Inorganic Fillers and Their Effects on the Properties of Flax/PLA Composites after UV Degradation

Abstract

1. Introduction

2. Experimental

2.1. Materials

| Sample Types | Thickness (mm) | PLA (wt.%) | PBAT % | Flax (%) | TiO2 (%) | Filler (%) (Talcum + CaCO3) | Total (%) |

|---|---|---|---|---|---|---|---|

| CNW | 2.7 | 70.48% | 0.00% | 29.52% | 0.00% | 0.00% | 100.00% |

| KW | 2.0 | 74.70% | 0.00% | 20.31% | 4.98% | 0.00% | 100.00% |

| KWF_1 | 2.8 | 46.41% | 9.61% | 21.55% | 3.00% | 19.00% | 100.00% |

| KWF_2 | 2.1 | 37.30% | 8.09% | 27.66% | 3.00% | 24.00% | 100.00% |

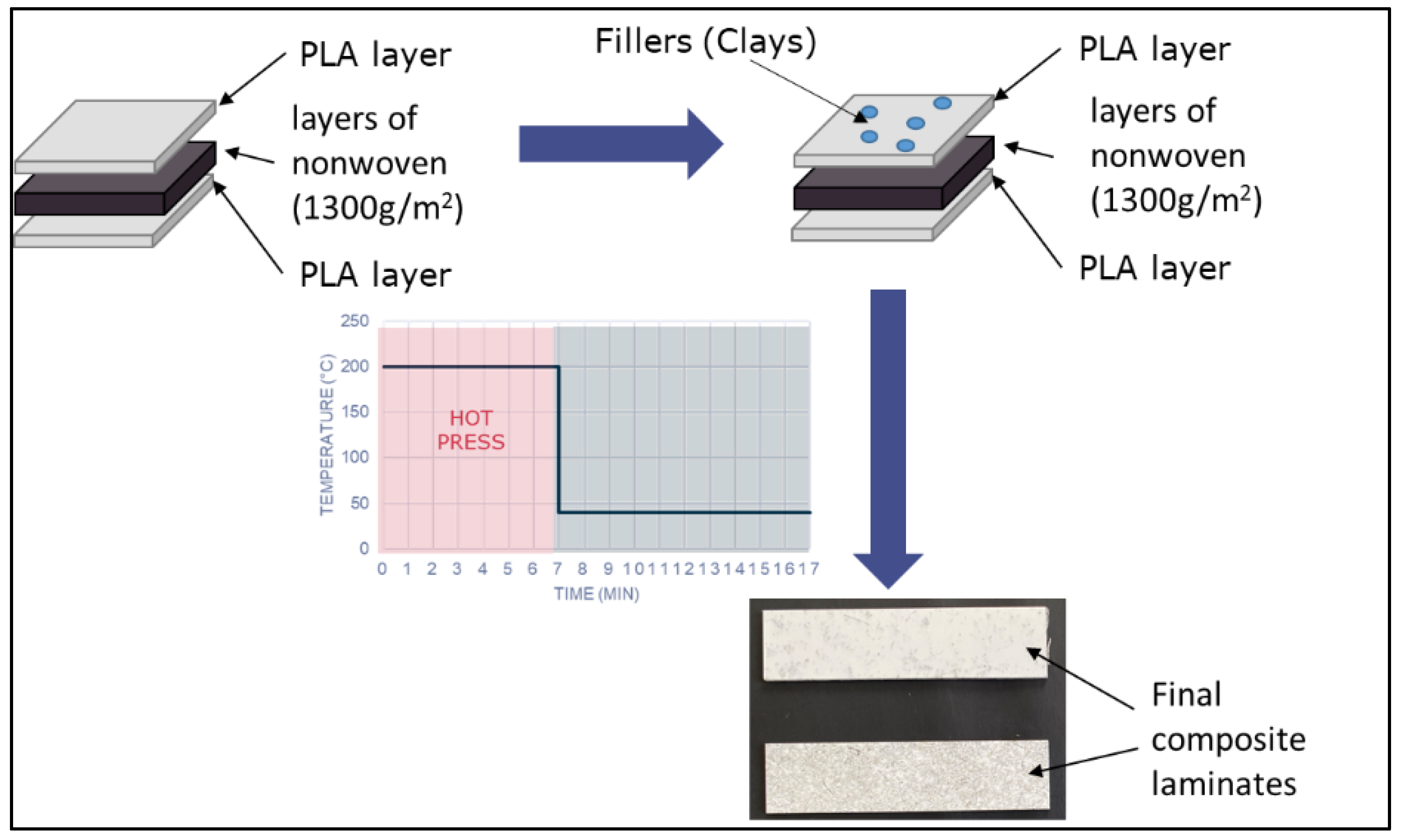

2.2. Fabrication of Laminates

2.3. Specimen Preparation

2.4. Accelerated UV Exposure

2.5. Physical Characterisation

