Abstract

Background: This systematic review aims to evaluate the color stability of resin composite CAD/CAM blocks (CCB) when submitted to staining solutions. Methods: A systematic search was performed on different databases (Embase, Medline, Scopus, Web of Science). Search terms were: ‘polymer infiltrated’, ‘polymer-based’, ‘resin nanoceramic’, ‘resin ceramic’, ‘hybrid composite’, ‘hybrid ceramic’, ‘composite ceramic’, ‘resin infiltrated’, ‘CAD-CAM’, ‘CAD/CAM’, ‘color stability’, ‘staining’, ‘staining susceptibility’, ‘color change’, ‘color difference’. Inclusion criteria: in vitro articles published in the English language until 18 September 2022 without initial time restriction evaluating the color stability of CCB when submitted to staining solutions. Exclusion criteria: studies investigating color change induced by smoke or whitening treatments; studies not including a clinical evaluation of the results using the thresholds for color perceptibility and acceptability. Risk of bias assessment using the QUIN tool. Findings: Out of the 378 initially retrieved articles, 19 were included in this review. They investigated 17 different CCBs and different artificial staining by liquid protocols, including coffee, red wine, tea, and cola. CCBs exceeded clinical acceptability thresholds for color shift in 18 out of 19 studies, with a significantly higher color stability than conventional hybrid resin-based composites (RBCs), and a significantly lower color stability than ceramic materials. The identified differences in CCBs in color stability can be attributed to the material’s composition, but also to the heterogeneity of staining procedures. Interpretation and clinical implication: Clinicians should be aware that, although to a lower degree when compared to RBCs used in direct or indirect procedures, CCBs undergo color changes to a higher degree in comparison to ceramic materials.

1. Introduction

In less than 40 years, CAD/CAM technology has experienced constant hardware and software improvements that have resulted in easier use and more reliable clinical performance [1,2,3]. Along with progress in technology, new materials have been developed for CAD/CAM restorations, such as glass ceramics, zirconia, and composites, allowing clinicians the choice of different mechanical [4,5] and optical [6] properties. Although the use of direct resin-based composite (RBC) restorations is largely diffused and able to provide reliable and esthetic results both for anterior [7,8] and posterior [9] direct restorations, some drawbacks have been reported, such as weak mechanical properties [10] and lack of color stability.

When compared with RBCs used in direct restorations, indirect ones are characterized by higher mechanical properties and color stability, mainly due to the higher degree of conversion that can be obtained with extra-oral curing. Today, indirect RBCs are extensively used as a reliable alternative to ceramic restorations to produce inlays or onlays [11].

CAD/CAM composite blocks [12] (CCB) (also referred as resin nano-ceramic [13,14,15,16,17,18,19], resin ceramic [20], resin-based composites blocks [21,22,23,24], nanohybrid restorative materials [25], nano-hybrid ceramic [26], hybrid composites [27], hybrid ceramic [28]) have recently gained popularity as they are considered to offer a higher quality compared to composite used in a conventional manual procedure in both direct and indirect restorations. This is mainly due to the standardized industrial production processes, for which high temperature and/or high-pressure polymerization are used. These are able to maximize polymer cross-linking [12] and, therefore, the material’s properties. Other advantages of CCBs are that they are more easily finalized than ceramics, because after milling no firing process is needed. Furthermore, they are easy to finish and polish, and repair [12].

Since the introduction of the first CCB (MZ100, 3M ESPE, St. Paul, MN, USA) in the early 2000s [29], several CCBs have been marketed. Due to the heterogeneity of the available CCBs, it is worthwhile analyzing their behavior to understand possible clinical drawbacks. One of the known limits of resin-based materials is the propensity to color change in the long term due to intrinsic and extrinsic factors [30]. Intrinsic factors are related to the material’s composition, such as the type of resin matrix, fillers, and polymerization initiators [31]. Extrinsic factors are related to the absorption of pigments coming from external sources, such as food or drinks. Some commonly used beverages like coffee, tea, coke, red wine, and juices can affect the color stability of composite resins [32].

With patients’ increasing esthetic demands, the color stability of restorative materials has become pivotal in determining the long-term clinical success and the longevity of a restoration. Objectives: a comprehensive systematic literature review was conducted to investigate the color stability of CCBs when submitted to artificial staining.

2. Materials and Methods

This systematic review followed the Preferred Reporting Items for Systematic reviews and Meta-Analyses (PRISMA) statement [33].

2.1. Eligibility Criteria

Population: We included in vitro studies analyzing color change of composite CAD/CAM blocks obtained by artificial staining by liquids. Examples of liquids we included: coffee, tea, cola, juices.

