Use of Yarn and Carded Jute as Epoxy Matrix Reinforcement for the Production of Composite Materials for Application in the Wind Sector: A Preliminary Analysis for the Manufacture of Blades for Low-Intensity Winds

Abstract

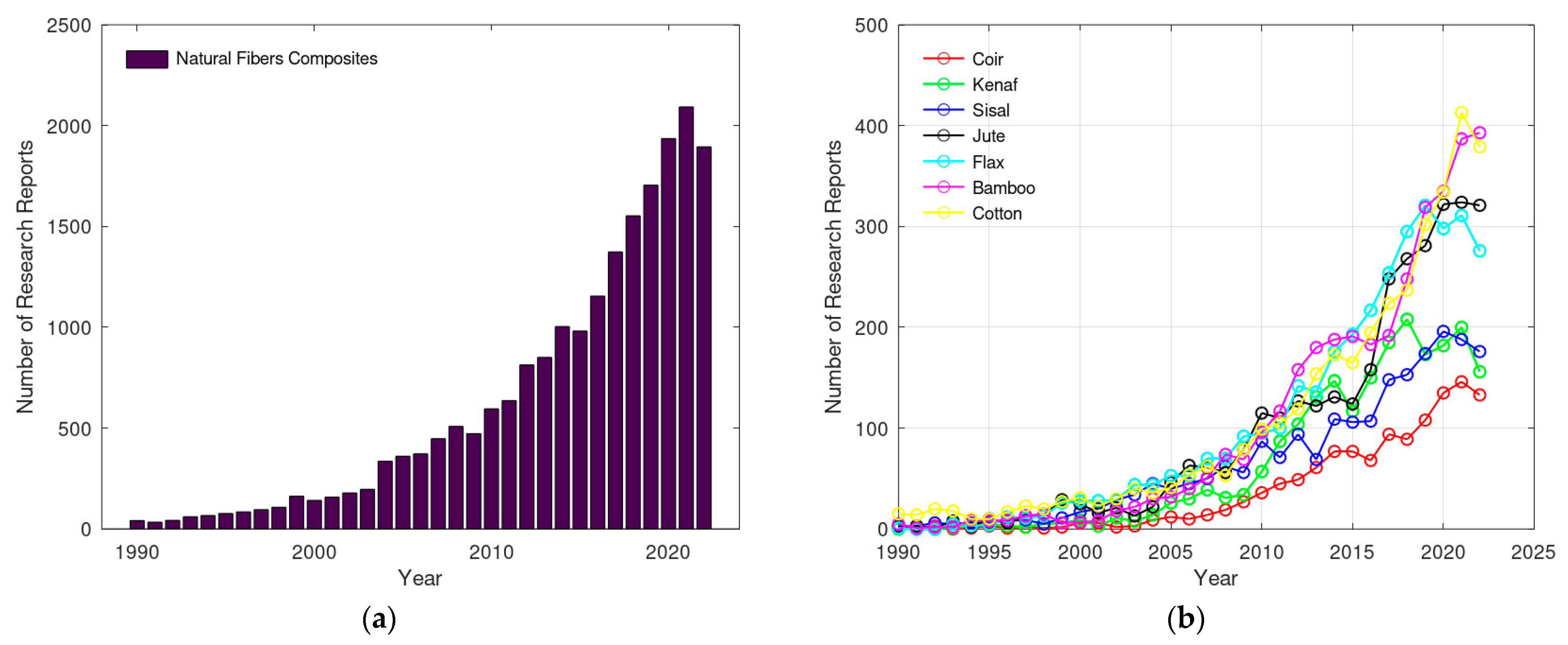

:1. Introduction

2. Materials and Methods

2.1. Materials

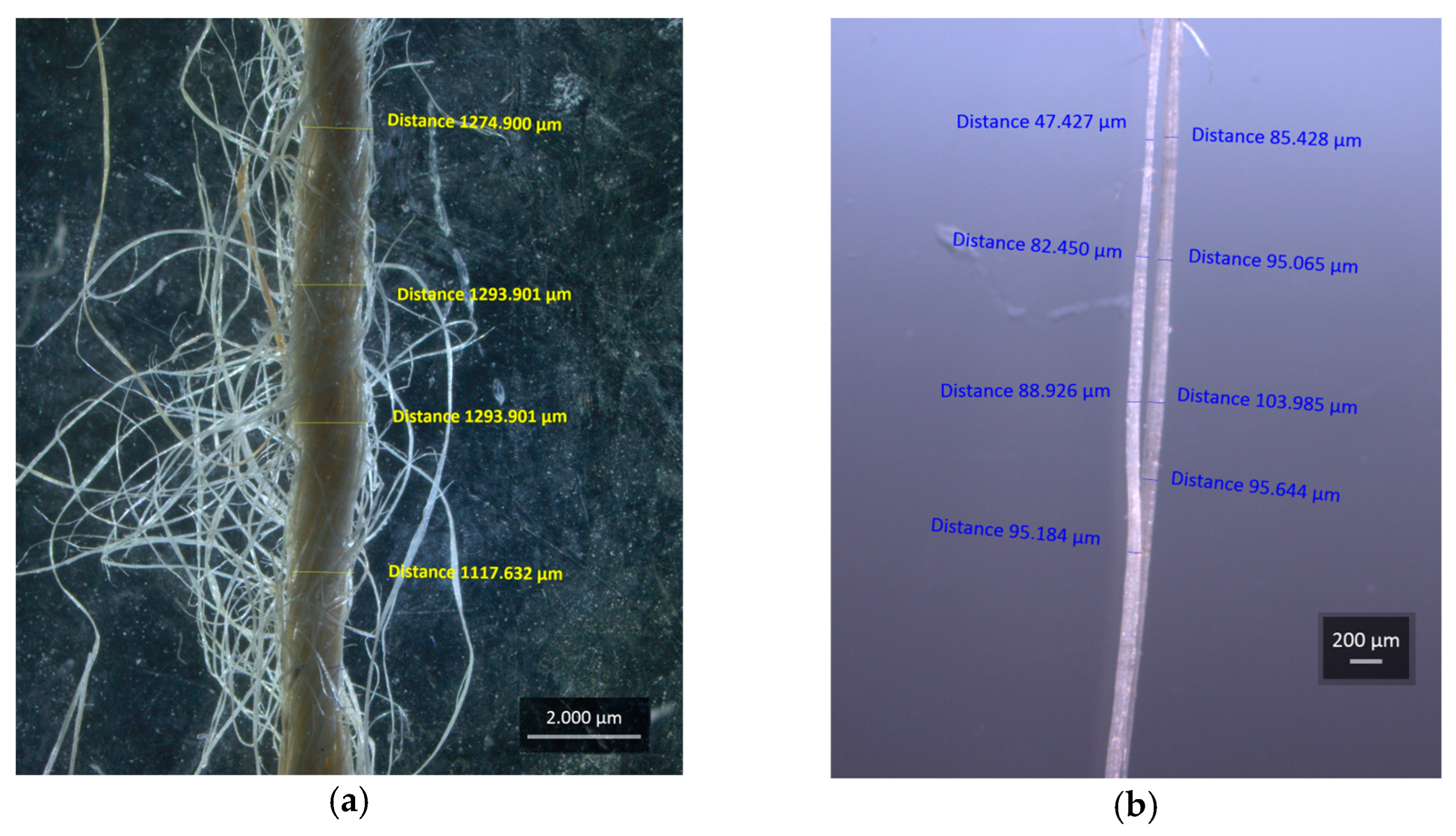

2.2. Characterization of Jute Yarn (JY) and Carded Fiber (CF)

2.2.1. Diameter Determination

