Utilizing Polyethylene Terephthalate PET in Concrete: A Review

Abstract

1. Introduction

2. Plastic Waste Properties

3. Polyethylene Terephthalate (PET)

4. PET Waste Sources

5. Pros and Cons of Utilizing PET in Concrete

- Adding PET fibers to the concrete improves energy absorption.

- The ductility of concrete is significantly enhanced by the presence of PET fibers.

- Utilizing PET in concrete reduces post-cracks, and this is affected by PET fiber shape.

- PET fibers can increase the tensile, compressive, and flexural strengths of concrete if the recommended optimum dosage is used.

- Advantages related to the environment and PET recycling

- Concrete workability is decreased significantly with the presence of PET in the concrete mix.

- Utilizing PET in concrete requires a concrete mix design to reach optimum results.

- Replacing a high ratio of fine or coarse aggregate results in a major drop in concrete strength.

- Adding high amounts of PET fiber to the mix results in a reduction in the overall properties of the concrete.

- PET fiber production is complicated and requires extensive labor.

6. Utilizing PET in Concrete

7. Properties of Concrete Containing PET

7.1. Fresh Properties

7.2. Fresh and Dry Density

7.3. Water Absorption

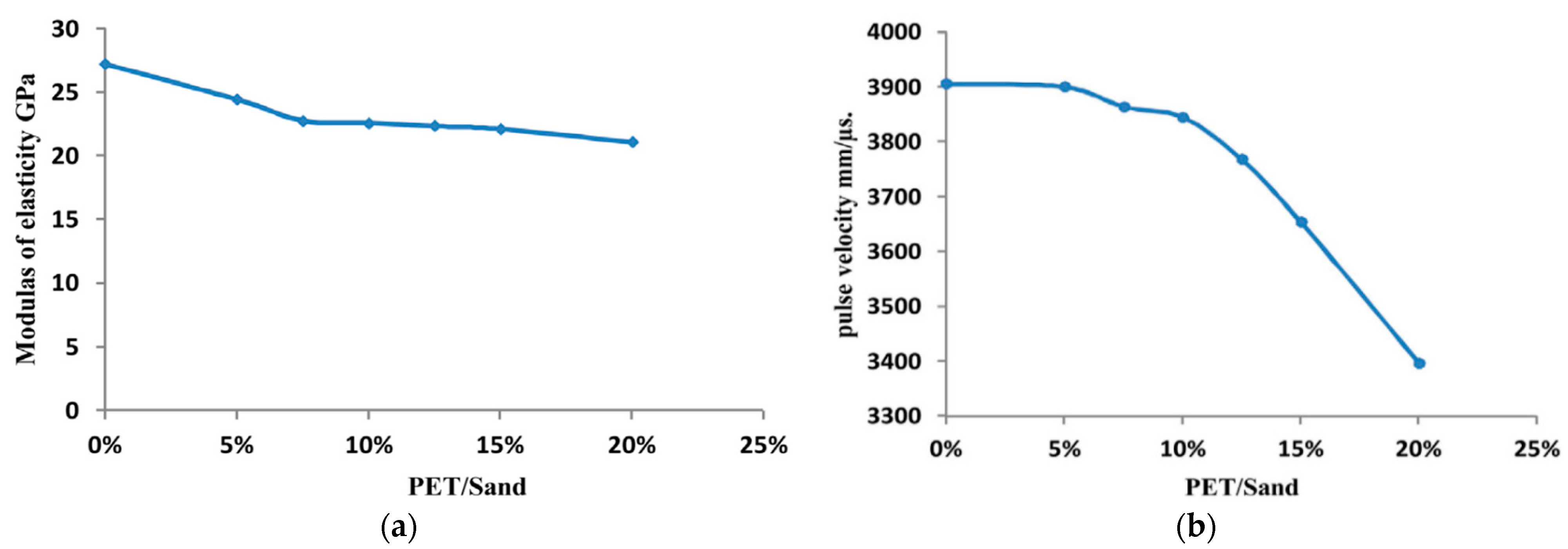

7.4. Ultrasonic Pulse Velocity

7.5. Modulus of Elasticity

7.6. Effects of PET on the Microstructure of Concrete

7.7. Compressive Strength

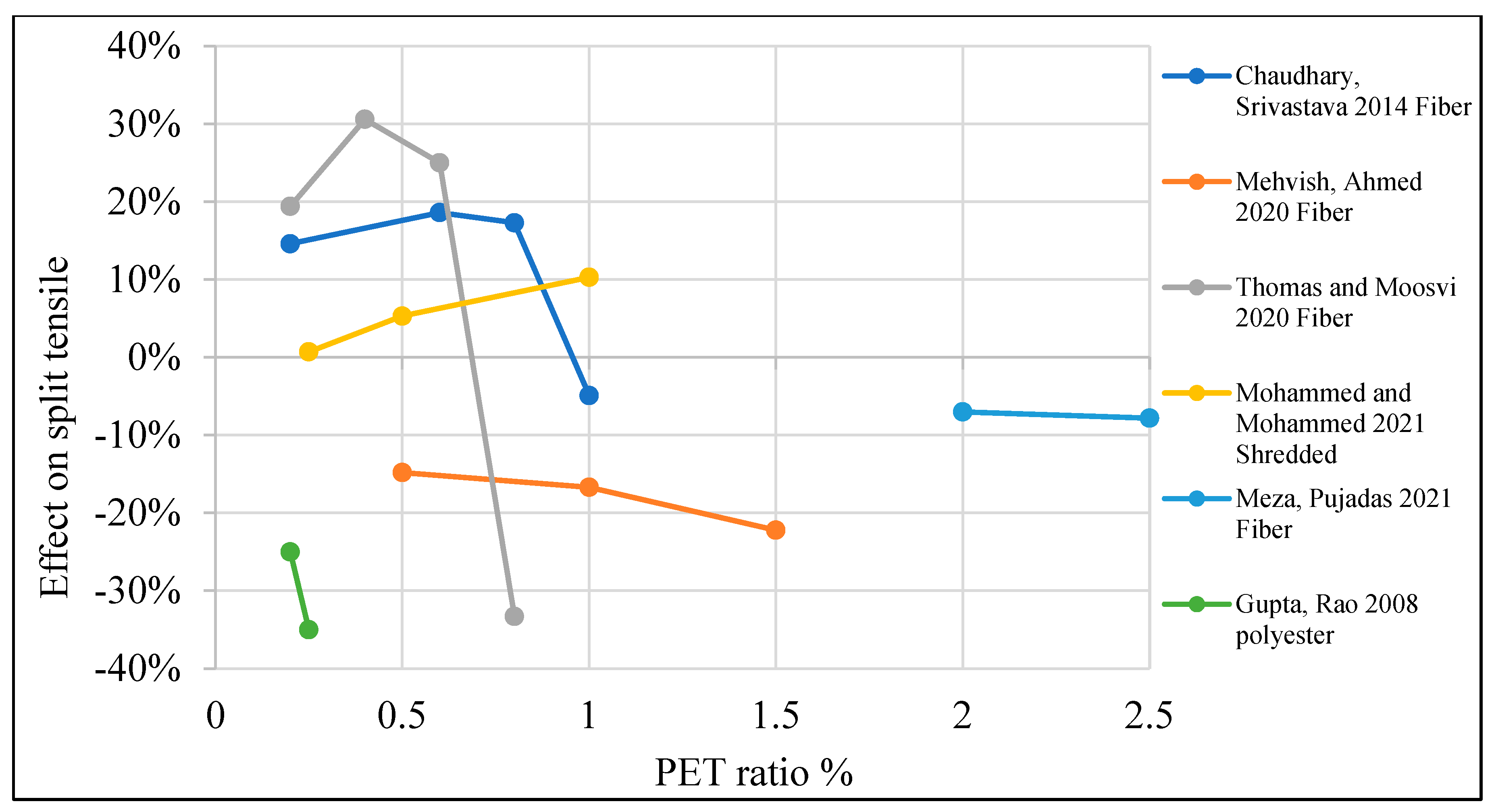

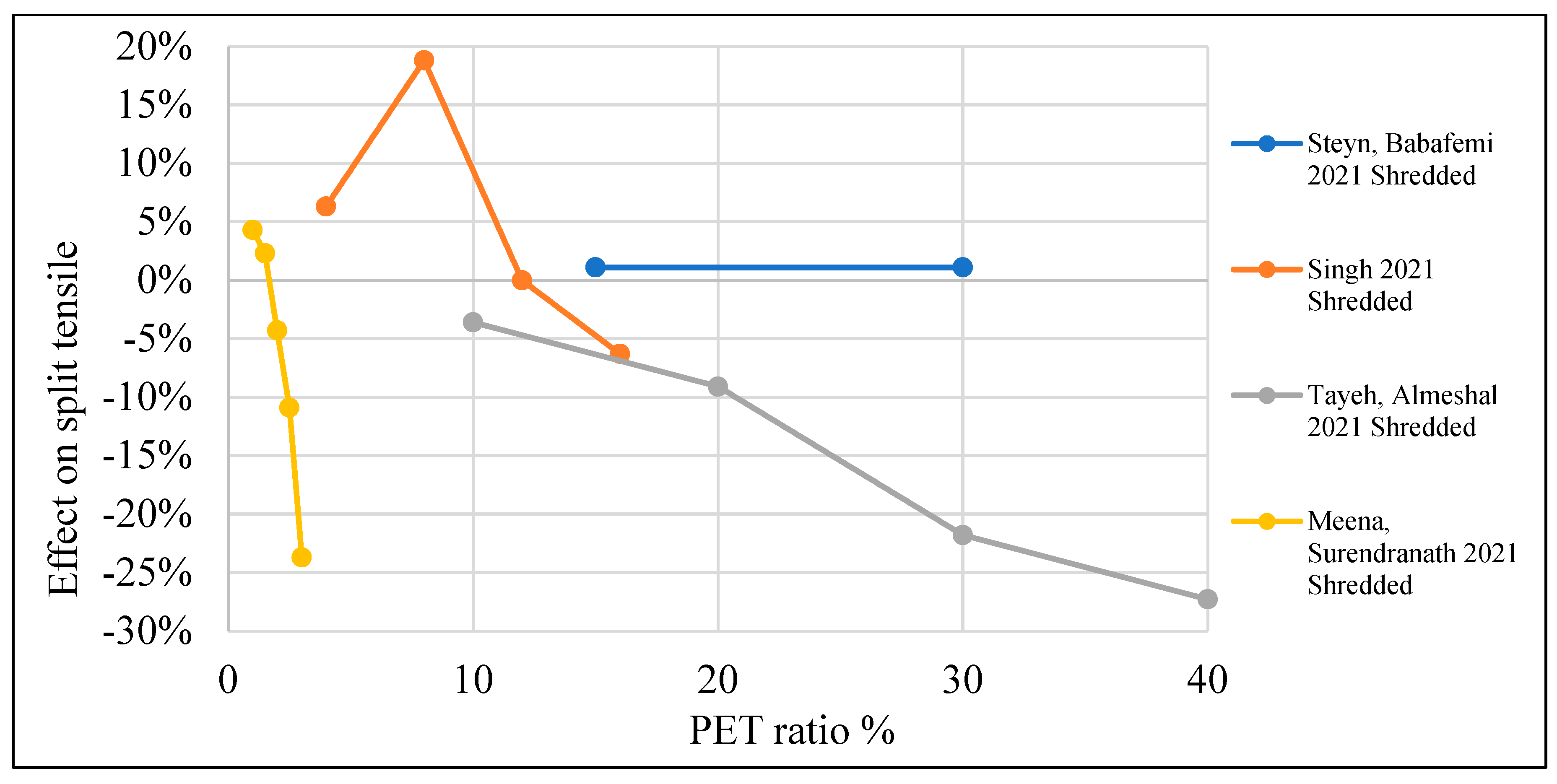

7.8. Splitting Tensile Strength

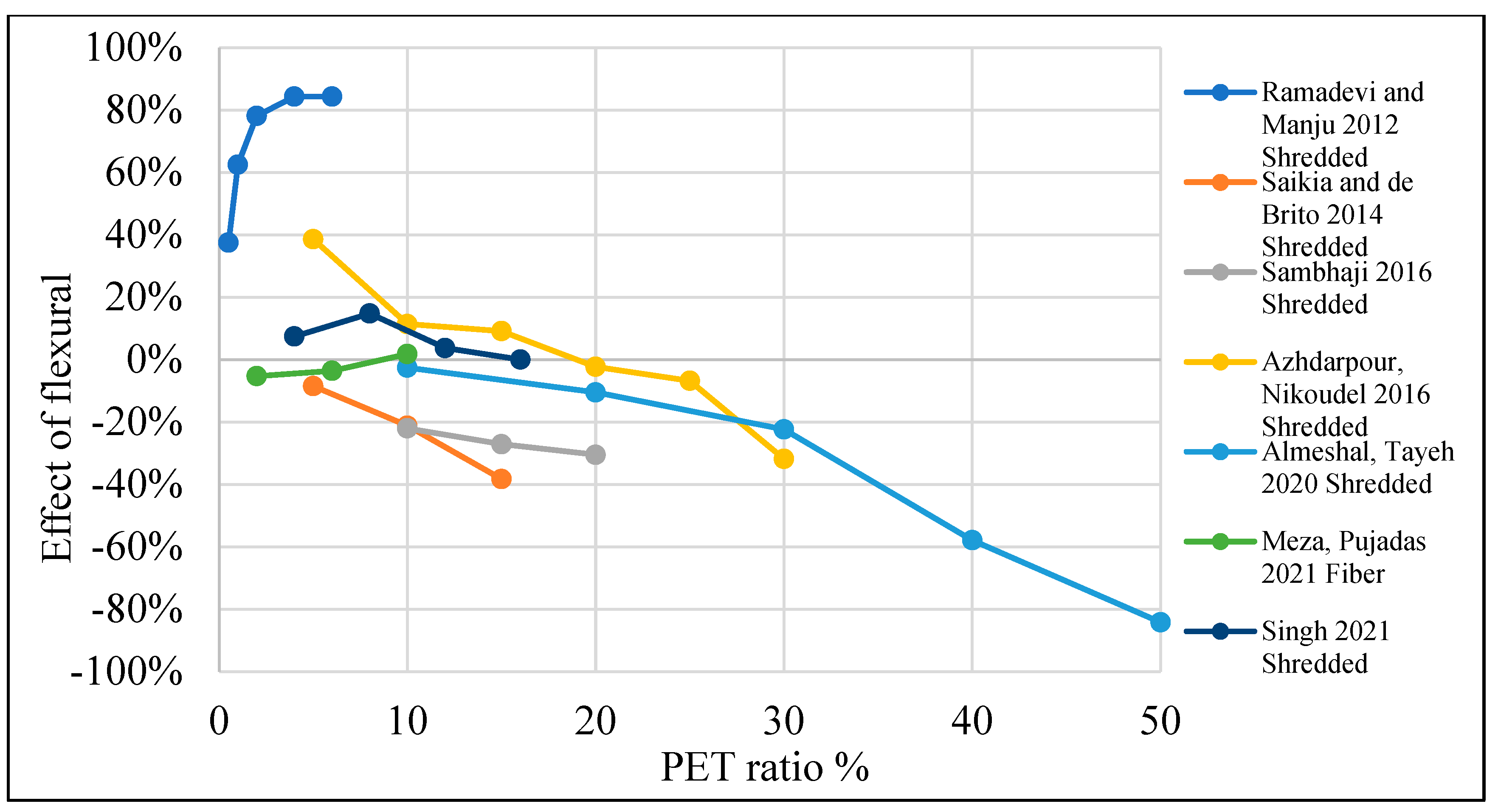

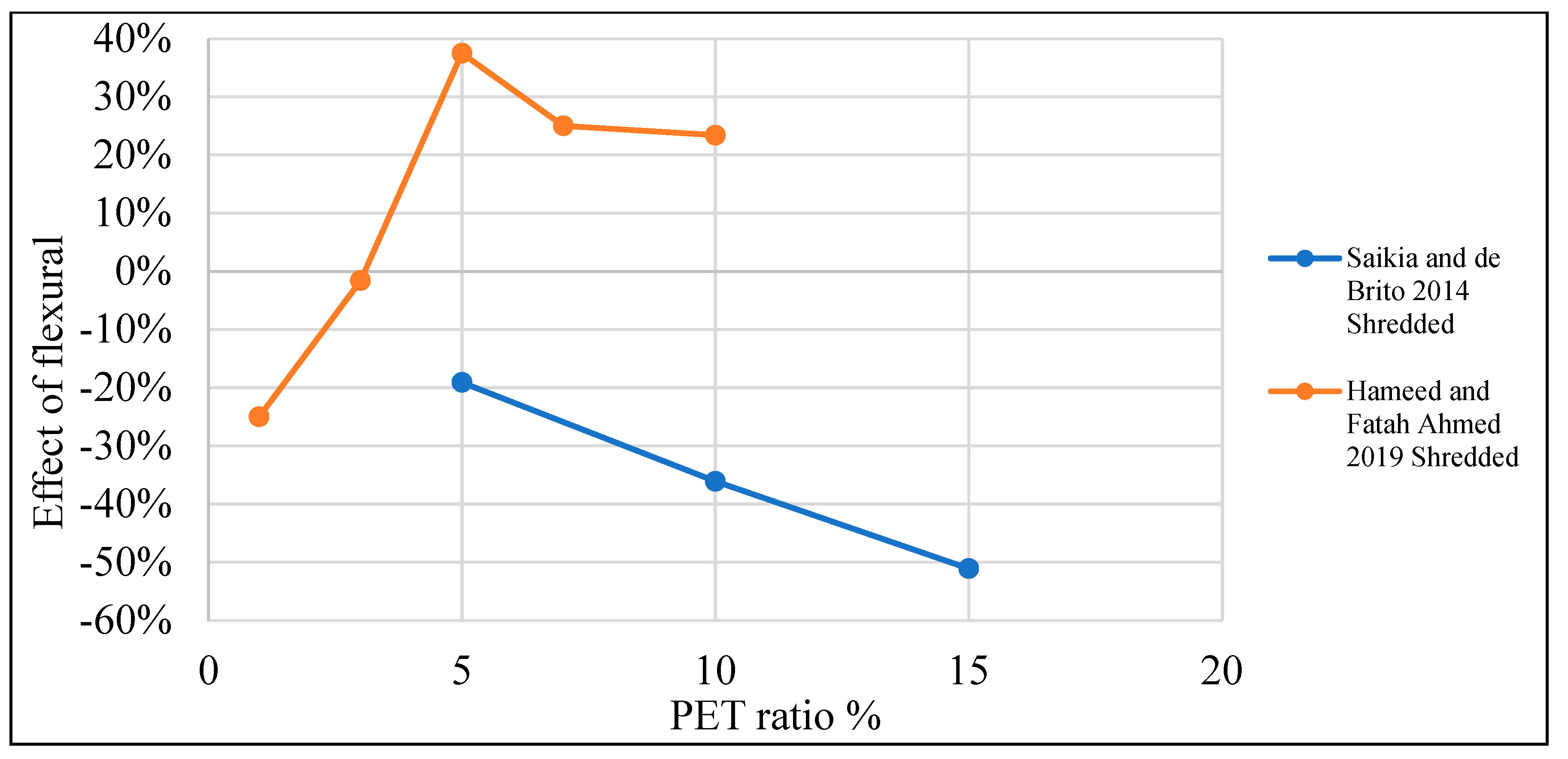

7.9. Flexural Strength

| Author | Sample ID | Parameter/Remarks | F’c (Mpa) | Ft (Mpa) | Flexural (Mpa) | Slump Test (cm) | Dry Density (kg/m3) | Material Types | Dimension L × W × T (mm) | Ratio % V | Replacement/Addition |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Choi, Moon [48] | 53P0 | w/c: 0.53 SP: 0.3% | 31.5 | 10 | 2300 | Crushed PET | 0 | Replacing by volume fine aggregate | |||

| 53P25 | 29.7 | 15.3 | 2220 | 25 | |||||||

| 53P50 | 26.3 | 19.9 | 2130 | 50 | |||||||

| 53P75 | 21.8 | 22.3 | 2010 | 75 | |||||||

| 49P0 | w/c: 0.49 SP: 0.3% | 34.6 | 10.5 | 2300 | 0 | ||||||

| 49P25 | 33.7 | 15.4 | 2230 | 25 | |||||||

| 49P50 | 29.1 | 18.0 | 2120 | 50 | |||||||

| 49P75 | 23.2 | 21.4 | 2000 | 75 | |||||||

| 45P0 | w/c: 0.45 SP: 0.3% | 37.2 | 13.5 | 2300 | 0 | ||||||

| 45P25 | 33.8 | 16.9 | 2260 | 25 | |||||||

| 45P50 | 31.8 | 18.4 | 2160 | 50 | |||||||

| 45P75 | 24.9 | 20.5 | 1940 | 75 | |||||||

| Ochi, Okubo [49] | C11 | Cement: 334 kg Fine agg. 973 kg Coarse agg. 743 kg Water 217 L w/c 0.65Cement: 334 kg Fine agg. 973 kg Coarse agg. 743 kg Water 217 L | 32.1 | 3.82 | 16.5 | PET | 30 mm with 15 mm max aggregate size | 0.0 | Adding as volumetric ratio | ||

| C12 | 31.4 | 3.72 | 16.0 | 0.5 | |||||||

| C13 | 34.8 | 4.12 | 3.5 | 1.0 | |||||||

| C14 | 34.1 | 4.80 | 4.0 | 1.5 | |||||||