2.5.1. Colour Measurement

2.5.2. Surface Morphology

2.6. Mechanical Testing

2.6.1. Tensile and Flexural Testing

2.6.2. Surface Roughness Measurement

2.6.3. Shore Hardness Measurement

3. Results and Discussions

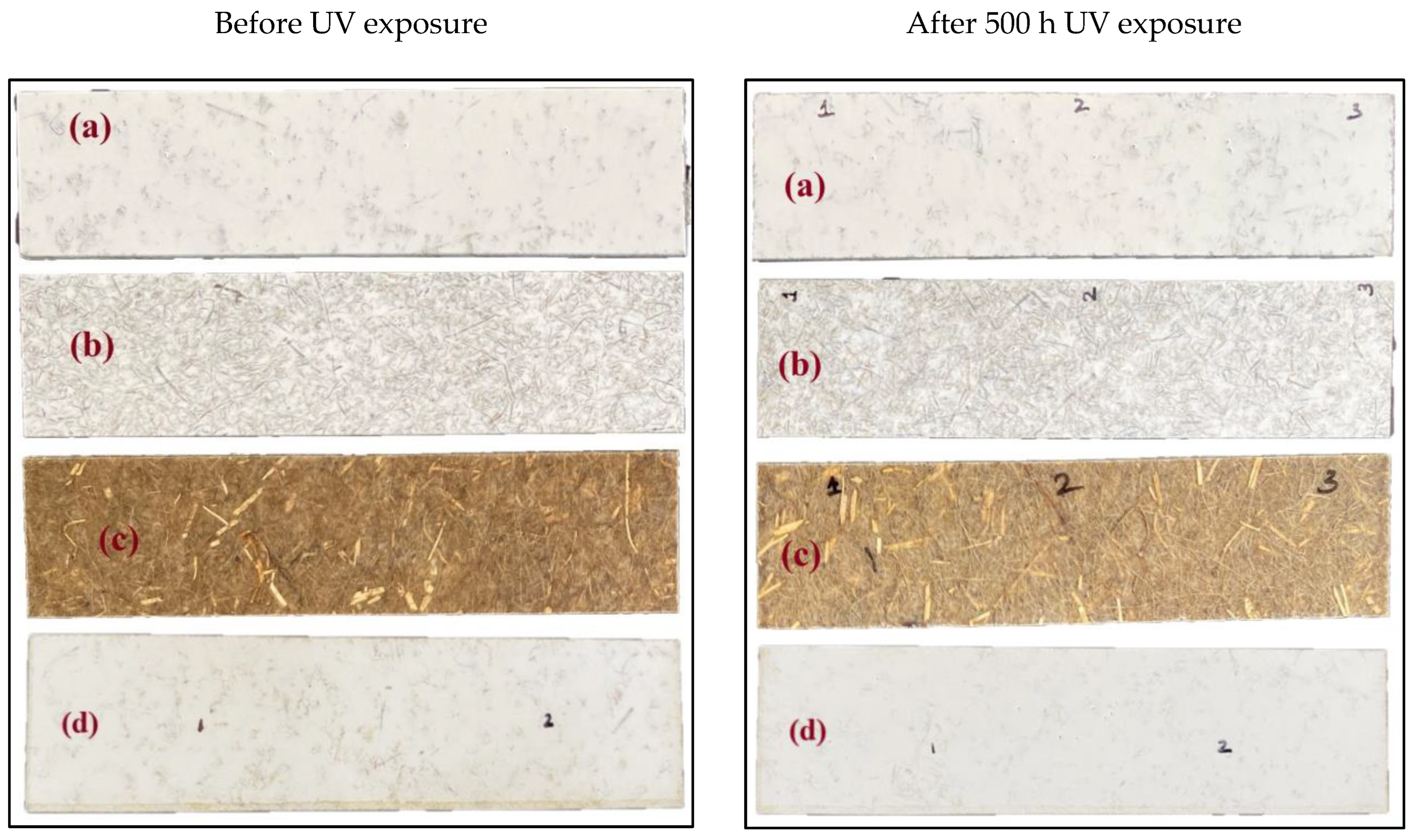

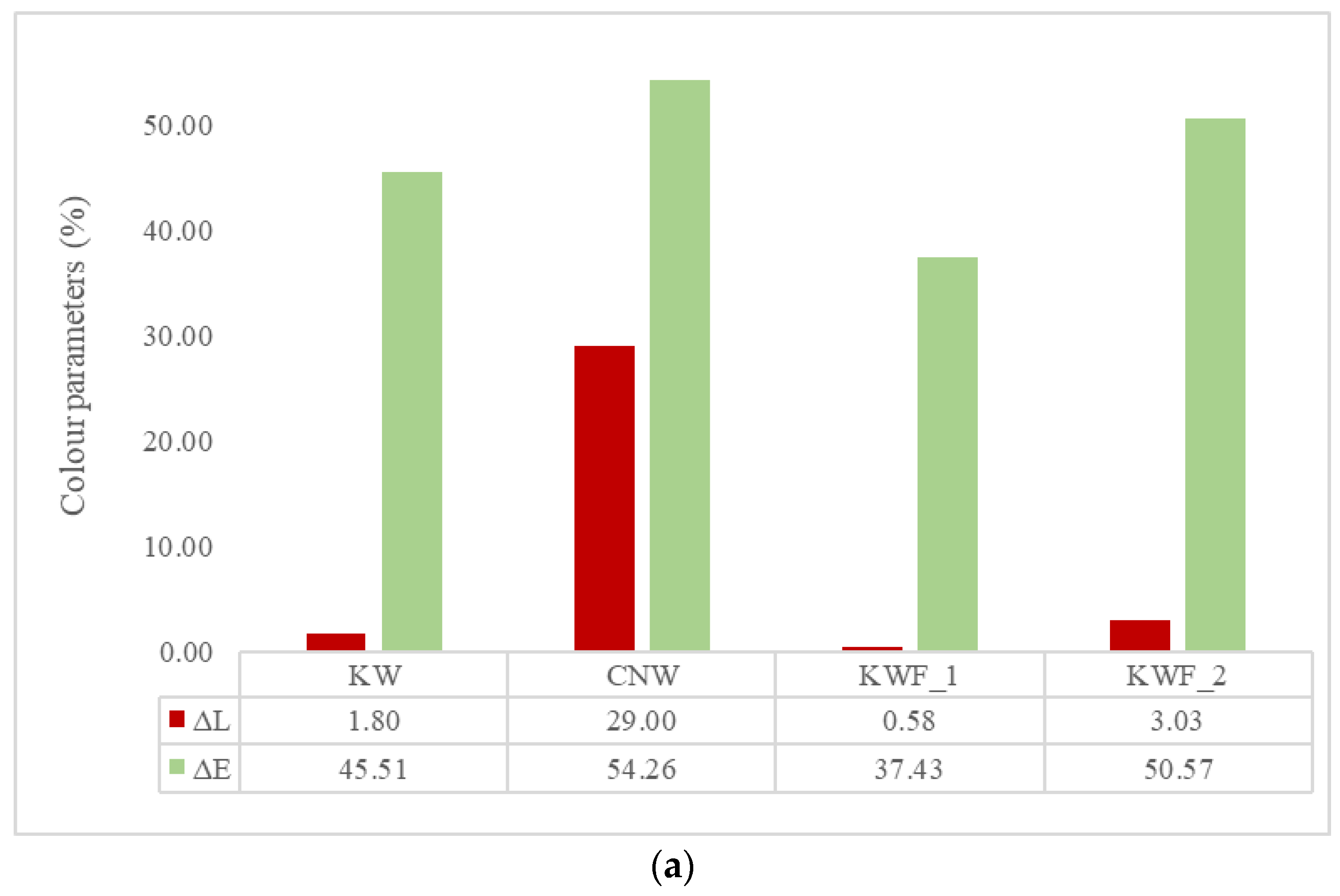

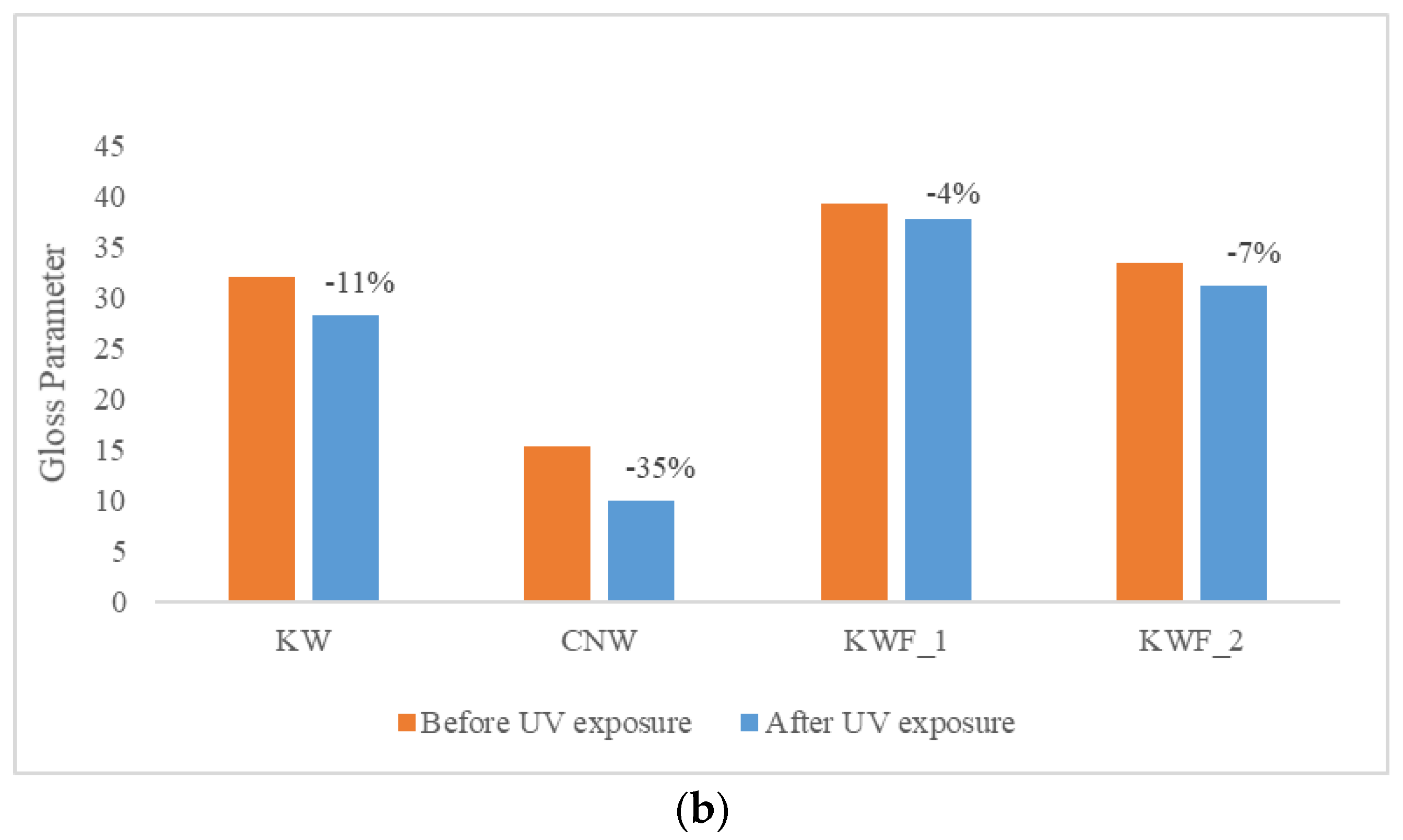

3.1. Effect of UV Exposure on the Surface Colour

