Mechanical Performances Analysis and Prediction of Short Plant Fiber-Reinforced PLA Composites

Abstract

:1. Introduction

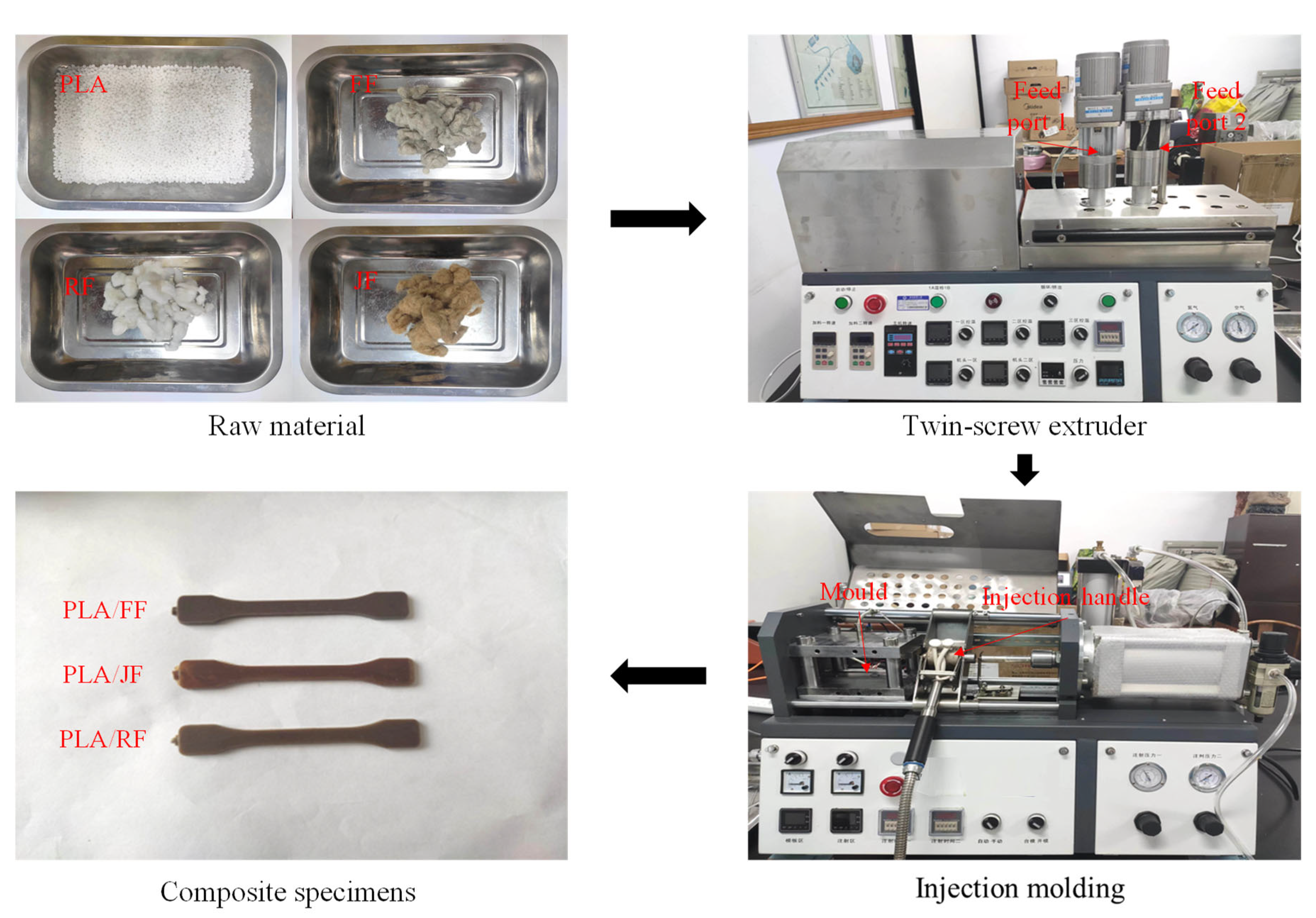

2. Experimental

2.1. Materials

2.2. Sample Preparation

2.3. Performance Testing

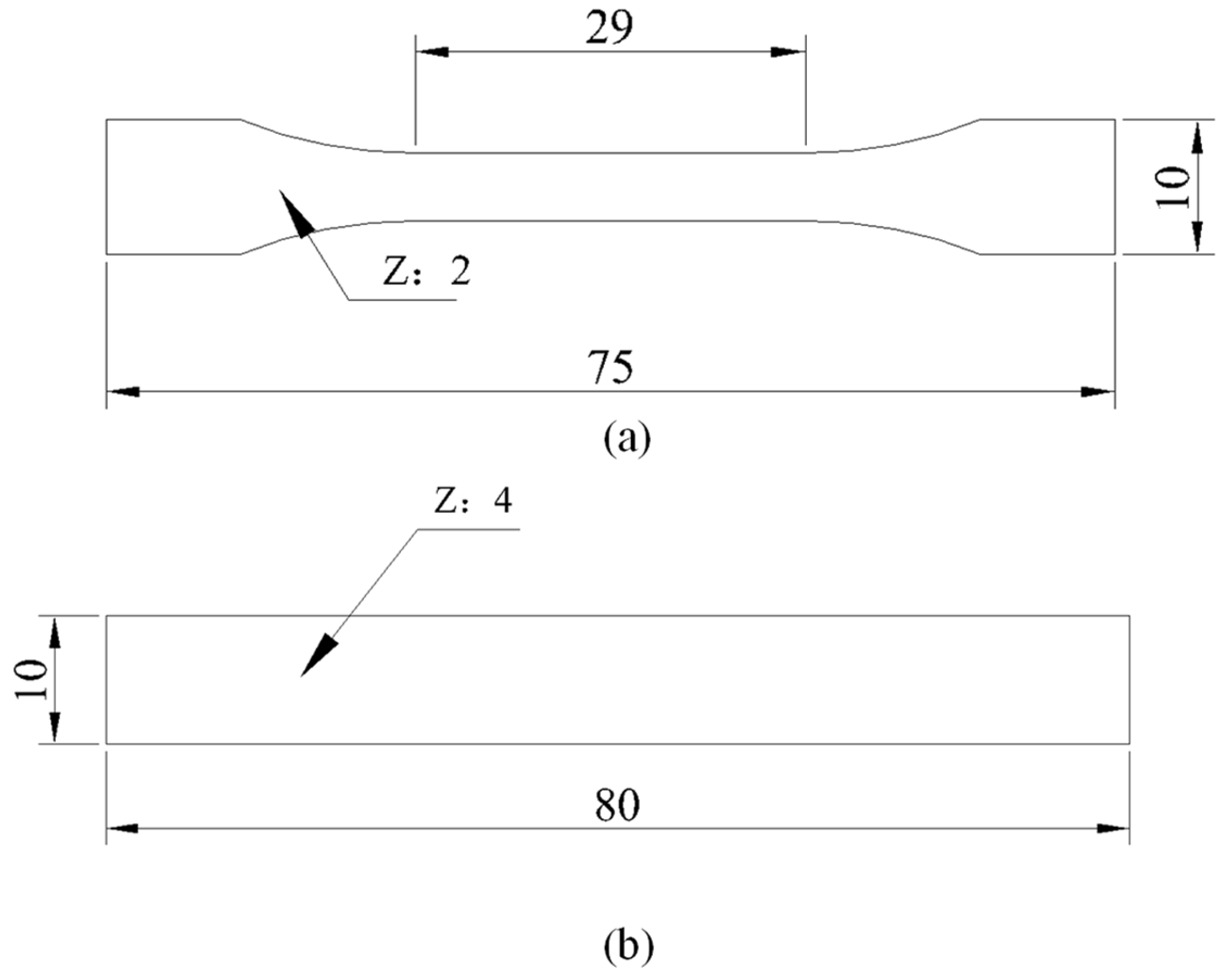

2.3.1. Mechanical Test

2.3.2. Scanning Electron Microscope (SEM)

2.3.3. Fourier Transform Infrared Spectroscopy (FTIR)

2.3.4. Differential Thermal Analysis (DSC)

3. Results and Discussion

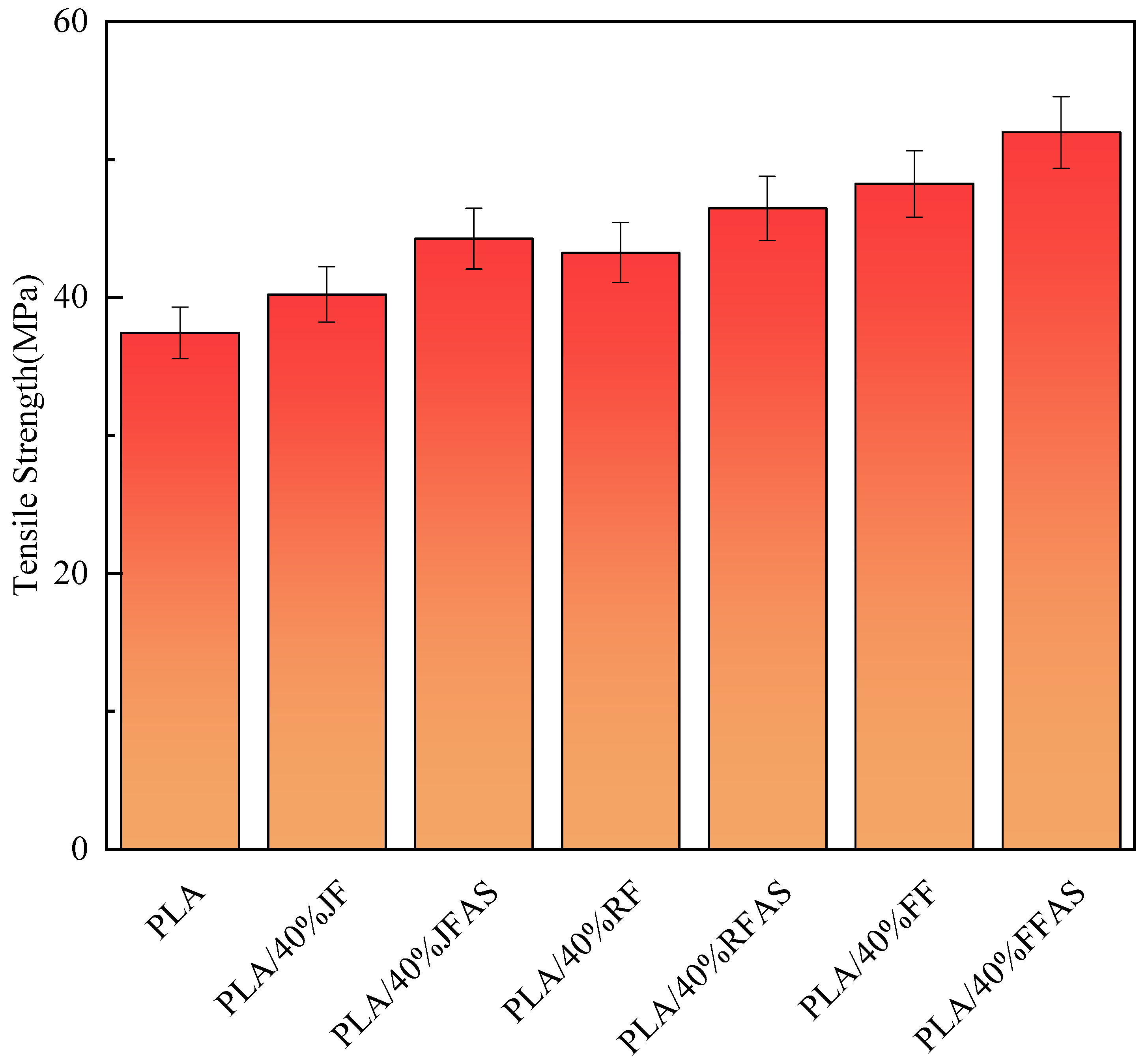

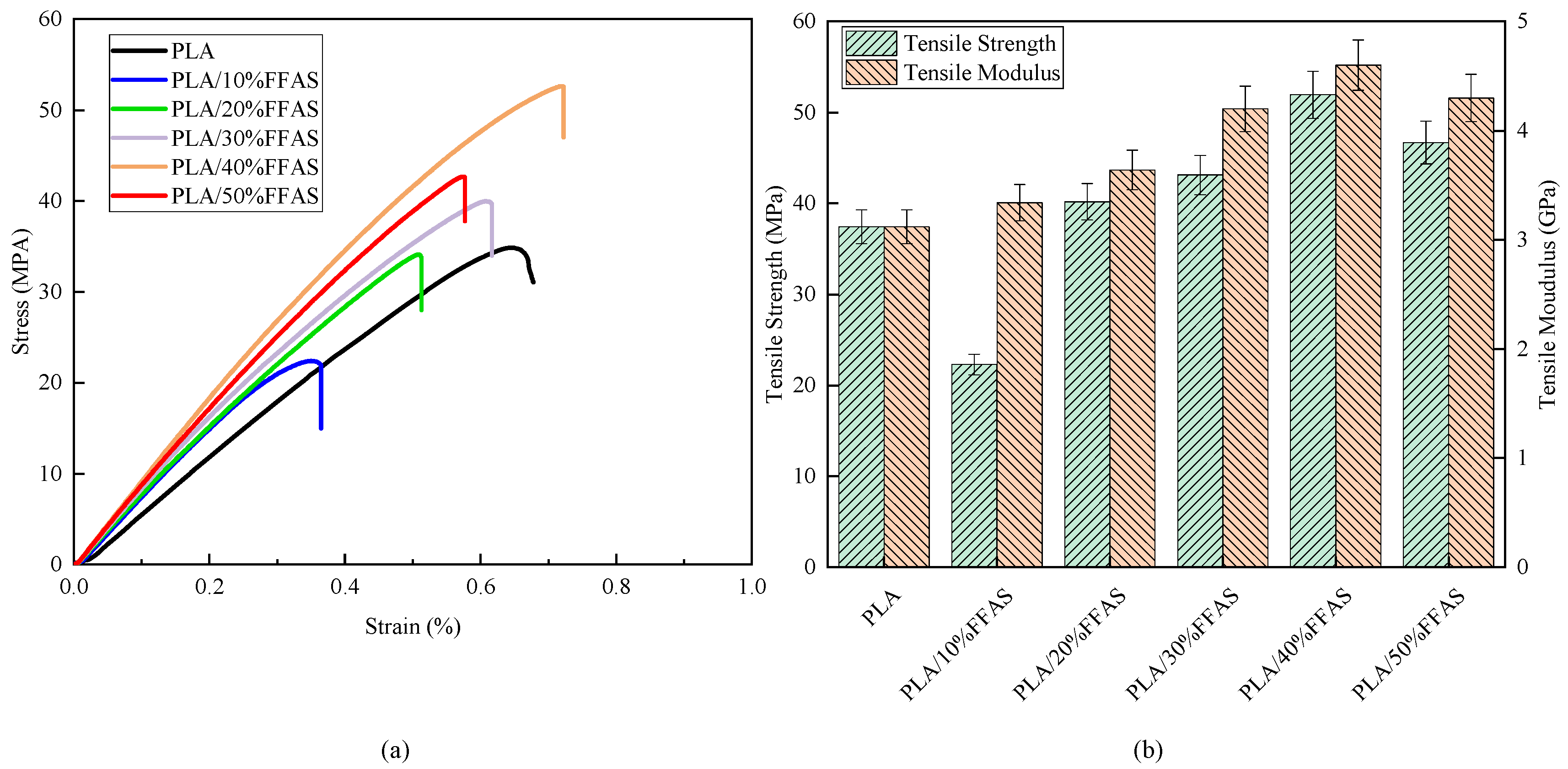

3.1. Mechanical Test

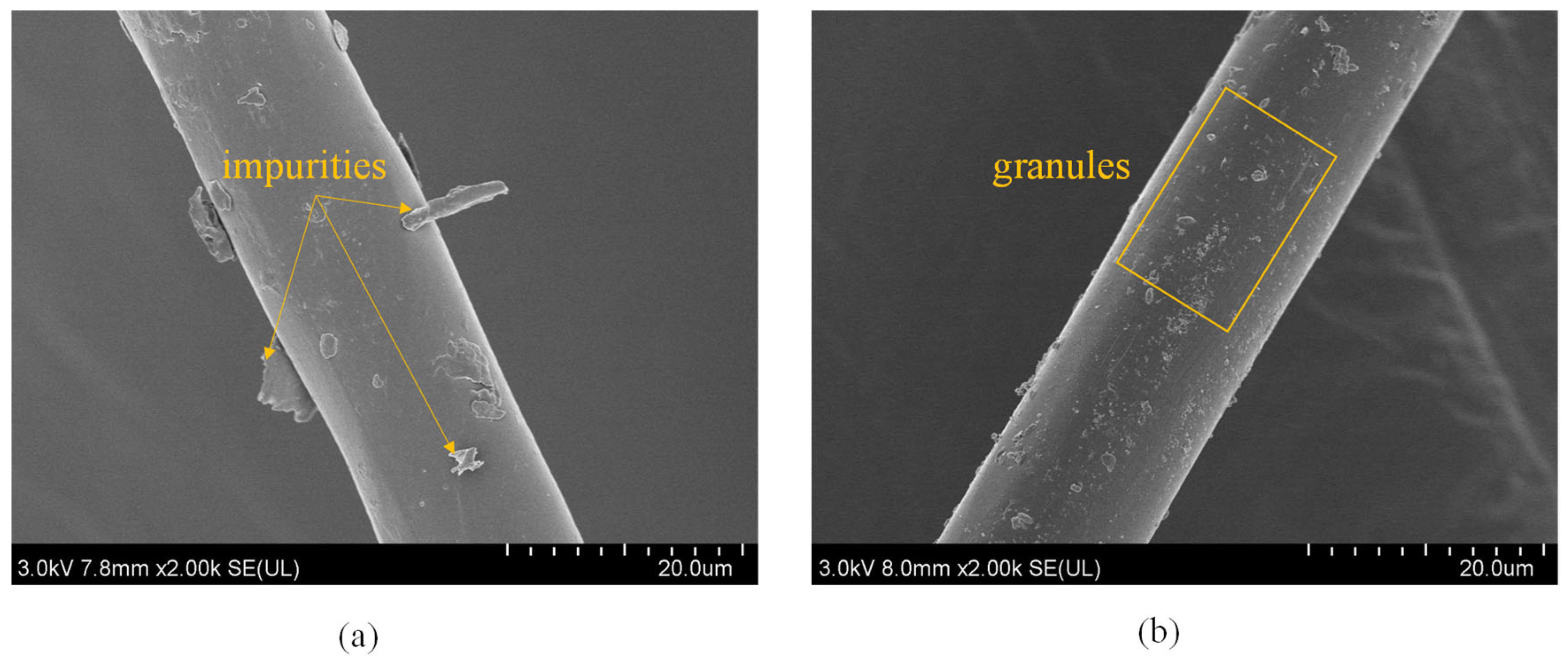

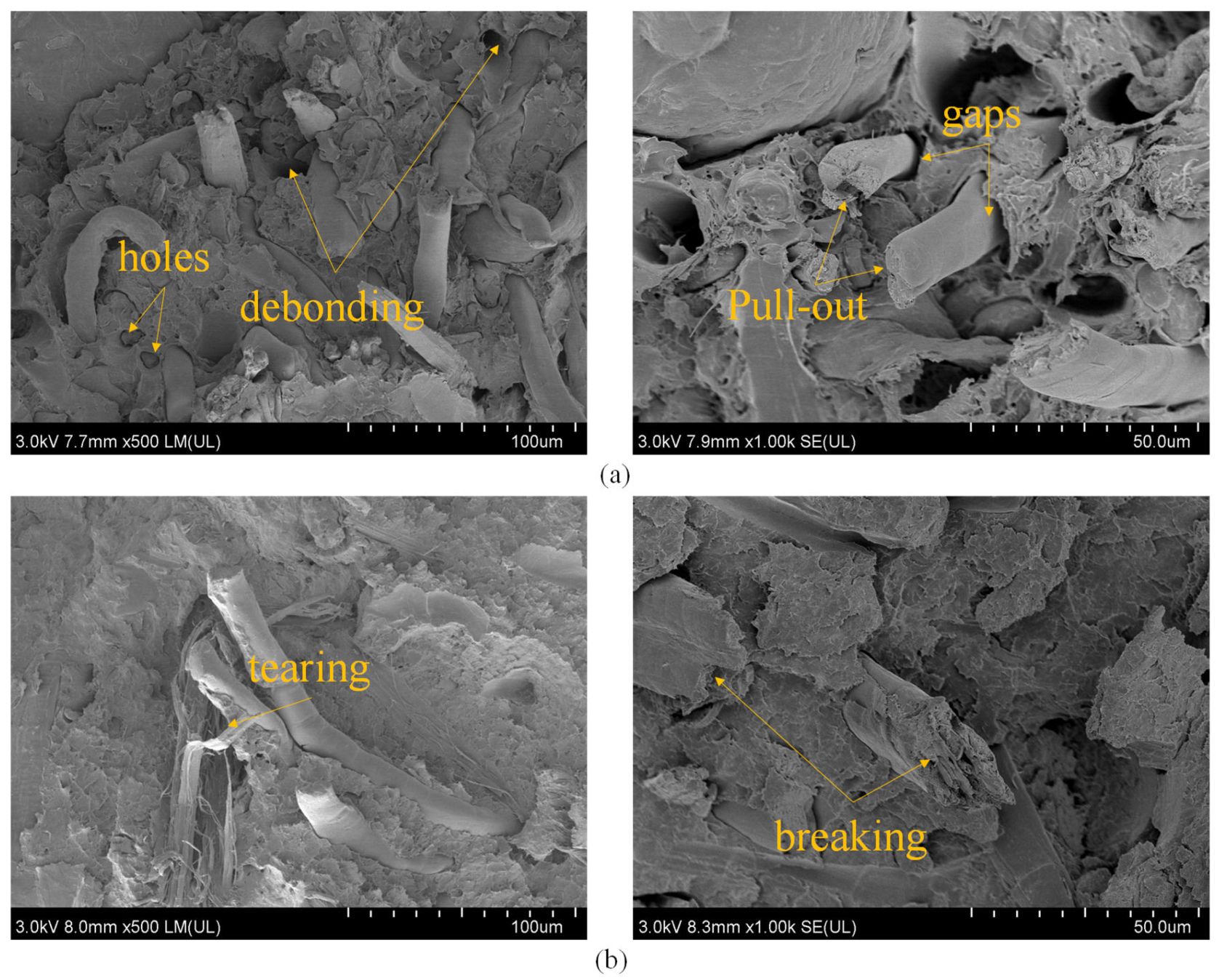

3.2. SEM Results