| C21 | 34.8 | 4.12 | 9.5 | 0.0 | |||||||

| C22 | 34.8 | 3.97 | 0.5 | ||||||||

| C23 | 39.6 | 4.21 | 1.0 | ||||||||

| C24 | 38.8 | 5.29 | 1.5 | ||||||||

| C31 | w/c 0.60 Cement: 334 kg Fine agg. 973 kg Coarse agg. 743 kg Water 217 L w/c 0.55 | 45.1 | 4.21 | 7.0 | 0.0 | ||||||

| C32 | 45.6 | 4.41 | 0.5 | ||||||||

| C33 | 47.8 | 4.85 | 1.0 | ||||||||

| C34 | 43.7 | 5.73 | 1.5 | ||||||||

| Gupta, Rao [26] | 1 | 49.6 | 3.39 | 4.7 | PET polyester fiber | 6 mm length × 0.0445 diameter | 0.0 | Adding as volumetric ratio | |||

| 2 | 59.8 | - | 4.5 | 0.2 | |||||||

| 3 | 60.0 | 2.23 | 5.0 | 0.25 | |||||||

| 4 | 48.0 | - | 4.4 | 1.0 | |||||||

| Choi, Moon [50] | W/C53 | Cement: 336 kg Fine agg. 844 kg Coarse agg. 930 kg Water 178 L SP 1.008 kg/m3 | 32.1 | 3.3 | 10 | 2300 | Shredded PET | 5–15 | 0 | Fine aggregate replacing | |

| W/C53 | 30.2 | 2.8 | 15.3 | 2260 | 25 | ||||||

| W/C53 | 26.8 | 2.4 | 19.9 | 2160 | 50 | ||||||

| W/C53 | 22.4 | 2.0 | 22.3 | 1950 | 75 | ||||||

| W/C49 | Cement: 367 kg Fine agg. 805 kg Coarse agg. 939 kg Water 180 L SP 1.101 kg/m3 | 36.4 | 3.0 | 10.5 | 2300 | 0 | |||||

| W/C49 | 35.3 | 2.8 | 15.4 | 2230 | 25 | ||||||

| W/C49 | 30.3 | 2.4 | 18 | 2110 | 50 | ||||||

| W/C49 | 24.4 | 2.0 | 21.4 | 2000 | 75 | ||||||

| W/C45 | Cement: 402 kg Fine agg. 771 kg Coarse agg. 941 kg Water 181 L SP 1.206 kg/m3 | 38.0 | 3.0 | 13.5 | 2300 | 0 | |||||

| W/C45 | 34.0 | 2.8 | 16.9 | 2220 | 25 | ||||||

| W/C45 | 32.3 | 2.4 | 18.4 | 2130 | 50 | ||||||

| W/C45 | 27.7 | 2.0 | 20.5 | 2000 | 75 | ||||||

| Albano, Camacho [51] | C0 | Cement: 19.1 kg Fine agg. 68.6 kg Coarse agg. 43.6 kg w/c: 0.6 | 28.0 | 23.3 | 7.8 | Shredded PET | - | 0 | Replacing by volume fine aggregate | ||

| CS | 22.9 | 16.9 | 4.0 | 22.3 mm | 10 | ||||||

| CS6 | 22.5 | 21.7 | 5.2 | 22.3/33.4 mm | 10 | ||||||

| CB6 | 22.1 | 22.2 | 3.0 | 33.4 mm | 10 | ||||||

| CSW | 17.5 | 14.5 | 2.2 | 22.3 mm | 20 | ||||||

| CSBW | 18.5 | 17.3 | 1.9 | 22.3/33.4 mm | 20 | ||||||

| CBW6 | 14.1 | 14.5 | 0.0 | 33.4 mm | 20 | ||||||

| S15 | Cement: 24.1 kg Fine agg. 64.9 kg Coarse agg. 41.2 kg w/c: 0.5 | 21.4 | 28.0 | 8.6 | - | 0 | |||||

| SB5 | 16.9 | 24.4 | 6.5 | 22.3 mm | 10 | ||||||

| B15 | 18.5 | 25.1 | 7.5 | 22.3/33.4 mm | 10 | ||||||

| S25 | 14.3 | 23.6 | 7.0 | 33.4 mm | 10 | ||||||

| CSB5 | 13.3 | 18.8 | 4.2 | 22.3 mm | 20 | ||||||

| CB20 | 12.9 | 21.8 | 4.7 | 22.3/33.4 mm | 20 | ||||||

| 9.1 | 19.0 | 0.0 | 33.4 mm | 20 | |||||||

| Ramadevi and Manju [109] | C0 | Cement: 425.78 kg Fine agg. 516.05 kg Coarse agg. 1175.92 kg w/c: 0.45 | 31 | 1.88 | 3.2 | Shredded PET | 0 | Replacing by volume fine aggregate | |||

| C0.5 | 33.1 | 1.99 | 4.4 | 0.5 | |||||||

| C1 | 40.1 | 2.04 | 5.2 | 1 | |||||||

| C2 | 39.8 | 2.11 | 5.7 | 2 | |||||||

| C4 | 38.7 | 2.07 | 5.9 | 4 | |||||||

| C6 | 38.1 | 2.04 | 5.9 | 6 | |||||||

| Pelisser, Montedo [28] | 1 | 1:2.3:2.7:0.62 | 29.2 | 3.75 | 10.0 | PET polyester fiber | 10 mm length × 25–30 μm diameter | 0.0 | Adding as volumetric ratio | ||