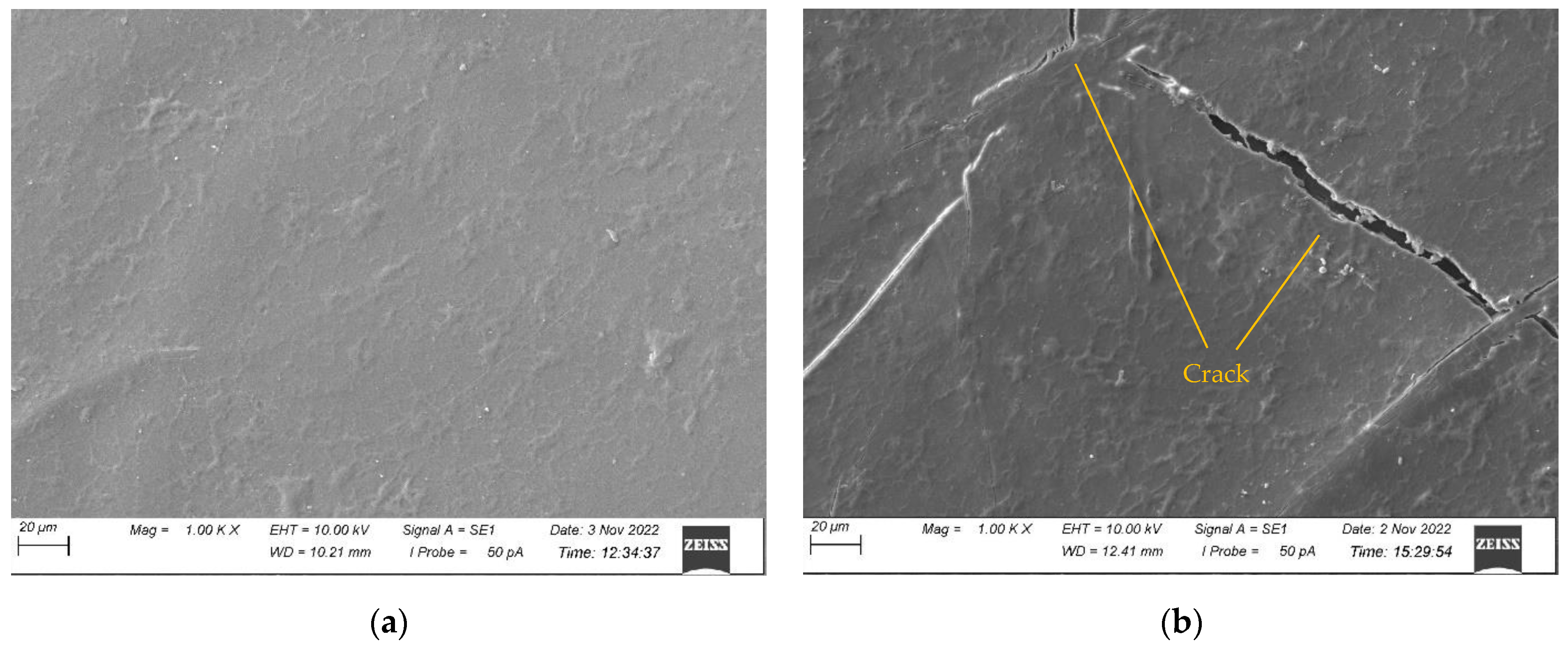

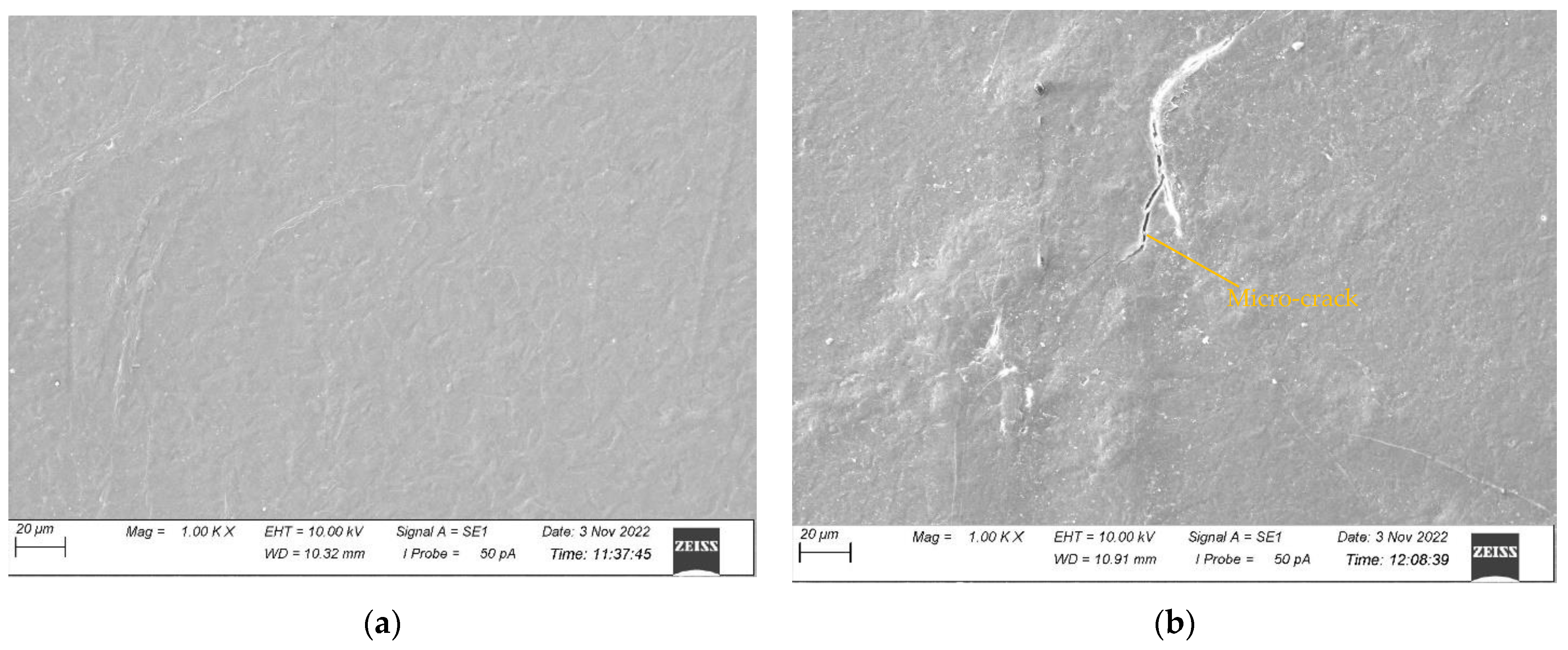

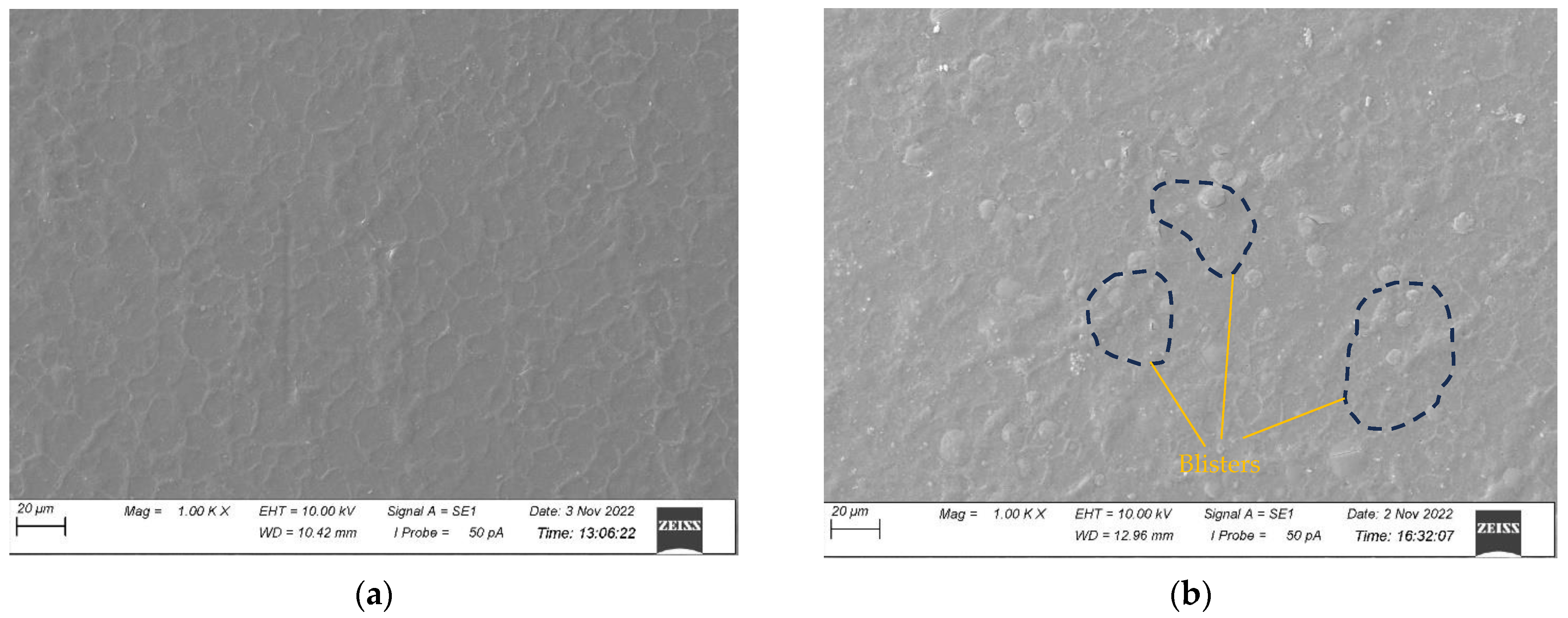

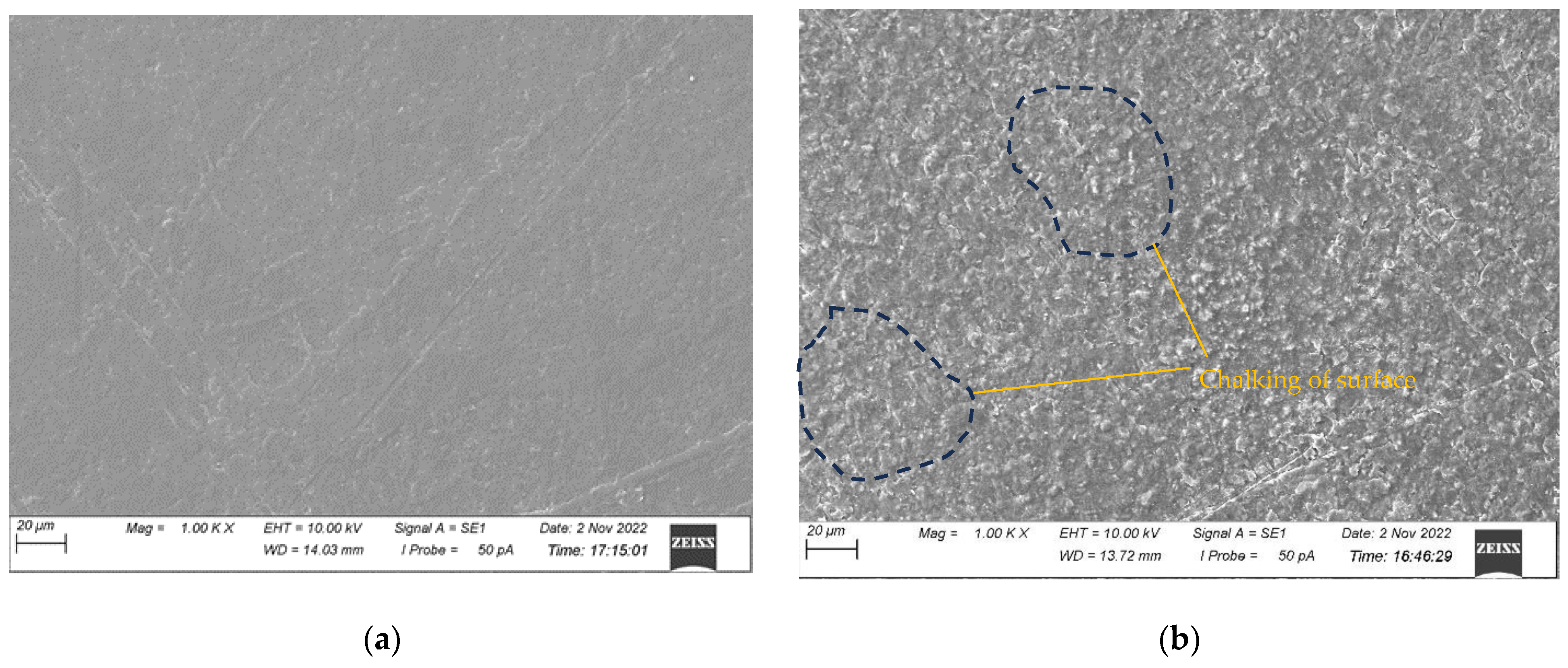

3.2. Effect of UV Exposure on the Surface Morphology

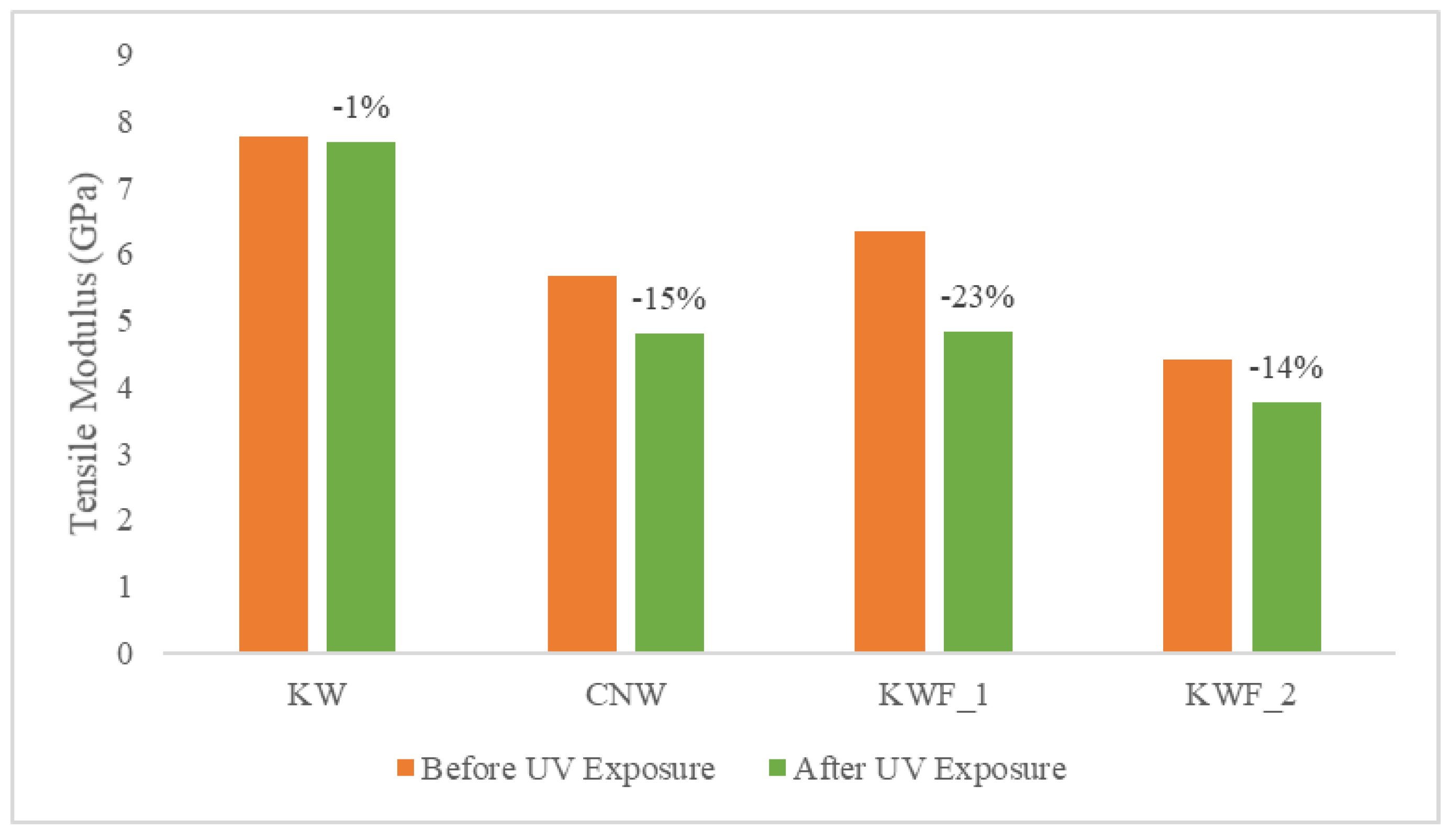

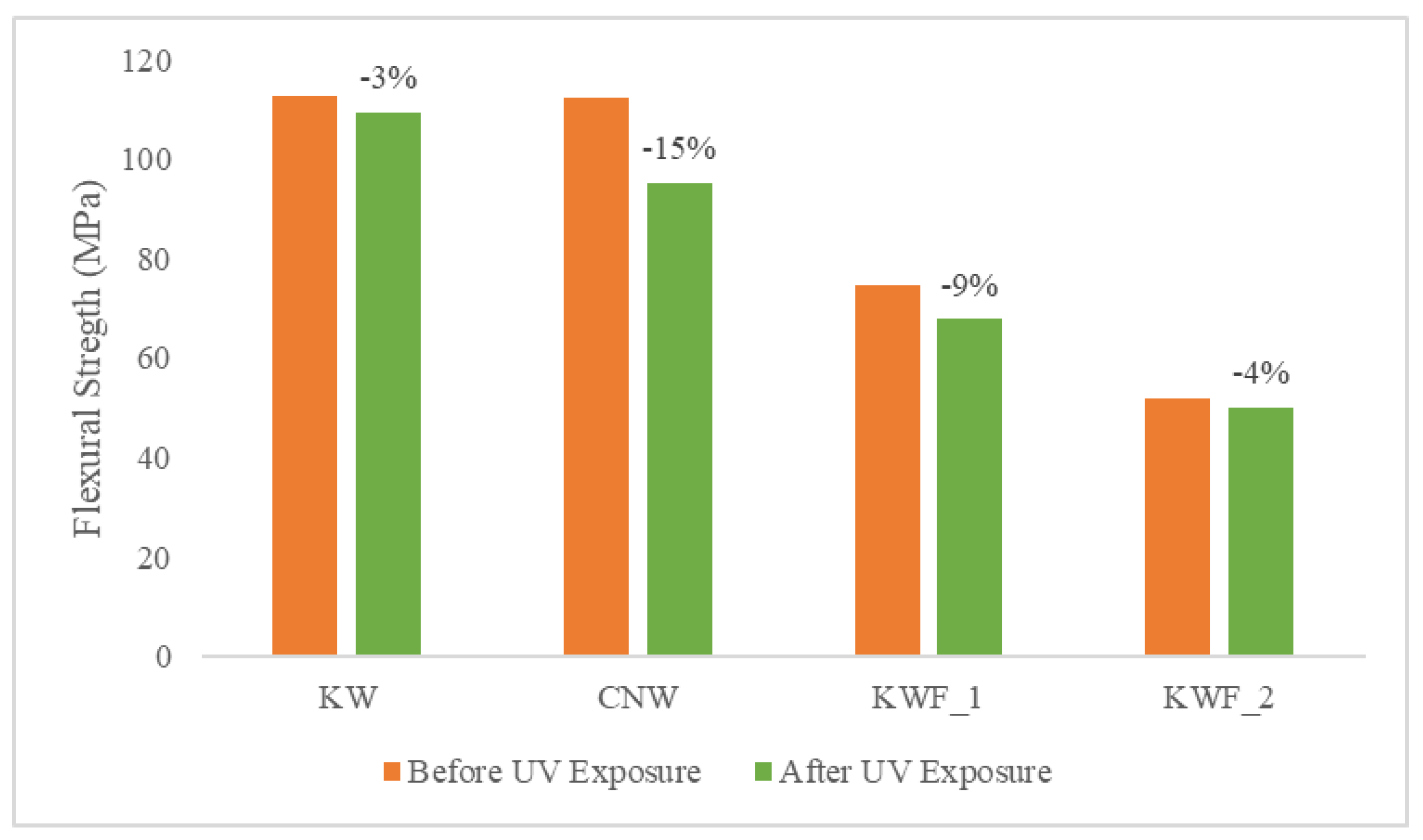

3.3. Effect of UV Exposure on Tensile and Flexural Properties