2.2.2. Twist Angle Determination

2.2.3. Fiber Density Determination

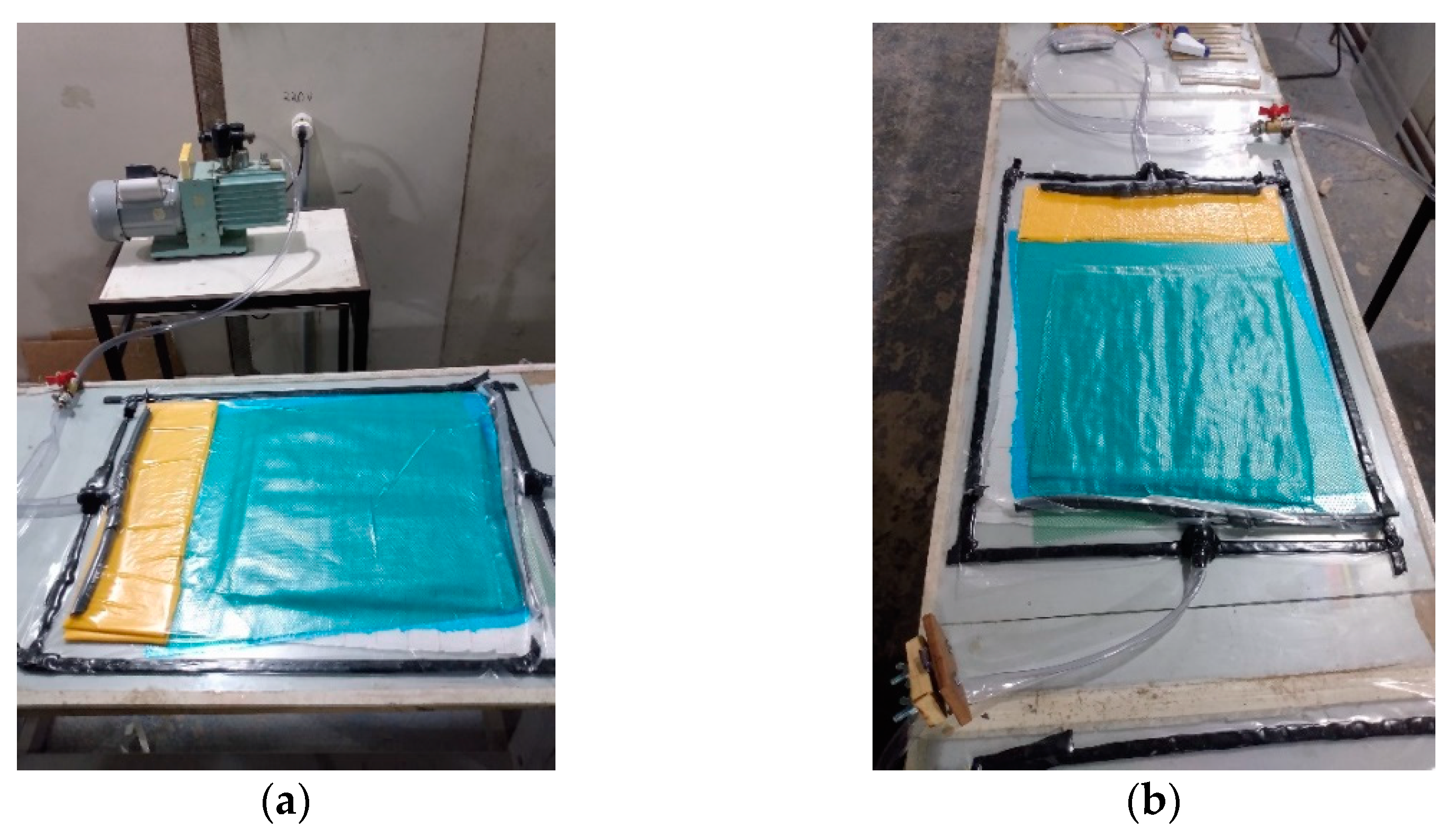

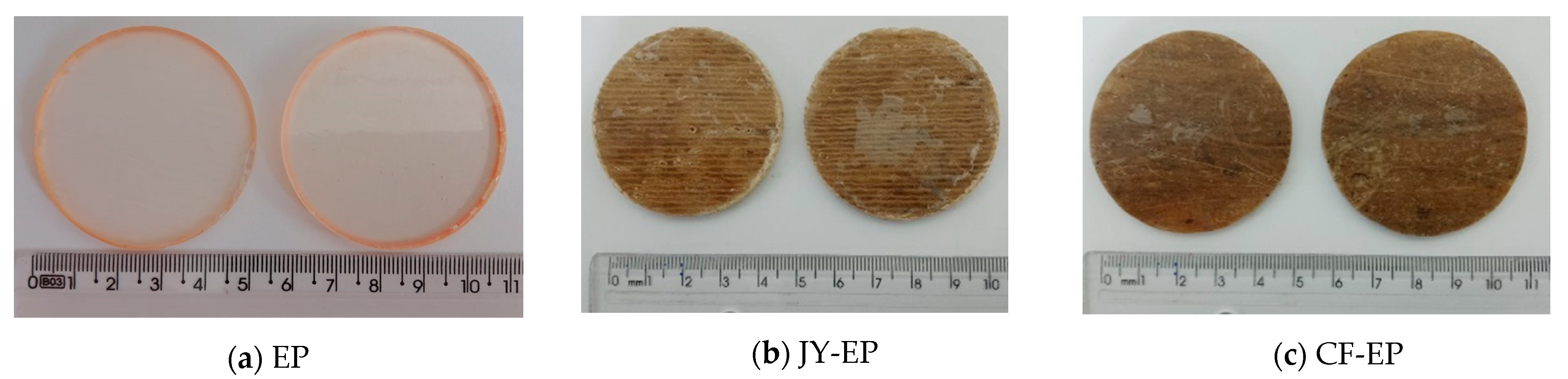

2.3. Confection of Test Specimens

2.4. Density and Voids Determination

2.5. Mechanical Tests

2.5.1. Tensile Testing

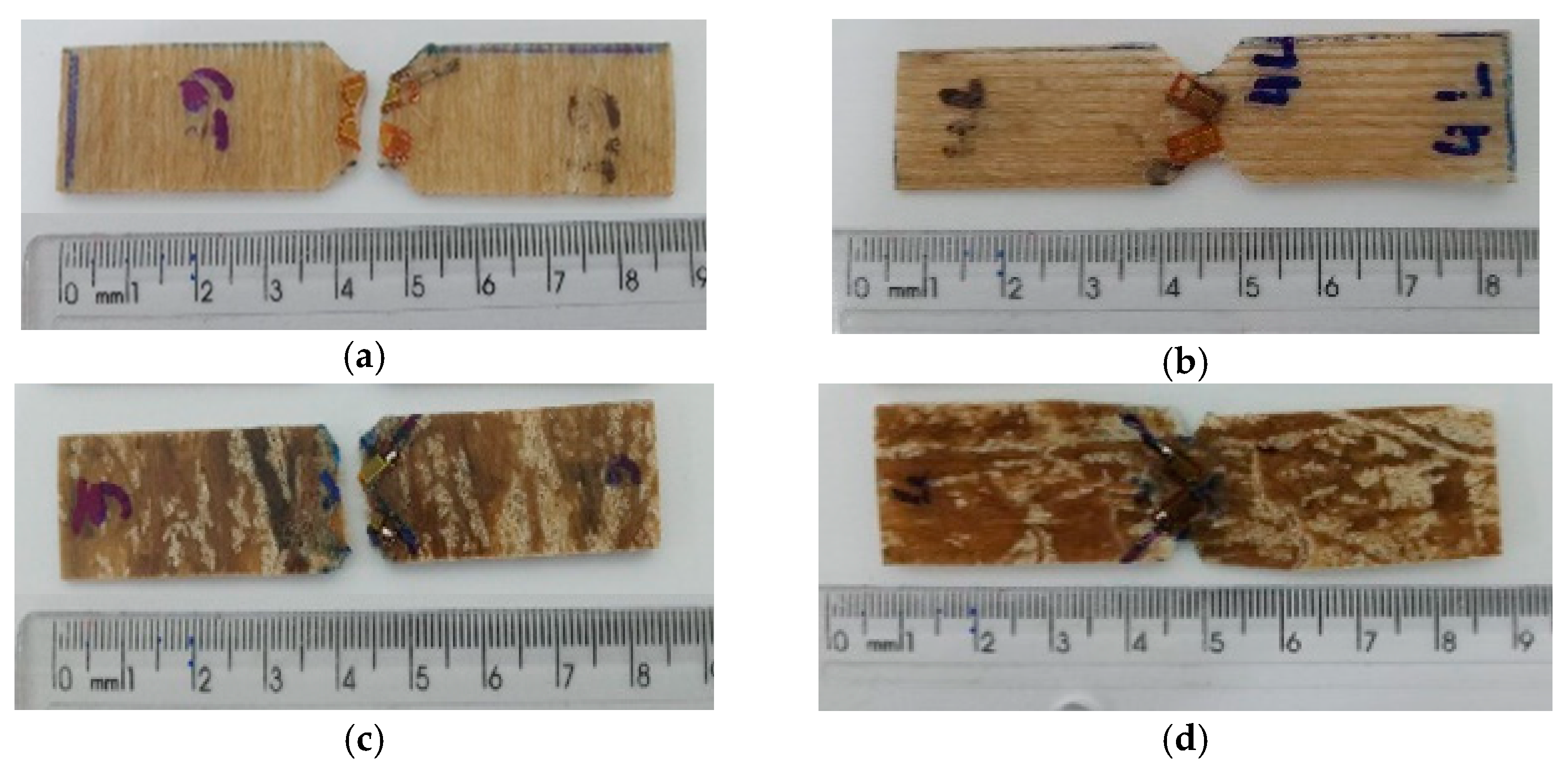

2.5.2. Shear Testing

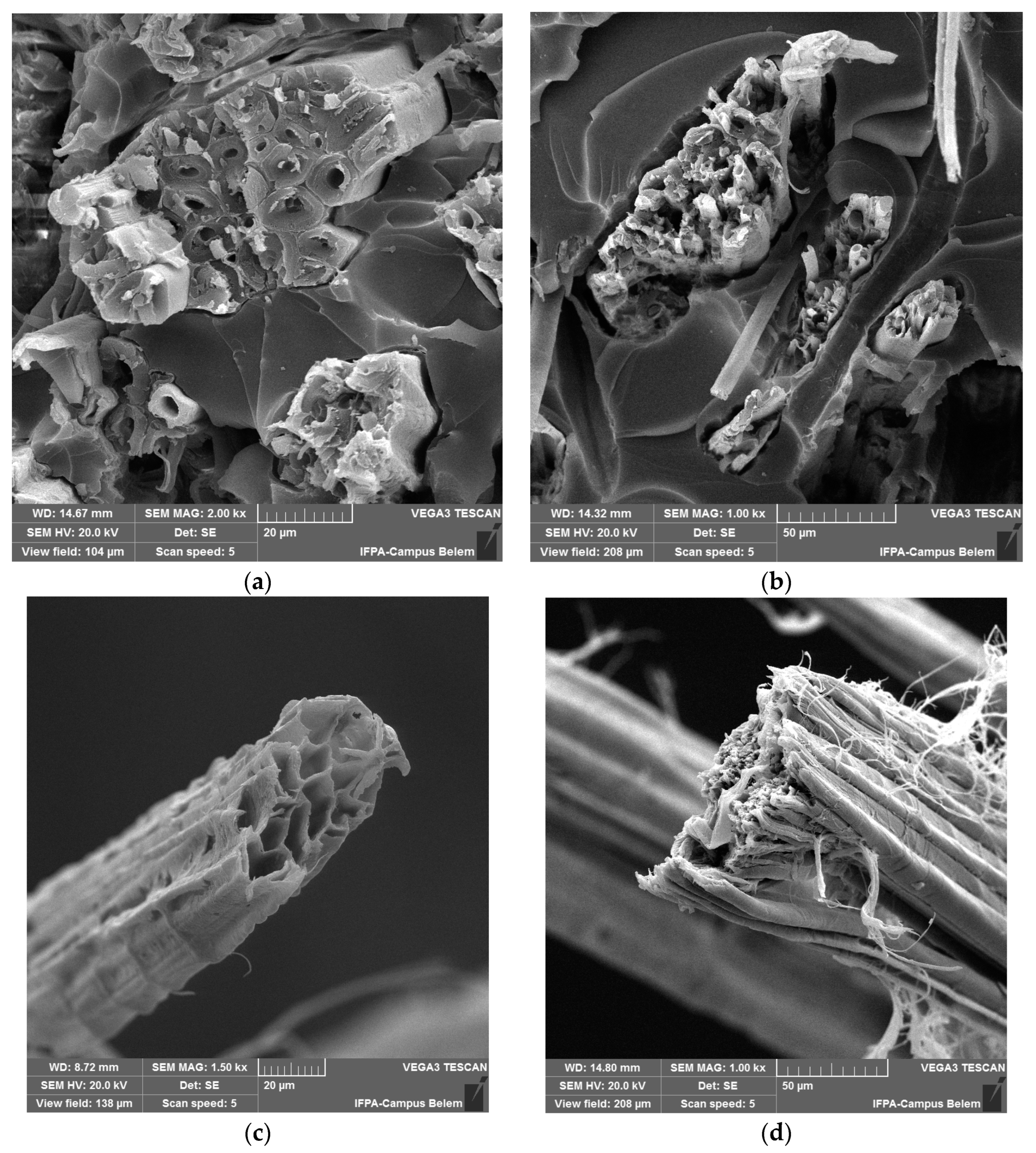

2.6. Scanning Electron Microscope (SEM)

2.7. Modeling

2.8. Statistical Analysis

3. Results and Discussions