| 2 | 28.3 | 3.6 | 15.5 | 0.05 | |||||||

| 3 | 27.0 | 4.2 | 7.0 | 0.18 | |||||||

| 4 | 29.5 | 4.4 | 5.0 | 0.30 | |||||||

| 5 | 28.3 | 4.23 | 15.5 | 15 mm length × 25–30 μm diameter | 0.05 | ||||||

| 6 | 27.0 | 4.2 | 7.0 | 0.18 | |||||||

| 7 | 29.5 | 4.5 | 5.0 | 20 mm length × 25–30 μm diameter | 0.30 | ||||||

| 8 | 28.3 | 4.3 | 15.5 | 0.05 | |||||||

| 9 | 27.0 | 4.26 | 7.0 | 0.18 | |||||||

| 10 | 29.5 | 4.47 | 5.0 | 0.30 | |||||||

| Chaudhary, Srivastava [104] | A1 | Mix proportion: 1:1.65:3 w/c: 0.46 Slump test 100 mm | 26.7 | 2.25 | PET | Low-density PET | 0 | By weight | |||

| A2 | 32.7 | 2.58 | 0.4 | ||||||||

| A3 | 35.8 | 2.67 | 0.6 | ||||||||

| A4 | 36 | 2.64 | 0.8 | ||||||||

| A5 | 23.5 | 2.14 | 1 | ||||||||

| Fraternali, Spadea [105] | CR | Cement: 496 kg Fine agg. 944.1 kg Coarse agg. I 605 kg Coarse agg II 170 kg Water 187.9 kg w/c: 0.38 SP 4.35 kg | 33.9 | PET | - | - | By total weight | ||||

| C0.55L | 32.0 | 1.1 × 40 mm | 0.55 | ||||||||

| C0.55S | 31.1 | 0.7 × 52 mm | 0.55 | ||||||||

| Saikia and de Brito [52] | Ref | Cement: 350 kg Fine agg. 802.7 kg Coarse agg. 996.4 kg Water 185.5 kg | 46.3 | 3.4 | 4.7 | 12.7 | 2378 | Crushed PET | - | 0 | Coarse aggregate replacement by weight |

| PC5 | 33.9 | 2.4 | 3.8 | 12.0 | 2326 | Coarse | 5 | ||||

| PC10 | 24.7 | 1.8 | 3.0 | 12.0 | 2277 | Coarse | 10 | ||||

| PC15 | 17.2 | 1.2 | 2.3 | - | 2233 | Coarse | 15 | ||||

| PF5 | 40.6 | 3.1 | 4.3 | 12.2 | 2336 | Fine | 5 | ||||

| PF10 | 33.7 | 2.6 | 3.7 | 12.2 | 2290 | Fine | 10 | ||||

| PF15 | 29.4 | 2.2 | 2.9 | 12.0 | 2243 | Fine | 15 | Fine aggregate replacement by weight | |||

| PP5 | 40.8 | 3.2 | 4.5 | 12.2 | 2347 | Pilled fine | 5 | ||||

| PP10 | 39.1 | 3.1 | 4.2 | 12.2 | 2297 | Pilled fine | 10 | ||||

| PP15 | 35.2 | 2.8 | 3.9 | 13.2 | 2254 | Pilled fine | 15 | ||||

| Sambhaji [53] | Pl1 | Cement: 380 kg Fine agg. 715 kg Coarse agg. 1020 kg w/c: 0.53 kg | 44.2 | 5.9 | 7.8 | 2400 | Shredded PET | Length 0.15–12 mm and width 0.15–4 mm | 0 | Fine aggregate replacement by weight | |

| Pl2 | 33.2 | 4.6 | 2.6 | 2320 | 10 | ||||||

| Pl3 | 29.4 | 4.3 | 1.6 | 2250 | 15 | ||||||

| Pl4 | 29.8 | 4.1 | 0.4 | 2230 | 20 | ||||||

| Borg, Baldacchino [106] | Control | Cement: 409 kg Fine agg. 900 kg Coarse agg. 736 kg Water 225 L w/c: 0.55 SP 4.09 kg | 28.6 | 3.55 | - | - | 0.0 | Volume fraction | |||

| S5-0.5 | 26.2 | 3.51 | Straight PET | 50 mm L | 0.5 | ||||||

| S5-1 | 25.2 | 4.21 | Straight PET | 50 mm L | 1.0 | ||||||

| S5-1.5 | 26.8 | 4.21 | Straight PET | 50 mm L | 1.5 | ||||||

| S3-1 | 27.9 | 3.94 | Straight PET | 30 mm L | 1.0 | ||||||

| D5-0.5 | 27.8 | 3.71 | Deformed PET | 50 mm L | 0.5 | ||||||

| D5-1 | 28.5 | 4.32 | Deformed PET | 50 mm L | 1.0 | ||||||

| D5-1.5 | 27.1 | 4.00 | Deformed PET | 50 mm L | 1.5 | ||||||

| D3-1 | 27.8 | 4.10 | Deformed PET | 30 mm L | 1.0 | ||||||

| Azhdarpour, Nikoudel [73] | P0 | Cement: 10.08 kg Fine agg. I 18.9 kg Fine agg. II 6.3 kg Coarse agg. 25.2 kg Water 0.5 | 35 | 2.5 | 4.4 | 2160 | PET | Crushed | 0 | Replacing fine aggregate | |

| P5 | 51 | 3.1 | 6.1 | 2115 | 5 | ||||||

| P10 | 38 | 3.3 | 4.9 | 2080 | 10 | ||||||

| P15 | 31 | 2.9 | 4.8 | 2050 | 15 | ||||||

| P20 | 29 | 2.8 | 4.3 | 2020 | 20 | ||||||

| P25 | 22 | 2.2 | 4.1 | 1980 | 25 | ||||||

| P30 | 19 | 1.6 | 3.0 | 1930 | 30 | ||||||

| Islam, Meherier [54] | WC420 | Cement: 461.5 kg Fine agg. 534.2 kg Coarse agg. 1024 kg w/c: 0.42 | 33.4 | 0.20 | 2150 | Crushed and transformed to aggregate PET | 0 | Replacing coarse aggregate by weight | |||

| WC422 | 30.3 | 1.85 | 2060 | 20 | |||||||

| WC423 | 27.1 | 2.00 | 2037 | 30 | |||||||

| WC424 | 25.9 | 2.00 | 2035 | 40 | |||||||

| WC425 | 20.4 | 0.95 | 1980 | 50 | |||||||

| WC480 | Cement: 499 kg Fine agg. 519.8 kg Coarse agg. 996.4 kg w/c: 0.48 | 32.1 | 3.1 | 2145 | 0 | ||||||

| WC482 | 27.6 | 3.5 | 2050 | 20 | |||||||

| WC483 | 26.4 | 3.8 | 2010 | 30 | |||||||

| WC484 | 24.4 | 4.0 | 2000 | 40 | |||||||

| WC485 | 19.4 | 4.8 | 1970 | 50 | |||||||

| WC570 | Cement: 431.6 kg Fine agg. 499.6 kg Coarse agg.: 957.7 kg w/c: 0.57 | 31.6 | 10.0 | 2150 | |||||||

| WC572 | 24.2 | 9.0 | 2005 | 0 | |||||||

| WC573 | 24.3 | 10.5 | 1995 | 20 | |||||||

| WC574 | 22.8 | 13.1 | 1985 | 30 | |||||||

| WC575 | 17.4 | 15.9 | 1925 | 40 | |||||||

| Nursyamsi and Zebua [113] | FM601 | Cement: 367.27 kg Fine agg. 518.85 kg Coarse agg. 600.88 kg w/c: 0.55 | 13.8 | Shredded and transferred to coarse aggregate PET | Finance modulus | 6.0 | Replacing by volume coarse aggregate | ||||

| FM65 | 16.2 | 6.5 | |||||||||

| FM70 | 16.5 | 7.0 | |||||||||

| Hameed and Fatah Ahmed [74] | A | Mortar | 20.6 | 2.3 | 6.4 | 2300 | Crushed PET | 0 | Replacing by volume coarse aggregate | ||

| B | Concrete 0.35 w/c | 16.0 | 0 | ||||||||

| C | Concrete 0. 5 w/c | 15.1 | 0 | ||||||||

| D | Concrete 0.4 w/c | 15.4 | 0 | ||||||||

| E | Mortar | 20.7 | 2.6 | 4.8 | 2280 | 1 | |||||

| G | Mortar | 17.1 | 4.1 | 6.3 | 2270 | 3 | |||||

| I | Mortar | 17.9 | 4.7 | 8.8 | 2180 | 5 | |||||

| K | Mortar | 17.5 | 3.7 | 8.0 | 2220 | 7 | |||||

| L | Mortar | 16.6 | 5.5 | 7.9 | 2150 | 10 | |||||

| Mustafa, Hanafi [55] | Plain | Cement: 400 kg Fine agg. 800 kg Coarse agg. 970 kg | 42 | 16 | 2210 | PET | 0 | Replacing fine aggregate | |||

| PW5 | 39 | 13 | 2050 | 5 | |||||||

| PW10 | 37 | 11 | 1990 | 10 | |||||||

| PW20 | 32 | 8 | 1960 | 20 | |||||||

| Alani, Bunnori [56] | U0 | Cement: 1080 kg Fine agg. 760 kg Coarse agg. 380 kg Water 184 L w/c: 0.65 SP 54 kg | 134 | 19.5 | PET | 40 × 3.5 × 0.3 | 0 | Partial fine aggregate replacement | |||

| U20G | 142 | 21.0 | 20 | ||||||||

| U40G | 140 | 22.5 | 40 | ||||||||

| U0P | 138 | 17.0 | 0 | ||||||||

| U20GP | 145 | 17.5 | 20 | ||||||||

| U40GP | 140 | 19.0 | 40 | ||||||||

| Gurunandan, Phalgun [27] | CC | Cement: 380.1 kg Fine agg. 859 kg Coarse agg 1095kg Water 152 L SP 4.14 lt Added 0.13% PET Three ratios of shredded rubber were added (7.5%, 15%, and 22.5%) | 41.8 | 3.74 | 7.00 | 10 | 2489 | PET polyester fiber | - | 0 | Adding cement by weight |

| RC7 | 31.8 | 2.89 | 6.44 | - | - | 0.5 | |||||

| RC15 | 24.0 | 2.34 | 5.47 | - | - | 0.5 | |||||

| RC22 | 13.8 | 1.91 | 3..00 | - | - | 0.5 | |||||

| FR7 | 25.9 | 2.7 | 5.55 | - | - | 0.5 | |||||

| FR15 | 19.8 | 1.88 | 4.65 | - | - | 0.5 | |||||

| FR22 | 9.4 | 1.13 | 2.80 | - | - | 0.5 | |||||

| Almeshal, Tayeh [36] | PET0 | Cement: 370 kg Fine agg. 600 kg Coarse agg. 1250 kg w/c: 0.54 | 28.5 | 3.11 | 7.6 | - | - | 0 | Replacing fine aggregate | ||

| PET10 | 28.2 | 2.78 | 7.4 | 10 | |||||||

| PET20 | 27.3 | 2.51 | 6.8 | 20 | |||||||

| PET30 | 19.7 | 2.01 | 5.9 | PET | Crushed | 30 | |||||

| PET40 | 11.4 | 1.74 | 3.2 | 40 | |||||||

| PET50 | 2.7 | 0.45 | 1.2 | 50 | |||||||

| Hanuseac, Dumitrescu [75] | S0 | Cement: 324 kg Fine agg. 803 kg Coarse agg. 558 kg Fly ash: 32.4 kg Water 180 L SP 32.4 kg | 33.5 | 3.9 | 2260 | PET | Chopped | 0 | Replacing fine aggregate | ||

| S1 | 23.6 | 2.1 | 2100 | 50 | |||||||

| S2 | 20.4 | 2.2 | 2000 | 70 | |||||||

| S3 | 14.7 | 1.9 | 1900 | 90 | |||||||

| Mehvish, Ahmed [57] | 1-C | Cement: 10 kg Fine agg. 15 kg Coarse agg. 30 kg Water 4.5 L | 26.0 | 2.70 | 3.10 | 2.5 | PET | 20 × 30 | 0.0 | Adding as a ratio of cement weight | |

| 2-0.5% | 24.6 | 2.30 | 2.90 | 2.7 | 0.5 | ||||||

| 3-1.0% | 24.3 | 2.25 | 2.85 | 2.8 | 1.0 | ||||||

| 4-1.5% | 24.2 | 2.10 | 2.70 | 3.3 | 1.5 | ||||||

| Thomas and Moosvi [43] | CS | M50 | 83 | 2.6 | 7.5 | 9.7 | PET fiber | 0.25 × 2.3 mm | 0.0 | Addition | |