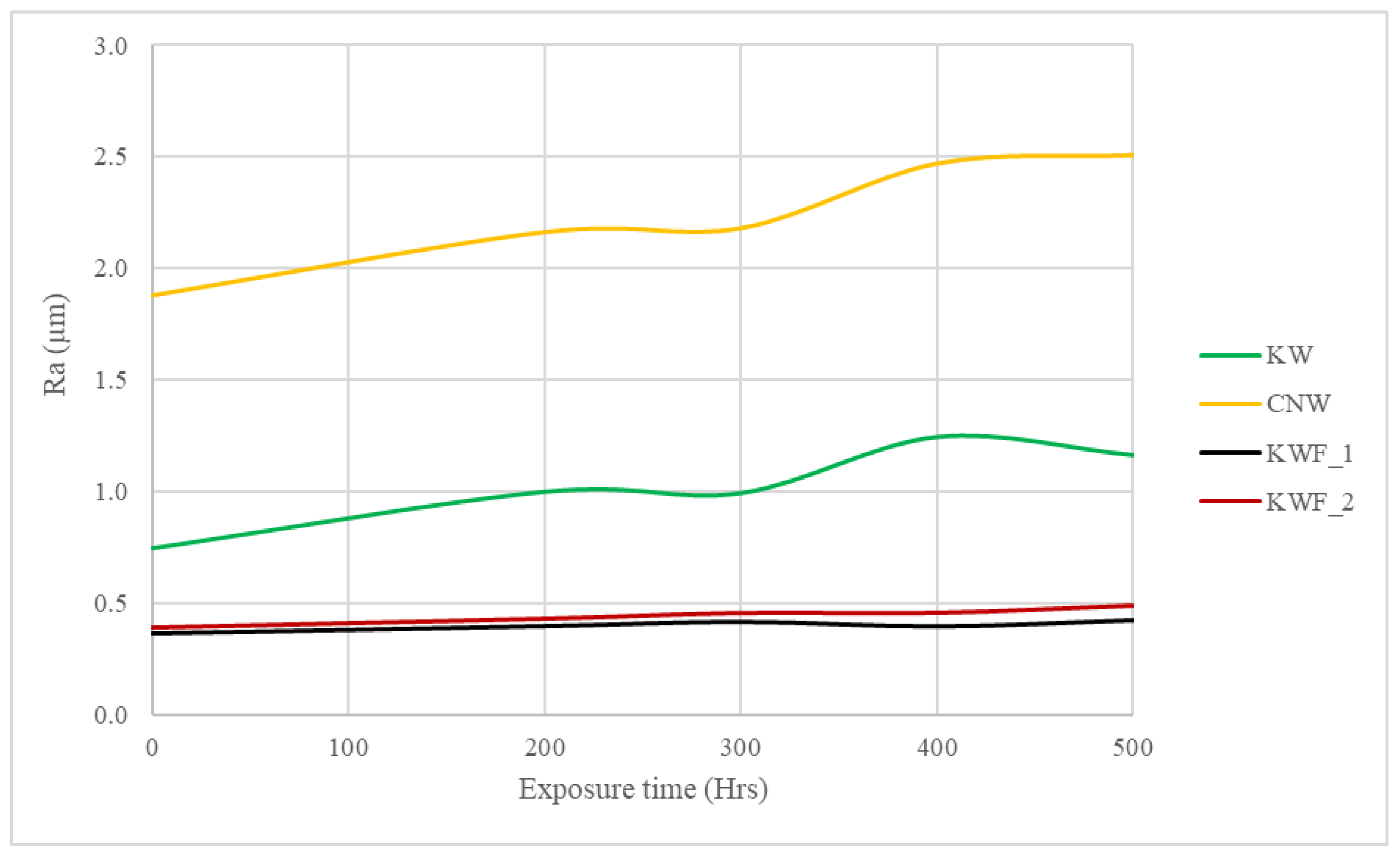

3.4. Effect of UV Exposure on Surface Roughness

3.5. Effect of UV Exposure on Shore Hardness

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Vinod, A.; Sanjay, M.R.; Suchart, S.; Jyotishkumar, P. Renewable and sustainable biobased materials: An assessment on biofibers, biofilms, biopolymers and biocomposites. J. Clean. Prod. 2020, 258, 120978. [Google Scholar] [CrossRef]

- Brebu, M. Environmental Degradation of Plastic Composites with Natural Fillers—A Review. Polymers 2020, 12, 166. [Google Scholar] [CrossRef]

- Przyborski, P. Ultraviolet Radiation: How It Affects Life on Earth. Available online: https://earthobservatory.nasa.gov/features/UVB/uvb_radiation3.php (accessed on 17 July 2021).

