Feasibility of Sustainable Asphalt Concrete Materials Utilizing Waste Plastic Aggregate, Epoxy Resin, and Magnesium-Based Additive

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Asphalt

2.1.2. Mineral Aggregates

2.1.3. Waste Plastic Aggregate (WPA)

2.2. Experimental Methods

2.2.1. Aggregate Property Test

2.2.2. Mixture Design

2.2.3. Mixing Process

2.2.4. Curing Conditions

2.2.5. Volume Characteristic Evaluation

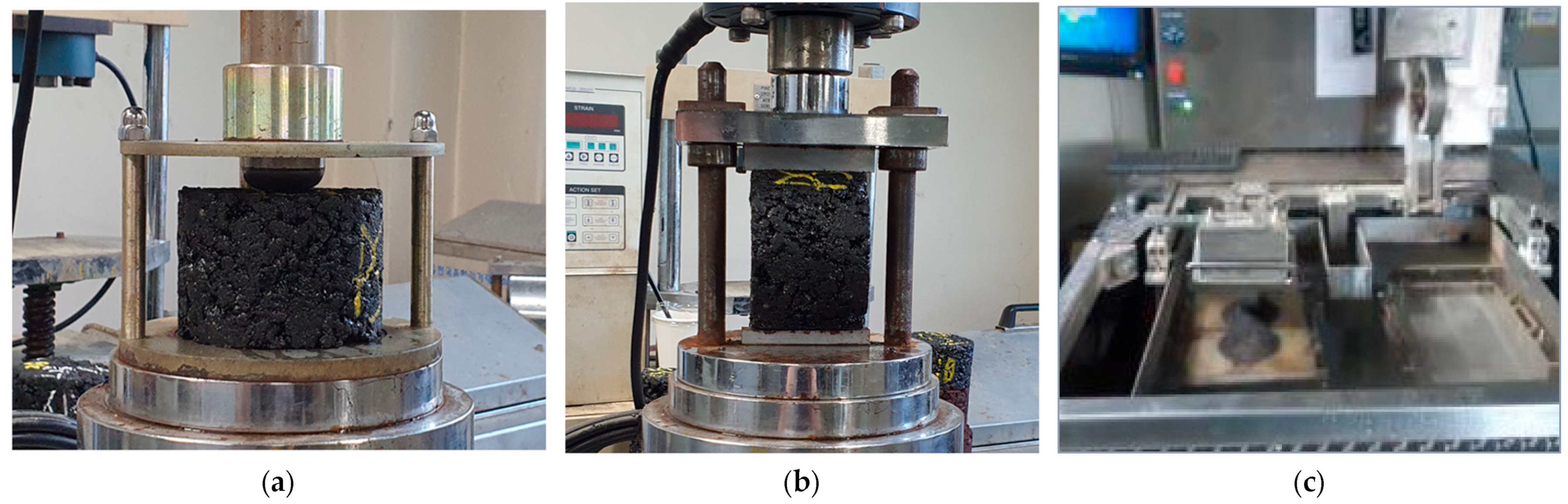

2.2.6. Durability Test Items and Contents

| Test Item | Temp. (°C) | Condition | Loading | Note |

|---|---|---|---|---|

| Deformation strength (SD) | 60 | 30 mm/min | MOLIT 2017 [32,33] (Figure 2a) | |

| Indirect tensile strength (ITS) | 25 | Dry | 50.8 mm/min | KS F 2382 [36] (Figure 2b) |

| Wheel tracking (WT) | 60 | // | 42 pass/min | AAHSTO 324 [38] (Figure 2c) |

| Tensile strength ratio (TSR) | 60, 25 | Wet 60 24 h | 50.8 mm/min | KS F 2398 [37] |

