Thermal and Mechanical Properties of Reprocessed Polylactide/Titanium Dioxide Nanocomposites for Material Extrusion Additive Manufacturing

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Production of Reprocessed PLA

2.3. Manufacturing of Nanocomposites

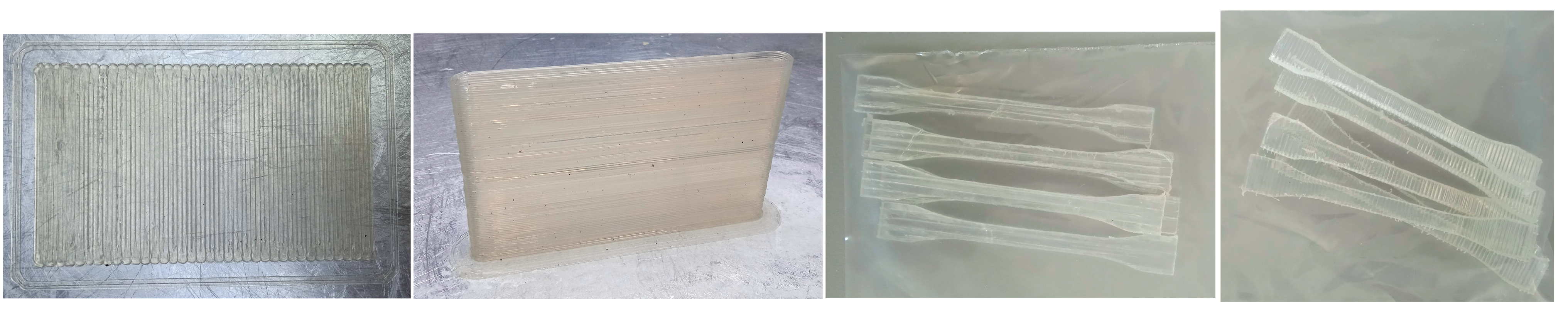

2.4. Printing

2.5. Cutting of Samples

2.6. Characterization and Testing

3. Results

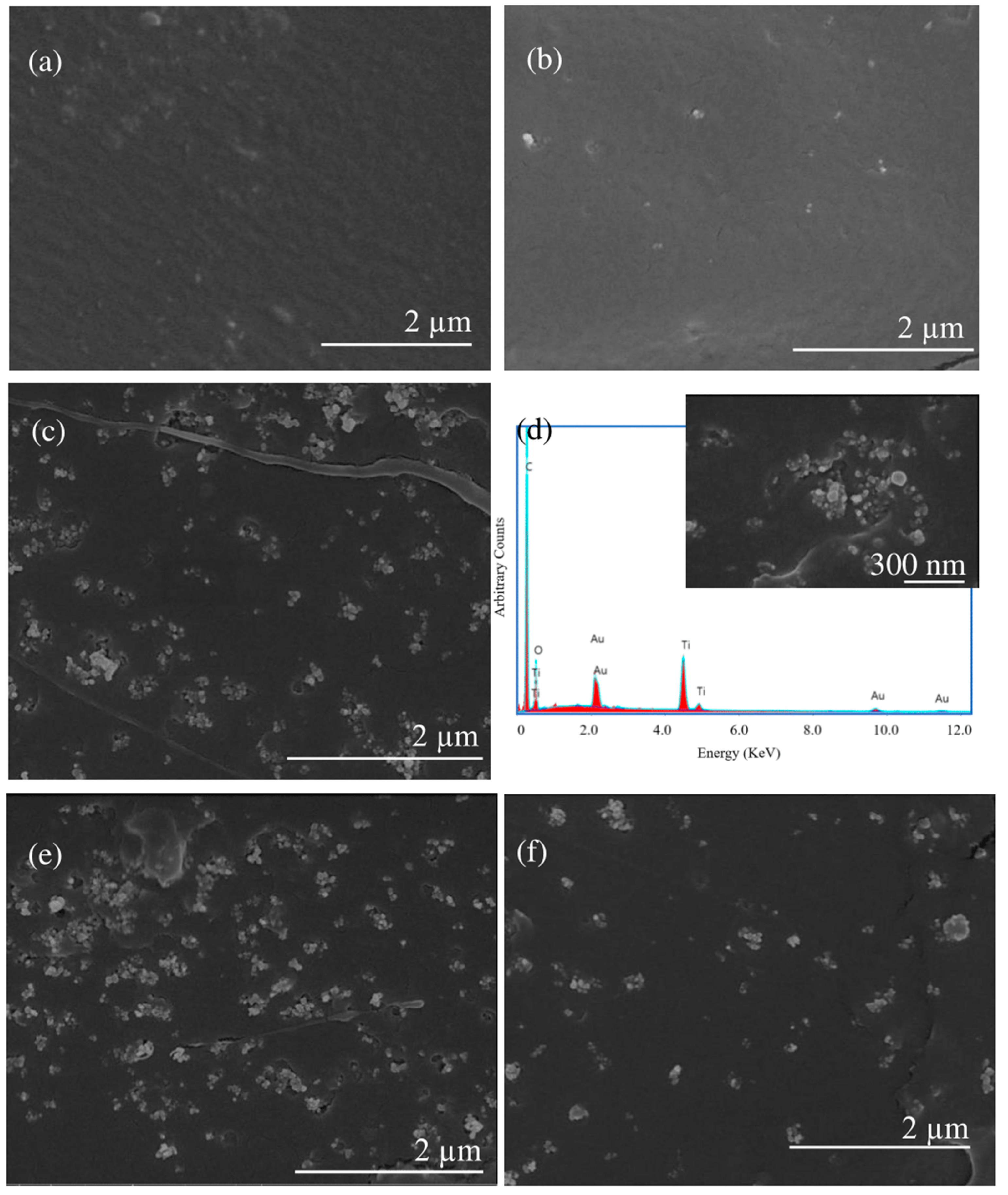

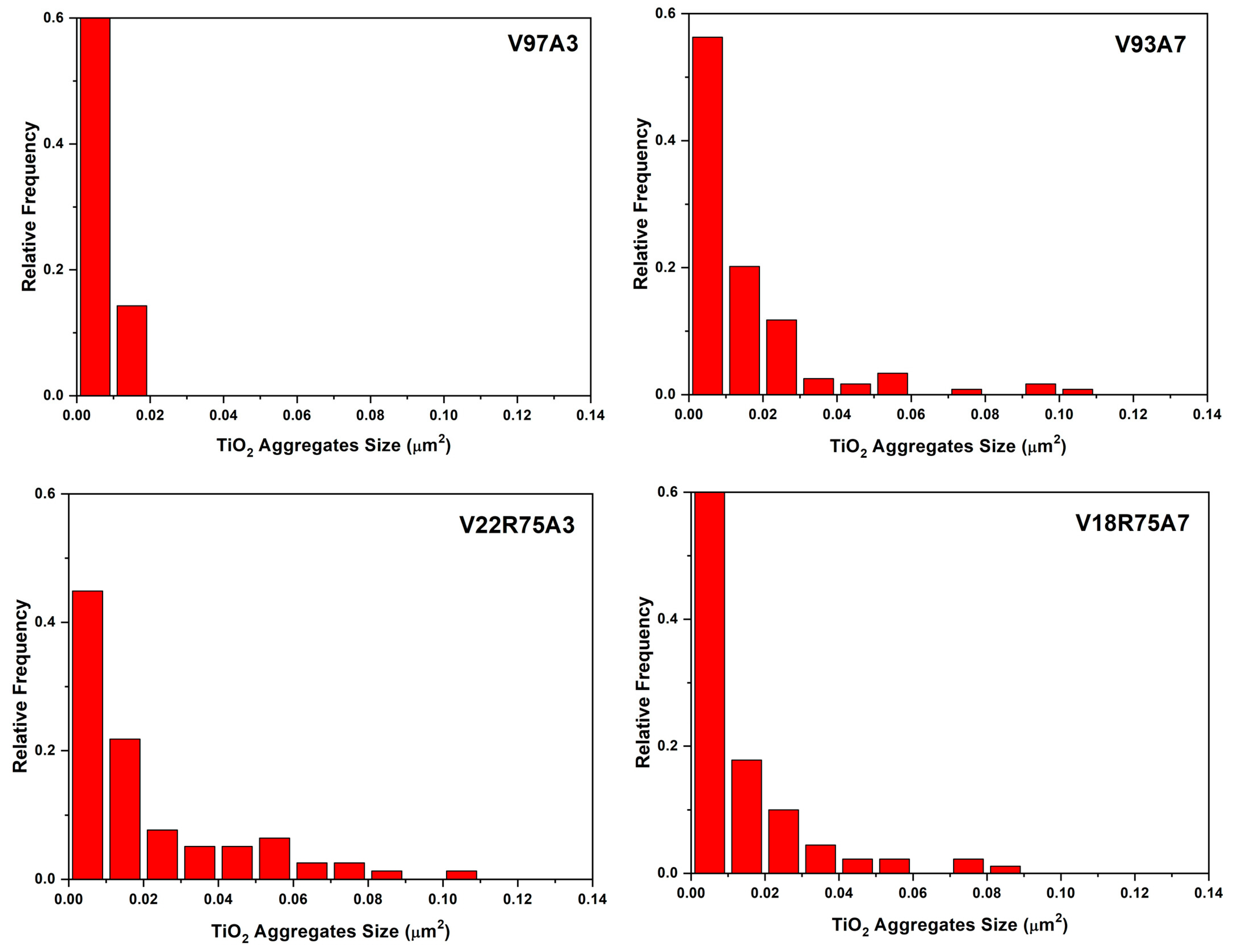

3.1. Scanning Electron Microscopy

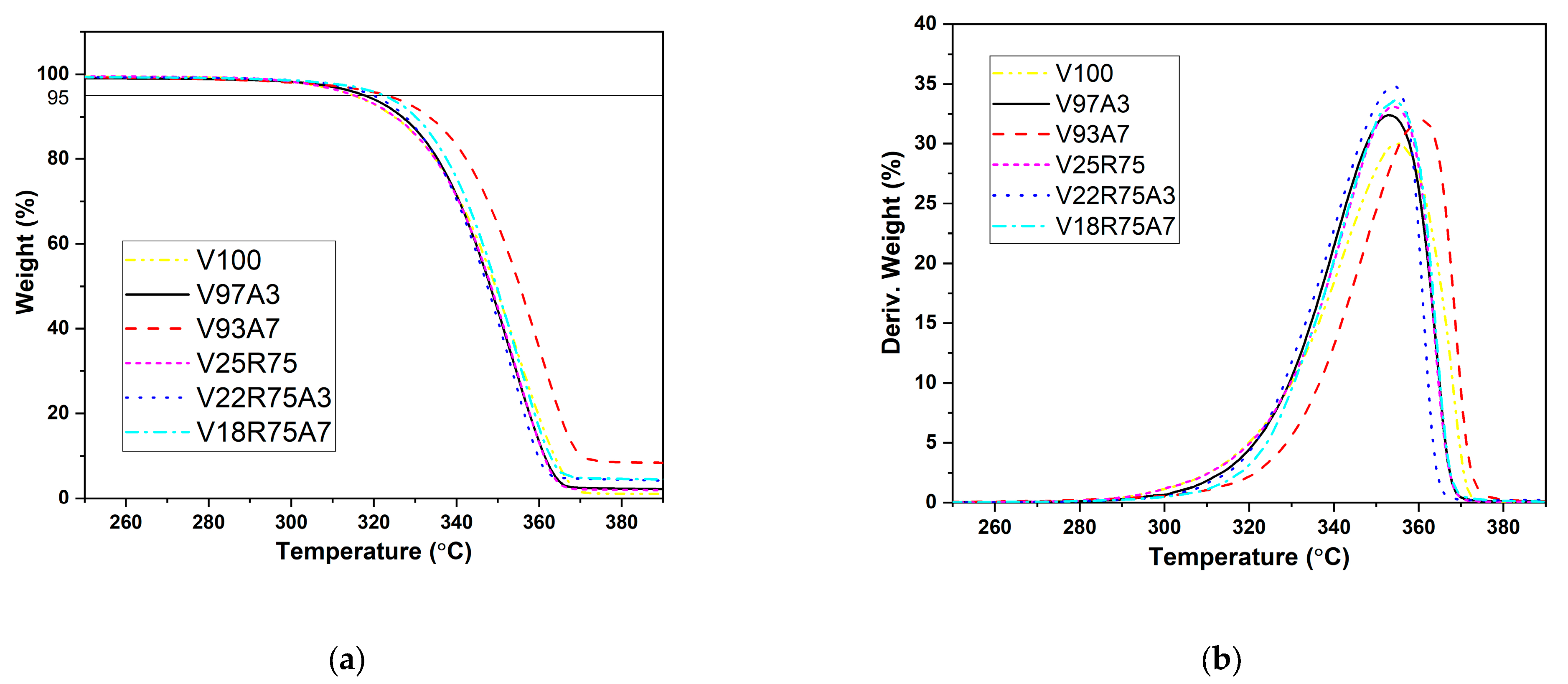

3.2. Thermogravimetric Analysis

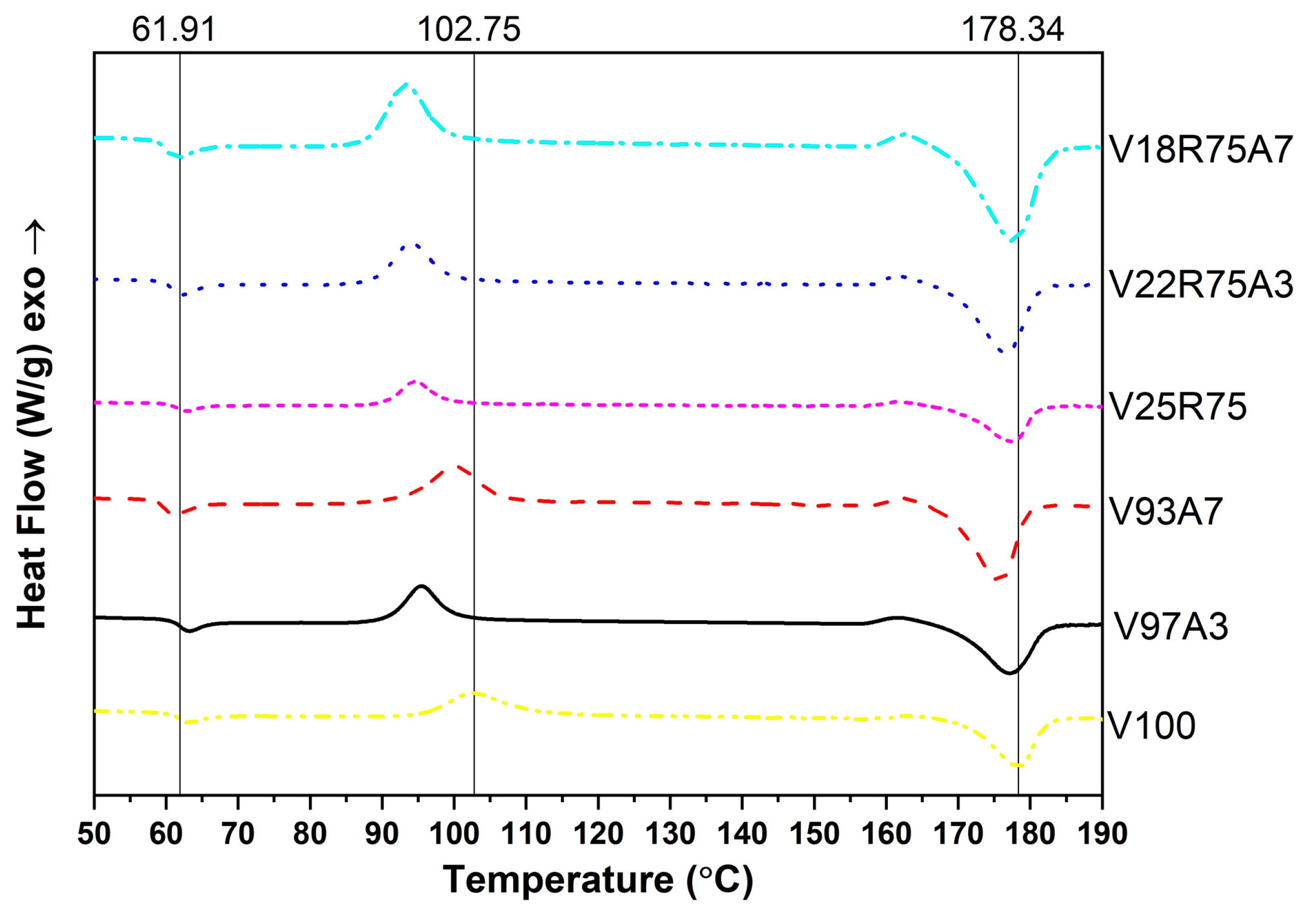

3.3. Differential Scanning Calorimetry

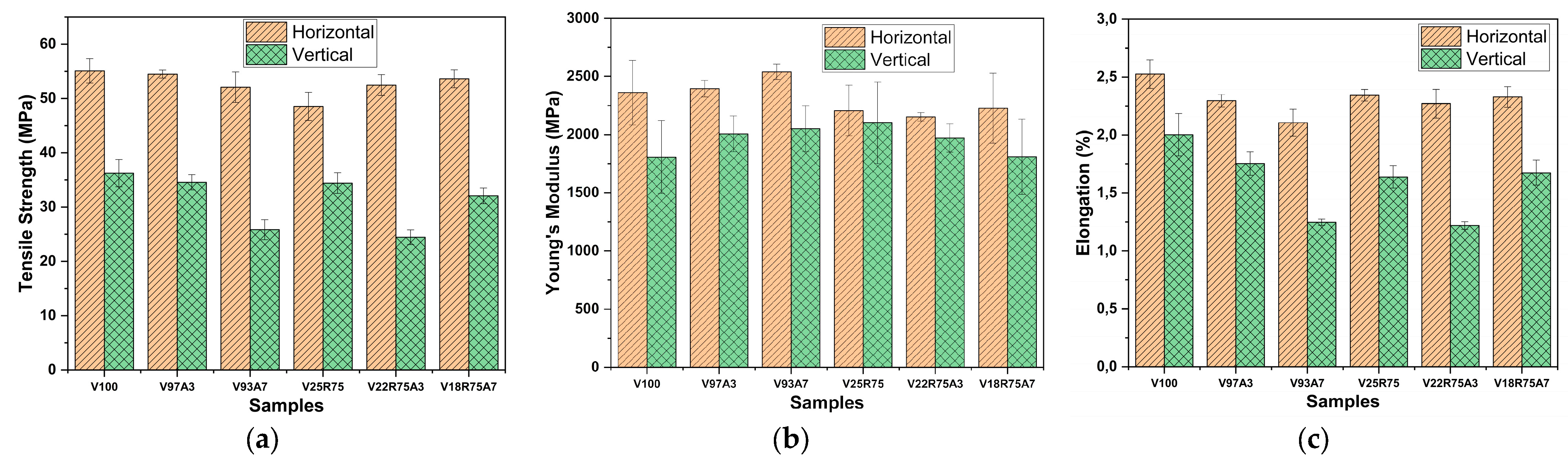

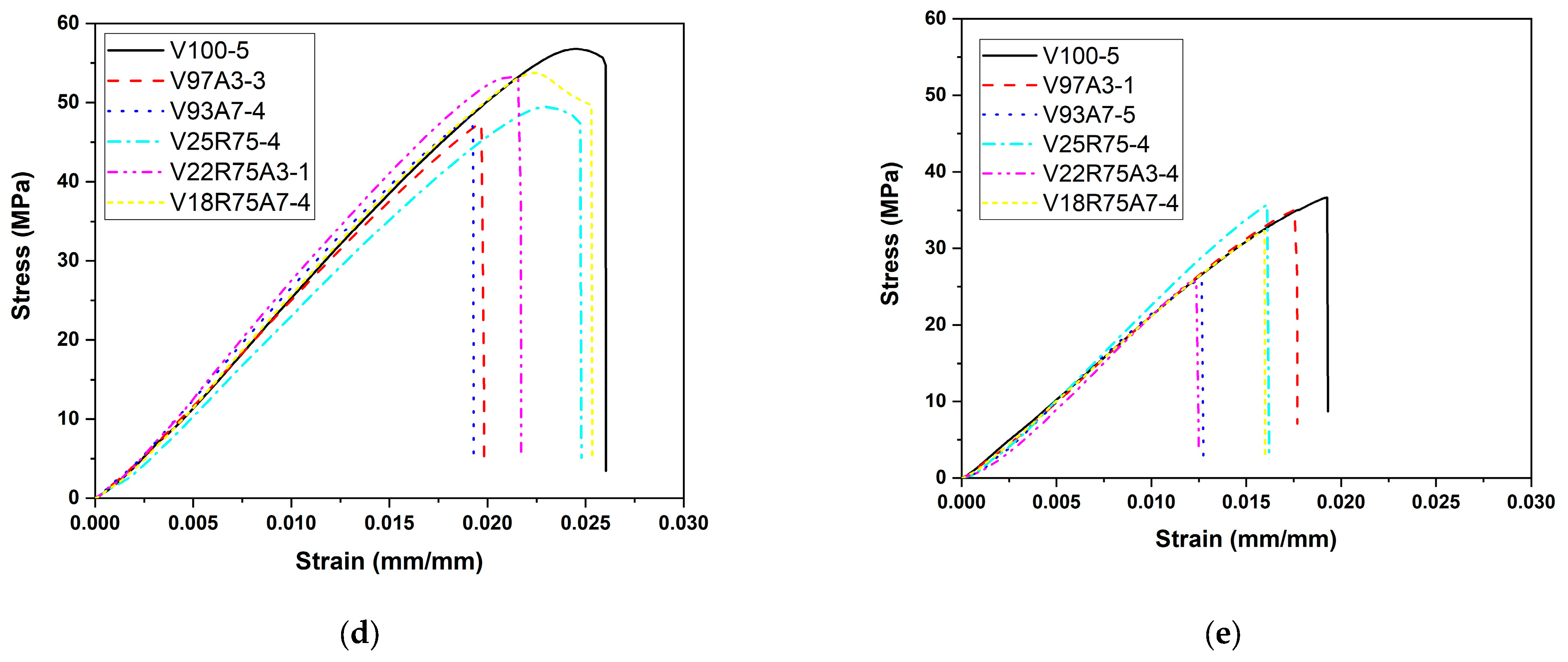

