Exploring the Prospects of Macadamia Nutshells for Bio-Synthetic Polymer Composites: A Review

Abstract

:1. Introduction

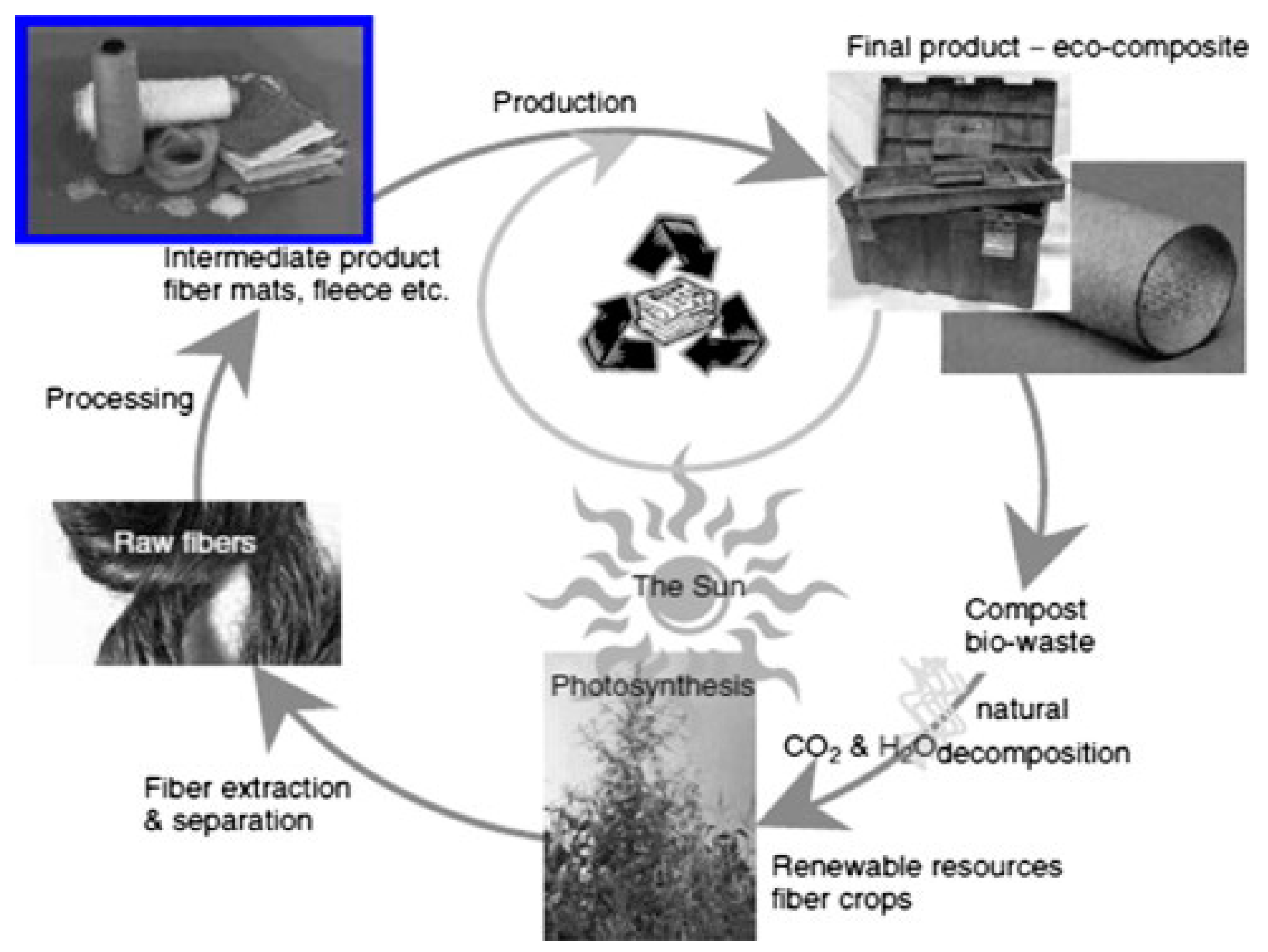

2. Bio-Synthetic Polymer Composites

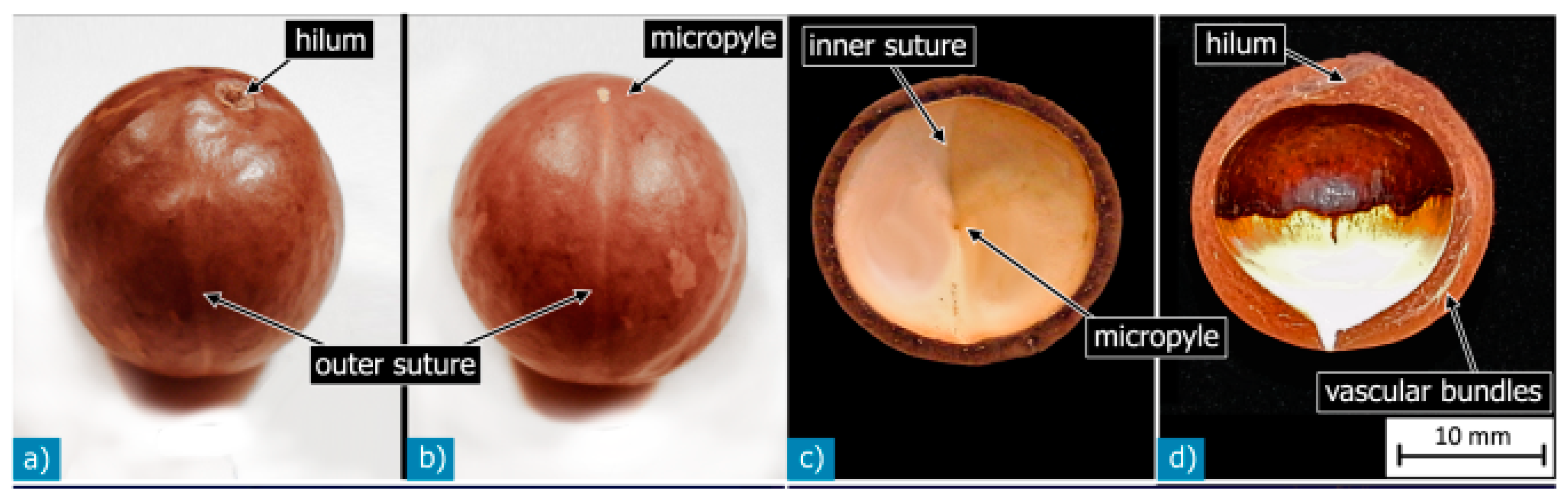

