Synergistic Effect of Nanoparticles: Enhanced Mechanical and Corrosion Protection Properties of Epoxy Coatings Incorporated with SiO2 and ZrO2

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

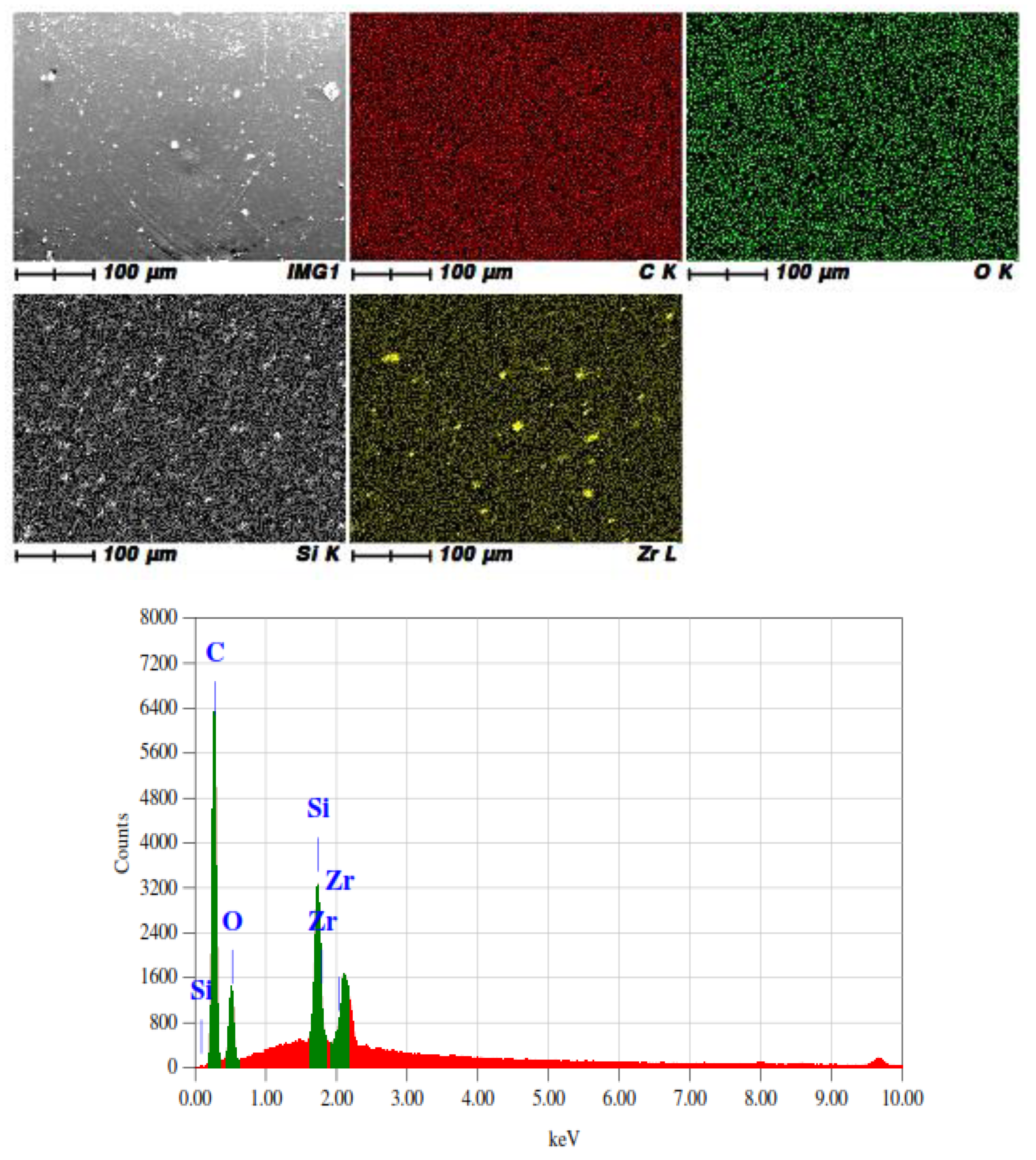

3.1. Scanning Electron Microscope (SEM)

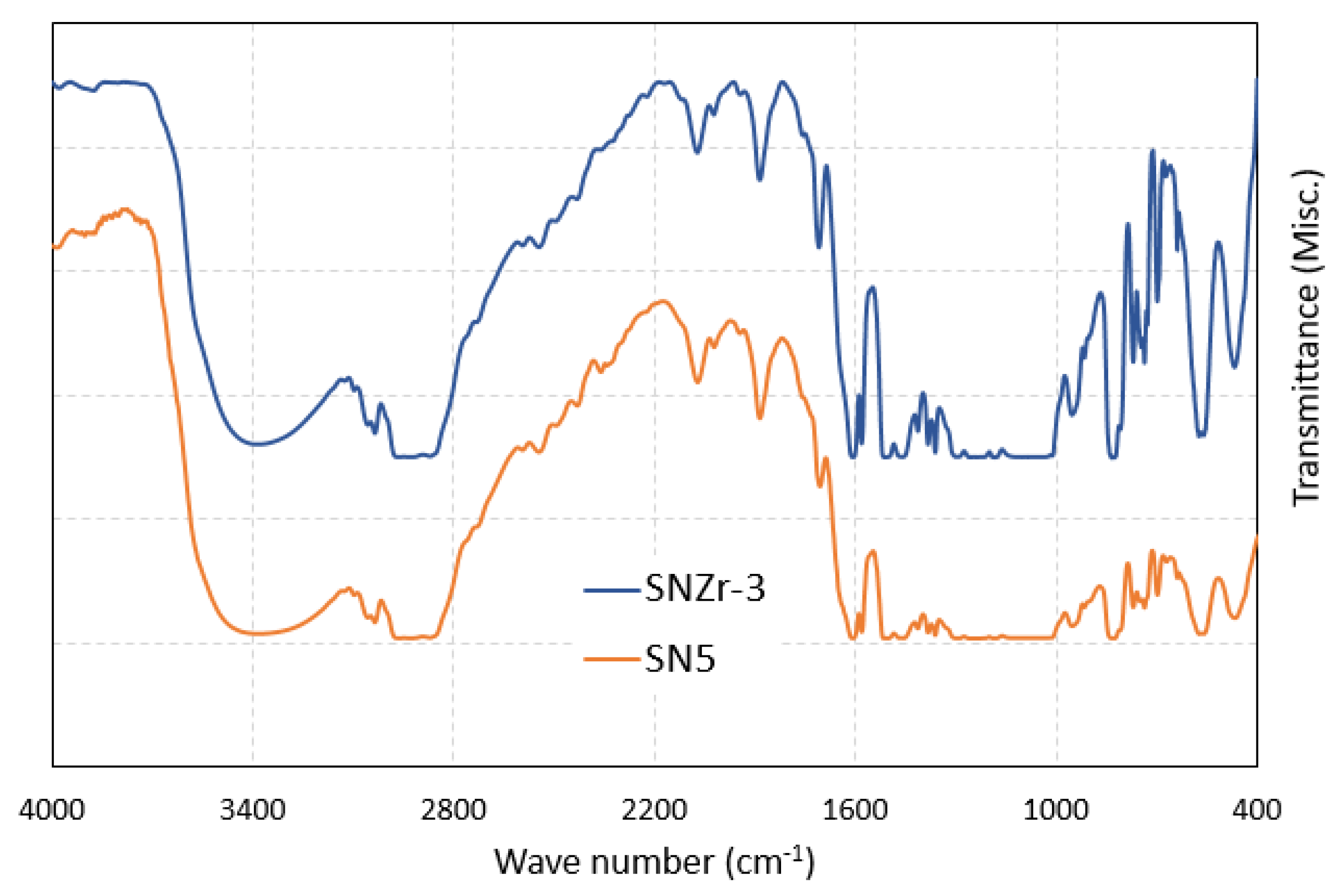