3.1. Diameter and Twist Angle Characterization

3.2. Results of Applied Tests

3.2.1. Physical Properties of Fibers

3.2.2. Physical Properties of Composites

3.2.3. Mechanical Properties of Composites in Tensile

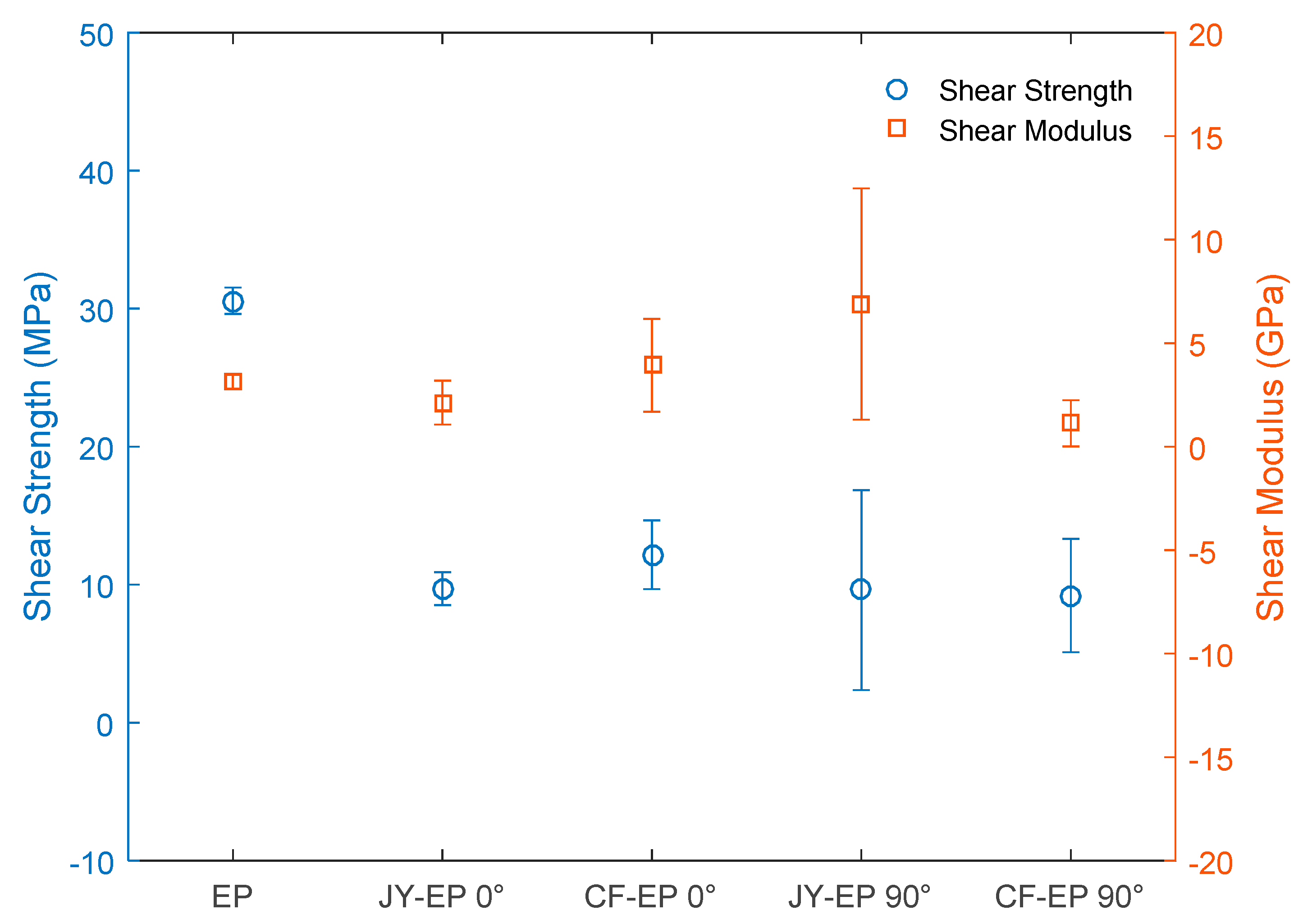

3.2.4. Mechanical Properties of Composites in Shear

3.3. Statistical Analysis

3.3.1. Statistical Analysis in Tensile

3.3.2. Statistical Analysis in Shear

3.4. Computational Modeling of Blades for the S1210 Profile and Environmental Considerations

4. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yang, H.; Chen, J.; Pang, X.; Chen, G. A New Aero-Structural Optimization Method for Wind Turbine Blades Used in Low Wind Speed Areas. Compos. Struct. 2019, 207, 446–459. [Google Scholar] [CrossRef]

- Barnes, R.H.; Morozov, E.V.; Shankar, K. Improved Methodology for Design of Low Wind Speed Specific Wind Turbine Blades. Compos. Struct. 2015, 119, 677–684. [Google Scholar] [CrossRef]

