Production and Characterization of Cellulosic Pulp from Mango Agro-Industrial Waste and Potential Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Proximate Analysis of Mango’s Tegument

2.3. Cellulosic Pulp: Alkali Treatment

2.4. Cellulosic Pulp: Acid Treatment

2.5. Yield of the Pulping Process

2.6. Color Analysis

2.7. Chemical Analysis of the Fibers

2.8. Fourier Transform Infrared Spectroscopy (FTIR) of the Fibers

2.9. Thermogravimetric Analysis (TGA) of the Fibers

2.10. X-ray Diffraction Analysis (XRD) of the Fibers

2.11. Scanning Electron Microscopy (SEM) of the Fibers

2.12. Statistical Analysis

3. Results and Discussion

3.1. Proximate Chemical Composition of Mango’s Tegument

3.2. Yield of Cellulosic Pulps

3.3. Effect of Alkali and Acid Treatments on the Color of the Cellulosic Pulps

3.4. Holocellulose, Lignin, and Extractives in the Untreated Fibers and Cellulosic Pulps

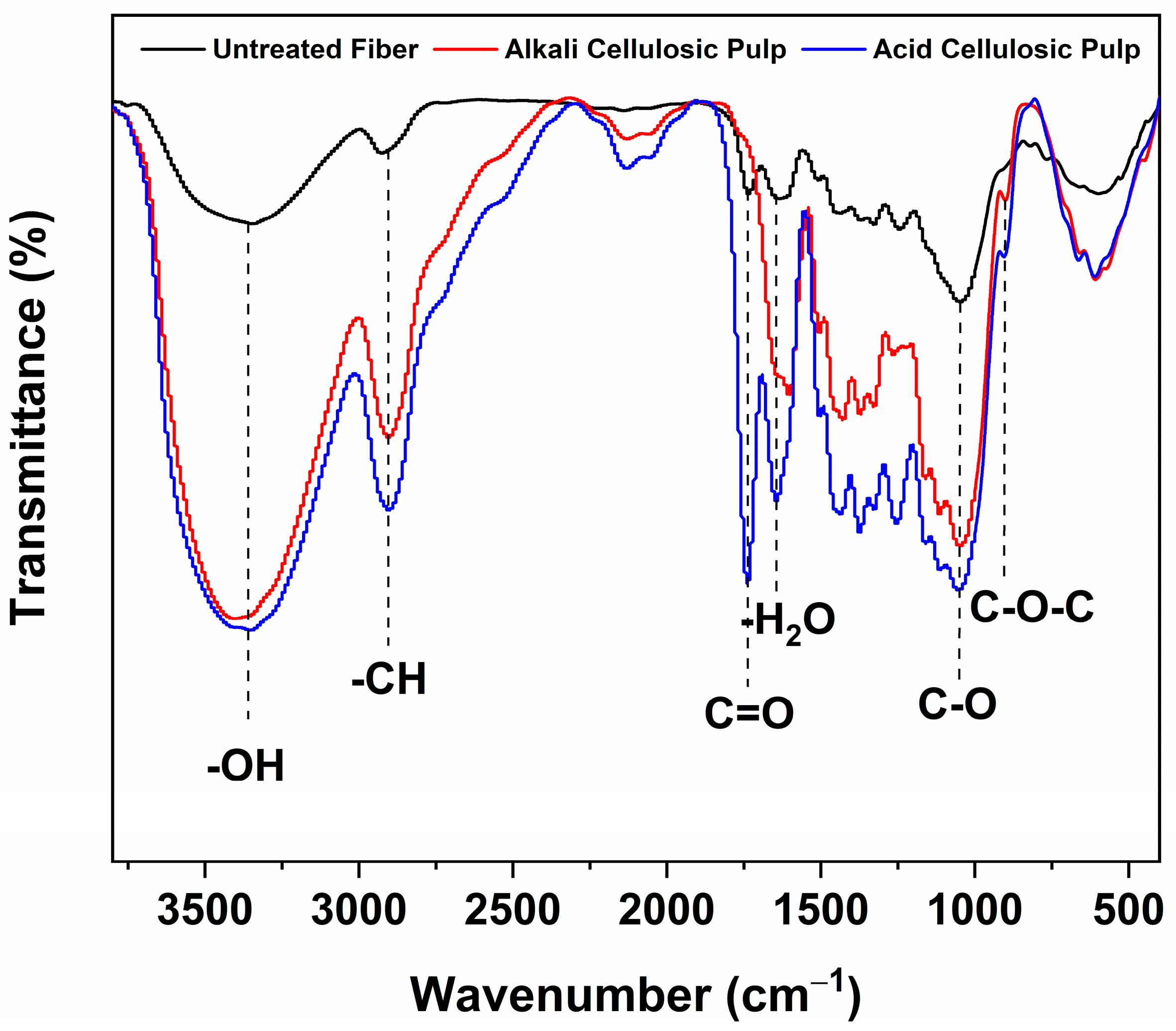

3.5. Fourier Transform Infrared Spectroscopy of the Cellulosic Pulps

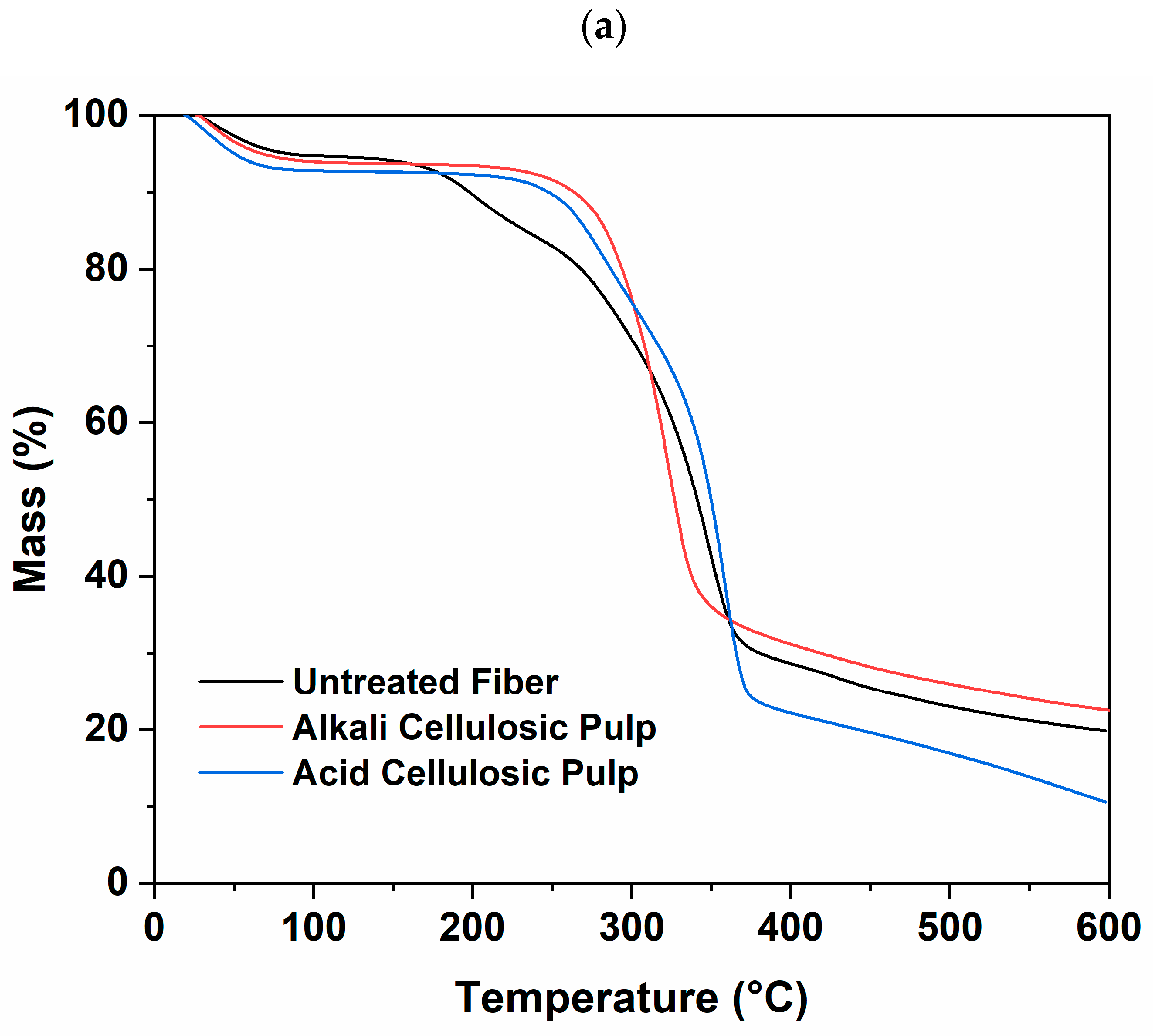

3.6. Thermal Analysis of Cellulosic Pulps

3.7. X-ray Diffraction Analysis (XRD) of Cellulosic Pulps

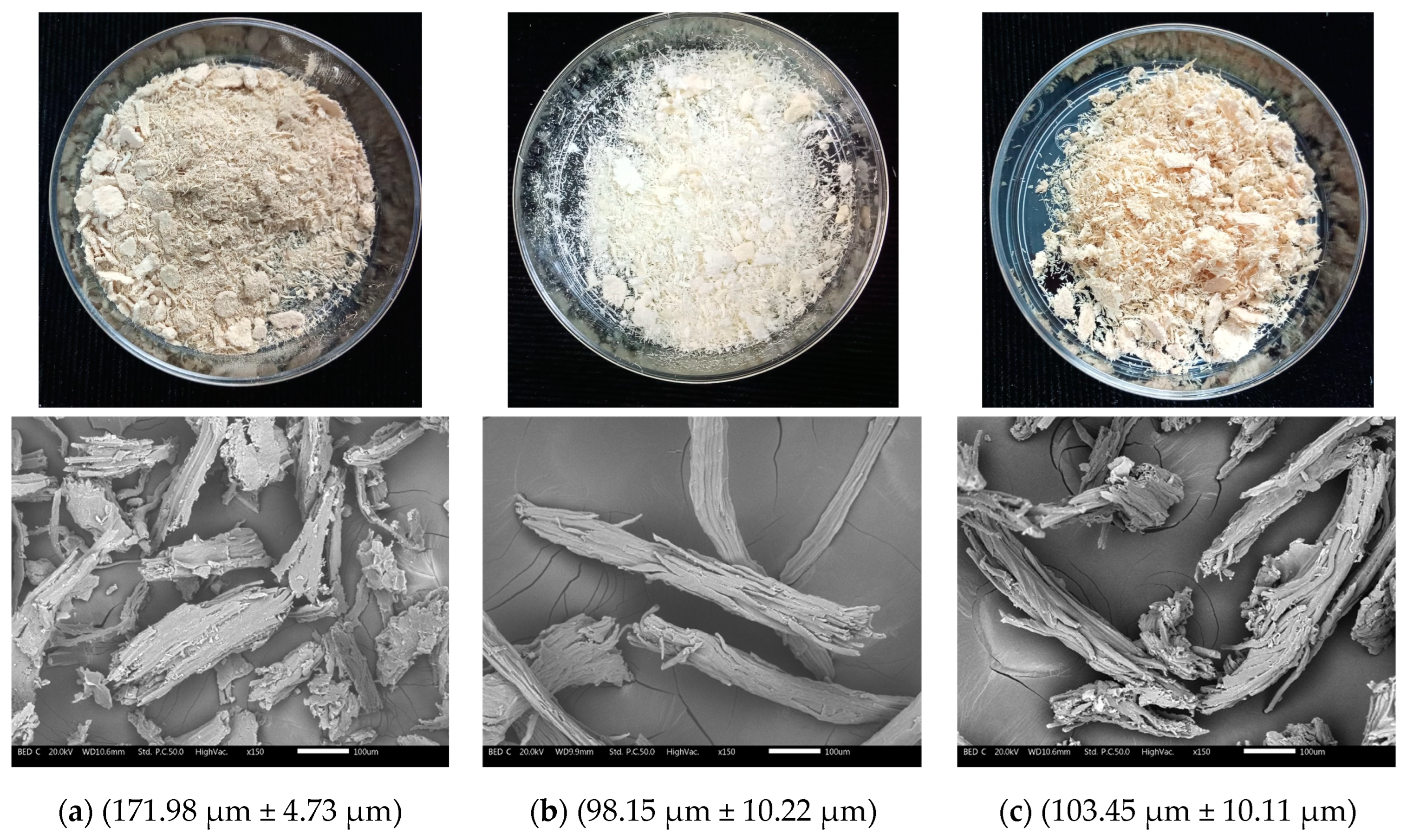

3.8. Morphology of the Cellulosic Pulps

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Morales-Caselles, C.; Viejo, J.; Martí, E.; González-Fernández, D.; Pragnell-Raasch, H.; González-Gordillo, J.I.; Montero, E.; Arroyo, G.M.; Hanke, G.; Salvo, V.S.; et al. An Inshore–Offshore Sorting System Revealed from Global Classification of Ocean Litter. Nat. Sustain. 2021, 4, 484–493. [Google Scholar] [CrossRef]

- Dybka-Stepien, K.; Antolak, H.; Kmiotek, M.; Piechota, D.; Koziróg, A. Disposable Food Packaging and Serving Materials—Trends and Biodegradability. Polymers 2021, 13, 3606. [Google Scholar] [CrossRef]