3.2. Fourier Transform Infrared Spectroscopy (FTIR)

3.3. Thermogravimetric Analysis (TGA)

3.4. Mechanical Properties and Nanoindentation

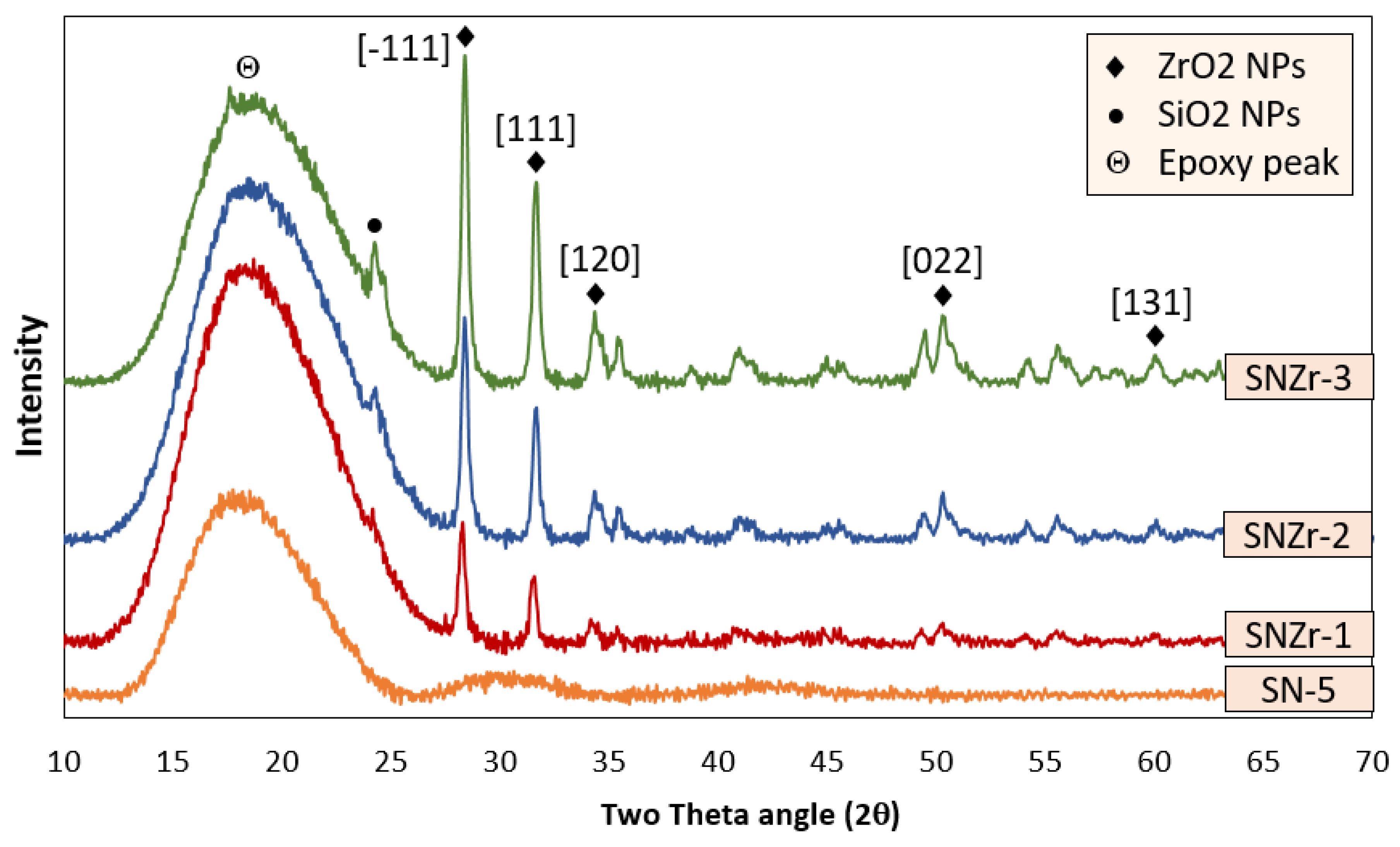

3.5. X-ray Diffraction Analysis

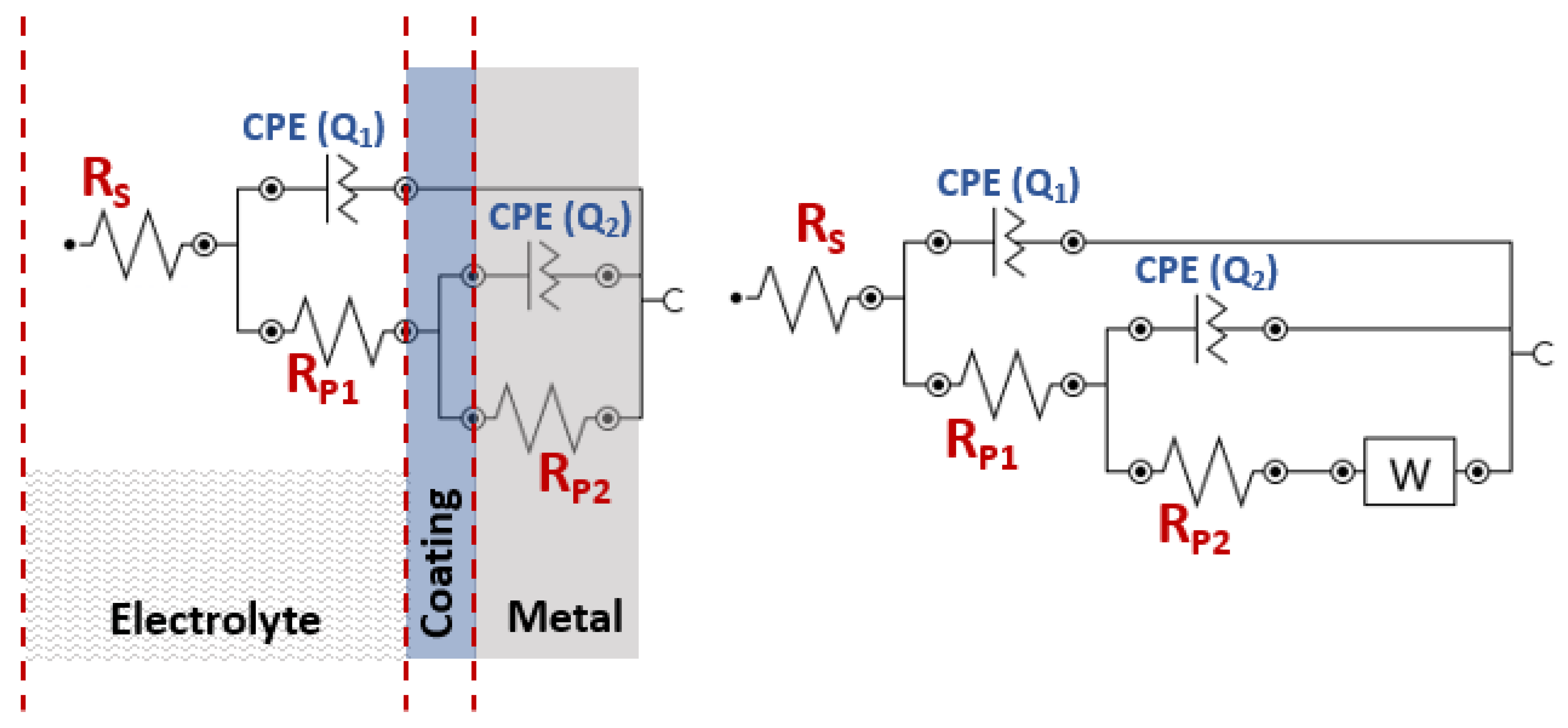

3.6. Electrochemical Impedance Spectroscopy (EIS)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bu, M.; Zhang, X.; Zhou, T.; Lei, C. Fully bio-based epoxy resins derived from magnolol and varying furan amines: Cure kinetics, superior mechanical and thermal properties. Eur. Polym. J. 2022, 180, 111595. [Google Scholar] [CrossRef]