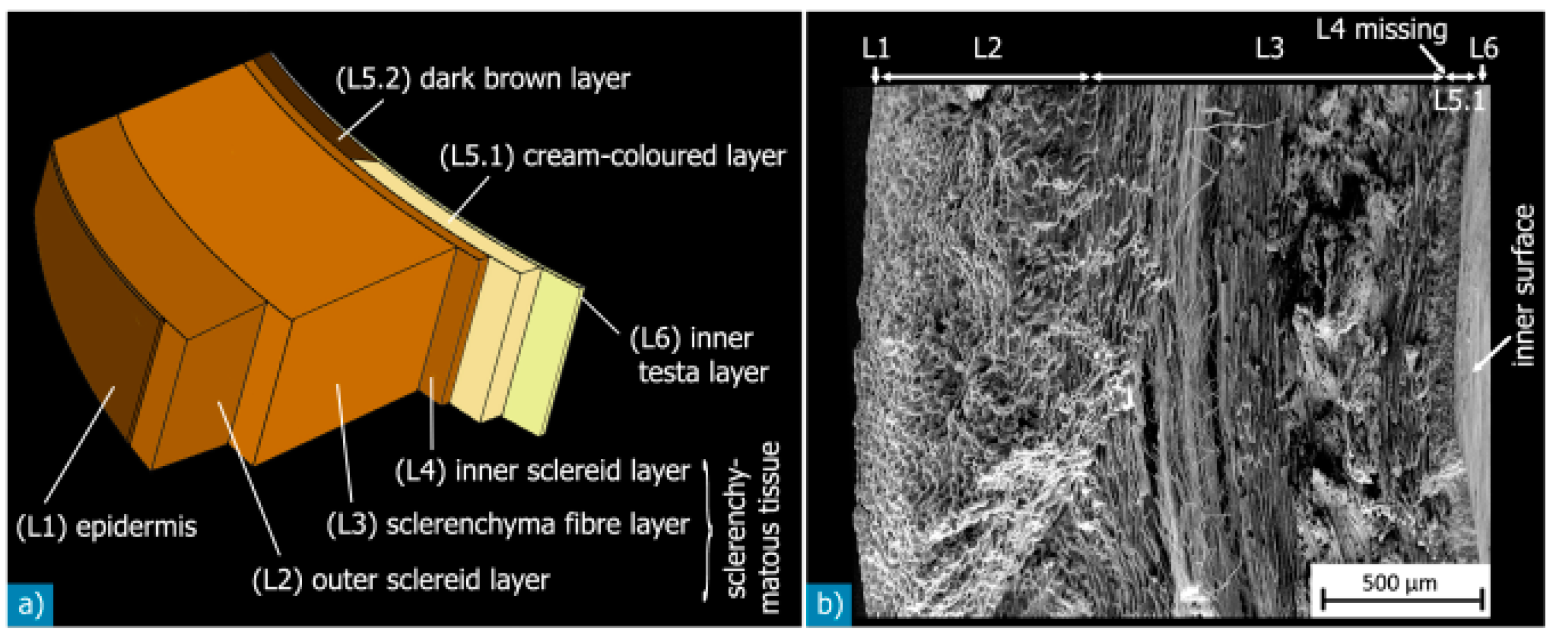

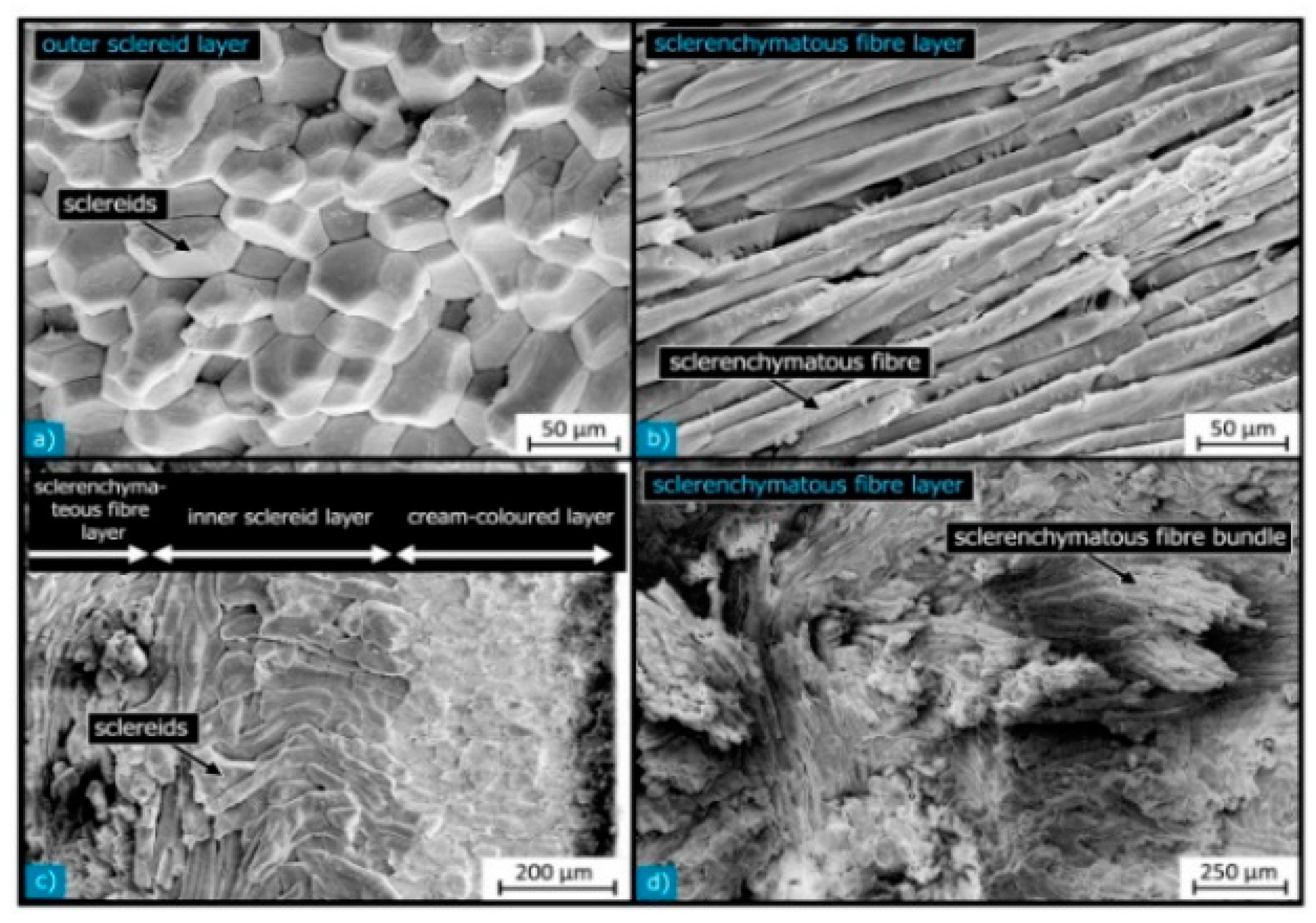

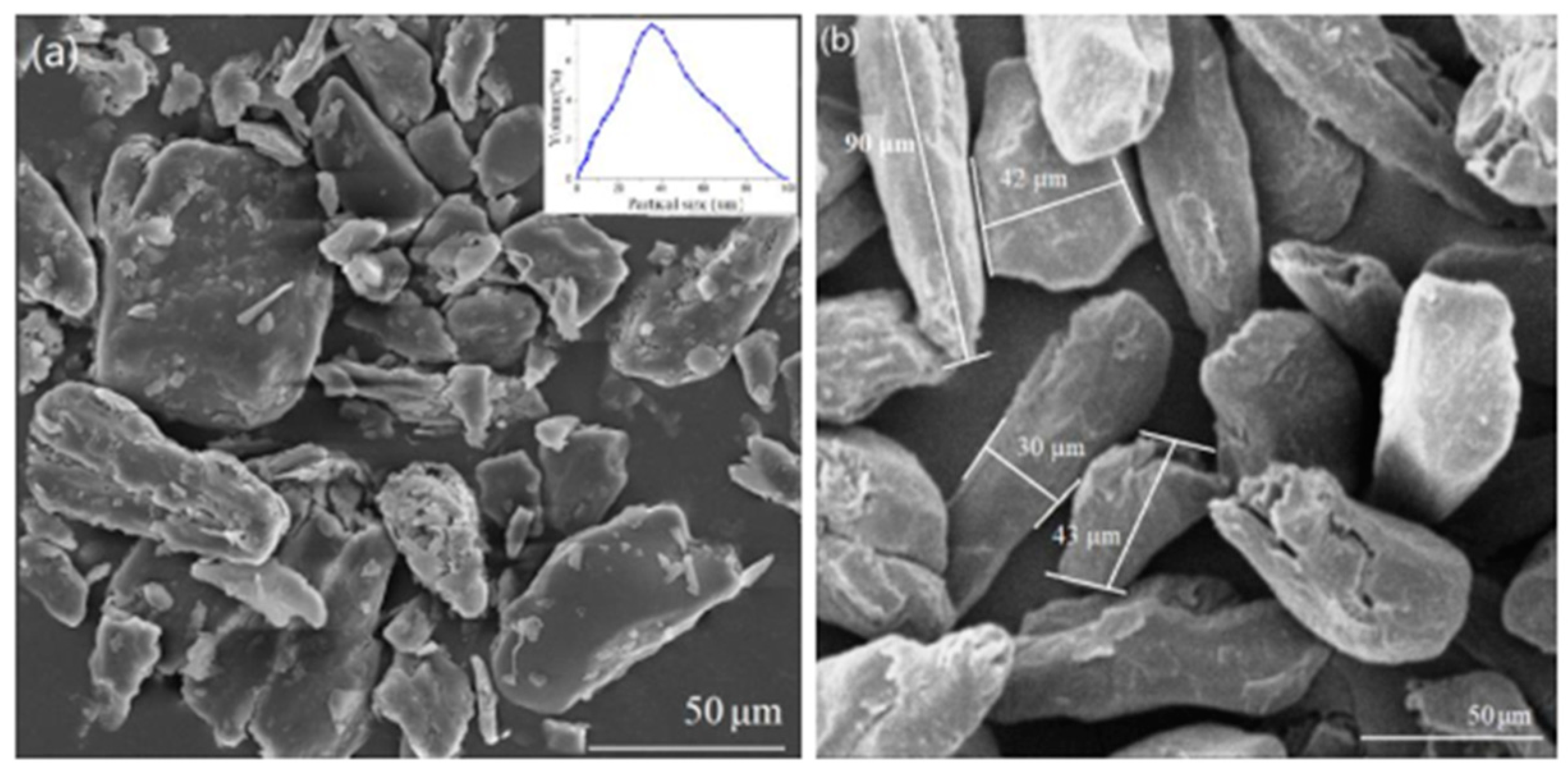

3. Macadamia Nutshells

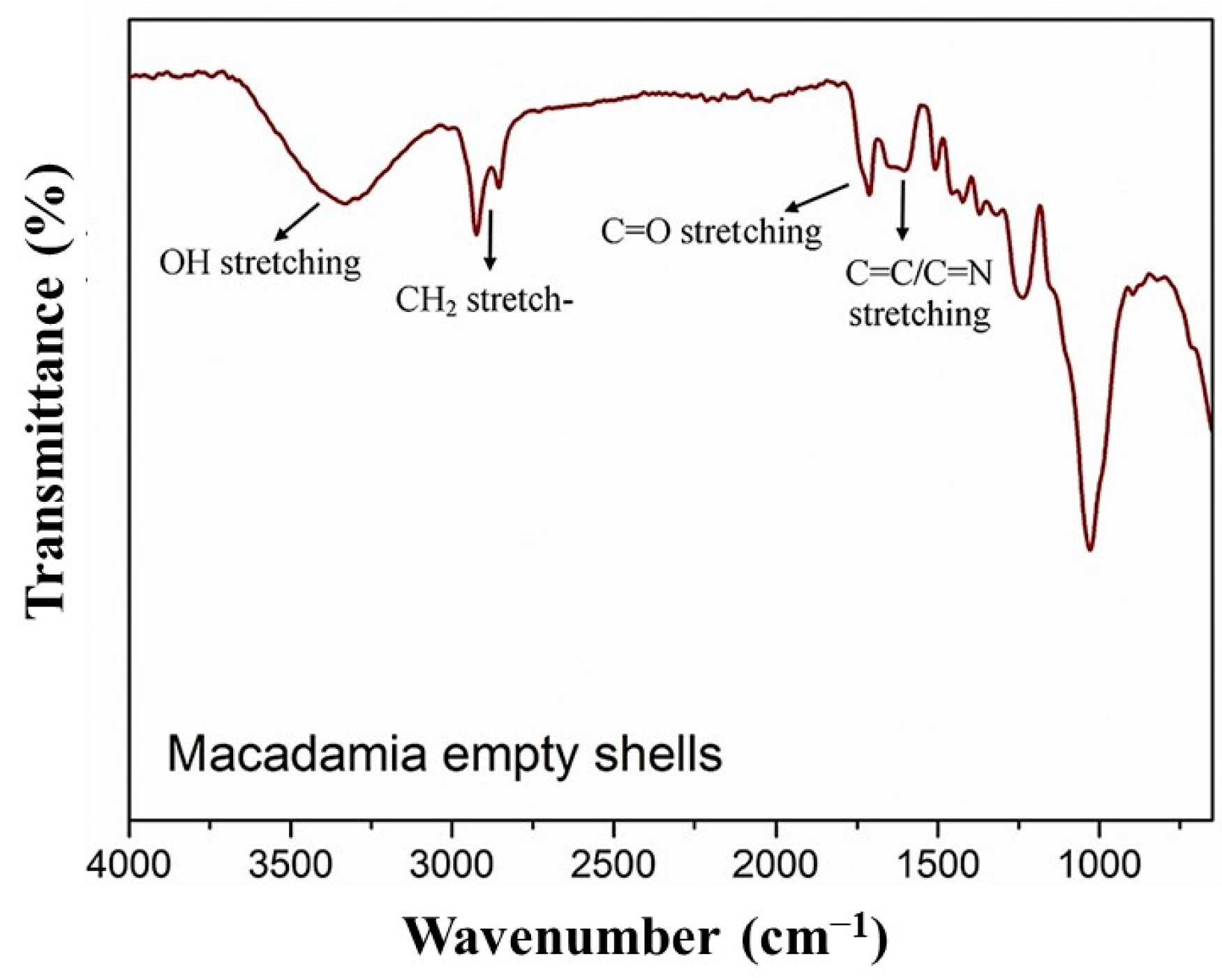

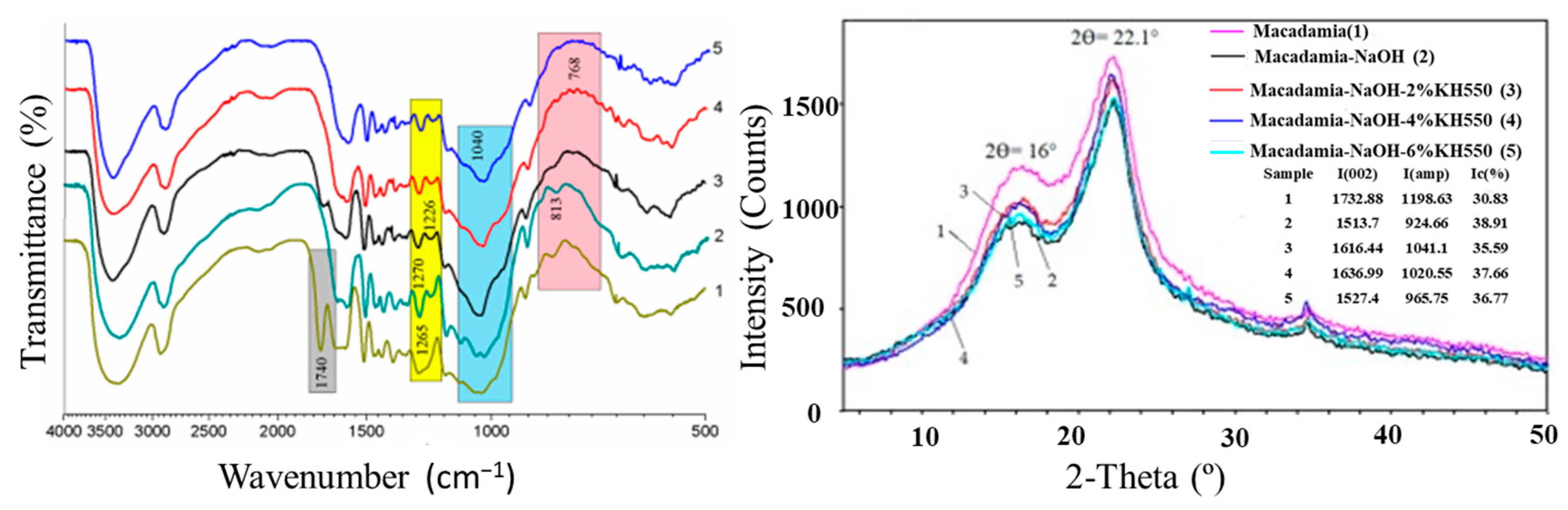

