Hydrothermal Effect on Ramie-Fiber-Reinforced Polymer Composite Plates: Water Uptake and Mechanical Properties

Abstract

1. Introduction

- (1)

- Low density: the relative density of natural fiber is approximately 1.5, while that of glass fiber is 2.6.

- (2)

- The price is low: the cost per kilogram of natural fiber is USD 0.9~1.08 less than that of glass fiber.

- (3)

- Low energy consumption: to produce the same product, the use of NFRP consumes less non-renewable energy than other materials.

- (1)

- Resin swelling after moisture absorption leads to interface debonding and destruction.

- (2)

- The osmotic pressure of water in the pores leads to debonding and failure of the fiber–resin interface.

2. Experimental

2.1. Materials and Sample Preparation

2.1.1. Materials

2.1.2. RFRP Sample Fabrication

2.1.3. Humid Environments

2.1.4. Moisture Absorption and Desorption Tests

2.1.5. The Mechanical Properties Test

3. Results and Discussion

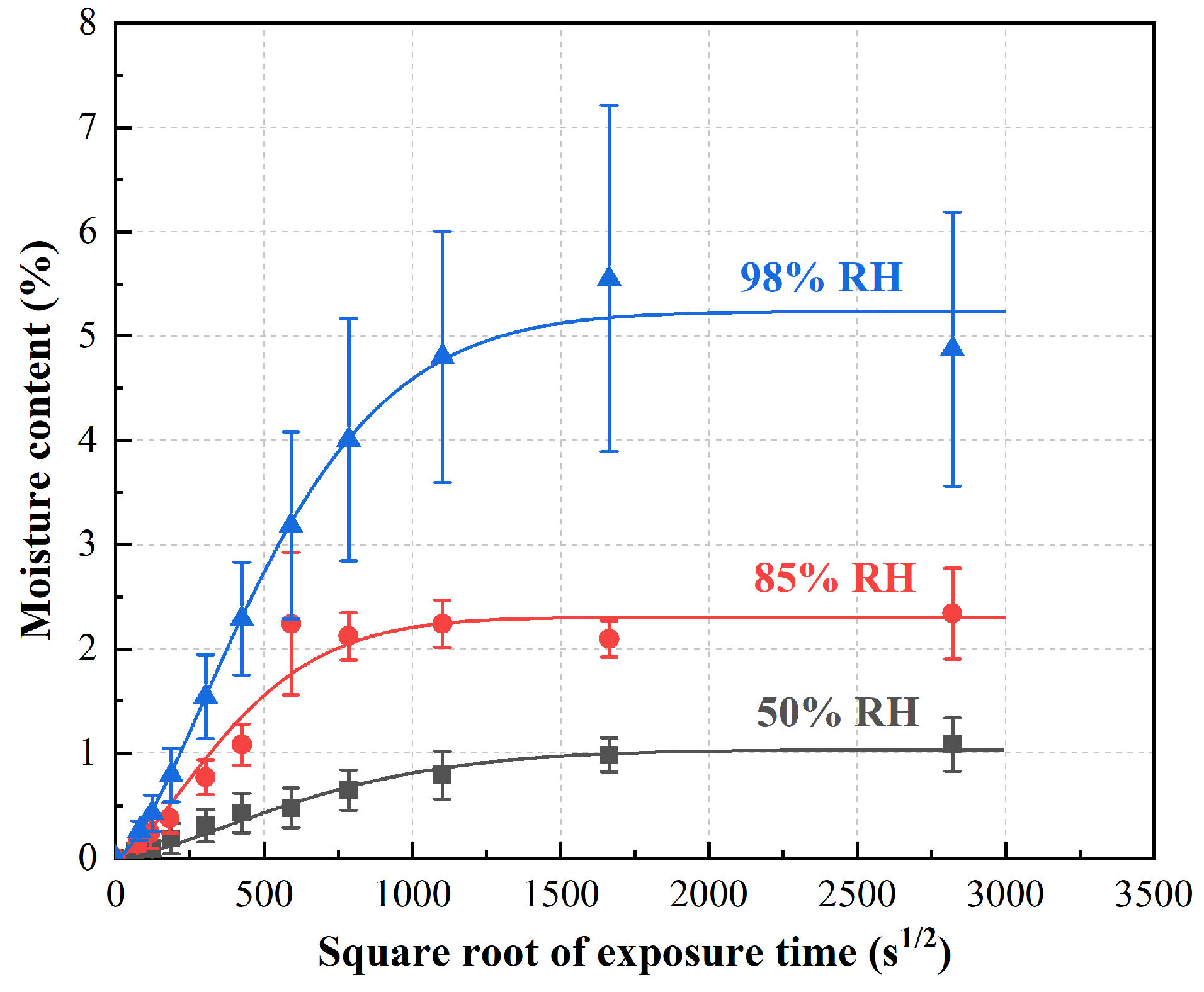