- Gukendran, K.; Sambathkumar, M.; Prakash Raj, T.; Nalinkumar, S.; Nivaas, B.; Sai Pranesh Kumar, B. Effect of various stitching patterns on mechanical properties of jute reinforced composite. Mater. Today Proc. 2023, 80, 882–887. [Google Scholar] [CrossRef]

- Karthi, N.; Kumaresan, K.; Sathish, S.; Gokulkumar, S.; Prabhu, L.; Vigneshkumar, N. An Overview: Natural Fiber Reinforced Hybrid Composites, Chemical Treatments and Application Areas. Mater. Today Proc. 2019, 27, 2828–2834. [Google Scholar] [CrossRef]

- Rangappa, S.M. Lignocellulosic Fiber Reinforced Composite: Progress, Performance, Properties, Applications and Future Perspectives. Polym. Compos. 2022, 43, 645–691. [Google Scholar] [CrossRef]

- Maciel, N.D.O.R.; Ferreira, J.B.; Vieira, J.D.S.; Ribeiro, C.G.D.; Lopes, F.P.D.; Margem, F.M.; Monteiro, S.N.; Vieira, C.M.F.; Silva, L.C. Da Comparative Tensile Strength Analysis between Epoxy Composites Reinforced with Curaua Fiber and Glass Fiber. J. Mater. Res. Technol. 2018, 7, 561–565. [Google Scholar] [CrossRef]

- Belfkira, Z.; Mounir, H.; El Marjani, A. Structural Optimization of a Horizontal Axis Wind Turbine Blade Made from New Hybrid Composites with Kenaf Fibers. Compos. Struct. 2021, 260, 113252. [Google Scholar] [CrossRef]

- Sood, M.; Dwivedi, G. Effect of Fiber Treatment on Flexural Properties of Natural Fiber Reinforced Composites: A Review. Egypt. J. Pet. 2018, 27, 775–783. [Google Scholar] [CrossRef]

- Zhao, X.; Tu, W.; Chen, Q.; Wang, G. Progressive Modeling of Transverse Thermal Conductivity of Unidirectional Natural Fiber Composites. Int. J. Therm. Sci. 2021, 162, 106782. [Google Scholar] [CrossRef]

- Chaudhary, V.; Ahmad, F. A Review on Plant Fiber Reinforced Thermoset Polymers for Structural and Frictional Composites. Polym. Test. 2020, 91, 106792. [Google Scholar] [CrossRef]

- de Lima, T.E.S.; de Azevedo, A.R.G.; Marvila, M.T.; Candido, V.S.; Fediuk, R.; Monteiro, S.N. Potential of Using Amazon Natural Fibers to Reinforce Cementitious Composites: A Review. Polymers 2022, 14, 647. [Google Scholar] [CrossRef] [PubMed]

- Stanciu, M.D.; Draghicescu, H.T.; Tamas, F.; Terciu, O.M. Mechanical and Rheological Behaviour of Composites Reinforced with Natural Fibers. Polymers 2020, 12, 1402. [Google Scholar] [CrossRef] [PubMed]

- Scopus Database Scopus. Available online: https://www.scopus.com/search/form.uri?display=basic#basic (accessed on 16 February 2023).

- Souza, A.T.; Pereira, F.; Neuba, L.D.M.; Clay, A.; Rangel, A.; Azevedo, G. De Caranan Fiber from Mauritiella Armata Palm Tree as Novel Reinforcement for Epoxy Composites. Polymers 2020, 12, 2037. [Google Scholar] [CrossRef]

- Madhusudhana, H.K.; Prasanna Kumar, M.; Patil, A.Y.; Keshavamurthy, R.; Yunus Khan, T.M.; Badruddin, I.A.; Kamangar, S. Analysis of the Effect of Parameters on Fracture Toughness of Hemp Fiber Reinforced Hybrid Composites Using the Anova Method. Polymers 2021, 13, 3013. [Google Scholar] [CrossRef]

- Roy, K.; Debnath, C.S.; Tzounis, L.; Pongwisuthiruchte, A.; Potiyaraj, P. Effect of Various Surface Treatments on the Performance of Jute Fibers Filled Natural Rubber(NR) Composites. Polymers 2020, 12, 369. [Google Scholar] [CrossRef]

- Rani, M.; Choudhary, P.; Krishnan, V.; Zafar, S. A Review on Recycling and Reuse Methods for Carbon Fiber/Glass Fiber Composites Waste from Wind Turbine Blades. Compos. B Eng. 2021, 215, 108768. [Google Scholar] [CrossRef]

- Tanguy, M.; Bourmaud, A.; Beaugrand, J.; Gaudry, T.; Baley, C. Polypropylene Reinforcement with Flax or Jute Fiber; Influence of Microstructure and Constituents Properties on the Performance of Composite. Compos. B Eng. 2018, 139, 64–74. [Google Scholar] [CrossRef]

- Awais, H.; Nawab, Y.; Amjad, A.; Anjang, A.; Akil, H.; Zainol, M.S. Composites Part C: Open Access Environmental Benign Natural Fiber Reinforced Thermoplastic Composites: A Review. Compos. Part C Open Access 2021, 4, 100082. [Google Scholar] [CrossRef]

- Ribeiro, M.M.; Pinheiro, M.A.; Rodrigues, J.d.S.; Ramos, R.P.B.; Corrêa, A.d.C.; Monteiro, S.N.; da Silva, A.C.R.; Candido, V.S. Comparison of Young’s Modulus of Continuous and Aligned Lignocellulosic Jute and Mallow Fibers Reinforced Polyester Composites Determined Both Experimentally and from Theoretical Prediction Models. Polymers 2022, 14, 401. [Google Scholar] [CrossRef]

- Ganesan, K.; Kailasanathan, C.; Rajini, N.; Ismail, S.O.; Ayrilmis, N.; Mohammad, F.; Al-Lohedan, H.A.; Tawfeek, A.M.; Issa, Z.A.; Aldhayan, D.M. Assessment on Hybrid Jute/Coir Fibers Reinforced Polyester Composite with Hybrid Fillers under Different Environmental Conditions. Constr. Build. Mater. 2021, 301, 124117. [Google Scholar] [CrossRef]

- Ahamed, B.; Hasan, M.; Yousuf, A.; Anwarul, M.; Saifullah, A. Composites Part C: Open Access High Performance Short Jute Fiber Preforms for Thermoset Composite Applications. Compos. Part C Open Access 2022, 9, 100318. [Google Scholar] [CrossRef]