4. Chemical Properties

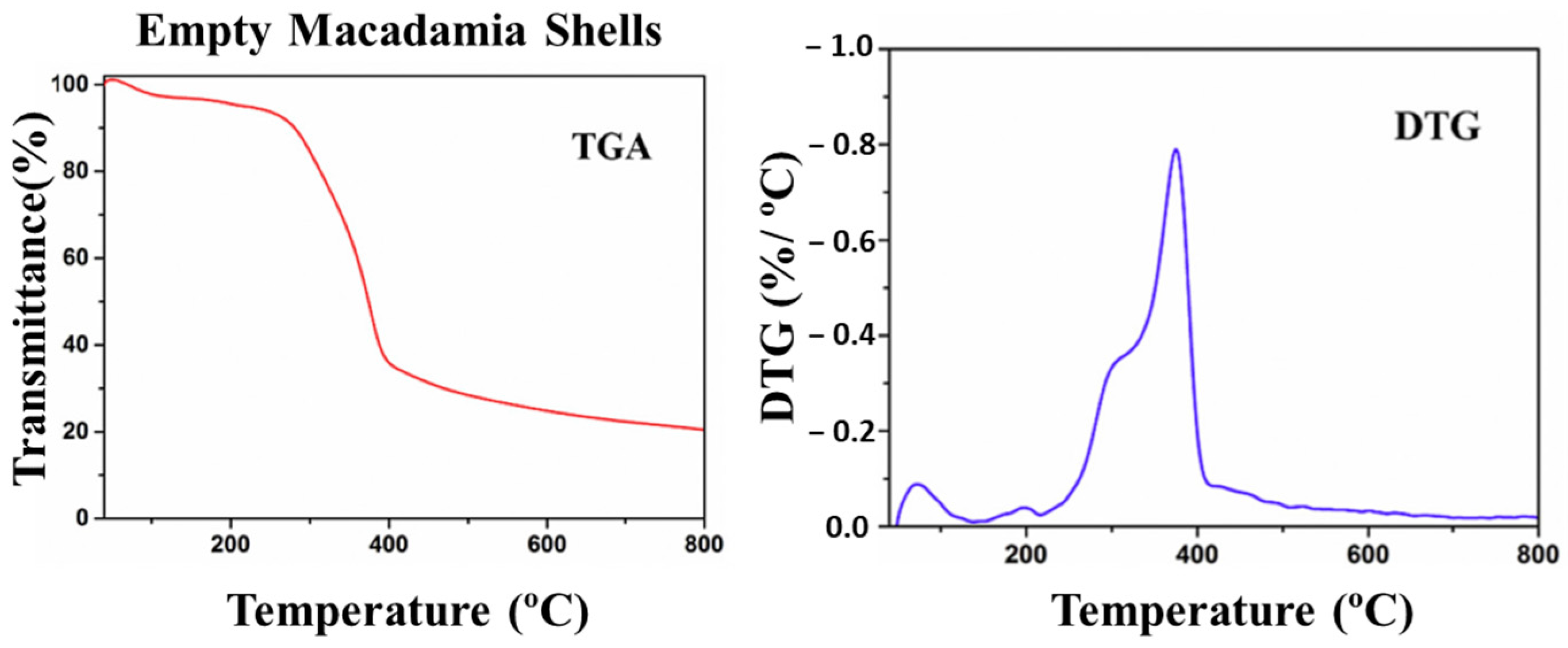

5. Thermal Analysis

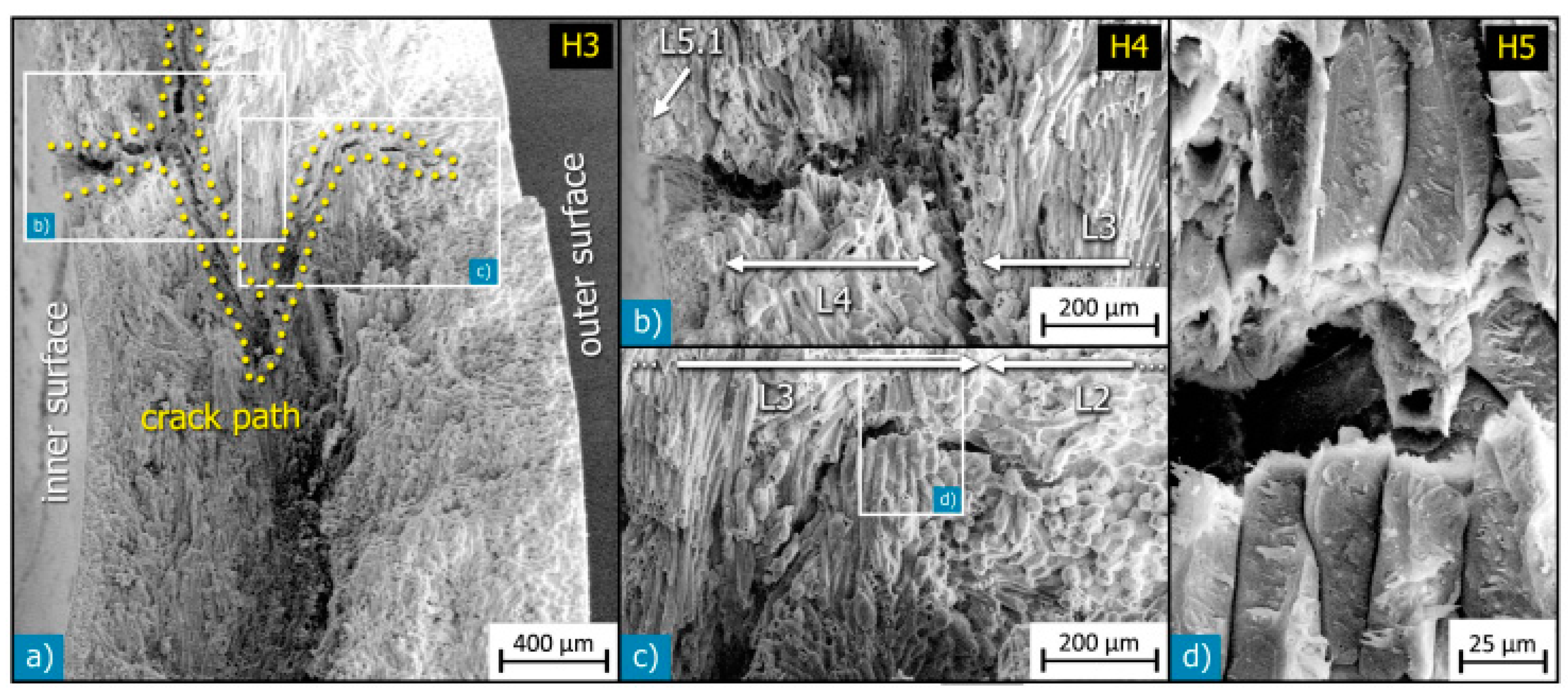

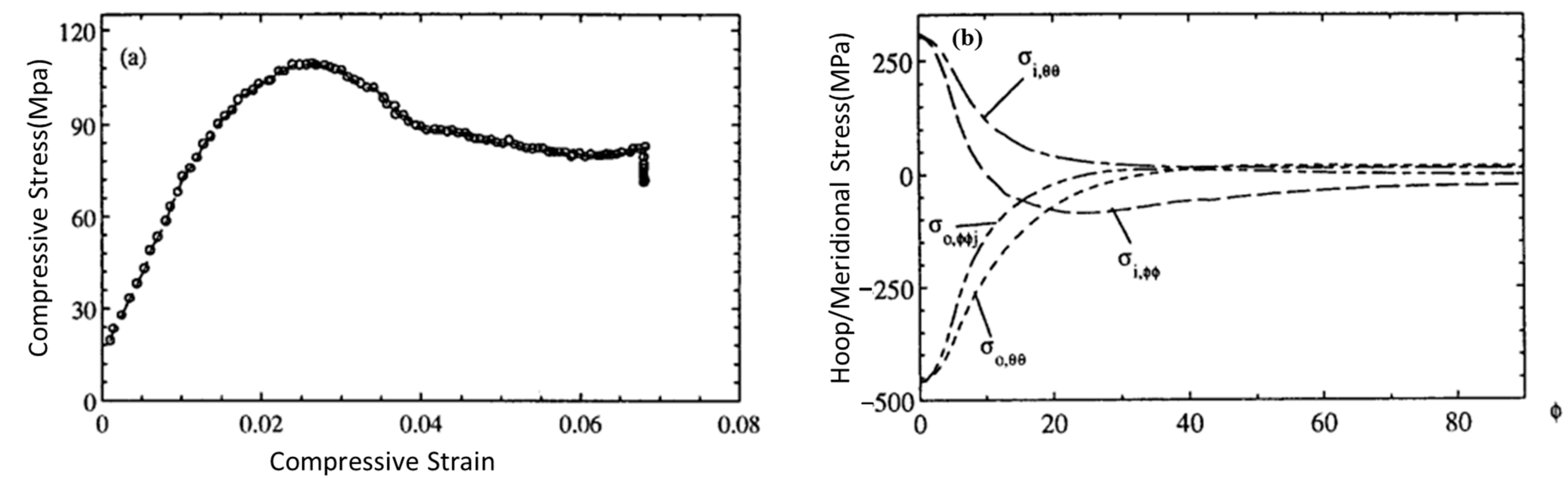

6. Mechanical Properties

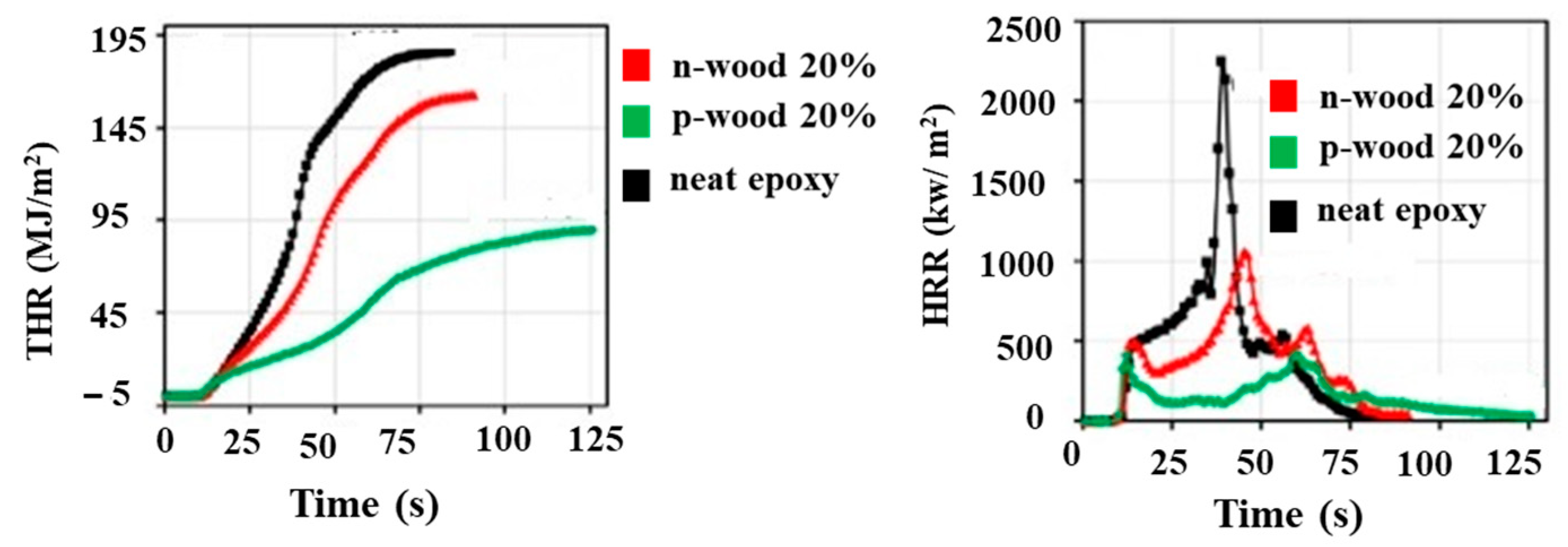