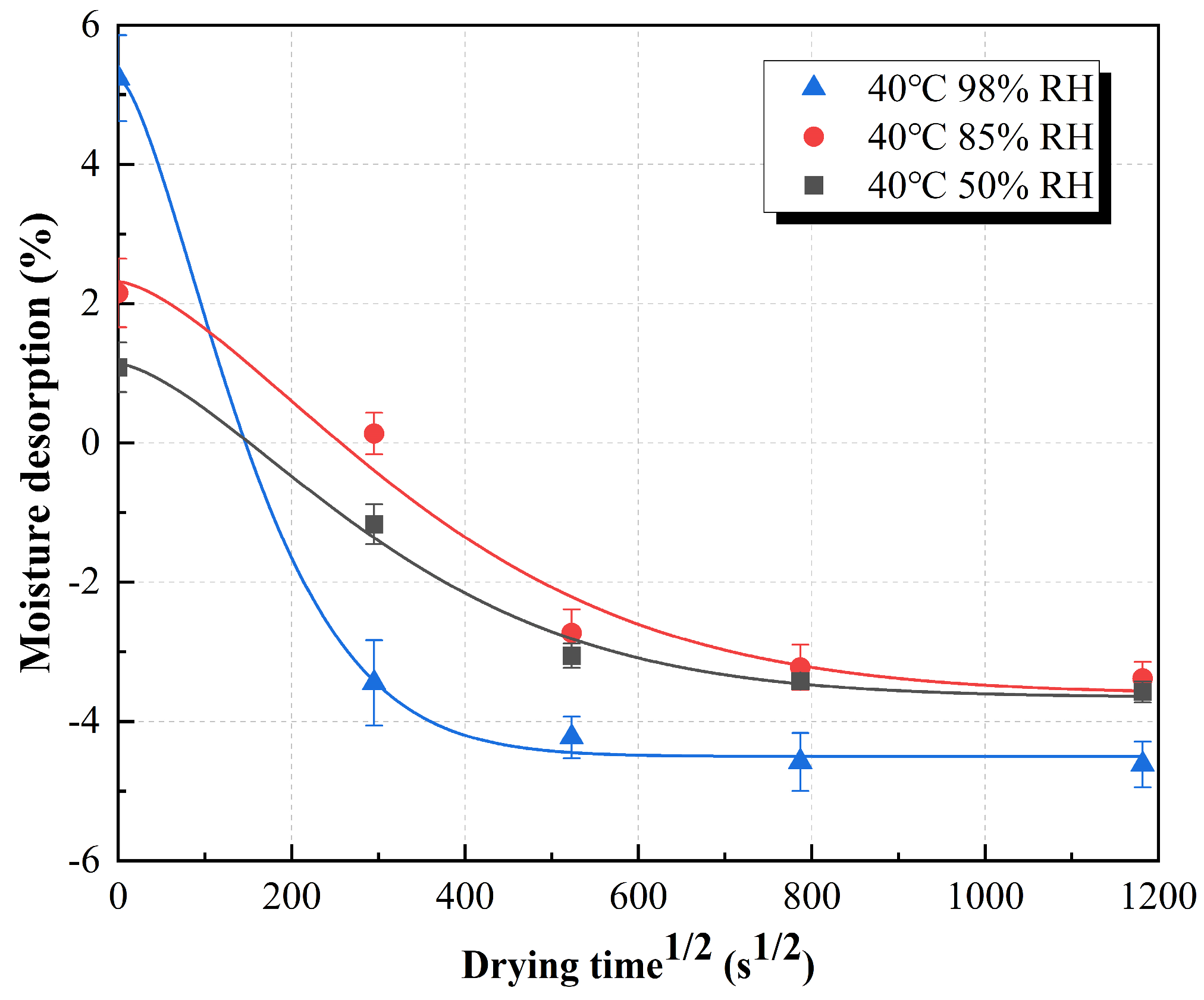

3.1. Moisture Absorption and Desorption

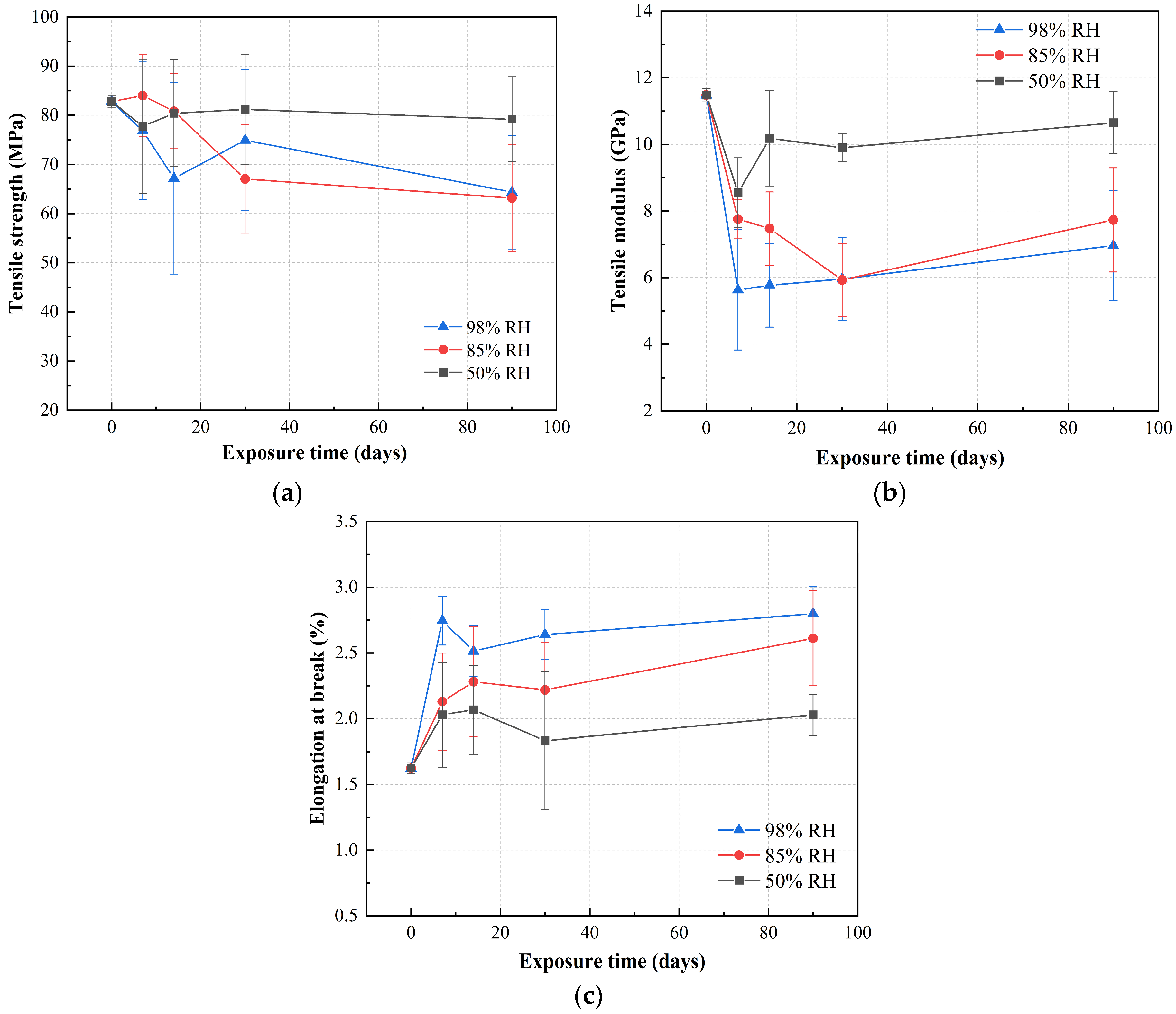

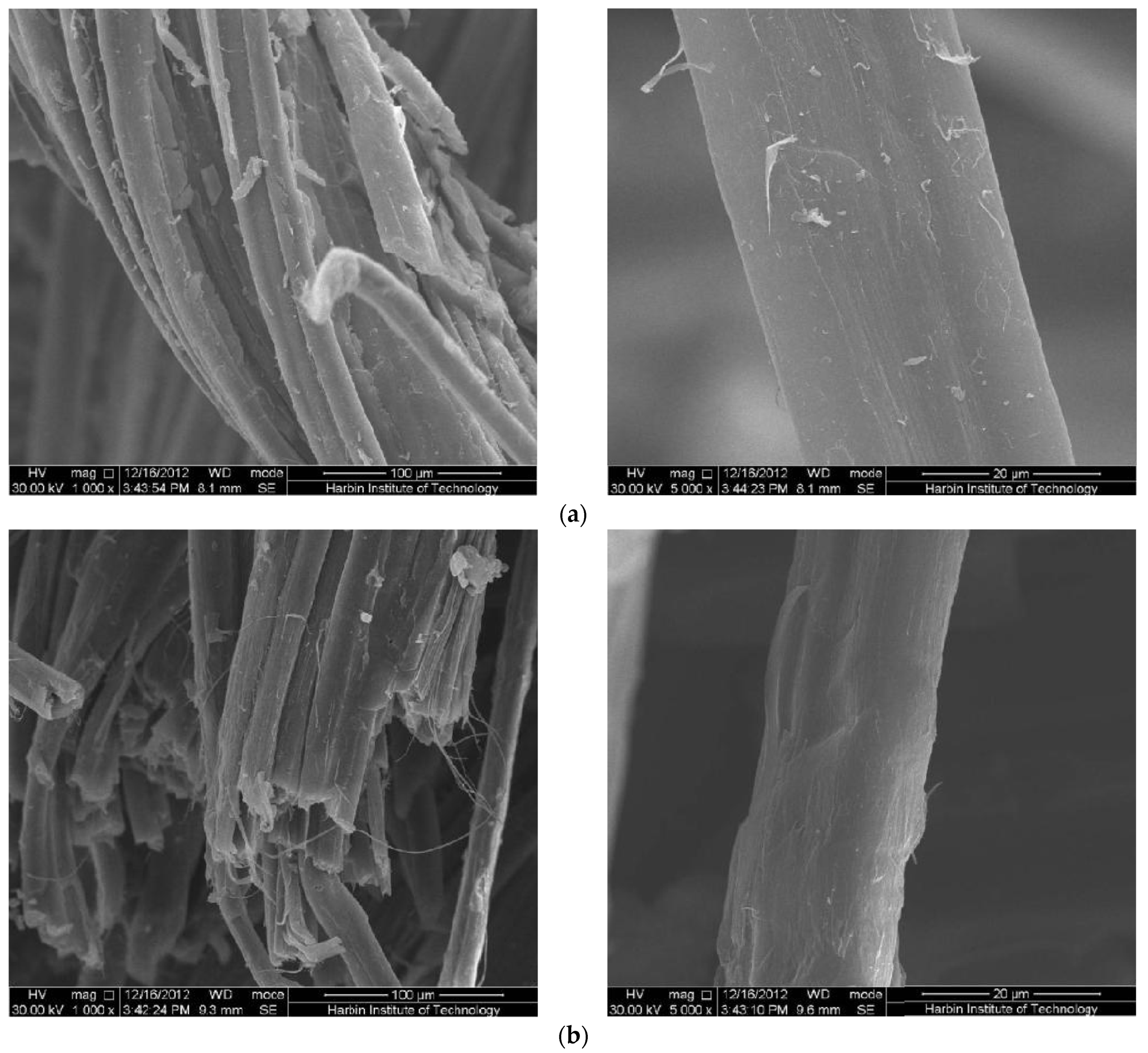

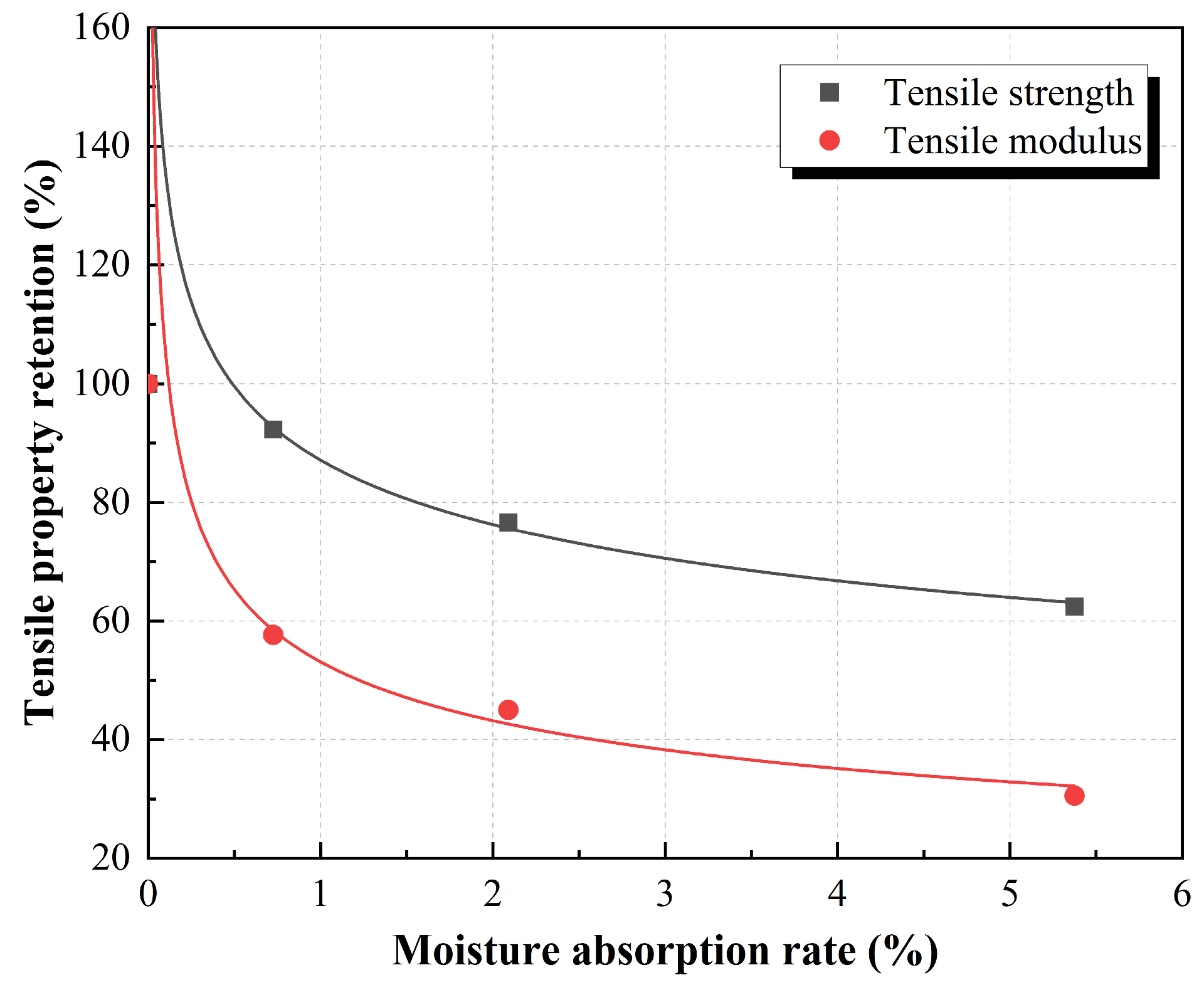

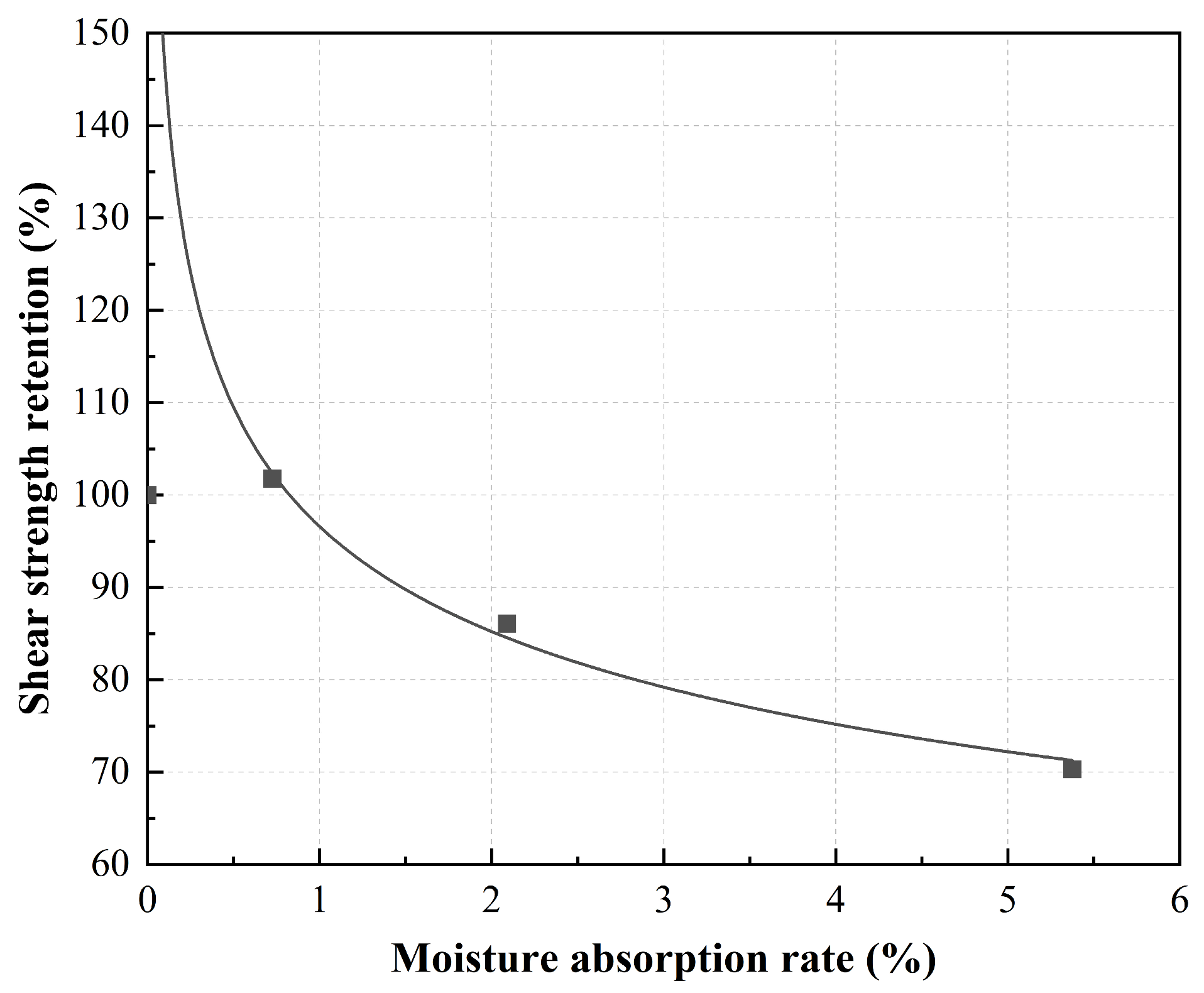

3.2. Degradation of Mechanical Properties

3.3. Mechanical Properties of Dried Samples

4. Summary and Conclusions

- (1)

- The moisture absorption and diffusion of ramie-fiber-reinforced polymer composites (RFRP) in a hydrothermal environment conform to Fick’s law. The equilibrium moisture absorption rate is mainly determined by the ambient humidity. As the ambient humidity increases, the equilibrium moisture absorption rate increases.