Outcome: To be included, articles should use a color-change formula to evaluate color stability.

Inclusion Criteria:

- In vitro studies investigating color stability of composite CAD/CAM blocks;

- In vitro studies including artificial staining procedures by liquids;

- Studies using color difference clinical thresholds to analyze the color difference values;

- Publications in English language;

Exclusion Criteria

- 5.

- In vitro studies with a sample size of less than five test specimens in each subgroup;

- 6.

- In vitro studies investigating color stability of hybrid dental ceramic CAD/CAM blocks (polymer-infiltrated ceramic networks);

- 7.

- In vitro studies investigating color stability of CAD/CAM materials for temporary restorations;

- 8.

- Clinical trials, case reports, reviews, or animal studies;

- 9.

- Papers analyzing color stability only with water aging/thermocycling procedures;

- 10.

- Papers analyzing color stability with whitening procedures;

- 11.

- Papers analyzing color stability with mouth rinses;

- 12.

- Papers analyzing color stability with smoking procedures;

2.2. Information Sources

One reviewer (GP) conducted a search for English language articles published in dental journals until 18 September 2022 in the following electronic databases: PubMed, Embase, Web of Science, Scopus. A manual search was also conducted.

2.3. Search Strategy

Searches used a combination of MeSH terms and free text words, as follows: ‘polymer infiltrated’, ‘polymer-based’, ‘resin nano-ceramic’, ‘resin ceramic’ ‘hybrid composite’, ‘hybrid ceramic’, ‘composite ceramic’, ‘resin infiltrated’, ‘composite’, ‘nano-hybrid’, ‘CAD-CAM’, ‘CAD/CAM’, ‘color stability’, ‘staining’, ‘staining susceptibility’, ‘color change’, ‘color difference’. All strategies were based on the search strategy developed for PubMed (Table 1) and were appropriately revised for each database to account for differences in controlled vocabulary and syntax rules.

Table 1.

Search conducted in Medline/PubMed database.

2.4. Selection Process

For the selection of studies, two authors (G.P. and M.M.) independently reviewed titles and abstracts of the studies according to the inclusion criteria. Final inclusion of studies was based on screening and assessing full texts, and with consensus of the authors of the current review.

2.5. Data Items

An extraction form was used to collect retrieved data items: type of CCB, comparison with other materials, staining liquids, staining protocol, time of color assessment, type of spectrophotometer, color difference formula, specimens finished, specimen repolished, clinical thresholds, outcomes.

2.6. Study Risk of Bias Assessment

The risk of bias assessment used the QUIN tool (risk-of-bias tool for assessing in vitro studies conducted in dentistry) [34]. The study’s quality assessment was conducted according to a fixed set of domains of bias (Clearly stated aims/objectives; Detailed explanation of sample size calculation; Detailed explanation of sampling technique; Details of comparison group; Detailed explanation of methodology; Operator details; Randomization; Method of measurement of outcome; Outcome assessor details; Blinding Statistical analysis; Presentation of results). QUIN final assessment was performed by categorizing each of the study features at ‘low’, ‘medium’, or ‘high’ risk of bias. Both reviewers (G.P. and F.D.P.) independently conducted the assessment, and any uncertainties or disagreements were then resolved by discussion.

3. Results

3.1. Study Selection and Study Characteristics

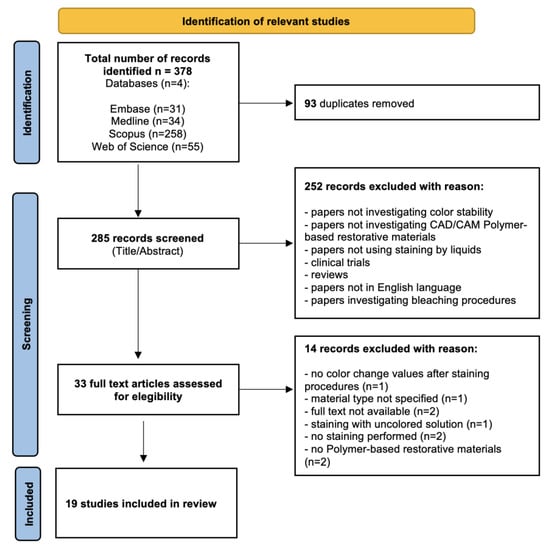

The study selection process according to the PRISMA checklist is reported in Figure 1.

Figure 1.

Identification of relevant studies.

A total of 378 studies were identified through the initial database search. Following duplicates removal, 285 records were screened by title and abstract. During the screening process, 252 records were excluded as not relevant to the subject, and 33 were selected for full-text assessment. Finally, 19 studies were included in this systematic review as they met the inclusion criteria.