3.4. Tensile Testing

4. Conclusions

- Regarding the manufacturing of the granules, the extruder’s technical setup varies for every granule type and is experimentally established. The screw speed varies from 130 rpm for a mixture of 25% PLA and 75% rPLA to 100 rpm for nanocomposites based on rPLA.

- The printing parameters were established experimentally too. The multiplier values for horizontal and vertical printed samples change from 0.16 for PLA to 0.27 for the mixture of PLA and rPLA. Other printing parameters were constant.

- All granules showed good flowability and printable quality.

- Even though all blends showed nanoparticle agglomerations, they were uniformly distributed.

- The thermal stability has a rising tendency when increasing the additive’s content. The T5%loss rises by 10 °C for nanocomposites with 7% TiO2 compared with PLA.

- The crystallization temperature and degree of crystallinity of nanocomposites decreased with the addition of TiO2. For example, PLA has a degree of crystallinity of about 15%, the nanocomposite with 3% TiO2 is 11%, and the one with 7% TiO2 is 9%. The same tendency can be seen for samples with reprocessed PLA, so the mixture of PLA and rPLA has a degree of crystallinity of about 20%, the nanocomposite with 3% TiO2 is 15%, and the one with 7% TiO2 is 10%.

- Tensile testing showed that adding nanoparticles to pure PLA reduces the tensile strength and increases the Young’s Modulus in both printing