- Liu, L.; Zhao, M.; Pei, X.; Liu, S.; Luo, S.; Yan, M.; Shao, R.; Sun, Y.; Xu, W.; Xu, Z. Improving corrosion resistance of epoxy coating by optimizing the stress distribution and dispersion of SiO2 filler. Prog. Org. Coat. 2023, 179, 107522. [Google Scholar] [CrossRef]

- Kandeloos, A.J.; Attar, M.M. The diffusion and adhesion relationship between free films and epoxy coated mild steel. Prog. Org. Coat. 2023, 179, 107561. [Google Scholar] [CrossRef]

- Poulston, S.; Bennett, R.A.; Faraldi, P.; Hyde, T.I.; Pidria, M.F.; Houel, V.; Wagland, A. Characterization of protective coatings for planar automotive gas sensors. Sens. Actuators B Chem. 2005, 110, 209–217. [Google Scholar] [CrossRef]

- Makhlouf, A.S.H. Protective coatings for automotive, aerospace and military applications: Current prospects and future trends. In Handbook of Smart Coatings for Materials Protection; Woodhead Publishing: Shaxton, UK, 2014; pp. 121–131. [Google Scholar] [CrossRef]

- Yang, H.; Qin, L.; Wang, F.; Mawignon, F.J.; Dong, M.; Wu, Y.; Zhang, Y.; Ma, Z. A facile method to fabricate the durable and self-protective coating for marine applications. Surf. Coat. Technol. 2023, 452, 129124. [Google Scholar] [CrossRef]

- Ou, J.; Wang, J.; Zhou, J.; Liu, S.; Yu, Y.; Pang, X.; Yang, S. Construction and study on corrosion protective property of polydopamine-based 3-layer organic coatings on aluminum substrate. Prog. Org. Coat. 2010, 68, 244–247. [Google Scholar] [CrossRef]

- Yang, J.; Dai, J.; Liu, X.; Fu, S.; Zong, E.; Song, P. A lignin-based epoxy/TiO2 hybrid nanoparticle for multifunctional bio-based epoxy with improved mechanical, UV absorption and antibacterial properties. Int. J. Biol. Macromol. 2022, 210, 85–93. [Google Scholar] [CrossRef]

- Korkmaz, Y.; Gültekin, K. Improvement of structural, thermal and mechanical properties of epoxy composites and bonded joints exposed to water environment by incorporating boron nanoparticles. Int. J. Adhes. Adhes. 2022, 116, 103141. [Google Scholar] [CrossRef]

- Sadowski, Ł.; Kampa, Ł.; Chowaniec, A.; Królicka, A.; Żak, A.; Abdoulpour, H.; Vantadori, S. Enhanced adhesive performance of epoxy resin coating by a novel bonding agent. Constr. Build. Mater. 2021, 301, 124078. [Google Scholar] [CrossRef]

- Wang, Y.; Yan, L.; Ling, Y.; Ge, Y.; Huang, C.; Zhou, S.; Xia, S.; Liang, M.; Zou, H. Enhanced mechanical and adhesive properties of PDMS coatings via in-situ formation of uniformly dispersed epoxy reinforcing phase. Prog. Org. Coat. 2023, 174, 107319. [Google Scholar] [CrossRef]

- Kumar Singh, S.; Gunwant, D.; Vedrtnam, A.; Kumar, A.; Jain, A. Synthesis, characterization, and modelling the behavior of in-situ ZrO2 nanoparticles dispersed epoxy nanocomposite. Eng. Fract. Mech. 2022, 263, 108300. [Google Scholar] [CrossRef]

- Bharadwaja, K.; Srinivasa Rao, S.; Baburao, T. Epoxy/SIO2 nanocomposite mechanical properties and tribological performance. Mater. Today Proc. 2022, 62, 1712–1716. [Google Scholar] [CrossRef]

- Mishra, T.; Mandal, P.; Rout, A.K.; Sahoo, D. A state-of-the-art review on potential applications of natural fiber-reinforced polymer composite filled with inorganic nanoparticle. Compos. Part C Open Access 2022, 9, 100298. [Google Scholar] [CrossRef]

- Boumaza, M.; Khan, R.; Zahrani, S. RETRACTED: An experimental investigation of the effects of nanoparticles on the mechanical properties of epoxy coating. Thin Solid Film. 2016, 620, 160–164. [Google Scholar] [CrossRef]

- Allahverdi, A.; Ehsani, M.; Janpour, H.; Ahmadi, S. The effect of nanosilica on mechanical, thermal and morphological properties of epoxy coating. Prog. Org. Coat. 2012, 75, 543–548. [Google Scholar] [CrossRef]