- Khalid, M.Y.; Al Rashid, A.; Arif, Z.U.; Sheikh, M.F.; Arshad, H.; Nasir, M.A. Tensile Strength Evaluation of Glass/Jute Fibers Reinforced Composites: An Experimental and Numerical Approach. Results Eng. 2021, 10, 100232. [Google Scholar] [CrossRef]

- Chaturvedi, R.; Pappu, A.; Tyagi, P.; Patidar, R.; Khan, A.; Mishra, A.; Gupta, M.K.; Thakur, V.K. Next-Generation High-Performance Sustainable Hybrid Composite Materials from Silica-Rich Granite Waste Particulates and Jute Textile Fibers in Epoxy Resin. Ind. Crops Prod. 2022, 177, 114527. [Google Scholar] [CrossRef]

- Sajin, J.B.; Christu Paul, R.; Binoj, J.S.; Brailson Mansingh, B.; Gerald Arul Selvan, M.; Goh, K.L.; Rimal Isaac, R.S.; Senthil Saravanan, M.S. Impact of Fiber Length on Mechanical, Morphological and Thermal Analysis of Chemical Treated Jute Fiber Polymer Composites for Sustainable Applications. Curr. Res. Green Sustain. Chem. 2022, 5, 100241. [Google Scholar] [CrossRef]

- Mahmoud Zaghloul, M.Y.; Yousry Zaghloul, M.M.; Yousry Zaghloul, M.M. Developments in Polyester Composite Materials—An In-Depth Review on Natural Fibers and Nano Fillers. Compos. Struct. 2021, 278, 114698. [Google Scholar] [CrossRef]

- Senthilrajan, S.; Venkateshwaran, N.; Naresh, K.; Velmurugan, R.; Gupta, N.K. Effects of Jute Fiber Length and Weight Percentage on Quasi-Static Flexural and Dynamic Mechanical Properties of Jute/Polyester Composites for Thin-Walled Structure Applications. Thin-Walled Struct. 2022, 179, 109719. [Google Scholar] [CrossRef]

- Stanciu, M.D.; Nastac, S.M. Prediction of the Damage Effect on Fiberglass-Reinforced Polymer Matrix Composites for Wind Turbine Blades. Polymers 2022, 14, 1471. [Google Scholar] [CrossRef]

- Mekonnen, B.Y.; Mamo, Y.J. Tensile and Flexural Analysis of a Hybrid Bamboo/Jute Fiber-Reinforced Composite with Polyester Matrix as a Sustainable Green Material for Wind Turbine Blades. Int. J. Eng. Trans. B Appl. 2020, 33, 314–319. [Google Scholar] [CrossRef]

- Pickering, K.L.; Efendy, M.G.A.; Le, T.M. A Review of Recent Developments in Natural Fiber Composites and Their Mechanical Performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef]

- Miliket, T.A.; Ageze, M.B.; Tigabu, M.T.; Zeleke, M.A. Experimental Characterizations of Hybrid Natural Fiber-Reinforced Composite for Wind Turbine Blades. Heliyon 2022, 8, e09092. [Google Scholar] [CrossRef]

- Available online: http://www.cresesb.cepel.br/index.php?section=atlas_eolico (accessed on 7 August 2023).

- Smail, B.Y.; Moumen, E.A.; Imad, A.; Lmai, F.; Elminor, H. The Effects of Environmental Conditions on the Mechanical Properties of Jute Yarns. Mater. Today Proc. 2019, 30, 860–864. [Google Scholar] [CrossRef]

- Pires, E.N.; Merlini, C.; Al-Qureshi, H.A.; Salmória, G.V.; Barra, G.M.O. Effect of Alkaline Treatment of Jute Fibers on the Mechanical Behavior of Epoxy Matrix Composites. Polimeros 2012, 22, 339–344. [Google Scholar] [CrossRef]

- ASTM D 638-14; Standard Test Method for Tensile Properties of Plastics 1. ASTM International: West Conshohocken, PA, USA, 2022. [CrossRef]

- ASTM D3039/D3039M-00; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D5379/D5379M 98; Standard Test Method for Shear Properties of Composite Materials by the V-Notched Beam Method 1. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM D792-13; Standard Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement. American Society for Testing and Materials: West Conshohocken, PA, USA, 2008; p. 6. [CrossRef]

- Alshabib, A.; Silikas, N.; Watts, D.C. Hardness and Fracture Toughness of Resin-Composite Materials with and without Fibers. Dent. Mater. 2019, 35, 1194–1203. [Google Scholar] [CrossRef] [PubMed]

- Filho, E.G.; de Filho, O.; da Luz, F.S.; Fujiyama, R.T.; Da Silva, A.C.R.; Candido, V.S.; Monteiro, S.N.E. Effect of Chemical Treatment and Length of Ra Ffi a Fiber (Raphia vinifera) on Mechanical Stiff Meaning of Polyester Composites. Polym. Artic. 2020, 12, 2899. [Google Scholar] [CrossRef]

- Domingo, R.; De Agustina, B.; Marín, M.M. An Analysis of the Forces in the Cryogenic Peripheral Milling of Composites Reinforced with Carbon Fiber. Procedia Manuf. 2019, 41, 423–429. [Google Scholar] [CrossRef]

- Lassila, L.; Keulemans, F.; Säilynoja, E.; Vallittu, P.K.; Garoushi, S. Mechanical Properties and Fracture Behavior of Flowable Fiber Reinforced Composite Restorations. Dent. Mater. 2018, 34, 598–606. [Google Scholar] [CrossRef]

- Khan, Z.; Tehami, W.; Mehmood, Z. Effect of Moisture/Liquid Absorption on Mechanical Properties of Composites. In Proceedings of the 6th International Conference on Aerospace Science and Engineering, ICASE 2019, Islamabad, Pakistan, 12–14 November 2019. [Google Scholar] [CrossRef]

- Jesus, T.; De Fraxe, P. Nova Técnica Para Extração de Fibras de Juta e Malva Em Processo a Seco No Estado Do Amazonas: O Resgate Da Utopia. Inclusão Soc. 2018, 12, 161–171. [Google Scholar]

- Shi, J.; Yuan, S.; Zhang, W.; Wang, G.; Zhang, J.; Chen, H.; Cheng, H. Jute Yarn-Wound Composites: Optimization of Methods for Evaluating Mechanical Properties and Improvement of Mechanical Properties. J. Mater. Res. Technol. 2022, 21, 827–840. [Google Scholar] [CrossRef]

- Shah, D.U.; Schubel, P.J.; Clifford, M.J. Can Flax Replace E-Glass in Structural Composites? A Small Wind Turbine Blade Case Study. Compos. B Eng. 2013, 52, 172–181. [Google Scholar] [CrossRef]