| 0FRBC | 90 | 3.6 | 10 | 8.9 | 0.0 | ||||||

| 2FRBC | 95 | 4.3 | 13 | 8.5 | 0.2 | ||||||

| 4FRBC | 96 | 4.7 | 17 | 8.1 | 0.4 | ||||||

| 6FRBC | 82 | 4.5 | 9 | 8.0 | 0.6 | ||||||

| 8FRBC | 78 | 2.4 | 8 | 7.4 | 0.8 | ||||||

| Meena, Surendranath [58] | C251 | Cement: 390 kg Fine agg. 835.1 kg Coarse agg. 457.3 kg Water 156.1 L Specific gravity 1.23 Density 1270 kg/m3 | 30.2 | 24.8 | 8.3 | 2520 | PET | Aspect ratio 10 | 0.5 | Fine aggregate replacing | |

| C251 | 31.3 | 25.4 | 7.7 | 2520 | Aspect ratio 10 | 1.0 | |||||

| C251 | 30.8 | 24.8 | 7.5 | 2510 | Aspect ratio 10 | 1.5 | |||||

| C251 | 29.2 | 22.7 | 7.2 | 2510 | Aspect ratio 10 | 2.0 | |||||

| C251 | 27.0 | 21.6 | 7.0 | 2510 | Aspect ratio 10 | 2.5 | |||||

| C251 | 24.3 | 18.4 | 5.7 | 2510 | Aspect ratio 10 | 3.0 | |||||

| C252 | Cement: 390 kg Fine agg. 835.1 kg Coarse agg. 457.3 kg Water 156.1 L | 31.3 | 25.7 | 8.3 | 2520 | Aspect ratio 20 | 0.5 | ||||

| C252 | 34.1 | 26.8 | 6.3 | 2520 | Aspect ratio 20 | 1.0 | |||||

| C252 | 32.4 | 26.3 | 5.3 | 2520 | Aspect ratio 20 | 1.5 | |||||

| C252 | 30.7 | 24.6 | 5.2 | 2510 | Aspect ratio 20 | 2.0 | |||||

| C252 | 29.0 | 22.9 | 4.7 | 2500 | Aspect ratio 20 | 2.5 | |||||

| C252 | 25.7 | 19.6 | 4.3 | 2490 | Aspect ratio 20 | 3.0 | |||||

| C301 | Cement: 376 kg Fine agg. 535 kg Coarse agg. 534 kg Water 180.3 L | 45.4 | 35.6 | 6.7 | 2540 | Aspect ratio 10 | 0.5 | ||||

| C301 | 47.0 | 37.3 | 6.3 | 2540 | Aspect ratio 10 | 1.0 | |||||

| C301 | 46.1 | 36.7 | 5.7 | 2540 | Aspect ratio 10 | 1.5 | |||||

| C301 | 43.2 | 34.6 | 4.7 | 2530 | Aspect ratio 10 | 2.0 | |||||

| C301 | 37.3 | 29.7 | 4.8 | 2520 | Aspect ratio 10 | 2.5 | |||||

| C301 | 34.6 | 27.5 | 4.2 | 2520 | Aspect ratio 10 | 3.0 | |||||

| C302 | Cement: 376 kg Fine agg. 535 kg Coarse agg. 801 kg Water 180.3 L | 48.6 | 38 | 6.7 | 2540 | Aspect ratio 20 | 0.5 | ||||

| C302 | 48.6 | 39.1 | 4.7 | 2520 | Aspect ratio 20 | 1.0 | |||||

| C302 | 48.4 | 37.4 | 3.8 | 2520 | Aspect ratio 20 | 1.5 | |||||

| C302 | 43.6 | 34.6 | 4.0 | 2510 | Aspect ratio 20 | 2.0 | |||||

| C302 | 40.2 | 31.6 | 3.3 | 2510 | Aspect ratio 20 | 2.5 | |||||

| C302 | 37.4 | 29 | 2.7 | 2510 | Aspect ratio 20 | 3.0 | |||||

| Liu, Nafees [59] | 0SF0 | Cement: 367.27 kg Fine agg. 852.73 kg Coarse agg. 928 kg Water 202 L SP 0–14 mL/kg w/c: 0.55 Silica fume 0–73.45 kg | 20.5 | 3.4 | 8.6 | 2360 | PET | 0 | Replacing fine aggregate | ||

| 1SF2 | 21.4 | 8.1 | 2290 | 1 | |||||||

| 3SF6 | 20.7 | 7.8 | 2140 | 3 | |||||||

| 5SF10 | 20.6 | 7.5 | 1990 | 5 | |||||||

| 7SF14 | 19.1 | 7.6 | 1890 | 7 | |||||||

| 10SF17 | 18.1 | - | - | 10 | |||||||

| 15SF20 | 16.8 | - | - | 15 | |||||||

| Steyn, Babafemi [60] 2021 | Ref1 | Cement: 448 kg Fine agg. 757 kg Coarse agg. 937 kg Water 224 L w/c: 0.5 | 44.6 | 4.55 | 11.3 | - | 0 | Replacing fine aggregate | |||

| Ref2 | 42.7 | 4.47 | 8.5 | - | 0 | ||||||

| Pac15 | 44.6 | 4.6 | 8.5 | PET | 15 | ||||||

| Pac30 | 33.1 | 4.6 | 7.0 | PET | 30 | ||||||

| Rac15 | 31.7 | 4.6 | 7.8 | Rubber | 15 | ||||||

| Rac30 | 22.3 | 4.6 | 5.0 | Rubber | 30 | ||||||

| Gac15 | 48.0 | 4.6 | 10.2 | Glass | 15 | ||||||

| Gac30 | 45.4 | 4.6 | 7.0 | Glass | 30 | ||||||

| Mohammed and Mohammed [107] | MC | 1:1.2:2.4 w/c: 0.5 | 39.8 | 3.28 | 5.89 | PET | - | 0.0 | Volume fraction | ||

| 20-0.25 | 39.9 | 3.53 | 5.11 | 0.44 × 20 mm | 0.25 | ||||||

| 35-0.25 | 37.8 | 3.28 | 5.67 | 0.44 × 35 mm | 0.25 | ||||||

| 50-0.25 | 34.8 | 3.1 | 5.57 | 0.44 × 50 mm | 0.25 | ||||||

| 20-0.5 | 41.2 | 3.38 | 6.06 | 0.44 × 20 mm | 0.5 | ||||||

| 35-0.5 | 38.4 | 3.37 | 5.81 | 0.44 × 35 mm | 0.5 | ||||||

| 50-0.5 | 37.7 | 3.61 | 5.92 | 0.44 × 50 mm | 0.5 | ||||||

| 20-1 | 36.7 | 3.63 | 5.61 | 0.44 × 20 mm | 1.0 | ||||||

| 35-1 | 39.1 | 3.74 | 4.45 | 0.44 × 35 mm | 1.0 | ||||||

| 50-1 | 36.1 | 3.48 | 4.31 | 0.44 × 50 mm | 1.0 | ||||||

| 20-0.5 | 36.3 | 3.01 | 5.48 | 0.11 × 20 mm | 0.5 | ||||||

| 35-0.5 | 33.8 | 3.18 | 5.32 | 0.11 × 35 mm | 0.5 | ||||||

| 50-0.5 | 33.4 | 3.01 | 4.64 | 0.11 × 50 mm | 0.5 | ||||||

| Jain, Siddique [108] | A0 | Cement: 425.73 kg Fine agg. 653.92 kg Coarse agg. 1177 kg Water 191.6 kg | 26.7 | Crushed PET | 0.0 | Adding concrete by weight | |||||

| A1 | 25.9 | 0.5 | |||||||||

| A2 | 22.7 | 1.0 | |||||||||

| A3 | 15.5 | 2.0 | |||||||||

| A4 | 7.1 | 3.0 | |||||||||

| A5 | 3.8 | 5.0 | |||||||||

| Meza, Pujadas [61] | Control | Cement: 383 kg Fine agg. 672 kg Coarse agg. 1100 kg w/c: 0.6 | 31.0 | 2.50 | 2.8 | 4.8 | Fibers PET | - | 0 | Adding concrete by weight | |

| 2-50 | 30.0 | 2.30 | 2.6 | 3.5 | 53.5 × 3 × 0.3 | 2 | |||||

| 2-110 | 29.0 | 2.35 | 2.7 | 3.8 | 117.8 × 3 × 0.3 | 2 | |||||

| 6-80 | 29.5 | 2.20 | 2.7 | 3.8 | 85.6 × 3 × 0.3 | 6 | |||||

| 10-50 | 29.3 | 2.25 | 2.8 | 3.9 | 53.5 × 3 × 0.3 | 10 | |||||

| 10-110 | 28.0 | 2.30 | 2.9 | 3.9 | 117.8 × 3 × 0.3 | 10 | |||||

| Singh [62] | 1 | M40 | 43.8 | 3.2 | 5.4 | 7.2 | Shredded PET | 1.18 mm | 0 | Fine aggregate replacement by weight | |

| 2 | 44.5 | 3.4 | 5.8 | 6.8 | 4 | ||||||

| 3 | 48.6 | 3.8 | 6.2 | 6.5 | 8 | ||||||

| 4 | 43.5 | 3.2 | 5.6 | 5.7 | 12 | ||||||

| 5 | 40.2 | 3 | 5.4 | 5.2 | 16 | ||||||

| Tayeh, Almeshal [63] | RCM | Cement: 350 kg Fine agg. 619 kg Coarse agg. 1246 kg w/c: 0.51 kg SP 2.5% for 10% PET | 5.5 | 10.0 | 2310 | Shredded PET | 0 | Fine aggregate replacement by weight | |||

