Viscoplastic Modeling of Surface Relief Grating Growth on Isotropic and Preoriented Azopolymer Films

Abstract

1. Introduction

2. Materials and Methods

Theoretical Approach

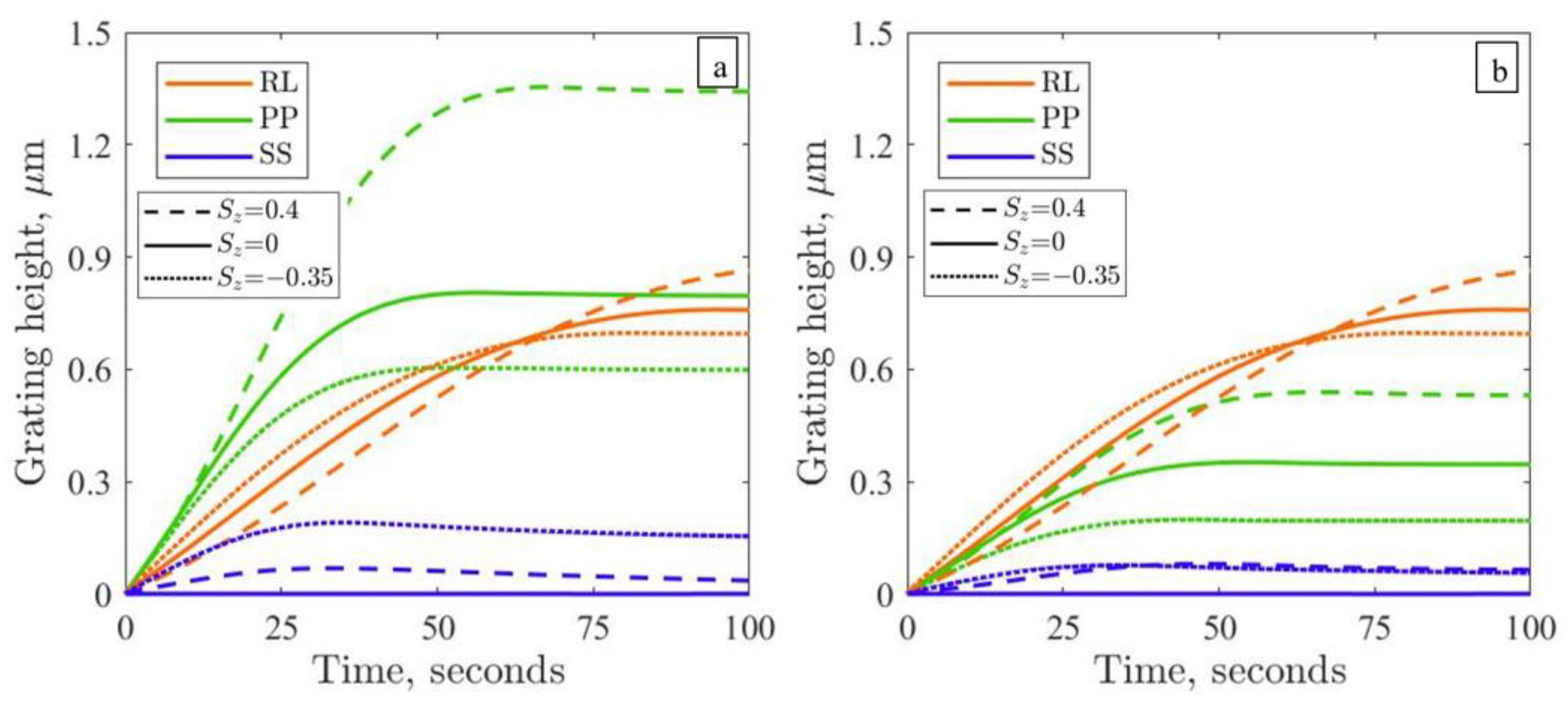

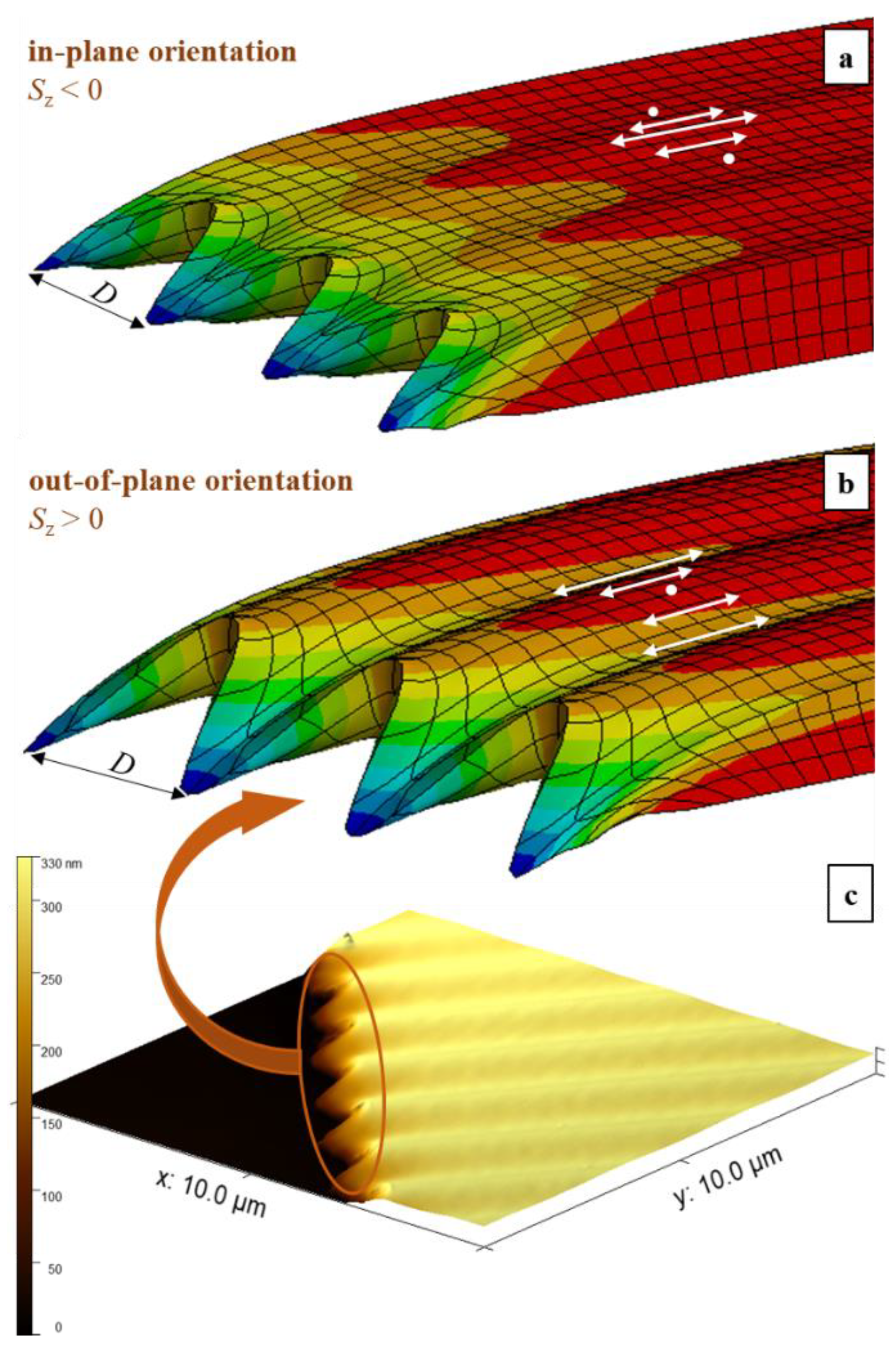

3. Results

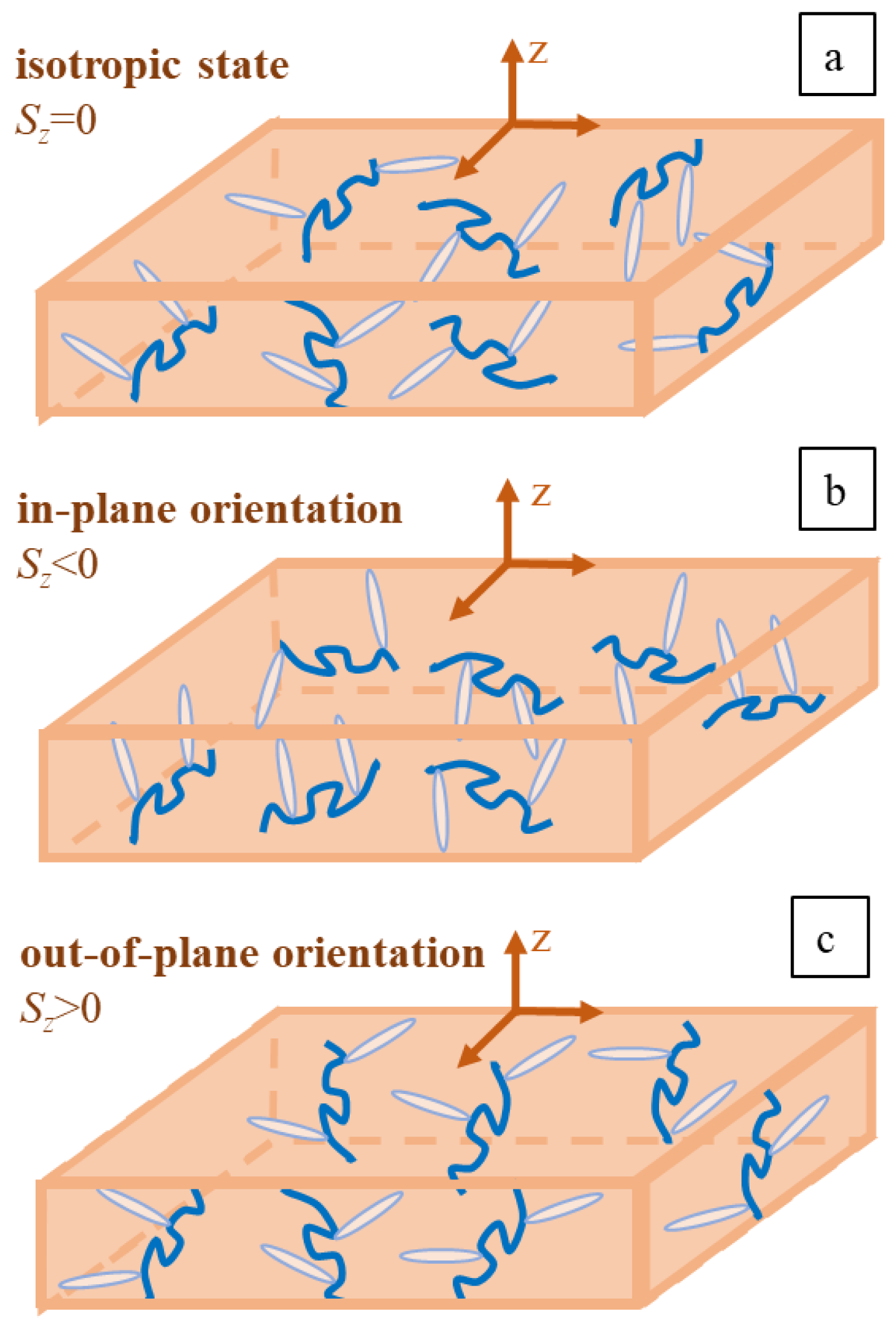

- Polymer backbones tend to lie in the plane of substrate, .

- Polymer backbones have a tendency to align along the z-axis, .

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Stracke, A.; Wendorff, J.H.; Goldmann, D.; Janietz, D.; Stiller, B. Gain effects in optical storage: Thermal induction of a surface relief grating in a smectic liquid crystal. Adv. Mater. 2000, 12, 282–285. [Google Scholar] [CrossRef]

- Natansohn, A.; Rochon, P. Photoinduced motions in azobenzene-based amorphous polymers: Possible photonic devices. Adv. Mater. 1999, 11, 1387–1391. [Google Scholar] [CrossRef]

- Oscurato, S.L.; Reda, F.; Salvatore, M.; Borbone, F.; Maddalena, P.; Ambrosio, A. Large-Scale Multiplexed Azopolymer Gratings with Engineered Diffraction Behavior. Adv. Mater. Interfaces 2021, 8, 2101375. [Google Scholar] [CrossRef]

