Ballistic Performance, Thermal and Chemical Characterization of Ubim Fiber (Geonoma baculifera) Reinforced Epoxy Matrix Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

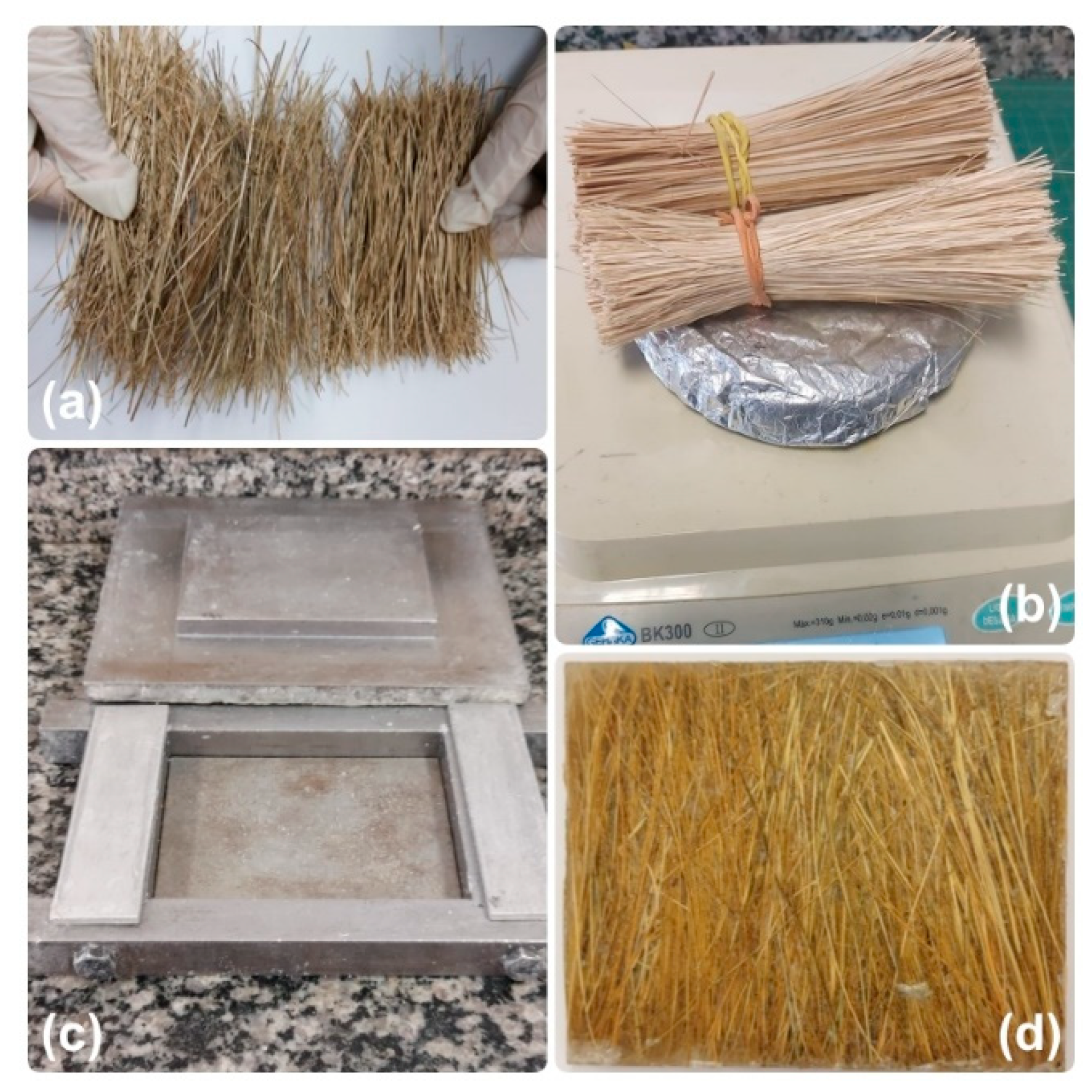

2.2. Composites Preparation

2.3. Characterization

2.3.1. Fourier Transform Infrared Spectroscopy (FTIR)

2.3.2. Thermogravimetric Analysis (TGA)

2.3.3. Differential Scanning Calorimetry (DSC)

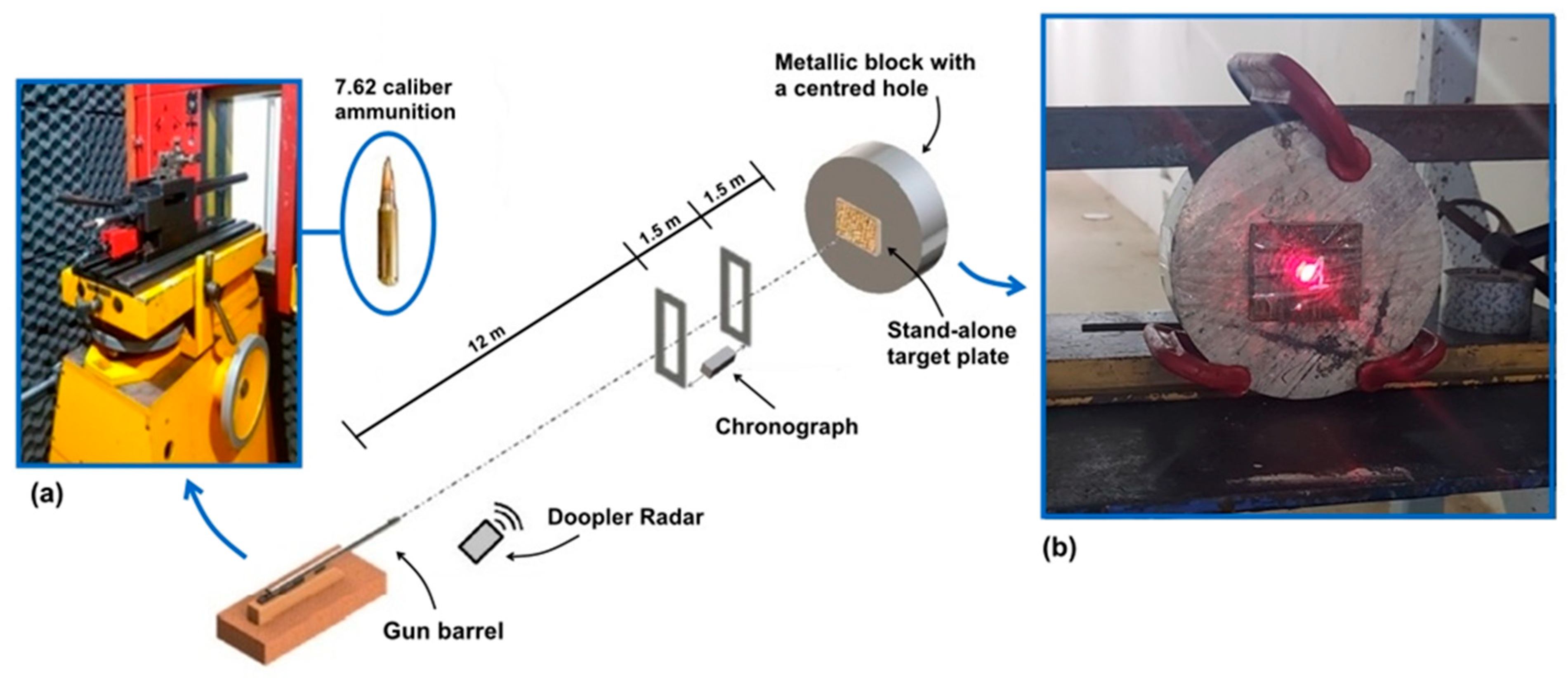

2.3.4. Ballistic Tests

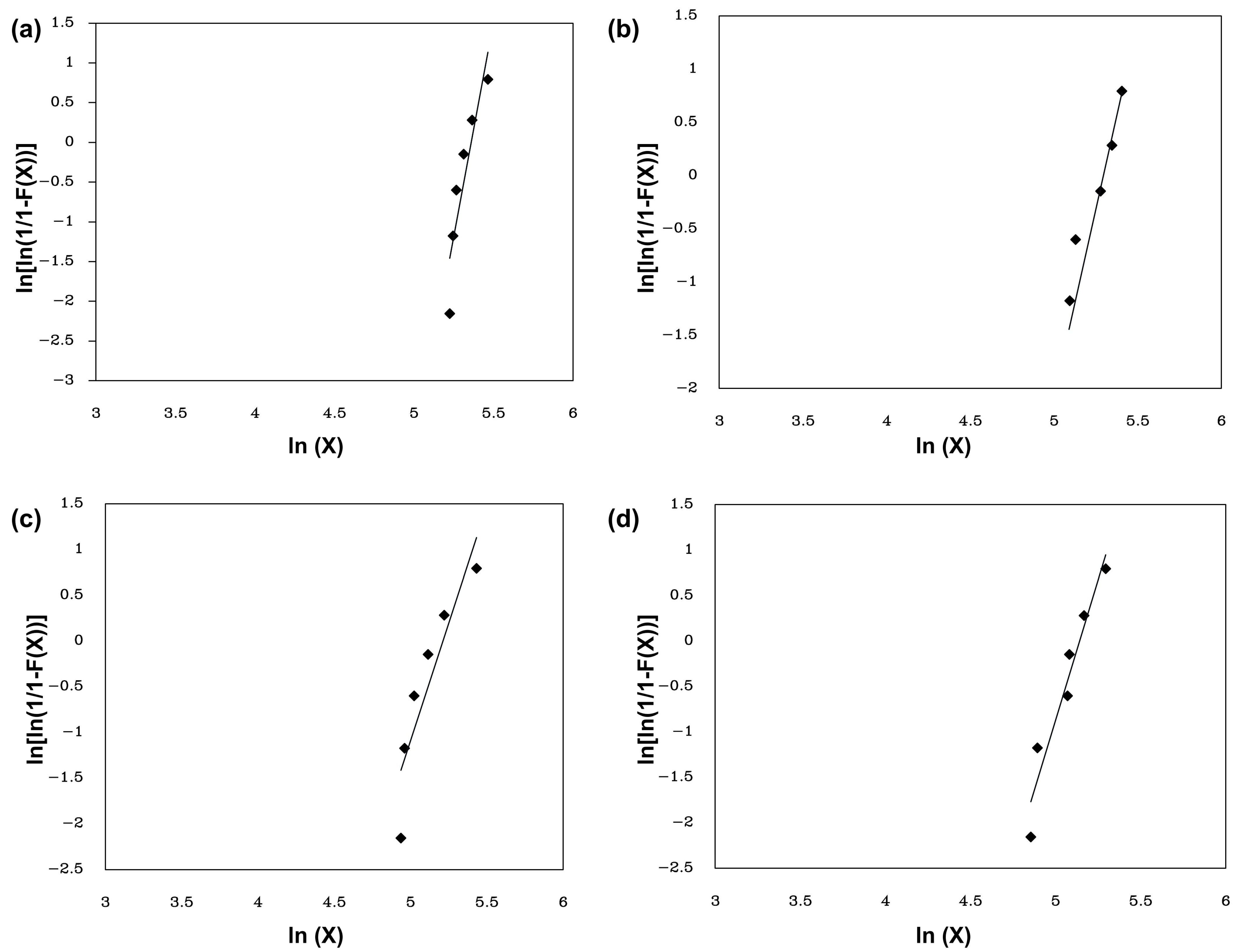

2.3.5. Weibull Statistical Analysis

3. Results and Discussion

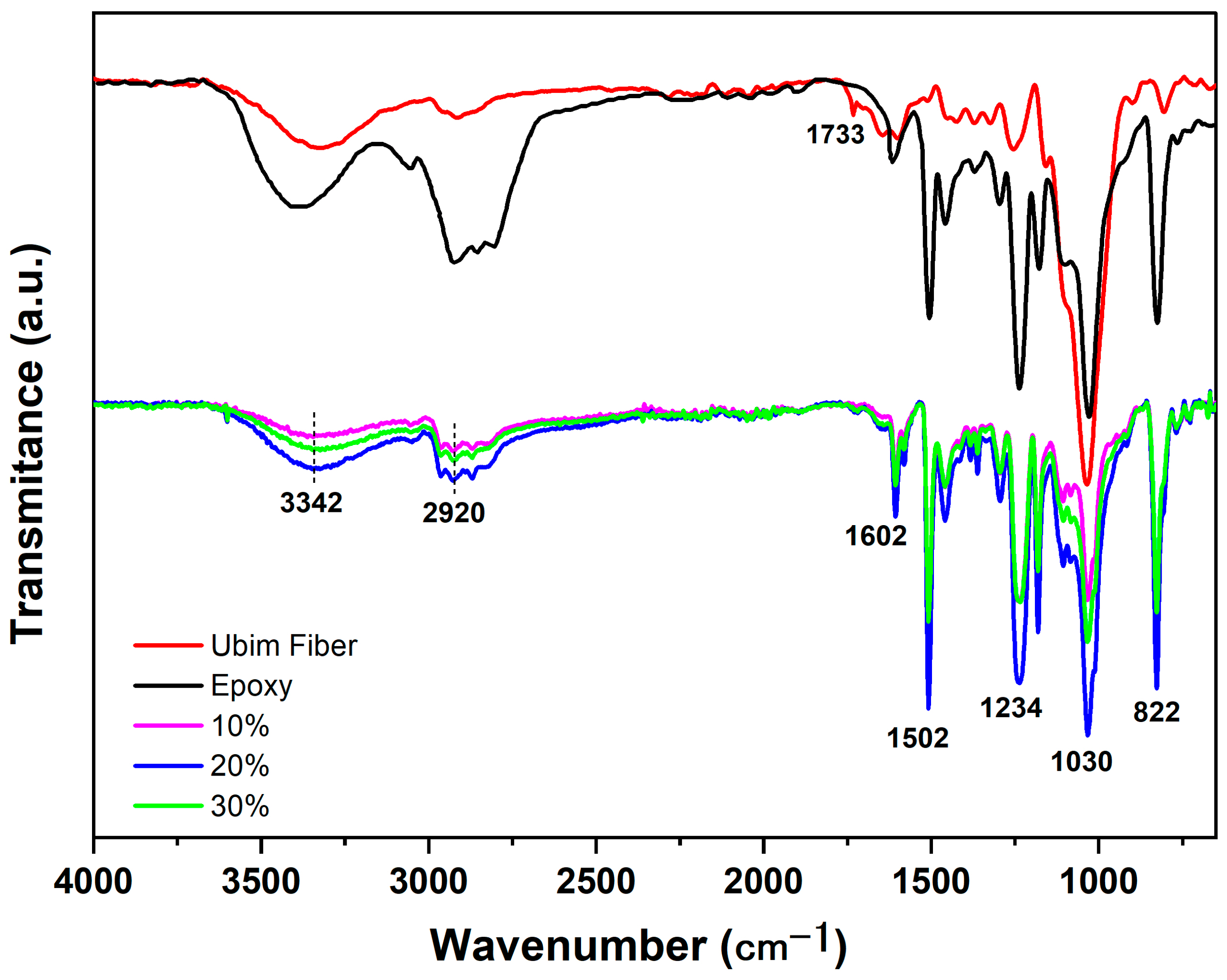

3.1. FTIR Results

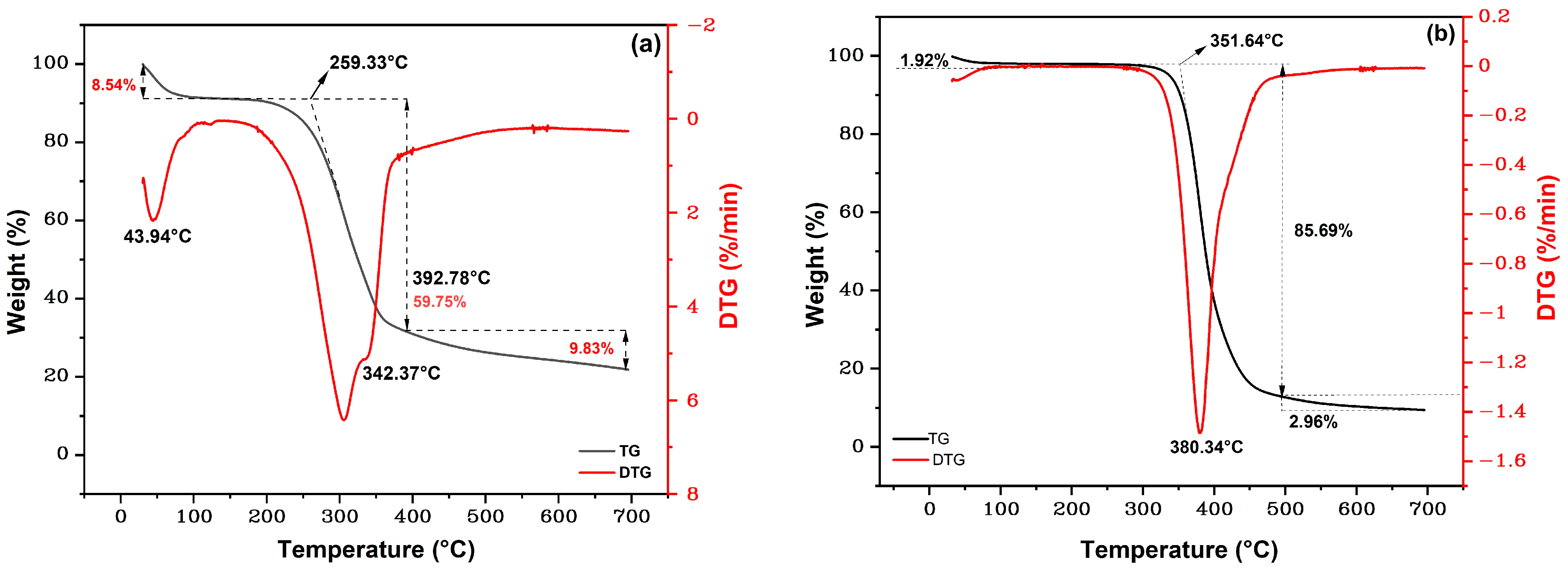

3.2. Thermogravimetric Analysis (TGA)

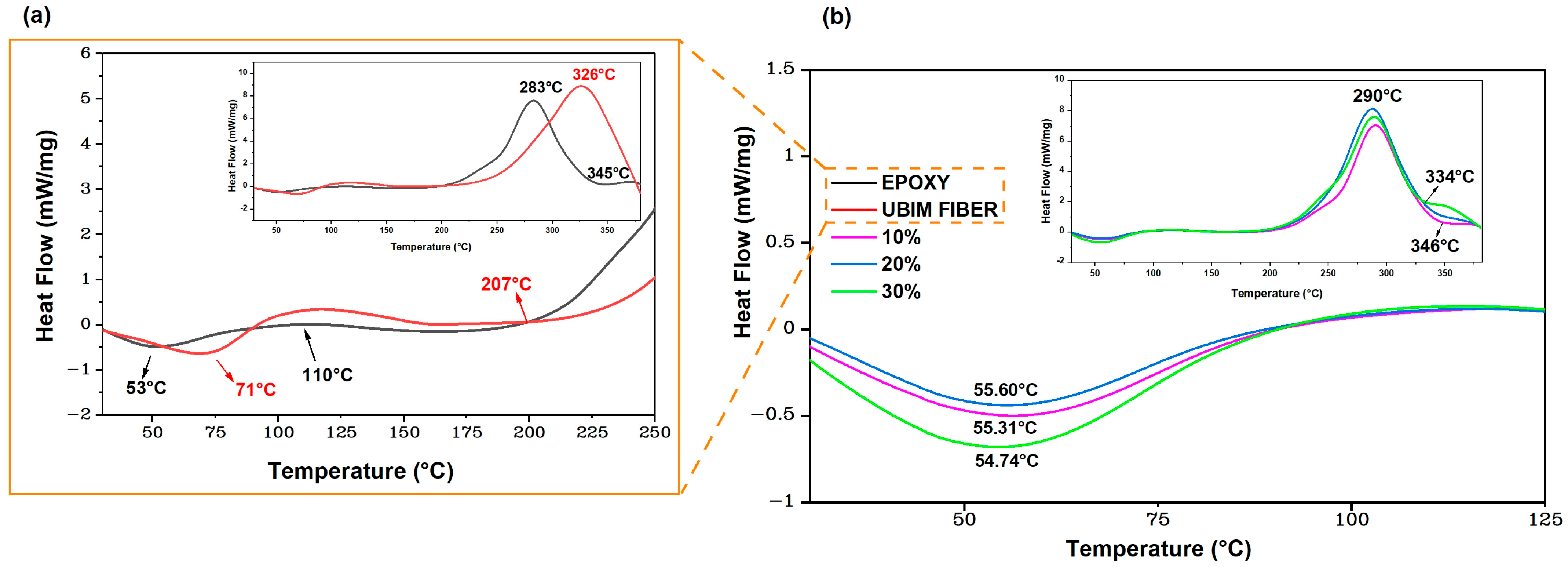

3.3. Differential Scanning Calorimetry

3.4. Ballistic Tests

4. Summary and Conclusions

