Wettability and Frictional Studies of PEEK Composites against Co-Cr Alloys with Surface Textures

Abstract

:1. Introduction

2. Materials and Methods

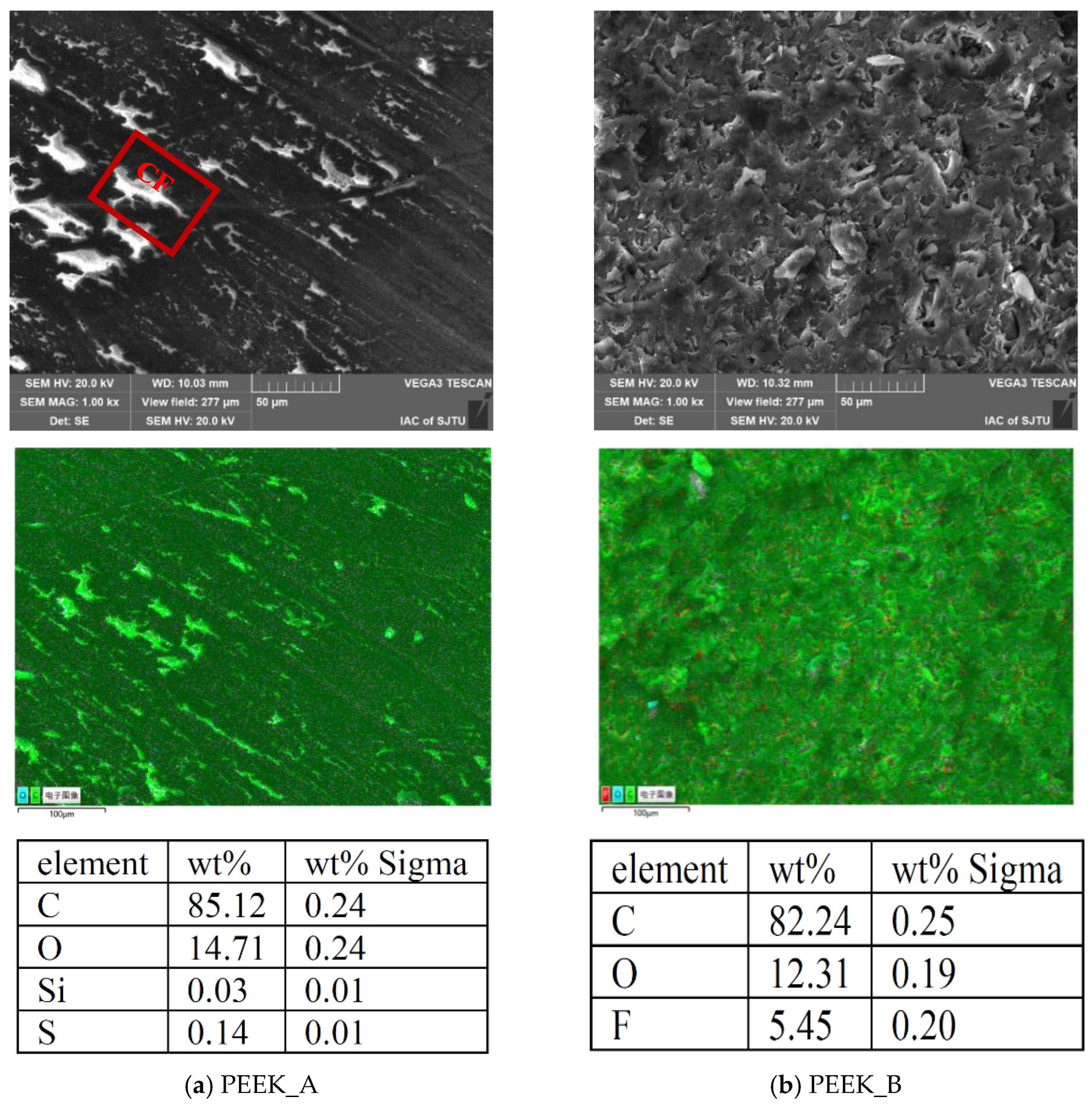

2.1. Materials of PEEK Blend Pin and Co-Cr Alloy Disc