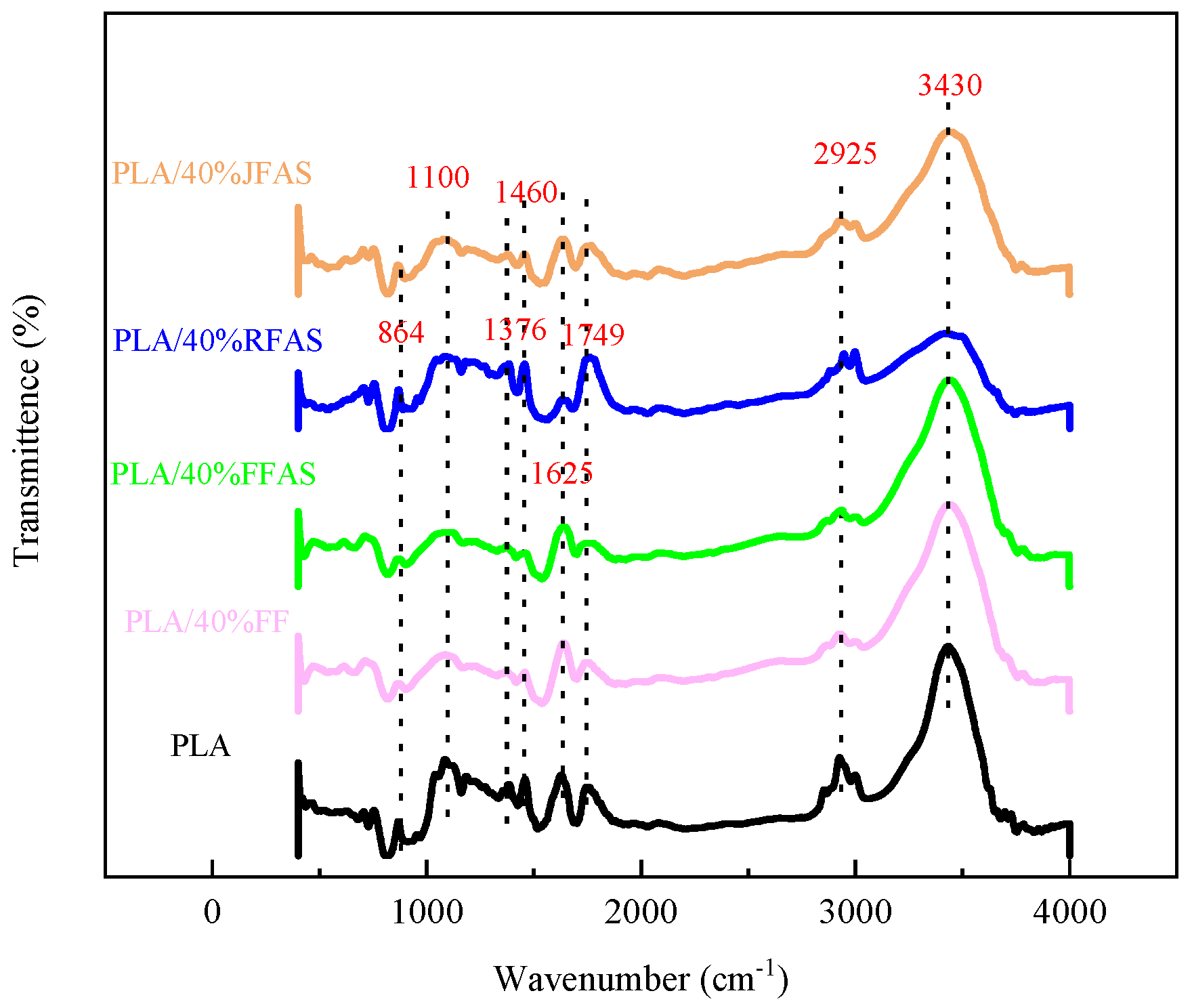

3.3. FTIR Results

4. Finite Element Simulation

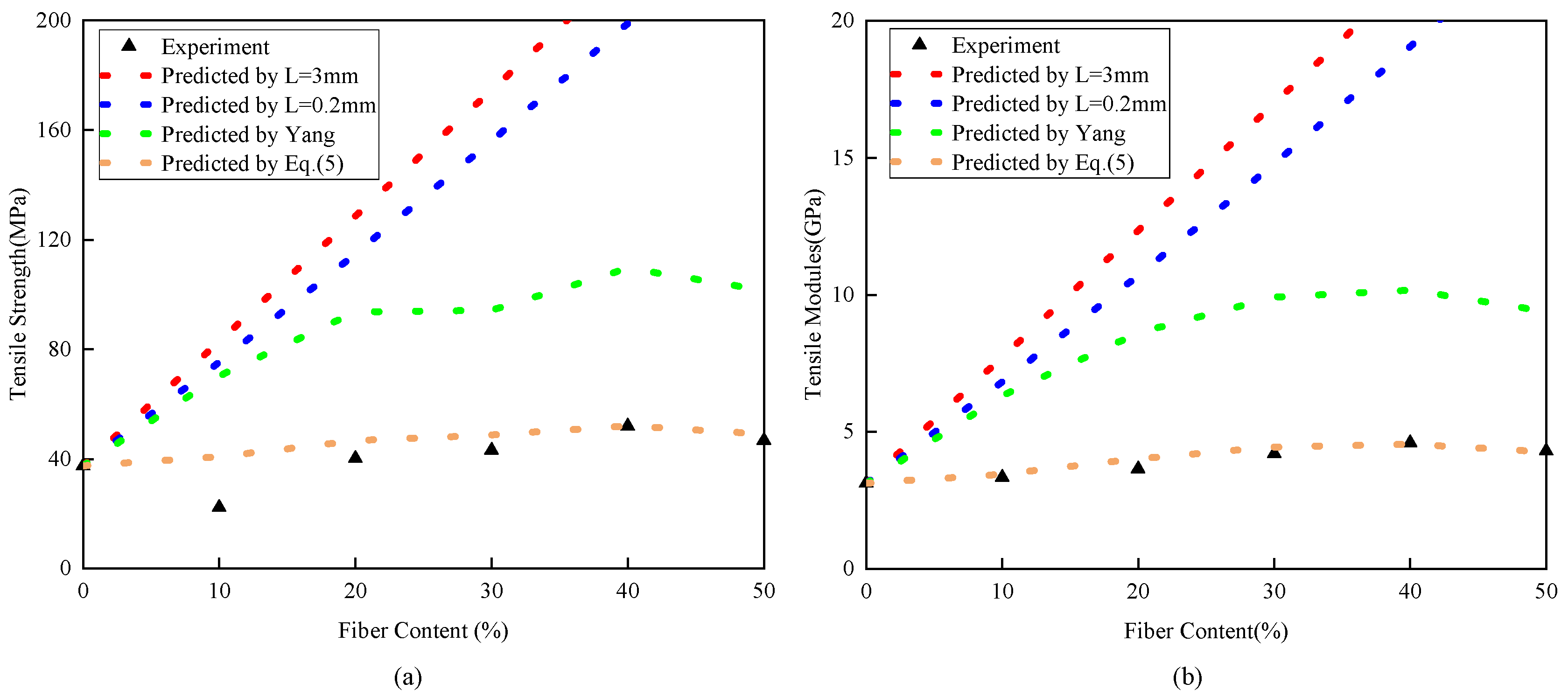

4.1. Theoretical Analyses

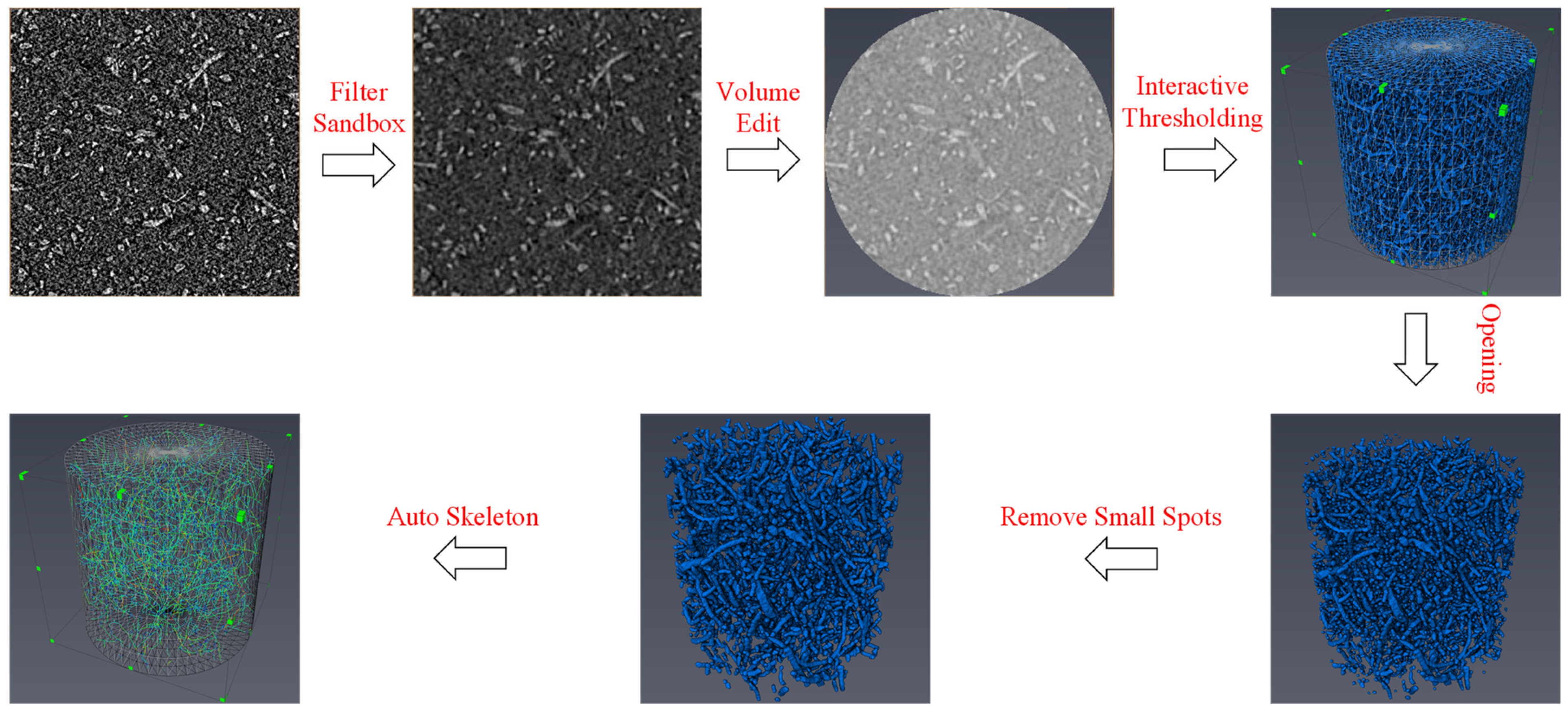

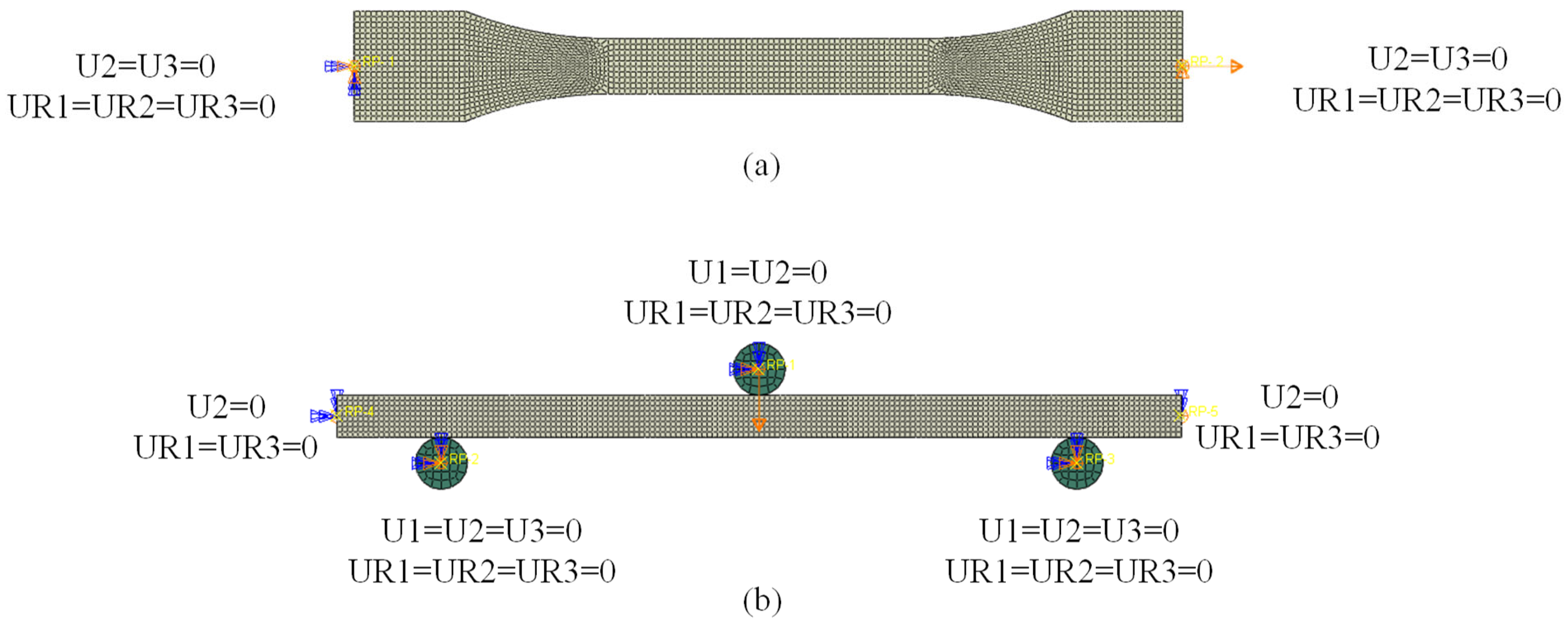

4.2. Numerical Simulation Methods

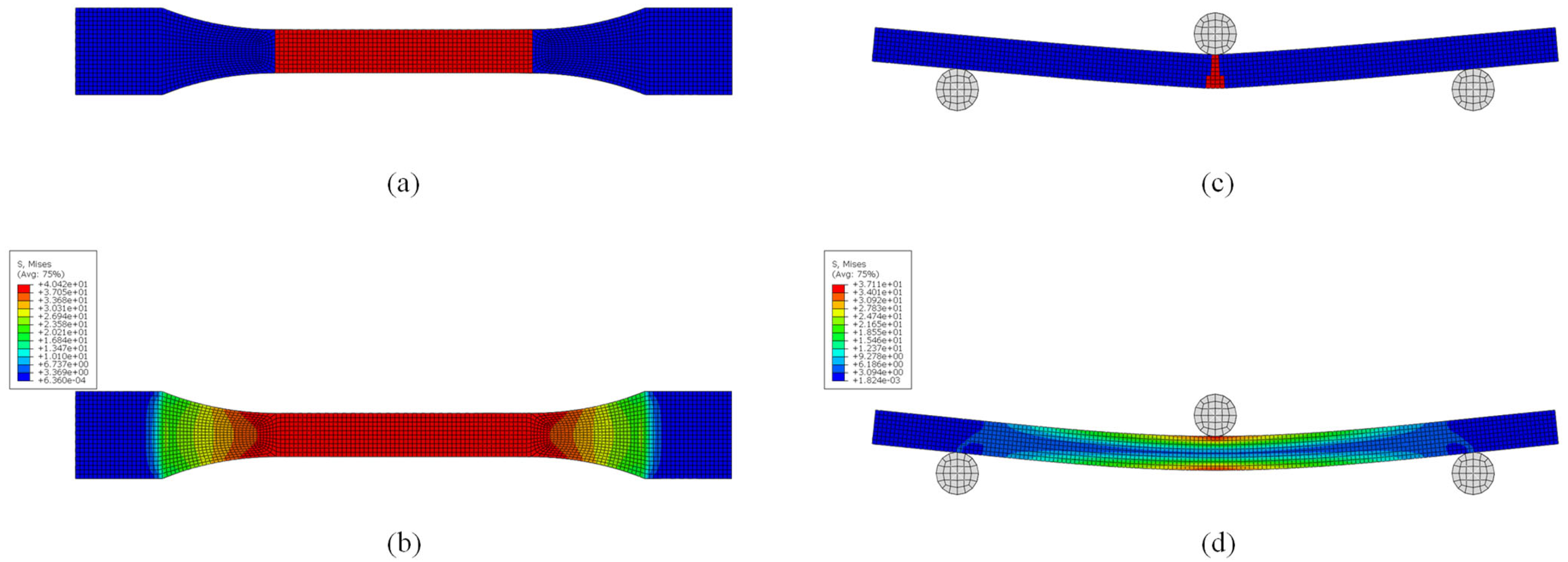

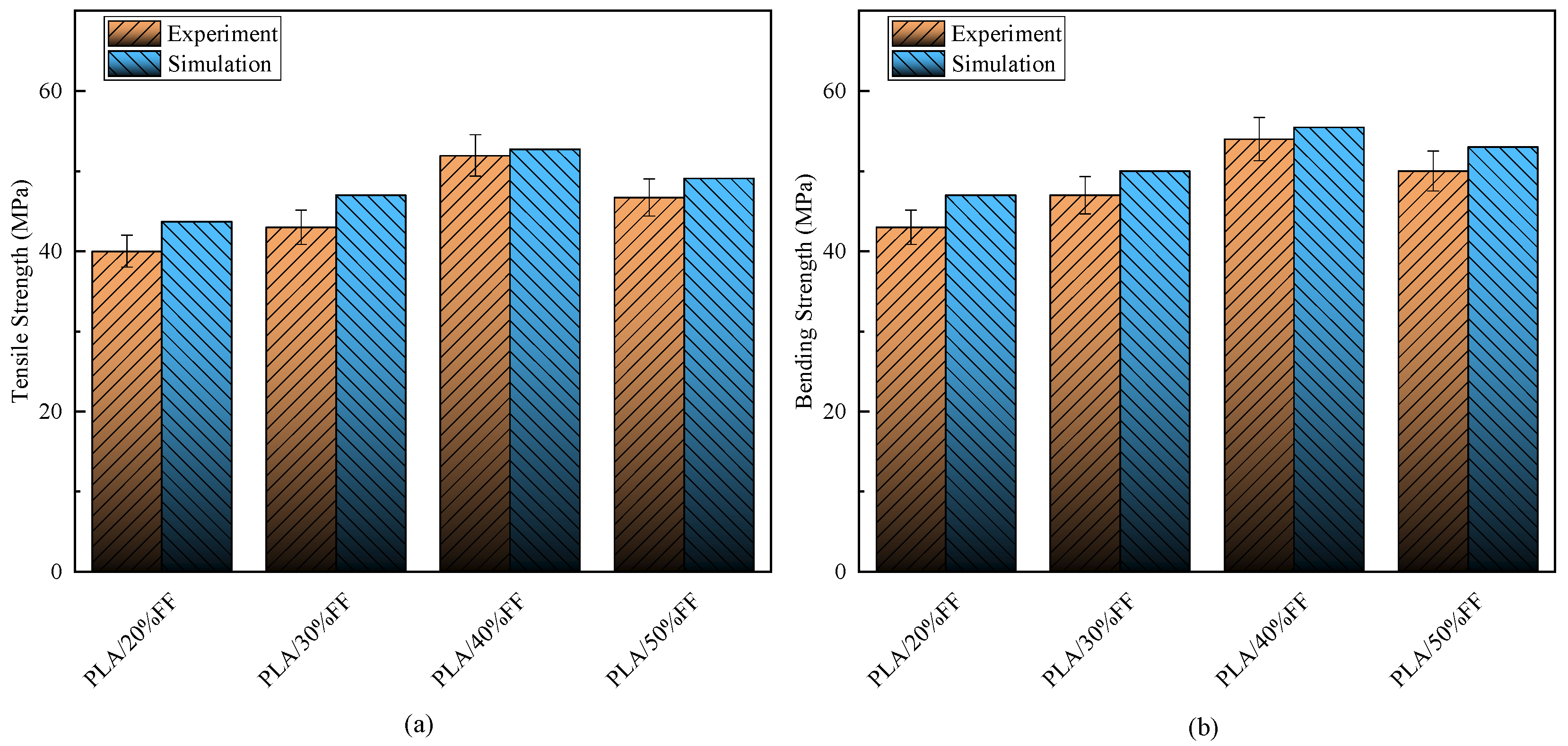

4.3. Analysis of Simulation Results

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Raj, S.A.; Muthukumaran, E.; Jayakrishna, K. A Case Study of 3D Printed PLA and Its Mechanical Properties. Mater. Today Proc. 2018, 5, 11219–11226. [Google Scholar] [CrossRef]