| PL10 | 5.3 | 13.0 | 2250 | 10 | |||||||

| PL20 | 5.0 | 16.5 | 2240 | 20 | |||||||

| PL30 | 4.3 | 23.0 | 2210 | 30 | |||||||

| PL40 | 4.0 | 28.0 | 2160 | 40 |

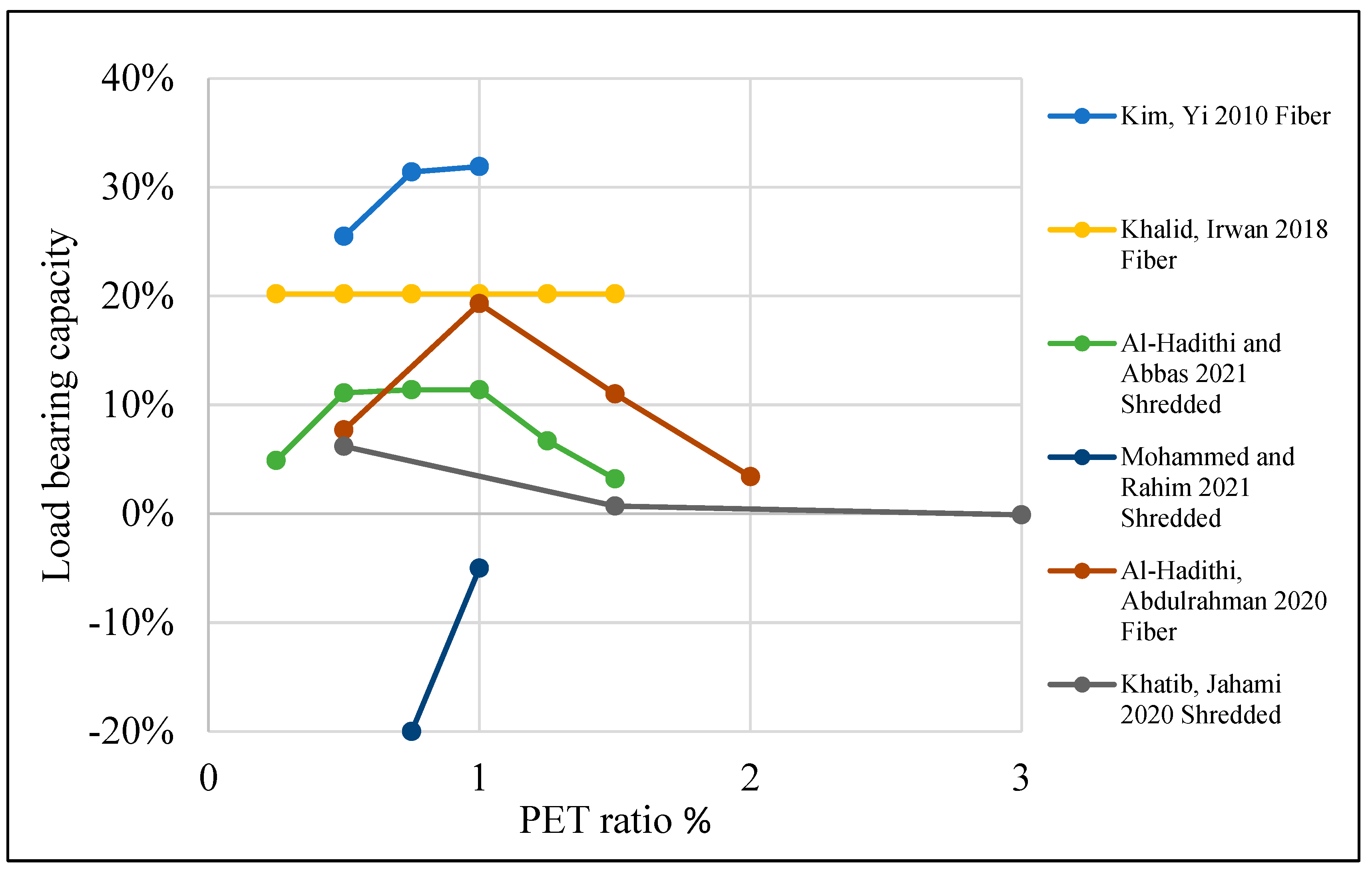

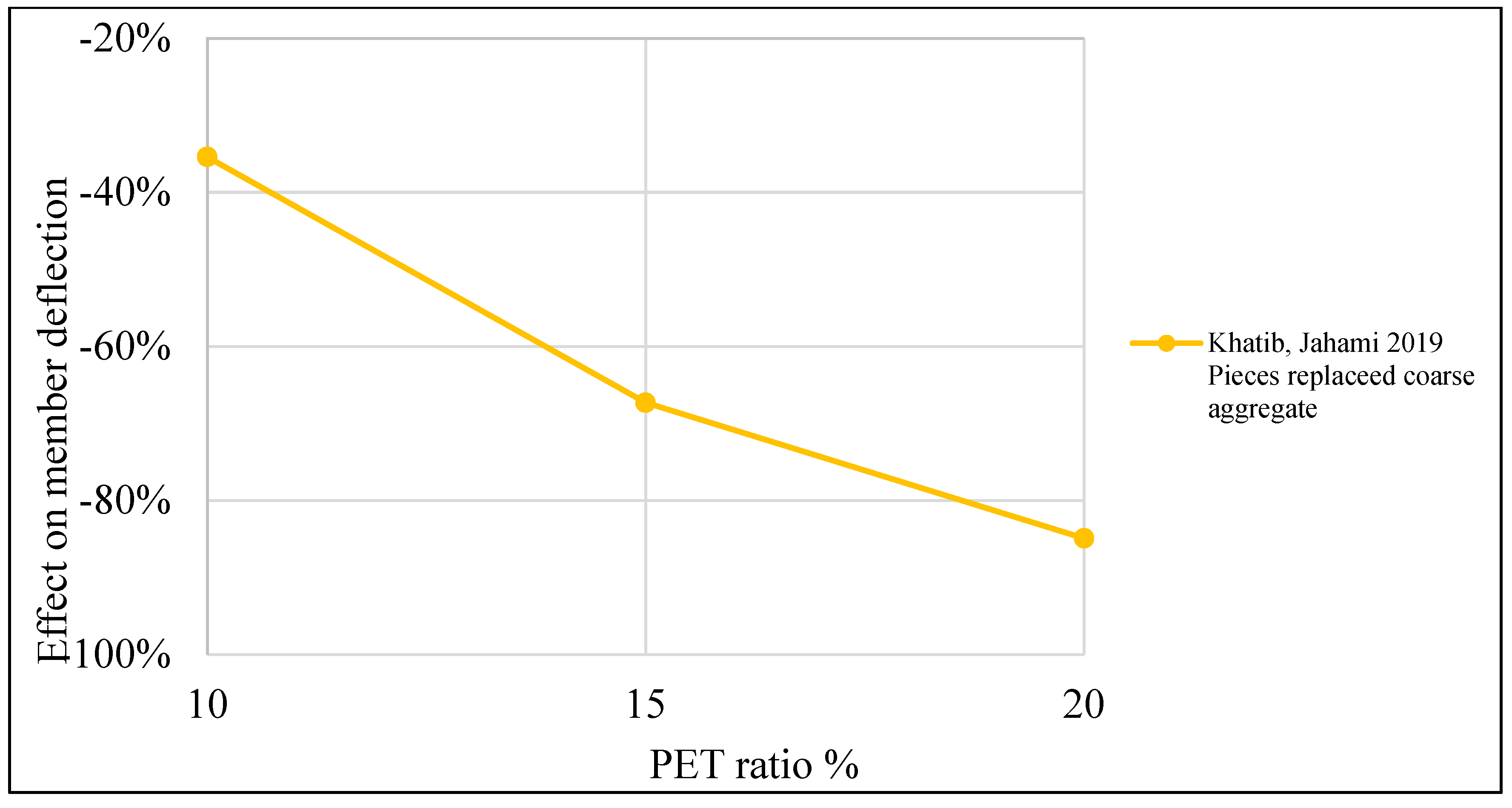

8. Effects of PET on the Structural Behavior of RC Beams

9. Saving

10. Conclusions

- PET can be utilized successfully and effectively to replace traditional fine or coarse aggregate.

- As the volume ratio of the utilized PET increased, concrete workability decreased.

- If a concrete mixture with a high ratio of PET is used, water-reducing admixtures are required.

- The fresh density of concrete containing PET is reduced if PET is added to the mixture. This is due to the low specific gravity of PET compared to the specific gravity of natural fine or coarse aggregate.

- The permeability of concrete is reduced when a low ratio of PET is used, up to 5%.

- Compressive strength is increased by about 5% when 0.2–0.4% PET is added to the concrete mixture. Beyond this ratio, compressive strength is gradually reduced.

- PET polyester fiber can increase compressive strength by 10% to 20% when 0.2 to 0.3% is added.

- For concrete compressive strength, the optimum PET ratio as a natural aggregate replacement is 1%.

- The split tensile strength of concrete using PET is remarkably increased by 10–20% when a 0.4–1% PET ratio is used. In the case of using PET as a replacement material, adding 1–8% would increase split tensile strength by 1–20%. On the other hand, if PET is used as a coarse aggregate replacement, that would negatively affect the split tensile strength.

- In the case of adding PET polyester to the concrete, this leads to a reduction in split tensile strength.

- Adding PET as an addition material to the concrete mix has no observed enhancement, apart from several authors who claimed different points of view.

- Adding PET as a replacement for fine aggregate would increase flexural strength by 40% when a 0.5–6% ratio is used. In the case of PET being used as a coarse aggregate replacement, that would negatively affect the flexural strength.

- Load-carrying capacity is improved when PET is used in the concrete mix. A 10–20% enhancement is observed when 0.5–1.25% is added.

- Adding 0.25% PET polyester leads to a slight increase in flexure strength of about 6 to 15%.

- Adding PET increases deflection by 20–40% when 0.25–2% is added to the mix, resulting in growth in member ductility. A reduction in deflection and ductility is observed when PET is used as a partial aggregate replacement, and the ratio goes beyond 10% with a non-remarkable enhancement in load-carrying capacity.

- Using PET on several floors of a building could reduce the quantity of concrete by about 5%.

- PET presence enhances cracking performance.

11. Future Direction, Gaps, and Recommendations

- Although many studies have investigated the effects of PET length on concrete behavior, the aspect ratio effect is rarely studied.

- One of the drawbacks of utilizing PET is a reduction in slump test measurement. Therefore, it is recommended to study the effects of different mix designs and additives on increasing workability in PET concrete.

- Further study is needed on the effects of PET ratio on concrete thermal conductivity and its result on the construction of energy-efficient buildings as environmental concerns.

- Many studies investigated the effects of different PET ratios on post-cracking without considering the effects of different PET geometry on post-cracking.

- Further study is needed on the effects of different PET lengths and geometry on split tensile strength.

- Further study is needed on utilizing a higher PET percentage as a partial fine aggregate replacement without affecting the overall mechanical properties of concrete; the current optimum replacement ratio is 1–5%.

- Durability is an important aspect and needs further studies looking at abrasion resistance, long-term shrinkage, and creep.

- The economic evaluation of utilizing PET in concrete needs to be investigated, considering the savings generated by the incorporation of PET as well as the advantages of saving time in the disposal of plastic waste.

- There has been little consideration for a recycling analysis comparison between traditional plastic waste and recycling PET in concrete.

- There was a lack of research on modeling concrete using PET.

- Further study is needed on the effects of using nanomaterials in concrete containing PET.

- Examine the effects of the PET ratio on water permeability, gas permeability, chloride resistance, and freeze-thaw resistance.

- Demonstrate the effects of elevated temperatures on concrete containing PET.

- An experimental study is required to investigate the fatigue and toughness resistance of concrete containing PET.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Sulyman, M.; Haponiuk, J.; Formela, K. Utilization of recycled polyethylene terephthalate (PET) in engineering materials: A review. Int. J. Environ. Sci. Dev. 2016, 7, 100. [Google Scholar] [CrossRef]

- Almeshal, I.; Tayeh, B.A.; Alyousef, R.; Alabduljabbar, H.; Mustafa Mohamed, A.; Alaskar, A. Use of recycled plastic as fine aggregate in cementitious composites: A review. Constr. Build. Mater. 2020, 253, 119146. [Google Scholar] [CrossRef]

- Rahmani, E.; Dehestani, M.; Beygi, M.H.A.; Allahyari, H.; Nikbin, I.M. On the mechanical properties of concrete containing waste PET particles. Constr. Build. Mater. 2013, 47, 1302–1308. [Google Scholar] [CrossRef]

- Skominas, R.; Zvinakevičius, L.; Gurskis, V.; Šadzevičius, R. Evaluation of suitability to use plastic waste in concrete production. In Proceedings of the International Scientific Conference Rural Development, Akademija, Litwa, 23–24 November 2017; Aleksandras Stulginskis University: Akademija, Lithuania, 2017; pp. 428–432. [Google Scholar]

- Abu-Saleem, M.; Zhuge, Y.; Hassanli, R.; Ellis, M.; Rahman, M.; Levett, P. Evaluation of concrete performance with different types of recycled plastic waste for kerb application. Constr. Build. Mater. 2021, 293, 123477. [Google Scholar] [CrossRef]

- Rafiq, A.H.; Al-kamaki, Y.S.S. The effect of adding waste plastic fibers on the concrete properties and shear strength of rc beams: A review. J. Duhok Univ. 2022, 25, 507–530. [Google Scholar] [CrossRef]

- Mir, B.A. Laboratory Study on the Effect of Plastic Waste Additive on Shear Strength of Marginal Soil. In Sustainable Civil Engineering Practices: Select Proceedings of ICSCEP 2019; Springer: Singapore, 2020; Volume 72, pp. 89–99. [Google Scholar]

- Qaidi, S.M.A.; Al-Kamaki, Y.S.S. State-of-the-Art Review: Concrete Made of Recycled Waste PET as Fine Aggregate. J. Duhok Univ. 2020, 23, 412–429. [Google Scholar] [CrossRef]

- Mohammed, A.A.; Rahim, A.A.F.; Al-Kamaki, Y.S. Flexural behavior of composite T-beam made of plastic waste aggregate concrete web and high-strength concrete flange. Structures 2023, 47, 2138–2147. [Google Scholar]

- Panyakapo, P.; Panyakapo, M. Reuse of thermosetting plastic waste for lightweight concrete. Waste Manag. 2008, 28, 1581–1588. [Google Scholar] [CrossRef] [PubMed]

- Alqahtani, F.K.; Ghataora, G.; Khan, M.I.; Dirar, S. Novel lightweight concrete containing manufactured plastic aggregate. Constr. Build. Mater. 2017, 148, 386–397. [Google Scholar] [CrossRef]

- Jacob-Vaillancourt, C.; Sorelli, L. Characterization of concrete composites with recycled plastic aggregates from postconsumer material streams. Constr. Build. Mater. 2018, 182, 561–572. [Google Scholar] [CrossRef]

- Hama, S.M.; Hilal, N.N. 5-Fresh properties of concrete containing plastic aggregate. In Use of Recycled Plastics in Eco-efficient Concrete; Pacheco-Torgal, F., Khatib, J., Colangelo, F., Tuladhar, R., Eds.; Woodhead Publishing: Cambridge, UK, 2019; pp. 85–114. [Google Scholar]

- Jabarin, S.A. Polyethylene terephthalate chemistry and preparation. Polym. Mater. Encycl. 1996, 4, 6079–6085. [Google Scholar]

- Pearce, E.M.; Lewin, M. Handbook of Fiber Chemistry; Marcel Dekker: New York, NY, USA, 1998. [Google Scholar]

- Bottenbruch, L.; Anders, S. Engineering Thermoplastics: Polycarbonates, Polyacetals, Polyesters, Cellulose Esters; Hanser Verlag: Munich, Germany, 1996. [Google Scholar]

- Becker, Y.; Mendez, M.P.; Rodriguez, Y. Polymer modified asphalt. Vis. Tecnol. 2001, 9, 39–50. [Google Scholar]

- Moghaddam, T.B.; Karim, M.R. Properties of SMA mixtures containing waste Polyethylene Terephthalate. World Acad. Sci. Eng. Technol. 2012, 6, 612–622. [Google Scholar]

- Chowdhury, S.; Maniar, A.T.; Suganya, O. Polyethylene terephthalate (PET) waste as building solution. Int. J. Chem. Environ. Biol. Sci 2013, 1, 308–312. [Google Scholar]

- Adnan, H.M.; Dawood, A.O. Recycling of plastic box waste in the concrete mixture as a percentage of fine aggregate. Constr. Build. Mater. 2021, 284, 122666. [Google Scholar] [CrossRef]

- Ahmed, H.U.; Faraj, R.H.; Hilal, N.; Mohammed, A.A.; Sherwani, A.F.H. Use of recycled fibers in concrete composites: A systematic comprehensive review. Compos. Part B Eng. 2021, 215, 108769. [Google Scholar] [CrossRef]

- Bahij, S.; Omary, S.; Feugeas, F.; Faqiri, A. Fresh and hardened properties of concrete containing different forms of plastic waste–A review. Waste Manag. 2020, 113, 157–175. [Google Scholar] [CrossRef]

- Thosar, C.P.; Husain, D.M. Reuse of plastic waste as replacement of sand in concrete. Int. J. Innov. Res. Sci. Eng. Technol. 2017, 6, 789–794. [Google Scholar]

