Study on Blending Modification of Bisphenol A Epoxy

Abstract

:1. Introduction

2. Test Section

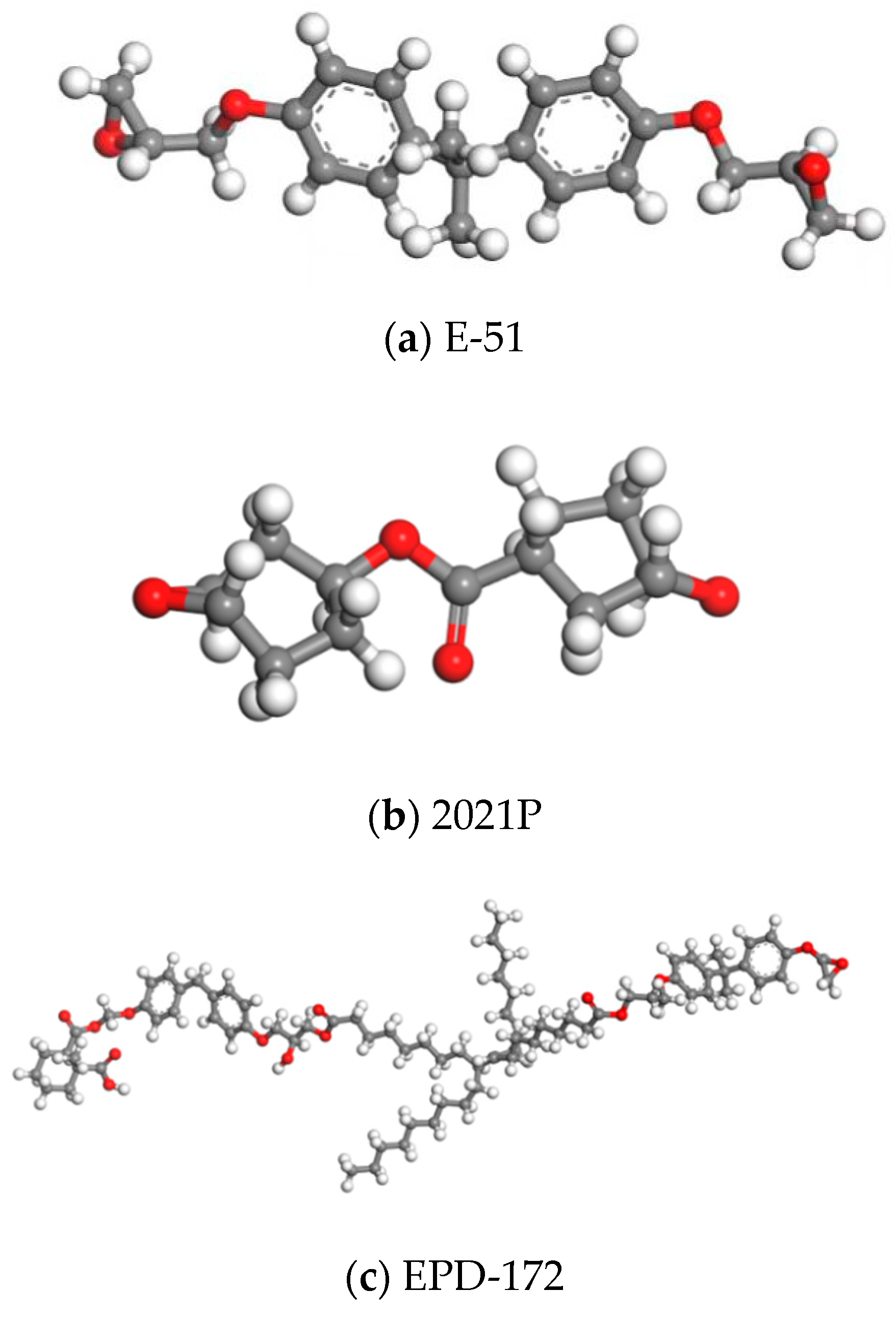

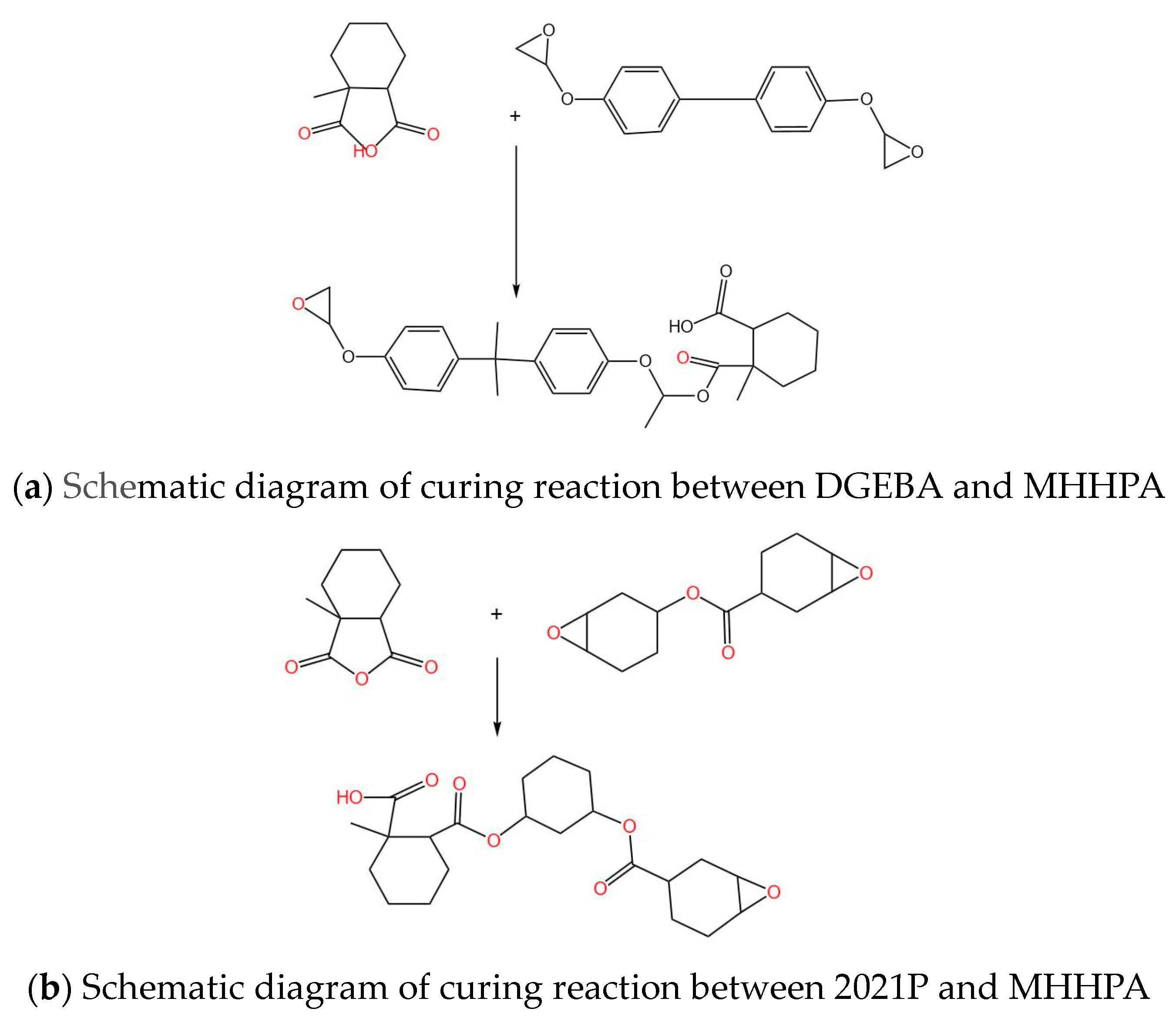

2.1. Test Material

2.2. Sample Preparation

2.3. Test and Characterization

2.3.1. Wet-Heat Aging Test

2.3.2. Salt Spray Aging Test

2.3.3. Electrical Performance Test

2.3.4. Mechanical Property Test

3. Test Results and Analysis

3.1. Electrical Insulation Property

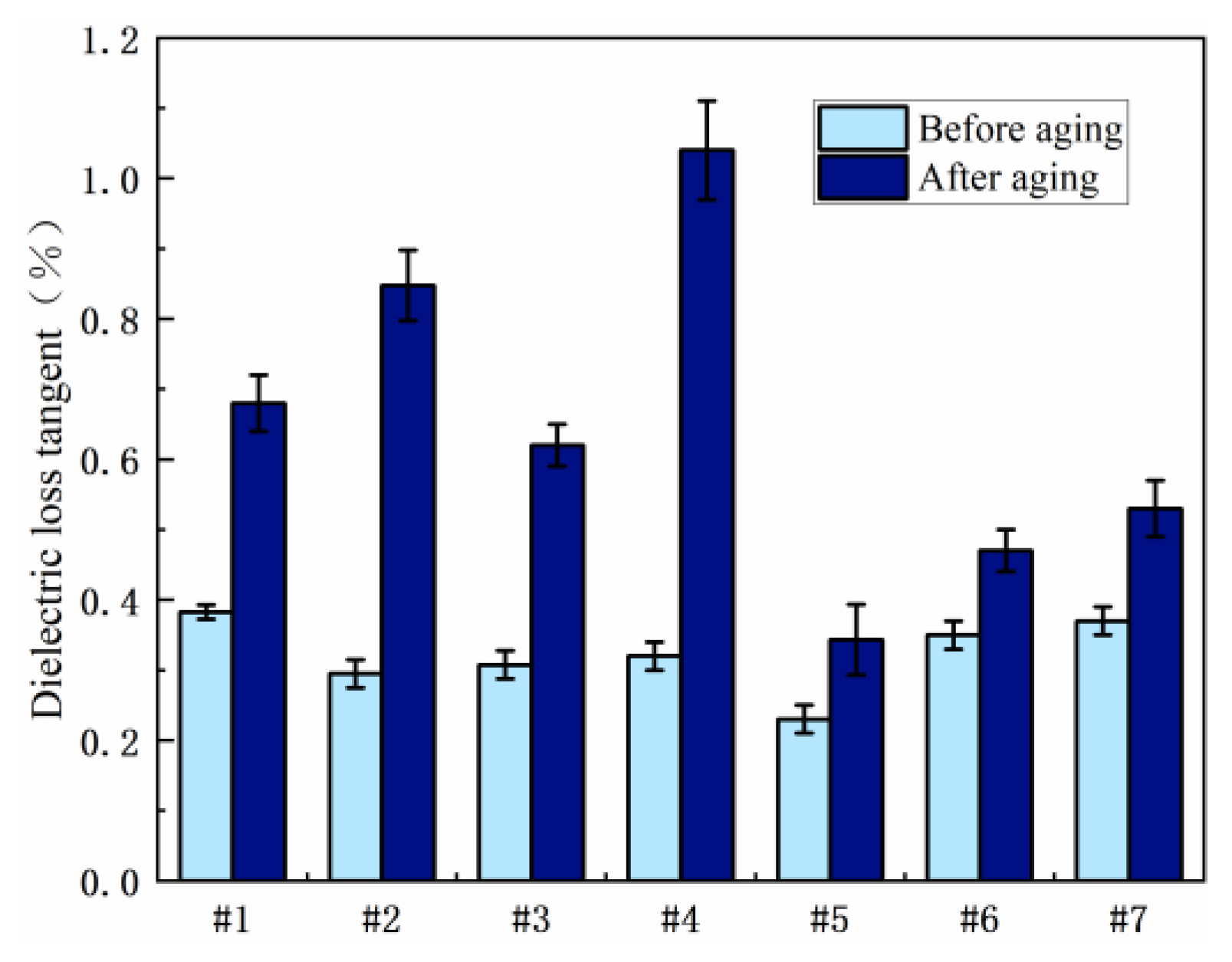

3.1.1. Dielectric Loss Tangent

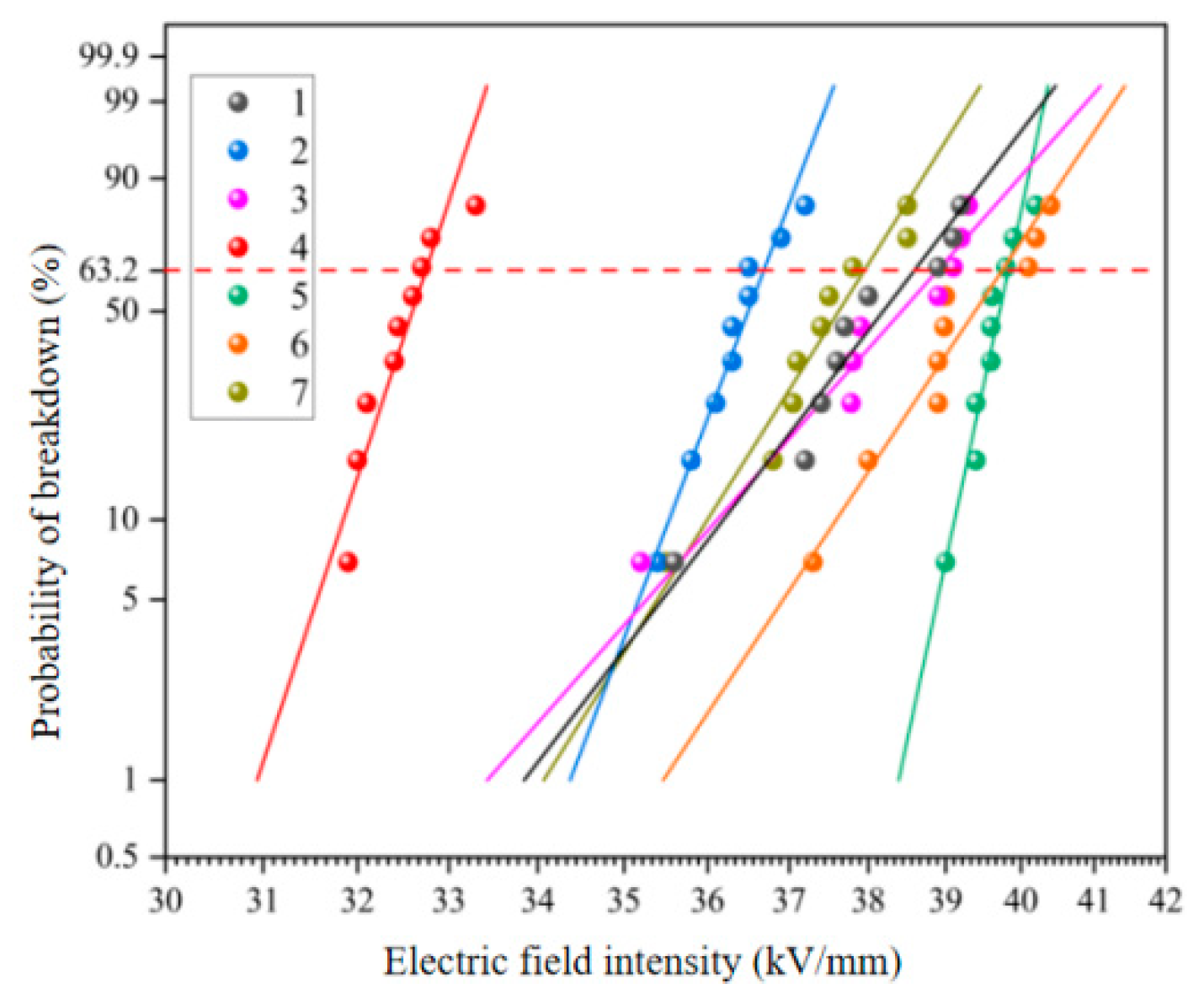

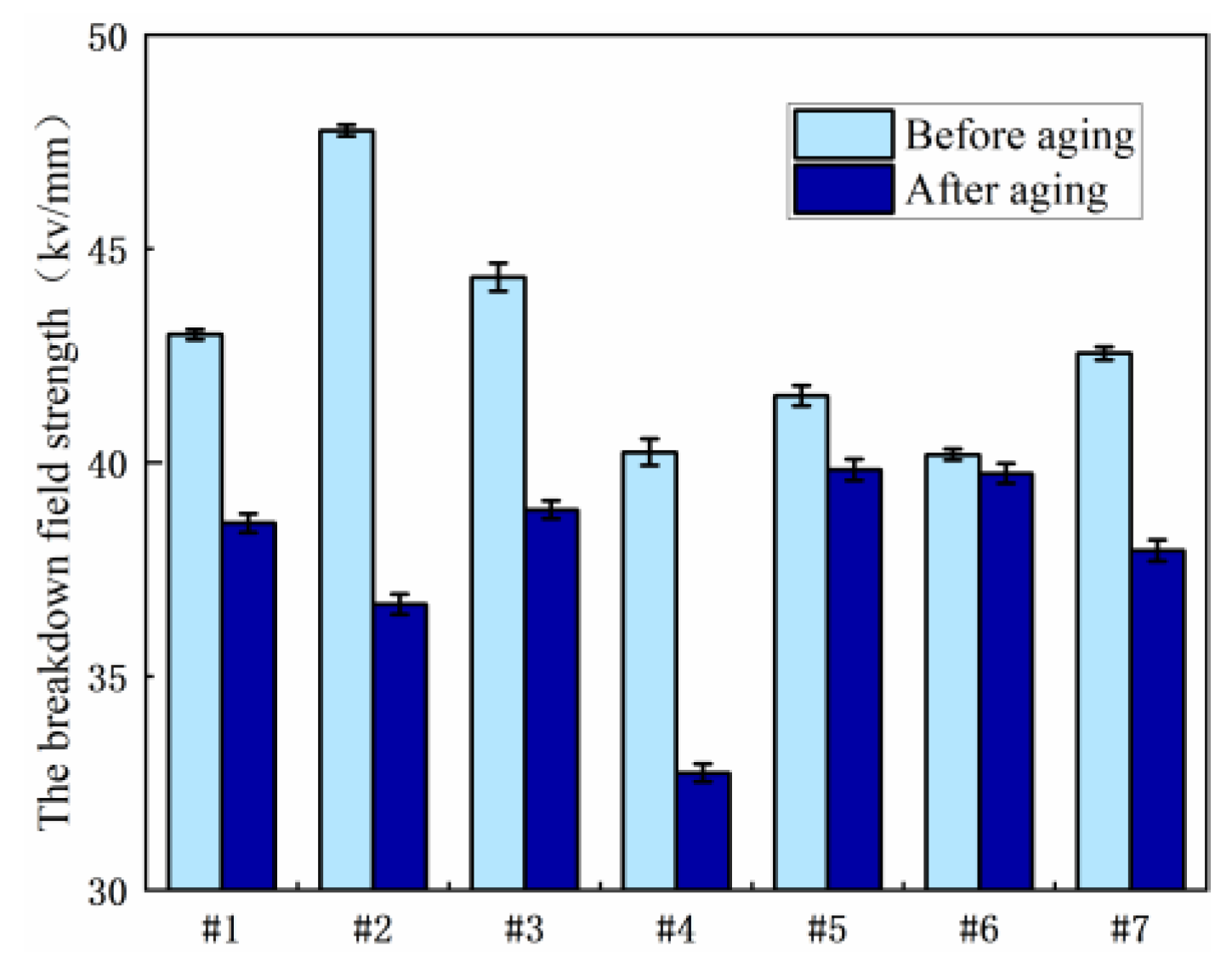

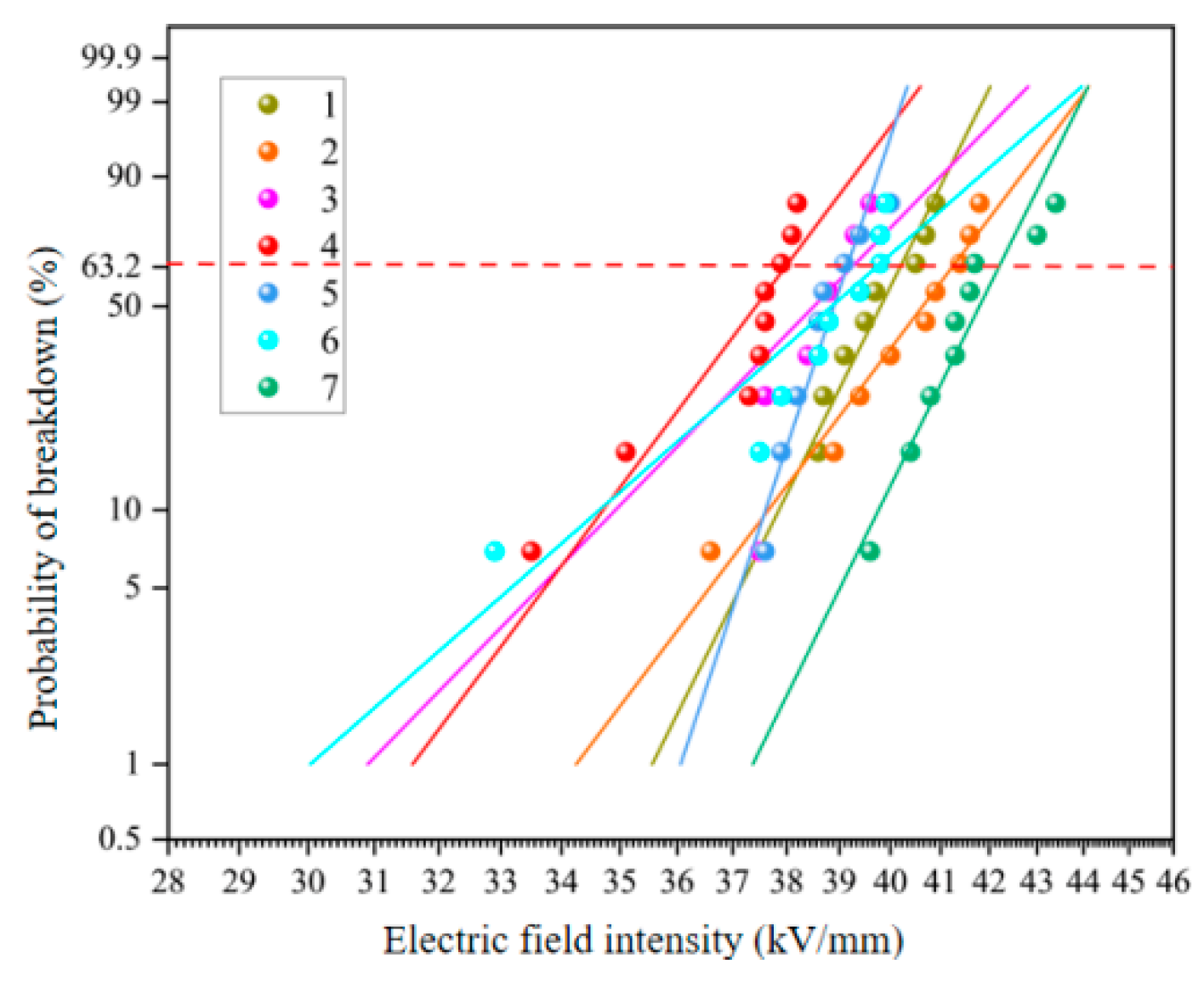

3.1.2. The Breakdown Voltage

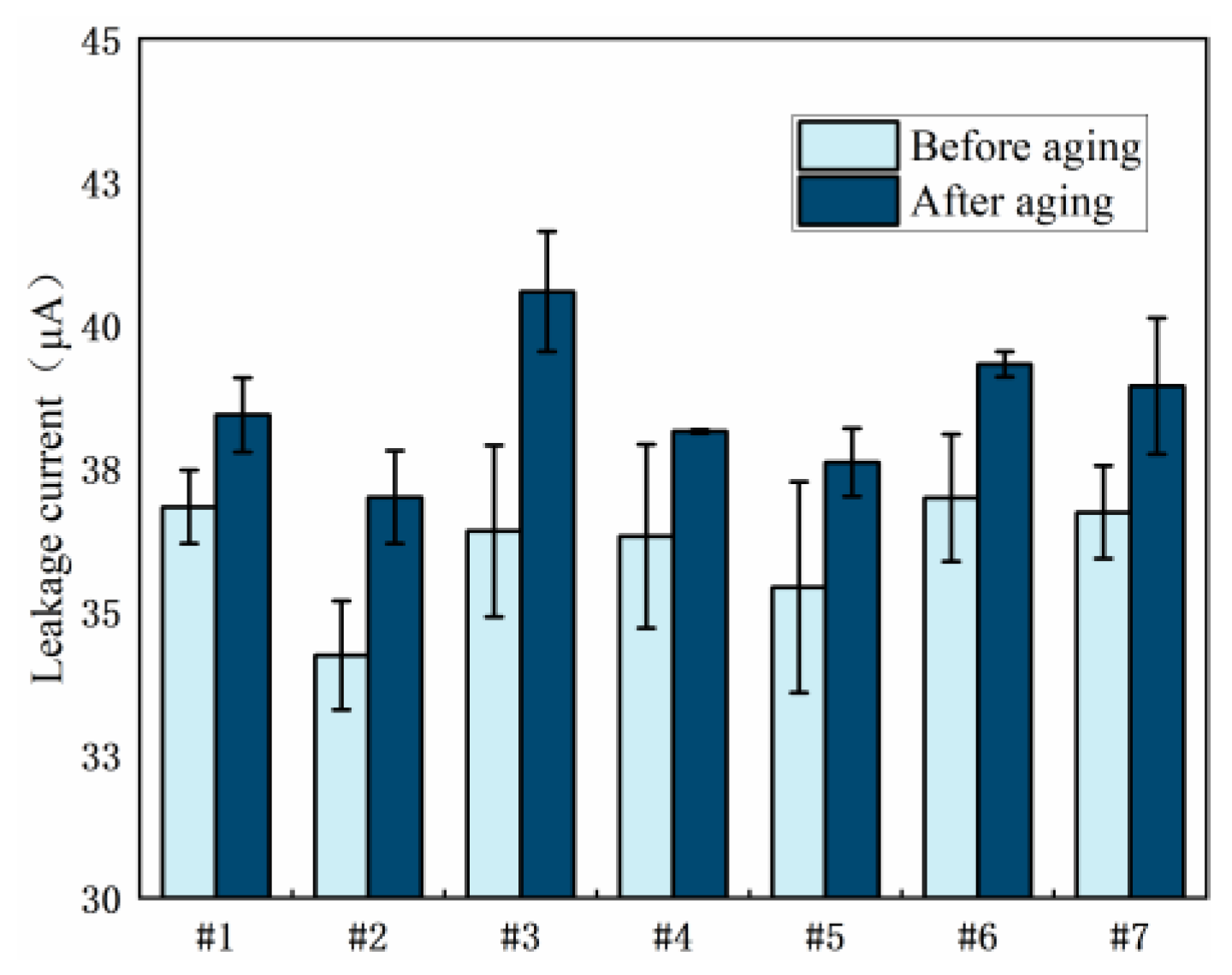

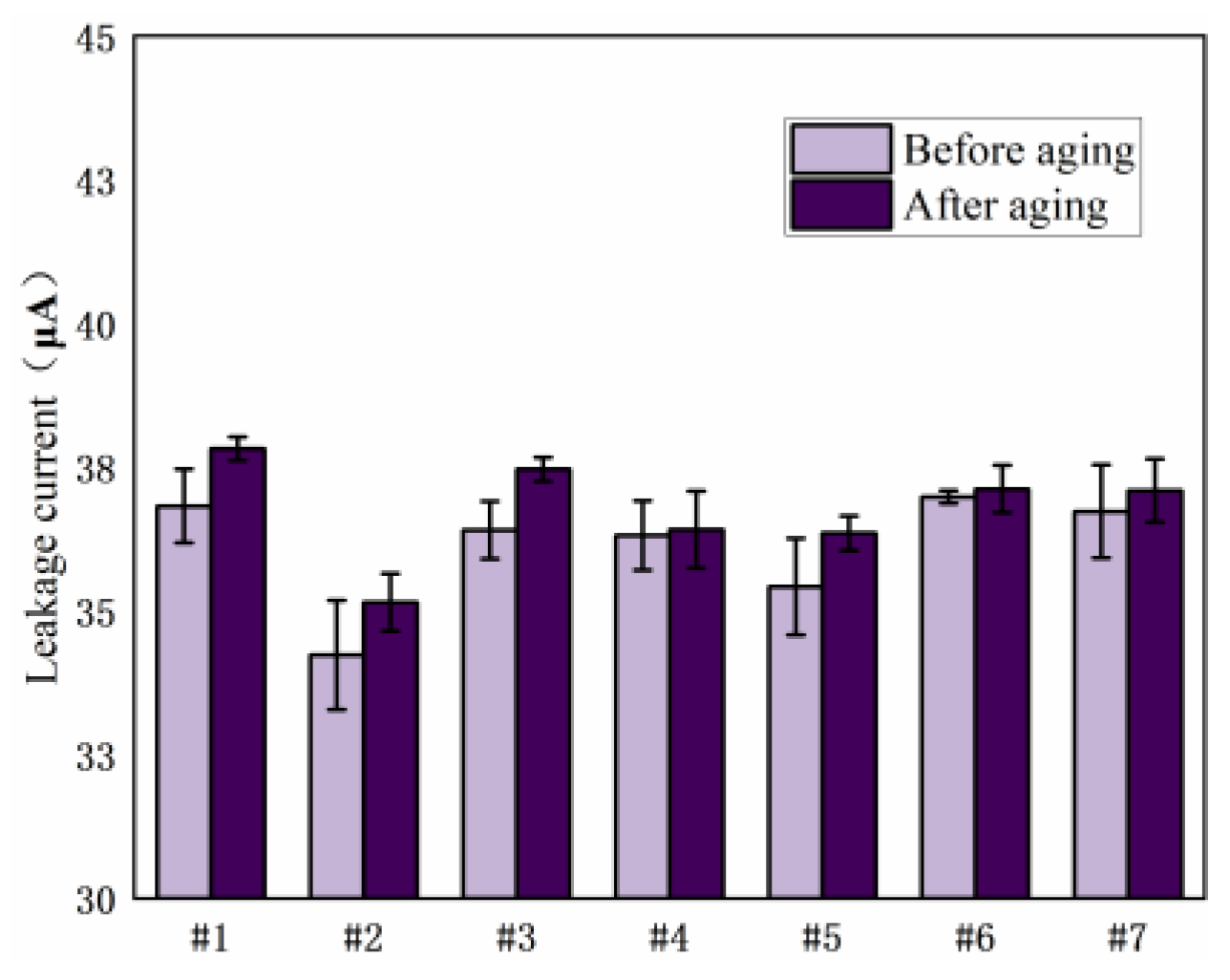

3.1.3. Leakage Current

3.2. Mechanical Properties

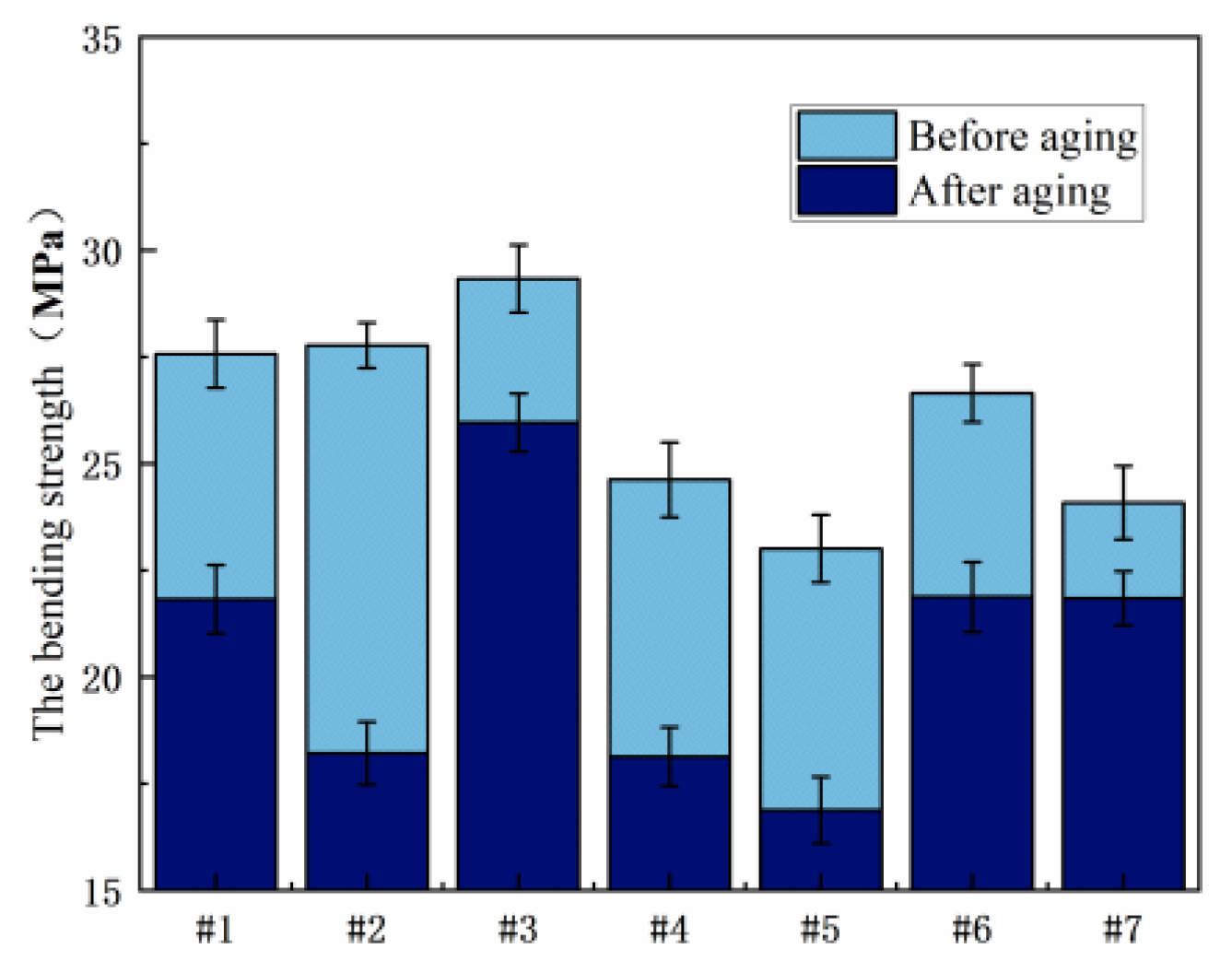

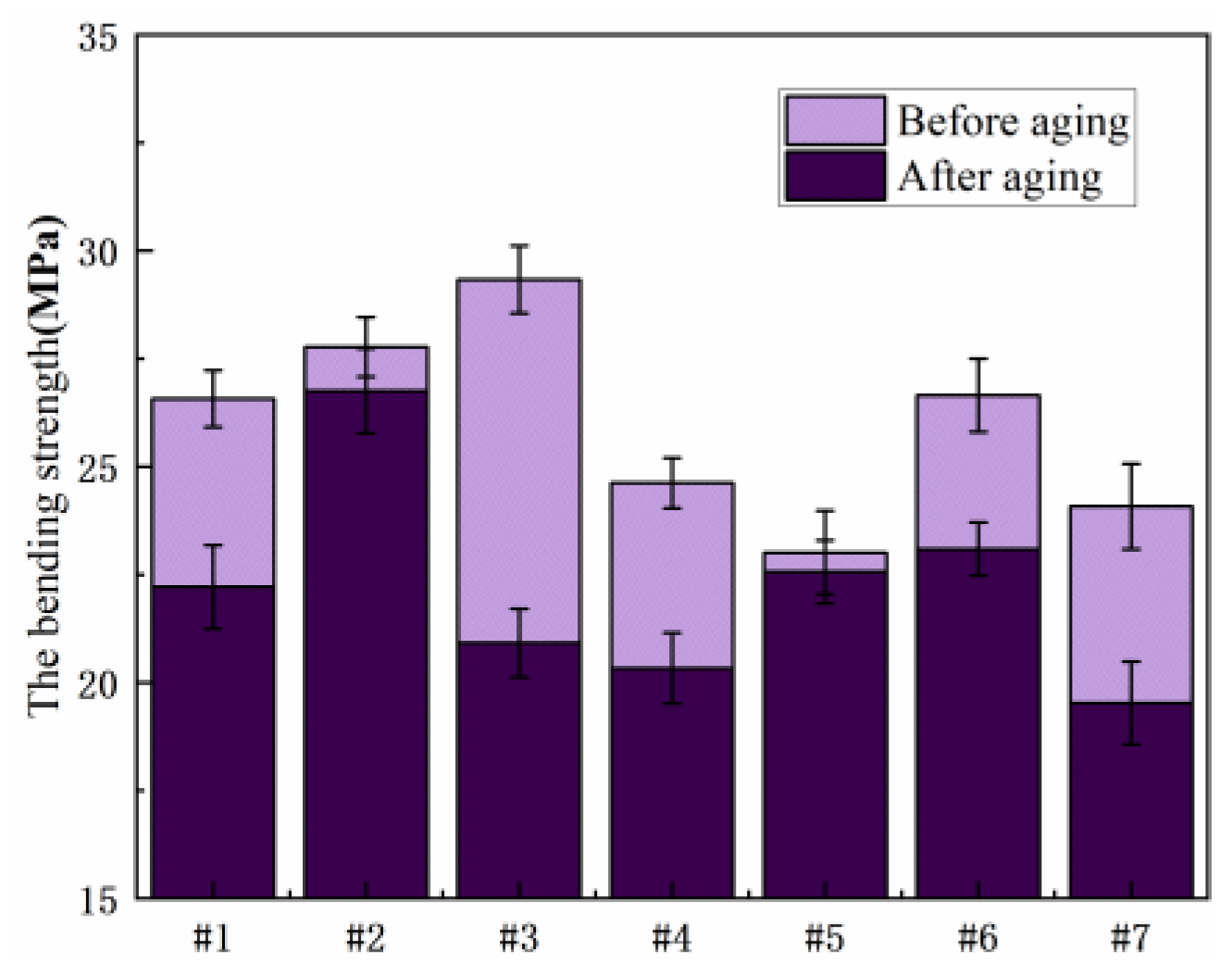