| Deformation strength ratio (SDR) | 60, 25 | Wet 60 48 h | 30 mm/min | - |

3. Results and Discussion

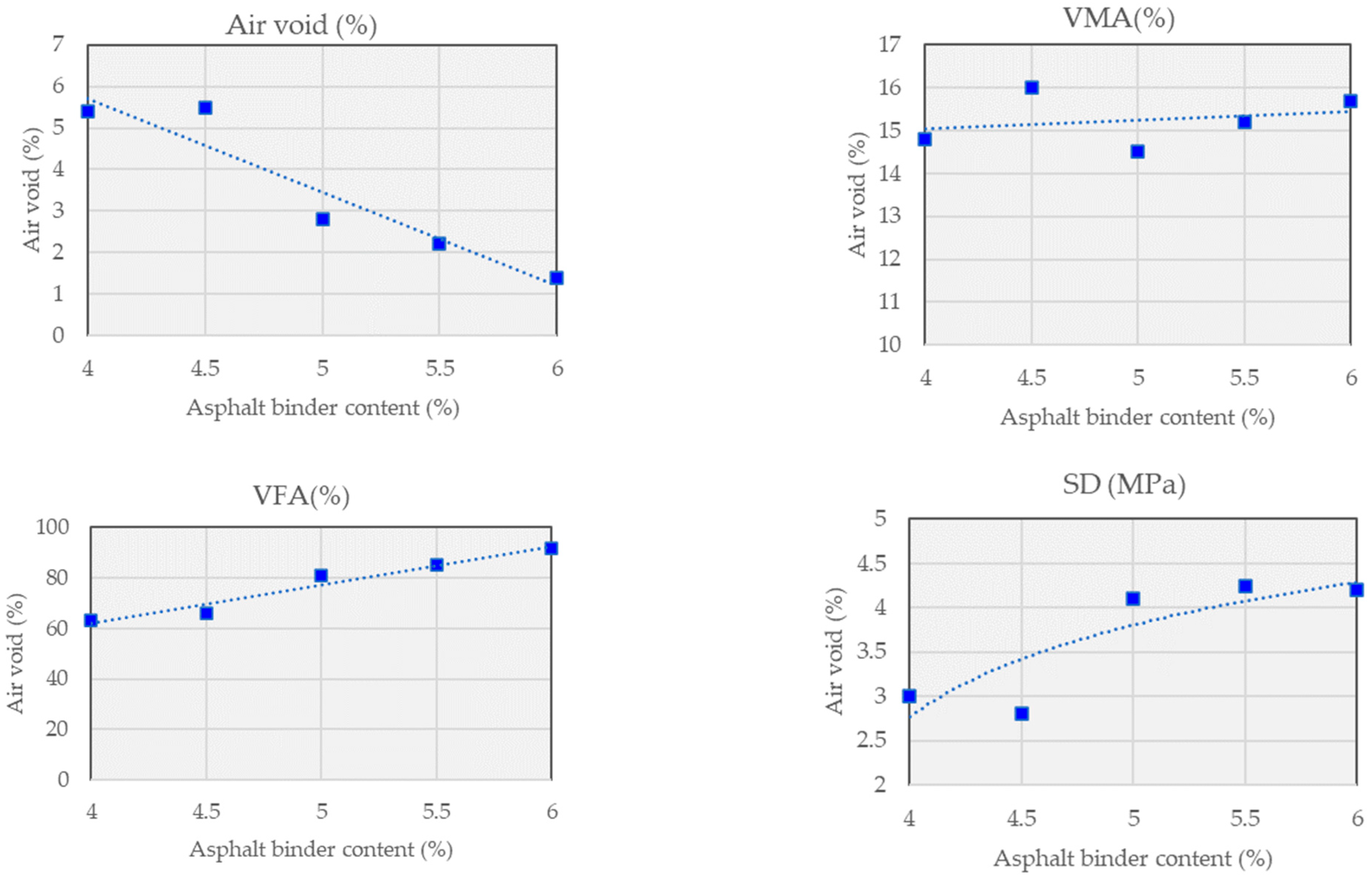

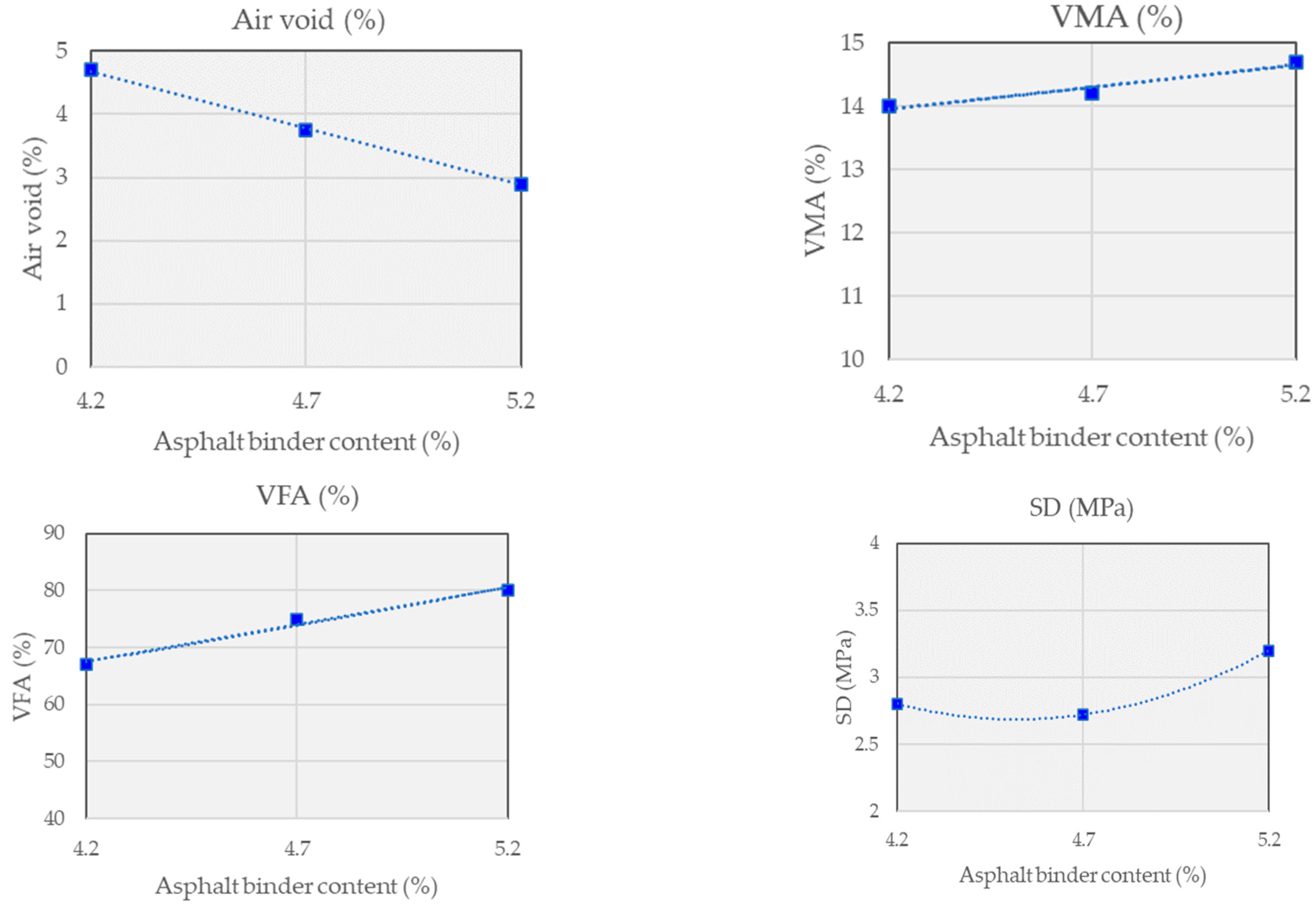

3.1. Mixture Design Results

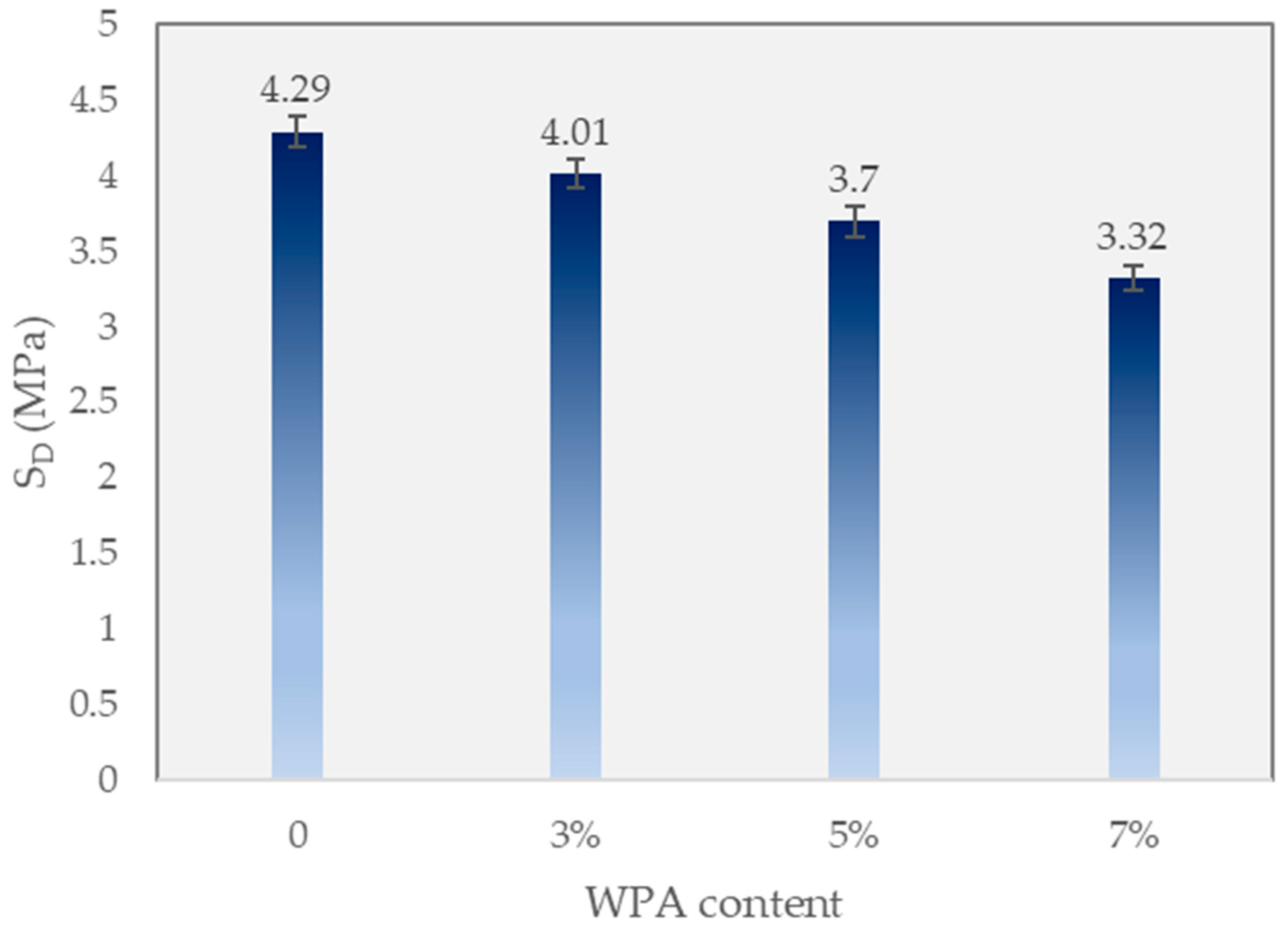

3.2. Deformation Strength (SD)

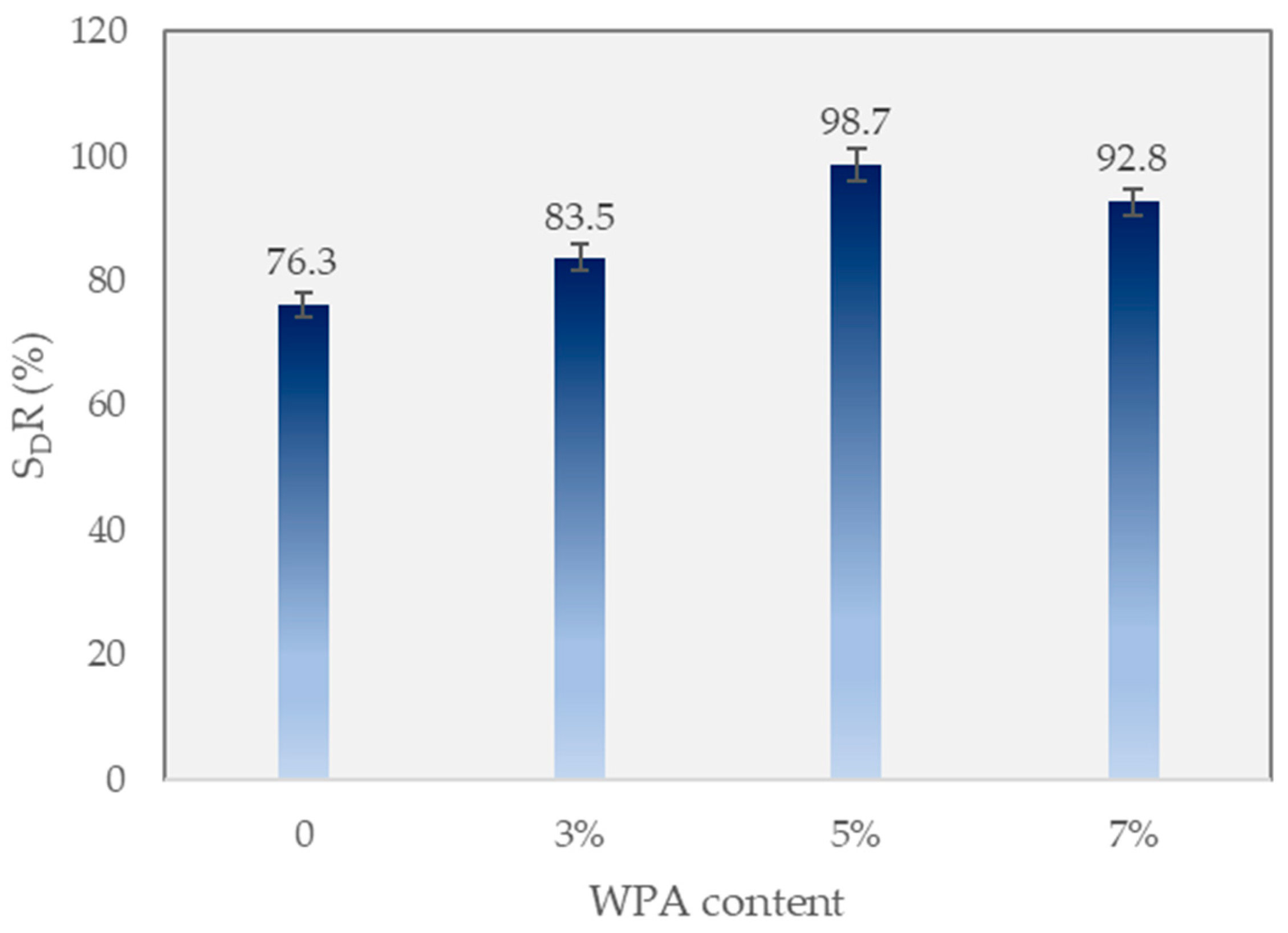

3.3. Strain Strength Ratio (SDR)

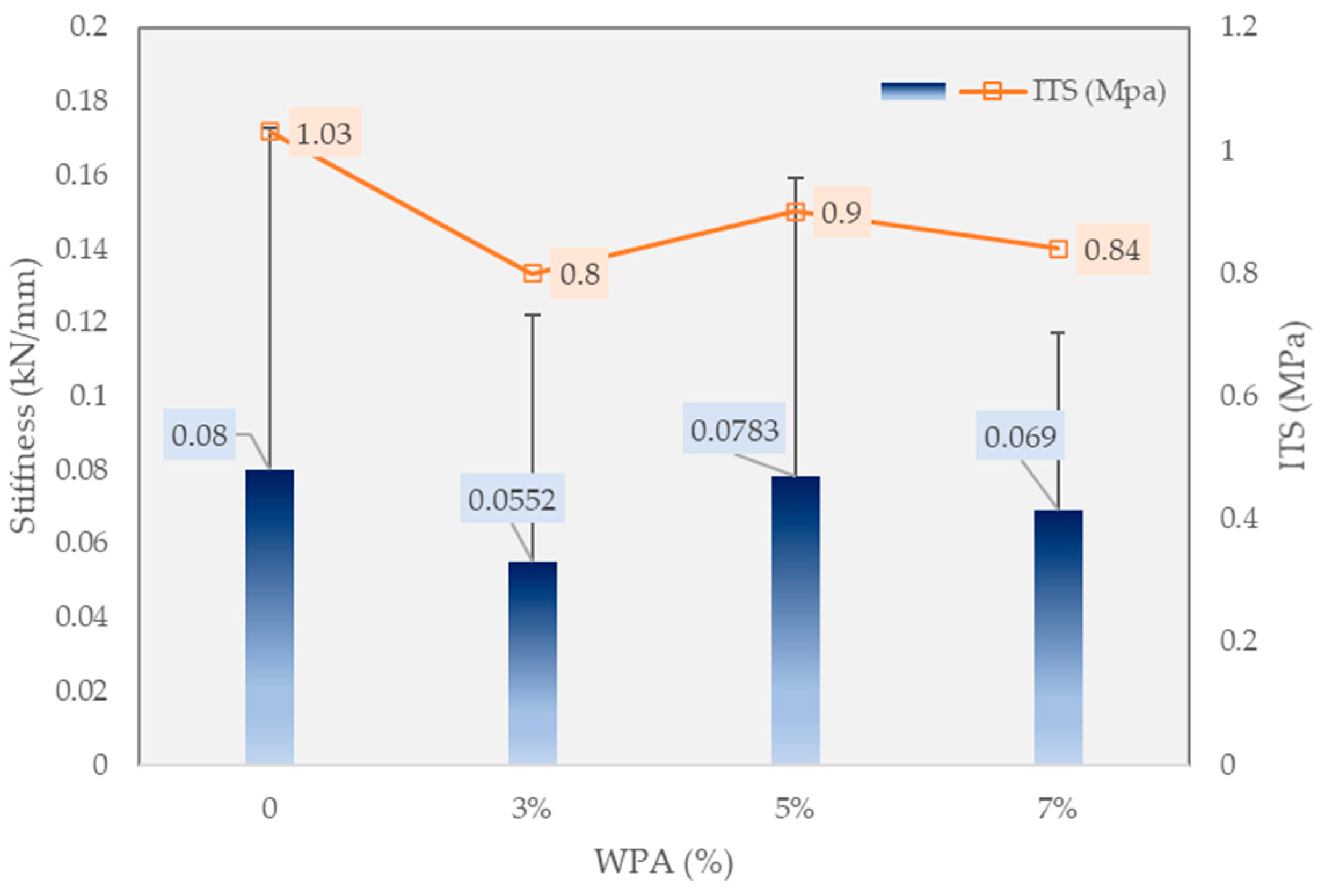

3.4. Indirect Tensile Strength (ITS)

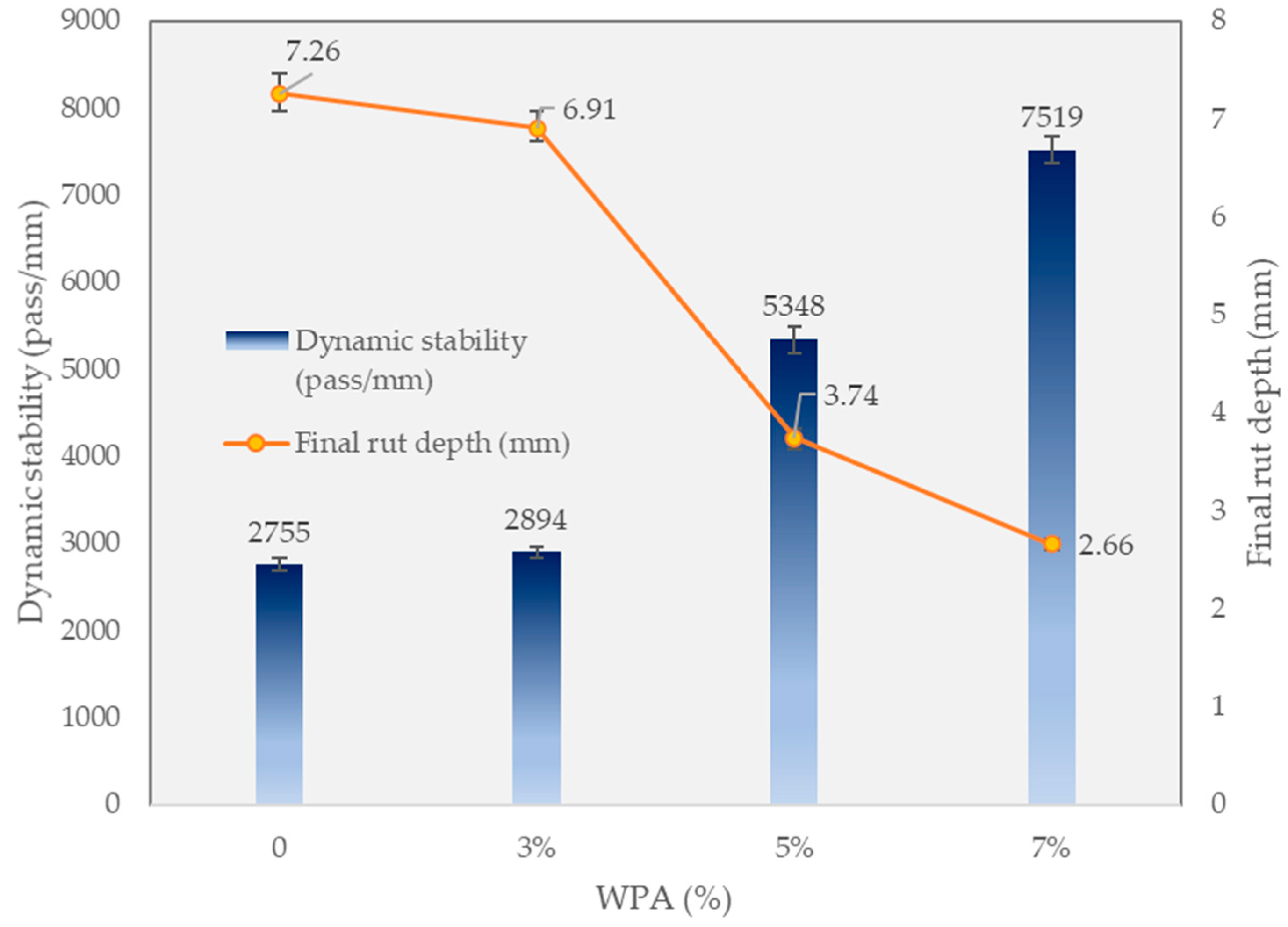

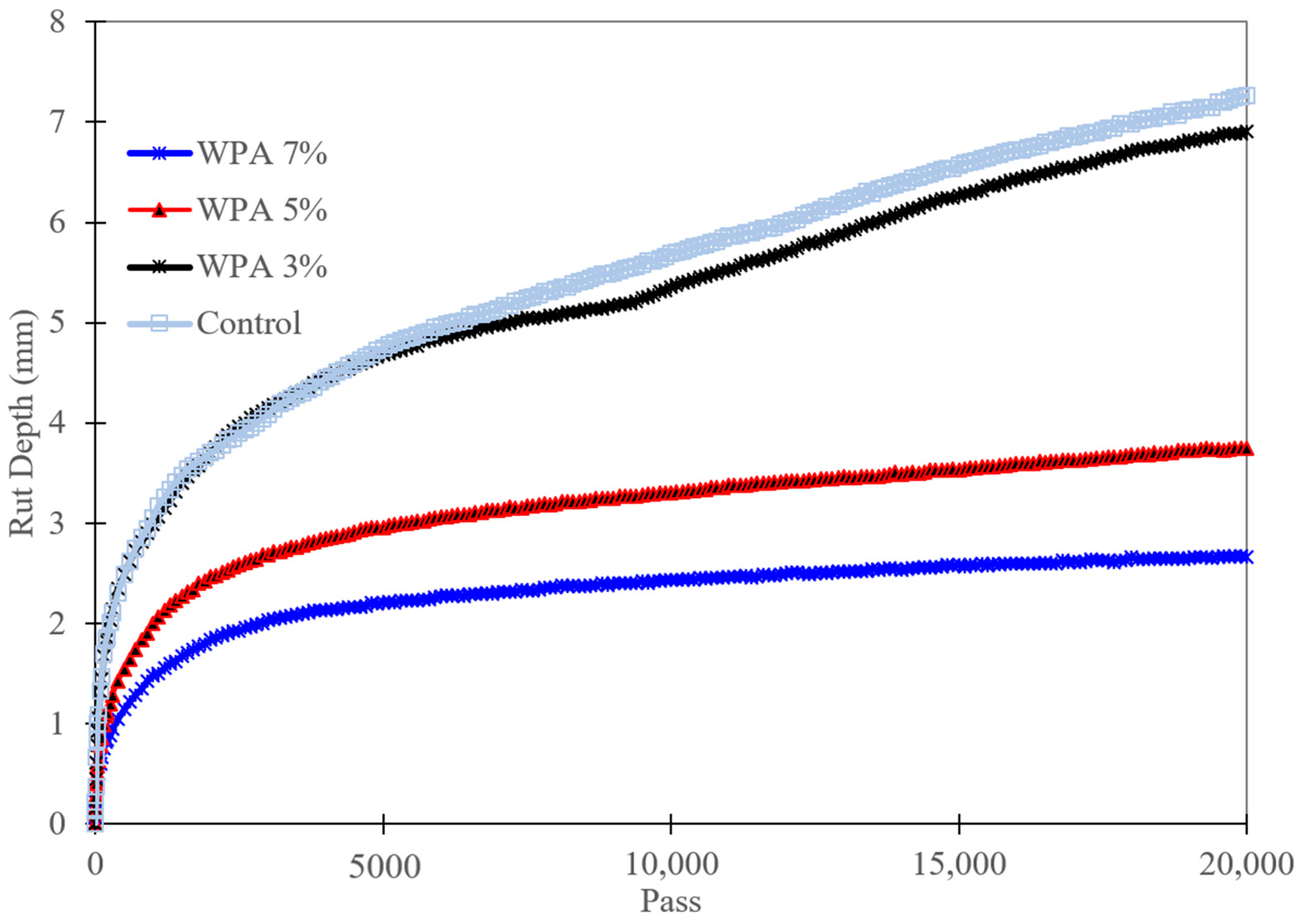

3.5. Wheel Tracking (WT) Rut Depth and Dynamic Stability

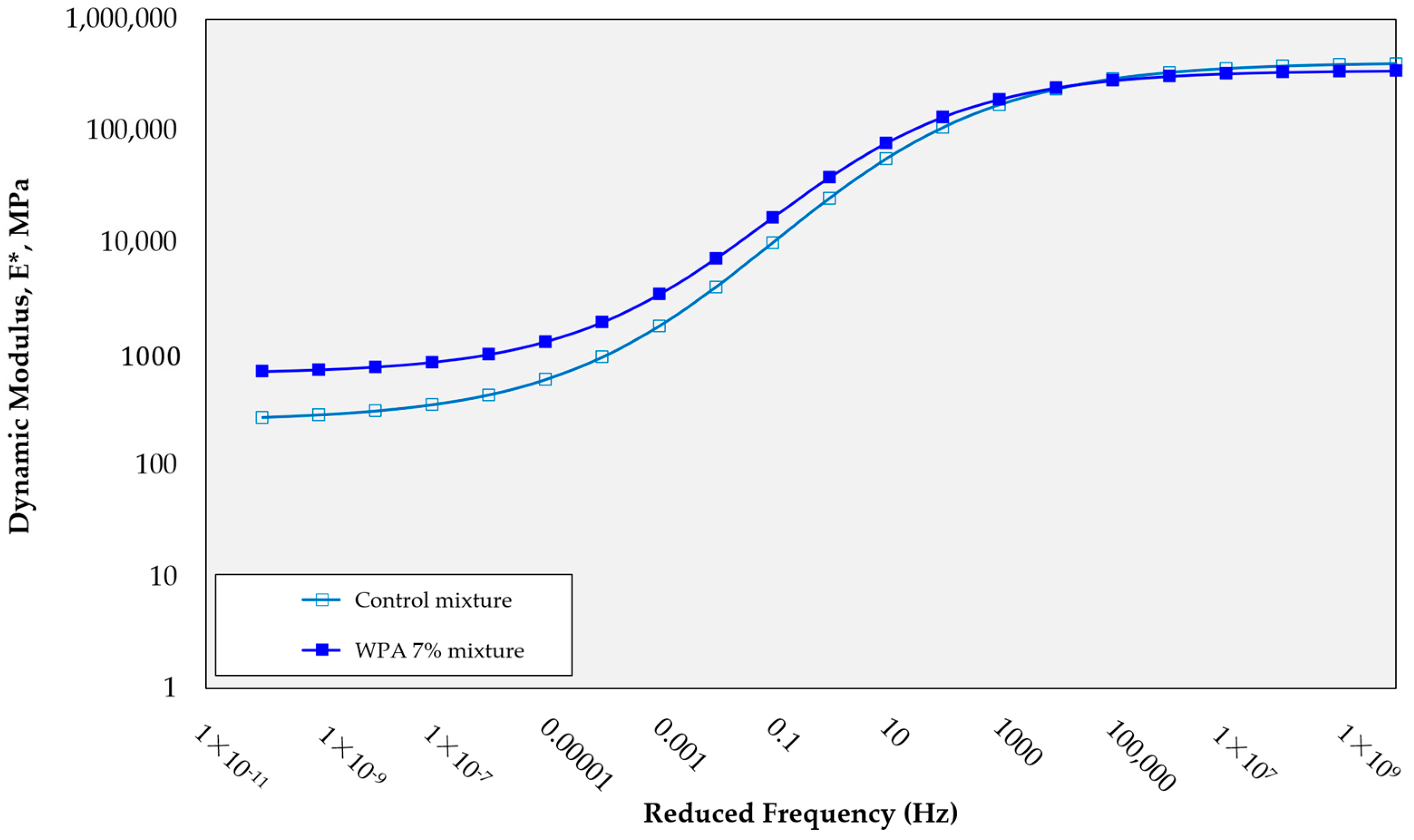

3.6. Dynamic Modulus Test

3.7. Discussion

4. Conclusions

- -

- The control mixture, without any WPA, exhibited a deformation strength of 4.29 MPa. The WPCM mixture with 3% wt WPA and epoxy reinforcement had a deformation strength of 4.01 MPa. Increasing the WPA content to 5% and 7% wt resulted in deformation strengths of 3.7 MPa and 3.32 MPa, respectively. The presence of epoxy resin enhanced the bond between WPA and the asphalt binder, improving cohesion and load-bearing capacity.