- DeLuisi, J.J. Measurements of the extraterrestrial solar radiant flux from 2981 to 4000 Å and its transmission through the earth’s atmosphere as it is affected by dust and ozone. J. Geophys. Res. 1975, 80, 345–354. [Google Scholar] [CrossRef]

- Weilnboeck, F.; Bruce, R.L.; Engelmann, S.; Oehrlein, G.S.; Nest, D.; Chung, T.Y.; Hudson, E.A. Photoresist modifications by plasma vacuum ultraviolet radiation: The role of polymer structure and plasma chemistry. J. Vac. Sci. Technol. B Nanotechnol. Microelectron. 2010, 28, 993–1004. [Google Scholar] [CrossRef]

- Tor-Świątek, A.; Garbacz, Ł. UV Degradation Influence on the Selected Physical Properties of Extruded PVC/Ceramic Composites. Adv. Sci. Technol. Res. J. 2022, 16, 282–294. [Google Scholar] [CrossRef]

- Muasher, M.; Sain, M. The efficacy of photostabilizers on the color change of wood filled plastic composites. Polym. Degrad. Stab. 2006, 91, 1156–1165. [Google Scholar] [CrossRef]

- Dachowski, R.; Kostrzewa, P. The Use of Waste Materials in the Construction Industry. Procedia Eng. 2016, 161, 754–758. [Google Scholar] [CrossRef]

- Klepka, T.; Goliszek, M.; Podkościelna, B.; Sevastyanova, O. Preparation, Thermal, and Mechanical Characterization of UV-Cured Polymer Biocomposites with Lignin. Polymers 2020, 12, 1159. [Google Scholar]

- Klepka, T.; Garbacz, Ł.; Miękoś, E.; Zieliński, M.; Sroczyński, D. Effect of batched water exposed to a constant magnetic field on the properties of concrete filled with waste fly ash, phosphogypsum and starch. Polimery 2022, 67, 53–60. [Google Scholar]

- Feldman, D. Polymer Weathering: Photo-Oxidation. J. Polym. Environ. 2002, 10, 163–173. [Google Scholar] [CrossRef]

- Salikhov, R.B.; Bazunova, M.V.; Salikhov, T.R.; Bazunova, A.A.; Zakharov, V.P. Study of the effect of photooxidative processes on the surface morphology and physico-mechanical characteristics of biodegradable materials based on secondary polypropylene and chalk additives. Lett. Mater. 2020, 10, 288–293. [Google Scholar] [CrossRef]

- Lu, T.; Solis-Ramos, E.; Yi, Y.; Kumosa, M. UV degradation model for polymers and polymer matrix composites. Polym. Degrad. Stab. 2018, 154, 203–210. [Google Scholar] [CrossRef]

- Vahabi, H.; Sonnier, R.; Ferry, L. Effects of ageing on the fire behaviour of flame-retarded polymers: A review. Polym. Int. 2015, 64, 313–328. [Google Scholar] [CrossRef]

- Celebi, M.; Altun, M.; Ovali, S. The effect of UV additives on thermo-oxidative and color stability of pistachio shell reinforced polypropylene composites. Polym. Polym. Compos. 2022, 30, 09673911221081700. [Google Scholar] [CrossRef]

- Valadez-Gonzalez, A.; Cervantes-Uc, J.M.; Veleva, L. Mineral filler influence on the photo-oxidation of high-density polyethylene: I. Accelerated UV chamber exposure test. Polym. Degrad. Stab. 1999, 63, 253–260. [Google Scholar] [CrossRef]

- Wang, H.; Peng, X.; Meng, S.; Zhong, W.; Du, W.; Du, Q. Poly(methyl methacrylate)/silica/titania ternary nanocomposites with greatly improved thermal and ultraviolet-shielding properties. Polym. Degrad. Stab. 2006, 91, 1455–1461. [Google Scholar] [CrossRef]

- Pal, M.K.; Singh, B.; Gautam, J. Thermal stability and UV-shielding properties of polymethyl methacrylate and polystyrene modified with calcium carbonate nanoparticles. J. Therm. Anal. Calorim. 2012, 107, 85–96. [Google Scholar] [CrossRef]

- Pal, M.K.; Gautam, J. Effects of inorganic nanofillers on the thermal degradation and UV-absorbance properties of polyvinyl acetate. J. Therm. Anal. Calorim. 2013, 111, 689–701. [Google Scholar] [CrossRef]

- Arora, A.; Choudhary, V.; Sharma, D.K. Effect of clay content and clay/surfactant on the mechanical, thermal and barrier properties of polystyrene/organoclay nanocomposites. J. Polym. Res. 2011, 18, 843–857. [Google Scholar] [CrossRef]

- Wang, Y.; Li, Y.; Jia, W.; Yue, C.; Ma, D. Study on anti-aging performance of composite materials of PP-g-AN/PP/SiO2. In Advanced Materials Research; Trans Tech Publications Ltd.: Freienbach, Switzerland, 2013. [Google Scholar]

- Inácioa, A.L.N.; Nonatob, R.C.; Bonse, B.C. Mechanical and thermal behavior of aged composites of recycled PP/EPDM/talc reinforced with bamboo fiber. Polym. Test. 2018, 72, 357–363. [Google Scholar] [CrossRef]

- Gadioli, R.; Morais, J.A.; Waldman, W.R.; De Paoli, M.A. The role of lignin in polypropylene composites with semi-bleached cellulose fibers: Mechanical properties and its activity as antioxidant. Polym. Degrad. Stab. 2014, 108, 23–34. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, C.; Weng, Y. Effects of CaCO3 surface modification and water spraying on the weathering properties of PBAT/CaCO3 films. Polym. Test. 2021, 102, 107334. [Google Scholar] [CrossRef]

- Joseph, P.V.; Rabello, M.S.; Mattoso, L.H.C.; Joseph, K.; Thomas, S. Environmental effects on the degradation behaviour of sisal fibre reinforced polypropylene composites. Compos. Sci. Technol. 2002, 62, 1357–1372. [Google Scholar] [CrossRef]

- Barczewski, M.; Andrzejewski, J.; Matykiewicz, D.; Krygier, A.; Kloziński, A. Influence of accelerated weathering on mechanicaland thermomechanical properties of poly(lactic acid)composites with natural waste filler. Polimery 2019, 64, 119–125. [Google Scholar] [CrossRef]

- Sanvezzo, P.B.; Branciforti, M.C. Recycling of industrial waste based on jute fiber-polypropylene: Manufacture of sustainable fiber-reinforced polymer composites and their characterization before and after accelerated aging. Ind. Crops Prod. 2021, 168, 113568. [Google Scholar] [CrossRef]