3.2.1. Bending Characteristics

3.2.2. Tensile Characteristic

4. Conclusions

- Adding a certain amount of alicyclic epoxy resin or toughened dimer acid to modify bisphenol A epoxy resin can improve the bending strength and tensile strength of bisphenol A epoxy resin system and improve its mechanical properties, but too much alicyclic epoxy or toughened dimeric acid modified bisphenol A epoxy can degrade its mechanical properties.

- The addition of alicyclic epoxy resin and toughened dimeric acid modified bisphenol A epoxy resin can reduce the leakage current and dielectric loss of bisphenol A epoxy resin system, improve its penetration resistance and improve the electrical insulation performance of the resin system. On the whole, the electrical insulation performance of 2021P blend system before aging was better than that of EPD blend system. The breakdown field strength and leakage current of 2021P blend resin with 10 wt% additive were significantly better than those of other samples before aging, however, the electrical properties of the resin system decreased with an increase in the epoxy content, and the electrical insulation performance of the aging EPD system was better than that of the 2021P system as a whole. The electrical insulation performance of EPD blend resin with 10 wt% additive is the most stable after aging.

- By comparing the electrical and mechanical properties of the seven mixed resin systems before and after wet heat aging and salt spray aging, the dielectric and electrical properties of No. 3 and No. 5 are better, the bending properties of No. 3 and No. 6 are better and the tensile properties of No. 2 and No. 6 are better. All in all, it can be seen that 2021P blend resin with 10 wt% and 20 wt% addition and EPD blend