The Thermal and Mechanical Behaviour of Wood-PLA Composites Processed by Additive Manufacturing for Building Insulation

Abstract

1. Introduction

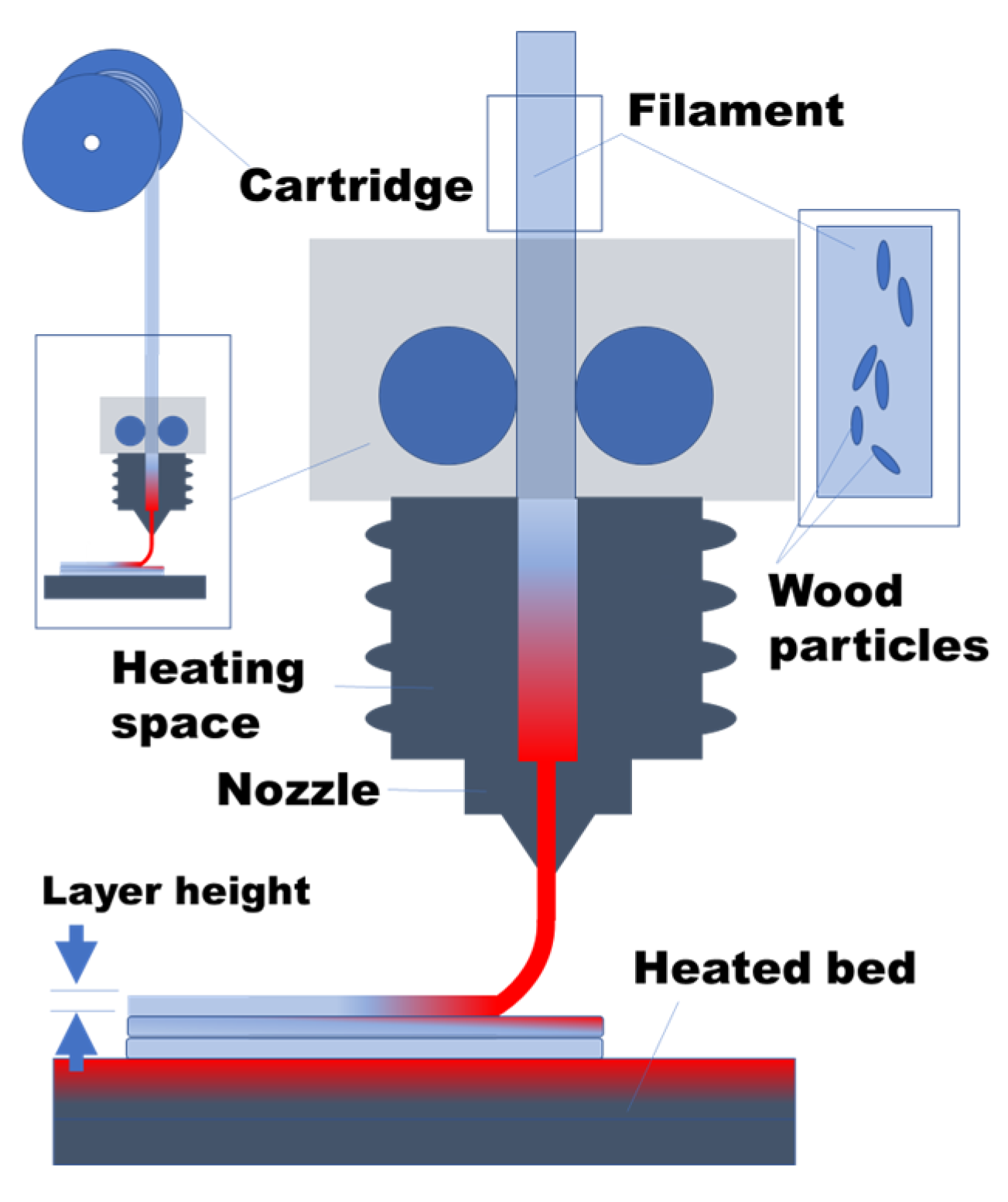

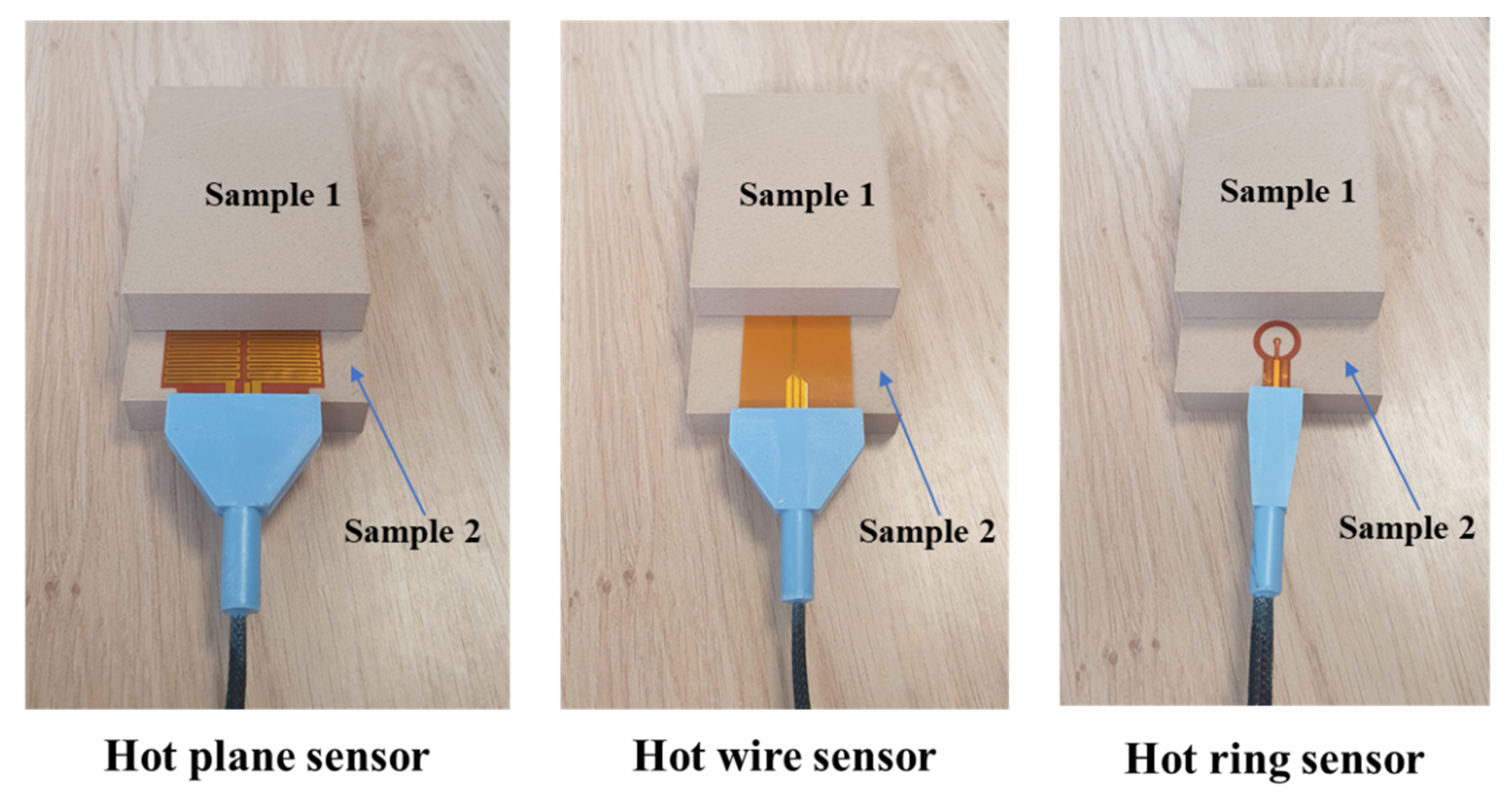

2. Experimental Layout

3. Results and Discussion

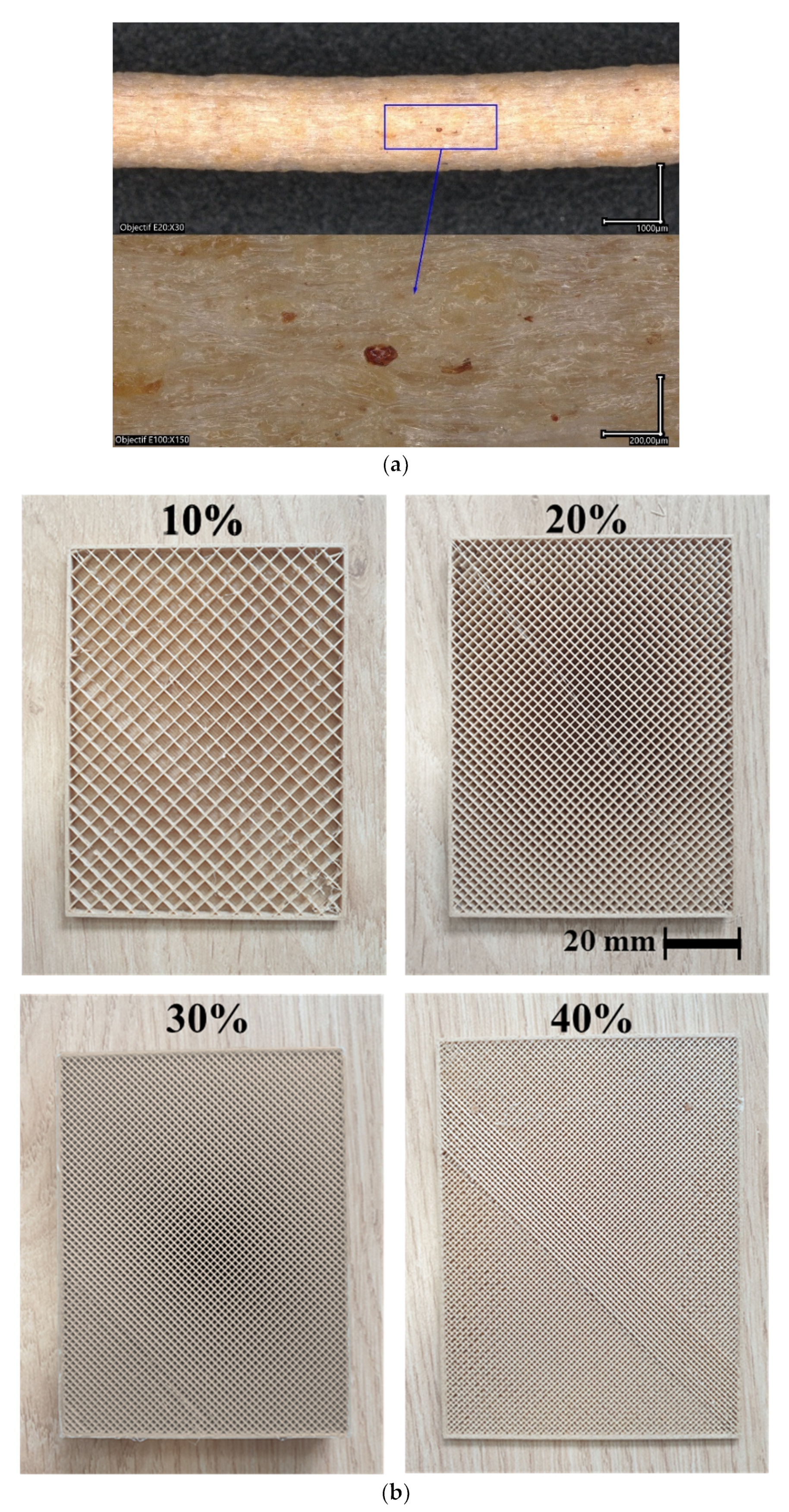

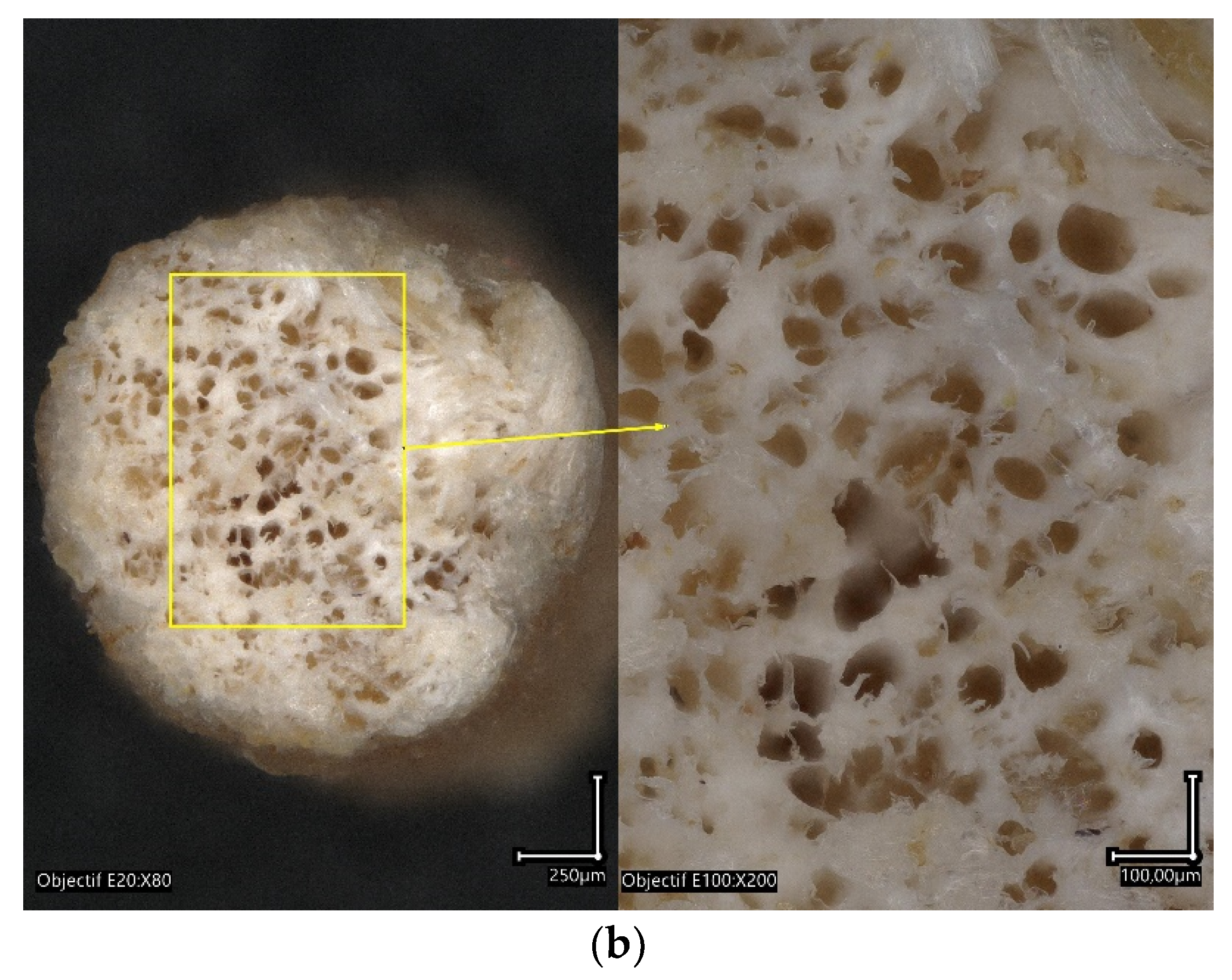

3.1. Morphology of PHW Filament

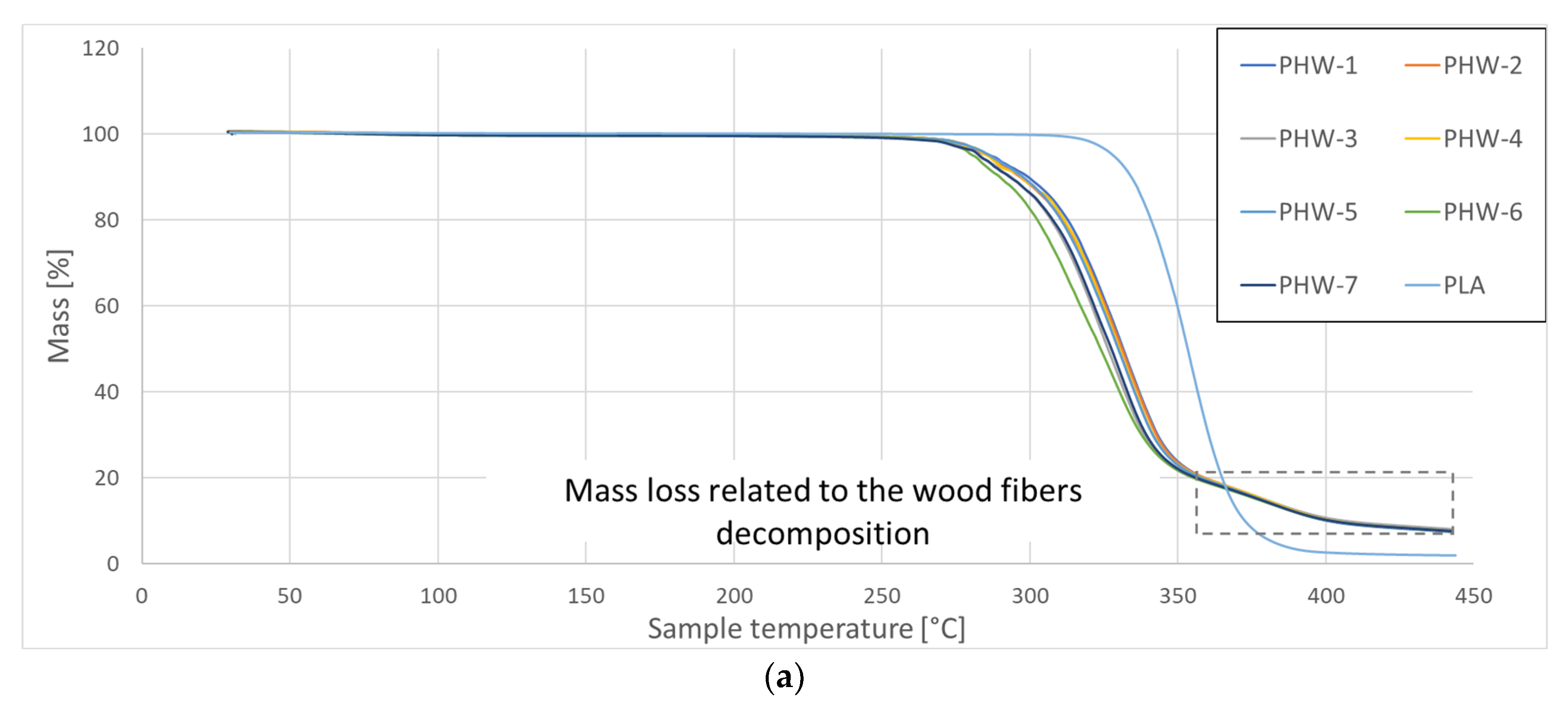

3.2. Thermal Properties of as-Received and Extruded Filaments

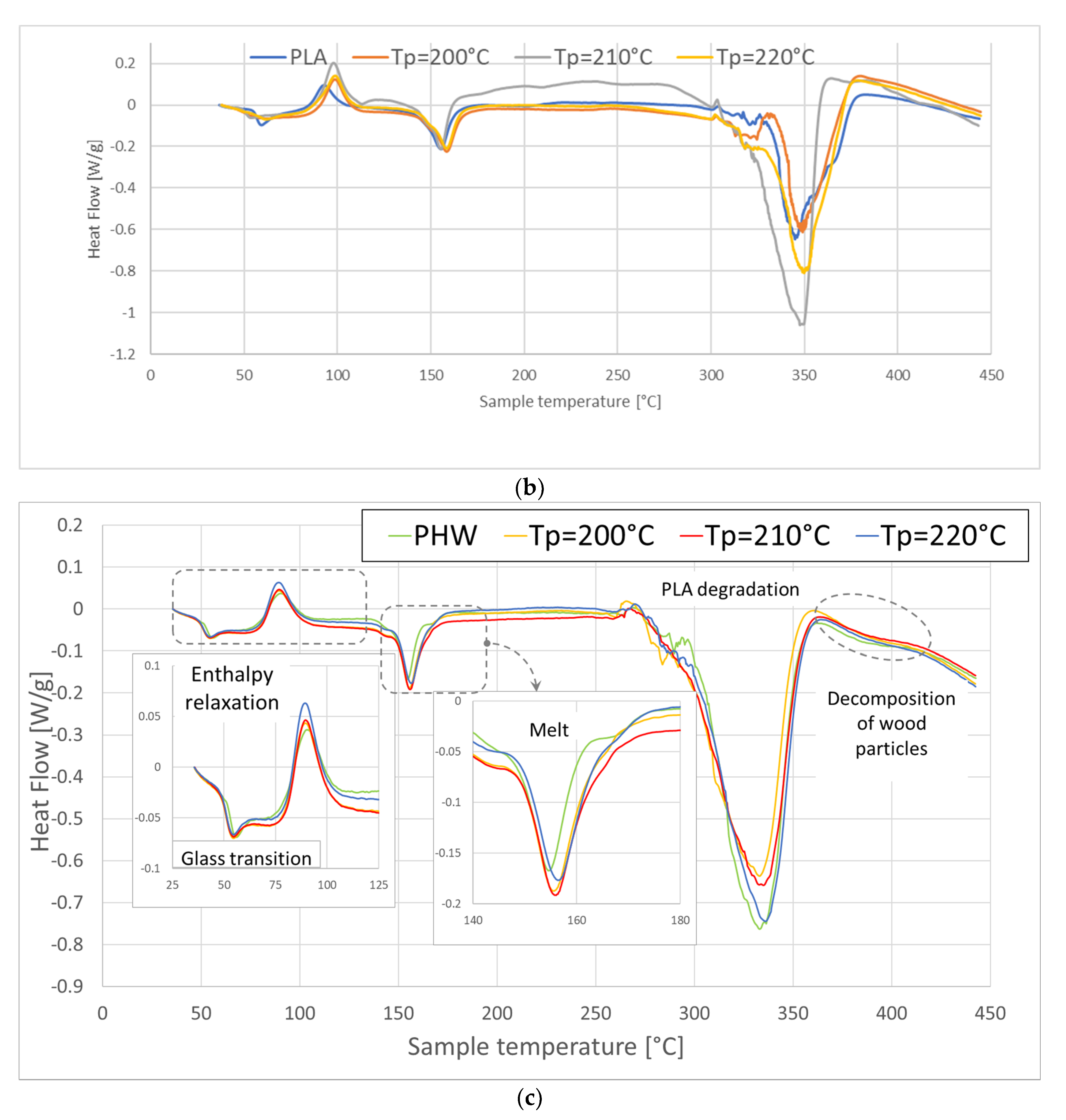

3.3. Thermal Properties of 3D Printed Wood-PLA Filament

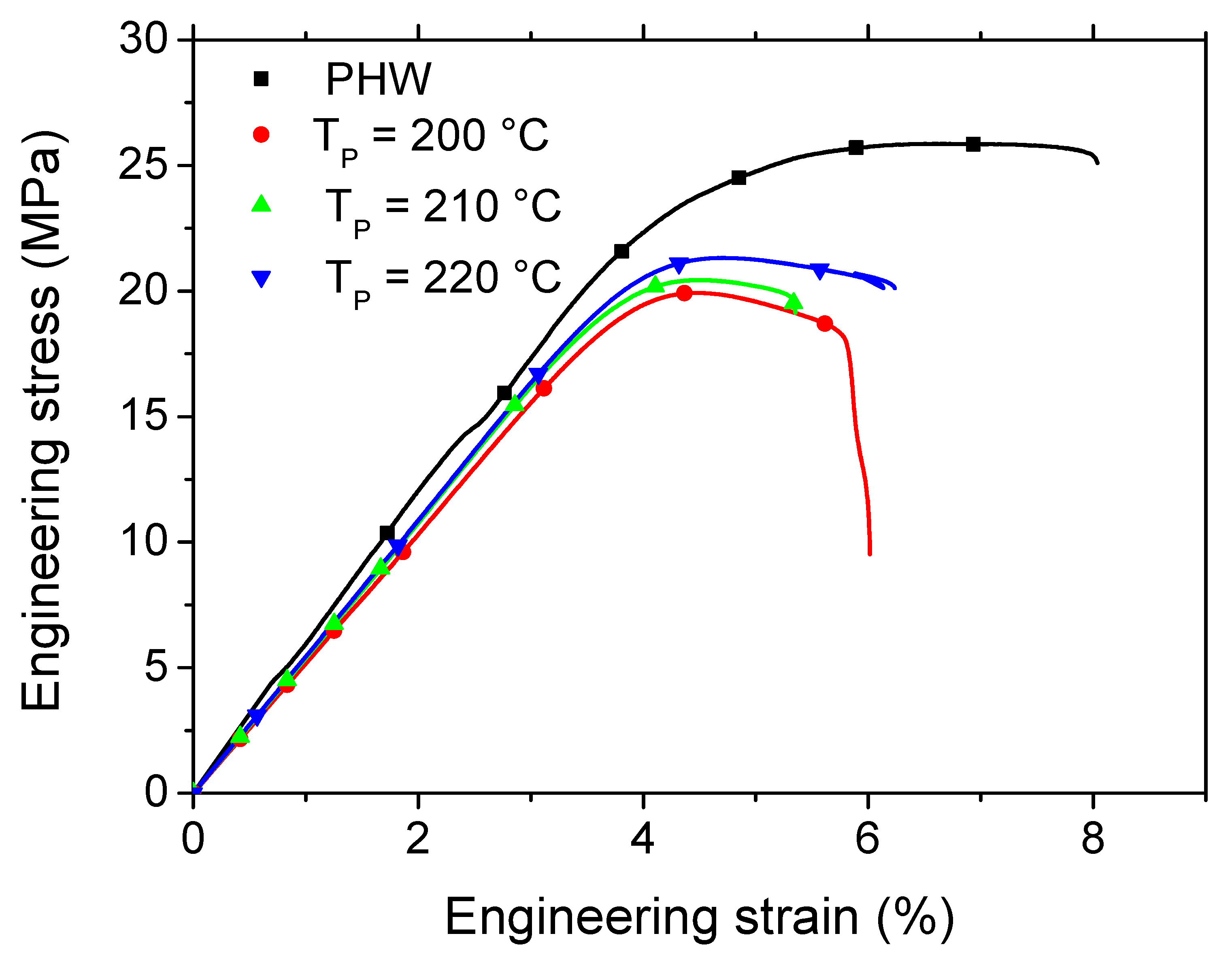

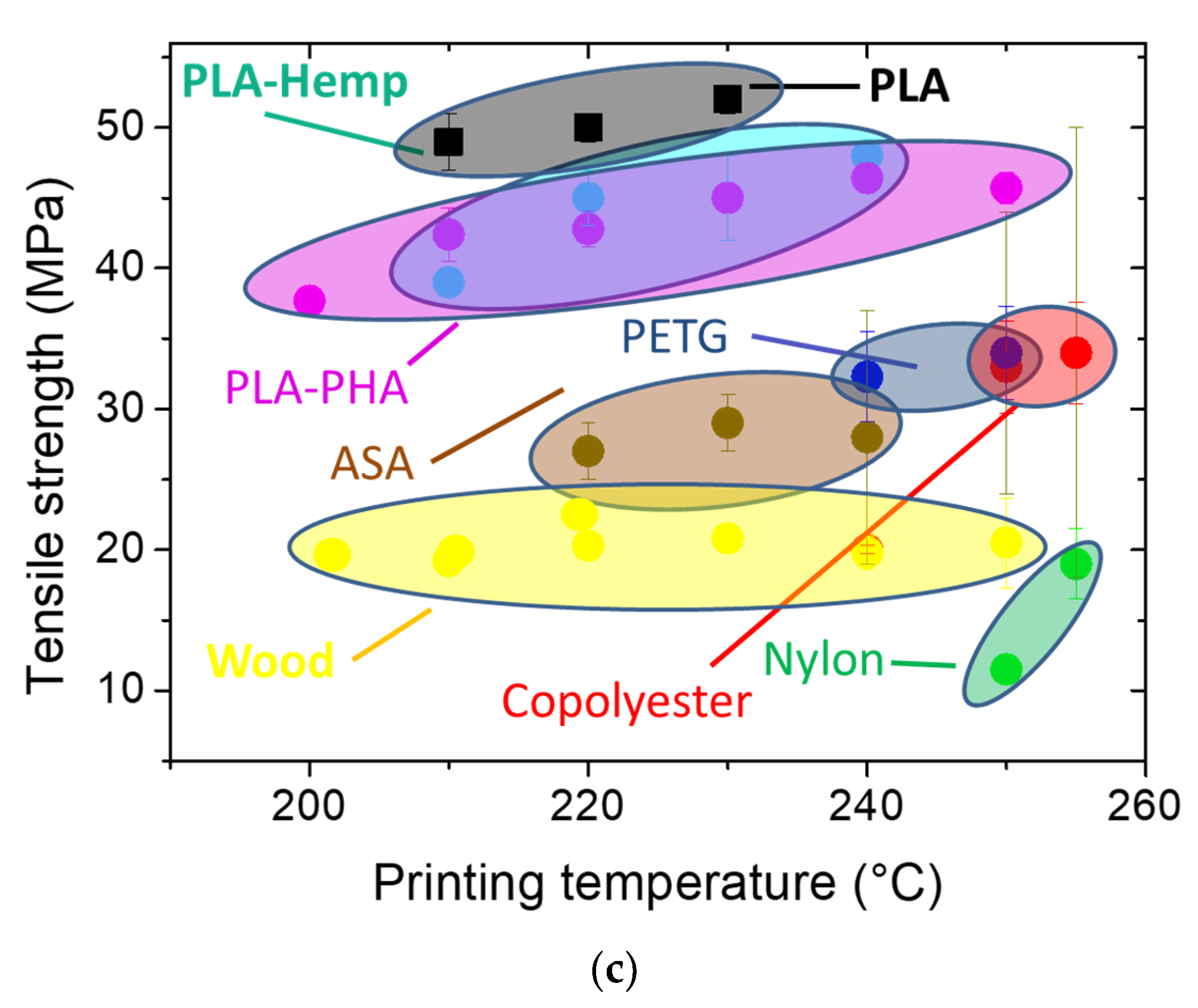

3.4. Mechanical Performance of as-Received and Printed Wood-PLA Material

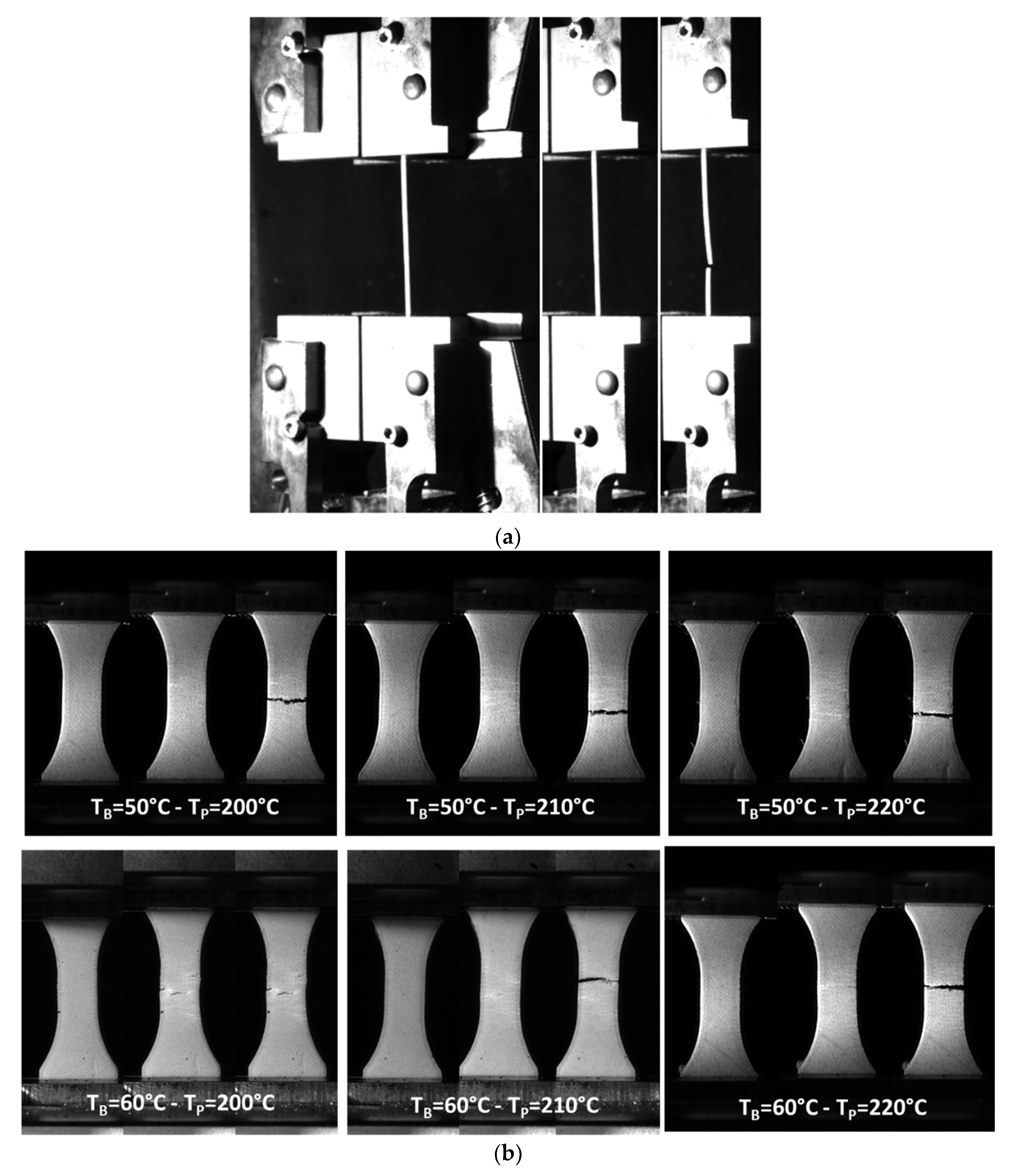

3.5. Filament Arrangement and Fracture Patterns