- Ghanbari, A.; Attar, M.M. A study on the anticorrosion performance of epoxy nanocomposite coatings containing epoxy-silane treated nano-silica on mild steel substrate. J. Ind. Eng. Chem. 2015, 23, 145–153. [Google Scholar] [CrossRef]

- Yang, G.; Heo, Y.J.; Park, S.J. Effect of Morphology of Calcium Carbonate on Toughness Behavior and Thermal Stability of Epoxy-Based Composites. Processes 2019, 7, 178. [Google Scholar] [CrossRef]

- Conradi, M.; Kocijan, A.; Kek-Merl, D.; Zorko, M.; Verpoest, I. Mechanical and anticorrosion properties of nanosilica-filled epoxy-resin composite coatings. Appl. Surf. Sci. 2014, 292, 432–437. [Google Scholar] [CrossRef]

- Sfameni, S.; Lawnick, T.; Rando, G.; Visco, A.; Textor, T.; Plutino, M.R. Super-Hydrophobicity of Polyester Fabrics Driven by Functional Sustainable Fluorine-Free Silane-Based Coatings. Gels 2023, 9, 109. [Google Scholar] [CrossRef]

- Aliakbari, M.; Jazani, O.M.; Sohrabian, M.; Jouyandeh, M.; Saeb, M.R. Multi-nationality epoxy adhesives on trial for future nanocomposite developments. Prog. Org. Coat. 2019, 133, 376–386. [Google Scholar] [CrossRef]

- Medina, R.; Haupert, F.; Schlarb, A.K. Improvement of tensile properties and toughness of an epoxy resin by nanozirconium-dioxide reinforcement. J. Mater. Sci. 2008, 43, 3245–3252. [Google Scholar] [CrossRef]

- Alam, M.A.; Samad, U.A.; Anis, A.; Sherif, E.-S.M.; Abdo, H.S.; Al-Zahrani, S.M. The Effect of Zirconia Nanoparticles on Thermal, Mechanical, and Corrosion Behavior of Nanocomposite Epoxy Coatings on Steel Substrates. Materials 2023, 16, 4813. [Google Scholar] [CrossRef] [PubMed]

- Alam, M.A.; Samad, U.A.; Sherif, E.S.M.; Poulose, A.M.; Mohammed, J.A.; Alharthi, N.; Al-Zahrani, S.M. Influence of SiO2 Content and Exposure Periods on the Anticorrosion Behavior of Epoxy Nanocomposite Coatings. Coatings 2020, 10, 118. [Google Scholar] [CrossRef]

- Alam, M.A.; Samad, U.A.; Alam, M.; Anis, A.; Al-Zahrani, S.M. Enhancement in Nanomechanical, Thermal, and Abrasion Properties of SiO2 Nanoparticle-Modified Epoxy Coatings. Coatings 2020, 10, 310. [Google Scholar] [CrossRef]

- D4366-16; A. D4366 Standard Test Methods for Hardness of Organic Coatings by Pendulum Damping Tests. ASTM International: West Conshohocken, PA, USA, 2021. Available online: https://www.astm.org/d4366-16r21.html (accessed on 12 July 2023).

- D7027-20; A. D7027 Standard Test Method for Evaluation of Scratch Resistance of Polymeric Coatings and Plastics Using an Instrumented Scratch Machine. ASTM International: West Conshohocken, PA, USA, 2020. Available online: https://www.astm.org/d7027-20.html (accessed on 12 July 2023).

- D2794; Standard Test Method for Resistance of Organic Coatings to the Effects of Rapid Deformation (Impact). ASTM International: West Conshohocken, PA, USA, 2019. Available online: https://www.astm.org/d2794-93r19.html (accessed on 12 July 2023).

- Matin, E.; Attar, M.M.; Ramezanzadeh, B. Investigation of corrosion protection properties of an epoxy nanocomposite loaded with polysiloxane surface modified nanosilica particles on the steel substrate. Prog. Org. Coat. 2015, 78, 395–403. [Google Scholar] [CrossRef]

- Khan, R.; Azhar, M.R.; Anis, A.; Alam, M.A.; Boumaza, M.; Al-Zahrani, S.M. Facile synthesis of epoxy nanocomposite coatings using inorganic nanoparticles for enhanced thermo-mechanical properties: A comparative study. J. Coat. Technol. Res. 2016, 13, 159–169. [Google Scholar] [CrossRef]

- Tran, T.N.; Pham, T.V.A.; Le, M.L.P.; Nguyen, T.P.T.; Tran, V.M. Synthesis of amorphous silica and sulfonic acid functionalized silica used as reinforced phase for polymer electrolyte membrane. Adv. Nat. Sci. Nanosci. Nanotechnol. 2013, 4, 045007. [Google Scholar] [CrossRef]

- Akkalamattam Maitheen Kunju, R.; Gopalakrishnan, J. Polyaniline nanorod adsorbed on reduced graphene oxide nanosheet for enhanced dielectric, viscoelastic and thermal properties of epoxy nanocomposites. Polym. Eng. Sci. 2021, 61, 1755–1772. [Google Scholar] [CrossRef]

- Aradhana, R.; Mohanty, S.; Nayak, S.K. Synergistic effect of polypyrrole and reduced graphene oxide on mechanical, electrical and thermal properties of epoxy adhesives. Polymer 2019, 166, 215–228. [Google Scholar] [CrossRef]

- Nguyen, T.A.; Nguyen, H.; Nguyen, T.V.; Thai, H.; Shi, X. Effect of nanoparticles on the thermal and mechanical properties of epoxy coatings. J. Nanosci. Nanotechnol. 2016, 16, 9874–9881. [Google Scholar] [CrossRef]

- ASTM-D638-14; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2014; Volume 8, pp. 59–67.