- Su, Y.; Yang, B.; Liu, J.; Sun, B.; Cao, C.; Zou, X.; Lutes, R.; He, Z. Prospects for Replacement of Some Plastics in Packaging with Lignocellulose Materials: A Brief Review. BioResources 2018, 13, 4550–4576. [Google Scholar] [CrossRef] [Green Version]

- Kim, G.; Irvine, A.; Rogers, N.; Cornish, S. Sustainable Food Packaging in 2040. 2023. Available online: https://www.upmspecialtypapers.com/sustainable-packaging/sustainable-food-packaging-trends-2040/ (accessed on 15 June 2023).

- Kamali, M.; Khodaparast, Z. Review on Recent Developments on Pulp and Paper Mill Wastewater Treatment. Ecotoxicol. Environ. Saf. 2015, 114, 326–342. [Google Scholar] [CrossRef]

- Baruah, J.; Nath, B.K.; Sharma, R.; Kumar, S.; Chandra Deka, R.; Chanda Baruah, D.; Eeshan, K. Recent Trends in the Pretreatment of Lignocellulosic Biomass for Value-Added Products. Front. Energy Res. 2018, 6, 141. [Google Scholar] [CrossRef]

- Giummarella, N.; Pu, Y.; Ragauskas, A.; Lawoko, M. A Critical Review on the Analysis of Lignin Carbohydrate Bonds. Green Chem. 2019, 21, 1573–1595. [Google Scholar] [CrossRef]

- Kittiphoom, S. Utilization of Mango Seed. Int. Food Res. J. 2012, 19, 1325–1335. [Google Scholar]

- El-Kady, T.; Abd El-Rahman, M.; Toliba, A.O.; Abo El-maty, S. Evaluation of Mango Seed Kernel Extract as Natural Occurring Phenolic Rich Antioxidant Compound. Bull. Natl. Nutr. Inst. 2017, 48, 1–30. [Google Scholar] [CrossRef] [Green Version]

- Food and Agriculture Organization of the United Nations (FAO) Faostat Database. Available online: www.fao.org/faostat. (accessed on 15 June 2023).

- Aggarwal, P.; Kaur, A.; Bhise, S. Value-Added Processing and Utilization of Mango by-Products. In Handbook of Mango Fruit: Production, Postharvest Science, Processing Technology and Nutrition; Siddiq, M., Brecht, J.K., Sidhu, J.S., Eds.; John Wiley & Sons Ltd.: Oxford, UK, 2017; pp. 279–293. ISBN 9781119014362. [Google Scholar]

- García-Mahecha, M.; Soto-Valdez, H.; Carvajal-Millan, E.; Madera-Santana, T.J.; Lomelí-Ramírez, M.G.; Colín-Chávez, C. Bioactive Compounds in Extracts from the Agro-Industrial Waste of Mango. Molecules 2023, 28, 458. [Google Scholar] [CrossRef]

- García-Mahecha, M.; Carvajal-Millan, E.; Madera-Santana, T.J.; Soto-Valdez, H.; Lomelí-Ramírez, M.G.; Colín-Chávez, C.; Peralta, E.; Val-Félix, L.Á. Oportunidades Con Potencial Para El Aprovechamiento de Los Componentes Mayoritarios de Residuos Agroindustriales de Mango. In Tecnología, Ingeniería y Biotecnología de Alimentos de Origen Vegetal: Aprovecha miento de sus Subproductos; Montoya-Ballesteros, L.C., Tiznado-Hernández, M.E., Madera-Santana, T.J., Ayala-Zavala, J.F., González-Aguilar, G., Eds.; Editorial LIBERMEX-CIAD: Hermosillo, Sonora, 2022; pp. 17–32. ISBN 978-607-98479-7-5. [Google Scholar]

- AOAC. Official Methods of Analysis of AOAC International, 18th ed.; AOAC International: Gaitherburg, Maryland, 2011. [Google Scholar]

- Cordeiro, E.M.S.; Nunes, Y.L.; Mattos, A.L.A.; Rosa, M.F.; de sá Sousa, M.M.F.; Ito, E.N. Polymer Biocomposites and Nanobiocomposites Obtained from Mango Seeds. Macromol. Symp. 2014, 344, 39–54. [Google Scholar] [CrossRef]

- Curtis Patiño, J. Microtecnia Vegetal; Editorial Trillas S.A. de C.V.: Mexico City, Mexico, 1986. [Google Scholar]