- The results of the TGA analysis indicated that there was intermediate thermal stability in the composites when compared to the thermal behavior of both neat epoxy resin and ubim fiber. The volumetric fraction of fibers added as reinforcement influenced the thermal stability of the composites. The initial degradation temperature, as well as the maximum degradation temperature, decreased as more fiber was added. On average, the composites had significant mass loss above 325 °C, which may be a working proposition for the limited use of ubim fiber epoxy composites around this temperature.

- The DSC curves revealed a slight increase in the temperature of the endothermic peak of the composites in relation to the peak of the pure epoxy, observed by the displacement of the curves. This difference is related to the amount of fibers added as reinforcement due to the moisture present in the ubim fiber, in addition to a possible contribution of the epoxy matrix to the glass transition temperature (Tg).

- The Tg was obtained at 71 °C for the ubim fiber, at 53 °C for the pure epoxy resin, and ranging from 54.74 to 55.60 °C for the ubim fiber reinforced epoxy composites.

- The FTIR analysis showed expected results, with bands referring to molecular vibrations of functional groups belonging to the basic constituents of natural lignocellulosic fibers (NLFs), such as OH, CH2, C-O, and C-O-C, highly rich in cellulose, hemicellulose, and lignin.

- These results emphasize the importance of using NLFs as reinforcement in polymeric composites and add value to the existing knowledge about fibers, especially ubim, which has not yet been published in the literature. This study should contribute to the multiple applications expected for ubim fiber-reinforced epoxy composites in terms of thermal stability and chemical properties.