- Shimoboji, T.; Larenas, E.; Fowler, T.; Kulkarni, S.; Hoffman, A.S.; Stayton, P.S. Photoresponsive polymer-enzyme switches. Proc. Natl. Acad. Sci. USA 2002, 99, 16592–16596. [Google Scholar] [CrossRef] [PubMed]

- Banghart, M.; Borges, K.; Isacoff, E.; Trauner, D.; Kramer, R.H. Light-activated ion channels for remote control of neuronal firing. Nat. Neurosci. 2004, 7, 1381–1386. [Google Scholar] [CrossRef]

- Goulet-Hanssens, A.; Barrett, C.J. Photo-control of biological systems with azobenzene polymers. J. Polym. Sci. Part A Polym. Chem. 2013, 51, 3058–3070. [Google Scholar] [CrossRef]

- Konrad, D.B.; Frank, J.A.; Trauner, D. Synthesis of Redshifted Azobenzene Photoswitches by Late-Stage Functionalization. Chemistry 2016, 22, 4364–4368. [Google Scholar] [CrossRef]

- Zakrevskyy, Y.; Cywinski, P.; Cywinska, M.; Paasche, J.; Lomadze, N.; Reich, O.; Löhmannsröben, H.-G.; Santer, S. Interaction of photosensitive surfactant with DNA and poly acrylic acid. J. Chem. Phys. 2014, 140, 044907. [Google Scholar] [CrossRef]

- Schimka, S.; Santer, S.; Mujkic-Ninnemann, N.M.; Bleger, D.; Hartmann, L.; Wehle, M.; Lipowsky, R.; Santer, M. Photosensitive Peptidomimetic for Light-Controlled, Reversible DNA Compaction. Biomacromolecules 2016, 17, 1959–1968. [Google Scholar] [CrossRef]

- Chigrinov, V.G.; Kozenkov, V.M.; Kwok, H.-S. Photoalignment of Liquid Crystalline Materials: Physics and Applications; Wiley Publishing: Hoboken, NJ, USA, 2008. [Google Scholar]

- Tabiryan, N.V.; Roberts, D.E.; Liao, Z.; Hwang, J.-Y.; Moran, M.; Ouskova, O.; Pshenichnyi, A.; Sigley, J.; Tabirian, A.; Vergara, R.; et al. Advances in Transparent Planar Optics: Enabling Large Aperture, Ultrathin Lenses. Adv. Opt. Mater. 2021, 9, 2001692. [Google Scholar] [CrossRef]

- Yu, Y.L.; Nakano, M.; Ikeda, T. Directed bending of a polymer film by light-Miniaturizing a simple photomechanical system could expand its range of applications. Nature 2003, 425, 145. [Google Scholar] [CrossRef] [PubMed]

- Ryabchun, A.; Bobrovsky, A. Photocontrollable Deformations of Polymer Particles in Elastic Matrix. Adv. Opt. Mater. 2019, 7, 1901486. [Google Scholar] [CrossRef]

- Lancia, F.; Ryabchun, A.; Nguindjel, A.-D.; Kwangmettatam, S.; Katsonis, N. Mechanical adaptability of artificial muscles from nanoscale molecular action. Nat. Commun. 2019, 10, 4819. [Google Scholar] [CrossRef] [PubMed]

- Bléger, D.; Hecht, S. Visible-Light-Activated Molecular Switches. Angew. Chem. Int. Ed. 2015, 54, 11338–11349. [Google Scholar] [CrossRef]

- Bléger, D. Orchestrating Molecular Motion with Light – From Single (macro)Molecules to Materials. Macromol. Chem. Phys. 2016, 217, 189–198. [Google Scholar] [CrossRef]

- Koch, M.; Saphiannikova, M.; Guskova, O. Cyclic Photoisomerization of Azobenzene in Atomistic Simulations: Modeling the Effect of Light on Columnar Aggregates of Azo Stars. Molecules 2021, 26, 7674. [Google Scholar] [CrossRef]

- Koch, M. The Influence of Light on a Three-Arm Azobenzene Star: A Computational Study. PhD Thesis, TU Dresden, Dresden, Germany, 2022. [Google Scholar]