- Chicos, L.A.; Pop, M.A.; Zaharia, S.M.; Lancea, C.; Buican, G.R.; Pascariu, I.S.; Stamate, V.M. Fused Filament Fabrication of Short Glass Fiber-Reinforced Polylactic Acid Composites: Infill Density Influence on Mechanical and Thermal Properties. Polymers 2022, 14, 4988. [Google Scholar] [CrossRef] [PubMed]

- Shih, Y.F.; Huang, C.C. Polylactic acid (PLA)/banana fiber (BF) biodegradable green composites. J. Polym. Res. 2011, 18, 2335–2340. [Google Scholar] [CrossRef]

- Shukor, F.; Hassan, A.; Islam, M.S.; Mokhtar, M.; Hasan, M. Effect of ammonium polyphosphate on flame retardancy, thermal stability and mechanical properties of alkali treated kenaf fiber filled PLA biocomposites. Mater. Des. 2014, 54, 425–429. [Google Scholar] [CrossRef]

- Rajeshkumar, G.; Seshadri, S.A.; Devnani, G.; Sanjay, M.; Siengchin, S.; Maran, J.P.; Al-Dhabi, N.A.; Karuppiah, P.; Mariadhas, V.A.; Sivarajasekar, N.; et al. Environment friendly, renewable and sustainable poly lactic acid (PLA) based natural fiber reinforced composites—A comprehensive review. J. Clean. Prod. 2021, 310, 127483. [Google Scholar] [CrossRef]

- Alam, P.; Mamalis, D.; Robert, C.; Floreani, C.; Brádaigh, C.M. The fatigue of carbon fibre reinforced plastics—A review. Compos. Part B Eng. 2019, 166, 555–579. [Google Scholar] [CrossRef]

- Sanivada, U.K.; Marmol, G.; Brito, F.P.; Fangueiro, R. PLA Composites Reinforced with Flax and Jute Fibers-A Review of Recent Trends, Processing Parameters and Mechanical Properties. Polymers 2020, 12, 2373. [Google Scholar] [CrossRef]