- The ballistic tests of residual velocity indicated that the energy absorbed by the composite plates decreased as the ubim fiber content increased. The same behavior was observed in the limit velocity measurements.

- The absorbed energy (Eabs) and the Weibull characteristic parameter were found to be quite similar within standard deviations.

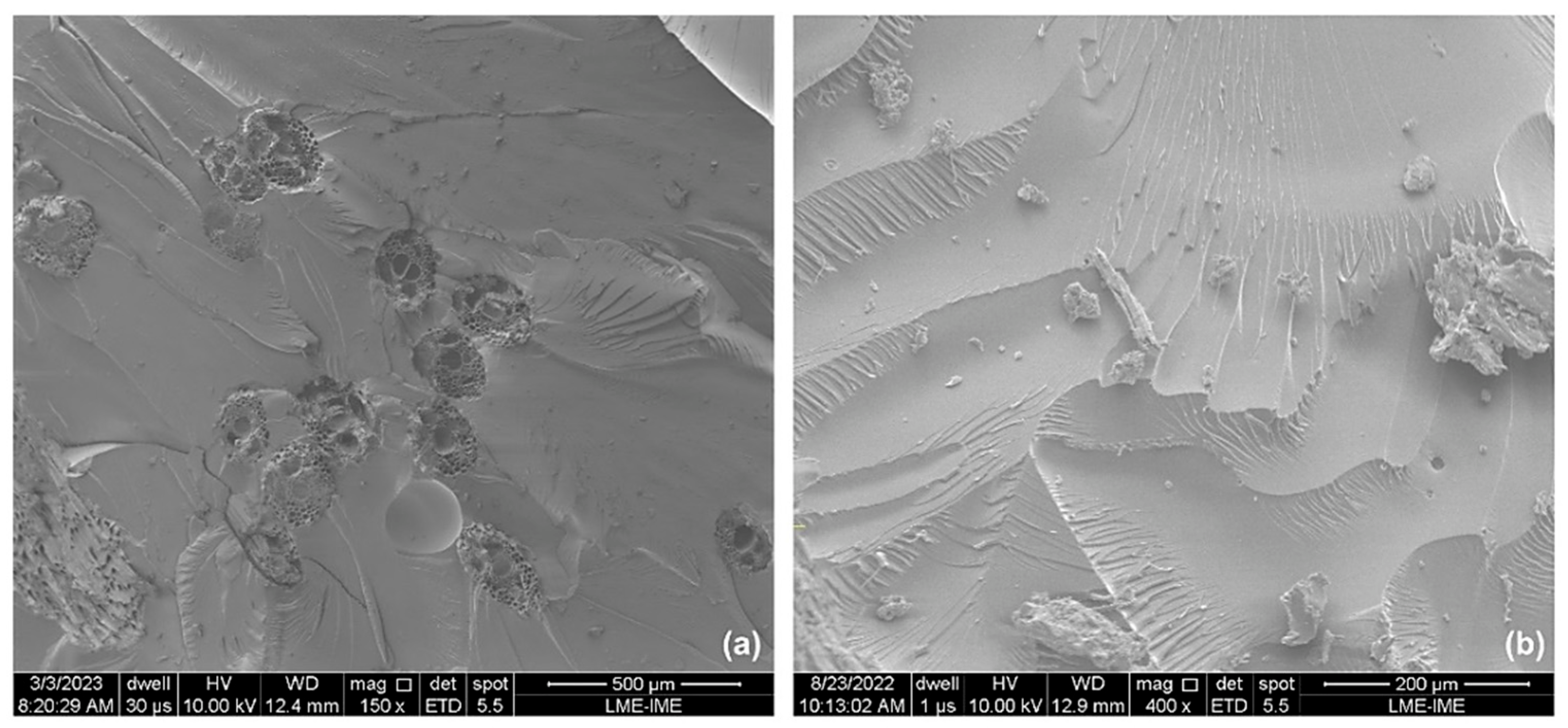

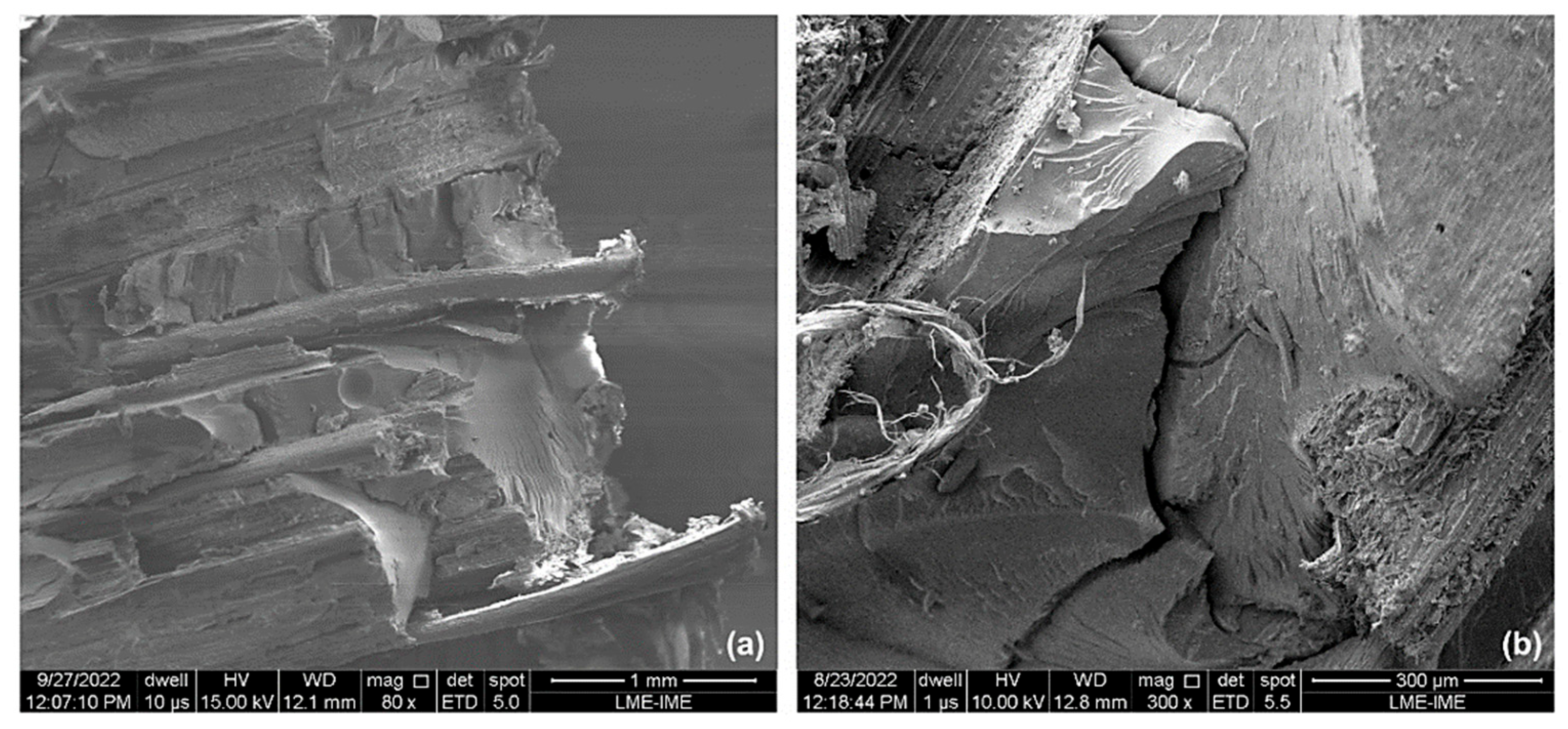

- The visible macrocracks developed in the composites containing 10 and 20 vol% of ubim fibers compromise their potential application in ballistic armor. However, in the composite with 30 vol% of fibers, only the projectile’s perforation hole was visible, indicating that its integrity was maintained.