7. Macadamia Nutshell Reinforced Composites

7.1. Composites with Poly Lactic Acid

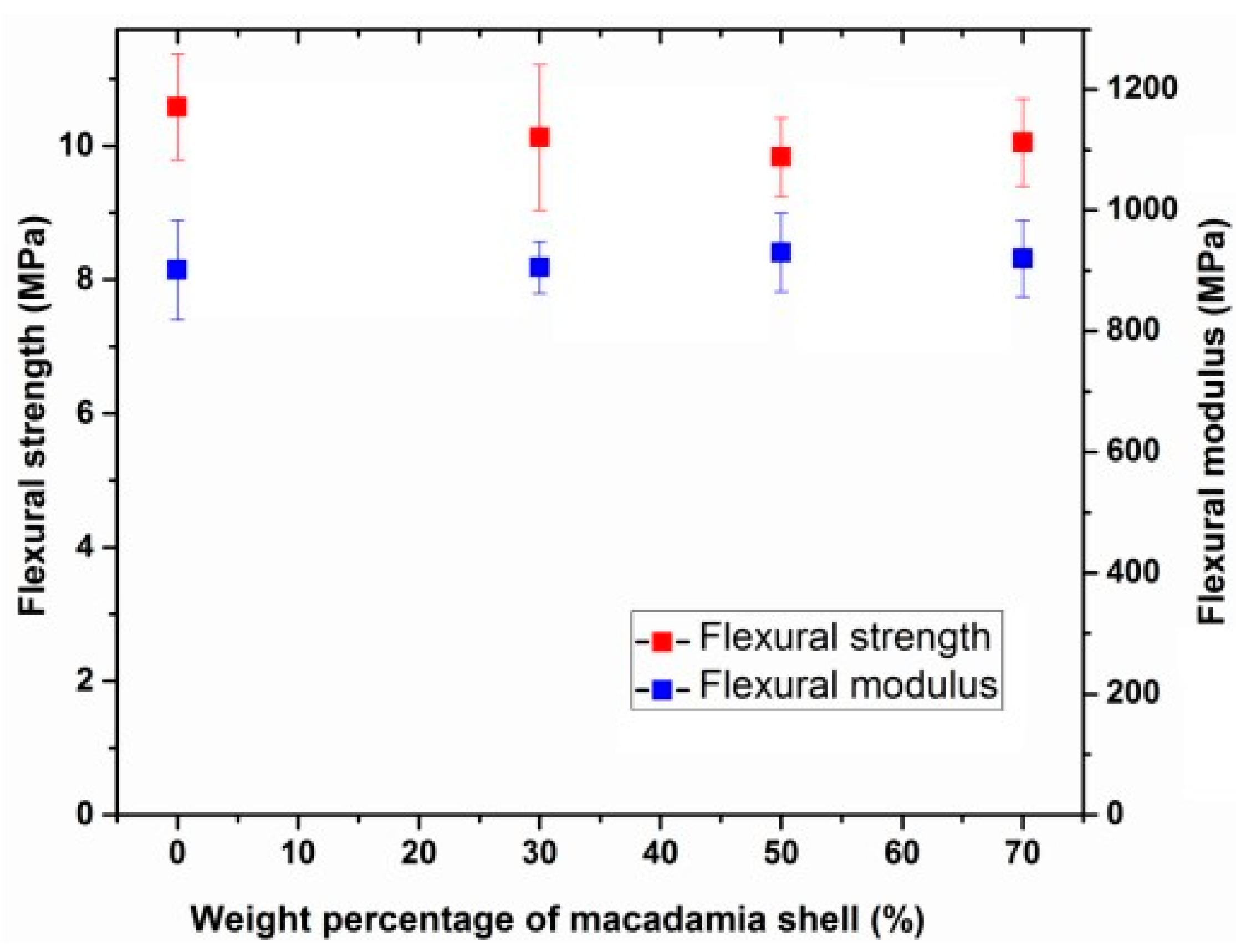

7.2. Composites with Polyethylene and Polyester

7.3. Composites with Polypropylene (PP)