- Kiaei, M.; Tajik, M.; Vaysi, R. Chemical and Biometrical Properties of Plum Wood and Its Application in Pulp and Paper Production. Maderas Cienc. Y Tecnol. 2014, 16, 313–322. [Google Scholar] [CrossRef] [Green Version]

- Sridach, W. Pulping and Paper Properties of Palmyra Palm Fruit Fibers. Songklanakarin J. Sci. Technol. 2010, 32, 201–205. [Google Scholar]

- Pathare, P.B.; Opara, U.L.; Al-Said, F.A. Colour Measurement and Analysis in Fresh and Processed Foods: A Review. Food Bioprocess. Technol. 2012, 6, 36–60. [Google Scholar] [CrossRef]

- TAPPI T-264 Cm-07; Preparation of Wood for Chemical Analysis. TAPPI: Peachtree Corners, GA, USA, 2007.

- ASTM D1104-56; Method of Test for Holocellulose in Wood (Withdrawn 1985). ASTM International: Singapore, 1978.

- Álvarez, A.; Cachero, S.; González-Sánchez, C.; Montejo-Bernardo, J.; Pizarro, C.; Bueno, J.L. Novel Method for Holocellulose Analysis of Non-Woody Biomass Wastes. Carbohydr. Polym. 2018, 189, 250–256. [Google Scholar] [CrossRef] [PubMed]

- TAPPI T 222 Om-21; Acid-Insoluble Lignin in Wood and Pulp. TAPPI: Peachtree Corners, GA, USA, 2021.

- Ilangovan, M.; Guna, V.; Prajwal, B.; Jiang, Q.; Reddy, N. Extraction and Characterisation of Natural Cellulose Fibers from Kigelia Africana. Carbohydr. Polym. 2020, 236, 115996. [Google Scholar] [CrossRef] [PubMed]

- Torres-León, C.; Ramírez-Guzmán, N.; Ascacio-Valdés, J.; Serna-Cock, L.; dos Santos Correia, M.T.; Contreras-Esquivel, J.C.; Aguilar, C.N. Solid-State Fermentation with Aspergillus Niger to Enhance the Phenolic Contents and Antioxidative Activity of Mexican Mango Seed: A Promising Source of Natural Antioxidants. LWT 2019, 112, 108236. [Google Scholar] [CrossRef]

- Serna-Cock, L.; Torres-León, C. Potencial Agroindustrial de Cáscaras de Mango (Mangifera Indica) Variedades Keitt y Tommy Atkins. Acta Agronómica 2014, 64, 110–115. [Google Scholar] [CrossRef]

- Gomes, C.L.; Goncalves, E.; Suarez, C.A.G.; Rodrigues, D.D.S.; Montano, I.C. Effect of Reaction Time and Sodium Hydroxide Concentration on Delignification and Enzimatic Hydrolysis of Brewer’s Spent Grain from Two Brazilian Brewers. Celullose Chem. Technol. 2021, 55, 101–112. [Google Scholar] [CrossRef]

- Fauzee, S.N.; Othaman, R. Extraction and Dissolution of Cellulose from Nypa Fruit Husk for Nanofibers Fabrication. AIP Conf. Proc. 2013, 1571, 904–910. [Google Scholar] [CrossRef] [Green Version]

- Sridach, W. The Environmentally Benign Pulping Process of Non-Wood Fibers. Suranaree J. Sci. Technol. 2010, 17, 105–123. [Google Scholar]

- Mboowa, D. A Review of the Traditional Pulping Methods and the Recent Improvements in the Pulping Processes. Biomass Convers. Biorefinery 2021, 1–12. [Google Scholar] [CrossRef]

- Mussatto, S.I.; Rocha, G.J.M.; Roberto, I.C. Hydrogen Peroxide Bleaching of Cellulose Pulps Obtained from Brewer’s Spent Grain. Cellulose 2008, 15, 641–649. [Google Scholar] [CrossRef] [Green Version]

- Khiari, R.; Mhenni, M.F.; Belgacem, M.N.; Mauret, E. Chemical Composition and Pulping of Date Palm Rachis and Posidonia Oceanica—A Comparison with Other Wood and Non-Wood Fibre Sources. Bioresour. Technol. 2010, 101, 775–780. [Google Scholar] [CrossRef]

- Gutiérrez, A.; del Río, J.C. Chemical Characterization of Pitch Deposits Produced in the Manufacturing of High-Quality Paper Pulps from Hemp Fibers. Bioresour. Technol. 2005, 96, 1445–1450. [Google Scholar] [CrossRef] [Green Version]