- (2)

- Mechanical properties of RFRP in a hydrothermal environment decline quickly in the first week, and then tend to be flat, and the mechanical properties of the material decrease significantly with the increase in humidity.

- (3)

- The water molecules reduce the interfacial bonding performance, which leads to the degradation of the mechanical properties of the ramie-fiber-reinforced composites in the hydrothermal environment, especially the significant decrease of the modulus.

- (4)

- After RFRP was treated in a hydrothermal environment, its weight loss was between 2.5% and 4.5%, and it increased with the increase in humidity. After drying, the mechanical properties of the RFRP significantly recover, similar to the initial value, and water has an irreversible effect on RFRP.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications. Polymers 2019, 11, 1667. [Google Scholar] [PubMed]

- Amjad, A.; Anjang Ab Rahman, A.; Awais, H.; Zainol Abidin, M.S.; Khan, J. A review investigating the influence of nanofiller addition on the mechanical, thermal and water absorption properties of cellulosic fibre reinforced polymer composite. J. Ind. Text. 2022, 51 (Suppl. S1), 65S–100S. [Google Scholar] [CrossRef]

- Chen, C.; Yang, Y.; Yu, J.; Yu, J.; Tan, H.; Sui, L.; Zhou, Y.J. Eco-friendly and mechanically reliable alternative to synthetic FRP in externally bonded strengthening of RC beams: Natural FRP. Compos. Struct. 2020, 241, 112081. [Google Scholar] [CrossRef]

- Awais, H.; Nawab, Y.; Anjang, A.; Akil, H.M.; Abidin, M.S.Z. Mechanical properties of continuous natural fibres (jute, hemp, flax) reinforced polypropylene composites modified with hollow glass microspheres. Fibers Polym. 2020, 21, 2076–2083. [Google Scholar] [CrossRef]

- Lian, C.; Liu, R.; Zhang, S.; Yuan, J.; Luo, J.; Yang, F.; Fei, B. Ultrastructure of parenchyma cell wall in bamboo (Phyllostachys edulis) culms. Cellulose 2020, 27, 7321–7329. [Google Scholar] [CrossRef]

- Dinwoodie, J.M. Timber: Its Nature and Behaviour; CRC Press: Boca Raton, FL, USA, 2000. [Google Scholar]

- Cheng, D.; Weng, B.; Chen, Y.; Zhai, S.; Wang, C.; Xu, R.; Guo, J.; Lv, Y.; Shi, L.; Guo, Y. Characterization of potential cellulose fiber from Luffa vine: A study on physicochemical and structural properties. Int. J. Biol. Macromol. 2020, 164, 2247–2257. [Google Scholar] [CrossRef]

- Bekele, A.E.; Lemu, H.G.; Jiru, M.G. Experimental study of physical, chemical and mechanical properties of enset and sisal fibers. Polym. Test. 2022, 106, 107453. [Google Scholar] [CrossRef]

- Sukmawan, R.; Kusmono; Wildan, M.W. Easy production of acetylated cellulose nanofibers from sisal fibers by conventional high-speed blender. Biomass-Convers. Biorefinery 2023, 1–12. [Google Scholar] [CrossRef]

- Mohammed, M.; Jawad, A.J.A.M.; Mohammed, A.M.; Oleiwi, J.K.; Adam, T.; Osman, A.F.; Dahham, O.S.; Betar, B.O.; Gopinath, S.C.; Jaafar, M. Challenges and advancement in water absorption of natural fiber-reinforced polymer composites. Polym. Test. 2023, 124, 108083. [Google Scholar]

- Karim, M.A.; Abdullah, M.Z.; Deifalla, A.F.; Azab, M.; Waqar, A. An assessment of the processing parameters and application of fibre-reinforced polymers (FRPs) in the petroleum and natural gas industries: A review. Results Eng. 2023, 18, 101091. [Google Scholar]

- Mohammed, M.; Rahman, R.; Mohammed, A.M.; Adam, T.; Betar, B.O.; Osman, A.F.; Dahham, O.S. Surface treatment to improve water repellence and compatibility of natural fiber with polymer matrix: Recent advancement. Polym. Test. 2022, 115, 107707. [Google Scholar] [CrossRef]

- Wang, A.; Liu, X.; Yue, Q.; Xian, G. Tensile properties hybrid effect of unidirectional flax/carbon fiber hybrid reinforced polymer composites. J. Mater. Res. Technol. 2023, 24, 1373–1389. [Google Scholar] [CrossRef]

- Espert, A.; Vilaplana, F.; Karlsson, S. Comparison of water absorption in natural cellulosic fibres from wood and one-year crops in polypropylene composites and its influence on their mechanical properties. Compos. Part A Appl. Sci. Manuf. 2004, 35, 1267–1276. [Google Scholar] [CrossRef]

- Moudood, A.; Rahman, A.; Khanlou, H.M.; Hall, W.; Öchsner, A.; Francucci, G. Environmental effects on the durability and the mechanical performance of flax fiber/bio-epoxy composites. Compos. Part B Eng. 2019, 171, 284–293. [Google Scholar] [CrossRef]