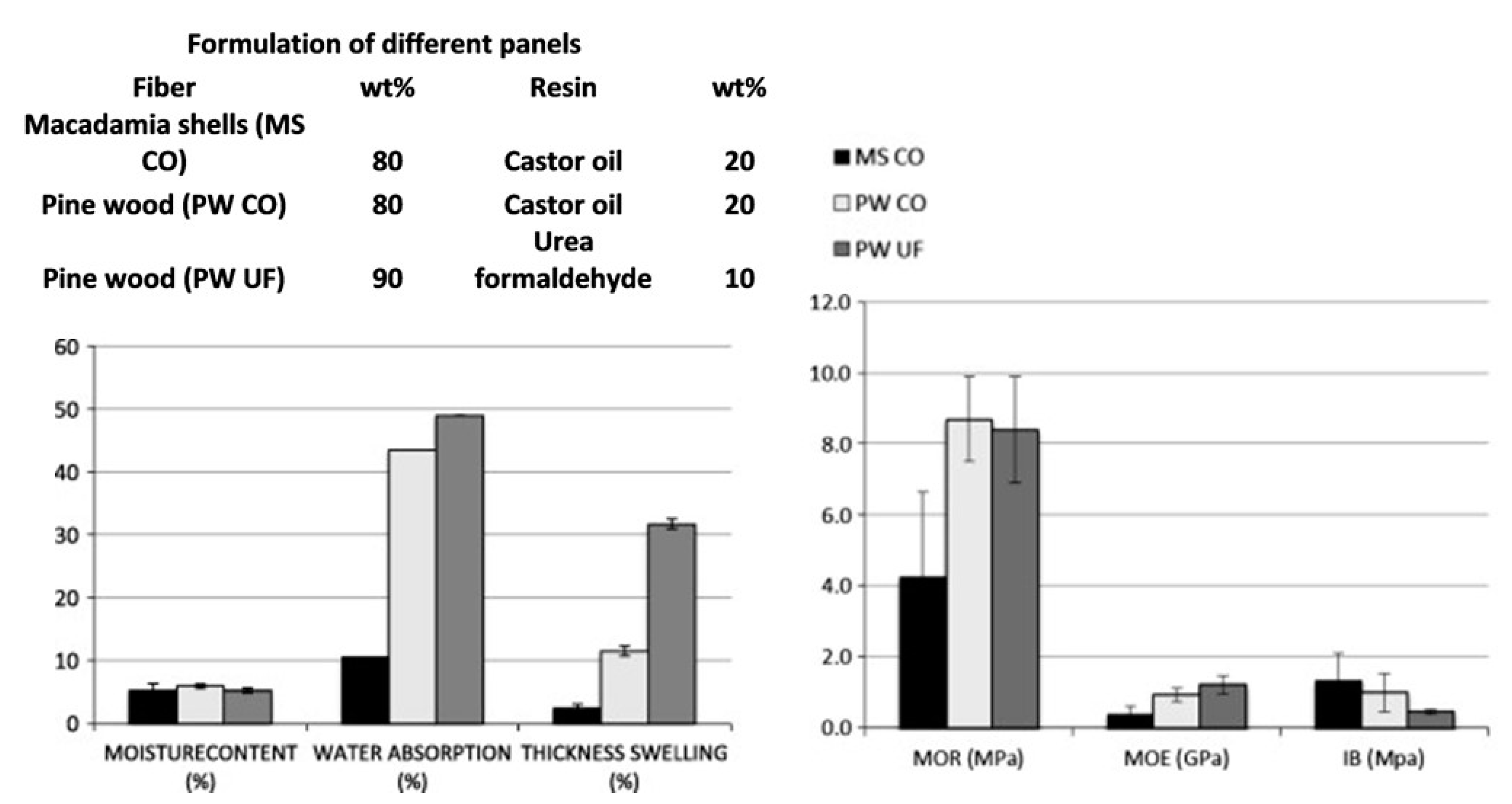

7.4. Composites with Some Resins

7.5. Composites from Waste Macadamia Nutshells and Automotive Waste Plastic

7.6. Macadamia Nutshell Fillers Studied for Purposes Other Than Composites

8. Concluding Remarks

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fowler, P.A.; Hughes, J.M.; Elias, R.M. Biocomposites: Technology, environmental credentials and market forces. J. Sci. Food Agric. 2006, 86, 1781–1789. [Google Scholar] [CrossRef]