- Kalagi, G.R.; Patil, R.; Nayak, N. Experimental Study on Mechanical Properties of Natural Fiber Reinforced Polymer Composite Materials for Wind Turbine Blades. Mater. Today Proc. 2018, 5, 2588–2596. [Google Scholar] [CrossRef]

- Lau, K.T.; Hung, P.Y.; Zhu, M.H.; Hui, D. Properties of Natural Fiber Composites for Structural Engineering Applications. Compos. B Eng. 2018, 136, 222–233. [Google Scholar] [CrossRef]

- Meng, H.; Lien, F.; Glinka, G.; Geiger, P. Study on fatigue life of bend-twist coupling wind turbine blade based on anisotropic beam model and stress-based fatigue analysis method. Compos. Struct. 2019, 208, 678–701. [Google Scholar] [CrossRef]

- Kaewniam, P.; Cao, M.; Alkayem, N.F.; Li, D.; Manoach, E. Recent advances in damage detection of wind turbine blades: A state-of-the-art review. Renew. Sustain. Energy Rev. 2022, 167, 112723. [Google Scholar] [CrossRef]

- Pourrajabian, A.; Dehghan, M.; Javed, A.; Wood, D. Choosing an appropriate timber for a small wind turbine blade> A comparative study. Renew. Sustain. Energy Rev. 2019, 100, 1–8. [Google Scholar] [CrossRef]

| Density (g/cm3) | Diameter (μm) | Strain Failure (%) | Tensile Strength (MPa) | Young’s Modulus (Gpa) | Reference |

|---|---|---|---|---|---|

| - | 40.5 | 2.01 | 277 | 15.6 | [18] |

| 1.3–1.5 | - | 1.5–1.8 | 200–800 | 20–55 | [19] |

| 1.482 | 78 | 1.7–4.1 | 380.87 | 17.95 | [20] |

| 1.5 | 90–115 | 1.16–1.80 | 393–773 | 19.0–26.5 | [21] |

| 1.48 | 45 | 1.1 | 270 | 33 | [22] |

| 1.4 | - | 1.5–1.7 | 390–770 | 20–30 | [23] |

| Composition | Nomenclature | Orientation | Quantity Matrix | Quantity Fibers | Number of Samples for Tensile Testing | Number of Samples for Shear Test |

|---|---|---|---|---|---|---|

| (°) | (wt%) | (wt%) | ||||

| Epoxy Resin | - | 100 | 0 | 6 | 3 | |

| JY-EP 0° | Jute Yarn-Epoxy Resin | 0 | 70 | 30 | 6 | 3 |

| JY-EP 90° | Jute Yarn-Epoxy Resin | 90 | 70 | 30 | 6 | 3 |

| CF-EP 0° | Carded Fiber-Epoxy Resin | 0 | 70 | 30 | 6 | 3 |

| CF-EP 90° | Carded Fiber-Epoxy Resin | 90 | 70 | 30 | 6 | 3 |

| Composite 30 wt.% | Density (g/cm3) | Voids Fractions (%) | |

|---|---|---|---|

| EP | 1.16 | 4.4 | This work |

| JY-EP | 1.25 | 5.0 | |

| CF-EP | 1.24 | 6.5 | |

| J-C-PE * | 1.195 | 4.4 | [21] |

| Composite | Orientation | Fiber Volume Fraction | Tensile Strength | Young’s Modulus | Total Strain |

|---|---|---|---|---|---|

| (°) | (%) | (MPa) | (GPa) | (mm/mm) | |

| EP | - | 0 | 41.434 ± 1.182 | 3.608 ± 2.924 | 0.0266 ± 0.018 |

| JY-EP 0° | 0° | 30 | 47.398 ± 3.771 | 9.860 ± 0.784 | 0.0169 ± 0.012 |

| CF-EP 0° | 0° | 30 | 35.307 ± 5.546 | 4.169 ± 0.650 | 0.0088 ± 0.001 |

| JY-EP 90° | 90° | 30 | 10.215 ± 1.982 | 3.375 ± 0.935 | 0.0351 ± 0.023 |

| CF-EP 90° | 90° | 30 | 3.535 ± 0.919 | 1.423 ± 0.695 | 0.0041 ± 0.002 |

| Composite | Orientation | Fiber Volume Fraction | Shear Strength | Shear Modulus | Shear Strain |

|---|---|---|---|---|---|

| (°) | (%) | (MPa) | (GPa) | (mm/mm) | |

| 0EP | - | 0 | 30.580 ± 0.9569 | 3.142 ± 0.328 | 0.00530 ± 0.0043 |

| JY-EP 0° | 0° | 30 | 9.712 ± 1.1944 | 2.129 ± 1.061 | 0.00355 ± 0.0005 |

| CF-EP 0° | 0° | 30 | 12.169 ± 2.4899 | 3.930 ± 2.2462 | 0.00198 ± 0.0035 |

| JY-EP 90° | 90° | 30 | 9.602 ± 7.241 | 6.897 ± 5.588 | 0.002637 ± 0.0021 |

| CF-EP 90° | 90° | 30 | 9.204 ± 4.1084 | 1.130 ± 1.1165 | 0.005753 ± 0.0027 |

| Maximum Strength (MPa) | ||||||

|---|---|---|---|---|---|---|

| Source | Sum of Squares | Degrees of Freedom | Mean of Squares | F (Calculated) | F Critical | p-Value |

| Between the groups | 9453.70 | 4 | 2363.43 | 353.88 | 2.76 | 1.0 × 10−21 |

| Inside the group | 166.96 | 25 | 6.68 | |||

| Total | 9620.66 | 29 | ||||

| Young’s Modulus (GPa) | ||||||

| Source | Sum of Squares | Degrees of Freedom | Mean of Squares | F (Calculated) | F Critical | p-Value |

| Between the groups | 238.01 | 4 | 59.50 | 26.14 | 2.76 | 1.0 × 10−8 |

| Inside the group | 56.90 | 25 | 2.28 | |||

| Total | 294.91 | 29 | ||||

| Total Strain (mm/mm) | ||||||

| Source | Sum of Squares | Degrees of Freedom | Mean of Squares | F (Calculated) | F Critical | p-Value |