- -

- Pure uniaxial tension, which localizes at the periphery. This mechanism is related to the presence of an external frame that promotes uniaxial deformation in the loading direction

- -

- Combined uniaxial and shear deformation, which is related to the misalignment of the filament within the raster, with respect to the loading conditions.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Beny, F.; Canas, S.; Chavanne, M.; Deutsch, D.; Persoz, L.; Tuel. Report of the Intergovernmental Panel on Climate Change; Shifters, T., Ed.; GIEC: Tamil Nadu, India, 2022. [Google Scholar]

- CEREMA. Reducing The Environmental Impact of Building in The Evolution of Mobility and Planning 2022; Center for Studies and Expertise on Risks, the Environment: Lyon, France, 2022. [Google Scholar]

- Bousshine, S.; Ouakarrouch, M.; Bybi, A.; Laaroussi, N.; Garoum, M.; Tilioua, A. Acoustical and thermal characterization of sustainable materials derived from vegetable, agricultural, and animal fibers. Appl. Acoust. 2021, 187, 108520. [Google Scholar] [CrossRef]

- Ouakarrouch, M.; El Azhary, K.; Laaroussi, N.; Garoum, M.; Kifani-Sahban, F. Thermal performances and environmental analysis of a new composite building material based on gypsum plaster and chicken feathers waste. Therm. Sci. Eng. Prog. 2020, 19, 100642. [Google Scholar] [CrossRef]

- Colinart, T.; Pajeot, M.; Vinceslas, T.; De Menibus, A.H.; Lecompte, T. Thermal conductivity of biobased insulation building materials measured by hot disk: Possibilities and recommendation. J. Build. Eng. 2021, 43, 102858. [Google Scholar] [CrossRef]