- del Río, J.C.; Romero, J.; Gutiérrez, A. Analysis of Pitch Deposits Produced in Kraft Pulp Mills Using a Totally Chlorine Free Bleaching Sequence. J. Chromatogr. A 2000, 874, 235–245. [Google Scholar] [CrossRef] [Green Version]

- Saini, S.; Kadam, A.A.; Kumar, V.; Gaikwad, K.K.; Singh, S.P.; Dutt, D. Conversion of Rice Straw into Disposable Food-Serving Bowl via Refiner Mechanical Pulping: An Environmentally Benign Approach to Mitigate Stubble Burning and Plastic Pollution. Biomass Convers. Biorefinery 2021, 13, 6797–6806. [Google Scholar] [CrossRef]

- Borrega, M.; Sixta, H. Purification of Cellulosic Pulp by Hot Water Extraction. Cellulose 2013, 20, 2803–2812. [Google Scholar] [CrossRef] [Green Version]

- Daud, Z.; Kassim, A.S.M.; Aripin, A.M.; Awang, H.; Hatta, M.Z.M. Chemical Composition and Morphological of Cocoa Pod Husks and Cassava Peels for Pulp and Paper Production. Aust. J. Basic. Appl. Sci. 2013, 7, 406–411. [Google Scholar]

- Jiménez, L.; Pérez, A.; de la Torre, M.J.; Moral, A.; Serrano, L. Characterization of Vine Shoots, Cotton Stalks, Leucaena Leucocephala and Chamaecytisus Proliferus, and of Their Ethyleneglycol Pulps. Bioresour. Technol. 2007, 98, 3487–3490. [Google Scholar] [CrossRef]

- Ashori, A.; Harun, J.; Raverty, W.; Nor, M.; Yusoff, M.N.M. Chemical and Morphological Characteristics of Malaysian Cultivated Kenaf (Hibiscus Cannabinus) Fiber. Polym. Plast. Technol. Eng. 2006, 45, 131–134. [Google Scholar] [CrossRef]

- Mwaikambo, L.Y.; Ansell, M.P. Chemical Modification of Hemp, Sisal, Jute, and Kapok Fibers by Alkalization. J. Apllied Polym. Sci. 2002, 84, 2222–2234. [Google Scholar] [CrossRef]

- Reddy, J.P.; Rhim, J.W. Extraction and Characterization of Cellulose Microfibers from Agricultural Wastes of Onion and Garlic. J. Nat. Fibers 2018, 15, 465–473. [Google Scholar] [CrossRef]

- Ohlmaier-Delgadillo, F.; Carvajal-Millán, E.; López-Franco, Y.; Islas-osuna, M.A.; Micard, V.; Antoine-assor, C.; Rascón-Chu, A. Ferulated Pectins and Ferulated Arabinoxylans Mixed Gel Electrosprayed Microbeads. Molecules 2021, 26, 2478. [Google Scholar] [CrossRef]

- Chen, H.; Yu, Y.; Zhong, T.; Wu, Y.; Li, Y.; Wu, Z.; Fei, B. Effect of Alkali Treatment on Microstructure and Mechanical Properties of Individual Bamboo Fibers. Cellulose 2017, 24, 333–347. [Google Scholar] [CrossRef]

- Sofla, M.R.K.; Brown, R.J.; Tsuzuki, T.; Rainey, J.T. A Comparison of Cellulose Nanocrystals and Cellulose Nanofibres Extracted from Bagasse Using Acid and Ball Milling Methods. Adv. Nat. Sci. Nanosci. Nanotechnol. 2016, 7, 035004. [Google Scholar] [CrossRef]

- Yingkamhaeng, N.; Sukyai, P. The Potential of Mango Peel Utilization for Cellulose Extraction by Hydrothermal Pretreatment. In Proceedings of the Annual Meeting of the Thai Society for Bio-Technology and International Conference, Chiang Rai, Thailand, 26–29 November 2014; pp. 101–109. [Google Scholar]

- Sharan, U.G.; Dhamarikar, M.; Dharkar, A.; Chaturvedi, S.; Tiwari, S.; Namdeo, R. Surface Modification of Banana Fiber: A Review. Mater. Today Proc. 2021, 43, 904–915. [Google Scholar] [CrossRef]

- Chand, F.M.N. Natural Fibers and Their Composites. In Tribology of Natural Fiber Polymer Composites; Limited, E.W.P., Ed.; CRC Press LLC: Boca Raton, FL, USA, 2008; pp. 2–58. [Google Scholar]