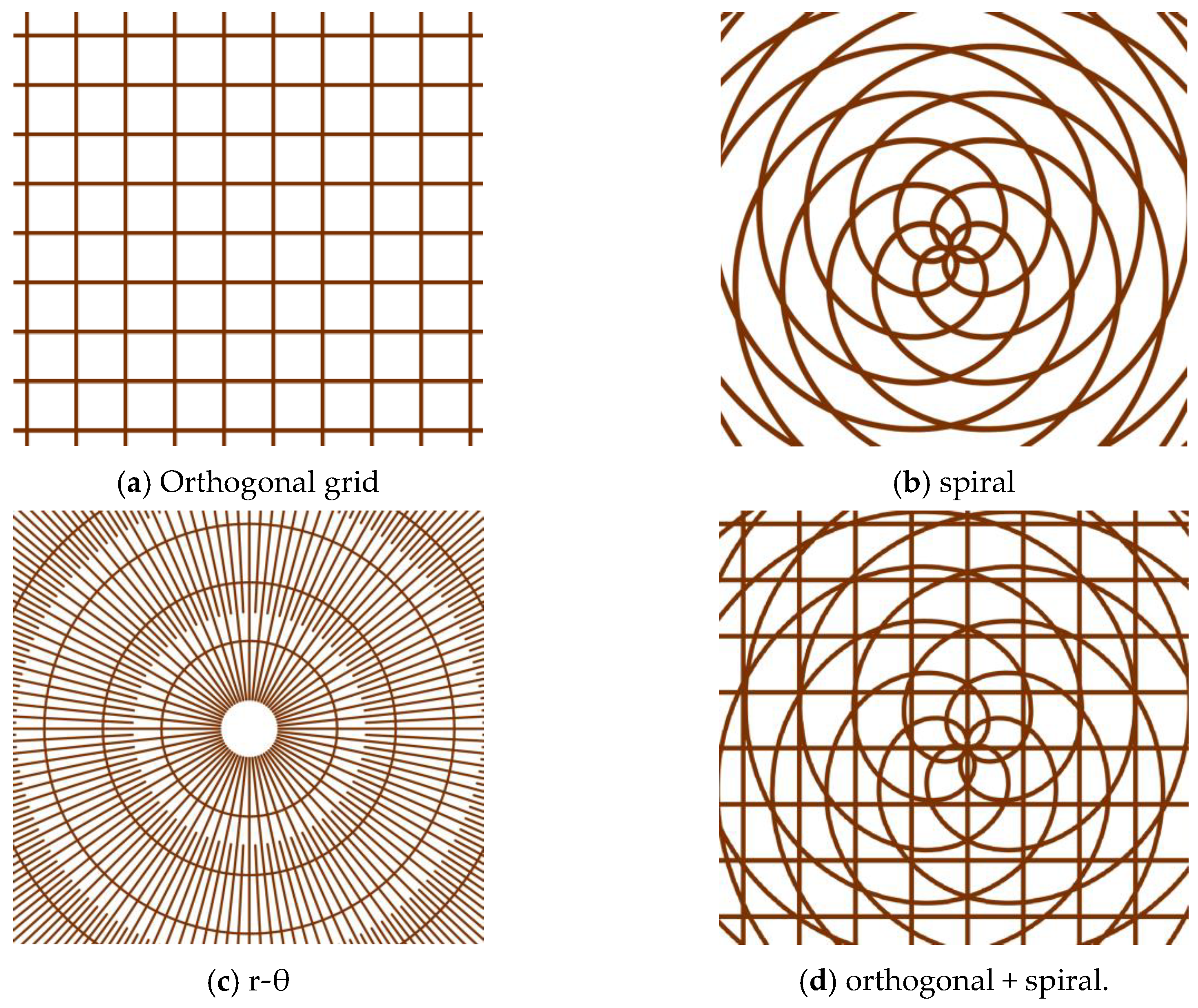

2.2. Femtosecond Laser Processing on Disc Surfaces with Single and Multiple Patterns

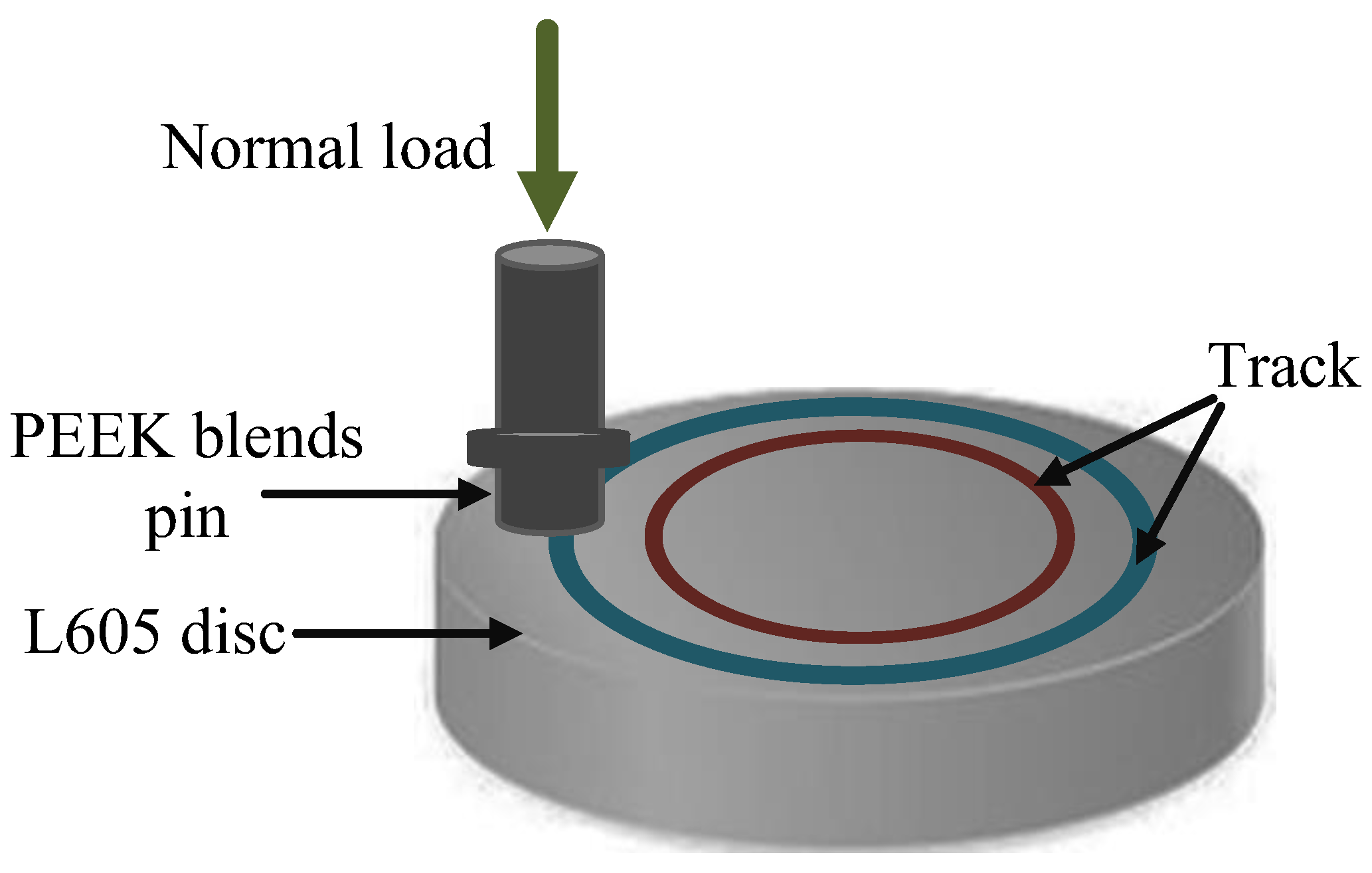

2.3. Dry Friction Experiments

2.4. Wear Characteristics of PEEK Blends