- Ricciardi, P.; Buratti, C. Environmental quality of university classrooms: Subjective and objective evaluation of the thermal, acoustic, and lighting comfort conditions. Build. Environ. 2018, 127, 23–36. [Google Scholar] [CrossRef]

- Jadhav, A.; Jadhav, V.S. A review on 3D printing: An additive manufacturing technology. Mater. Today Proc. 2022, 62, 2094–2099. [Google Scholar] [CrossRef]

- Praveena, B.A.; Lokesh, N.; Buradi, A.; Santhosh, N.; Praveena, B.L.; Vignesh, R. A comprehensive review of emerging additive manufacturing (3D printing technology): Methods, materials, applications, challenges, trends and future potential. Mater. Today Proc. 2021, 52, 1309–1313. [Google Scholar] [CrossRef]

- Pasco, J.; Lei, Z.; Aranas, C. Additive Manufacturing in Off-Site Construction: Review and Future Directions. Buildings 2022, 12, 53. [Google Scholar] [CrossRef]

- Penumakala, P.K.; Santo, J.; Thomas, A. A critical review on the fused deposition modeling of thermoplastic polymer composites. Compos. Part B Eng. 2020, 201, 108336. [Google Scholar] [CrossRef]

- Yadav, A.; Rohru, P.; Babbar, A.; Kumar, R.; Ranjan, N.; Chohan, J.S.; Kumar, R.; Gupta, M. Fused filament fabrication: A state-of-the-art review of the technology, materials, properties and defects. Int. J. Interact. Des. Manuf. (IJIDeM) 2022, 16, 1–23. [Google Scholar] [CrossRef]

- Fico, D.; Rizzo, D.; Casciaro, R.; Corcione, C.E. A Review of Polymer-Based Materials for Fused Filament Fabrication (FFF): Focus on Sustainability and Recycled Materials. Polymers 2022, 14, 465. [Google Scholar] [CrossRef]

- Ulkir, O. Energy-Consumption-Based Life Cycle Assessment of Additive-Manufactured Product with Different Types of Materials. Polymers 2023, 15, 1466. [Google Scholar] [CrossRef]

- Mazzanti, V.; Malagutti, L.; Mollica, F. FDM 3D Printing of Polymers Containing Natural Fillers: A Review of their Mechanical Properties. Polymers 2019, 11, 1094. [Google Scholar] [CrossRef]

- Travieso-Rodriguez, J.A.; Zandi, M.D.; Jerez-Mesa, R.; Lluma-Fuentes, J. Fatigue behavior of PLA-wood composite manufactured by fused filament fabrication. J. Mater. Res. Technol. 2020, 9, 8507–8516. [Google Scholar] [CrossRef]

- Dana, H.R.; El Mansori, M. Investigations on the mechanical properties of PLA/Flax fibre composites obtained by Fused Filament Fabrication. Plast. Rubber Compos. 2022, 51, 393–406. [Google Scholar] [CrossRef]

- Doğru, A.; Sözen, A.; Seydibeyoğlu, M.; Neşer, G. Hemp Reinforced Polylactic Acid (PLA) Composite Produced By Fused Filament Fabrication (FFF). Hacet. J. Biol. Chem. 2022, 50, 239–246. [Google Scholar] [CrossRef]