- Vallejos, M.E.; Aguado, R.J.; Morcillo-Martin, R.; Mendez, J.A.; Vilaseca, F.; Tarres, Q.; Mutje, P. Behavior of the Flexural Strength of Hemp/Polypropylene Composites: Evaluation of the Intrinsic Flexural Strength of Untreated Hemp Strands. Polymers 2023, 15, 371. [Google Scholar] [CrossRef]

- Wang, Z.; Feng, W.; Ban, J.; Yang, Z.; Fang, X.; Ding, T.; Liu, B.; Zhao, J. Sisal-Fiber-Reinforced Polypropylene Flame-Retardant Composites: Preparation and Properties. Polymers 2023, 15, 893. [Google Scholar] [CrossRef]

- Ozturk, B.; Ozturk, S. Effects of Resin Type and Fiber Length on the Mechanical and Tribological Properties of Brake Friction Materials. Tribol. Lett. 2011, 42, 339–350. [Google Scholar] [CrossRef]

- Gamon, G.; Evon, P.; Rigal, L. Twin-screw extrusion impact on natural fibre morphology and material properties in poly(lactic acid) based biocomposites. Ind. Crops Prod. 2013, 46, 173–185. [Google Scholar] [CrossRef]

- Jariwala, H.; Jain, P. A review on mechanical behavior of natural fiber reinforced polymer composites and its applications. J. Reinf. Plast. Compos. 2019, 38, 441–453. [Google Scholar] [CrossRef]

- Le Duigou, A.; Barbe, A.; Guillou, E.; Castro, M. 3D printing of continuous flax fibre reinforced biocomposites for structural applications. Mater. Des. 2019, 180, 107884. [Google Scholar] [CrossRef]