- -

- The inclusion of WPA in the asphalt mixtures affected the indirect tensile strength (ITS) and stiffness properties. The optimal WPA content for balancing strength and stiffness varied, with the 5% wt WPA mixture demonstrating a slightly improved ITS of 0.9 MPa and increased stiffness of 2.7 kN/mm compared to the 3% wt WPA mix. Higher WPA content did not necessarily lead to improved ITS and stiffness. These findings contribute to the development of sustainable asphalt mixtures with enhanced performance and resilience.

- -

- The control mixture showed moderate rutting resistance, with a final rut depth of 7.26 mm. Increasing the WPA content resulted in significant reductions in rut depth, with the 3% wt WPA mixture achieving 6.91 mm and the 5% wt WPA mixture further reducing it to 3.74 mm. The best-performing mixture was the 7% wt WPA, exhibiting exceptional performance with a final rut depth of 2.66 mm and a dynamic stability of 7519 passes per millimeter. The addition of epoxy resin enhanced cohesion and adhesion between plastic particles and the asphalt binder, contributing to improved performance.

- -

- The inclusion of epoxy resin in the WPA mixture also played a critical role in preventing stripping points and improving adhesion between the asphalt binder and the aggregate.

- -

- The dynamic modulus of the WPA mixture at very low frequencies is significantly higher (696 MPa) than that of the control mixture (270 MPa). This notable difference underscores the outstanding rutting resistance of the WPA mixture, particularly in low-speed zones and at low frequencies.

- -

- The inclusion of WPA in the asphalt mixtures, along with a fixed 3% wt epoxy resin content by weight, significantly improves the SDR. The control mixture exhibits an SDR of 76.3%, while the WPCM mixtures with 3%, 5%, and 7% wt WPA content achieve SDR values of 83.5%, 98.7%, and 92.8%, respectively.

