A Printing Strategy for Embedding Conductor Paths into FFF Printed Parts

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

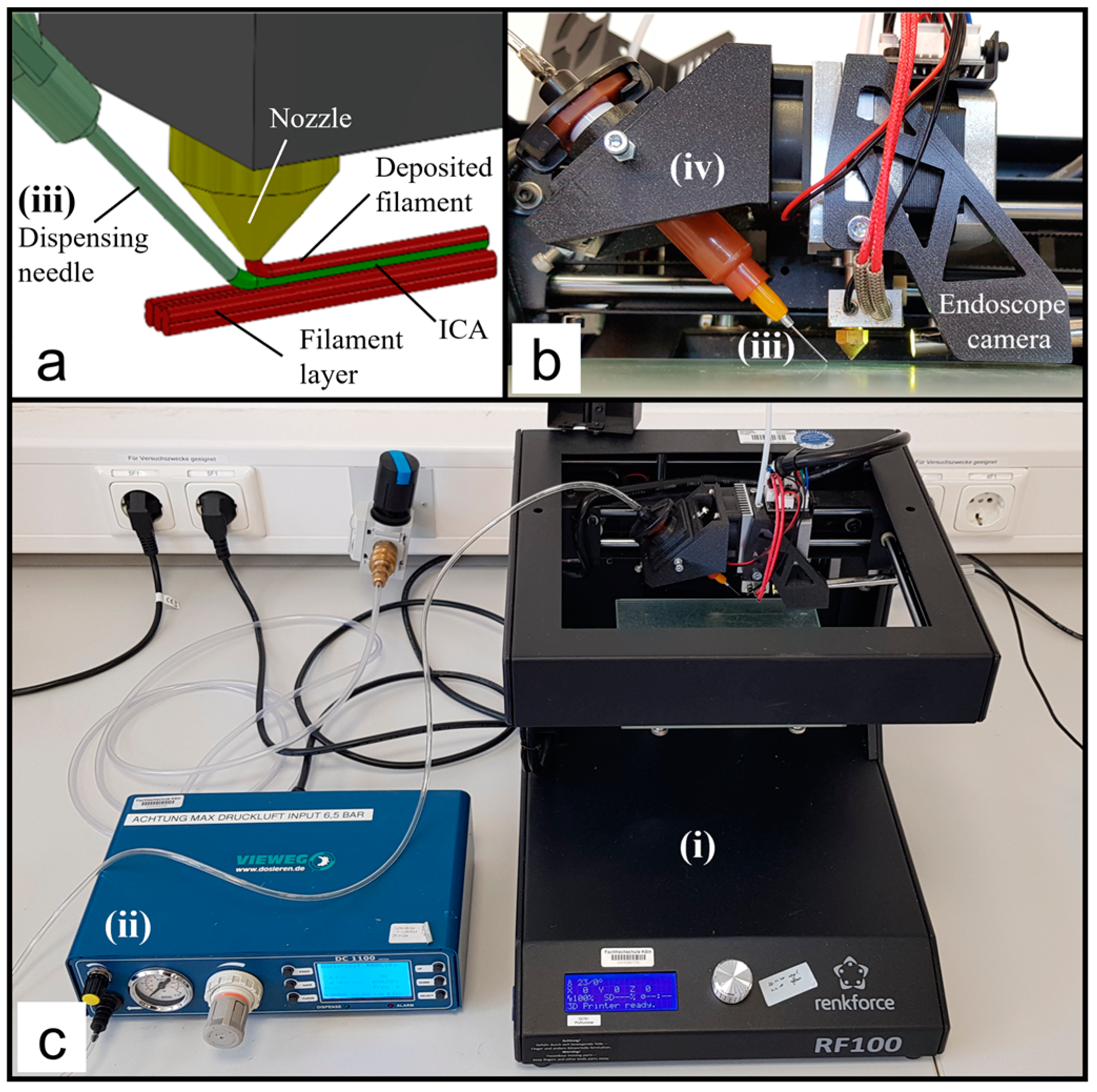

2.2. FFF Printer Customization

- (i)

- A Cartesian XY-head, single extruder FFF printer (RF100 by Renkforce, Hirschau, Germany). The printhead moves along a X and Y gantry. The distance of the nozzle to the non-heated build platform is set by the movement of the print bed in Z direction.

- (ii)

- A digital dispenser (model DC1100 by VIEWEG GmbH, Kranzberg, Germany) for dosing the ICA using the time-pressure technique.