3. Results and Discussion

3.1. Topographic Characteristics of Laser-Textured Surfaces on Discs

3.2. Wettability of PEEK Blend Pins and Co-Cr Alloy Discs

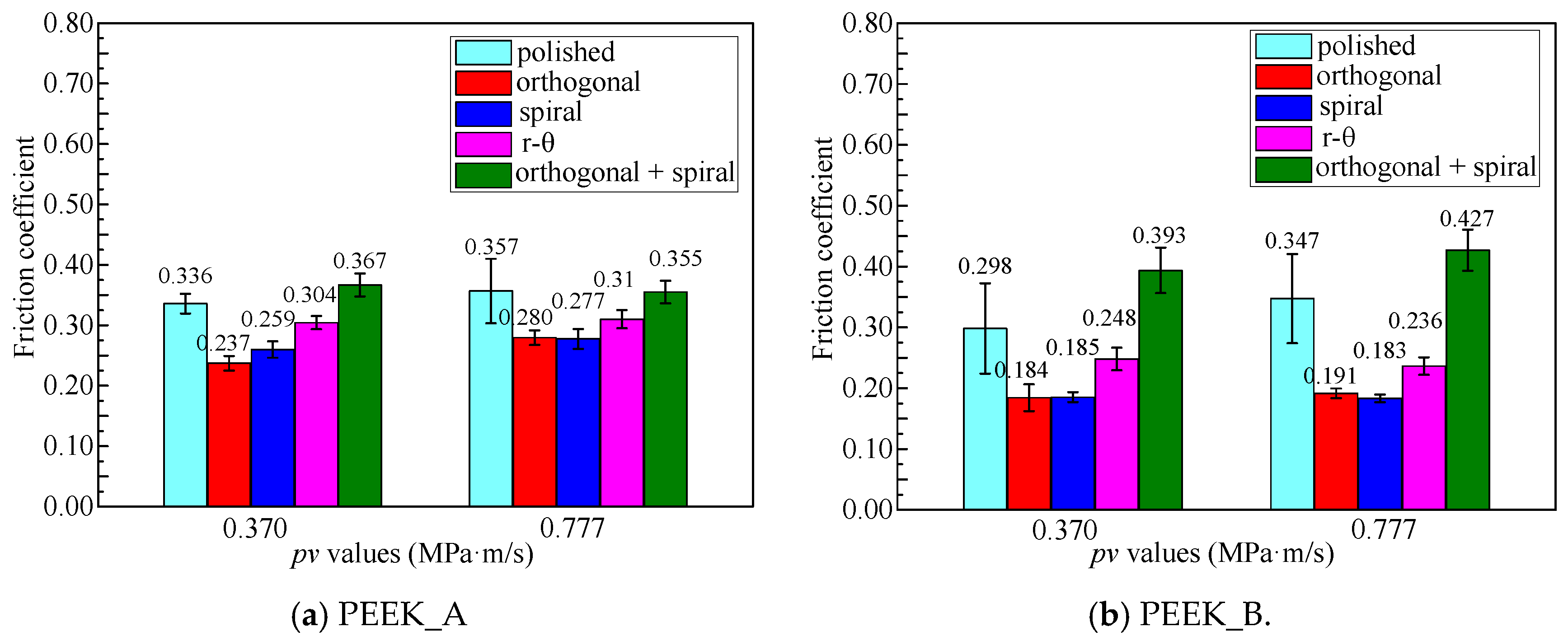

3.3. Effects of Textured Surfaces on Frictional Properties