- SEM analysis revealed that the main damage responsible for macrocracks is associated with detachment and delamination of the fiber/matrix, indicating poor adhesion at the interface. Additionally, fiber breakage and river marks were frequently observed.

- The more intense performance of the brittle fracture mechanisms of the epoxy resin tended to dissipate more energy, which may explain the high absorption energy in the composites with a smaller volumetric fraction.

- The ballistic performance of the composites, even though it may have been reduced due to the increase in ubim fiber content, still compares to that of other natural fibers documented in the literature, making it a viable alternative for use in ballistic armor.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Kumar, R.; Haq, M.I.U.; Raina, A.; Anand, A. Industrial applications of natural fiber-reinforced polymer composites—Challenges and opportunities. Int. J. Sustain. Eng. 2018, 12, 212–220. [Google Scholar] [CrossRef]

- Li, M.; Pu, Y.; Thomas, V.M.; Yoo, C.G.; Ozcan, S.; Deng, Y.; Nelson, K.; Ragauskas, A.J. Recent advancements of plant-based natural fiber—Reinforced composites and their applications. Compos. Part B Eng. 2020, 200, 108254. [Google Scholar] [CrossRef]

- Hasan, K.M.F.; Horváth, P.G.; Alpár, T. Potential Natural Fiber Polymeric Nanobiocomposites: A Review. Polymers 2020, 12, 1072. [Google Scholar] [CrossRef]

- Zhang, Z.; Cai, S.; Li, Y.; Wang, Z.; Long, Y.; Yu, T.; Shen, Y. High performances of plant fiber reinforced composites—A new insight from hierarchical microstructures. Compos. Sci. Technol. 2020, 194, 108151. [Google Scholar] [CrossRef]

- Rangappa, S.M.; Madhu, P.; Jawaid, M.; Senthamaraikannan, P.; Senthil, S.; Pradeep, S. Characterization and properties of natural fiber polymer composites: A comprehensive review. J. Clean. Prod. 2018, 172, 566–581. [Google Scholar] [CrossRef]

- Pickering, K.; Efendy, M.A.; Le, T. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A 2016, 83, 98–112. [Google Scholar] [CrossRef]

- Mohammed, L.; Ansari, M.; Pua, G.; Jawaid, M.; Islam, S. A Review on Natural Fiber Reinforced Polymer Composite and Its Applications. Int. J. Polym. Sci. 2015, 2015, 243947. [Google Scholar] [CrossRef]

- Thakur, V.; Thakur, M.K.; Gupta, R.K. Review: Raw Natural Fiber—Based Polymer Composites. Int. J. Polym. Anal. Charact. 2014, 19, 256–271. [Google Scholar] [CrossRef]

- Armanfard, A.; Melenka, G. Experimental evaluation of carbon fibre, fibreglass and aramid tubular braided composites under combined tension–torsion loading. Compos. Struct. 2021, 269, 114049. [Google Scholar] [CrossRef]

- Cao, C.; Peng, J.; Liang, X.; Saiz, E.; Wolf, S.; Wagner, H.D.; Jiang, L.; Cheng, Q. Strong, conductive aramid fiber func-tionalized by graphene. Compos. Part A 2021, 140, 106161. [Google Scholar] [CrossRef]

- Potluri, R.; Krishna, N.C. Potential and applications of green composites in industrial space. Mater. Today: Proc. 2020, 22, 2041–2048. [Google Scholar] [CrossRef]

- Bressiani Júnior, I.; Belini, U.L.; Ellenberger, A.; Keinert, A.C. Fibras naturais e compósitos nas indústrias de mobilidade. Ix Sustentável 2020, 6, 4–129. [Google Scholar] [CrossRef]

- Di Bella, G.; Mistretta, M.C.; Galtieri, G.; Borsellino, C.; Valenza, A. Effects of natural fibres reinforcement in lime plasters (kenaf and sisal vs. Polypropylene). Constr. Build. Mater. 2014, 58, 159–165. [Google Scholar] [CrossRef]

- Oliveira, M.S.; Filho, F.D.C.G.; Da Luz, F.S.; Pereira, A.C.; Demóstenes, L.C.D.C.; Nascimento, L.F.C.; Lopera, H.A.C.; Monteiro, S.N. Statistical analysis of notch toughness of epoxy matrix composites reinforced with fique fabric. J. Mater. Res. Technol 2019, 8, 6051–6057. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Drelich, J.W.; Lopera, H.A.C.; Nascimento, L.F.C.; da Luz, F.S.; da Silva, L.C.; dos Santos, J.L.; da Costa Garcia Filho, F.; de Assis, F.S.; Lima, É.P.; et al. Natural Fibers Reinforced Polymer Composites Applied in Ballistic Multilayered Armor for Personal Protection—An Overview. In Green Materials Engineering. The Minerals, Metals & Materials Series; Ikhmayies, S., Li, J., Vieira, C., Margem, J.I., de Oliveira Braga, F., Eds.; Springer: Cham, Switzerland, 2019. [Google Scholar] [CrossRef]

- Garcia Filho, F.D.C.; Oliveira, M.S.; Pereira, A.C.; Nascimento, L.F.C.; Matheus, J.R.G.; Monteiro, S.N. Ballistic behavior of epoxy matrix composites reinforced with piassava fiber against high energy ammunition. J. Mater. Res. Technol. 2020, 9, 1734–1741. [Google Scholar] [CrossRef]

- de Mendonça Neuba, L.; Pereira Junio, R.F.; Ribeiro, M.P.; Souza, A.T.; de Sousa Lima, E.; Garcia Filho, F.D.C.; da Silva Figueiredo, A.B.-H.; de Oliveira Braga, F.; de Azevedo, A.R.G.; Monteiro, S.N.; et al. Promising mechanical, thermal, and ballistic properties of novel epoxy composites reinforced with Cyperus malaccensis sedge fiber. Polymers 2020, 12, 1776. [Google Scholar] [CrossRef]

- Henderson, A.; Galeano, G.; Bernal, R. Field Guide to the Palms of the Americas; Princeton University Press: Princeton, NJ, USA, 2019; Volume 5390, p. 223. [Google Scholar]

- Oliveira, J.; Potiguara, R.C.D.V.; Lobato, L.C.B. Vegetal fibers used in artisan fishing in the Salgado region, Pará. Bol. Mus. Para. Emílio Goeldi. Ciênc. Hum. 2006, 1, 113–127. [Google Scholar] [CrossRef]

- Ouarhim, W.; Zari, N.; Bouhfid, R. Mechanical performance of natural fibers-based thermosetting composites. In Mechanical and Physical Testing of Biocomposites, Fibre—Reinforced Composites and Hybrid Composites; Woodhead Publishing: Sawston, UK, 2019; pp. 43–60. [Google Scholar] [CrossRef]

- Ahmad, F.; Choi, H.S.; Park, M.K. A review: Natural fiber composites selection in view of mechanical, light weight, and economic properties. Macromol. Mater. Eng. 2015, 300, 10–24. [Google Scholar] [CrossRef]

- Nayak, S.Y.; Sultan, M.T.H.; Shenoy, S.B.; Kini, C.R.; Samant, R.; Shah, A.U.M.; Amuthakkannan, P. Potential of natural fibers in composites for ballistic applications—A review. J. Nat. Fibers 2022, 19, 1648–1658. [Google Scholar] [CrossRef]