3.2. Composite Block Specimen Characteristics

Among the identified studies, 17 (n = 17) composite blocks were investigated. Composition of these materials is listed in Table 2. The most studied CCB (n = 12) was Lava Ultimate (3M Espe, St. Paul, MN, USA), followed by Cerasmart (GC, Bunkyo-ku, Tokyo, Japan) (n = 5).

Table 2.

Composition of CCBs investigated by papers included in current review.

Data from the retrieved papers were chronologically reported in two predefined data extraction forms (Table 3 and Table 4).

Table 3.

List of the in vitro studies included in the review after the screening process. CCB: CAD/CAM composite block; TC: thermocycling. (1: TC= thermocycling; 2: ∆E00= color change obtained with CIEDE2000 formula; 3: PICN= polymer infiltrated ceramic network; 4: ∆E= color change value obtained with CIELAB formula.).

Table 4.

Color change of CAD/CAM composite blocks investigated by the papers included in the current review. (1: ∆E00 = color change obtained with CIEDE2000 formula; 2: ∆E= color change value obtained with CIELAB formula).

3.3. Artificial Staining Procedures

Artificial staining procedures were different among the retrieved studies. The staining solutions used were coffee (n = 15), red wine (n = 9), cola (n = 7), tea (n = 5), ginger (n = 2), and juice (n = 2). Specimens were immersed in the staining media for different time periods that ranged from 2 days to 12 weeks. Most of the studies renewed liquids at different intervals. The immersion was static and ran from some minutes per day to continuous immersion for the entire staining periods. Most of the studies kept the liquid temperature stable at 37°C (n = 13). For other studies, the liquids were kept at room temperature (n = 2) or thermocycled (n = 2). In two studies, information on storage temperature was not reported.

3.4. Color Assessment

Seventeen studies out of the nineteen examined used a spectrophotometer to assess color change, while two used a spectroradiometer. Among the spectrophotometers, the most used (n = 8) was EasyShade (Vita Zahnfabrik, Bad Säckingen, Germany). In ten papers, the CIEDE2000 color difference formula was used, while in seven the CIELAB formula was used. In only two studies were both formulas used. Seventeen papers compared the color stability of CCB with other materials, while two compared different CCBs.

3.5. Surface Treatment

Sixteen of the retrieved studies performed surface finishing and polishing before staining procedures. These procedures were fairly uniform among the studies because fourteen out of sixteen used silicon carbide abrasive papers (and twelve with 1200 grit as a final step) and two used abrasive disks. Only one paper performed a repolishing step after the staining procedure.

3.6. Clinical Thresholds and Comparison with Other Materials

CCBs showed color change beyond clinically acceptable thresholds in all studies except for one [15]. When compared with other materials, CCBs immersed in coffee solutions showed a significantly higher color change than lithium disilicate [13,15,19,28,35,36,37], zirconia-reinforced lithium silicate [15,22], hybrid ceramic [17,18,19,21,35,36,37], and feldspatic ceramic [13,26,37]. CCBs immersed in red wine showed a significantly higher color change than zirconia-reinforced lithium silicate [13,19,22,38], hybrid ceramic [14], and feldspatic ceramic [13,24]. Conversely, CCBs showed higher color stability when compared with hybrid resin composites for direct restorations [12,28].

3.7. Qualitative Assessment of the Investigations

The Quality Assessment Tool For In Vitro Studies (QUIN Tool) was used to evaluate in vitro papers included in this review (Table 5). A high risk of bias could be found in all RCTs except for one [36] regarding blinding, mostly owing to the fact that blinding of participants and personnel was not applied or declared. Randomization was clearly stated in only five investigations [15,19,27,28,36]. Eleven studies reported complete information regarding sample size calculations [12,14,16,19,24,25,26,28,36,37,38], eight regarding sampling technique [12,15,16,25,27,28,37,38], and two regarding the comparison (control) group [28,36].

Table 5.

Risk of Bias.

4. Discussion

In recent years, the request for esthetic dental restorations has considerably increased. Today, RBCs are the most widely used materials for direct and for indirect restorative procedures because of their excellent esthetic and mechanical properties [39,40].

CCBs are claimed to provide better mechanical and optical properties than their traditional direct and indirect resin counterparts thanks to the benefits of the industrial production processes [12]. Amid other advantages, they are claimed to reduce one of the primary drawbacks of direct and indirect RBCs, which is color stability. This can compromise the esthetic outcomes of the restorations over time [41]. Despite their increasing use, very little is known on the color changes of CCBs. Therefore, the purpose of this review was to evaluate the color stability of CCBs.