- Oksman, K.; Skrifvars, M.; Selin, J.F. Natural fibres as reinforcement in polylactic acid (PLA) composites. Compos. Sci. Technol. 2003, 63, 1317–1324. [Google Scholar] [CrossRef]

- Zhan, J.H.; Li, J.; Wang, G.L.; Guan, Y.J.; Zhao, G.Q.; Lin, J.; Naceur, H.; Coutellier, D. Review on the performances, foaming and injection molding simulation of natural fiber composites. Polym. Compos. 2021, 42, 1305–1324. [Google Scholar] [CrossRef]

- Cheung, H.Y.; Ho, M.P.; Lau, K.T.; Cardona, F.; Hui, D. Natural fibre-reinforced composites for bioengineering and environmental engineering applications. Compos. Part B-Eng. 2009, 40, 655–663. [Google Scholar] [CrossRef]

- Kian, L.K.; Saba, N.; Jawaid, M.; Sultan, M.T.H. A review on processing techniques of bast fibers nanocellulose and its polylactic acid (PLA) nanocomposites. Int. J. Biol. Macromol. 2019, 121, 1314–1328. [Google Scholar] [CrossRef]

- Martinelli, F.R.B.; Ribeiro, F.R.C.; Marvila, M.T.; Monteiro, S.N.; Filho, F.d.C.G.; Azevedo, A.R.G.d. A Review of the Use of Coconut Fiber in Cement Composites. Polymers 2023, 15, 1309. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.X.; Liu, M.H.; Sun, J.F.; Wang, J.; Tian, S. Study on the effect of hybrid fiber length on tensile strength of sealing composites. J. Eng. Fibers Fabr. 2020, 15. [Google Scholar] [CrossRef]

- Bajpai, P.K.; Singh, I.; Madaan, J. Comparative studies of mechanical and morphological properties of polylactic acid and polypropylene based natural fiber composites. J. Reinf. Plast. Compos. 2012, 31, 1712–1724. [Google Scholar] [CrossRef]

- Latif, R.; Wakeel, S.; Khan, N.Z.; Siddiquee, A.N.; Verma, S.L.; Khan, Z.A. Surface treatments of plant fibers and their effects on mechanical properties of fiber-reinforced composites: A review. J. Reinf. Plast. Compos. 2019, 38, 15–30. [Google Scholar] [CrossRef]

- Jiang, A.J.; Xi, J.L.; Wu, H.W. Effect of surface treatment on the morphology of sisal fibers in sisal/polylactic acid composites. J. Reinf. Plast. Compos. 2012, 31, 621–630. [Google Scholar] [CrossRef]

- Zafar, M.T.; Maiti, S.N.; Ghosh, A.K. Effect of surface treatments of jute fibers on the microstructural and mechanical responses of poly(lactic acid)/jute fiber biocomposites. RSC Adv. 2016, 6, 73373–73382. [Google Scholar] [CrossRef]

- Saleh, A.A.; Saleh, M.A.; Al Haron, M.H.; Farag, M. Insights into the effect of moisture absorption and fiber content on the mechanical behavior of starch-date-palm fiber composites. Starch Starke 2017, 69, 1600254. [Google Scholar] [CrossRef]

- Le, T.M.; Pickering, K.L. The potential of harakeke fibre as reinforcement in polymer matrix composites including modelling of long harakeke fibre composite strength. Compos. Part A Appl. Sci. Manuf. 2015, 76, 44–53. [Google Scholar] [CrossRef]

- Hamamousse, K.; Sereir, Z.; Benzidane, R.; Gehring, F.; Gomina, M.; Poilane, C. Experimental and numerical studies on the low-velocity impact response of orthogrid epoxy panels reinforced with short plant fibers. Compos. Struct. 2019, 211, 469–480. [Google Scholar] [CrossRef]

- Modniks, J.; Andersons, J. Modeling elastic properties of short flax fiber-reinforced composites by orientation averaging. Comput. Mater. Sci. 2010, 50, 595–599. [Google Scholar] [CrossRef]

- Zhong, Y.C.; Tran, L.Q.N.; Kureemun, U.; Lee, H.P. Prediction of the mechanical behavior of flax polypropylene composites based on multi-scale finite element analysis. J. Mater. Sci. 2017, 52, 4957–4967. [Google Scholar] [CrossRef]

- Kari, S.; Berger, H.; Gabbert, U. Numerical evaluation of effective material properties of randomly distributed short cylindrical fibre composites. Comput. Mater. Sci. 2007, 39, 198–204. [Google Scholar] [CrossRef]

- Kumar, R.S.; Muralidharan, N.D. Mechanical Characteristics Study of Chemically Modified Kenaf Fiber Reinforced Epoxy Composites. J. Nat. Fibers 2022, 19, 2457–2467. [Google Scholar] [CrossRef]

- Rigolin, T.R.; Takahashi, M.C.; Kondo, D.L.; Bettini, S.H.P. Compatibilizer Acidity in Coir-Reinforced PLA Composites: Matrix Degradation and Composite Properties. J. Polym. Environ. 2019, 27, 1096–1104. [Google Scholar] [CrossRef]

- Tham, M.W.; Fazita, M.R.N.; Khalil, H.; Jaafar, M.; Rashedi, A.; Haafiz, M.K.M. Biocomposites based on poly(lactic acid) matrix and reinforced with natural fiber fabrics: The effect of fiber type and compatibilizer content. Polym. Compos. 2022, 43, 4191–4209. [Google Scholar] [CrossRef]

- Shen, J.H.; Li, X.C.; Yan, X. Mechanical and Acoustic Properties of Jute Fiber-Reinforced Polypropylene Composites. Acs Omega 2021, 6, 31154–31160. [Google Scholar] [CrossRef] [PubMed]

- Kamran, M.J.; Jayamani, E.; Heng, S.K.; Wong, Y.C.; Rahman, M.R.; Al-Bogami, A.S.; Huda, D.; Bin Bakri, M.K.; Rahman, M.M. Characterization and Comparative Study on Chemically Treated Luffa Fiber as Reinforcement for Polylactic Acid Bio-composites. Bioresources 2022, 17, 2576–2597. [Google Scholar] [CrossRef]

- Tee, Y.B.; Talib, R.A.; Abdan, K.; Chin, N.L.; Basha, R.K.; Yunos, K.F.M. Thermally Grafting Aminosilane onto Kenaf-Derived Cellulose and Its Influence on the Thermal Properties of Poly(Lactic Acid) Composites. Bioresources 2013, 8, 4468–4483. [Google Scholar] [CrossRef]

- Alao, P.F.; Marrot, L.; Kallakas, H.; Just, A.; Poltimae, T.; Kers, J. Effect of Hemp Fiber Surface Treatment on the Moisture/Water Resistance and Reaction to Fire of Reinforced PLA Composites. Materials 2021, 14, 4332. [Google Scholar] [CrossRef]

- Xiao, X.; Zhong, Y.C.; Cheng, M.Y.; Sheng, L.; Wang, D.; Li, S.X. Improved hygrothermal durability of flax/polypropylene composites after chemical treatments through a hybrid approach. Cellulose 2021, 28, 11209–11229. [Google Scholar] [CrossRef]

- Liu, Y.C.; Xie, J.; Wu, N.; Ma, Y.H.; Menon, C.; Tong, J. Characterization of natural cellulose fiber from corn stalk waste subjected to different surface treatments. Cellulose 2019, 26, 4707–4719. [Google Scholar] [CrossRef]

- Zhu, Z.H.; Hao, M.Y.; Zhang, N. Influence of contents of chemical compositions on the mechanical property of sisal fibers and sisal fibers reinforced PLA composites. J. Nat. Fibers 2020, 17, 101–112. [Google Scholar] [CrossRef]

- Orue, A.; Eceiza, A.; Arbelaiz, A. The effect of sisal fiber surface treatments, plasticizer addition and annealing process on the crystallization and the thermo-mechanical properties of poly (lactic acid) composites. Ind. Crops Prod. 2018, 118, 321–333. [Google Scholar] [CrossRef]