3.4. Wear Rate of PEEK Blends against Co-Cr Alloy Discs

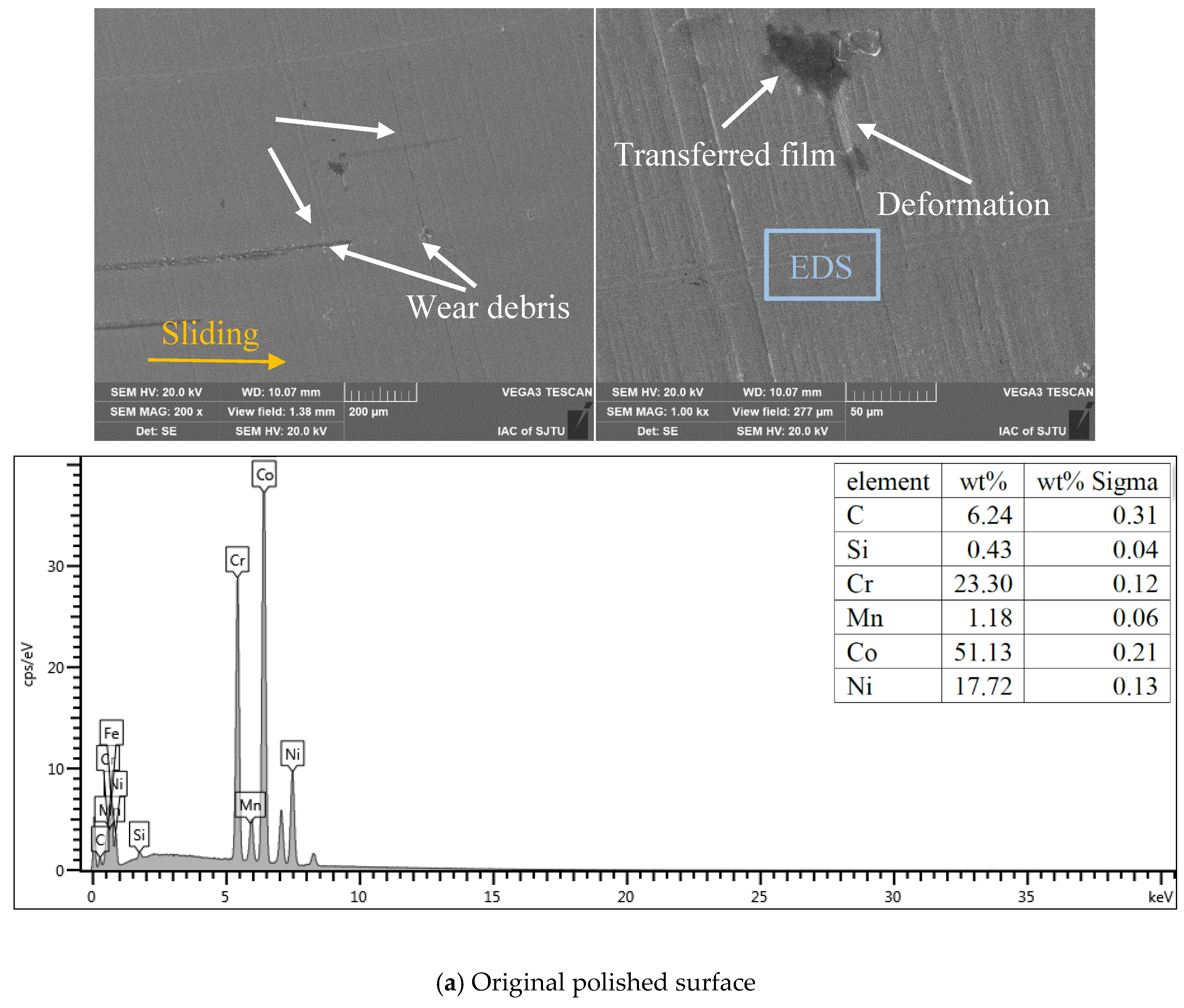

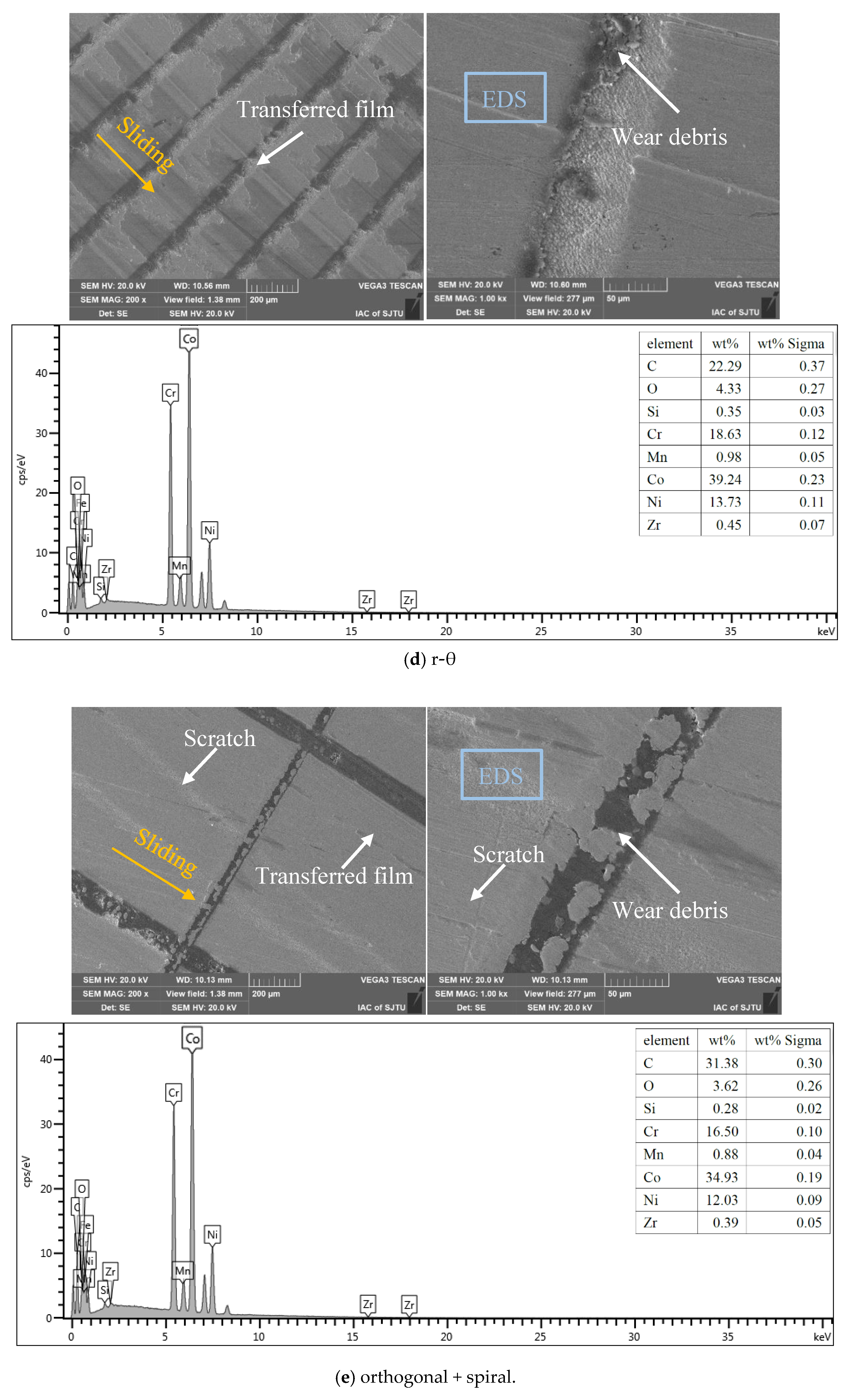

3.5. Effects of Textural Morphology and Transferred Film

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liao, Y.; Cao, L.; Wang, Q.; Li, S.; Lin, Z.; Li, W.; Zhang, P.; Yu, C. Enhanced tribological properties of PEEK-based composite coatings reinforced by PTFE and graphite. J. Appl. Polym. Sci. 2021, 139, 51878. [Google Scholar] [CrossRef]