directions. However, this effect is not observed in nanocomposites with rPLA. Nanocomposite from primary and secondary PLA with 7% nano-TiO2 has almost the same mechanical characteristics as PLA.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sasse, J.; Pelzer, L.; Schön, M.; Ghaddar, T.; Hopmann, C. Investigation of Recycled and Coextruded PLA Filament for Additive Manufacturing. Polymers 2022, 14, 2407. [Google Scholar] [CrossRef]

- Patel, A.; Taufik, M. Extrusion-Based Technology in Additive Manufacturing: A Comprehensive Review. Arab. J. Sci. Eng. 2022, 1–34. [Google Scholar] [CrossRef]

- Marchewka, J.; Laska, J. Processing of poly-l-lactide and poly(l-lactide-co-trimethylene carbonate) blends by fused filament fabrication and fused granulate fabrication using RepRap 3D printer. Int. J. Adv. Manuf. Technol. 2020, 106, 4933–4944. [Google Scholar] [CrossRef]

- Bellini, A.; Shor, L.; Guceri, S.I. New developments in fused deposition modeling of ceramics. Rapid Prototyp. J. 2005, 11, 214–220. [Google Scholar] [CrossRef]

- Duty, C.E.; Kunc, V.; Compton, B.; Post, B.; Erdman, D.; Smith, R.; Lind, R.; Lloyd, P.; Love, L. Structure and mechanical behavior of Big Area Additive Manufacturing (BAAM) materials. Rapid Prototyp. J. 2017, 23, 181–189. [Google Scholar] [CrossRef]

- Nieto, D.M.; López, V.C.; Molina, S.I. Large-format polymeric pellet-based additive manufacturing for the naval industry. Addit. Manuf. 2018, 23, 79–85. [Google Scholar] [CrossRef]