- (iii)

- A 5 cc syringe barrel and a dispensing tip with an inner cannula diameter of 0.34 mm (GONANO Dosiertechnik GmbH, Breitstetten, Germany), and both are lightproof against UV light.

- (iv)

- A 3D-printed holder to attach the dispensing system to the print head. The dispensing needle is aligned with the nozzle by four thrust screws. The ICA is applied in front of the plastic deposition. Due to this arrangement, the embedding of the ICA is done linearly from right to left (Figure 2a,b). Since the dispensing needle is 1 mm lower than the nozzle, the syringe cartridge with the dispensing needle is only inserted while the ICA is being deposited.

2.3. Process Parameters

2.4. Experimental Approach

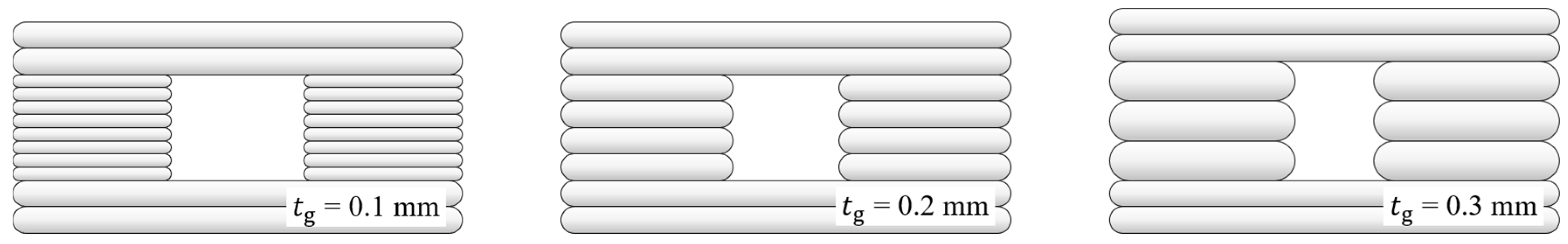