- Irie, M.; Fukaminato, T.; Matsuda, K.; Kobatake, S. Photochromism of diarylethene molecules and crystals: Memories, switches, and actuators. Chem. Rev. 2014, 114, 12174–12277. [Google Scholar] [CrossRef]

- Ragazzon, G.; Baroncini, M.; Silvi, S.; Venturi, M.; Credi, A. Light-powered autonomous and directional molecular motion of a dissipative self-assembling system. Nat. Nanotechnol. 2015, 10, 70–75. [Google Scholar] [CrossRef]

- Merino, E.; Ribagorda, M. Control over molecular motion using the cis-trans photoisomerization of the azo group. Beilstein J. Org. Chem. 2012, 8, 1071–1090. [Google Scholar] [CrossRef]

- Oscurato, S.L.; Salvatore, M.; Maddalena, P.; Ambrosio, A. From nanoscopic to macroscopic photo-driven motion in azobenzene-containing materials. Nanophotonics 2018, 7, 1387–1422. [Google Scholar] [CrossRef]

- Oscurato, S.L.; Borbone, F.; Maddalena, P.; Ambrosio, A. Light-driven wettability tailoring of azopolymer surfaces with reconfigured three-dimensional posts. ACS Appl. Mater. Interfaces 2017, 9, 30133–30142. [Google Scholar] [CrossRef] [PubMed]

- Pirani, F.; Angelini, A.; Ricciardi, S.; Frascella, F.; Descrovi, E. Laser-induced anisotropic wettability on azopolymeric micro-structures. Appl. Phys. Lett. 2017, 110, 101603. [Google Scholar] [CrossRef]

- Umlandt, M.; Kopyshev, A.; Pasechnik, S.V.; Zakharov, A.V.; Lomadze, N.; Santer, S. Light-Triggered Manipulations of Droplets All in One: Reversible Wetting, Transport, Splitting, and Merging. ACS Appl. Mater. Interfaces 2022, 14, 41412. [Google Scholar] [CrossRef] [PubMed]

- Wani, O.M.; Zeng, H.; Priimagi, A. A light-driven artificial flytrap. Nat. Commun. 2017, 8, 15546. [Google Scholar] [CrossRef] [PubMed]

- Pagliusi, P.; Audia, B.; Provenzano, C.; Piñol, M.; Oriol, L.; Cipparrone, G. Tunable Surface Patterning of Azopolymer by Vectorial Holography: The Role of Photoanisotropies in the Driving Force. ACS Appl. Mater. Interfaces 2019, 11, 34471–34477. [Google Scholar] [CrossRef]

- Priimagi, A.; Shevchenko, A. Azopolymer-Based Micro- and Nanopatterning for Photonic Applications. J. Polym. Sci. Part B Polym. Phys. 2014, 52, 163–182. [Google Scholar] [CrossRef]

- Hsu, C.; Xu, Z.; Wang, X. Holographic Recording and Hierarchical Surface Patterning on Periodic Submicrometer Pillar Arrays of Azo Molecular Glass via Polarized Light Irradiation. Adv. Funct. Mater. 2018, 28, 1802506. [Google Scholar] [CrossRef]

- Bagheri, S.; Giessen, H.; Neubrech, F. Large-Area Antenna-Assisted SEIRA Substrates by Laser Interference Lithography. Adv. Opt. Mater. 2014, 2, 1050–1056. [Google Scholar] [CrossRef]

- Reda, F.; Salvatore, M.; Borbone, F.; Maddalena, P.; Oscurato, S.L. Accurate Morphology-Related Diffraction Behavior of Light-Induced Surface Relief Gratings on Azopolymers. ACS Mater. Lett. 2022, 4, 953–959. [Google Scholar] [CrossRef]

- Rochon, P.; Batalla, E.; Natansohn, A. Optically induced surface gratings on azoaromatic polymer-films. Appl. Phys. Lett. 1995, 66, 136–138. [Google Scholar] [CrossRef]

- Kim, D.Y.; Tripathy, S.K.; Li, L.; Kumar, J. Laser-induced holographic surface-relief gratings on nonlinear-optical polymer-films. Appl. Phys. Lett. 1995, 66, 1166–1168. [Google Scholar] [CrossRef]