resin with 10 wt% addition have superior comprehensive performance and strong aging resistance, which is suitable for the research and development of new composite materials.

- Considering economic and other factors comprehensively, EPD172 and BFRP-2021P are used as composite insulating cross arm core rod materials in harsh climates, such as high humidity and salt, which have broad application prospects.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wu, X.; Cai, W.; Li, J.; Sun, Q.; Zhu, X.; He, C.; Ke, R. Application progress of power fiber reinforced composites. Compos. Mater. Sci. Eng. 2021, 11, 116–128. [Google Scholar]

- Alsaadi, M.; Erklig, A. UV accelerated aging and sewage sludge ash particle effects on mode I interlaminar fracture properties of glass fiber/epoxy composites. Iran. Polym. J. 2021, 30, 811–820. [Google Scholar] [CrossRef]

- Nie, Z.X.; Wang, L.M.; Yang, C.R. Aging Characteristics of Interface between Core and Sheath of Composite Insulators Under Water and High Temperature. Proc. CSEE 2018, 38, 4601–4611, 4661. [Google Scholar]

- Li, G.M.; Du, G.; Zhou, H.L.; Yang, J.; Pang, Z.K.; Chen, L. Aging characteristics and failure Mechanism of Epoxy resin in Hot and humid environment. High Volt. Electr. Appar. 2022, 58, 87–92. [Google Scholar]

- Zhang, J.; Yang, C.R.; Li, P.; Li, F.; Xu, C.L.; Guo, Z.Y. Aging mechanism and properties of epoxy resin and its composites by acid salt spray. Eng. Plast. Appl. 2023, 51, 121–128. [Google Scholar]

- Douar, M.A.; Beroual, A.; Souche, X. Degradation of various polymeric materials in clean and salt fog conditions: Measurements of AC flashover voltage and assessment of surface damages. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 391–399. [Google Scholar] [CrossRef]