- -

- While this research provides valuable insights into the use of WPA and epoxy resin in asphalt mixtures, further field studies are necessary to assess their long-term durability. Future research should explore the effects of different types and sizes of waste plastic materials, investigate synergistic combinations with additives/modifiers, and conduct life-cycle assessments for a comprehensive understanding of their sustainability and cost-effectiveness.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sun, M.; Jing, S.; Wu, H.; Zhong, J.; Yang, Y.; Zhu, Y.; Xu, Q. Preparation Scheme Optimization of Thermosetting Polyurethane Modified Asphalt. Polymers 2023, 15, 2327. [Google Scholar] [CrossRef]

- Lin, P.; Liu, X.; Ren, S.; Xu, J.; Li, Y.; Li, M. Effects of Bitumen Thickness on the Aging Behavior of High-Content Polymer-Modified Asphalt Mixture. Polymers 2023, 15, 2325. [Google Scholar] [CrossRef]

- Zhang, S.; Yang, Y.; Guo, R.; Yan, Y.; Huan, H.; Wan, B. Study on the Low-Temperature Pre-Desulfurization of Crumb Rubber-Modified Asphalt. Polymers 2023, 15, 2273. [Google Scholar] [CrossRef]

- Li, Z.; Guo, T.; Chen, Y.; Zhang, T.; Tang, D.; Hao, M.; Zhao, X.; Liu, J. Study on Road Performance of Polyurethane Cold-Recycled Mixture. Polymers 2023, 15, 1958. [Google Scholar] [CrossRef]

- Khan, I.M.; Kabir, S.; Alhussain, M.A.; Almansoor, F.F. Asphalt Design Using Recycled Plastic and Crumb-Rubber Waste for Sustainable Pavement Construction. Procedia Eng. 2016, 145, 1557–1564. [Google Scholar] [CrossRef]

- Andrews, K.; Dernayka, S.; Amin Mir, M.; Ali Khasawneh, M. Review of the Utilization of Plastic Waste in Asphalt Pavements in Hot Climate Conditions—KSA as a Case Study. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Duarte, G.M.; Faxina, A.L. Asphalt Concrete Mixtures Modified with Polymeric Waste by the Wet and Dry Processes: A Literature Review. Constr. Build. Mater. 2021, 312, 125408. [Google Scholar] [CrossRef]