- Díaz, C.; Fuentes, G. Tribological studies comparison between UHMWPE and PEEK for prosthesis application. Surf. Coat. Technol. 2017, 325, 656–660. [Google Scholar] [CrossRef]

- Özmen, Y. Si3N4 as a biomaterial and its tribo-characterization under water lubrication. Lubr. Sci. 2016, 28, 243–254. [Google Scholar] [CrossRef]

- Li, X.; Guo, Z.; Huang, Q.; Yuan, C. Application of Bionic Tribology in Water-Lubricated Bearing: A Review. J. Bionic Eng. 2022, 19, 902–934. [Google Scholar] [CrossRef]

- Sharma, S.K.; Grewal, H.S. Tribological Behavior of Bioinspired Surfaces. Biomimetics 2023, 8, 62. [Google Scholar] [CrossRef]

- Hariharan, G.; Krishnamachary, P.C.; Binoj, J.S.; Mansingh, B.B. Influence of SiC Nanoparticles Reinforcement in Areca/Tamarind Hybrid Biopolymer Composites: Thermo-mechanical, Tribological and Morphological Features. J. Bionic Eng. 2023, 20, 1723–1736. [Google Scholar] [CrossRef]

- Lu, Y. Fabrication of a lotus leaf-like hierarchical structure to induce an air lubricant for drag reduction. Surf. Coat. Technol. 2017, 331, 48–56. [Google Scholar] [CrossRef]

- Li, X.; Deng, J.; Lu, Y.; Zhang, L.; Sun, J.; Wu, F. Tribological behavior of ZrO2/WS2 coating surfaces with biomimetic shark-skin structure. Ceram. Int. 2019, 45, 21759–21767. [Google Scholar] [CrossRef]

- Brinksmeier, E.; Karpuschewski, B.; Yan, J.; Schönemann, L. Manufacturing of multiscale structured surfaces. CIRP Ann. 2020, 69, 717–739. [Google Scholar] [CrossRef]

- Vishnoi, M.; Kumar, P.; Murtaza, Q. Surface texturing techniques to enhance tribological performance: A review. Surf. Interfaces 2021, 27, 101463. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Costa, H.L.; Baykara, M.Z.; Martini, A. Synergetic effects of surface texturing and solid lubricants to tailor friction and wear—A review. Tribol. Int. 2020, 155, 106792. [Google Scholar] [CrossRef]

- Ali, S.; Kurniawan, R.; Chul, P.G.; Ko, T.J. Tribological properties of hierarchical micro-dimples produced on a cylindrical surface by dual-frequency texturing. Friction 2023, 11, 246–258. [Google Scholar] [CrossRef]

- Hara, K.; Fukuda, T.; Taguchi, K.; Isobe, H. Surface Texturing Technique Based on Ultrasonic Turning for Improving Tribological Properties. Int. J. Autom. Technol. 2022, 16, 78–86. [Google Scholar] [CrossRef]

- Lin, X.; Li, J.; Xie, S.; Xia, R.; Liu, J.; Luo, L. Effect of groove textures on tribological properties of 40CrNiMoA steel under starved grease lubrication. Surf. Topogra-Metro. 2022, 10, 045018. [Google Scholar] [CrossRef]

- Joshua, S.P.; Babu, P.D. Friction and Wear Characteristics for Laser Surface Textured Rolling Bearing Steel: Effect of Pattern Density, Depth, and Area. Trans. Indian Inst. Met. 2022, 75, 2923–2930. [Google Scholar] [CrossRef]

- King, J.A.; Tomasi, J.M.; Klimek-McDonald, D.R.; Miskioglu, I.; Odegard, G.M.; King, T.R.; Sutherland, J.W. Effects of carbon fillers on the conductivity and tensile properties of polyetheretherketone composites. Polym. Compos. 2018, 39, E807–E816. [Google Scholar] [CrossRef]

- Dufils, J.; Faverjon, F.; Héau, C.; Donnet, C.; Benayoun, S.; Valette, S. Combination of laser surface texturing and DLC coating on PEEK for enhanced tribological properties. Surf. Coatings Technol. 2017, 329, 29–41. [Google Scholar] [CrossRef]

- Geng, Y.-M.; Ren, D.-N.; Li, S.-Y.; Li, Z.-Y.; Shen, X.-Q.; Yuan, Y.-Y. Hydroxyapatite-incorporation improves bone formation on endosseous PEEK implant in canine tibia. J. Appl. Biomater. Func. 2020, 18, 2280800020975172. [Google Scholar] [CrossRef]