- Toshchevikov, V.; Saphiannikova, M.; Heinrich, G. Microscopic Theory of Light-Induced Deformation in Amorphous Side-Chain Azobenzene Polymers. J. Phys. Chem. B 2009, 113, 5032–5045. [Google Scholar] [CrossRef] [PubMed]

- Toshchevikov, V.; Ilnytskyi, J.; Saphiannikova, M. Photoisomerization Kinetics and Mechanical Stress in Azobenzene-Containing Materials. J. Phys. Chem. Lett. 2017, 8, 1094–1098. [Google Scholar] [CrossRef] [PubMed]

- Toshchevikov, V.; Petrova, T.; Saphiannikova, M. Kinetics of Ordering and Deformation in Photosensitive Azobenzene LC Networks. Polymers 2018, 10, 531. [Google Scholar] [CrossRef]

- Toshchevikov, V.; Saphiannikova, M. Photo-Ordering and Deformation in Azobenzene-Containing Polymer Networks under Irradiation with Elliptically Polarized Light. Processes 2023, 11, 129. [Google Scholar] [CrossRef]

- Fuhrmann, T.; Tsutsui, T. Synthesis and properties of a hole-conducting, photopatternable molecular glass. Chem. Mater. 1999, 11, 2226–2232. [Google Scholar] [CrossRef]

- Shirota, Y. Photo- and electroactive amorphous molecular materials—Molecular design, syntheses, reactions, properties, and applications. J. Mater. Chem. 2005, 15, 75–93. [Google Scholar] [CrossRef]

- Saphiannikova, M.; Toshchevikov, V. Optical deformations of azobenzene polymers: Orientation approach vs. photofluidization concept. J. Soc. Inf. Disp. 2015, 23, 146–153. [Google Scholar] [CrossRef]

- Yadav, B.; Domurath, J.; Kim, K.; Lee, S.; Saphiannikova, M. Orientation Approach to Directional Photodeformations in Glassy Side-Chain Azopolymers. J. Phys. Chem. B 2019, 123, 3337–3347. [Google Scholar] [CrossRef]

- Yadav, B.; Domurath, J.; Saphiannikova, M. Modeling of Stripe Patterns in Photosensitive Azopolymers. Polymers 2020, 12, 735. [Google Scholar] [CrossRef]

- Loebner, S.; Yadav, B.; Lomadze, N.; Tverdokhleb, N.; Donner, H.; Saphiannikova, M.; Santer, S. Local Direction of Optomechanical Stress in Azobenzene Containing Polymers During Surface Relief Grating Formation. Macromol. Mater. Eng. 2022, 31, 2100990. [Google Scholar] [CrossRef]

- Holme, N.C.R.; Nikolova, L.; Ramanujam, P.S.; Hvilsted, S. An analysis of the anisotropic and topographic gratings in a side-chain liquid crystalline azobenzene polyester. Appl. Phys. Lett. 1997, 70, 1518–1520. [Google Scholar]

- Viswanathan, N.K.; Balasubramanian, S.; Li, L.; Tripathy, S.K.; Kumar, J. A detailed investigation of the polarization-dependent surface-relief-grating formation process on azo polymer films. Jpn. J. Appl. Phys. Part 1 Regul. Pap. Short Notes Rev. Pap. 1999, 38, 5928–5937. [Google Scholar] [CrossRef]

- Lagugne-Labarthet, F.; Buffeteau, T.; Sourisseau, C. Azopolymer holographic diffraction gratings: Time dependent analyses of the diffraction efficiency, birefringence, and surface modulation induced by two linearly polarized interfering beams. J. Phys. Chem. B 1999, 103, 6690–6699. [Google Scholar] [CrossRef]

- Rekola, H.; Berdin, A.; Fedele, C.; Virkki, M.; Priimagi, A. Digital holographic microscopy for real-time observation of surface-relief grating formation on azobenzene-containing films. Sci. Rep. 2020, 10, 19642. [Google Scholar] [CrossRef]

- Sobolewska, A.; Bartkiewicz, S. Surface relief grating in azo-polymer obtained for s-s polarization configuration of the writing beams. Appl. Phys. Lett. 2012, 101, 193301. [Google Scholar] [CrossRef]