- Yang, Z.Z.; Feng, X.H.; Xu, M.; Rodrigue, D. Properties of Poplar Fiber/PLA Composites: Comparison on the Effect of Maleic Anhydride and KH550 Modification of Poplar Fiber. Polymers 2020, 12, 729. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.X.; Mo, X.Z.; Pang, J.Y.; Yang, F. Effects of silica on the morphology, structure, and properties of thermoplastic cassava starch/poly(vinyl alcohol) blends. J. Appl. Polym. Sci. 2016, 133, 44020. [Google Scholar] [CrossRef]

- Li, Z.Y.; Liu, Z.; Lei, Z.; Zhu, P. An innovative computational framework for the analysis of complex mechanical behaviors of short fiber reinforced polymer composites. Compos. Struct. 2021, 277, 114594. [Google Scholar] [CrossRef]

- Yang, M.Q.; Li, W.G.; He, Y.; Zhang, X.Y.; Li, Y.; Zhao, Z.Y.; Dong, P.; Zheng, S.F.; Wang, L.D. Modeling the temperature dependent ultimate tensile strength of fiber/polymer composites considering fiber agglomeration. Compos. Sci. Technol. 2021, 213, 108905. [Google Scholar] [CrossRef]

- Facca, A.G.; Kortschot, M.T.; Yan, N. Predicting the tensile strength of natural fibre reinforced thermoplastics. Compos. Sci. Technol. 2007, 67, 2454–2466. [Google Scholar] [CrossRef]

| Material | ||||

|---|---|---|---|---|

| Flax Fiber | 1.5 | 500 | 50 | 2 |

| Jute Fiber | 1.46 | 400 | 40 | 1.8 |

| Ramie Fiber | 1.5 | 460 | 45 | 2 |

| PLA | 1.24 | 40 | 3 | 4 |

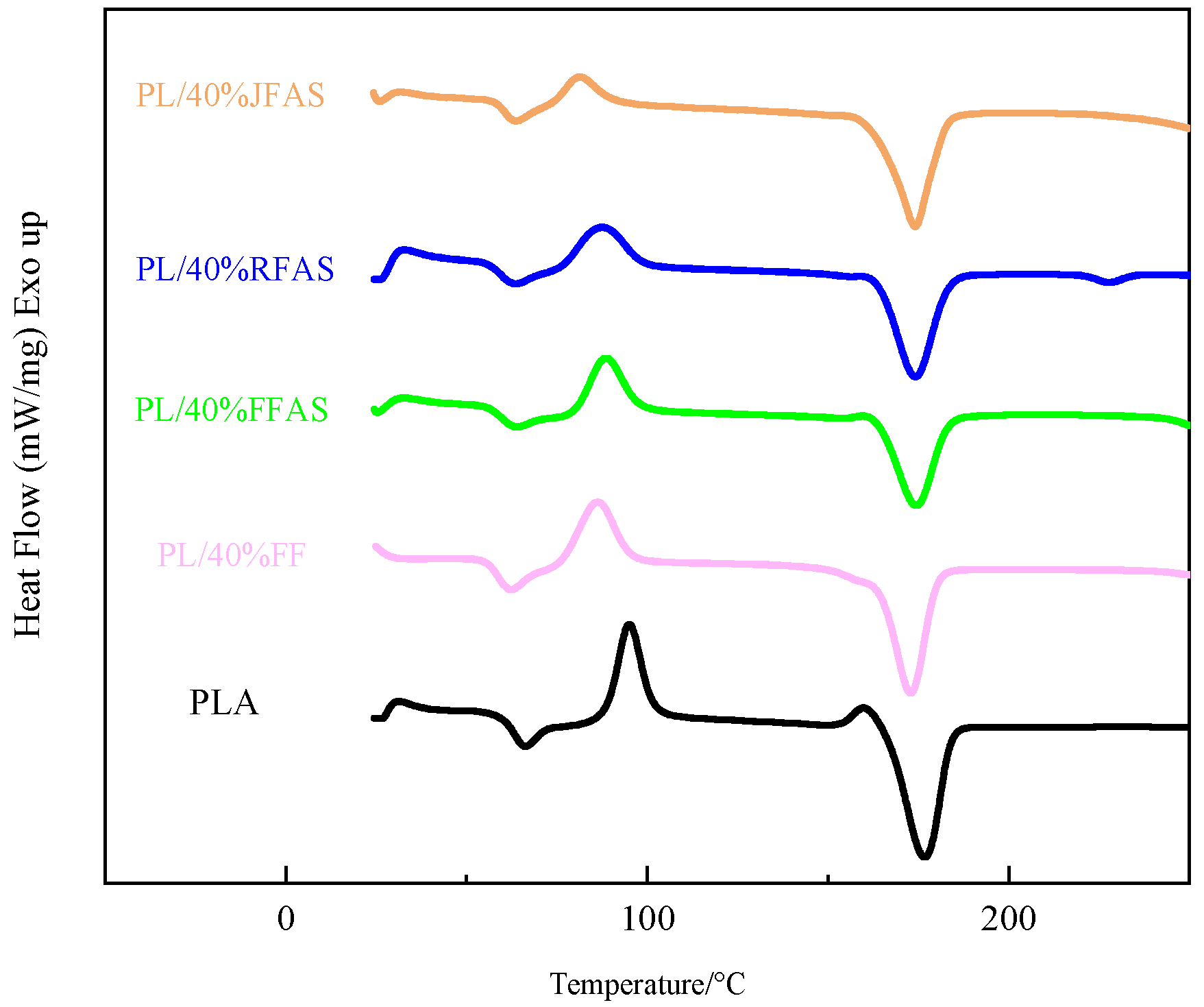

| Sample | Tg(°C) | Tcc(°C) | Tm(°C) | Xc(%) |

|---|---|---|---|---|

| PLA | 61.62 | 95.03 | 176.76 | 50.11 |

| PLA/40%FF | 59.53 | 86.25 | 172.84 | 42.37 |

| PLA/40%FFAS | 60.06 | 88.53 | 174.47 | 44.34 |

| PLA/40%RFAS | 59.87 | 87.48 | 174.16 | 43.21 |

| PLA/40%JFAS | 58.94 | 81.29 | 174.17 | 42.53 |

| Parameter Type | Numerical Value |

|---|---|

| Elastic modulus (GPa) | 3.1 |

| Poisson’s ratio | 0.3 |

| Tensile strength (MPa) | 37.43 |

| Compressive strength (MPa) | 42.21 |

| Shear strength (MPa) | 20.79 |

| Experiment | Simulation | Error Range (%) | ||

|---|---|---|---|---|

| Tensile | Load (N) | 348.59 | 360.42 | 3 |

| Displacement (mm) | 0.48 | 0.50 | 4 | |

| Bend | Load (N) | 66.34 | 68.72 | 4 |

| Displacement (mm) | 2.06 | 2.12 | 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mu, W.; Chen, X.; Li, S.; Sun, Y.; Wang, Q.; Na, J. Mechanical Performances Analysis and Prediction of Short Plant Fiber-Reinforced PLA Composites. Polymers 2023, 15, 3222. https://doi.org/10.3390/polym15153222

Mu W, Chen X, Li S, Sun Y, Wang Q, Na J. Mechanical Performances Analysis and Prediction of Short Plant Fiber-Reinforced PLA Composites. Polymers. 2023; 15(15):3222. https://doi.org/10.3390/polym15153222

Chicago/Turabian StyleMu, Wenlong, Xianglin Chen, Shijie Li, Yufeng Sun, Qingpeng Wang, and Jingxin Na. 2023. "Mechanical Performances Analysis and Prediction of Short Plant Fiber-Reinforced PLA Composites" Polymers 15, no. 15: 3222. https://doi.org/10.3390/polym15153222

APA StyleMu, W., Chen, X., Li, S., Sun, Y., Wang, Q., & Na, J. (2023). Mechanical Performances Analysis and Prediction of Short Plant Fiber-Reinforced PLA Composites. Polymers, 15(15), 3222. https://doi.org/10.3390/polym15153222