- Cai, M.; Zhang, X.; Sun, B.; Takagi, H.; Waterhouse, G.I.N.; Li, Y. Durable mechanical properties of unidirectional flax fiber/phenolic composites under hydrothermal aging. Compos. Sci. Technol. 2022, 220, 109264. [Google Scholar] [CrossRef]

- Jia, Y.; Fiedler, B.; Yang, W.; Feng, X.; Tang, J.; Liu, J.; Zhang, P. Durability of Plant Fiber Composites for Structural Application: A Brief Review. Materials 2023, 16, 3962. [Google Scholar] [CrossRef] [PubMed]

- Wang, A.; Xian, G.; Li, H.J.P. Effects of fiber surface grafting with nano-clay on the hydrothermal ageing behaviors of flax fiber/epoxy composite plates. Polymers 2019, 11, 1278. [Google Scholar] [CrossRef] [PubMed]

- Amiri Delouei, A.; Emamian, A.; Karimnejad, S.; Sajjadi, H.; Jing, D. Two-dimensional temperature distribution in FGM sectors with the power-law variation in radial and circumferential directions. J. Therm. Anal. Calorim. 2021, 144, 611–621. [Google Scholar] [CrossRef]

- Amiri Delouei, A.; Emamian, A.; Sajjadi, H.; Atashafrooz, M.; Li, Y.; Wang, L.-P.; Jing, D.; Xie, G. A comprehensive review on multi-dimensional heat conduction of Multi-layer and composite Structures: Analytical Solutions. J. Therm. Sci. 2021, 30, 1875–1907. [Google Scholar] [CrossRef]

- Yeh, S.-K.; Hu, C.-R.; Rizkiana, M.B.; Kuo, C.-H.J.C.; Materials, B. Effect of fiber size, cyclic moisture absorption and fungal decay on the durability of natural fiber composites. Constr. Build. Mater. 2021, 286, 122819. [Google Scholar] [CrossRef]

- Wang, B.; Panigrahi, S.; Tabil, L.; Crerar, W. Pre-treatment of flax fibers for use in rotationally molded biocomposites. J. Reinf. Plast. Compos. 2007, 26, 447–463. [Google Scholar] [CrossRef]

- Fraga, A.; Frullloni, E.; De la Osa, O.; Kenny, J.M.; Vázquez, A. Relationship between water absorption and dielectric behaviour of natural fibre composite materials. Polym. Test. 2006, 25, 181–187. [Google Scholar] [CrossRef]

- Mazzanti, V.; de Luna, M.S.; Pariante, R.; Mollica, F.; Filippone, G. Natural fiber-induced degradation in PLA-hemp biocomposites in the molten state. Compos. Part A Appl. Sci. Manuf. 2020, 137, 105990. [Google Scholar] [CrossRef]

- Pan, Y.; Zhong, Z. A micromechanical model for the mechanical degradation of natural fiber reinforced composites induced by moisture absorption. Mech. Mater. 2015, 85, 7–15. [Google Scholar] [CrossRef]

- Gunti, R.; Ratna Prasad, A.; Gupta, A. Mechanical and degradation properties of natural fiber-reinforced PLA composites: Jute, sisal, and elephant grass. Polym. Compos. 2018, 39, 1125–1136. [Google Scholar] [CrossRef]

- Rehman, M.; Gang, D.; Liu, Q.; Chen, Y.; Wang, B.; Peng, D.; Liu, L. Ramie, a multipurpose crop: Potential applications, constraints and improvement strategies. Ind. Crops Prod. 2019, 137, 300–307. [Google Scholar] [CrossRef]

- Kipriotis, E.; Heping, X.; Vafeiadakis, T.; Kiprioti, M.; Alexopoulou, D.E. Ramie and kenaf as feed crops. Ind. Crops Prod. 2015, 68, 126–130. [Google Scholar] [CrossRef]

- Beg, M.D.H.; Pickering, K.L. Reprocessing of wood fibre reinforced polypropylene composites. Part II: Hygrothermal ageing and its effects. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1565–1571. [Google Scholar] [CrossRef]

- Ji, M.; Li, J.; Li, F.; Wang, X.; Man, J.; Li, J.; Zhang, C.; Peng, S. A biodegradable chitosan-based composite film reinforced by ramie fibre and lignin for food packaging. Carbohydr. Polym. 2022, 281, 119078. [Google Scholar] [CrossRef]

- Petrenko, D.; Klushin, V.; Zelenskaya, A.; Yatsenko, A.; Sotnikov, A.; Ulyankina, A.; Smirnova, N. Natural fiber reinforced biomass-derived poly (ester-urethane–acrylate) composites for sustainable engineering applications. J. Polym. Res. 2022, 29, 503. [Google Scholar] [CrossRef]