4.1. Type of Material

Regarding the examined materials, Lava Ultimate was the most investigated, followed by Cerasmart. Acar et al. [35] reported that Lava Ultimate, after 5,000 thermocycles in coffee, showed color change values higher than the clinical acceptability threshold when compared to lithium disilicate and polymer-infiltrated ceramic network (Enamic). This result, despite the paper presenting a high risk of bias, could be related to the composition of the material: Lava Ultimate consists of a hydrophobic urethane-dimethacrylate (UDMA) and a hydrophilic triethylene-glycol-dimethacrylate (TEGDMA). TEGDMA is generally added to the composition of RBCs because it is more viscous than bisphenol-glycidyl-methacrylate (Bis-GMA) and permits copolymerization, diluting Bis-GMA and increasing composite sculptability. TEGDMA, however, increases the hydrophilicity of the composite, resulting in an increased susceptibility to staining [42,43].

Lava Ultimate contains Bis-GMA and its ethoxylated form (Bis-EMA). Dental materials containing Bis-GMA show the highest degree of water sorption and, therefore, liquid dyes, when compared with those based on UDMA, TEGDMA, and BisEMA [44].

Al Amri et al. [36], Eldwakhly et al. [15], and Schürmann and Olms [17] confirmed Lava Ultimate’s lower color stability when compared to ceramic materials. Furthermore, these papers show low or medium risk of bias; therefore, their findings could be considered reliable.

Three papers included in this review compared Lava Ultimate with Cerasmart. Two of them showed significant higher color stability for Cerasmart [14,19], while the third, with a lower risk of bias, reported no significant differences [36]. The higher Cerasmart color stability may be related to the absence of Bis-GMA in its composition, thus confirming that this monomer is responsible for water uptake and, therefore, possibly for discoloration.

4.2. Spectrophotometric Analysis and Clinical Thresholds

Spectrophotometric analysis allows for an objective color comparison. Color coordinates are measured, and differences are compared by CIELAB or CIEDE2000 formulas, which are the most frequently used to analyze color changes [45]. The Perceptibility Threshold (PT) refers to the magnitude of color difference that is visually detectable by the human eye, while the Acceptability Threshold (AT) corresponds to the magnitude of color difference that is considered clinically not acceptable [46]. The CIEDE2000 color difference formula [47] is considered to be a better indicator of human capability to detect perceptible and acceptable color differences, and was used by the majority of the papers (10 out of 19) included in this review. Differences detected by spectrophotometers can be evaluated from a statistical point of view or by utilizing the PT or AT. The statistical outcome of color measurements should always be integrated with PT and AT to validate clinical consistency. For this reason, papers that did not take into consideration clinical thresholds [46] for the interpretation of the results were not included in the current review. The most frequently used instrument used for color measurements was the spectrophotometer. Among the spectrophotometers, Easyshade (Vita Zahnfabrik) was the most widely used. This type of spectrophotometer is designed to be a clinical device (working in “tooth mode”) and it is not recommended for in vitro testing. The results of studies performed with such a device should be cautiously evaluated, and a bench-top spectrophotometer should be preferred [48].

4.3. Staining Solution

The level of CCB color change, as with conventional RBCs, is closely related to the type of staining solution [49,50]. Depending on the staining liquid used to evaluate color stability, colorants can deposit either on the surface [51] or in the structure [52] of the tested material, or the liquid can induce staining, altering the surface because of low pH [49,50]. Probably due to its increased use among the population, coffee is the most investigated staining media in the papers evaluated in this review. Coffee induces staining through a yellow coloring pigment that is characterized by different polarities [30,53]. Red wine, the second most used solution in this review, has staining capability and contains alcohol that may lead to rough surfaces and, consequently, pigment adsorption [49,50,54]. It has also been reported that ethanol, contained in red wine, has a solvent effect on the monomers, increasing potential discoloration [55,56]. Other dyes investigated in the paper analyzed in the current review, such as tea, cola, energy drink, and juices, are responsible for CCB color changes, but to a lower degree compared to coffee and wine, generally below AT.

4.4. Effects of Surface Treatment on Discoloration

Some of the included studies investigated the effects of surface treatments on color stability of CCBs submitted to staining with colored dyes. Unlike conventional hybrid composites used in direct procedures, CCBs are not characterized by a surface-resin-rich layer, which could be responsible for higher color changes if not removed by finishing and polishing procedures [41]. However, it has been reported that after milling, finishing and polishing CCBs may reduce surface roughness and, therefore, staining [57]. Aydin et al. [23] reported that polishing a specimen’s surface produced a lower color change when compared with a control group (unpolished). However, both groups exceeded the AT, confirming that clinical thresholds should always be referenced for a correct data interpretation. Sagsoz et al. [20] also confirmed that polishing is crucial for all materials, as differences were observed between polished and unpolished specimens. Moreover, the authors reported significant differences in color stability when different finishing and polishing systems were used, suggesting that each material requires a specific finishing/polishing system for optimal performance.

