerical investigation of the mechanical properties of the additive manufactured bone scaffolds fabricated by FDM: The effect of layer penetration and post-heating. J. Mech. Behav. Biomed. Mater. 2016, 59, 241–250. [Google Scholar] [CrossRef]

- Bauer, J.; Hengsbach, S.; Tesari, I.; Schwaiger, R.; Kraft, O. High-strength cellular ceramic composites with 3D microarchitecture. Proc. Natl. Acad. Sci. USA 2014, 111, 2453–2458. [Google Scholar] [CrossRef]

- Lach, R.; Grellmann, W.; Han, Y.; Krüger, P. Fracture Mechanics Characterization of ABS Materials—Influence of Morphology and Temperature. Eng. Mater. 2001, 317–334. [Google Scholar] [CrossRef]

- Dettenmaier, M.; Kausch, H.-H. New type of crazes in oriented polycarbonate. Polymer 1980, 21, 1232–1234. [Google Scholar] [CrossRef]

- Lach, R.; Grellmann, W. Estimation of the resistance against stable crack initiation and unstable crack propagation using R-curves and stability assessment diagrams in ductile polymeric ABS-materials. In Proceedings of the 13th European Conference on Fracture (ECF 13), San Sebastian, Spain, 6–9 September 2000; CD-ROM Polymer and Composites, No. 20. pp. 1–8. [Google Scholar]

- Božić, Ž.; Schmauder, S.; Wolf, H. The effect of residual stresses on fatigue crack propagation in welded stiffened panels. Eng. Fail. Anal. 2018, 84, 346–357. [Google Scholar] [CrossRef]

- Wiest, A.; MacDougall, C.A.; Conner, R.D. Optimization of cellular solids for energy absorption. Scr. Mater. 2014, 84, 7–10. [Google Scholar] [CrossRef]

- Fang, Q.; Zhang, J.; Zhang, Y.; Liu, J.; Gong, Z. Mesoscopic investigation of closed-cell aluminum foams on energy absorption capability under impact. Compos. Struct. 2015, 124, 409–420. [Google Scholar] [CrossRef]

- Lapčík, L.; Sepetcioğlu, H.; Murtaja, Y.; Lapčíková, B.; Vašina, M.; Ovsík, M.; Staněk, M.; Gautam, S. Study of mechanical properties of epoxy/graphene and epoxy/halloysite nanocomposites. Nanotechnol. Rev. 2023, 12, 20220520. [Google Scholar] [CrossRef]

- Pantazopoulos, G.A. A Process-Based Approach in Failure Analysis. J Fail. Anal. Prev. 2014, 14, 551–553. [Google Scholar] [CrossRef]

| Type of Structure | Specific Volume (%) | Label | Cross-Section View | Diameter of a Strut (mm) | Structure Length (mm) |

|---|---|---|---|---|---|

| Cartesian | 24 | C24 |  | 1 | 90 |

| 42 | C42 | 1.4 | 90 | ||

| 60 | C60 | 1.8 | 90 | ||

| Octagonal | 24 | O24 |  | 1 | 90 |

| 42 | O42 | 1.4 | 90 | ||

| 60 | O60 | 1.7 | 88 | ||

| Rhomboid | 24 | R24 |  | 1 | 88 |

| 42 | R42 | 1.35 | 90 | ||

| 60 | R60 | 1.7 | 90 | ||

| Starlit | 24 | S24 |  | 1 | 88 |

| 42 | S42 | 1.4 | 90 | ||

| 60 | S60 | 1.8 | 88 |

| Structure Type | Specific Volume (%) | Label | Force (N) | Yield Strength (MPa) | Ultimate Strength (MPa) | Young’s Modulus (MPa) |

|---|---|---|---|---|---|---|

| Cartesian | 24 | C24 | 215 ± 10 | 3.62 ± 0.22 | 4.15 ± 0.19 | 548 ± 12 |

| 42 | C42 | 748 ± 20 | 6.70 ± 0.24 | 7.29 ± 0.20 | 904 ± 22 | |

| 60 | C60 | 1193 ± 45 | 7.35 ± 0.36 | 7.86 ± 0.30 | 1173 ± 25 | |

| Octagonal | 24 | O24 | 220 ± 12 | 3.60 ± 0.20 | 4.06 ± 0.17 | 390 ± 9 |

| 42 | O42 | 709 ± 9 | 5.55 ± 0.29 | 6.61 ± 0.33 | 627 ± 10 | |

| 60 | O60 | 1183 ± 56 | 6.44 ± 0.31 | 7.08 ± 0.34 | 817 ± 17 | |

| Rhomboid | 24 | R24 | 256 ± 9 | 1.60 ± 0.05 | 2.60 ± 0.09 | 197 ± 5 |

| 42 | R42 | 803 ± 23 | 3.04 ± 0.12 | 4.23 ± 0.12 | 331 ± 10 | |

| 60 | R60 | 1384 ± 56 | 4.98 ± 0.27 | 5.71 ± 0.23 | 545 ± 16 | |

| Starlit | 24 | S24 | 306 ± 15 | 4.77 ± 0.25 | 4.82 ± 0.24 | 491 ± 14 |

| 42 | S42 | 934 ± 42 | 5.23 ± 0.26 | 5.83 ± 0.26 | 645 ± 14 | |

| 60 | S60 | 1501 ± 70 | 5.43 ± 0.30 | 6.25 ± 0.29 | 974 ± 19 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Monkova, K.; Monka, P.P.; Hricová, R.; Hausnerova, B.; Knapčíková, L. Tensile Properties of Four Types of ABS Lattice Structures—A Comparative Study. Polymers 2023, 15, 4090. https://doi.org/10.3390/polym15204090

Monkova K, Monka PP, Hricová R, Hausnerova B, Knapčíková L. Tensile Properties of Four Types of ABS Lattice Structures—A Comparative Study. Polymers. 2023; 15(20):4090. https://doi.org/10.3390/polym15204090

Chicago/Turabian StyleMonkova, Katarina, Peter Pavol Monka, Romana Hricová, Berenika Hausnerova, and Lucia Knapčíková. 2023. "Tensile Properties of Four Types of ABS Lattice Structures—A Comparative Study" Polymers 15, no. 20: 4090. https://doi.org/10.3390/polym15204090

APA StyleMonkova, K., Monka, P. P., Hricová, R., Hausnerova, B., & Knapčíková, L. (2023). Tensile Properties of Four Types of ABS Lattice Structures—A Comparative Study. Polymers, 15(20), 4090. https://doi.org/10.3390/polym15204090