- Yakdoumi, F.Z.; Hadj-Hamou, A.S. Effectiveness assessment of TiO2-Al2O3 nano-mixture as a filler material for improvement of packaging performance of PLA nanocomposite films. J. Polym. Eng. 2020, 40, 848–858. [Google Scholar] [CrossRef]

- Anderson, I.; Raza, I.; Iannucci, L.; Curtis, P.T.; Ruppert, D.S.; Harrysson, O.L.; Marcellin-Little, D.J.; Abumoussa, S.; Dahners, L.E.; Weinhold, P.S.; et al. Mechanical Properties of Specimens 3D Printed with Virgin and Recycled Polylactic Acid. 3D Print. Addit. Manuf. 2017, 4, 110–115. [Google Scholar] [CrossRef]

- Mofokeng, J.P.; Luyt, A.S. Dynamic mechanical properties of PLA/PHBV, PLA/PCL, PHBV/PCL blends and their nanocomposites with TiO2 as nanofiller. Thermochim. Acta 2015, 613, 41–53. [Google Scholar] [CrossRef]

- Zhuang, W.; Liu, J.; Zhang, J.H.; Hu, B.X.; Shen, J. Preparation, characterization, and properties of TiO2/PLA nanocomposites by in situ polymerization. Polym. Compos. 2009, 30, 1074–1080. [Google Scholar] [CrossRef]

- Beltr, F.R.; Arrieta, M.P.; Elena, D.; Lozano-p, A.A.; Cenis, J.L.; Gaspar, G.; De, U. Effect of Yerba Mate and Silk Fibroin Nanoparticles on the Migration Properties in Ethanolic Food Simulants and Composting Disintegrability of Recycled PLA Nanocomposites. Polymers 2021, 13, 1925. [Google Scholar] [CrossRef] [PubMed]

- Ranakoti, L.; Gangil, B.; Mishra, S.K.; Singh, T.; Sharma, S.; Ilyas, R.; El-Khatib, S. Critical Review on Polylactic Acid: Properties, Structure, Processing, Biocomposites, and Nanocomposites. Materials 2022, 15, 4312. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Li, D.; Zhang, H.; Su, G.; Li, G. Preparation and properties of poly(lactic acid)/sesbania gum/nano-TiO2 composites. Polym. Bull. 2018, 75, 623–635. [Google Scholar] [CrossRef]

- Meng, B.; Tao, J.; Deng, J.; Wu, Z.; Yang, M. Toughening of polylactide with higher loading of nano-titania particles coated by poly(ε-caprolactone). Mater. Lett. 2011, 65, 729–732. [Google Scholar] [CrossRef]

- Yerezhep, D.; Tychengulova, A.; Sokolov, D.; Aldiyarov, A. A Multifaceted Approach for Cryogenic Waste Tire Recycling. Polymers 2021, 13, 2494. [Google Scholar] [CrossRef] [PubMed]

- Peinado, V.; Castell, P.; García, L.; Fernández, Á. Effect of Extrusion on the Mechanical and Rheological Properties of a Reinforced Poly(Lactic Acid): Reprocessing and Recycling of Biobased Materials. Materials 2015, 8, 7106–7117. [Google Scholar] [CrossRef]

- Cruz Sanchez, F.A.; Boudaoud, H.; Hoppe, S.; Camargo, M. Polymer recycling in an open-source additive manufacturing context: Mechanical issues. Addit. Manuf. 2017, 17, 87–105. [Google Scholar] [CrossRef]

- Babagowda; Math, R.K.; Goutham, R.; Prasad, K.S. Study of Effects on Mechanical Properties of PLA Filament which is blended with Recycled PLA Materials. IOP Conf. Series Mater. Sci. Eng. 2018, 310, 012103. [Google Scholar] [CrossRef]

- Hassan, T.; Salam, A.; Khan, A.; Khan, S.U.; Khanzada, H.; Wasim, M.; Khan, M.Q.; Kim, I.S. Functional nanocomposites and their potential applications: A review. J. Polym. Res. 2021, 28, 36. [Google Scholar] [CrossRef]

- Roussenova, M.; Hughes, D.; Enrione, J.; Diaz-Calderon, P.; Sivaniah, E.; Song, Q.; Ubbink, J.; Beavis, P.; Swain, A.; Alam, M. Free Volume, Molecular Mobility and Polymer Structure: Towards the Rational Design of Multi-Functional Materials. Acta Phys. Pol. A 2014, 125, 801–805. [Google Scholar] [CrossRef]

- Reijnders, L. The release of TiO2 and SiO2 nanoparticles from nanocomposites. Polym. Degrad. Stab. 2009, 94, 873–876. [Google Scholar] [CrossRef]

- Zhang, H.; Huang, J.; Yang, L.; Chen, R.; Zou, W.; Lin, X.; Qu, J. Preparation, characterization and properties of PLA/TiO2 nanocomposites based on a novel vane extruder. RSC Adv. 2015, 5, 4639–4647. [Google Scholar] [CrossRef]

- Buzarovska, A.; Grozdanov, A. Biodegradable poly(L-lactic acid)/TiO2 nanocomposites: Thermal properties and degradation. J. Appl. Polym. Sci. 2011, 123, 2187–2193. [Google Scholar] [CrossRef]

- Nakayama, N.; Hayashi, T. Preparation and characterization of poly(l-lactic acid)/TiO2 nanoparticle nanocomposite films with high transparency and efficient photodegradability. Polym. Degrad. Stab. 2007, 92, 1255–1264. [Google Scholar] [CrossRef]