5. Conclusions

Based on the findings of this systematic review, and considering the risk of bias, the following conclusion can be drawn:

- Resin-based blocks for CAD/CAM procedures show higher color stability than direct or indirect (laboratory) RBCs;

- Resin-based blocks for CAD/CAM procedures show lower color stability than ceramic materials;

- The color stability of CCBs mainly depends on material composition and staining media, but finishing/polishing procedures also have an influence.

Author Contributions

Conceptualization, G.P. and M.M.; methodology, M.M. and F.D.P.; software, M.M. and F.D.P.; validation, A.V., N.S. and G.C.; formal analysis, G.P.; investigation, M.M. and F.D.P.; resources, M.M. and F.D.P.; data curation, M.M. and F.D.P.; writing—original draft preparation, G.P. and M.M.; writing—review and editing, L.B. and A.V.; visualization, C.M. and E.G.; supervision, N.S. and A.V. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Duret, F.; Blouin, J.L.; Duret, B. CAD-CAM in Dentistry. J. Am. Dent. Assoc. 1988, 117, 715–720. [Google Scholar] [CrossRef]

- Mörmann, W.H.; Brandestini, M.; Lutz, F.; Barbakow, F. Chairside Computer-Aided Direct Ceramic Inlays. Quintessence Int. 1989, 20, 329–339. [Google Scholar] [PubMed]

- Fasbinder, D.J. Clinical Performance of Chairside CAD/CAM Restorations. J. Am. Dent. Assoc. 2006, 137, 22S–31S. [Google Scholar] [CrossRef]

- Baldi, A.; Comba, A.; Tempesta, R.M.; Carossa, M.; Pereira, G.K.R.; Valandro, L.F.; Paolone, G.; Vichi, A.; Goracci, C.; Scotti, N. External Marginal Gap Variation and Residual Fracture Resistance of Composite and Lithium-Silicate CAD/CAM Overlays after Cyclic Fatigue over Endodontically-Treated Molars. Polymers 2021, 13, 3002. [Google Scholar] [CrossRef] [PubMed]

- Baldi, A.; Comba, A.; Ferrero, G.; Italia, E.; Michelotto Tempesta, R.; Paolone, G.; Mazzoni, A.; Breschi, L.; Scotti, N. External Gap Progression after Cyclic Fatigue of Adhesive Overlays and Crowns Made with High Translucency Zirconia or Lithium Silicate. J. Esthet. Restor. Dent. 2022, 34, 557–564. [Google Scholar] [CrossRef] [PubMed]

- Comba, A.; Paolone, G.; Baldi, A.; Vichi, A.; Goracci, C.; Bertozzi, G.; Scotti, N. Effects of Substrate and Cement Shade on the Translucency and Color of CAD/CAM Lithium-Disilicate and Zirconia Ceramic Materials. Polymers 2022, 14, 1778. [Google Scholar] [CrossRef] [PubMed]

- Manauta, J.; Salat, A.; Putignano, A.; Devoto, W.; Paolone, G.; Hardan, L.S. Stratification in Anterior Teeth Using One Dentine Shade and a Predefined Thickness of Enamel: A New Concept in Composite Layering–Part II. Odontostomatol. Trop. 2014, 37, 5–13. [Google Scholar]

- Manauta, J.; Salat, A.; Putignano, A.; Devoto, W.; Paolone, G.; Hardan, L.S. Stratification in Anterior Teeth Using One Dentine Shade and a Predefined Thickness of Enamel: A New Concept in Composite Layering–Part I. Odontostomatol. Trop. 2014, 37, 5–16. [Google Scholar]

- Scolavino, S.; Paolone, G.; Orsini, G.; Devoto, W.; Putignano, A. The Simultaneous Modeling Technique: Closing Gaps in Posteriors. Int. J. Esthet. Dent. 2016, 11, 58–81. [Google Scholar]

- Ferracane, J.L. Hygroscopic and Hydrolytic Effects in Dental Polymer Networks. Dent. Mater. 2006, 22, 211–222. [Google Scholar] [CrossRef]

- Angeletaki, F.; Gkogkos, A.; Papazoglou, E.; Kloukos, D. Direct versus Indirect Inlay/Onlay Composite Restorations in Posterior Teeth. A Systematic Review and Meta-Analysis. J. Dent. 2016, 53, 12–21. [Google Scholar] [CrossRef] [PubMed]