- Tripathi, G.; Srivastava, D. Studies on the physico-mechanical and thermal characteristics of blends of DGEBA epoxy,3,4 epoxy cyclohexylmethyl,3′,4′-epoxycylohexane carboxylate and carboxyl terminated butadiene co-acrylonitrile (CTBN). Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2008, 496, 483–493. [Google Scholar] [CrossRef]

- Li, Y.; Ye, L.; Zhao, X.W. Salt-Spray Corrosion Behavior and Aging Molecular Mechanism of Carbon Fiber Reinforced Epoxy Resin Composites. Polym. Mater. Sci. Eng. 2023, 1–8. [Google Scholar]

- Li, F.; Wang, T.Y.; Zhang, J.; Fan, L.; Yang, C.R.; Shi, X. Research on the aging properties of epoxy vinyl resin and its composite materials under high temperature and high pressure mineralized water conditions. Compos. Sci. Eng. 2022, 343, 82–88. [Google Scholar]

- Kim, D.; Kim, J.H.; Kwon, S.; Lee, S.O.; Seo, B.; Lim, C.-S. The studies of physical properties of dimeric fatty acid-modified thiodiphenyl epoxy resins. Polym. Bull. 2017, 74, 4595–4605. [Google Scholar] [CrossRef]

- Yang, C.; Tang, X.D.; Li, J.J.; Feng, X.F.; Cao, Y.F.; Gao, Z.Q. Bisphenol A type epoxy resin synthesis technology progress. China Plast. 2023, 2, 106–112. [Google Scholar]

- Liu, H.C.; Guo, Z.P.; Liu, Y.P.; Zhou, S.S.; Wu, X. Comparison of electrical dendritic properties of Iticonic-based epoxy resin and bisphenol A epoxy resin. High Volt. Technol. 2022, 48, 2607–2615. [Google Scholar]

- Guo, Z.P. Properties Analysis of Iticonic Acid Based Epoxy Resin and Its Electrical Dendritic Properties; North China Electric Power University: Beijing, China, 2022. [Google Scholar]

- Shen, Y.F.; Liang, X.; Wang, J.; Wu, C.; Wang, G.; Gao, C. Pollution characteristics of AC 500 kV composite cross-arm in high altitude area. High Volt. Eng. 2017, 43, 2760–2768. [Google Scholar]