2.4.1. Groove Layer Height

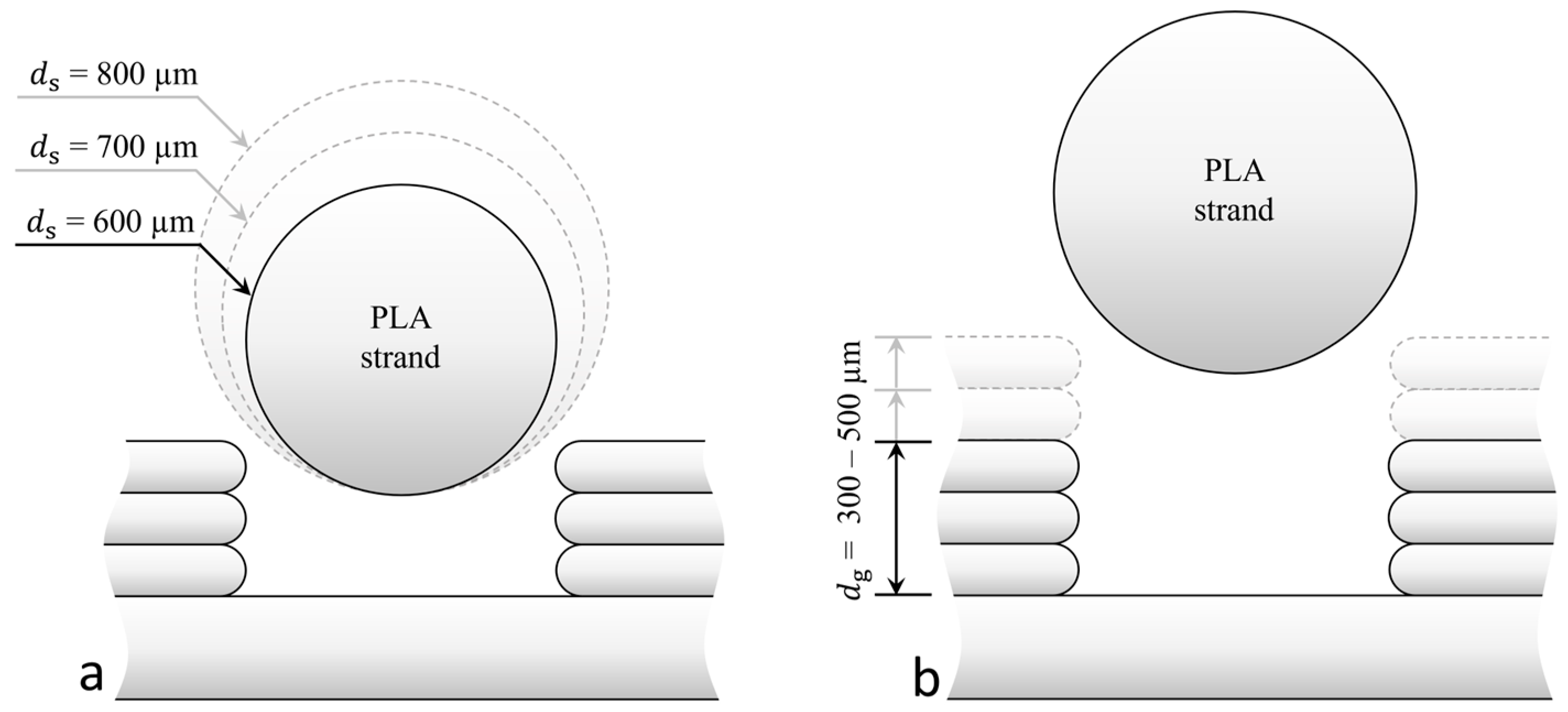

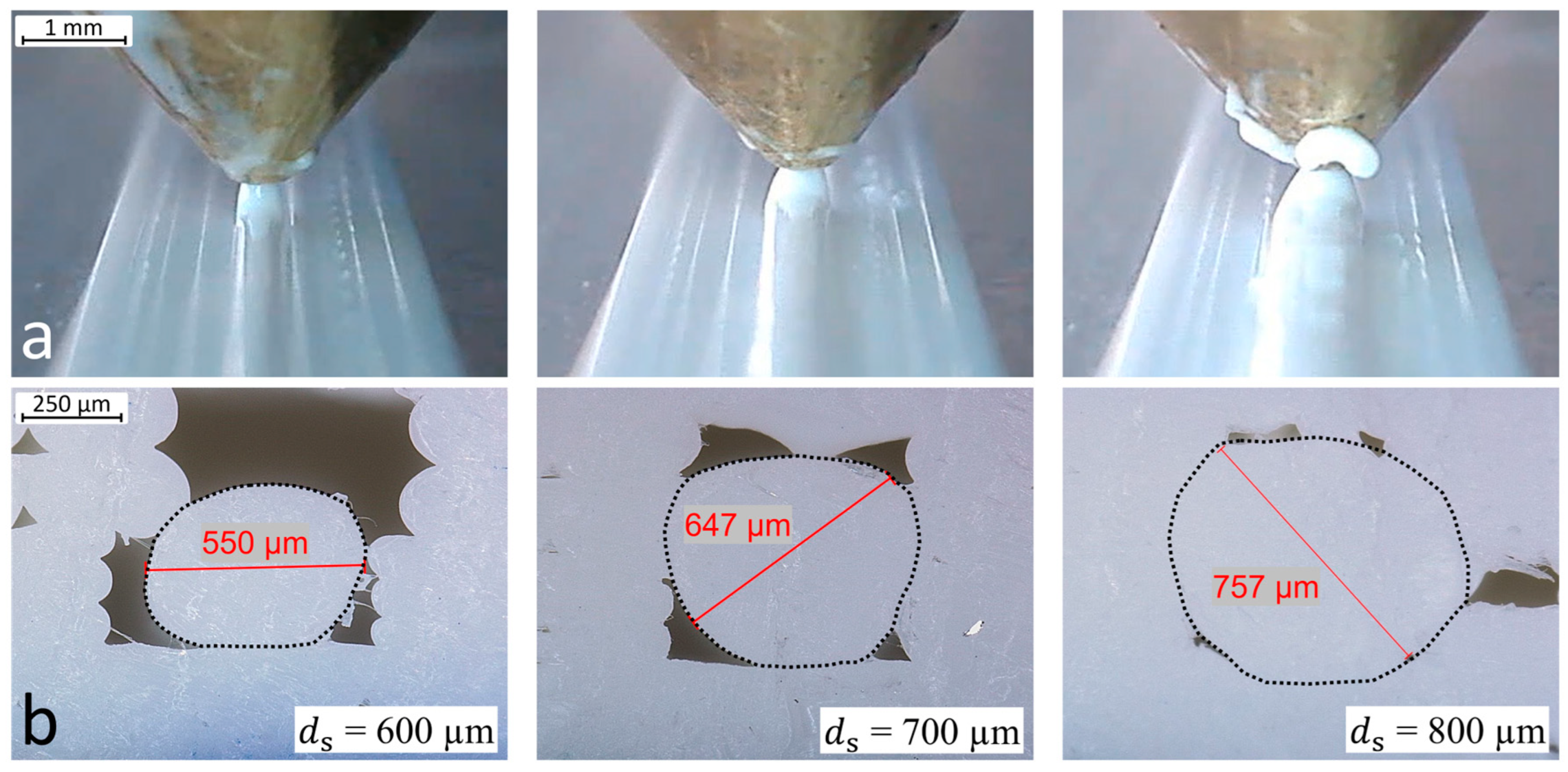

2.4.2. Strand Diameter

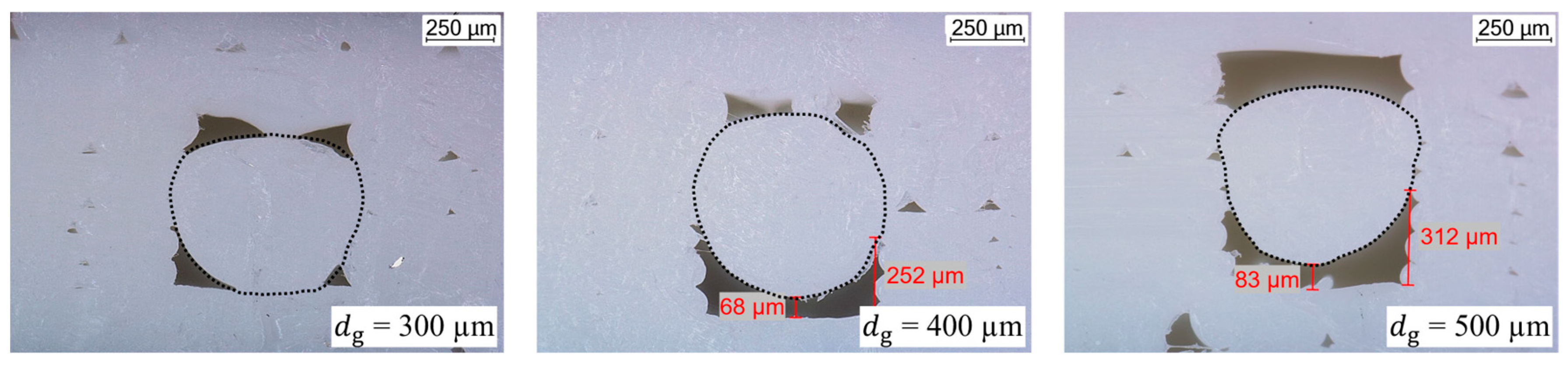

2.4.3. Groove Depth

2.4.4. Groove Sealing Strategy Evaluation

3. Results and Discussion

3.1. Groove Layer Height

3.2. Strand Diameter

3.3. Groove Depth

3.4. Groove Sealing Strategy Evaluation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Borghetti, M.; Cantu, E.; Sardini, E.; Serpelloni, M. Printed Sensors for Smart Objects in Industry 4.0. In Proceedings of the 6th International Forum on Research and Technologies for Society and Industry, IEEE RTSI, Naples, Italy, 6–9 September 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 57–62, ISBN 978-1-6654-4135-3. [Google Scholar]

- Liang, M.; Wu, J.; Yu, X.; Xin, H. 3D printing technology for RF and THz antennas. In Proceedings of the 2016 International Symposium on Antennas and Propagation (ISAP), Okinawa, Japan, 24–28 October 2016; pp. 536–537. [Google Scholar]

- Goh, G.L.; Dikshit, V.; Koneru, R.; Peh, Z.K.; Lu, W.; Goh, G.D.; Yeong, W.Y. Fabrication of design-optimized multifunctional safety cage with conformal circuits for drone using hybrid 3D printing technology. Int. J. Adv. Manuf. Technol. 2022, 120, 2573–2586. [Google Scholar] [CrossRef]

- Cai, N.; Sun, P.; Jiang, S. Rapid prototyping and customizable multifunctional structures: 3D-printing technology promotes the rapid development of TENGs. J. Mater. Chem. A 2021, 9, 16255–16280. [Google Scholar] [CrossRef]