- Long, J.; Li, C.; Li, Y. Enhancement of Mechanical and Bond Properties of Epoxy Adhesives Modified by SiO2 Nanoparticles with Active Groups. Polymers 2022, 14, 2052. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R.; Wang, H.; Wang, X.; Guan, J.; Li, M.; Chen, Y. Rubber-Composite-Nanoparticle-Modified Epoxy Powder Coatings with Low Curing Temperature and High Toughness. Polymers 2022, 15, 195. [Google Scholar] [CrossRef]

- Gershoni, G.; Dodiuk, H.; Tenne, R.; Kenig, S. Cationically Polymerized Epoxy and Radiation-Cured Acrylate Blend Nanocomposites Based on WS2 Nanoparticles Part B: Mechanical and Physical Properties. J. Compos. Sci. 2023, 7, 42. [Google Scholar] [CrossRef]

- D6412; A. D6412/D6412M Standard Specification for Epoxy (Flexible) Adhesive For Bonding Metallic and Nonmetallic Materials. ASTM International: West Conshohocken, PA, USA, 2020. Available online: https://www.astm.org/d6412_d6412m-99r20.html (accessed on 12 July 2023).

- Chudoba, T.; Richter, F. Investigation of creep behaviour under load during indentation experiments and its influence on hardness and modulus results. Surf. Coat. Technol. 2001, 148, 191–198. [Google Scholar] [CrossRef]

- Samad, U.A.; Alam, M.A.; Anis, A.; Abdo, H.S.; Shaikh, H.; Al-Zahrani, S.M. Nanomechanical and Electrochemical Properties of ZnO-Nanoparticle-Filled Epoxy Coatings. Coatings 2022, 12, 282. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Arora, G.; Pathak, H. Nanoindentation characterization of polymer nanocomposites for elastic and viscoelastic properties: Experimental and mathematical approach. Compos. Part C Open Access 2021, 4, 100103. [Google Scholar] [CrossRef]

- Bansal, S.A.; Singh, A.P.; Kumar, S. Reinforcing Graphene Oxide Nanoparticles to Enhance Viscoelastic Performance of Epoxy Nanocomposites. J. Nanosci. Nanotechnol. 2019, 19, 4000–4006. [Google Scholar] [CrossRef]

- Birru, A.K.; Shiva, K.; David, S.G.S. Study on Density and Hardness of Reinforced Zinc Oxide Nanoparticles in Epoxy Composites. Mater. Today Proc. 2015, 2, 4402–4406. [Google Scholar] [CrossRef]

- Rong, Z.; Sun, W.; Xiao, H.; Jiang, G. Effects of nano-SiO2 particles on the mechanical and microstructural properties of ultra-high performance cementitious composites. Cem. Concr. Compos. 2015, 56, 25–31. [Google Scholar] [CrossRef]

- Cruz-Manzo, S.; Greenwood, P. Introduction to electrochemical impedance spectroscopy. In Electrochemical Phenomena in the Cathode Impedance Spectrum of PEM Fuel Cells; Elsevier: Amsterdam, The Netherlands, 2022; pp. 3–40. [Google Scholar] [CrossRef]

- Abdo, H.S.; Samad, U.A.; Abdo, M.S.; Alkhammash, H.I.; Aijaz, M.O. Electrochemical Behavior of Inductively Sintered Al/TiO2 Nanocomposites Reinforced by Electrospun Ceramic Nanofibers. Polymers 2021, 13, 4319. [Google Scholar] [CrossRef] [PubMed]

- Abdo, H.S.; Seikh, A.H.; Mandal, B.B.; Mohammed, J.A.; Ragab, S.A.; Abdo, M.S. Microstructural Characterization and Corrosion-Resistance Behavior of Dual-Phase Steels Compared to Conventional Rebar. Crystals 2020, 10, 1068. [Google Scholar] [CrossRef]

- Abdo, H.S.; Seikh, A.H.; Mohammed, J.A.; Uzzaman, T. Ameliorative Corrosion Resistance and Microstructure Characterization of 2205 Duplex Stainless Steel by Regulating the Parameters of Pulsed Nd:YAG Laser Beam Welding. Metals 2021, 11, 1206. [Google Scholar] [CrossRef]