- Watanabe, R.; Sugahara, A.; Hagihara, H.; Sakamoto, K.; Nakajima, Y.; Naganawa, Y. Polypropylene-Based Nanocomposite with Enhanced Aging Stability by Surface Grafting of Silica Nanofillers with a Silane Coupling Agent Containing an Antioxidant. ACS Omega 2020, 5, 12431–12439. [Google Scholar] [CrossRef]

- Valadez-Gonzalez, A.; Veleva, L. Mineral filler influence on the photo-oxidation mechanism degradation of high-density polyethylene. Part II: Natural exposure test. Polym. Degrad. Stab. 2004, 83, 139–148. [Google Scholar] [CrossRef]

- Yang, R.; Yu, J.; Liu, Y.; Wang, K. Effects of inorganic fillers on the natural photo-oxidation of high-density polyethylene. Polym. Degrad. Stab. 2005, 88, 333–340. [Google Scholar] [CrossRef]

- Seldén, R.; Nyström, B.; Långström, R. UV aging of poly(propylene)/wood-fiber composites. Polym. Compos. 2004, 25, 543–553. [Google Scholar] [CrossRef]

- Tochacek, J.; Vrátníčková, Z. Polymer life-time prediction: The role of temperature in UV accelerated ageing of polypropylene and its copolymers. Polym. Test. 2014, 36, 82–87. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, R.; Luo, J. Enhancing weathering resistance of UV-curable coatings by using TiO2 particles as filler. Prog. Org. Coat. 2022, 169, 106936. [Google Scholar] [CrossRef]

- Yousif, E.; Haddad, R. Photodegradation and photostabilization of polymers, especially polystyrene: Review. Springerplus 2013, 2, 398. [Google Scholar] [CrossRef]

- Zapata, P.A.; Palza, H.; Díaz, B.; Armijo, A.; Sepúlveda, F.; Ortiz, J.A.; Ramírez, M.P.; Oyarzún, C. Effect of CaCO3 Nanoparticles on the Mechanical and Photo-Degradation Properties of LDPE. Molecules 2019, 24, 126. [Google Scholar] [CrossRef]

- Piekarska, K.; Piorkowska, E.; Bojda, J. The influence of matrix crystallinity, filler grain size and modification on properties of PLA/calcium carbonate composites. Polym. Test. 2017, 62, 203–209. [Google Scholar] [CrossRef]

- Luo, Z.; Wang, Y.; Wang, H.; Feng, S. Impact of nano-CaCO3-LDPE packaging on quality of fresh-cut sugarcane. J. Sci. Food Agric. 2014, 94, 3273–3280. [Google Scholar] [CrossRef]

- Silapasorn, K.; Sombatsompop, K.; Kositchaiyong, A.; Wimolmala, E.; Markpin, T. Effect of chemical structure of thermoplastics on antibacterial activity and physical diffusion of triclosan doped in vinyl thermoplastics and their composites with CaCO3. J. Appl. Polym. Sci. 2011, 121, 253–261. [Google Scholar] [CrossRef]

- BS EN ISO 527-2:1996; Plastics—Determination of Tensile Properties—Part 2: Test Conditions for Moulding and Extrusion Plastics. BSI: London, UK, 1996.

- BS EN ISO 178:2010+A1:2013; Plastics—Determination of Flexural Properties. BSI: London, UK, 2010.

- ASTM D2244; Standard Practice for Calculation of Color Tolerances and Color Differences from Instrumentally Measured Color Coordinates. Conshohocken, PA, USA, 2021. Available online: https://www.astm.org/d2244-21.html (accessed on 17 July 2021).

- Fabiyi, J.S.; McDonald, A.G.; Wolcott, M.P.; Griffiths, P.R. Wood plastic composites weathering: Visual appearance andchemical changes. Polym. Degrad. Stab. 2008, 93, 1405–1414. [Google Scholar] [CrossRef]

- Zapata, P.A.; Palza, H.; Cruz, L.S.; Lieberwirth, I.; Catalina, F.; Corrales, T.; Rabagliati, F.M. Polyethylene and poly(ethylene-co-1-octadecene) composites with TiO2 based nanoparticles by metallocenic “in situ” polymerization. Polymer 2013, 54, 2690–2698. [Google Scholar] [CrossRef]

- Sun, Z.; Fan, H.; Chen, Y.; Huang, J. Synthesis of self-matting waterborne polyurethane coatings with excellent transmittance. Polym. Int. 2018, 67, 78–84. [Google Scholar] [CrossRef]

| Material | Mean Tensile Modulus (GPa) ± SD # | Mean UTS (MPa) ± SD # |

|---|---|---|

| CNW | 5.67 ± 0.51 | 39.81 ± 5.29 |

| KW | 7.78 ± 0.49 | 40.52 ± 4.90 |

| KWF_1 | 6.34 ± 0.29 | 32.22 ± 2.76 |

| KWF_2 | 4.40 ± 0.37 | 17.63 ± 1.61 |

| Material | Flexural Modulus (GPa) ± SD # | Flexural Strength (MPa) ± SD # |

|---|---|---|

| CNW | 5.90 ± 1.46 | 112.35 ± 5.13 |

| KW | 6.19 ± 0.16 | 112.81 ± 4.40 |

| KWF_1 | 4.22 ± 0.23 | 74.78 ± 1.54 |

| KWF_2 | 3.62 ± 0.25 | 51.99 ± 3.34 |

| Material | Before UV Exposure± SD # | After UV Exposure± SD # |

|---|---|---|

| CNW | 85.0 ± 0.70 | 87.0 ± 0.50 |

| KW | 84.8 ± 0.54 | 85.0 ± 0.48 |

| KWF_1 | 81.6 ± 0.55 | 81.8 ± 0.38 |

| KWF_2 | 78.5 ± 0.50 | 78.0 ± 1.22 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sit, M.; Dashatan, S.; Zhang, Z.; Dhakal, H.N.; Khalfallah, M.; Gamer, N.; Ling, J. Inorganic Fillers and Their Effects on the Properties of Flax/PLA Composites after UV Degradation. Polymers 2023, 15, 3221. https://doi.org/10.3390/polym15153221

Sit M, Dashatan S, Zhang Z, Dhakal HN, Khalfallah M, Gamer N, Ling J. Inorganic Fillers and Their Effects on the Properties of Flax/PLA Composites after UV Degradation. Polymers. 2023; 15(15):3221. https://doi.org/10.3390/polym15153221

Chicago/Turabian StyleSit, Moumita, Saeid Dashatan, Zhongyi Zhang, Hom Nath Dhakal, Moussa Khalfallah, Nicolas Gamer, and Jarren Ling. 2023. "Inorganic Fillers and Their Effects on the Properties of Flax/PLA Composites after UV Degradation" Polymers 15, no. 15: 3221. https://doi.org/10.3390/polym15153221

APA StyleSit, M., Dashatan, S., Zhang, Z., Dhakal, H. N., Khalfallah, M., Gamer, N., & Ling, J. (2023). Inorganic Fillers and Their Effects on the Properties of Flax/PLA Composites after UV Degradation. Polymers, 15(15), 3221. https://doi.org/10.3390/polym15153221