- Rana, A.K.; Thakur, V.K.; Khan, A. Thermal Degradation of a Phenolic Resin, Vegetable Fibers, and Derived Composites. In Vegetable Fiber Composites and Their Technological Applications; Jawaid, M., Khan, A., Eds.; Springer Nature: Berlin/Heidelberg, Germany, 2021; pp. 178–214. ISBN 9811618542. [Google Scholar]

- Henrique, M.A.; Alves, H.S.; Flauzino, W.P.N.; Pasquini, D. Valorization of an Agro-Industrial Waste, Mango Seed, by the Extraction and Characterization of Its Cellulose Nanocrystals. J. Environ. Manage. 2013, 121, 202–209. [Google Scholar] [CrossRef]

- Motaung, T.E.; Anandjiwala, R.D. Effect of Alkali and Acid Treatment on Thermal Degradation Kinetics of Sugar Cane Bagasse. Ind. Crop. Prod. 2015, 74, 472–477. [Google Scholar] [CrossRef]

- Kathirselvam, M.; Kumaravel, A.; Arthanarieswaran, V.P.; Saravanakumar, S.S. Characterization of Cellulose Fibers in Thespesia Populnea Barks: Influence of Alkali Treatment. Carbohydr. Polym. 2019, 217, 178–189. [Google Scholar] [CrossRef]

- Bascón-Villegas, I.; Espinosa, E.; Sánchez, R.; Tarrés, Q.; Pérez-Rodríguez, F.; Rodríguez, A. Horticultural Plant Residues as New Source for Lignocellulose Nanofibers Isolation: Application on the Recycling Paperboard Process. Molecules 2020, 25, 3275. [Google Scholar] [CrossRef]

- Petroudy, S.R.D. Physical and Mechanical Properties of Natural Fibers. In Advanced High Strength Natural Fibre Composites in Construction; Mizi, F., Feng, F., Eds.; Woodhead Publishing: Cambridge, UK, 2017; pp. 59–83. ISBN 9780081004111. [Google Scholar]

- Costa Santos, E.B.; Gomes Moreno, C.; Barros, P.; de Moura, J.J.A.; Danusa de Carvalho Fima, F.; Ries, A.; Ramos Wellen, R.M.; Balbino da Silva, L. Effect of Alkaline and Hot Water Treatments on the Structure and Morphology of Piassava Fibers. Mater. Res. 2018, 21, 1–11. [Google Scholar]

- Moghaddam, M.K.; Mortazavi, S.M. Physical and Chemical Properties of Natural Fibers Extracted from Typha Australis Leaves. J. Nat. Fibers 2016, 13, 353–361. [Google Scholar] [CrossRef]

- Azeem, F.; Mao, N.; Faisal, S. Effect of Alkali Treatment of Lower Concentrations on the Structure and Tensile Properties of Pakistan’s Coarse Cotton Fibre. J. Text. Inst. 2019, 110, 1499–1507. [Google Scholar] [CrossRef]

| Treatment | Number | Concentration Reagents | Processing Time (h) | Processing Temperature (°C) |