- Nouri-Borujerdi, A.; Kazemi-Ranjbar, S. Thermal synergistic effect in hybrid filler epoxy composites consisting of graphene nanoplatelets and SiC particles. Therm. Sci. Eng. Prog. 2021, 25, 100964. [Google Scholar] [CrossRef]

| Sample | * Resin | Xylene (mL) | MIBK (mL) | SiO2 (wt%) | ZrO2 (wt%) | * Hardener | Ref. |

|---|---|---|---|---|---|---|---|

| SN5 | 83.34 | 10 | 10 | 5 | 0 | 16.66 | [24,25] |

| Zr2 | 83.34 | 10 | 10 | 0 | 2 | 16.66 | [23] |

| SNZr-1 | 83.34 | 10 | 10 | 5 | 1 | 16.66 | Current study |

| SNZr-2 | 83.34 | 10 | 10 | 5 | 2 | 16.66 | |

| SNZr-3 | 83.34 | 10 | 10 | 5 | 3 | 16.66 |

| Sample | Degradation Temperature 15% Loss (°C) | Degradation Temperature 25% Loss (°C) | Degradation Temperature 50% Loss (°C) | Degradation Temperature 75% Loss (°C) | Ref. |

|---|---|---|---|---|---|

| SN5 | 344.10 | 377.80 | 420.90 | 447.03 | [25] |

| Zr2 | 326.93 | 374.48 | 418.33 | 442.47 | [23] |

| SNZr-1 | 332.10 | 377.02 | 421.54 | 447.84 | Current study |

| SNZr-2 | 330.19 | 376.04 | 421.04 | 447.55 | |

| SNZr-3 | 335.25 | 375.80 | 421.97 | 449.10 |

| Sample | Ultimate Tensile Strength (UTS), MPa | Yield Strength (YS), MPa | Strain at Break, (mm/mm) | Ref. |