- Oliveira, M.S.; da Luz, F.S.; Teixeira Souza, A.; Demosthenes, L.C.d.C.; Pereira, A.C.; Garcia Filho, F.D.C.; Braga, F.D.O.; da Silva Figueiredo, A.B.-H.; Monteiro, S.N. Tucum Fiber from Amazon Astrocaryum Vulgare Palm Tree: Novel Reinforcement for Polymer Composites. Polymers 2020, 12, 2259. [Google Scholar] [CrossRef]

- Meliande, N.M.; da Silveira, P.H.P.M.; Monteiro, S.N.; Nascimento, L.F.C. Tensile Properties of Curaua—Aramid Hybrid Laminated Composites for Ballistic Helmet. Polymers 2022, 14, 2588. [Google Scholar] [CrossRef]

- Ribeiro, M.P.; Neuba, L.d.M.; da Silveira, P.H.P.M.; da Luz, F.S.; da Silva Figueiredo, A.B.-H.; Monteiro, S.N.; Moreira, M.O. Mechanical, Thermal and Ballistic Performance of Epoxy Composites Reinforced with Cannabis Sativa Hemp Fabric. J. Mater. Res. Technol. 2021, 12, 221–233. [Google Scholar] [CrossRef]

- E-1131; TGA Analysis Testing Services. ASTM International: West Conshohocken, PA, USA, 2020.

- NIJ 0101.06; National Criminal Justice Reference Service. US Department of Justice, & National Institute of Justice. Ballistic Resistance of Body Armor. National Institute of Justice: Washington, DC, USA, 2008.

- Yahaya, R.; Sapuan, S.M.; Jawaid, M.; Leman, Z.; Zainudin, E.S. Investigating ballistic impact properties of woven kenaf-aramid hybrid composites. Fibers Polym. 2016, 17, 275–281. [Google Scholar] [CrossRef]

- Oliveira, M.S.; Garcia Filho, F.C.; Pereira, A.C.; Nunes, L.F.; da Luz, F.S.; Braga, F.O.; Colorado, H.A.; Monteiro, S.N. Ballistic performance and statistical evaluation of multilayered armor with epoxy-fique fabric composites using the Weibull analysis. J. Mater. Res. Technol. 2019, 8, 5899–5908. [Google Scholar] [CrossRef]

- Vijay, R.; James Dhilip, J.D.; Gowtham, S.; Harikrishnan, S.; Chandru, B.; Amarnath, M.; Khan, A. Characterization of Natural Cellulose Fiber from the Barks of Vachellia Farnesiana. J. Nat. Fibers 2022, 19, 1343–1352. [Google Scholar] [CrossRef]

- Manimaran, P.; Senthamaraikannan, P.; Murugananthan, K.; Sanjay, M.R. Physicochemical Properties of New Cellulosic Fibers from Azadirachta Indica Plant. J. Nat. Fibers 2018, 15, 29–38. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, X.; Fa, C.; Zhang, Y.; Xiong, J.; Chen, H. Investigation on characteristics and properties of bagasse fibers: Performances of asphalt mixtures with bagasse fibers. Constr. Build. Mater. 2020, 248, 118648. [Google Scholar] [CrossRef]

- Neves, A.C.C.; Rohen, L.A.; Mantovani, D.P.; Carvalho, J.P.; Vieira, C.M.F.; Lopes, F.P.; Simonassi, N.T.; da Luz, F.S.; Monteiro, S.N. Comparative mechanical properties between biocomposites of Epoxy and polyester matrices reinforced by hemp fiber. J. Mater. Res. Technol. 2020, 9, 1296–1304. [Google Scholar] [CrossRef]

- Belouadah, Z.; Ati, A.; Rokbi, M. Characterization of New Natural Cellulosic Fiber from Lygeum Spartum L. Carbohydr Polym 2015, 134, 429–437. [Google Scholar] [CrossRef]

- Vinod, A.; Sanjay, M.R.; Siengchin, S. Fatigue and thermo-mechanical properties of chemically treated Morinda citrifolia fiber-reinforced bio-epoxy composite: A sustainable green material for cleaner production. J. Clean. Prod. 2021, 326, 129411. [Google Scholar] [CrossRef]

- Reis, R.H.M.; Cândido, V.S.; Nunes, L.F.; Monteiro, S.N. Chemical and morphological characterization of guaruman fiber. In Green Materials Engineering; Ikhmayies, S., Li, J., Vieira, C., Margem, J., de Oliveira Braga, F., Eds.; Springer: Cham, Switzerland, 2019; pp. 107–113. [Google Scholar] [CrossRef]

- Azam, F.; Ahmad, F.; Ahmad, S.; Zafar, M.S.; Ulker, Z. Synthesis and characterization of natural fibers reinforced alginate hydrogel fibers loaded with diclofenac sodium for wound dressings. Int. J. Biol. Macromol. 2023, 241, 124623. [Google Scholar] [CrossRef]

- Kayambu, A.; Ramasubbu, R. Physical Chemical and Surface Morphological Characterization of Areca Catechu Fiber. J. Nat. Fibers 2022, 19, 1–14. [Google Scholar] [CrossRef]

- Gopinath, R.; Billigraham, P.; Sathishkumar, T.P. Characterization Studies on New Cellulosic Fiber Extracted from Leucaena Leucocephala Tree. J. Nat. Fibers 2023, 20, 2157922. [Google Scholar] [CrossRef]

- Maheshwaran, M.V.; Hyness, N.R.J.; Senthamaraikannan, P.; Saravanakumar, S.S.; Sanjay, M.R. Characterization of natural cellulosic fiber from Epipremnum aureum stem. J. Nat. Fibers 2018, 15, 789–798. [Google Scholar] [CrossRef]

- da Silva, I.L.A.; Bevitori, A.B.; Rohen, L.A.; Muylaert Margem, F.; de Oliveira Braga, F.; Monteiro, S.N. Characterization by Fourier transform infrared (FTIR) analysis for natural jute fiber. Mater. Sci. Forum 2016, 869, 283–287. [Google Scholar] [CrossRef]

- Zhuang, J.; Li, M.; Pu, Y.; Ragauskas, A.; Yoo, C. Observation of Potential Contaminants in Processed Biomass Using Fourier Transform Infrared Spectroscopy. Appl. Sci. 2020, 10, 4345. [Google Scholar] [CrossRef]

- Biswas, M.C.; Ford, E. Using Sodium Polyacrylate to Gel-Spin Lignin/Poly (Vinyl Alcohol) Fiber at High Lignin Content. Polymers 2022, 14, 2736. [Google Scholar] [CrossRef]

- Belhadj, O.; Hammiche, D.; Boukerrou, A.; Gérard, J.F.; Duchet, J. Effect of alfa fiber loading on the mechanical, physical and dielectric properties of epoxy-amine composite. J. Compos. Mater. 2022, 56, 3563–3573. [Google Scholar] [CrossRef]

- González, M.G.; Cabanelas, J.C.; Baselga, J. Applications of FTIR on epoxy resins-identification, monitoring the curing process, phase separation and water uptake. Infrared Spectroscopy—Materials Science. Eng. Technol. 2012, 2, 261–284. [Google Scholar]

- Chee, S.S.; Jawaid, M.; Sultan, M.T.H. Thermal Stability and Dynamic Mechanical Properties of Kenaf/Bamboo Fibre Reinforced Epoxy Composites. Bioresources 2017, 12, 7118–7132. [Google Scholar]