- Xian, G.; Yin, P.; Kafodya, I.; Li, H.; Wang, W.-L. Durability study of ramie fiber fabric reinforced phenolic plates under humidity conditions. Sci. Eng. Compos. Mater. 2016, 23, 45–52. [Google Scholar] [CrossRef]

- Xiao, X.; Zhong, Y.; Cheng, M.; Sheng, L.; Wang, D.; Li, S. Improved hygrothermal durability of flax/polypropylene composites after chemical treatments through a hybrid approach. Cellulose 2021, 28, 11209–11229. [Google Scholar] [CrossRef]

- Loos, A.C.; Springer, G.S. Moisture absorption of graphite-epoxy composites immersed in liquids and in humid air. J. Compos. Mater. 1979, 13, 131–147. [Google Scholar] [CrossRef]

- Xian, G.; Guo, R.; Li, C. Combined effects of sustained bending loading, water immersion and fiber hybrid mode on the mechanical properties of carbon/glass fiber reinforced polymer composite. Compos. Struct. 2022, 281, 115060. [Google Scholar] [CrossRef]

| Saline Solution | Solubility at Room Temperature (g/mL) | Humidity (RH) |

|---|---|---|

| NaBr | 0.903 | 50% |

| KCl | 0.357 | 85% |

| K2SO4 | 0.120 | 98% |

| Hydrothermal Environment | Saturated Water Absorption Mm (%) | Diffusion Coefficient D (×10−6 mm2/s) |

|---|---|---|

| 40 °C 50% RH | 1.01 | 0.95 |

| 40 °C 85% RH | 2.31 | 2.52 |

| 40 °C 98% RH | 5.24 | 1.45 |

| Materials | a | b |

|---|---|---|

| RFRP | 0.06 | 4.93 |

| CFRP | 0.01~0.02 | 1 |

| Resin | 0.04~0.07 | 1~2 |

| Properties | Humidity Environments | Control | Standard Deviations | Three Monthes | Rate of Change | Drying | Rate of Change |

|---|---|---|---|---|---|---|---|

| Strength | 50% RH | 135.24 MPa | 9.87 MPa | 106.69 MPa | −21.11% | 121.56 MPa | −10.12% |

| 85% RH | 135.24 MPa | 9.87 MPa | 106.05 MPa | −21.58% | 133.11 MPa | −1.57% | |

| 95% RH | 135.24 MPa | 9.87 MPa | 119.14 MPa | −11.90% | 141.46 MPa | 4.60% | |

| Modulus | 50% RH | 9.69 GPa | 0.82 GPa | 7.71 GPa | −20.43% | 10.39 GPa | 7.22% |

| 85% RH | 9.69 GPa | 0.82 GPa | 6.22 GPa | −35.81% | 11.7 GPa | 20.74% | |

| 95% RH | 9.69 GPa | 0.82 GPa | 5.47 GPa | −43.55% | 11.28 GPa | 16.41% | |

| Deflection | 50% RH | 3.05 mm | 0.52 mm | 3.75 mm | 22.95% | 1.71 mm | −43.93% |

| 85% RH | 3.05 mm | 0.52 mm | 5.02 mm | 64.59% | 1.86 mm | −39.02% | |

| 95% RH | 3.05 mm | 0.52 mm | 4.14 mm | 35.74% | 2.15 mm | −29.51% |

| Humidity Environments | Control | Standard Deviations | Three Months | Rate of Change | Drying | Rate of Change |

|---|---|---|---|---|---|---|

| 50% RH | 18.26 MPa | 0.25 MPa | 18.70 MPa | 2.41% | 14.73 MPa | −19.33% |

| 85% RH | 18.26 MPa | 0.25 MPa | 17.30 MPa | −5.26% | 13.36 MPa | −26.83% |

| 95% RH | 18.26 MPa | 0.25 MPa | 16.80 MPa | −8.00% | 15.61 MPa | −14.51% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, A.; Yin, P.; Liu, X.; Xian, G. Hydrothermal Effect on Ramie-Fiber-Reinforced Polymer Composite Plates: Water Uptake and Mechanical Properties. Polymers 2023, 15, 3066. https://doi.org/10.3390/polym15143066

Wang A, Yin P, Liu X, Xian G. Hydrothermal Effect on Ramie-Fiber-Reinforced Polymer Composite Plates: Water Uptake and Mechanical Properties. Polymers. 2023; 15(14):3066. https://doi.org/10.3390/polym15143066

Chicago/Turabian StyleWang, Anni, Peng Yin, Xiaogang Liu, and Guijun Xian. 2023. "Hydrothermal Effect on Ramie-Fiber-Reinforced Polymer Composite Plates: Water Uptake and Mechanical Properties" Polymers 15, no. 14: 3066. https://doi.org/10.3390/polym15143066

APA StyleWang, A., Yin, P., Liu, X., & Xian, G. (2023). Hydrothermal Effect on Ramie-Fiber-Reinforced Polymer Composite Plates: Water Uptake and Mechanical Properties. Polymers, 15(14), 3066. https://doi.org/10.3390/polym15143066