- Kurtz, S.M.; Devine, J.N. PEEK biomaterials in trauma, orthopedic, and spinal implants. Biomaterials 2007, 32, 4845–4869. [Google Scholar] [CrossRef]

- Zhao, X.; Xiong, D.; Wu, X. Effects of Surface Oxidation Treatment of Carbon Fibers on Biotribological Properties of CF/PEEK Materials. J. Bionic Eng. 2017, 14, 640–647. [Google Scholar] [CrossRef]

- Pan, L.; Yapici, U. A comparative study on mechanical properties of carbon fiber/PEEK composites. Adv. Compos. Mater. 2016, 25, 359–374. [Google Scholar] [CrossRef]

- Cao, H.; Dong, X.; Qu, D.; Dong, C.; Zhao, C.; Sun, D.; Gu, L.; Wu, B. Transfer film growth of continuous carbon fiber reinforced thermoplastic poly(ether ether ketone) facilitated by surface texture during dry sliding. J. Mater. Sci. 2022, 57, 383–397. [Google Scholar] [CrossRef]

- Dong, X.; Dong, C.; Wu, B. Insight Into Surface Texture-Induced Dual Effects on Friction of WC-Co Dry Sliding Against Continuous Carbon Fiber-Reinforced Thermoplastic and Thermosetting Composites. Tribol. Trans. 2022, 65, 1110–1121. [Google Scholar] [CrossRef]

- Onodera, T.; Nunoshige, J.; Kawasaki, K.; Adachi, K.; Kurihara, K.; Kubo, M. Structure and Function of Transfer Film Formed from PTFE/PEEK Polymer Blend. J. Phys. Chem. C 2017, 121, 14589–14596. [Google Scholar] [CrossRef]

- DHaidar, D.R.; Alam, K.I.; Burris, D.L. Tribological Insensitivity of an Ultralow-Wear Poly(etheretherketone)–Polytetrafluoroethylene Polymer Blend to Changes in Environmental Moisture. J. Phys. Chem. C 2018, 122, 5518–5524. [Google Scholar] [CrossRef]

- Javaid, S.; Dey, M.; Kaabouch, N.; Gupta, S. On the potential of polyetheretherketone matrix composites reinforced with ternary nanolaminates for tribological and biomedical applications. J. Appl. Polym. Sci. 2020, 138, e49980. [Google Scholar] [CrossRef]

- Hou, X.; Bai, P.; Li, J.; Li, Y.; Cao, H.; Wen, X.; Meng, Y.; Ma, L.; Tian, Y. MoS2 reinforced PEEK composite for improved aqueous boundary lubrication. Friction 2023, 11, 1660–1672. [Google Scholar] [CrossRef]

- Friedrich, K.; Lu, Z.; Häger, A. Overview on polymer composites for friction and wear application. Theor. Appl. Fract. Mech. 1993, 19, 1–11. [Google Scholar] [CrossRef]

- Jin, Z.; Yao, Z.; Sun, Y.; Shen, H. Loading capacity of PEEK blends in terms of wear rate and temperature. Wear 2022, 496–497, 204306. [Google Scholar] [CrossRef]

- Liu, H.; Leng, Y.; Wan, G.; Huang, N. Corrosion susceptibility investigation of Ti–O film modified cobalt-chromium alloy (L-605) vascular stents by cyclic potentiodynamic polarization measurement. Surf. Coat. Technol. 2011, 206, 893–896. [Google Scholar] [CrossRef]

- Boedo, S.; Booker, J.F. A Novel Elastic Squeeze Film Total Hip Replacement. J. Tribol. 2013, 136, 011101. [Google Scholar] [CrossRef]

- Qiu, S.; Fuentes, C.A.; Zhang, D.; Van Vuure, A.W.; Seveno, D. Wettability of a Single Carbon Fiber. Langmuir 2016, 32, 9697–9705. [Google Scholar] [CrossRef]

- Xiong, Z.; Lai, Q.; Lu, J.; Qu, F.; Yu, H.; Chen, X.; Zhang, G.; Zhang, W.; Zhao, S. Silanization enabled superhydrophobic PTFE membrane with antiwetting and antifouling properties for robust membrane distillation. J. Membr. Sci. 2023, 674, 121546. [Google Scholar] [CrossRef]

- Khalkhali, M.; Kazemi, N.; Zhang, H.; Liu, Q. Wetting at the nanoscale: A molecular dynamics study. J. Chem. Phys. 2017, 146, 114704. [Google Scholar] [CrossRef] [PubMed]