- Hemachandra Reddy, K.; Reddy, B.M.; Reddy, R.M.; Reddy, P.V.; Reddy, Y.M.; Rao, H.R. Effects of Carbon Fiber Hybridization on Mechanical, Structural, and Thermal Properties of Cordia dichotoma Fiber-Reinforced Epoxy Composite. J. Nat. Fibers 2023, 20, 2216–2950. [Google Scholar] [CrossRef]

- Behera, S.; Mohanty, J.R.; Nath, G.; Mahanta, T.K. Exploring Properties of Short Randomly Oriented Rattan Fiber Reinforced Epoxy Composite for Automotive Application. J. Nat. Fibers 2023, 20, 2163024. [Google Scholar] [CrossRef]

- Silva, I.D.S.; Barros, J.J.P.; Albuquerque, A.; Jaques, N.G.; Fook, M.V.L.; Wellen, R.M.R. Insights into the curing kinetics of epoxy/PLA: Implications of the networking structure. Express Polym. Lett. 2020, 14, 12. [Google Scholar] [CrossRef]

- Ibraheem, S.; Standard, O.; Koshy, P.; Devasahyam, S.; Bandyopadhyay, S. SEM study of debonding/pull-out features FTIR analysis of bonding in fly ash-epoxy particulate composites. Int. J. Enhanc. Res. Sci. Technol. Eng 2016, 5, 230–244. [Google Scholar]

- Jiang, S.; Zha, S.; Xia, L.; Guan, R. Synthesis and characterization of diphenylsilanediol modified epoxy resin and curing agent. J. Adhes. Sci. Technol. Taylor Fr. 2015, 29, 641–656. [Google Scholar] [CrossRef]

- Şengül, B.; Tüzün, F.N. Investigation and assessment of epoxy resin adhesives using Fourier-transform infrared spectrometry. Mater. Und Werkst. 2023, 54, 345–358. [Google Scholar] [CrossRef]

- Abraham, E.; Deepa, B.; Pothan, L.A.; Jacob, M.; Thomas, S.; Cvelbar, U.; Anandjiwala, R. Extraction of Nanocellulose Fibrils from Lignocellulosic Fibres: A Novel Approach. Carbohydr. Polym. 2011, 86, 1468–1475. [Google Scholar] [CrossRef]

- Saravanakumar, S.S.; Kumaravel, A.; Nagarajan, T.; Sudhakar, P.; Baskaran, R. Characterization of a Novel Natural Cellulosic Fiber from Prosopis Juliflora Bark. Carbohydr. Polym. 2013, 92, 1928–1933. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Calado, V.; Rodriguez, R.J.S.; Margem, F.M. Thermogravimetric Stability of Polymer Composites Reinforced with Less Common Lignocellulosic Fibers—An Overview. J. Mater. Res. Technol. 2012, 1, 117–126. [Google Scholar] [CrossRef]

- Lima, R.N.; Paixão, R.L.; Marques, R.B.; Malveira, J.Q.; Furtini, J.A.O.; Rios, M.A.d.S. Investigação do Potencial do Talo e da Palha da Carnaúba para utilização como biocombustível. Matéria 2019, 24, 1–12. [Google Scholar] [CrossRef]

- Indran, S.; Edwin Raj, R.; Sreenivasan, V.S. Characterization of New Natural Cellulosic Fiber from Cissus Quadrangularis Root. Carbohydr. Polym. 2014, 110, 423–429. [Google Scholar] [CrossRef]

- Kathirselvam, M.; Kumaravel, A.; Arthanarieswaran, V.; Saravanakumar, S. Isolation and characterization of cellulose fibers from thespesia populnea barks: A study on physicochemical and structural properties. Int. J. Biol. Macromol. 2019, 129, 396–406. [Google Scholar] [CrossRef]

- Bhatnagar, A. Lightweight Ballistic Composites: Military and Law-Enforcement Applications; Woodhead Publishing: Sawston, UK, 2016. [Google Scholar]

- Yao, F.; Wu, Q.; Lei, Y.; Guo, W.; Xu, Y. Thermal Decomposition Kinetics of Natural Fibers: Activation Energy with Dynamic Thermogravimetric Analysis. Polym. Degrad. Stab. 2008, 93, 90–98. [Google Scholar] [CrossRef]

- Silva, T.T.D.; Silveira, P.H.P.M.D.; Ribeiro, M.P.; Lemos, M.F.; da Silva, A.P.; Monteiro, S.N.; Nascimento, L.F.C. Thermal and chemical characterization of kenaf fiber (Hibiscus cannabinus) reinforced epoxy matrix composites. Polymers 2021, 13, 2016. [Google Scholar] [CrossRef]

- Junio, R.F.P.; Nascimento, L.F.C.; Neuba, L.D.M.; Souza, A.T.; Moura, J.V.B.; Garcia Filho, F.D.C.; Monteiro, S.N. Copernicia prunifera leaf fiber: A promising new reinforcement for epoxy composites. Polymers 2020, 12, 2090. [Google Scholar] [CrossRef]

- Nascimento, L.F.C.; Da Luz, F.S.; Costa, U.O.; Braga, F.D.O.; Júnior, É.P.L.; Monteiro, S.N. Curing kinetic parameters of epoxy composite reinforced with mallow fibers. Materials 2019, 12, 3939. [Google Scholar] [CrossRef]

- Demosthenes, L.C.D.C.; Nascimento, L.F.C.; Monteiro, S.N.; Costa, U.O.; Garcia Filho, F.D.C.; Luz, F.S.D.; Oliveira, M.S.; Ramos, F.J.H.T.V.; Pereira, A.C.; Braga, F.O. Thermal and structural characterization of buriti fibers and their relevance in fabric reinforced composites. J. Mater. Res. Technol. 2020, 9, 115–123. [Google Scholar] [CrossRef]

- Souza, A.T.; Junio, R.F.P.; Neuba, L.D.M.; Candido, V.S.; Da Silva, A.C.R.; De Azevedo, A.R.G.; Monteiro, S.N.; Nascimento, L.F.C. Caranan fiber from mauritiella armata palm tree as novel reinforcement for epoxy composites. Polymers 2020, 12, 2037. [Google Scholar] [CrossRef]

- da Cunha, J.; Dos, S.C.; Nascimento, L.F.C.; da Luz, F.S.; Monteiro, S.N.; Lemos, M.F.; da Silva, C.G.; Simonassi, N.T. Physical and Mechanical Characterization of Titica Vine (Heteropsis Flexuosa) Incorporated Epoxy Matrix Composites. Polymers 2021, 13, 4079. [Google Scholar] [CrossRef]

- Boumediri, H.; Bezazi, A.; Del Pino, G.G.; Haddad, A.; Scarpa, F.; Dufresne, A. Extraction and characterization of vascular bundle and fiber strand from date palm rachis as potential bio-reinforcement in composite. Carbohydr. Polym. 2019, 222, 114997. [Google Scholar] [CrossRef]

- Ramachandran, M.; Bansal, S.; Raichurkar, P. Scrutiny of jute fiber poly-lactic acid (PLA) resin reinforced polymeric composite. J. Text. Assoc. 2016, 76, 372–375. [Google Scholar]

- Naveen, J.; Jawaid, M.; Zainudin, E.S.; Sultan, M.T.H.; Yahaya, R.; Abdul Majid, M.S. Thermal Degradation and Viscoelastic Properties of Kevlar/Cocos Nucifera Sheath Reinforced Epoxy Hybrid Composites. Compos. Struct. 2019, 219, 194–202. [Google Scholar] [CrossRef]