- Xiao, R.; Shen, Z.; Polaczyk, P.; Huang, B. Thermodynamic Properties of Aggregate Coated by Different Types of Waste Plastic: Adhesion and Moisture Resistance of Asphalt-Aggregate Systems. J. Mater. Civ. Eng. 2023, 35, 04023261. [Google Scholar] [CrossRef]

- Wong, T.L.X.; Mohd Hasan, M.R.; Peng, L.C. Recent Development, Utilization, Treatment and Performance of Solid Wastes Additives in Asphaltic Concrete Worldwide: A Review. J. Traffic Transp. Eng. 2022, 9, 693–724. [Google Scholar] [CrossRef]

- Audy, R.; Enfrin, M.; Boom, Y.J.; Giustozzi, F. Selection of Recycled Waste Plastic for Incorporation in Sustainable Asphalt Pavements: A Novel Multi-Criteria Screening Tool Based on 31 Sources of Plastic. Sci. Total Environ. 2022, 829, 154604. [Google Scholar] [CrossRef]

- Alrshoudi, F.; Abdus Samad, U.; Alothman, O.Y. Evaluation of the Effect of Recycled Polypropylene as Fine Aggregate Replacement on the Strength Performance and Chloride Penetration of Mortars. Polymers 2022, 14, 2806. [Google Scholar] [CrossRef]

- Shah, A.M.; Lodhi, R.H.; Javed, M.F.; Jasiński, M.; Jasińska, E.; Gono, M. Structural Performance of Waste Plastic Bottles Modified Asphalt: A Review. Resources 2023, 12, 10. [Google Scholar] [CrossRef]

- Xu, X.; Leng, Z.; Lan, J.; Wang, W.; Yu, J.; Bai, Y.; Sreeram, A.; Hu, J. Sustainable Practice in Pavement Engineering through Value-Added Collective Recycling of Waste Plastic and Waste Tyre Rubber. Engineering 2021, 7, 857–867. [Google Scholar] [CrossRef]

- Lee, J.U.; Hong, J.Y. Comparison of Surface Modification Methods for Improving the Compatibility of Recycled Plastic Film-Based Aggregates. Polymers 2021, 13, 3956. [Google Scholar] [CrossRef] [PubMed]

- Abeysinghe, S.; Gunasekara, C.; Bandara, C.; Nguyen, K.; Dissanayake, R.; Mendis, P. Engineering Performance of Concrete Incorporated with Recycled High-Density Polyethylene (HDPE)—A Systematic Review. Polymers 2021, 13, 1885. [Google Scholar] [CrossRef]

- Yao, L.; Leng, Z.; Lan, J.; Chen, R.; Jiang, J. Environmental and Economic Assessment of Collective Recycling Waste Plastic and Reclaimed Asphalt Pavement into Pavement Construction: A Case Study in Hong Kong. J. Clean. Prod. 2022, 336, 130405. [Google Scholar] [CrossRef]

- El Bitouri, Y.; Perrin, D. Compressive and Flexural Strengths of Mortars Containing ABS and WEEE Based Plastic Aggregates. Polymers 2022, 14, 3914. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.-Y.; Le, T.H.M. Laboratory and Full-Scale Testbed Study in the Feasibility of Styrene-Butadiene-Styrene Asphalt Pavement Having Epoxy Resin and Crumb Rubber Powder. Buildings 2023, 13, 652. [Google Scholar] [CrossRef]

- Kim, K.N.; Le, T.H.M. Durability of Polymer-Modified Asphalt Mixture with Wasted Tire Powder and Epoxy Resin under Tropical Climate Curing Conditions. Polymers 2023, 15, 2504. [Google Scholar] [CrossRef]

- Ba, H.; Guo, L.; Huan, H.; Zhang, S.; Lin, Z. Multi-Objective Optimization of Epoxy Resin Adhesive for Pavement Toughened by Self-Made Toughening Agent. Polymers 2023, 15, 1946. [Google Scholar] [CrossRef]

- Xue, Z.; Xu, W. A Study on High and Low Temperature Rheological Properties and Oil Corrosion Resistance of Epoxy Resin/SBS Composite Modified Bitumen. Polymers 2023, 15, 104. [Google Scholar] [CrossRef] [PubMed]

- Ren, S.; Hu, X. Fatigue Properties and Its Prediction of Polymer Concrete for the Repair of Asphalt Pavements. Polymers 2022, 14, 2941. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Ma, Z.; Zhou, J.; Wang, J.; Zhang, X.; Zhao, R.; Tong, J. Thermal Degradation Characteristics of Styrene-Butadiene-Styrene Copolymer Asphalt Binder Filled with an Inorganic Flame-Retarding Agent. Polymers 2022, 14, 3761. [Google Scholar] [CrossRef]

- ASTM D5; Standard Test Method for Penetration of Bituminous Materials. American Society for Testing and Materials: West Conshohocken, PA, USA, 2019.

- AASHTO T 48; Standard Method of Test for Flash Point of Asphalt Binder by Cleveland Open Cup. AASHTO: Washington, DC, USA, 2022.

- AASHTO T316; Standard Method of Test for Viscosity Determination of Asphalt Binder Using Rotational Viscometer. American Society for Testing and Materials: West Conshohocken, PA, USA, 2013.

- AASHTO T315; Standard Method of Test for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer (DSR). American Society for Testing and Materials: West Conshohocken, PA, USA, 2015.

- AASHTO T313; Standard Test Method for Determining the Flexural Creep Stiffness of Asphalt Binder Using the Bending Beam Rheometer (BBR). American Society for Testing and Materials: West Conshohocken, PA, USA, 2019.

- ASTM C127; Standard Test Method for Density, Relative Density (Specific Gravity), and Absorption of Coarse Aggregate. American Society for Testing and Materials: West Conshohocken, PA, USA, 2004.

- AASHTO T 27-14; Standard Method of Test for Sieve Analysis of Fine and Coarse Aggregates. AASHTO: Washington, DC, USA, 2015.

- KS F 2525; Korean Standards Service Network. Korea Standard Association: Seoul, Korea, 2007.

- MOLIT Guide for Asphalt Mixture Production and Construction. Ministry of Land, Infrastructure and Transport. 2015. Available online: https://www.molit.go.kr/english/USR/BORD0201/m_33276/LST.jsp?id=eng_law&cate=eng_law_03 (accessed on 10 June 2023).

- MOLIT (Ministry of Land, Infrastructure & Transport). 2017. Available online: https://www.molit.go.kr/english/USR/BORD0201/m_33276/LST.jsp?id=eng_law&cate=eng_law_02 (accessed on 10 June 2023).