- Yadavalli, N.S.; Santer, S. In-situ atomic force microscopy study of the mechanism of surface relief grating formation in photosensitive polymer films. J. Appl. Phys. 2013, 113, 224304. [Google Scholar] [CrossRef]

- Yadavalli, N.S.; Loebner, S.; Papke, T.; Sava, E.; Hurduc, N.; Santer, S. A comparative study of photoinduced deformation in azobenzene containing polymer films. Soft Matter 2016, 12, 2593–2603. [Google Scholar] [CrossRef]

- Kumar, J.; Li, L.; Jiang, X.L.; Kim, D.Y.; Lee, T.S.; Tripathy, S. Gradient force: The mechanism for surface relief grating formation in azobenzene functionalized polymers. Appl. Phys. Lett. 1998, 72, 2096–2098. [Google Scholar] [CrossRef]

- Viswanathan, N.K.; Kim, D.Y.; Bian, S.; Williams, J.; Liu, W.; Li, L.; Samuelson, L.; Kumar, J.; Tripathy, S.K. Surface relief structures on azo polymer films. J. Mater. Chem. 1999, 9, 1941–1955. [Google Scholar] [CrossRef]

- Bublitz, D.; Fleck, B.; Wenke, L. A model for surface-relief formation in azobenzene polymers. Appl. Phys. B 2001, 72, 931–936. [Google Scholar] [CrossRef]

- Saphiannikova, M.; Neher, D. Thermodynamic theory of light-induced material transport in amorphous azobenzene polymer films. J. Phys. Chem. B 2005, 109, 19428–19436. [Google Scholar] [CrossRef] [PubMed]

- Jelken, J.; Santer, S. Light induced reversible structuring of photosensitive polymer films. RSC Adv. 2019, 9, 20295–20305. [Google Scholar] [CrossRef] [PubMed]

- Fang, G.J.; Maclennan, J.E.; Yi, Y.; Glaser, M.A.; Farrow, M.; Korblova, E.; Walba, D.M.; Furtak, T.E.; Clark, N.A. Athermal photofluidization of glasses. Nat. Commun. 2013, 4, 1521. [Google Scholar] [CrossRef] [PubMed]

| Thickness, nm | Pretreatment | Height of SS Grating, nm |

|---|---|---|

| pDR1 | ||

| 300 | as prepared | 30 |

| heated 120 °C, 30 min | 2 | |

| R 100 mW/cm2, 10 min | 2 | |

| P 100 mW/cm2, 10 min | 2 | |

| R 10 mW/cm2, 10 min | 8 | |

| PAZO | ||

| 740 | as prepared | 65 |

| 810 | heated 120 °C, 1 h | 74 |

| 740 | R 100 mW/cm2, 1 h | 10 |

| 810 | P 100 mW/cm2, 1 h | 19 |

| 810 | R 10 mW/cm2, 1 h | 12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tverdokhleb, N.; Loebner, S.; Yadav, B.; Santer, S.; Saphiannikova, M. Viscoplastic Modeling of Surface Relief Grating Growth on Isotropic and Preoriented Azopolymer Films. Polymers 2023, 15, 463. https://doi.org/10.3390/polym15020463

Tverdokhleb N, Loebner S, Yadav B, Santer S, Saphiannikova M. Viscoplastic Modeling of Surface Relief Grating Growth on Isotropic and Preoriented Azopolymer Films. Polymers. 2023; 15(2):463. https://doi.org/10.3390/polym15020463

Chicago/Turabian StyleTverdokhleb, Nina, Sarah Loebner, Bharti Yadav, Svetlana Santer, and Marina Saphiannikova. 2023. "Viscoplastic Modeling of Surface Relief Grating Growth on Isotropic and Preoriented Azopolymer Films" Polymers 15, no. 2: 463. https://doi.org/10.3390/polym15020463

APA StyleTverdokhleb, N., Loebner, S., Yadav, B., Santer, S., & Saphiannikova, M. (2023). Viscoplastic Modeling of Surface Relief Grating Growth on Isotropic and Preoriented Azopolymer Films. Polymers, 15(2), 463. https://doi.org/10.3390/polym15020463