- Espera, A.H.; Dizon, J.R.C.; Chen, Q.; Advincula, R.C. 3D-printing and advanced manufacturing for electronics. Prog. Addit. Manuf. 2019, 4, 245–267. [Google Scholar] [CrossRef]

- de Pasquale, G. Additive Manufacturing of Micro-Electro-Mechanical Systems (MEMS). Micromachines 2021, 12, 1374. [Google Scholar] [CrossRef] [PubMed]

- Goh, G.L.; Zhang, H.; Chong, T.H.; Yeong, W.Y. 3D Printing of Multilayered and Multimaterial Electronics: A Review. Adv. Electron. Mater. 2021, 7, 2100445. [Google Scholar] [CrossRef]

- Park, Y.-G.; Yun, I.; Chung, W.G.; Park, W.; Lee, D.H.; Park, J.-U. High-Resolution 3D Printing for Electronics. Adv. Sci. 2022, 9, e2104623. [Google Scholar] [CrossRef] [PubMed]

- Hoerber, J.; Glasschroeder, J.; Pfeffer, M.; Schilp, J.; Zaeh, M.; Franke, J. Approaches for Additive Manufacturing of 3D Electronic Applications. Procedia CIRP 2014, 17, 806–811. [Google Scholar] [CrossRef]

- Lopes, A.J.; MacDonald, E.; Wicker, R.B. Integrating stereolithography and direct print technologies for 3D structural electronics fabrication. Rapid Prototyp. J. 2012, 18, 129–143. [Google Scholar] [CrossRef]

- Wasley, T.; Li, J.; Ta, D.; Shephard, J.; Stringer, J.; Smith, P.; Esenturk, E.; Connaughton, C.; Kay, R. Additive Manufacturing of High Resolution Embedded Electronic Systems. In Proceedings of the 26th Annual International Solid Freeform Fabrication, Austin, TX, USA, 10–12 August 2016; pp. 1838–1855. [Google Scholar]

- Elibiary, A.; Oakey, W.; Jun, S.; Sanz-Izquierdo, B.; Bird, D.; Mc Clelland, A. Fully 3D printed GPS antenna using a low-cost open-source printer. In Proceedings of the Loughborough Antennas & Propagation Conference (LAPC 2017), Loughborough, UK, 14–15 November 2017; pp. 1–4. [Google Scholar]

- Nassar, H.; Ntagios, M.; Navaraj, W.T.; Dahiva, R. Multi-Material 3D Printed Bendable Smart Sensing Structures. In Proceedings of the 2018 IEEE Sensors, New Delhi, India, 28–31 October 2018; pp. 1–4, ISBN 978-1-5386-4707-3. [Google Scholar]

- Wasserfall, F. Integration of Conductive Materials and SMD-Components into the FDM Printing Process for Direct Embedding of electronic Circuits. Ph.D. Thesis, Universität Hamburg, Hamburg, Germany, 2019. [Google Scholar]

- Arnal, N.; Ketterl, T.; Vega, Y.; Stratton, J.; Perkowski, C.; Deffenbaugh, P.; Church, K.; Weller, T. 3D multi-layer additive manufacturing of a 2.45 GHz RF front end. In Proceedings of the IEEE MTT-S International Microwave Symposium, Phoenix, AZ, USA, 17–22 May 2015; pp. 1–4, ISBN 0149-645X. [Google Scholar]

- Espalin, D.; Muse, D.W.; MacDonald, E.; Wicker, R.B. 3D Printing multifunctionality: Structures with electronics. Int. J. Adv. Manuf. Technol. 2014, 72, 963–978. [Google Scholar] [CrossRef]

- Ahmadloo, M.; Mousavi, P. A novel integrated dielectric-and-conductive ink 3D printing technique for fabrication of microwave devices. In Proceedings of the IEEE MTT-S International Microwave Symposium Digest (MTT), Seattle, WA, USA, 2–7 June 2013; pp. 1–3, ISBN 0149-645X. [Google Scholar]

- Yu, Z.; Huang, F.; Zhang, T.; Tang, C.; Cui, X.; Yang, C. Effects of different thermal sintering temperatures on pattern resistivity of printed silver ink with multiple particle sizes. AIP Adv. 2021, 11, 115116. [Google Scholar] [CrossRef]

- Olsen, E.; Overmeyer, L. Laser sintering of copper conductive traces on primer pre-treated additive manufactured 3D surfaces. Flex. Print. Electron. 2021, 6, 15006. [Google Scholar] [CrossRef]