- Askar, M.K.; Askar, L.K.; Al-Kamaki, Y.S.S.; Ferhadi, R. Effects of chopped CFRP fiber on mechanical properties of concrete. Heliyon 2023, 9, e13832. [Google Scholar] [CrossRef]

- Adnan, H.M.; Dawood, A.O. Strength behavior of reinforced concrete beam using re-cycle of PET wastes as synthetic fibers. Case Stud. Constr. Mater. 2020, 13, e00367. [Google Scholar] [CrossRef]

- Gupta, S.; Rao, V.K.; Sengupta, J. Evaluation of polyester fiber reinforced concrete for use in cement concrete pavement works. Road Mater. Pavement Des. 2008, 9, 441–461. [Google Scholar] [CrossRef]

- Gurunandan, M.; Phalgun, M.; Raghavendra, T.; Udayashankar, B. Mechanical and damping properties of rubberized concrete containing polyester fibers. J. Mater. Civ. Eng. 2019, 31, 04018395. [Google Scholar] [CrossRef]

- Pelisser, F.; Montedo, O.R.K.; Gleize, P.J.P.; Roman, H.R. Mechanical properties of recycled PET fibers in concrete. Mater. Res. 2012, 15, 679–686. [Google Scholar] [CrossRef]

- Akinyele, J.; Ajede, A. The use of granulated plastic waste in structural concrete. Afr. J. Sci. Technol. Innov. Dev. 2018, 10, 169–175. [Google Scholar] [CrossRef]

- Tang, Z.; Li, W.; Tam, V.W.; Xue, C. Advanced progress in recycling municipal and construction solid wastes for manufacturing sustainable construction materials. Resour. Conserv. Recycl. X 2020, 6, 100036. [Google Scholar] [CrossRef]

- Neville, A.M.; Brooks, J.J. Concrete Technology; Longman Scientific & Technical: Edinburgh Gate, UK, 1987. [Google Scholar]

- Askar, L.K.; Albarwary, I.H.M.; Askar, M.K. Use of Expanded Polystyrene (EPS) Beads in Silica-Fume Concrete. J. Duhok Univ. 2019, 22, 30–38. [Google Scholar] [CrossRef]

- ASTM C143/C143M-12; Standard Test Method for Slump of Hydraulic-Cement Concrete. ASTM International West Conshohocken: Conshohocken, PA, USA, 2012.

- ACI 211.3R-02 R09; Guide for Selecting Proportions for No-Slump Concrete Reported by ACI Committee 211. American Concrete Institute: Farmington Hills, MI, USA, 2011; pp. 1–26.

- BS EN 12350-3:2009; Testing Fresh Concrete: VeBe Test. British Standard Institution: London, UK, 2009.

- Almeshal, I.; Tayeh, B.A.; Alyousef, R.; Alabduljabbar, H.; Mohamed, A.M. Eco-friendly concrete containing recycled plastic as partial replacement for sand. J. Mater. Res. Technol. 2020, 9, 4631–4643. [Google Scholar] [CrossRef]

- Marthong, C.; Marthong, S. An experimental study on the effect of PET fibers on the behavior of exterior RC beam-column connection subjected to reversed cyclic loading. Structures 2016, 5, 175–185. [Google Scholar] [CrossRef]

- Al-Hadithi, A.I.; Abbas, M.A. The effects of adding waste plastic fibers on the mechanical properties and shear strength of reinforced concrete beams. Iraqi J. Civ. Eng. 2018, 12, 110–124. [Google Scholar] [CrossRef]

- Khatab, H.R.; Mohammed, S.J.; Hameed, L.A. Mechanical Properties of Concrete Contain Waste Fibers of Plastic Straps. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019. [Google Scholar]

- Pešić, N.; Živanović, S.; Garcia, R.; Papastergiou, P. Mechanical properties of concrete reinforced with recycled HDPE plastic fibres. Constr. Build. Mater. 2016, 115, 362–370. [Google Scholar] [CrossRef]

- Bhogayata, A.C.; Arora, N.K. Fresh and strength properties of concrete reinforced with metalized plastic waste fibers. Constr. Build. Mater. 2017, 146, 455–463. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Alyousef, R.; Lim, N.H.A.S.; Tahir, M.M.; Alabduljabbar, H.; Mohamed, A.M.; Samadi, M. Waste metalized film food packaging as low cost and ecofriendly fibrous materials in the production of sustainable and green concrete composites. J. Clean. Prod. 2020, 258, 120726. [Google Scholar] [CrossRef]

- Thomas, L.M.; Moosvi, S.A. Hardened properties of binary cement concrete with recycled PET bottle fiber: An experimental study. Mater. Today Proc. 2020, 32, 632–637. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Tahir, M.M.; Sam, A.R.M. The feasibility of improving impact resistance and strength properties of sustainable concrete composites by adding waste metalized plastic fibres. Constr. Build. Mater. 2018, 169, 223–236. [Google Scholar] [CrossRef]

- Dawood, A.O.; Al-Khazraji, H.; Falih, R.S. Physical and mechanical properties of concrete containing PET wastes as a partial replacement for fine aggregates. Case Stud. Constr. Mater. 2021, 14, e00482. [Google Scholar] [CrossRef]

- Miraldo, S.; Lopes, S.; Pacheco-Torgal, F.; Lopes, A. Advantages and shortcomings of the utilization of recycled wastes as aggregates in structural concretes. Constr. Build. Mater. 2021, 298, 123729. [Google Scholar] [CrossRef]

- Rai, B.; Rushad, S.T.; Kr, B.; Duggal, S. Study of waste plastic mix concrete with plasticizer. Int. Sch. Res. Not. 2012, 2012, 1–5. [Google Scholar] [CrossRef]

- Choi, Y.-W.; Moon, D.-J.; Chung, J.-S.; Cho, S.-K. Effects of waste PET bottles aggregate on the properties of concrete. Cem. Concr. Res. 2005, 35, 776–781. [Google Scholar] [CrossRef]

- Ochi, T.; Okubo, S.; Fukui, K. Development of recycled PET fiber and its application as concrete-reinforcing fiber. Cem. Concr. Compos. 2007, 29, 448–455. [Google Scholar] [CrossRef]

- Choi, Y.W.; Moon, D.J.; Kim, Y.J.; Lachemi, M. Characteristics of mortar and concrete containing fine aggregate manufactured from recycled waste polyethylene terephthalate bottles. Constr. Build. Mater. 2009, 23, 2829–2835. [Google Scholar] [CrossRef]

- Albano, C.; Camacho, N.; Hernández, M.; Matheus, A.; Gutierrez, A. Influence of content and particle size of waste pet bottles on concrete behavior at different w/c ratios. Waste Manag. 2009, 29, 2707–2716. [Google Scholar] [CrossRef]

- Saikia, N.; de Brito, J. Mechanical properties and abrasion behaviour of concrete containing shredded PET bottle waste as a partial substitution of natural aggregate. Constr. Build. Mater. 2014, 52, 236–244. [Google Scholar] [CrossRef]

- Sambhaji, P.P. Use of waste plastic in concrete mixture as aggregate replacement. Int. J. Adv. Eng. Res. Sci. 2016, 3, 236956. [Google Scholar]

- Islam, M.J.; Meherier, M.S.; Islam, A.K.M.R. Effects of waste PET as coarse aggregate on the fresh and harden properties of concrete. Constr. Build. Mater. 2016, 125, 946–951. [Google Scholar] [CrossRef]

- Mustafa, M.A.-T.; Hanafi, I.; Mahmoud, R.; Tayeh, B. Effect of partial replacement of sand by plastic waste on impact resistance of concrete: Experiment and simulation. Structures 2019, 20, 519–526. [Google Scholar] [CrossRef]

- Alani, A.H.; Bunnori, N.M.; Noaman, A.T.; Majid, T.A. Durability performance of a novel ultra-high-performance PET green concrete (UHPPGC). Constr. Build. Mater. 2019, 209, 395–405. [Google Scholar] [CrossRef]

- Mehvish, F.; Ahmed, A.; Saleem, M.M.; Saleem, M.A. Characterization of concrete incorporating waste polythene bags fibers. Pak. J. Eng. Appl. Sci. 2020, 26, 93–101. [Google Scholar]

- Meena, A.; Surendranath, A.; Ramana, P.V. Assessment of mechanical properties and workability for polyethylene terephthalate fiber reinforced concrete. Mater. Today Proc. 2021, V50, 2307–2314. [Google Scholar] [CrossRef]

- Liu, T.; Nafees, A.; Khan, S.; Javed, M.F.; Aslam, F.; Alabduljabbar, H.; Xiong, J.-J.; Ijaz Khan, M.; Malik, M.Y. Comparative study of mechanical properties between irradiated and regular plastic waste as a replacement of cement and fine aggregate for manufacturing of green concrete. Ain Shams Eng. J. 2021, 13, 101563. [Google Scholar] [CrossRef]

- Steyn, Z.C.; Babafemi, A.J.; Fataar, H.; Combrinck, R. Concrete containing waste recycled glass, plastic and rubber as sand replacement. Constr. Build. Mater. 2021, 269, 121242. [Google Scholar] [CrossRef]

- Meza, A.; Pujadas, P.; Meza, L.M.; Pardo-Bosch, F.; López-Carreño, R.D. Mechanical optimization of concrete with recycled PET fibres based on a statistical-experimental study. Materials 2021, 14, 240. [Google Scholar] [CrossRef] [PubMed]

- Singh, K. Partial replacement of cement with polyethylene terephthalate fiber to study its effect on various properties of concrete. Mater. Today: Proc. 2021, 37, 3270–3274. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Almeshal, I.; Magbool, H.M.; Alabduljabbar, H.; Alyousef, R. Performance of sustainable concrete containing different types of recycled plastic. J. Clean. Prod. 2021, 328, 129517. [Google Scholar] [CrossRef]

- Ramesan, A.; Babu, S.S.; Lal, A. Performance of light-weight concrete with plastic aggregate. Int. J. Eng. Res. Appl. 2015, 5, 105–110. [Google Scholar]

- Safi, B.; Saidi, M.; Aboutaleb, D.; Maallem, M. The use of plastic waste as fine aggregate in the self-compacting mortars: Effect on physical and mechanical properties. Constr. Build. Mater. 2013, 43, 436–442. [Google Scholar] [CrossRef]

- Al-Manaseer, A.; Dalal, T. Concrete containing plastic aggregates. Concr. Int. 1997, 19, 47–52. [Google Scholar]

- Silva, R.V.; de Brito, J.; Saikia, N. Influence of curing conditions on the durability-related performance of concrete made with selected plastic waste aggregates. Cem. Concr. Compos. 2013, 35, 23–31. [Google Scholar] [CrossRef]

- Dorf, R.C. The Engineering Handbook; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Kumar, K.S.; Baskar, K. Recycling of E-plastic waste as a construction material in developing countries. J. Mater. Cycles Waste Manag. 2015, 17, 718–724. [Google Scholar]

- Ismail, Z.Z.; Al-Hashmi, E.A. Use of waste plastic in concrete mixture as aggregate replacement. Waste Manag. 2008, 28, 2041–2047. [Google Scholar] [CrossRef]

- Hannawi, K.; Kamali-Bernard, S.; Prince, W. Physical and mechanical properties of mortars containing PET and PC waste aggregates. Waste Manag. 2010, 30, 2312–2320. [Google Scholar] [CrossRef]

- Marzouk, O.Y.; Dheilly, R.; Queneudec, M. Valorization of post-consumer waste plastic in cementitious concrete composites. Waste Manag. 2007, 27, 310–318. [Google Scholar] [CrossRef] [PubMed]

- Azhdarpour, A.M.; Nikoudel, M.R.; Taheri, M. The effect of using polyethylene terephthalate particles on physical and strength-related properties of concrete; a laboratory evaluation. Constr. Build. Mater. 2016, 109, 55–62. [Google Scholar] [CrossRef]

- Hameed, A.M.; Fatah Ahmed, B.A. Employment the plastic waste to produce the light weight concrete. Energy Procedia 2019, 157, 30–38. [Google Scholar] [CrossRef]

- Hanuseac, L.; Dumitrescu, L.; Barbuta, M.; Baran, I.; Bejan, G. Eco-Mechanical Index of Lightweight Concrete Mixtures with Recycled Materials. Procedia Manuf. 2020, 46, 667–674. [Google Scholar] [CrossRef]

- Kakooei, S.; Akil, H.M.; Jamshidi, M.; Rouhi, J. The effects of polypropylene fibers on the properties of reinforced concrete structures. Constr. Build. Mater. 2012, 27, 73–77. [Google Scholar] [CrossRef]

- Won, J.-P.; Jang, C.-I.; Lee, S.-W.; Lee, S.-J.; Kim, H.-Y. Long-term performance of recycled PET fibre-reinforced cement composites. Constr. Build. Mater. 2010, 24, 660–665. [Google Scholar] [CrossRef]

- Nassani, D.E.; Mermerdas, K.; Sakin, M. Fresh, Mechanical and Absorption Characteristics of Self-Consolidating Concretes Including Low Volume Waste PET Granules. Civ. Eng. J. 2017, 3, 809–820. [Google Scholar]

- Ezziane, M.; Kadri, T.; Molez, L.; Jauberthie, R.; Belhacen, A. High temperature behaviour of polypropylene fibres reinforced mortars. Fire Saf. J. 2015, 71, 324–331. [Google Scholar] [CrossRef]

- Coppola, B.; Courard, L.; Michel, F.; Incarnato, L.; Scarfato, P.; Di Maio, L. Hygro-thermal and durability properties of a lightweight mortar made with foamed plastic waste aggregates. Constr. Build. Mater. 2018, 170, 200–206. [Google Scholar] [CrossRef]

- Hasan, A.; Islam, M.; Karim, M.; Habib, M.; Wahid, M. Properties of concrete containing recycled plastic as coarse aggregate. In Proceedings of the International Conference on Recent Innovation in Civil Engineering for Sustainable Development, DUET, Gazipur, Bangladesh, 11–13 December 2015; pp. 152–157. [Google Scholar]

- ASTM C597-16; Standard Test Method for Pulse Velocity Through Concrete. ASTM International: West Conshohocken, PA, USA, 2009.