- Thumsorn, S.; Prasong, W.; Kurose, T.; Ishigami, A.; Kobayashi, Y.; Ito, H. Rheological Behavior and Dynamic Mechanical Properties for Interpretation of Layer Adhesion in FDM 3D Printing. Polymers 2022, 14, 2721. [Google Scholar] [CrossRef]

- Nieto, D.M.; Molina, S.I. Large-format fused deposition additive manufacturing: A review. Rapid Prototyp. J. 2020, 26, 793–799. [Google Scholar] [CrossRef]

- NatureWorks Ingeo TM Biopolymer 3D850 Technical Data Sheet 3D Printing Monofilament—General Purpose Grade. Available online: https://www.unicgroup.com/wp-content/uploads/2019/12/3D850.pdf (accessed on 1 January 2023).

- ISO/TC 61/SC 2; Mechanical Behavior ISO 527-1:2019 Plastics—Determination of Tensile Properties—Part 1: General Principles. ISO: Geneva, Switzerland, 2019; Volume 26.

- ISO/TC 61/SC 2; Mechanical behavior ISO 527-2:2012 Plastics—Determination of Tensile Properties—Part 2: Test Conditions for Moulding and Extrusion Plastics. ISO: Geneva, Switzerland, 2012; Volume 2012, p. 11.

- Schneider, C.A.; Rasband, W.S.; Eliceiri, K.W. NIH Image to ImageJ: 25 Years of image analysis. Nat. Methods 2012, 9, 671–675. [Google Scholar] [CrossRef]

- ISO/TC 61/SC 5; Physical-Chemical Properties ISO 11357-1:2016 Plastics—Differential Scanning Calorimetry (DSC)—Part 1: General Principles. ISO: Geneva, Switzerland, 2016; Volume 33.

- ISO/TC 61/SC 5; Physical-Chemical Properties ISO 11358-1:2014 Plastics—Thermogravimetry (TG) of Polymers—Part 1: General Principles. ISO: Geneva, Switzerland, 2014; Volume 1, p. 9.

- Dubois, P.; Zhang, J.; Jérôme, R.; Teyssié, P. Macromolecular engineering of polylactones and polylactides: 13. Synthesis of telechelic polyesters by coupling reactions. Polymer 1994, 35, 4998–5004. [Google Scholar] [CrossRef]

- Beltrán, F.; Lorenzo, V.; Acosta, J.; de la Orden, M.; Urreaga, J.M. Effect of simulated mechanical recycling processes on the structure and properties of poly(lactic acid). J. Environ. Manag. 2018, 216, 25–31. [Google Scholar] [CrossRef]

- Żenkiewicz, M.; Richert, J.; Rytlewski, P.; Moraczewski, K.; Stepczyńska, M.; Karasiewicz, T. Characterisation of multi-extruded poly(lactic acid). Polym. Test. 2009, 28, 412–418. [Google Scholar] [CrossRef]

- Pluta, M.; Galeski, A.; Alexandre, M.; Paul, M.-A.; Dubois, P. Polylactide/montmorillonite nanocomposites and microcomposites prepared by melt blending: Structure and some physical properties. J. Appl. Polym. Sci. 2002, 86, 1497–1506. [Google Scholar] [CrossRef]

- Nam, P.H.; Maiti, P.; Okamoto, M.; Kotaka, T.; Hasegawa, N.; Usuki, A. A hierarchical structure and properties of intercalated polypropylene/clay nanocomposites. Polymer 2001, 42, 9633–9640. [Google Scholar] [CrossRef]

- Luo, Y.-B.; Li, W.-D.; Wang, X.-L.; Xu, D.-Y.; Wang, Y.-Z. Preparation and properties of nanocomposites based on poly(lactic acid) and functionalized TiO2. Acta Mater. 2009, 57, 3182–3191. [Google Scholar] [CrossRef]

- Gorrasi, G.; Pantani, R. Hydrolysis and Biodegradation of Poly(lactic acid). In Synthesis, Structure and Properties of Poly(lactic acid); Springer International Publishing: Cham, Switzerland, 2018. [Google Scholar] [CrossRef]

- Prasong, W.; Ishigami, A.; Thumsorn, S.; Kurose, T.; Ito, H. Improvement of Interlayer Adhesion and Heat Resistance of Biodegradable Ternary Blend Composite 3D Printing. Polymers 2021, 13, 740. [Google Scholar] [CrossRef] [PubMed]