- Wang, Y.S.; Liu, Y.H.; Fan, H.N.; Wang, L.M. Hydrothermal Aging Characteristics of Silicone Rubber and Cycloaliphatic Epoxy Resin Composite Insulators Interface. High Volt. Eng. 2022, 48, 2028–2035. [Google Scholar]

- Liu, Y.P.; Wang, W.X.; Liu, H.C.; Zhang, M.J.; Liu, J.; Yu, H. Salt spray resistance of bisphenol A epoxy resin reinforced by basalt fiber and modified by aliphicyclic group. High Volt. Technol. 2023, 1–10. [Google Scholar]

- Visco, A.; Campo, N.; Cianciafara, P. Comparison of seawater absorption properties of thermoset resins based composites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 123–130. [Google Scholar] [CrossRef]

- Guzel, G.; Deveci, H. Physico-mechanical, thermal, and coating properties of composite materials prepared with epoxy resin/steel slag. Polym. Compos. 2017, 38, 1974–1981. [Google Scholar]

- Feng, J.; Guo, Z. Effects of temperature and frequency on dynamic mechanical properties of glass/epoxy composites. J. Mater. Sci. 2016, 51, 2747–2758. [Google Scholar] [CrossRef]

- Zhang, F.F.; Hou, Y.Y.; Wang, F.L.; Xu, S.J.; Deng, L.H.; Zhang, C.M. Bisphenol A type epoxy resin/aromatic amine curing system of curing kinetics study. China Adhes. 2023, 32, 7–15. [Google Scholar]

- Li, J.; Kong, X.X.; Du, B.X. Research progress of curing regulation on insulation properties of bisphenol A epoxy resin/anhydride system. J. Electr. Eng. 2023, 28, 547. [Google Scholar]

- Hua, Z.W.; Liang, G.X.; Lv, M.; Zhu, X.X. Study on the Mechanical Property of Resin-Curing Agent in EP Composite. New Chem. Mater. 2022, 50, 180–184. [Google Scholar]

- Liu, Y.P.; Liu, H.C.; Zhong, P.; Li, Y.D.; Yu, L.C.; Gao, L.J. Analysis of Influence of DC Aging on Spatial Charge Distribution Characteristics of 160kV DC Cable Materials. Insul. Mater. 2017, 50, 37–42, 48. [Google Scholar]

- Liu, J.; Jia, B.Y.; Tian, L.; Sun, Y.; Zheng, X.W.; Zhang, Z.M.; Yin, X.Y.; Liu, H.C. Effect of ultraviolet aging on properties of bisphenol A epoxy resin. Sci. Technol. Eng. 2022, 22, 8701–8707. [Google Scholar]

- Wang, Z.G. Preparation and Properties of Epoxy-Based High Voltage Insulating Dielectric; Shandong University of Science and Technology: Qingdao, China, 2020. [Google Scholar]

- Hao, J.; Dai, X.; Yang, L.; Liao, R.; Gao, J.; Du, Y.; Deng, Y. Physical mechanism analysis of conductivity and relaxation polarization behavior of oil⁃paper insulation based on broadband frequency domain spectroscopy. IEEE Trans. Dielectr. Electr. Insul. 2021, 28, 1571–1578. [Google Scholar] [CrossRef]

- Wang, X.J.; Wang, X.X.; Zhang, W. Research on capillary water absorption characteristics of porous ceramic materials. J. Tianjin Univ. (Nat. Sci. Eng. Technol. Ed.) 2021, 54, 324–330. [Google Scholar]

- Liu, C.; Liu, C.Y.; Xu, W.H. Reactor with acid anhydride/epoxy resin system for toughening research. J. Electr. Eng. Mater. 2023, 2, 41–43. [Google Scholar]

- Fei, X.C.; Sun, D.W.; Li, B.; Cai, B.H.; Li, Z.C. Research progress on aging failure mechanism of epoxy resin and its composites. Jiangsu Build. Mater. 2020, 1, 9–13. [Google Scholar]

- Li, Y.F.; Yao, X.L.; Sun, J.R.; Tian, X.Y.; Chen, J.L. Hydrothermal Aging Characteristics of Cured Epoxy Resin for Insulation Encapsulation. High Volt. Eng. 2021, 47, 3600–3607. [Google Scholar]

| Materials | Molecular Weight | Density (g/cm3) | Source |

|---|---|---|---|

| E-51 | 375.86 | 1.22 | Pelim Electric Technology Co., Ltd., Quzhou, China |

| 2021P | 252.31 | 1.17 | Daicel Corporation, Osaka, Japan |

| EPD-172 | LOHO HIGH-TECH, Shanghai, China | ||

| MHHPA | 168.19 | 1.16 | Guangzhou Desheng Chemical Co., Ltd., Guangzhou, China |

| DMP-30 | 265.40 | 0.97–0.99 |

| Sample | E51/wt% | 2021P/wt% | EPD-172/wt% |

|---|---|---|---|

| 1 | 100 | 0 | 0 |

| 2 | 90 | 10 | 0 |

| 3 | 80 | 20 | 0 |

| 4 | 70 | 30 | 0 |

| 5 | 90 | 0 | 10 |

| 6 | 80 | 0 | 20 |

| 7 | 70 | 0 | 30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, X.; Ma, L.; Chen, L.; Zhang, C.; Chen, X.; Li, X.; Fu, F.; Fu, C.; Lin, T.; Mao, W. Study on Blending Modification of Bisphenol A Epoxy. Polymers 2023, 15, 3263. https://doi.org/10.3390/polym15153263

Fu X, Ma L, Chen L, Zhang C, Chen X, Li X, Fu F, Fu C, Lin T, Mao W. Study on Blending Modification of Bisphenol A Epoxy. Polymers. 2023; 15(15):3263. https://doi.org/10.3390/polym15153263

Chicago/Turabian StyleFu, Xiaotao, Long Ma, Lincong Chen, Cong Zhang, Xiaolin Chen, Xinran Li, Fangda Fu, Chuanfu Fu, Taobei Lin, and Wensheng Mao. 2023. "Study on Blending Modification of Bisphenol A Epoxy" Polymers 15, no. 15: 3263. https://doi.org/10.3390/polym15153263

APA StyleFu, X., Ma, L., Chen, L., Zhang, C., Chen, X., Li, X., Fu, F., Fu, C., Lin, T., & Mao, W. (2023). Study on Blending Modification of Bisphenol A Epoxy. Polymers, 15(15), 3263. https://doi.org/10.3390/polym15153263