- Roshanghias, A.; Krivec, M.; Baumgart, M. Sintering strategies for inkjet printed metallic traces in 3D printed electronics. Flex. Print. Electron. 2017, 2, 45002. [Google Scholar] [CrossRef]

- Kronberger, R.; Grünwald, S.; Wienstroer, V.; Tsatsos, V. New Low-Cost FDM Technology for Printing Antennas. In Proceedings of the International Symposium on Antennas and Propagation (ISAP), Osaka, Japan, 25–28 January 2020; pp. 571–572. [Google Scholar]

- Delo. DELO DUALBOND® IC4753, Windach, Germany, 2022. Available online: https://www.delo-adhesives.com/us/service-center/downloads/downloads/datasheet/DELO%20DUALBOND_IC4753_TIDB-en.pdf?show=1&type=5001&cHash=39489453a92d624c4dafb22f7ea499a5 (accessed on 5 December 2022).

- Filamentworld. Filamentworld—PLA Filament, Neu-Ulm, Germany. 2022. Available online: https://www.filamentworld.de/shop/pla-filament-3d-drucker/weiss/ (accessed on 7 December 2022).

- Lehermeier, H.; Dorgan, J. Melt rheology of poly(lactic acid): Consequences of blending chain architectures. Polym. Eng. Sci. 2001, 41, 2172–2184. [Google Scholar] [CrossRef]

- Grünwald, S. Reproducible Dispensing of Liquids in the Nanolitre Range. Adhes Adhes Sealants 2018, 15, 28–31. [Google Scholar] [CrossRef]

- Plott, J.; Tian, X.; Shih, A. Measurement and Modeling of Forces in Extrusion-Based Additive Manufacturing of Flexible Silicone Elastomer with Thin Wall Structures. J. Manuf. Sci. Eng. 2018, 140, 091009. [Google Scholar] [CrossRef]

- Vyavahare, S.; Kumar, S.; Panghal, D. Experimental study of surface roughness, dimensional accuracy and time of fabrication of parts produced by fused deposition modelling. Rapid Prototyp. J. 2020, 26, 1535–1554. [Google Scholar] [CrossRef]

- Jin, Y.; Li, H.; He, Y.; Fu, J. Quantitative analysis of surface profile in fused deposition modelling. Addit. Manuf. 2015, 8, 142–148. [Google Scholar] [CrossRef]

- Abas, M.; Habib, T.; Noor, S.; Salah, B.; Zimon, D. Parametric Investigation and Optimization to Study the Effect of Process Parameters on the Dimensional Deviation of Fused Deposition Modeling of 3D Printed Parts. Polymers 2022, 14, 3667. [Google Scholar] [CrossRef] [PubMed]

- Deswal, S.; Narang, R.; Chhabra, D. Modeling and parametric optimization of FDM 3D printing process using hybrid techniques for enhancing dimensional preciseness. Int. J. Interact. Des. Manuf. 2019, 13, 1197–1214. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Nozzle diameter | 0.4 mm |

| Nozzle temperature | 210 °C |

| 3D printing layer height tp (part) | 0.2 mm |

| Groove width w | 600 µm |

| Strand deposit height h (Above top edge of the groove) | —100 µm |

| Print speed (during printing) | 3000 mm/min |

| Print speed (during embedding) | 300 mm/min |

| Parameter | Value |

|---|---|

| Cannula inner diameter | 0.34 mm |

| Cannula length | ½ in |

| Dosing speed | 300 mm/min |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Banko, T.; Grünwald, S.; Kronberger, R.; Seitz, H. A Printing Strategy for Embedding Conductor Paths into FFF Printed Parts. Polymers 2023, 15, 3498. https://doi.org/10.3390/polym15173498

Banko T, Grünwald S, Kronberger R, Seitz H. A Printing Strategy for Embedding Conductor Paths into FFF Printed Parts. Polymers. 2023; 15(17):3498. https://doi.org/10.3390/polym15173498

Chicago/Turabian StyleBanko, Timo, Stefan Grünwald, Rainer Kronberger, and Hermann Seitz. 2023. "A Printing Strategy for Embedding Conductor Paths into FFF Printed Parts" Polymers 15, no. 17: 3498. https://doi.org/10.3390/polym15173498

APA StyleBanko, T., Grünwald, S., Kronberger, R., & Seitz, H. (2023). A Printing Strategy for Embedding Conductor Paths into FFF Printed Parts. Polymers, 15(17), 3498. https://doi.org/10.3390/polym15173498