|---|---|---|---|---|

| SN5 | 2.32 | 0.721 | 0.37 | [25] |

| SNZr-1 | 3.05 | 0.968 | 0.30 | Current study |

| SNZr-2 | 3.33 | 1.256 | 0.23 | |

| SNZr-3 | 2.77 | 0.968 | 0.25 |

| Sample | DFT µm | Pendulum Hardness | Scratch (Kg) | Impact (N/mm2) | Ref. |

|---|---|---|---|---|---|

| SN5 | 100 ± 10 | 118 | 9 | 0.8825 | [25] |

| Zr2 | 100 ± 10 | 145 | 7.5 | 0.6067 | [23] |

| SNZr-1 | 100 ± 10 | 170 | 10 | 0.8274 | Current study |

| SNZr-2 | 100 ± 10 | 168 | 10 | 0.8274 | |

| SNZr-3 | 100 ± 10 | 169 | 10 | 0.7171 |

| Sample | Hardness (GPa) | Elastic Modulus (GPa) | Reference |

|---|---|---|---|

| SN5 | 0.150 | 3.284 | [25] |

| Zr2 | 0.121 | 3.211 | [23] |

| SNZr-1 | 0.157 | 3.451 | Current study |

| SNZr-2 | 0.159 | 3.553 | |

| SNZr-3 | 0.164 | 3.653 |

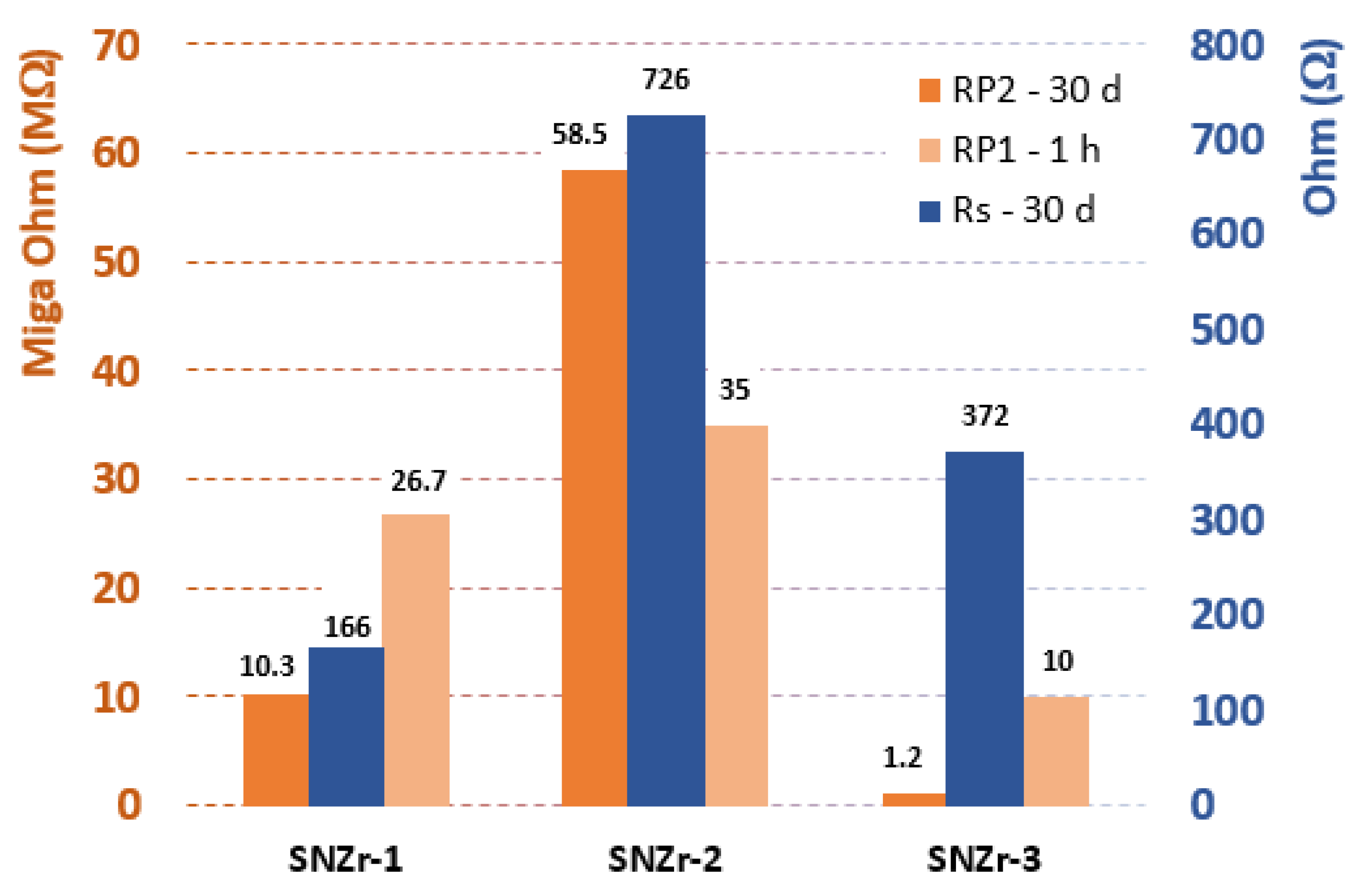

| Coating | Time | EIS Parameters | |||||||

|---|---|---|---|---|---|---|---|---|---|

| RS (Ω) | CPE (Q1) | RP1 (MΩ) | CPE (Q2) | RP2 (MΩ) | W (nMho) | ||||

| nMho | n | nMho | n | ||||||

| SNZr-1 | 1 h | 562 | 0.938 | 0.971 | 26.7 | 4.48 | 0.682 | 160 | - |

| 7 d | 258 | 1.15 | 0.967 | 1.93 | 2.51 | 0.667 | 6.48 | 994 | |

| 14 d | 231 | 1.13 | 0.968 | 2.27 | 1.78 | 0.694 | 8.60 | 675 | |

| 21 d | 151 | 1.11 | 0.971 | 1.55 | 1.80 | 0.692 | 8.53 | 710 | |

| 30 d | 166 | 1.13 | 0.971 | 1.64 | 1.56 | 0.705 | 10.3 | 614 | |

| SNZr-2 | 1 h | 321 | 1.01 | 0.973 | 35.0 | 0.636 | 0.647 | 11 × 103 | - |

| 7 d | 1180 | 1.91 | 0.927 | 2.10 | 26.9 | 0.759 | 10.4 | - | |

| 14 d | 200 | 0.848 | 0.999 | 68.5 | 86.3 | 0.484 | 28.9 | - | |

| 21 d | 2470 | 2.91 | 0.894 | 0.0861 | 70.1 | 0.540 | 82.5 | - | |

| 30 d | 726 | 1.94 | 0.930 | 0.0896 | 63.2 | 0.587 | 58.5 | - | |

| SNZr-3 | 1 h | 85.1 | 0.806 | 0.982 | 10.0 | 0.999 | 0.623 | 3.37 × 103 | - |

| 7 d | 1800 | 1.61 | 0.928 | 3.58 | 829 | 0.772 | 2.22 | - | |

| 14 d | 1620 | 1.55 | 0.932 | 2.75 | 1220 | 0.774 | 2.12 | - | |

| 21 d | 1480 | 1.40 | 0.940 | 2.47 | 1210 | 0.783 | 2.57 | - | |

| 30 d | 372 | 1.41 | 0.900 | 1.60 | 1090 | 0.512 | 1.20 | - | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Samad, U.A.; Alam, M.A.; Abdo, H.S.; Anis, A.; Al-Zahrani, S.M. Synergistic Effect of Nanoparticles: Enhanced Mechanical and Corrosion Protection Properties of Epoxy Coatings Incorporated with SiO2 and ZrO2. Polymers 2023, 15, 3100. https://doi.org/10.3390/polym15143100

Samad UA, Alam MA, Abdo HS, Anis A, Al-Zahrani SM. Synergistic Effect of Nanoparticles: Enhanced Mechanical and Corrosion Protection Properties of Epoxy Coatings Incorporated with SiO2 and ZrO2. Polymers. 2023; 15(14):3100. https://doi.org/10.3390/polym15143100

Chicago/Turabian StyleSamad, Ubair Abdus, Mohammad Asif Alam, Hany S. Abdo, Arfat Anis, and Saeed M. Al-Zahrani. 2023. "Synergistic Effect of Nanoparticles: Enhanced Mechanical and Corrosion Protection Properties of Epoxy Coatings Incorporated with SiO2 and ZrO2" Polymers 15, no. 14: 3100. https://doi.org/10.3390/polym15143100

APA StyleSamad, U. A., Alam, M. A., Abdo, H. S., Anis, A., & Al-Zahrani, S. M. (2023). Synergistic Effect of Nanoparticles: Enhanced Mechanical and Corrosion Protection Properties of Epoxy Coatings Incorporated with SiO2 and ZrO2. Polymers, 15(14), 3100. https://doi.org/10.3390/polym15143100