- Sutan, N.M.; Meganathan, M. A Comparison Between Direct and Indirect Method of Ultrasonic Pulse Velocity in Detecting Concrete Defects. J. Nondestruct. Test. 2003, 8, 1–9. [Google Scholar]

- Askar, M.K.; Selman, M.H.; Mohammed, S.I. Mechanical Properties of Concrete Reinforced with Alternative Fibers. J. Duhok Univ. 2020, 23, 149–158. [Google Scholar] [CrossRef]

- Hamouda, S.; Mirzaei, M.; Yu, Z. The Concrete Testing by Ultrasonic Pulse Velocity (UPV). In Proceedings of the MATEC Web of Conferences, Shanghai, China, 28 May 2016; p. 05017. [Google Scholar]

- Naik, T.R.; Malhotra, V.M.; Popovics, J.S. The ultrasonic pulse velocity method. In Handbook on Nondestructive Testing of Concrete, 2nd, ed.; CRC Press: Boca Raton, FL, USA, 2003; pp. 8-1–8-19. [Google Scholar]

- Belmokaddem, M.; Mahi, A.; Senhadji, Y.; Pekmezci, B.Y. Mechanical and physical properties and morphology of concrete containing plastic waste as aggregate. Constr. Build. Mater. 2020, 257, 119559. [Google Scholar] [CrossRef]

- Nikbin, I.M.; Rahimi, S.; Allahyari, H.; Fallah, F. Feasibility study of waste Poly Ethylene Terephthalate (PET) particles as aggregate replacement for acid erosion of sustainable structural normal and lightweight concrete. J. Clean. Prod. 2016, 126, 108–117. [Google Scholar] [CrossRef]

- Khatib, J.M.; Jahami, A.; Elkordi, A.; Abdelgader, H.; Sonebi, M. Structural Assessment of Reinforced Concrete Beams Incorporating Waste Plastic Straws. Environments 2020, 7, 96. [Google Scholar] [CrossRef]

- Boiny, H.U.; Alshkane, Y.M.; Rafiq, S.K. Mechanical properties of cement mortar by using polyethylene terephthalate fibers. In Proceedings of the 5th National and 1st International Conference on Modern Materials and Structures in Civil Engineering, Tehran, Iran, 26 October 2016. [Google Scholar]

- Alshkane, Y.M.; Rafiq, S.K.; Boiny, H.U. Correlation between Destructive and Non-Destructive Tests on the Mechanical Properties of Different Cement Mortar Mixtures incorporating Polyethylene Terephthalate Fibers. Sulaimania J. Eng. Sci. 2017, 4, 67–73. [Google Scholar] [CrossRef]

- Bui, N.K.; Satomi, T.; Takahashi, H. Recycling woven plastic sack waste and PET bottle waste as fiber in recycled aggregate concrete: An experimental study. Waste Manag. 2018, 78, 79–93. [Google Scholar] [CrossRef]

- Pauw, A. Static Modulus of Elasticity of Concrete as Affected by Density; University of Missouri: Columbia, MO, USA, 1960. [Google Scholar]

- ASTM C469/C469M-14; Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression. American Society for Testing and Materials: Philadelphia, PA, USA, 1987.

- Kangavar, M.E.; Lokuge, W.; Manalo, A.; Karunasena, W.; Frigione, M. Investigation on the properties of concrete with recycled polyethylene terephthalate (PET) granules as fine aggregate replacement. Case Stud. Constr. Mater. 2022, 16, e00934. [Google Scholar] [CrossRef]

- Bamigboye, G.; Tarverdi, K.; Adigun, D.; Daniel, B.; Okorie, U.; Adediran, J. An appraisal of the mechanical, microstructural, and thermal characteristics of concrete containing waste PET as coarse aggregate. Clean. Waste Syst. 2022, 1, 100001. [Google Scholar] [CrossRef]

- Aslani, F.; Liu, Y.; Wang, Y. The effect of NiTi shape memory alloy, polypropylene and steel fibres on the fresh and mechanical properties of self-compacting concrete. Constr. Build. Mater. 2019, 215, 644–659. [Google Scholar] [CrossRef]

- Faraj, R.H.; Hama Ali, H.F.; Sherwani, A.F.H.; Hassan, B.R.; Karim, H. Use of recycled plastic in self-compacting concrete: A comprehensive review on fresh and mechanical properties. J. Build. Eng. 2020, 30, 101283. [Google Scholar] [CrossRef]

- Ghernouti, Y.; Rabehi, B.; Bouziani, T.; Ghezraoui, H.; Makhloufi, A. Fresh and hardened properties of self-compacting concrete containing plastic bag waste fibers (WFSCC). Constr. Build. Mater. 2015, 82, 89–100. [Google Scholar]

- Askar, M.; Abduka, K.; Askar, L. Seismic Vulnerability Assessment of Reinforced Concrete Structures in Kurdistan Region-Iraq. J. Duhok Univ. 2020, 23, 116–130. [Google Scholar]

- ASTM C39/C39M-21; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM international: West Conshohocken, PA, USA, 2014.

- EN 12390-3:2019; Testing Hardened Concrete. Compressive Strength of Test Specimens. British Standard Institution: London, UK, 2009.

- Pereira, E.L.; de Oliveira Junior, A.L.; Fineza, A.G. Optimization of mechanical properties in concrete reinforced with fibers from solid urban wastes (PET bottles) for the production of ecological concrete. Constr. Build. Mater. 2017, 149, 837–848. [Google Scholar] [CrossRef]

- Chaudhary, M.; Srivastava, V.; Agarwal, V. Effect of waste low density polyethylene on mechanical properties of concrete. J. Acad. Ind. Res. 2014, 3, 123–126. [Google Scholar]

- Fraternali, F.; Spadea, S.; Berardi, V.P. Effects of recycled PET fibres on the mechanical properties and seawater curing of Portland cement-based concretes. Constr. Build. Mater. 2014, 61, 293–302. [Google Scholar]

- Borg, R.P.; Baldacchino, O.; Ferrara, L. Early age performance and mechanical characteristics of recycled PET fibre reinforced concrete. Constr. Build. Mater. 2016, 108, 29–47. [Google Scholar] [CrossRef]

- Mohammed, A.A.; Mohammed, I.I. Effect of Fiber Parameters on the Strength Properties of Concrete Reinforced with PET Waste Fibers. Iran. J. Sci. Technol. Trans. Civ. Eng. 2021, 45, 1493–1509. [Google Scholar]

- Jain, A.; Siddique, S.; Gupta, T.; Jain, S.; Sharma, R.K.; Chaudhary, S. Evaluation of concrete containing waste plastic shredded fibers: Ductility properties. Struct. Concr. 2021, 22, 566–575. [Google Scholar]

- Ramadevi, K.; Manju, R. Experimental investigation on the properties of concrete with plastic PET (bottle) fibres as fine aggregates. Int. J. Emerg. Technol. Adv. Eng. 2012, 2, 42–46. [Google Scholar]

- ASTM C496-96; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. American Society for Testing and Materials: Philadelphia, PA, USA, 1958.

- Frigione, M. Recycling of PET bottles as fine aggregate in concrete. Waste Manag. 2010, 30, 1101–1106. [Google Scholar] [CrossRef]

- Askar, M.K.; Hassan, A.F.; Al-Kamaki, Y.S.S. Flexural and shear strengthening of reinforced concrete beams using FRP composites: A state of the art. Case Stud. Constr. Mater. 2022, 17, e01189. [Google Scholar] [CrossRef]

- Nursyamsi; Zebua, W.S.B. The Influence of Pet Plastic Waste Gradations as Coarse Aggregate Towards Compressive Strength of Light Concrete. Procedia Eng. 2017, 171, 614–619. [Google Scholar] [CrossRef]

- Kim, S.B.; Yi, N.H.; Kim, H.Y.; Kim, J.-H.J.; Song, Y.-C. Material and structural performance evaluation of recycled PET fiber reinforced concrete. Cem. Concr. Compos. 2010, 32, 232–240. [Google Scholar]

- Foti, D. Use of recycled waste pet bottles fibers for the reinforcement of concrete. Compos. Struct. 2013, 96, 396–404. [Google Scholar]

- Mohammed, A.A. Flexural behavior and analysis of reinforced concrete beams made of recycled PET waste concrete. Constr. Build. Mater. 2017, 155, 593–604. [Google Scholar]

- Thomas, T.; Faisal, K. Influence of PET Bottle Mesh in Flexural Behaviour of Concrete Beam. Int. J. Eng. Res. Gen. Sci. 2018, 6, 12–15. [Google Scholar]

- Khalid, F.; Irwan, J.; Ibrahim, M.W.; Othman, N.; Shahidan, S. Performance of plastic wastes in fiber-reinforced concrete beams. Constr. Build. Mater. 2018, 183, 451–464. [Google Scholar]

- Khatib, J.; Jahami, A.; Elkordi, A.; Baalbaki, O. Structural performance of reinforced concrete beams containing plastic waste caps. Mag. Civ. Eng. 2019, 7, 73–79. [Google Scholar]

- Dawood, A.O.; Adnan, H.M. Experimental investigation of using PET wastes as tension bars in reinforced concrete beams. J. Univ. Babylon Eng. Sci. 2019, 27, 247–261. [Google Scholar]

- Al-Hadithi, A.I.; Abbas, M.A. Innovative technique of using carbon fibre reinforced polymer strips for shear reinforcement of reinforced concrete beams with waste plastic fibres. Eur. J. Environ. Civ. Eng. 2021, 25, 516–537. [Google Scholar]

- Mohammed, A.A.; Rahim, A.A.F. Experimental behavior and analysis of high strength concrete beams reinforced with PET waste fiber. Constr. Build. Mater. 2020, 244, 118350. [Google Scholar]

- Al-Hadithi, A.; Abdulrahman, M.; Al-Rawi, M. Flexural behaviour of reinforced concrete beams containing waste plastic fibers. Mater. Sci. Eng. 2020, 737, 012173. [Google Scholar]

- ACI 363R; High-Strength Concrete (ACI 363R): By ACI Committee 363-High-Strength Concrete. American Concrete Institute, ACI Special Publication: Farmington Hills, MI, USA, 2005; pp. 79–80.

- Busel, J.P. (Ed.) ACI-Committee-440. In Specification for Carbon and Glass Fiber-Reinforced Polymer Bar Materials for Concrete Reinforcement; American Concrete Institute: Farmington Hills, MI, USA, 2008. [Google Scholar]

- Alqahtani, F.K.; Abotaleb, I.S.; ElMenshawy, M. Life cycle cost analysis of lightweight green concrete utilizing recycled plastic aggregates. J. Build. Eng. 2021, 40, 102670. [Google Scholar] [CrossRef]

| Material | ft (MPa) | E (GPa) | λ (W/m.k) | Specific Gravity |

|---|---|---|---|---|

| PET | 55–80 | 2.1–3.1 | 0.15 | 1.3–1.4 |

| PVC | 50–60 | 2.7–3.0 | 0.17–0.21 | 1.3–1.4 |

| PS | 30–55 | 3.1–3.3 | 0.105 | 1–1.1 |

| PP | 25–40 | 1.3–1.8 | 0.12 | 0.9–0.91 |

| PE | 18–30 | 0.6–1.4 | 0.33–0.52 | 1.2–1.28 |

| Aggregate | - | 70 | 2.29–2.78 | 2.55–2.65 |

| sand | - | 70 | 4.45 | 2.6–2.7 |

| Cement paste (w/c = 0.5) | 2.5–4.0 | 36–40 | 1 | 3.1–3.15 |

| Plastic Fiber (%) | 0.0 | 5.0 | 10 | 15 | 20 | 25 | 50 |

|---|---|---|---|---|---|---|---|

| Ezziane et al., 2015 [79] | 2.2 | 2.2 | 2.4 | 4.8 | |||

| Coppola et al., 2018 [80] | 7.2 | 7.2 | 7.4 | 7.2 | 7.2 | 7.6 | 8.0 |

| Hassan et al., 2015 [81] | 8.0 | 8.2 | 8.2 | 9.4 | 9.5 | 9.8 | 18.3 |

| Author | Beam ID | Beam DimensionB × H × L (cm) | Concrete Strength (MPa) | Fc’ (MPa) | Ft (MPa) | Sample Parameter/Remarks | Material Types | Dimension (mm) | Ratio % V | Ultimate Load (kN) | Ultimate Deflection (mm) | Failure Mode |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Kim, Yi [114] | NF | 10 × 10 ×40 | ** | 26 | 994 kg/m3 coarse agg. | PET | - | - | 121.6 | 169 | Flexural | |

| RPET 0.5 | 26 | 775 kg/m3 fine agg. | 0.2 × 1.3 × 50 | 0.5 | 152.6 | 165 | ||||||