- Quek, S.H.Q.; Yap, A.U.J.; Rosa, V.; Tan, K.B.C.; Teoh, K.H. Effect of Staining Beverages on Color and Translucency of CAD/CAM Composites. J. Esthet. Restor. Dent. 2018, 30, E9–E17. [Google Scholar] [CrossRef] [PubMed]

- Kocak, E.; Ekren, O.; Johnston, W.; Ucar, Y. Analysis of Color Differences in Stained Contemporary Esthetic Dental Materials. J. Prosthet. Dent. 2021, 126, 438–445. [Google Scholar] [CrossRef]

- Barutçugil, Ç.; Bilgili, D.; Barutcigil, K.; Dündar, A.; Büyükkaplan, U.Ş.; Yilmaz, B. Discoloration and Translucency Changes of CAD-CAM Materials after Exposure to Beverages. J. Prosthet. Dent. 2019, 122, 325–331. [Google Scholar] [CrossRef] [PubMed]

- Eldwakhly, E.; Ahmed, D.R.M.; Soliman, M.; Abbas, M.M.; Badrawy, W. Color and Translucency Stability of Novel Restorative CAD/CAM Materials. Dent. Med. Probl. 2019, 56, 349–356. [Google Scholar] [CrossRef]

- Sarikaya, I.; Yerliyurt, K.; Hayran, Y. Effect of Surface Finishing on the Colour Stability and Translucency of Dental Ceramics. BMC Oral Health 2018, 18, 40. [Google Scholar] [CrossRef]

- Schurmann, M.; Olms, C. Shade Stability of Polymer-Infiltrated and Resin Nano Ceramics. Open Dent. J. 2018, 12, 791–800. [Google Scholar] [CrossRef]

- Schurmann, M.; Olms, C. Shade Stability of Polymer Infiltrated and Resin Nano Ceramic Crowns after Dynamic Chewing Simulation. Eur. J. Prosthodont. Restor. Dent. 2018, 26, 174–183. [Google Scholar] [CrossRef] [PubMed]

- Stamenković, D.D.; Tango, R.N.; Todorović, A.; Karasan, D.; Sailer, I.; Paravina, R.D. Staining and Aging-Dependent Changes in Color of CAD-CAM Materials. J. Prosthet. Dent. 2021, 126, 672–678. [Google Scholar] [CrossRef]

- Sagsoz, O.; Demirci, T.; Demirci, G.; Sagsoz, N.P.; Yildiz, M. The Effects of Different Polishing Techniques on the Staining Resistance of CAD/CAM Resinceramics. J. Adv. Prosthodont. 2016, 8, 417–422. [Google Scholar] [CrossRef]

- Comba, A.; Baldi, A.; Carossa, M.; Michelotto, T.R.; Garino, E.; Llubani, X.; Rozzi, D.; Mikonis, J.; Paolone, G.; Scotti, N. Post-Fatigue Fracture Resistance of Lithium Disilicate and Polymer-Infiltrated Ceramic Network Indirect Restorations over Endodontically-Treated Molars with Different Preparation Designs: An In-Vitro Study. Polymers 2022, 23, 5084. [Google Scholar] [CrossRef]

- Aydın, N.; Karaoğlanoğlu, S.; Oktay, E.A.; Kılıçarslan, M.A. Investigating the Color Changes on Resin-Based CAD/CAM Blocks. J. Esthet. Restor. Dent. 2020, 32, 251–256. [Google Scholar] [CrossRef]

- Aydin, N.; Karaoglanoglu, S.; Oktay, E.; Ersoz, B. Superficial Effects of Different Finishing and Polishing Systems on the Surface Roughness and Color Change of Resin-Based CAD/CAM Blocks. Odovtos Int. J. Dent. Sci. 2021, 23, 87–97. [Google Scholar] [CrossRef]

- Dalforno, R.F.; Auzani, M.L.; Zucuni, C.P.; da Silva Rodrigues, C.; May, L.G. Color and Translucency Stability of CAD/CAM Restorative Materials. Braz. J. Oral Sci. 2022, 21, e224265. [Google Scholar] [CrossRef]

- Elsaka, S.; Taibah, S.; Elnaghy, A. Effect of Staining Beverages and Bleaching on Optical Properties of a CAD/CAM Nanohybrid and Nanoceramic Restorative Material. BMC Oral Health 2022, 22, 96. [Google Scholar] [CrossRef]

- Jalali, H.; Mostafavi, A.; Balaghi, F. The Effect of Coloring Beverages on Color Stability of Hybrid Ceramics with Different Surface Treatments. Pesqui. Bras. Em Odontopediatria E Clin. Integr. 2022, 22, 1–11. [Google Scholar] [CrossRef]