- Li, J.; Aung, H.H.; Du, B. Curing Regime-Modulating Insulation Performance of Anhydride-Cured Epoxy Resin: A Review. Molecules 2023, 28, 547. [Google Scholar] [CrossRef] [PubMed]

- KS F2364; Test Method for Percent Air Voids in Compacted Dense and Open Bituminous Paving Mixture. Korea Standard Association: Seoul, Korea, 2016.

- KS F 2382; Test Method for Indirect Tensile Strength of Asphalt Mixture. Korea Standard Association: Seoul, Korea, 2010.

- KS F 2398; Test Method for Moisture Resistance of Asphalt Mixture. Korea Standard Association: Seoul, Korea, 2010.

- AASHTO TP62-2017; Standard Method of Test for Determining Dynamic Modulus of Hot Mix Asphalt (HMA). American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2017.

- Ullah, S.; Raheel, M.; Khan, R.; Tariq Khan, M. Characterization of Physical & Mechanical Properties of Asphalt Concrete Containing Low- & High-Density Polyethylene Waste as Aggregates. Constr. Build. Mater. 2021, 301, 124127. [Google Scholar] [CrossRef]

- Jing, F.; Wang, R.; Zhao, R.; Li, C.; Cai, J.; Ding, G.; Wang, Q.; Xie, H. Enhancement of Bonding and Mechanical Performance of Epoxy Asphalt Bond Coats with Graphene Nanoplatelets. Polymers 2023, 15, 412. [Google Scholar] [CrossRef]

- López-Montero, T.; Mañosa, J.; Miró, R.; Chimenos, J.M. Sustainable Asphalt Mixtures by Partial Replacement of Fine Aggregates with Low-Grade Magnesium Carbonate by-Product. Case Stud. Constr. Mater. 2023, 18, e01705. [Google Scholar] [CrossRef]

| Test Item | Specifications | PG 64-22 (Pen.60-80) | |

|---|---|---|---|

| Penetration at 25 °C, dmm [24] | - | 75.0 | |

| Flashpoint, °C [25] | >260 | 339.0 | |

| The softening point, °C [25] | - | 45.8 | |

| Penetration Ratio, % [24] | >55 | 64.1 | |

| Rotational viscosity at 120 °C, mm2/s [26] | - | 928 | |

| DSR | Original G*/sin δ (kPa, 64 °C) [27] | >1.0 | 1.41 |

| RTFO G*/sin δ (kPa, 64 °C) [27] | >2.2 | 3.28 | |

| BBR | Stiffness (MPa, −12 °C) [28] | <300 | 208 |

| M-value (−12 °C) [28] | >0.3 | 0.27 | |

| Adhesive Strength (MPa) | Stiffness (MPa) | Water Absorption (%) | Glass Transition Temperature (°C) | Viscosity (cps) |

|---|---|---|---|---|

| 4–6 | 2600 | <0.1 | 52 | 5900 |

| Classification | Density (g/cm3) | Absorption (%) | Abrasion (%) | |||

|---|---|---|---|---|---|---|

| Bulk | SSD | Apparent | ||||

| 20 mm | 2.748 | 2.761 | 2.785 | 0.485 | 26.109 | |

| 13 mm | 2.708 | 2.735 | 2.784 | 1.030 | 33.300 | |

| Fine Agg. | Screenings | 2.721 | 2.776 | 2.880 | 2.060 | |

| Filler | Limestone powder | 0.000 | 2.793 | |||

| Waste Plastic Agg. | Year | Gradation | Fineness Modulus | Bulk The Density of Agg. | Specific Gravity under Oven Dry | Solid Content of Agg. | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 25 mm | 20 mm | 10 mm | 5 mm | 2.5 mm | 1.2 mm | ||||||

| WPCM | 1st | 100 | 97.5 | 24.9 | 6.3 | 1.1 | 0.1 | 6.5 | 0.5 | 1.3 | 36.1 |

| Layer | Gradation | Mix by WPA | WPA Content (wt. %) | |||

|---|---|---|---|---|---|---|

| 0 | 3 | 5 | 7 | |||

| Base | BB-2 | Control | ○ | - | - | - |

| WPCM | - | ○ | ○ | ○ | ||

| Type | Gradation | Asphalt Content (wt. %) | Density | Air Voids (%) | VMA (%) | VFA (%) | SD (MPa) |

|---|---|---|---|---|---|---|---|

| Control | BB-2 | 4.0 | 2.389 | 5.4 | 14.8 | 63.4 | 3.03 |

| 4.5 | 2.370 | 5.5 | 15.9 | 65.7 | 2.79 | ||

| 5.0 | 2.421 | 2.7 | 14.6 | 81.4 | 4.09 | ||

| 5.5 | 2.416 | 2.2 | 15.2 | 85.5 | 4.26 | ||

| 6.0 | 2.419 | 1.4 | 15.6 | 91.3 | 4.24 | ||

| WPCM | BB-2 | 4.2 | 2.305 | 4.7 | 14.1 | 67.1 | 2.80 |

| 4.7 | 2.313 | 3.7 | 14.3 | 74.5 | 2.75 | ||

| 5.2 | 2.317 | 2.9 | 14.6 | 80.5 | 3.23 |

| Gradation | OAC (%) of Each Mix | |

|---|---|---|

| Control | WPCM | |

| BB-2 | 4.2 | 4.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, S.-Y.; Le, T.H.M. Feasibility of Sustainable Asphalt Concrete Materials Utilizing Waste Plastic Aggregate, Epoxy Resin, and Magnesium-Based Additive. Polymers 2023, 15, 3293. https://doi.org/10.3390/polym15153293

Lee S-Y, Le THM. Feasibility of Sustainable Asphalt Concrete Materials Utilizing Waste Plastic Aggregate, Epoxy Resin, and Magnesium-Based Additive. Polymers. 2023; 15(15):3293. https://doi.org/10.3390/polym15153293

Chicago/Turabian StyleLee, Sang-Yum, and Tri Ho Minh Le. 2023. "Feasibility of Sustainable Asphalt Concrete Materials Utilizing Waste Plastic Aggregate, Epoxy Resin, and Magnesium-Based Additive" Polymers 15, no. 15: 3293. https://doi.org/10.3390/polym15153293

APA StyleLee, S.-Y., & Le, T. H. M. (2023). Feasibility of Sustainable Asphalt Concrete Materials Utilizing Waste Plastic Aggregate, Epoxy Resin, and Magnesium-Based Additive. Polymers, 15(15), 3293. https://doi.org/10.3390/polym15153293