- Canevarolo, S.V., Jr. Polymer Science: A Textbook for Engineers and Technologists; Carl Hanser Verlag GmbH Co KG: Munich, Germany, 2019. [Google Scholar]

- Neves, P.P.; Costa, U.O.; Bezerra, W.B.A.; da Silva Figueiredo, A.B.-H.; Monteiro, S.N.; Nascimento, L.F.C. Dynamic and ballistic performance of uni and bidirectional pineapple leaf fibers (palf)-reinforced epoxy composites functionalized with graphene oxide. Polymers 2022, 14, 3249. [Google Scholar] [CrossRef]

- Luz, F.S.d.; Junior, E.P.L.; Louro, L.H.L.; Monteiro, S.N. Ballistic test of multilayered armor with intermediate epoxy composite reinforced with jute fabric. Mater. Res. 2015, 18, 170–177. [Google Scholar] [CrossRef]

- Neto, J.; Queiroz, H.; Aguiar, R.; Lima, R.; Cavalcanti, D.; Banea, M.D. A review of recent advances in hybrid natural fiber reinforced polymer composites. J. Renew. Mater. 2022, 10, 561–589. [Google Scholar] [CrossRef]

- Harish, S.; Michael, D.P.; Bensely, A.; Lal, D.M.; Rajadurai, A. Mechanical property evaluation of natural fiber coir composite. Mater. Charact. 2009, 6, 44–49. [Google Scholar] [CrossRef]

- de Assis, F.S.; Pereira, A.C.; da Costa Garcia Filho, F.; Lima, E.P., Jr.; Monteiro, S.N.; Weber, R.P. Performance of jute non-woven mat reinforced polyester matrix composite in multilayered armor. J. Mater. Res. Technol. 2018, 7, 535–540. [Google Scholar] [CrossRef]

- Bezerra, W.B.; Lazarus, B.S.; Costa, U.O.; Figueiredo, A.B.H.; Lima, É.P., Jr.; Luz, F.S.D.; Monteiro, S.N. Energy Absorption and Ballistic Performance of Epoxy Composite Reinforced with Arapaima Scales. Polymers 2023, 15, 1614. [Google Scholar] [CrossRef]

- Oliveira, M.S.; Luz, F.S.D.; Lopera, H.A.C.; Nascimento, L.F.C.; Garcia Filho, F.D.C.; Monteiro, S.N. Energy absorption and limit velocity of epoxy composites incorporated with fique fabric as ballistic armor—A brief report. Polymers 2021, 13, 2727. [Google Scholar] [CrossRef]

- Reis, R.H.M.; Nunes, L.F.; da Luz, F.S.; Candido, V.S.; da Silva, A.C.R.; Monteiro, S.N. Ballistic performance of guaruman fiber composites in multilayered armor system and as single target. Polymers 2021, 13, 1203. [Google Scholar] [CrossRef]

| Wavenumber (cm−1) | Functional Groups |

|---|---|

| 3400 | Stretching of (O-H) binding |

| 3055 | Stretching of (C-H) and oxirane ring |

| 2965–2873 | Stretching of (C-H) and (CH2) aromatic and aliphatic groups |

| 1610 | Stretching of (C=C) aromatic |

| 1509 | Stretching of (C-C) aromatics |

| 1241 | Stretching of (C-O) aromatic ring |

| 1035 | Stretching of (C-O-C) ethers |

| 830 | Stretching of (C-O-C) binding of the oxirane groups |

| Sample | Mass Loss Up to 200 °C (%) | Initial Degradation Temperature (°C) | Temperature of Maximum Degradation Rate (°C) | Mass Loss at the End of Second Stage (%) | Mass Loss at 700 °C (%) |

|---|---|---|---|---|---|

| Ubim | 8.54 | 259.33 | 305.68 | 68.29 | 78.12 |

| Epoxy | 1.92 | 351.64 | 380.34 | 87.61 | 90.57 |

| 10% | 2.92 | 325.21 | 360.01 | 85.44 | 89.73 |

| 20% | 2.73 | 331.01 | 366.56 | 85.34 | 89.87 |

| 30% | 3.11 | 335.24 | 369.77 | 84.95 | 89.09 |

| Samples | ||||

|---|---|---|---|---|

| Epoxy | 812.58 ± 3.84 | 786.28 ± 5.93 | 203.82 ± 18.92 | 204.82 ± 9.36 |

| 10 vol.% | 833.75 ± 12.81 | 810.28 ± 15.39 | 187.03 ± 25.99 | 195.98 ± 13.57 |

| 20 vol.% | 808.42 ± 9.84 | 786.56 ± 10.81 | 169.07 ± 33.73 | 185.98 ± 18.00 |

| 30 vol.% | 815.28 ± 8.70 | 794.85 ± 10.54 | 159.42 ± 26.32 | 180.79 ± 14.93 |

| Samples | Standard Deviation | β | θ | R2 |

|---|---|---|---|---|

| Epoxy | 17.27 | 10.74 | 212.84 | 0.83 |

| 10% | 23.73 | 7.06 | 199.19 | 0.84 |

| 20% | 30.79 | 5.13 | 183.55 | 0.82 |

| 30% | 24.03 | 6.20 | 170.91 | 0.93 |

| Composite | Eabs (J) | Reference |

|---|---|---|

| 10 vol.% ubim fibers | 187.03 | PW * |

| 20 vol.% ubim fibers | 169.07 | PW * |

| 30 vol.% ubim fibers | 159.42 | PW * |

| Epoxy/Piassava fibers | 272 | [16] |

| Epoxy/Arapaima Scales | 100 | [76] |

| Epoxy/PALF | 212 | [71] |

| Epoxy/Fique | 211 | [77] |

| Epoxy/Hemp | 108 | [25] |

| Guaruman | 105 | [78] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marchi, B.Z.; Silveira, P.H.P.M.d.; Bezerra, W.B.A.; Nascimento, L.F.C.; Lopes, F.P.D.; Candido, V.S.; Silva, A.C.R.d.; Monteiro, S.N. Ballistic Performance, Thermal and Chemical Characterization of Ubim Fiber (Geonoma baculifera) Reinforced Epoxy Matrix Composites. Polymers 2023, 15, 3220. https://doi.org/10.3390/polym15153220

Marchi BZ, Silveira PHPMd, Bezerra WBA, Nascimento LFC, Lopes FPD, Candido VS, Silva ACRd, Monteiro SN. Ballistic Performance, Thermal and Chemical Characterization of Ubim Fiber (Geonoma baculifera) Reinforced Epoxy Matrix Composites. Polymers. 2023; 15(15):3220. https://doi.org/10.3390/polym15153220

Chicago/Turabian StyleMarchi, Belayne Zanini, Pedro Henrique Poubel Mendonça da Silveira, Wendell Bruno Almeida Bezerra, Lucio Fabio Cassiano Nascimento, Felipe Perissé Duarte Lopes, Verônica Scarpini Candido, Alisson Clay Rios da Silva, and Sergio Neves Monteiro. 2023. "Ballistic Performance, Thermal and Chemical Characterization of Ubim Fiber (Geonoma baculifera) Reinforced Epoxy Matrix Composites" Polymers 15, no. 15: 3220. https://doi.org/10.3390/polym15153220

APA StyleMarchi, B. Z., Silveira, P. H. P. M. d., Bezerra, W. B. A., Nascimento, L. F. C., Lopes, F. P. D., Candido, V. S., Silva, A. C. R. d., & Monteiro, S. N. (2023). Ballistic Performance, Thermal and Chemical Characterization of Ubim Fiber (Geonoma baculifera) Reinforced Epoxy Matrix Composites. Polymers, 15(15), 3220. https://doi.org/10.3390/polym15153220