| Between the groups | 0.0035 | 4 | 8.83 × 10−4 | 4.3263 | 2.76 | 8.59 × 10−3 |

| Inside the group | 0.0051 | 25 | 2.04 × 10−4 | |||

| Total | 0.0086 | 29 | ||||

| Maximum Strength (MPa) (m.s.d = 1.287) | |||||

|---|---|---|---|---|---|

| 0EP | JY-EP 0° | CF-EP 0° | JY-EP 90° | CF-EP 90° | |

| 0EP | - | 0.004 | 0.23 | 0.0001 | 0.0001 |

| JY-EP 0° | 5.66 | - | 0.0001 | 0.0001 | 0.0001 |

| CF-EP 0° | 3.05 | 8.71 | - | 0.0001 | 0.0001 |

| JY-EP 90° | 29.59 | 35.24 | 26.53 | - | 0.0014 |

| CF-EP 90° | 35.92 | 41.58 | 32.87 | 6.33 | - |

| Young’s Modulus (GPa) (m.s.d. = 0.752) | |||||

| 0EP | JY-EP 0° | CF-EP 0° | JY-EP 90° | CF-EP 90° | |

| 0EP | - | 0.0001 | 0.98 | 0.96 | 0.050 |

| JY-EP 0° | 9.54 | - | 0.0001 | 0.0001 | 0.0001 |

| CF-EP 0° | 0.76 | 8.79 | - | 0.73 | 0.015 |

| JY-EP 90° | 0.98 | 10.53 | 1.74 | - | 0.20 |

| CF-EP 90° | 4.16 | 13.70 | 4.91 | 3.17 | - |

| Total Strain (mm/mm) (m.s.d. = 0.00711) | |||||

| 0EP | JY-EP 0° | CF-EP 0° | JY-EP 90° | CF-EP 90° | |

| 0EP | - | 0.93 | 0.45 | 0.62 | 0.17 |

| JY-EP 0° | 1.11 | - | 0.89 | 0.21 | 0.54 |

| CF-EP 0° | 2.40 | 1.29 | - | 0.034 | 0.97 |

| JY-EP 90° | 2.01 | 3.12 | 4.41 | - | 0.008 |

| CF-EP 90° | 3.30 | 2.19 | 0.90 | 5.31 | - |

| Shear Strength (MPa) | ||||||

|---|---|---|---|---|---|---|

| Source | Sum of Squares | Degrees of Freedom | Mean of Squares | F (Calculated) | F Critical | p-Value |

| Between the groups | 3.14 × 10−5 | 4 | 7.851 × 10−6 | 1.356 | 3.48 | 3.159 × 10−1 |

| Inside the group | 5.788 × 10−5 | 10 | 5.788 × 10−6 | - | - | - |

| Total | 8.928 × 10−5 | 14 | - | - | - | - |

| Shear Modulus (GPa) | ||||||

| Source | Sum of Squares | Degrees of Freedom | Mean of Squares | F (Calculated) | F Critical | p-Value |

| Between the groups | 157.40 | 4 | 39.35 | 0.65 | 3.48 | 6.36 × 10−1 |

| Inside the group | 600.51 | 10 | 60.05 | - | - | - |

| Total | 757.91 | 14 | - | - | - | - |

| Shear Strain (mm/mm) | ||||||

| Source | Sum of Squares | Degrees of Freedom | Mean of Squares | F (Calculated) | F Critical | p-Value |

| Between the groups | 5.96 × 10−4 | 4 | 1.49 × 10−4 | 17.4266 | 3.48 | 1.67 × 10−4 |

| Inside the group | 8.55 × 10−5 | 10 | 8.55 × 10−6 | - | - | - |

| Total | 0.000682 | 14 | - | - | - | - |

| Shear Strain (mm/mm) (m.s.d. = 0.00361) | |||||

|---|---|---|---|---|---|

| 0EP | JY-EP 0° | CF-EP 0° | JY-EP 90° | CF-EP 90° | |

| 0EP | - | 0.9444 | 0.0008718 | 0.7963 | 0.9996 |

| JY-EP 0° | 1.033 | - | 0.0003493 | 0.9947 | 0.8822 |

| CF-EP 0° | 8.598 | 9.631 | - | 0.0002215 | 0.00112 |

| JY-EP 90° | 1.575 | 0.5419 | 10.17 | - | 0.6946 |

| CF-EP 90° | 0.2707 | 1.303 | 8.327 | 1.845 | - |

| Composite | Wind Power | Rated Power | Tip Speed Rotation | Length Blade | |

|---|---|---|---|---|---|

| W/m3 | kW | m/s | m | ||

| Jute/Epoxy | 134.43 | 62 | 24.23 | 1.64 | This work |

| E-Glass/Flex/Epoxy | -- | 100 | 11.90 | 3.50 | [47] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cardoso, R.L.B.; da Silva Rodrigues, J.; Ramos, R.P.B.; de Castro Correa, A.; Leão Filha, E.M.; Monteiro, S.N.; da Silva, A.C.R.; Fujiyama, R.T.; Candido, V.S. Use of Yarn and Carded Jute as Epoxy Matrix Reinforcement for the Production of Composite Materials for Application in the Wind Sector: A Preliminary Analysis for the Manufacture of Blades for Low-Intensity Winds. Polymers 2023, 15, 3682. https://doi.org/10.3390/polym15183682

Cardoso RLB, da Silva Rodrigues J, Ramos RPB, de Castro Correa A, Leão Filha EM, Monteiro SN, da Silva ACR, Fujiyama RT, Candido VS. Use of Yarn and Carded Jute as Epoxy Matrix Reinforcement for the Production of Composite Materials for Application in the Wind Sector: A Preliminary Analysis for the Manufacture of Blades for Low-Intensity Winds. Polymers. 2023; 15(18):3682. https://doi.org/10.3390/polym15183682

Chicago/Turabian StyleCardoso, Robson Luis Baleeiro, Jean da Silva Rodrigues, Roberto Paulo Barbosa Ramos, Alessandro de Castro Correa, Elza Monteiro Leão Filha, Sergio Neves Monteiro, Alisson Clay Rios da Silva, Roberto Tetsuo Fujiyama, and Verônica Scarpini Candido. 2023. "Use of Yarn and Carded Jute as Epoxy Matrix Reinforcement for the Production of Composite Materials for Application in the Wind Sector: A Preliminary Analysis for the Manufacture of Blades for Low-Intensity Winds" Polymers 15, no. 18: 3682. https://doi.org/10.3390/polym15183682

APA StyleCardoso, R. L. B., da Silva Rodrigues, J., Ramos, R. P. B., de Castro Correa, A., Leão Filha, E. M., Monteiro, S. N., da Silva, A. C. R., Fujiyama, R. T., & Candido, V. S. (2023). Use of Yarn and Carded Jute as Epoxy Matrix Reinforcement for the Production of Composite Materials for Application in the Wind Sector: A Preliminary Analysis for the Manufacture of Blades for Low-Intensity Winds. Polymers, 15(18), 3682. https://doi.org/10.3390/polym15183682