| RPET 0.75 | 25 | 355 kg/m3 cement | 0.2 × 1.3 × 50 | 0.75 | 159.8 | 141.4 | ||||||

| RPET 1.0 | 24 | 161 kg/m3 water | 0.2 × 1.3 × 50 | 1 | 160.4 | 143.4 | ||||||

| PP 0.5 | 26 | 40 kg/m3 fly ash | 0.38 × 0.9 × 50 | 0.5 | 154 | 140.1 | ||||||

| PP 0.75 | 24.5 | 2.37 kg/m3 air entainer | 0.38 × 0.9 × 50 | 0.75 | 150.4 | 149.2 | ||||||

| PP 1.0 | 24 | w/c 0.41 Sand/Aggregate 43.8% | 1 | 156.6 | 144.2 | |||||||

| Foti [115] | B1 | 10 ×10 × 40 | ** | 53.2 | 2.34 | PET 0.5–0.75% (0.0%w) superplasticizer PET 1% (0.8% w) superplasticizer PET little beam (1.4% w) superplasticizer | PET | circular PET | - | 4 | 20 | Flexural |

| B2 | half bottle PET | 1W | 4.6 | 20 | ||||||||

| circular + 2 | ||||||||||||

| B3 | overlaped half | 1W | 3.1 | 20.4 | ||||||||

| half bottle + 2 | ||||||||||||

| B4 | overlaped half | 1W | 3.1 | 20.4 | ||||||||

| B5 | 10 × 20 × 110 | 51.5 | 2.3 | circular + 4 layer overlaped half half bottle + 4 layer overlaped half | 1W | 11 | - | |||||

| B6 | 1W | 11 | - | |||||||||

| Mohammed [116] | CH100 | ** | 33.1 | Concrete mix 1:1.25:2.5 w/c 0.5 Flexure-critical Shredded PET replacing fine aggregate | - | - | - | 40.4 | Flexural | |||

| PET510 | 27.1 | Shredded | <12.5 | 5 | 41.7 | |||||||

| PET1100 | 31.8 | PET | <12.5 | 10 | 39.9 | |||||||

| PET1510 | 32.6 | <12.5 | 15 | 42.2 | ||||||||

| CH200 | 31.4 | - | - | - | 112.8 | |||||||

| PET520 | 23.8 | Shredded | <12.5 | 5 | 105.1 | |||||||

| PET1200 | 24.9 | PET | <12.5 | 10 | 100.1 | |||||||

| PET1520 | 23.7 | <12.5 | 15 | 96 | ||||||||

| Thomas and Faisal [117] | Bc | 10 × 10 × 50 | ** | 25 | mix 1:1.45:2.68 w/c 0.45 | - | - | 13 | Flexural | |||

| BPET-mesh | PET mesh | 10 × 0.5 | 8.5 | |||||||||

| Khalid, Irwan [118] | B-normal | 15 × 30 × 250 | ** | 34.1 | 0.15 fr | Vf | - | 0 | 98.5 | 43.1 | ||

| B-RPET-5 | 34.5 | 0.22 fr | ring RPET-5 width | 0.25 | 99.3 | 43.3 | ||||||

| 35 | 0.5 | |||||||||||

| 35.3 | 0.75 | |||||||||||

| 34.5 | 1 | |||||||||||

| 34.8 | 1.25 | |||||||||||

| 35.3 | 1.5 | |||||||||||

| B-RPET-10 | 34.5 | 0.23 fr | ring RPET-10 width | 0.25 | 98.3 | 54.4 | ||||||

| 35 | 0.5 | |||||||||||

| 35.3 | 0.75 | |||||||||||

| 34.5 | 1 | |||||||||||

| 34.8 | 1.25 | |||||||||||

| 35.3 | 1.5 | |||||||||||

| B-IRE PET | 34.1 | 0.19 fr | PET irregular | 0.25 | 98.3 | 51.8 | ||||||

| 34.9 | 0.5 | |||||||||||

| 34 | 0.75 | |||||||||||

| 35.1 | 1 | |||||||||||

| 34.7 | 1.25 | |||||||||||

| 34.3 | 1.5 | |||||||||||

| B-WRE | 33.9 | 0.31 fr | Waste wire 55 mm | 0.25 | 98.3 | 53.7 | ||||||

| 34.2 | 0.5 | |||||||||||

| 35.3 | 0.75 | |||||||||||

| 35 | 1 | |||||||||||

| 34.9 | 1.25 | |||||||||||

| 34.8 | 1.5 | |||||||||||

| B-SYNT | 34.2 | 0.22 fr | Synthetic fibers | 0.25 | 103.2 | 57.9 | ||||||

| 34.5 | 0.5 | |||||||||||

| 34.4 | 0.75 | |||||||||||

| 34.2 | 1 | |||||||||||

| 34.8 | 1.25 | |||||||||||

| 34.9 | 1.5 | |||||||||||

| Khatib, Jahami [119] | PBC 0 | 20 × 30 × 120 | * | 15 | 942.7 kg/m3 coarse agg. 942.7 kg/m3 fine agg. 314 kg/m3 cement 188.5 kg/m3 water Replacing coarse aggregate | - | 0 | 92 | 120 | Flexural | ||

| PBC 10 | 16 | PP waste cap | 10 | 96 | 77.5 | |||||||

| PBC 15 | 17.5 | PP waste cap | 15 | 97 | 39.2 | |||||||

| PBC 20 | 18.5 | PP waste cap | 20 | 98 | 18.1 | |||||||

| Dawood and Adnan [120] | B1-S | 15 × 20 × 140 | ** | 35.8 | 3.1 fr | 1024 kg/m3 coarse agg. 649.644 kg/m3 fine agg. 95.12 kg/m3 cement 201.38 kg/m3 water 3.961 L/m3 superplasticizer w/c 0.41 Replacing main reinforcement | Steel bar | 82.5 | 12.7 | Flexural | ||

| B2 | No reo | 30 | 4 | |||||||||

| B3-P1 | Plastic bar 1 | 12.5 | 16 | |||||||||

| B4-P2 | Plastic bar 2 | 15 | 17 | |||||||||

| B5-P3 | Plastic bar 3 | 15 | 17 | |||||||||

| B6-P4 | Plastic bar 4 | 20 | 20 | |||||||||

| B7-P5 | Plastic bar 5 | 20 | 16 | |||||||||

| B8-P6 | Plastic bar 6 + steel | 85 | 27 | |||||||||

| B9-P7 | Plastic bar 7 + steel | 25 | 30 | |||||||||

| B10-P8 | Plastic bar 8 + steel | 30 | 29 | |||||||||

| B11-P9 | Plastic bar 9 + steel | 30 | 28 | |||||||||

| B12-P10 | Plastic bar 10 | 15 | 16 | |||||||||

| Al-Hadithi and Abbas [121] | Group A | 10 × 15 × 100 | ** | 32.9 | 2.93 | Shear-critical beams Steel shear reinforcement | ShreddedPET | 40 × 4 × 0.35 | 0 | 142.6 | 7.7 | Shear /Flexural shear |

| 33 | 3.06 | 0.25 | 143.1 | 7.4 | ||||||||

| 33.3 | 3.07 | 0.5 | 142.3 | 7.6 | ||||||||

| 34.6 | 3.18 | 0.75 | 150.1 | 7.5 | ||||||||

| 35.3 | 3.33 | 1 | 154.8 | 7.9 | ||||||||

| 32 | 3.47 | 1.25 | 147.5 | 8.2 | ||||||||

| 32 | 3.56 | 1.5 | 134.2 | 7 | ||||||||

| Group B | 32.9 | 2.93 | CFRP sheet shear reinforcement | ShreddedPET | 40 × 4 × 0.35 | 0 | 139.8 | 8.4 | ||||

| 33 | 3.06 | 0.25 | 146.7 | 8.1 | ||||||||

| 33.3 | 3.07 | 0.5 | 155.3 | 9.9 | ||||||||

| 34.6 | 3.18 | 0.75 | 155.8 | 10.7 | ||||||||

| 35.3 | 3.33 | 1 | 155.8 | 9.4 | ||||||||

| 32 | 3.47 | 1.25 | 149.2 | 8.6 | ||||||||

| 32 | 3.56 | 1.5 | 144.3 | 7.6 | ||||||||

| Mohammed and Rahim [122] | Bc | 12 × 15 × 120 | *** | 94.3 | 4.36 | 1075 kg/m3 coarse agg. 677.5 kg/m3 fine agg. 480 kg/m3 cement 79.9 kg/m3 water 104 kg/m3 silica fume 4.16 kg/m3 superplasticizer PET specific gravity 1.4 | - | - | 0 | 62.4 | 14.8 | Flexural |

| B-0.75-S | 84.7 | 3.95 | ShreddedPET | 1.4 × 20 | 0.75 | 47.9 | 16.5 | |||||

| B-0.75-H | 77.3 | 4.2 | 1.4 × 20 | 0.75 | 63.5 | 18.1 | ||||||

| B-0.75-L | 66.2 | 4.06 | 1.4 × 40 | 0.75 | 51.9 | 21.1 | ||||||

| B-1-S | 68.4 | 3.87 | 1.4 × 20 | 1 | 59.6 | 20.4 | ||||||

| B-1-H | 68.7 | 3.62 | mixed | 1 | 59.1 | 20.4 | ||||||

| Adnan and Dawood [25] | Bcr | 15 × 20 × 140 | ** | 30.3 | 4.53 fr | 1024 kg/m3 coarse agg. 649.644 kg/m3 fine agg. 496 kg/m3 cement 201.38 kg/m3 water 3.961 L/m3 superplasticizer water/cement ratio of 0.41 | - | - | - | Flexural | ||

| B1 | 31 | 4.25 fr | Machine PET | <25.4 | 1.5 | 82 | 12.6 | |||||

| B2 | 30.8 | 4.33 fr | Machine PET | <25.4 | 3 | 75 | 20 | |||||

| B3 | 43.1 | 4.91 fr | Hand PET | 4 × 40 | 1.5 | 72 | 15 | |||||

| B4 | 24.9 | 4.31 fr | Hand PET | 4 × 40 | 3 | 70 | 25 | |||||

| Al-Hadithi, Abdulrahman [123] | M1-26s | 10 × 15 × 110 | ** | 32.1 | Specific gravity 1.12 Mix design 1:1.5:3.15 w/c 0.43 | PET | 4 × 30 × 0.3 | 0 | 86.1 | 15.2 | Flexural | |

| M2-58As | 32.1 | 0 | 65.8 | 13.3 | ||||||||

| M3-6s | 32.1 | 0 | 29 | 9 | ||||||||

| M4-26s | 33.7 | 0.5 | 92.7 | 14.4 | ||||||||

| M5-58s | 33.7 | 0.5 | 72.5 | 12.5 | ||||||||

| M6-6s | 33.7 | 0.5 | 35 | 7.2 | ||||||||

| M7-26s | 35.5 | 1 | 102.7 | 13.3 | ||||||||

| M8-58s | 35.5 | 1 | 81.3 | 11.1 | ||||||||

| M9-6s | 35.5 | 1 | 38.1 | 6.8 | ||||||||

| M10-26s | 34.6 | 1.5 | 95.6 | 12.3 | ||||||||

| M11-58s | 34.6 | 1.5 | 75.8 | 9.8 | ||||||||

| M12-6s | 34.6 | 1.5 | 35.3 | 6.4 | ||||||||

| M13-26s | 33.3 | 2 | 89 | 11.9 | ||||||||

| M14-58s | 33.3 | 2 | 69.7 | 9.6 | ||||||||

| M15-6s | 33.3 | 2 | 33 | 6 | ||||||||

| Khatib, Jahami [89] | PS-0.0 | 20 × 30 × 150 | ** | 38.7 | 4.19 | 1340 kg/m3 coarse agg. 670 kg/m3 fine agg. 670 kg/m3 cement 270 kg/m3 water Mix design 1:1:2 w/c 0.4 Shredded waste plastic PP | - | - | 0 | 181.4 | 15.5 | Flexural |

| PS-0.5 | 40 | 4.28 | PP shredded | 2 × 30 | 0.5 | 192.7 | 25.5 | |||||

| PS-1.5 | 36.5 | 4.33 | PP shredded | 2 × 30 | 1.5 | 182.7 | 29 | |||||

| PS-3.0 | 36 | 4.47 | PP shredded | 2 × 30 | 3 | 181.3 | 38.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Askar, M.K.; Al-Kamaki, Y.S.S.; Hassan, A. Utilizing Polyethylene Terephthalate PET in Concrete: A Review. Polymers 2023, 15, 3320. https://doi.org/10.3390/polym15153320

Askar MK, Al-Kamaki YSS, Hassan A. Utilizing Polyethylene Terephthalate PET in Concrete: A Review. Polymers. 2023; 15(15):3320. https://doi.org/10.3390/polym15153320

Chicago/Turabian StyleAskar, Mand Kamal, Yaman S. S. Al-Kamaki, and Ali Hassan. 2023. "Utilizing Polyethylene Terephthalate PET in Concrete: A Review" Polymers 15, no. 15: 3320. https://doi.org/10.3390/polym15153320

APA StyleAskar, M. K., Al-Kamaki, Y. S. S., & Hassan, A. (2023). Utilizing Polyethylene Terephthalate PET in Concrete: A Review. Polymers, 15(15), 3320. https://doi.org/10.3390/polym15153320