- Wickramasinghe, S.; Do, T.; Tran, P. FDM-Based 3D Printing of Polymer and Associated Composite: A Review on Mechanical Properties, Defects and Treatments. Polymers 2020, 12, 1529. [Google Scholar] [CrossRef]

| Sample Designation | Weight Ratio (%) | ||

|---|---|---|---|

| Virgin Polylactide | Reprocessed Polylactide | Nanoparticles of Titanium Dioxide | |

| V100 | 100 | 0 | 0 |

| V97A3 | 97 | 0 | 3 |

| V93A7 | 93 | 0 | 7 |

| V25R75 | 25 | 75 | 0 |

| V22R75A3 | 22 | 75 | 3 |

| V18R75A7 | 18 | 75 | 7 |

| Sample Code | Central Unit | Dehumidifier | Dosimeter | Winder | Pelletizing Machine | Work Pressure (Bar) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Screw Speed (rpm) | T1 (°C) | T2 (°C) | T3 (°C) | T4 (°C) | T5 (°C) | Initial Material Temperature (°C) | D1 (rpm) | D2 (rpm) | Winder Speed (m/min) | Cutting (rpm) | Pull (rpm) | ||

| rPLA | 126 | 180 | 180 | 190 | 200 | 200 | 60 | 2.5 | - | 2.3 | 44 | 32 | 3 |

| V97A3 | 130 | 185 | 190 | 190 | 180 | 175 | 60 | 1.5 | 3 | 1.75 | 27 | 20 | 7 |

| V93A7 | 130 | 185 | 190 | 190 | 180 | 175 | 60 | 0.5 | 6 | 1.75 | 27 | 20 | 7 |

| V25R75 | 130 | 185 | 190 | 190 | 180 | 175 | 60 | 1.5 | 3 | 1.75 | 27 | 20 | 8 |

| V22R75A3 | 100 | 185 | 190 | 190 | 180 | 185 | 60 | 1.5 | 5 | 1.20 | 27 | 20 | 7 |

| V18R75A7 | 100 | 185 | 190 | 190 | 180 | 185 | 60 | 1.5 | 5 | 1.20 | 48 | 18 | 8 |

| Nozzle Diameter (mm) | Bead Width (mm) | Layer Height (mm) |

|---|---|---|

| 2 | 2 | 1 |

| Composite | Multiplier Horizontal Specimens | Multiplier Vertical Specimens | Temperature of Extruder (°C) | Temperature of the Bed (°C) | Print Speed Horizontal Specimen (mm/s) | Print Speed Vertical Specimen (mm/s) |

|---|---|---|---|---|---|---|

| V100 | 0.16 | 0.16 | 205/210/215 | 50 | 50 | 23 |

| V97A3 | 0.22 | 0.22 | ||||

| V93A7 | 0.18 | 0.20 | ||||

| V25R75 | 0.26 | 0.27 | ||||

| V22R75A3 | 0.22 | 0.22 | ||||

| V18R75A7 | 0.23 | 0.24 |

| Sample Code | V100 | V97A3 | V93A7 | V25R75 | V22R75A3 | V18R75A7 |

|---|---|---|---|---|---|---|

| T5%loss | 312.000 | 317.803 | 322.191 | 315.117 | 319.000 | 322.000 |

| Tmax | 355.114 | 352.859 | 361.042 | 354.037 | 353.930 | 354.227 |

| Sample Code | Tg (°C) | Tc (°C) | ∆Hc (J/g) | Tm (°C) | ∆Hm (J/g) | Xc (%) |

|---|---|---|---|---|---|---|

| V100 | 61.91 | 102.75 | 31.83 | 178.34 | 46.08 | 15 |

| V97A3 | 62.16 | 95.57 | 31.25 | 177.18 | 41.62 | 11 |

| V93A7 | 60.19 | 99.97 | 37.34 | 175.66 | 46.03 | 9 |

| V25R75 | 62.57 | 94.69 | 26.61 | 177.29 | 45.02 | 20 |

| V22R75A3 | 60.86 | 93.96 | 29.15 | 176.54 | 43.22 | 15 |

| V18R75A7 | 60.25 | 93.09 | 36.43 | 177.67 | 44.66 | 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bergaliyeva, S.; Sales, D.L.; Jiménez Cabello, J.M.; Burgos Pintos, P.; Fernández Delgado, N.; Marzo Gago, P.; Zammit, A.; Molina, S.I. Thermal and Mechanical Properties of Reprocessed Polylactide/Titanium Dioxide Nanocomposites for Material Extrusion Additive Manufacturing. Polymers 2023, 15, 3458. https://doi.org/10.3390/polym15163458

Bergaliyeva S, Sales DL, Jiménez Cabello JM, Burgos Pintos P, Fernández Delgado N, Marzo Gago P, Zammit A, Molina SI. Thermal and Mechanical Properties of Reprocessed Polylactide/Titanium Dioxide Nanocomposites for Material Extrusion Additive Manufacturing. Polymers. 2023; 15(16):3458. https://doi.org/10.3390/polym15163458

Chicago/Turabian StyleBergaliyeva, Saltanat, David L. Sales, José María Jiménez Cabello, Pedro Burgos Pintos, Natalia Fernández Delgado, Patricia Marzo Gago, Ann Zammit, and Sergio I. Molina. 2023. "Thermal and Mechanical Properties of Reprocessed Polylactide/Titanium Dioxide Nanocomposites for Material Extrusion Additive Manufacturing" Polymers 15, no. 16: 3458. https://doi.org/10.3390/polym15163458

APA StyleBergaliyeva, S., Sales, D. L., Jiménez Cabello, J. M., Burgos Pintos, P., Fernández Delgado, N., Marzo Gago, P., Zammit, A., & Molina, S. I. (2023). Thermal and Mechanical Properties of Reprocessed Polylactide/Titanium Dioxide Nanocomposites for Material Extrusion Additive Manufacturing. Polymers, 15(16), 3458. https://doi.org/10.3390/polym15163458