|---|---|---|---|---|

| Alkali NaOH (w/v) | 1 | 4% | 1 | 80 |

| 2 | 4% | 2 | 80 | |

| 3 | 2% | 1 | 80 | |

| 4 | 2% | 2 | 80 | |

| Acid Proportion CH3COOH:H2O2 | 5 | 1:1 | 1 | 60 |

| 6 | 1:1 | 2 | 60 | |

| 7 | 1:1 | 1 | 70 | |

| 8 | 1:1 | 2 | 70 | |

| 9 | 2:1 | 1 | 60 | |

| 10 | 2:1 | 2 | 60 | |

| 11 | 2:1 | 1 | 70 | |

| 12 | 2:1 | 2 | 70 |

| Treatment | Number | Yield (% w/w) |

|---|---|---|

| Alkali NaOH (w/v) | 1 | 37.64 ± 0.21 a |

| 2 | 38.25 ± 1.83 a | |

| 3 | 42.24 ± 0.85 b | |

| 4 | 42.02 ± 0.45 b | |

| Acid Proportion CH3COOH:H2O2 | 5 | 46.97 ± 0.48 C |

| 6 | 44.67 ± 1.44 B | |

| 7 | 45.12 ± 0.91 B | |

| 8 | 40.49 ± 0.31 A | |

| 9 | 47.98 ± 0.23 C | |

| 10 | 45.75 ± 0.32 B | |

| 11 | 45.95 ± 0.84 B | |

| 12 | 40.63 ± 0.83 A |

| Treatment No. | Hue | ∆E |

|---|---|---|

| Untreated fibers | 82.61 ± 1.92 aC | - |

| 1 | 107.26 ± 0.49 d | 10.14 ± 0.13 |

| 2 | 104.88 ± 1.28 c | 9.76 ± 0.07 |

| 3 | 104.12 ± 1.78 c | 11.04 ± 0.19 |

| 4 | 101.58 ± 1.12 b | 9.80 ± 0.05 |

| 5 | 78.10 ± 1.42 B | 3.81 ± 1.27 |

| 6 | 79.68 ± 2.24 B | 3.48 ± 0.03 |

| 7 | 75.97 ± 1.37 A | 3.48 ± 0.02 |

| 8 | 84.96 ± 0.94 D | 3.04 ± 0.58 |

| 9 | 78.47 ± 0.61 B | 4.69 ± 0.11 |

| 10 | 77.78 ± 1.34 B | 3.16 ± 0.03 |

| 11 | 77.94 ± 0.17 B | 4.16 ± 0.32 |

| 12 | 83.24 ± 0.32 CD | 1.11 ± 0.57 |

| Treatment No. | Organic Extractives (%) | Water Extractives (%) | Holocelullose Content (%) * |

|---|---|---|---|

| Untreated fibers | 4.64 ± 1.02 bB | 17.39 ± 0.62 bC | 67.17 ± 1.63 aaB |

| 1 | 1.54 ± 0.02 a | 6.04 ± 0.26 a | 74.62 ± 0.74 b |

| 2 | 1.64 ± 0.17 a | 4.90 ± 0.46 a | 74.47 ± 0.74 b |

| 3 | 1.53 ± 0.09 a | 4.89 ± 0.42 a | 73.99 ± 0.86 b |

| 4 | 1.17 ± 0.09 a | 5.35 ± 1.10 a | 73.33 ± 1.55 b |

| 5 | 0.74 ± 0.047 A | 6.11 ± 0.64 A | 87.54 ± 0.82 cB |

| 6 | 0.65 ± 0.07 A | 9.19 ± 1.23 B | 80.08 ± 0.37 bB |

| 7 | 0.61 ± 0.04 A | 6.55 ± 0.42 A | 82.07 ± 0.68 cA |

| 8 | 1.33 ± 0.28 A | 11.85 ± 0.30 B | 77.76 ± 0.71 bA |

| 9 | 1.13 ± 0.12 A | 5.73 ± 0.49 A | 84.03 ± 0.60 cB |

| 10 | 1.07 ± 0.35 A | 7.64 ± 0.01 B | 81.46 ± 0.18 bB |

| 11 | 0.69 ± 0.07 A | 7.11 ± 0.38 A | 81.93 ± 0.03 cA |

| 12 | 0.51 ± 0.04 A | 11.64 ± 0.27 B | 78.18 ± 0.72 bA |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

García-Mahecha, M.; Soto-Valdez, H.; Peralta, E.; Carvajal-Millan, E.; Madera-Santana, T.J.; Lomelí-Ramírez, M.G.; Colín-Chávez, C. Production and Characterization of Cellulosic Pulp from Mango Agro-Industrial Waste and Potential Applications. Polymers 2023, 15, 3163. https://doi.org/10.3390/polym15153163

García-Mahecha M, Soto-Valdez H, Peralta E, Carvajal-Millan E, Madera-Santana TJ, Lomelí-Ramírez MG, Colín-Chávez C. Production and Characterization of Cellulosic Pulp from Mango Agro-Industrial Waste and Potential Applications. Polymers. 2023; 15(15):3163. https://doi.org/10.3390/polym15153163

Chicago/Turabian StyleGarcía-Mahecha, Maribel, Herlinda Soto-Valdez, Elizabeth Peralta, Elizabeth Carvajal-Millan, Tomás Jesús Madera-Santana, María Guadalupe Lomelí-Ramírez, and Citlali Colín-Chávez. 2023. "Production and Characterization of Cellulosic Pulp from Mango Agro-Industrial Waste and Potential Applications" Polymers 15, no. 15: 3163. https://doi.org/10.3390/polym15153163

APA StyleGarcía-Mahecha, M., Soto-Valdez, H., Peralta, E., Carvajal-Millan, E., Madera-Santana, T. J., Lomelí-Ramírez, M. G., & Colín-Chávez, C. (2023). Production and Characterization of Cellulosic Pulp from Mango Agro-Industrial Waste and Potential Applications. Polymers, 15(15), 3163. https://doi.org/10.3390/polym15153163