- Kang, Y.-A.; Lee, H.-A.; Chang, J.; Moon, W.; Chung, S.H.; Lim, B.-S. Color Stability of Dental Reinforced CAD/CAM Hybrid Composite Blocks Compared to Regular Blocks. Materials 2020, 13, 4722. [Google Scholar] [CrossRef] [PubMed]

- Silva, A.; Geng-Vivanco, R.; Tonani-Torrieri, R.; Pires-de-Souza, F. Stain Resistance and Surface Roughness of CAD/CAM Processed Hybrid Ceramic. Color Res. Appl. 2021, 46, 901–908. [Google Scholar] [CrossRef]

- Vichi, A.; Goracci, C.; Carrabba, M.; Tozzi, G.; Louca, C. Flexural Resistance of CAD-CAM Blocks. Part 3: Polymer-Based Restorative Materials for Permanent Restorations. Am. J. Dent. 2020, 33, 243–247. [Google Scholar]

- Barutcigil, Ç.; Yıldız, M. Intrinsic and Extrinsic Discoloration of Dimethacrylate and Silorane Based Composites. J. Dent. 2012, 40 (Suppl. S1), e57–e63. [Google Scholar] [CrossRef]

- Barutcigil, Ç.; Barutcigil, K.; Özarslan, M.M.; Dündar, A.; Yilmaz, B. Color of Bulk-Fill Composite Resin Restorative Materials. J. Esthet. Restor. Dent. 2018, 30, E3–E8. [Google Scholar] [CrossRef] [PubMed]

- Paolone, G.; Pavan, F.; Guglielmi, P.C.; Scotti, N.; Cantatore, G.; Vichi, A. In Vitro Procedures for Color Stability Evaluation of Dental Resin-Based Composites Exposed to Smoke: A Scoping Review. Dent. Mater J. 2022. [Google Scholar] [CrossRef] [PubMed]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef] [PubMed]

- Sheth, V.H.; Shah, N.P.; Jain, R.; Bhanushali, N.; Bhatnagar, V. Development and Validation of a Risk-of-Bias Tool for Assessing in Vitro Studies Conducted in Dentistry: The QUIN. J. Prosthet. Dent. 2022, june, 1–5. [Google Scholar] [CrossRef]

- Acar, O.; Yilmaz, B.; Altintas, S.H.; Chandrasekaran, I.; Johnston, W.M. Color Stainability of CAD/CAM and Nanocomposite Resin Materials. J. Prosthet. Dent. 2016, 115, 71–75. [Google Scholar] [CrossRef] [PubMed]

- Al Amri, M.D.; Labban, N.; Alhijji, S.; Alamri, H.; Iskandar, M.; Platt, J.A. In Vitro Evaluation of Translucency and Color Stability of CAD/CAM Polymer-Infiltrated Ceramic Materials after Accelerated Aging. J. Prosthodont. 2021, 30, 318–328. [Google Scholar] [CrossRef]

- Lawson, N.C.; Burgess, J.O. Gloss and Stain Resistance of Ceramic-Polymer CAD/CAM Restorative Blocks. J. Esthet. Restor. Dent. 2016, 28, S40–S45. [Google Scholar] [CrossRef] [PubMed]

- Seyidaliyeva, A.; Rues, S.; Evagorou, Z.; Hassel, A.J.; Rammelsberg, P.; Zenthöfer, A. Color Stability of Polymer-Infiltrated-Ceramics Compared with Lithium Disilicate Ceramics and Composite. J. Esthet. Restor. Dent. 2020, 32, 43–50. [Google Scholar] [CrossRef] [PubMed]

- Demarco, F.F.; Collares, K.; Coelho-de-Souza, F.H.; Correa, M.B.; Cenci, M.S.; Moraes, R.R.; Opdam, N.J.M. Anterior Composite Restorations: A Systematic Review on Long-Term Survival and Reasons for Failure. Dent. Mater. 2015, 31, 1214–1224. [Google Scholar] [CrossRef] [PubMed]

- Paolone, G. Direct Composite Restorations in Anterior Teeth. Managing Symmetry in Central Incisors. Int. J. Esthet. Dent. 2014, 9, 12–25. [Google Scholar]

- Paolone, G.; Formiga, S.; De Palma, F.; Abbruzzese, L.; Chirico, L.; Scolavino, S.; Goracci, C.; Cantatore, G.; Vichi, A. Color Stability of Resin-Based Composites: Staining Procedures with Liquids-A Narrative Review. J. Esthet. Restor. Dent. 2022, 34, 865–887. [Google Scholar] [CrossRef]