- Wechsler, A.; Ramirez, M.; Crosky, A.; Zaharia, M.; Jones, H.; Ballerini, A.; Nunez, M.; Sahajwalla, V. Sustainable furniture panel composites from forestry and food industry by-products in Australia. In Proceedings of the eddBE2011 Sustainable Wellbeing, Brisbane, Australia, 27–29 April 2011; pp. 88–93, ISBN 978-0-98-05827-4-1. [Google Scholar]

- Kowitz, T.J.; Mason, R.L.; Bowden, R.P.; Isaacs, A.R. Storage of Macadamia Nut-in-Shell. In Australian Macadamia Society News Bulletin; IFIQ, Department of Primary Industries: Hamilton, Australia, 1996; pp. 61–67. [Google Scholar]

- Bae, J.-S.; Su, S. Macadamia nut shell-derived carbon composites for post combustion CO2 capture. Int. J. Greenh. Gas Control 2013, 19, 174–182. [Google Scholar] [CrossRef]

- Wang, C.-H.; Zhang, L.; Mai, Y.-W. Deformation and fracture of Macadamia nuts; Part 1: Deformation analysis of nut-in-shell. Int. J. Fracture 1994, 69, 51–65. [Google Scholar] [CrossRef]

- Rajarao, R.; Sahajwalla, V. A cleaner, sustainable approach for synthesising high purity silicon carbide and silicon nitride nanopowders using macadamia shell waste. J. Cleaner Prod. 2016, 133, 1277–1282. [Google Scholar] [CrossRef]

- Andrade, L.S.; Silva, N.G.S.; Cortat, L.I.C.O.; Mulinari, D.R. Approach in Macadamia integrifolia residue based low-density polyethylene composites on mechanical and thermal performance. J. Appl. Polym. Sci. 2021, 138, e50613. [Google Scholar] [CrossRef]

- Wambua, P.; Ivens, J.; Verpoest, I. Natural fibres: Can they replace glass in fibre reinforced plastics? Compos. Sci. Technol. 2003, 63, 1259–1264. [Google Scholar] [CrossRef]

- Nishino, T.; Hirao, K.; Kotera, M.; Nakamae, K.; Inagaki, H. Kenaf reinforced biodegradable composite. Compos. Sci. Technol. 2003, 63, 1281–1286. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Gassan, J. Composites reinforced with cellulose based fibres. Prog. Polym. Sci. 1999, 24, 221–274. [Google Scholar] [CrossRef]

- Bullions, T.A.; Hoffman, D.; Gillespie, R.A.; Price-O’Brien, J.; Loos, A.C. Contributions of feather fibers and various cellulose fibers to the mechanical properties of polypropylene matrix composites. Compos. Sci. Technol. 2006, 66, 102–114. [Google Scholar] [CrossRef]

- Akil, H.M.; Omar, M.F.; Mazuki, A.A.M.; Safiee, S.; Ishak, Z.A.M.; Abu Bakar, A. Kenaf fiber reinforced composites: A review. Mater. Des. 2011, 32, 4107–4121. [Google Scholar] [CrossRef]

- Wang, C.-H.; Mai, Y.-W. Deformation and fracture of Macadamia nuts; Part 2: Microstructure and fracture mechanics analysis of nutshell. Int. J. Fract. 1994, 67, 67–85. [Google Scholar] [CrossRef]

- Schuler, P.; Speck, T.; Bührig-Polaczek, A.; Fleck, C. Structure-Function Relationships in Macadamia integrifolia Seed Coats—Fundamentals of the Hierarchical Microstructure. PLoS ONE 2014, 9, e102913. [Google Scholar] [CrossRef] [PubMed]

- Cholake, S.T.; Rajarao, R.; Henderson, P.; Rajagopal, R.R.; Sahajwalla, V. Composite panels obtained from automotive waste plastics and agricultural macadamia shell waste. J. Cleaner Prod. 2017, 151, 163–171. [Google Scholar] [CrossRef]

- Jennings, J.S.; Macmillan, N.H. A tough nut to crack. J. Mater. Sci. 1986, 21, 1517–1524. [Google Scholar] [CrossRef]

- Dong, C.; Davies, I.J. Flexural properties of macadamia nutshell particle reinforced polyester composites. Compos. Part B 2012, 43, 2751–2756. [Google Scholar] [CrossRef]

- Kumar, U.; Maroufi, S.; Rajarao, R.; Mayyas, M.; Mansuri, I.; Joshi, R.K.; Sahajwalla, V. Cleaner production of iron by using waste macadamia biomass as a carbon resource. J. Cleaner Prod. 2017, 158, 218–224. [Google Scholar] [CrossRef]

- Gokdai, D.; Borazan, A.A.; Acikbas, G. Effect of Marble: Pine Cone Waste Ratios on Mechanical Properties of Polyester Matrix Composites. Waste Biomass Valor. 2017, 8, 1855–1862. [Google Scholar] [CrossRef]

- Dong, C.; Davies, I.J. Mechanical properties of Macadamia nutshell powder and PLA bio-composites. Aust. J. Mech. Eng. 2017, 15, 150–156. [Google Scholar] [CrossRef]

- Ramdani, N.; Derradji, M.; Mokhnache, E.O. Natural fiber reinforced polybenzoxazine composites: A review. Mater. Today Commun. 2022, 31, 103645. [Google Scholar] [CrossRef]

- Cipriano, J.d.P.; Zanini, N.C.; Dantas, I.R.; Mulinari, D.R. Mechanical Properties of Polypropylene Composites Reinforced with Macadamia Nutshell Fibers. J. Renew. Mater. 2019, 7, 1047. [Google Scholar] [CrossRef]

- Sesana, R.; Delprete, C.; Sangermano, M. Mechanical behavior of macadamia nutshells. In AIAS 2019 International Conference on Stress Analysis; Elsevier B.V.: Amsterdam, The Netherlands, 2019; pp. 829–836. [Google Scholar]

- Suárez, L.; Castellano, J.; Tcharkhtchi, A.; Ortega, Z. Are Natural-Based Composites Sustainable? Polymers 2021, 13, 2326. [Google Scholar] [CrossRef] [PubMed]

- Pokharel, A.; Falua, K.J.; Babaei-Ghazvini, A.; Acharya, B. Biobased Polymer Composites: A Review. J. Compos. Sci. 2022, 6, 255. [Google Scholar] [CrossRef]

- Kumar, R.; Ofosu, O.; Anandjiwala, R.D. Macadamia Nutshell Powder Filled Poly Lactic Acid Composites with Triacetin as a Plasticizer. J. Biobased Mater. Bioenergy 2013, 7, 541–548. [Google Scholar] [CrossRef]

- Song, X.; He, W.; Qin, H.; Yang, S.; Wen, S. Fused Deposition Modeling of Poly(lactic acid)/Macadamia Composites—Thermal, Mechanical Properties and Scaffolds. Materials 2020, 13, 258. [Google Scholar] [CrossRef]