- Liu, Z.; Lei, Q.; Xing, S. Mechanical characteristics of wood, ceramic, metal and carbon fiber-based PLA composites fabricated by FDM. J. Mater. Res. Technol. 2019, 8, 3741–3751. [Google Scholar] [CrossRef]

- Kananathan, J.; Samykano, M.; Kadirgama, K.; Ramasamy, D.; Rahman, M.M. Comprehensive investigation and prediction model for mechanical properties of coconut wood–polylactic acid composites filaments for FDM 3D printing. Eur. J. Wood Wood Prod. 2021, 80, 75–100. [Google Scholar] [CrossRef]

- Tao, Y.; Wang, H.; Li, Z.; Li, P.; Shi, S.Q. Development and Application of Wood Flour-Filled Polylactic Acid Composite Filament for 3D Printing. Materials 2017, 10, 339. [Google Scholar] [CrossRef]

- Yang, T.-C.; Yeh, C.-H. Morphology and Mechanical Properties of 3D Printed Wood Fiber/Polylactic Acid Composite Parts Using Fused Deposition Modeling (FDM): The Effects of Printing Speed. Polymers 2020, 12, 1334. [Google Scholar] [CrossRef]

- Hassana, O.B.; Guessasma, S.; Belhabib, S.; Nouri, H. Explaining the Difference Between Real Part and Virtual Design of 3D Printed Porous Polymer at the Microstructural Level. Macromol. Mater. Eng. 2016, 301, 566–576. [Google Scholar] [CrossRef]

- ISO-1183-1:2019; Plastics—Methods for Determining the Ddensity of Non-Cellular Plastics—part 1: Immersion Method, Liquid Medium Pycnometer Method and Titration Method. ISO/TC 61/SC 5; International Organization for Standardization: Geneva, Switzerland, 2019; p. 13. Available online: https://www.iso.org/standard/74990.html (accessed on 23 May 2023).

- ISO-527-1:2019; Plastics—Determination of Tensile Properties—Part 1: General Principles. ISO/TC 61/SC 2; International Organization for Standardization: Geneva, Switzerland, 2019; p. 29. Available online: https://www.iso.org/standard/75824.html (accessed on 23 May 2023).

- ISO-178:2019; Plastics—Determination of Flexural Properties. ISO/TC 61/SC 2; International Organization for Standardization: Geneva, Switzerland, 2019; p. 26. Available online: https://www.iso.org/standard/70513.html (accessed on 23 May 2023).

- ISO-179-1:2010; Plastics—Determination of Charpy Impact Properties—Part 1: Non-Instrumented Impact Test. ISO/TC 61/SC 2; International Organization for Standardization: Geneva, Switzerland, 2019; p. 22. Available online: https://www.iso.org/standard/44852.html (accessed on 23 May 2023).

- Guessasma, S.; Belhabib, S. Infill Strategy in 3D Printed PLA Carbon Composites: Effect on Tensile Performance. Polymers 2022, 14, 4221. [Google Scholar] [CrossRef] [PubMed]

- Belarbi, Y.E.; Guessasma, S.; Belhabib, S.; Benmahiddine, F.; Hamami, A.E.A. Effect of Printing Parameters on Mechanical Behaviour of PLA-Flax Printed Structures by Fused Deposition Modelling. Materials 2021, 14, 5883. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.-C.; Kim, D.-Y.; Lee, J.-E.; Park, K. Improvement of mechanical properties and surface finish of 3d-printed polylactic acid parts by constrained remelting. Adv. Mater. Lett. 2017, 8, 1199–1203. [Google Scholar] [CrossRef]

- Belarbi, Y.E.; Benmahiddine, F.; Hamami, A.E.A.; Guessasma, S.; Belhabib, S. Hygrothermal and Microstructural Investigation of PLA and PLA-Flax Printed Structures. Fibers 2022, 10, 24. [Google Scholar] [CrossRef]

- Nagy, B.; Simon, T.K.; Nemes, R. Effect of built-in mineral wool insulations durability on its thermal and mechanical performance. J. Therm. Anal. Calorim. 2019, 139, 169–181. [Google Scholar] [CrossRef]

- Bae, M.; Ahn, H.; Kang, J.; Choi, G.; Choi, H. Determination of the Long-Term Thermal Performance of Foam Insulation Materials through Heat and Slicing Acceleration. Polymers 2022, 14, 4926. [Google Scholar] [CrossRef]

- Guessasma, S.; Belhabib, S.; Altin, A. On the Tensile Behaviour of Bio-Sourced 3D-Printed Structures from a Microstructural Perspective. Polymers 2020, 12, 1060. [Google Scholar] [CrossRef]

- Guessasma, S.; Belhabib, S.; Nouri, H.; Ben Hassana, O. Anisotropic damage inferred to 3D printed polymers using fused deposition modelling and subject to severe compression. Eur. Polym. J. 2016, 85, 324–340. [Google Scholar] [CrossRef]

| Property | Level |

|---|---|

| Wire diameter, (mm) | 1.75 ± 0.05 mm |

| Density, (g/cm3) | 1.15 g/cm3 (ISO 1183) [23] |

| Tensile modulus, (MPa) | 3290 (ISO 527) [24] |

| Tensile strength, (MPa) | 46 (ISO 527) |

| Tensile strain at tensile strength, (%) | 4.6 (ISO 527) |

| Tensile stress at break, (MPa) | 42 (ISO 527) |

| Tensile strain at break, (MPa) | 5.5 (ISO 527) |

| Flexural modulus, (MPa) | 3930 MPa (ISO 178) [25] |

| Flexural strain at break, (%) | 5% (ISO 178) |

| Sharpy notched impact strength, (kJ/m2) | 4.2 (ISO 179-1/1 eA) [26] |

| Sharpy impact strength, (kJ/m2) | 19.0 (ISO 179-1/1 eU) |

| Glass transition temperature, °C | 55 °C |

| Printing temperature, °C | 195–220 °C |

| Bed temperature, °C | 50–60 °C |

| Printing speed, mm/s | 40–100 |

| Printing Condition | Value |

|---|---|

| Nozzle diameter, mm | 0.4 |

| Layer height, mm | 0.2 |

| Wall thickness, mm | 0.8 |

| Top/bottom thickness, mm | 0.6 |

| Printing speed, mm/s | 50 |

| Building sequence, deg. | +45/−45 |

| Material | Thermal Conductivity | Thermal Effusivity | Thermal Diffusivity |

|---|---|---|---|

| 3D printed PHW | 0.14/50/0 | 2.1/50/0 | 1.5/100/30 |

| Glass wool | 0.1/30/0 | 1/30/0 | 1/65/25 |

| Synthetic foam | 0.8/35/0 | 1/30/0 | 0.61/60/25 |

| Material | Thermal Transitions: E/O/P/E | ||||

|---|---|---|---|---|---|

| PHW—as-received | 3.8 ± 0.92 51 ± 0.8 56 ± 0.4 63 ± 1.1 | 13.9 ± 0.40 80 ± 0.5 90 ± 0.5 103 ± 0.7 | 20.8 ± 0.66 147 ± 0.5 155 ± 0.2 161 ± 0.3 | 310.2 ± 17.24 285 ± 10.6 331 ± 2.9 353 ± 4.9 | 5.5 ± 1.05 264 ± 1.2 387 ± 1.5 411 ± 1.6 |