- Cai, Y.; Chang, W.; Luo, X.; Qin, Y. Superhydrophobicity of microstructured surfaces on zirconia by nanosecond pulsed laser. J. Micromanuf. 2018, 2, 5–14. [Google Scholar] [CrossRef]

- Breki, A.; Kurakin, M.; Liashenko, D.; Moskvin, S.; Balakin, S. Laws carbonite friction VK8 solid alloy in water environment. Mater. Today Proc. 2020, 30, 718–721. [Google Scholar] [CrossRef]

- Zhan, X.; Yi, P.; Liu, Y.; Xiao, P.; Zhu, X.; Ma, J. Effects of single- and multi-shape laser-textured surfaces on tribological properties under dry friction. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 234, 1382–1392. [Google Scholar] [CrossRef]

| Parameters | Standard [29] | PEEK_A | PEEK_B |

|---|---|---|---|

| Density (g/cm3) | ISO 1183 | 1.4 | 1.44 |

| Melting point (°C) | ISO 11357 | 341 | 341 |

| Thermal conductivity (W/mK) (23 °C) | ISO 22007-4 | 0.66 | 0.82 |

| Tensile strength (MPa) | ISO 527 | 260 | 140 |

| Bending strength (MPa) | ISO 178 | 380 | 190 |

| Elastic modulus (MPa) | ISO 527 | 6000 | 5500 |

| Ball indentation Hardness (MPa) | ISO 2039-1 | 298 | 250 |

| Parameters | L605 |

|---|---|

| Density (g/cm3) | 9.10 |

| Melting point (°C) | 1330~1410 |

| Thermal conductivity (W/mK) (100 °C) | 10.5 |

| Tensile strength (MPa) | 1000 |

| Bending strength (MPa) | 500 |

| Elastic modulus (GPa) | 243 |

| Brinell hardness (MPa) | 282 |

| Laser Parameter Values | Surface Textures | |||

|---|---|---|---|---|

| Orthogonal | Spiral | r-θ | Orthogonal + Spiral | |

| Wavelength (nm) | 1030 | 1030 | 1030 | 1030 |

| Pulse duration (fs) | 218 | 218 | 218 | 218 |

| Pulse frequency (kHz) | 1000 | 1000 | 1000 | 1000 |

| Laser spot diameter (μm) | 12 | 12 | 12 | 12 |

| Scanning speed (mm/s) | 1000 | 1000 | 1000 | 1000 |

| Pulsed laser power (W) | 20 | 20 | 20 | 20 (grid), 5 (spiral) |

| Processing cycles | 10 | 10 | 20 | 100 (grid), 10 (spiral) |

| Area density ratio (%) | 25 | 23 | 56 | 57 |

| Pin Material | PEEK_A | PEEK_A | PEEK_B | PEEK_B |

|---|---|---|---|---|

| Friction test number | 1 | 2 | 3 | 4 |

| Diameter of the pin, d0 (mm) | 6 | 6 | 6 | 6 |

| Diameter of the track, d (mm) | 20 | 30 | 20 | 30 |

| Rotational speed, n (rpm) | 200 | 200 | 200 | 200 |

| Friction test time, t (s) | 1800 | 1800 | 1800 | 1800 |

| Sliding velocity, v (m/s) | 0.209 | 0.314 | 0.209 | 0.314 |

| Sliding distance, l (m) | 376.2 | 565.2 | 376.2 | 565.2 |

| Applied normal load, FN (N) | 50 | 70 | 50 | 70 |

| Specific press, p (MPa) | 1.768 | 2.476 | 1.768 | 2.476 |

| pv value (MPa·m/s) | 0.370 | 0.777 | 0.370 | 0.777 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Yao, Z.; Du, H.; Song, J.; Jin, Z.; Xu, W. Wettability and Frictional Studies of PEEK Composites against Co-Cr Alloys with Surface Textures. Polymers 2023, 15, 4006. https://doi.org/10.3390/polym15194006

Zhang X, Yao Z, Du H, Song J, Jin Z, Xu W. Wettability and Frictional Studies of PEEK Composites against Co-Cr Alloys with Surface Textures. Polymers. 2023; 15(19):4006. https://doi.org/10.3390/polym15194006

Chicago/Turabian StyleZhang, Xifang, Zhenqiang Yao, Haifeng Du, Jiacheng Song, Zhiyi Jin, and Wei Xu. 2023. "Wettability and Frictional Studies of PEEK Composites against Co-Cr Alloys with Surface Textures" Polymers 15, no. 19: 4006. https://doi.org/10.3390/polym15194006

APA StyleZhang, X., Yao, Z., Du, H., Song, J., Jin, Z., & Xu, W. (2023). Wettability and Frictional Studies of PEEK Composites against Co-Cr Alloys with Surface Textures. Polymers, 15(19), 4006. https://doi.org/10.3390/polym15194006