- Kalachandra, S.; Turner, D.T. Water Sorption of Polymethacrylate Networks: Bis-GMA/TEGDM Copolymers. J. Biomed. Mater. Res. 1987, 21, 329–338. [Google Scholar] [CrossRef] [PubMed]

- Ren, Y.-F.; Feng, L.; Serban, D.; Malmstrom, H.S. Effects of Common Beverage Colorants on Color Stability of Dental Composite Resins: The Utility of a Thermocycling Stain Challenge Model in Vitro. J. Dent. 2012, 40 (Suppl. S1), e48–e56. [Google Scholar] [CrossRef]

- Gajewski, V.E.S.; Pfeifer, C.S.; Fróes-Salgado, N.R.G.; Boaro, L.C.C.; Braga, R.R. Monomers Used in Resin Composites: Degree of Conversion, Mechanical Properties and Water Sorption/Solubility. Braz. Dent. J. 2012, 23, 508–514. [Google Scholar] [CrossRef] [PubMed]

- Paravina, R.D.; Ghinea, R.; Herrera, L.J.; Bona, A.D.; Igiel, C.; Linninger, M.; Sakai, M.; Takahashi, H.; Tashkandi, E.; Del Mar Perez, M. Color Difference Thresholds in Dentistry. J. Esthet. Restor. Dent. 2015, 27, S1–S9. [Google Scholar] [CrossRef]

- Paravina, R.D.; Pérez, M.M.; Ghinea, R. Acceptability and Perceptibility Thresholds in Dentistry: A Comprehensive Review of Clinical and Research Applications. J. Esthet. Restor. Dent. 2019, 31, 103–112. [Google Scholar] [CrossRef] [PubMed]

- Luo, M.R.; Cui, G.; Rigg, B. The Development of the CIE 2000 Colour-Difference Formula: CIEDE2000. Color Res. Appl. 2001, 26, 340–350. [Google Scholar] [CrossRef]

- Akl, M.A.; Sim, C.P.C.; Nunn, M.E.; Zeng, L.L.; Hamza, T.A.; Wee, A.G. Validation of Two Clinical Color Measuring Instruments for Use in Dental Research. J. Dent. 2022, 125, 104223. [Google Scholar] [CrossRef]

- Topcu, F.T.; Sahinkesen, G.; Yamanel, K.; Erdemir, U.; Oktay, E.A.; Ersahan, S. Influence of Different Drinks on the Colour Stability of Dental Resin Composites. Eur. J. Dent. 2009, 3, 50–56. [Google Scholar] [CrossRef]

- Malekipour, M.R.; Sharafi, A.; Kazemi, S.; Khazaei, S.; Shirani, F. Comparison of Color Stability of a Composite Resin in Different Color Media. Dent. Res. J. 2012, 9, 441–446. [Google Scholar]

- de Anfe, T.E.A.; Agra, C.M.; Vieira, G.F. Evaluation of the Possibility of Removing Staining by Repolishing Composite Resins Submitted to Artificial Aging. J. Esthet. Restor. Dent. 2011, 23, 260–267. [Google Scholar] [CrossRef]

- Erdemir, U.; Kaner, A.O.; Eren, M.M.; Ozan, G.; Yıldız, E. Color Stability of Bulk-Fill Composites Immersed in Different Drinks. Color Res. Appl. 2018, 43, 785–793. [Google Scholar] [CrossRef]

- Um, C.M.; Ruyter, I.E. Staining of Resin-Based Veneering Materials with Coffee and Tea. Quintessence Int. 1991, 22, 377–386. [Google Scholar]

- Ertaş, E.; Güler, A.U.; Yücel, A.C.; Köprülü, H.; Güler, E. Color Stability of Resin Composites after Immersion in Different Drinks. Dent. Mater. J. 2006, 25, 371–376. [Google Scholar] [CrossRef] [PubMed]

- Llena, C.; Fernández, S.; Forner, L. Color Stability of Nanohybrid Resin-Based Composites, Ormocers and Compomers. Clin. Oral. Investig. 2017, 21, 1071–1077. [Google Scholar] [CrossRef]

- Manojlovic, D.; Lenhardt, L.; Milićević, B.; Antonov, M.; Miletic, V.; Dramićanin, M.D. Evaluation of Staining-Dependent Colour Changes in Resin Composites Using Principal Component Analysis. Sci. Rep. 2015, 5, 14638. [Google Scholar] [CrossRef] [PubMed]

- Fasbinder, D.J.; Neiva, G.F. Surface Evaluation of Polishing Techniques for New Resilient CAD/CAM Restorative Materials. J. Esthet. Restor. Dent. 2016, 28, 56–66. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).