- Song, X.; He, W.; Han, X.; Qin, H. Fused Deposition Modeling of Poly(lactic acid)/Nutshells Composite Filaments: Effect of Alkali Treatment. J. Polym. Environ. 2020, 28, 3139–3152. [Google Scholar] [CrossRef]

- Torun, S.B.; Tomak, E.D.; Cavdar, A.D.; Mengeloglu, F. Characterization of weathered MCC/nutshell reinforced composites. Polym. Test. 2021, 101, 107290. [Google Scholar] [CrossRef]

- Dong, C.; Parsons, D.; Davies, I.J. Tensile strength of pine needles and their feasibility as reinforcement in composite materials. J. Mater. Sci. 2014, 49, 8057–8062. [Google Scholar] [CrossRef]

- Cortat, L.O.; Zanini, N.C.; Barbosa, R.F.S.; de Souza, A.G.; Rosa, D.S.; Mulinari, D.R. A Sustainable Perspective for Macadamia Nutshell Residues Revalorization by Green Composites Development. J. Polym. Environ. 2021, 29, 3210–3226. [Google Scholar] [CrossRef]

- Silva, N.G.S.; Cortat, L.I.C.O.; Mulinari, D.R. Effect of Alkaline Treatment and Coupling Agent on Thermal and Mechanical Properties of Macadamia Nutshell Residues Based PP Composites. J. Polym. Environ. 2021, 29, 3271–3287. [Google Scholar] [CrossRef]

- Wechsler, A.; Zaharia, M.; Crosky, A.; Jones, H.; Ramírez, M.; Ballerini, A.; Nuñez, M.; Sahajwalla, V. Macadamia (Macadamia integrifolia) shell and castor (Rícinos communis) oil based sustainable particleboard: A comparison of its properties with conventional wood-based particleboard. Mater. Des. 2013, 50, 117–123. [Google Scholar] [CrossRef]

- Mirindi, D.; Onchiri, R.O.; Thuo, J. Physico-Mechanical Properties of Particleboards Produced from Macadamia Nutshell and Gum Arabic. Appl. Sci. 2021, 11, 11138. [Google Scholar] [CrossRef]

- Ferreira, B.S.; de Campos, C.I.; Gonçalves, M.T.T. Use of Macadamia Nutshell in the Production of Eucalyptus Salign Particleboards. Adv. Mater. Res. 2014, 1025–1026, 246–250. [Google Scholar] [CrossRef]

- Zabihi, O.; Ahmadi, M.; Yadav, R.; Mahmoodi, R.; Kalali, E.N.; Nikafshar, S.; Ferdowsi, M.R.G.; Wang, D.-Y.; Naebe, M. Novel Phosphorous-Based Deep Eutectic Solvents for the Production of Recyclable Macadamia Nutshell−Polymer Biocomposites with Improved Mechanical and Fire Safety Performances. ACS Sustain. Chem. Eng. 2021, 9, 4463–4476. [Google Scholar] [CrossRef]

- Bandeira, C.F.; Da Costa, A.C.A.; Montoro, S.R.; Costa, M.L.; Botelho, E.C. Thermal behavior evaluation of benzoxazine reinforced with macadamia biomass composites. J. Appl. Polym. Sci. 2022, 139, 52160. [Google Scholar] [CrossRef]

- Chang, Y.; Ren, Y.; Zhu, L.; Li, Y.; Li, T.; Ren, B. Preparation of macadamia nut shell porous carbon and its electrochemical performance as cathode material for lithium–sulfur batteries. Electrochim. Acta 2022, 420, 140454. [Google Scholar] [CrossRef]

- Girdis, J.; Gaudio, L.; Proust, G.; Loschke, S.; Dong, A. Rethinking Timber: Investigation into the Use of Waste Macadamia Nut Shells for Additive Manufacturing. JOM 2017, 69, 575–579. [Google Scholar] [CrossRef]

| Proximate Analysis (wt% as Received) | Ultimate Analysis (wt% as Received) | ||

|---|---|---|---|

| Moisture | 5.5 | C | 48.39 |

| Ash | 0.2 | O | 40.31 |

| Volatile matter | 73.5 | N | 0.333 |

| Fixed carbon | 20.8 | — | — |

| Analyte | Na | Mg | Al | Si | P | S | Cl | K |

|---|---|---|---|---|---|---|---|---|

| Concentration (%) | 0.0298 | 0.0450 | 0.0620 | 0.0770 | 0.0140 | 0.0400 | 0.0008 | 0.1550 |

| Analyte | Ca | Cr | Mn | Fe | Ni | Co | Cu | Zn |

| Concentration (%) | 0.0350 | 0.0008 | 0.0047 | 0.0113 | - | 0.0001 | 0.0015 | 0.0005 |

| Analyte | Se | Zr | Br | Ba | Rb | Hf | Cd | Pb |

| Concentration (%) | 0.0004 | - | 0.0004 | - | 0.0001 | - | 0.0001 | 0.0002 |

| Position | Equator | North/South Pole | N45 ° | S45 ° | |

|---|---|---|---|---|---|

| Direction | Polar | Equatorial | Polar/Equatorial | Equatorial | Equatorial |

| E (GPa) | 7.77 (±1.2) | 5.38 (±2.43) | 4.78 (±2.9) | 5.09 | 4.4 |

| σUTS (MPa) | 61.0 (±5.98) | 57.8 (±9.95) | — | 56.1 | 46.2 |

| KIC (MPa√m) | 0.81 (±0.18) | 0.64 (±0.09) | 0.85 (±0.05) | 0.9 | 0.83 |

| Heat Treatment | Green | Dried | Boiled |

|---|---|---|---|

| Young’s Modulus (GPa) | 6.2 | 5.66 | 5.95 |

| Tensile Strength (MPa) | 57.8 (±8.7) | 54.9 (±3.1) | 59 (±7) |

| Compressive Strength (MPa) | 80 (±12) | 84 (±9) | 76 (±8) |

| Fracture Toughness (MPa√m) | 0.78 (±0.12) | 0.77 (±0.1) | 0.80 (±0.15) |

| Work of Fracture (Jm−2) | 98 | 105 | 108 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, M.S.; Islam, M.M.; Epaarachchi, J.; Shibata, S. Exploring the Prospects of Macadamia Nutshells for Bio-Synthetic Polymer Composites: A Review. Polymers 2023, 15, 4007. https://doi.org/10.3390/polym15194007

Khan MS, Islam MM, Epaarachchi J, Shibata S. Exploring the Prospects of Macadamia Nutshells for Bio-Synthetic Polymer Composites: A Review. Polymers. 2023; 15(19):4007. https://doi.org/10.3390/polym15194007

Chicago/Turabian StyleKhan, Md Sefat, Md Mainul Islam, Jayantha Epaarachchi, and Shinichi Shibata. 2023. "Exploring the Prospects of Macadamia Nutshells for Bio-Synthetic Polymer Composites: A Review" Polymers 15, no. 19: 4007. https://doi.org/10.3390/polym15194007

APA StyleKhan, M. S., Islam, M. M., Epaarachchi, J., & Shibata, S. (2023). Exploring the Prospects of Macadamia Nutshells for Bio-Synthetic Polymer Composites: A Review. Polymers, 15(19), 4007. https://doi.org/10.3390/polym15194007