| PHW—TP = 200 °C | 3.1 ± 0.25 49 ± 0.4 54 ± 0.3 62 ± 1.0 | 15.3 ± 0.85 80 ± 0.2 90 ± 0.2 102 ± 0.4 | 21.7 ± 1.01 148 ± 0.3 156 ± 0.5 164 ± 0.6 | 318.8 ± 5.71 277 ± 3.3 334 ± 1.0 355 ± 1.6 | 4.1 ± 0.39 364 ± 2.9 386 ± 0.9 411 ± 1.0 |

| PHW—TP = 210 °C | 3.4 ± 0.12 49 ± 0.0 54 ± 0.3 62 ± 0.4 | 16.5 ± 0.13 80 ± 0.3 89 ± 0.4 102 ± 0.9 | 21.4 ± 0.55 149 ± 0.1 156 ± 0.2 164 ± 0.7 | 336.1 ± 46.83 279 ± 1.0 335 ± 1.5 357 ± 0.3 | 3.8 ± 0.65 368 ± 1.1 385 ± 1.4 411 ± 1.3 |

| PHW—TP = 220 °C | 3.2 ± 0.27 49 ± 0.1 54 ± 0.1 62 ± 0.3 | 16.2 ± 0.18 81 ± 0.2 89 ± 0.1 101 ± 0.5 | 23.1 ± 1.06 149 ± 0.2 156 ± 0.4 164 ± 0.4 | 328.6 ± 5.34 284 ± 0.4 335 ± 1.8 358 ± 1.8 | 2.6 ± 1.50 368 ± 0.7 385 ± 0.6 407 ± 5.9 |

| Property | Infill Rate (%) | |||

|---|---|---|---|---|

| Infill rate (%) | 10 | 20 | 30 | 40 |

| Density (kg/m3) | 168 ± 6 | 261 ± 1 | 333 ± 10 | 399 ± 2 |

| Thermal conductivity (mW/(mK)) | 49.50 ± 1.29 | 66.75 ± 1.43 | 73.25 ± 2.99 | 78.75 ± 2.36 |

| Thermal effusivity (Ws0.5/(m2K)) | 127 ± 4 | 179 ± 1 | 199 ± 4 | 221 ± 3 |

| Thermal diffusivity (×10−7 m2/s) | 1.98 ± 0.02 | 1.74 ± 0.05 | 1.59 ± 0.06 | 1.56 ± 0.05 |

| Property | Printing Temperature (°C) | ||

|---|---|---|---|

| 200 | 210 | 220 | |

| Thermal conductivity (mW/(mK)) | 49.50 ± 1.29 | 50.25 ± 0.96 | 52.25 ± 1.71 |

| Thermal effusivity (Ws0.5/(m2K)) | 127 ± 4 | 128 ± 2 | 128 ± 1 |

| Thermal diffusivity (×10−7 m2/s) | 1.98 ± 0.02 | 1.95 ± 0.01 | 1.91 ± 0.03 |

| Property | Material | |

|---|---|---|

| Material | Glass wool | Synthetic Foam |

| Density (kg/m3) | 106 ± 0.00 | 31.3 |

| Thermal conductivity (mW/(mK)) | 31.50 ± 1.00 | 36.00 ± 1.41 |

| Thermal effusivity (Ws0.5/(m2K)) | 61.00 + 1.15 | 70.50 ± 1.29 |

| Thermal diffusivity (×10−7 m2/s) | 4.08 ± 0.06 | 4.23 ± 0.05 |

| Material | TB (°C) | TP (°C) | EY (GPa) | σY (MPa) | σS (MPa) | σR (MPa) | εR (%) |

|---|---|---|---|---|---|---|---|

| PLA | - | - | 1.09 ± 0.14 | 42.56 ± 3.82 | 54 ± 0.00 | 47.83 ± 0.77 | 5.5 ± 1.8 |

| PHW | - | - | 0.54 ± 0.058 | 24.55 ± 0.481 | 25.53 ± 0.319 | 21.84 ± 2.539 | 7.6 ± 0.8 |

| 3D printed | 50 | 200 | 0.53 ± 0.010 | 18.71 ± 0.988 | 20.60 ± 1.101 | 18.65 ± 1.987 | 5.3 ± 1.99 |

| 60 | 200 | 0.53 ± 0.015 | 18.88 ± 0.524 | 20.70 ± 0.680 | 16.23 ± 5.834 | 5.6 ± 0.40 | |

| 50 | 210 | 0.53 ± 0.005 | 18.56 ± 0.589 | 20.39 ± 0.672 | 17.56 ± 0.075 | 5.6 ± 0.30 | |

| 60 | 210 | 0.53 ± 0.013 | 18.33 ± 0.883 | 20.12 ± 1.028 | 17.02 ± 3.681 | 5.6 ± 0.30 | |

| 50 | 220 | 0.53 ± 0.021 | 18.72 ± 1.078 | 20.62 ± 1.097 | 15.92 ± 5.515 | 6.1 ± 0.3 | |

| 60 | 220 | 0.54 ± 0.012 | 18.97 ± 0.229 | 21.12 ± 0.285 | 18.66 ± 2.058 | 6.2 ± 0.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bahar, A.; Hamami, A.E.A.; Benmahiddine, F.; Belhabib, S.; Belarbi, R.; Guessasma, S. The Thermal and Mechanical Behaviour of Wood-PLA Composites Processed by Additive Manufacturing for Building Insulation. Polymers 2023, 15, 3056. https://doi.org/10.3390/polym15143056

Bahar A, Hamami AEA, Benmahiddine F, Belhabib S, Belarbi R, Guessasma S. The Thermal and Mechanical Behaviour of Wood-PLA Composites Processed by Additive Manufacturing for Building Insulation. Polymers. 2023; 15(14):3056. https://doi.org/10.3390/polym15143056

Chicago/Turabian StyleBahar, Anis, Ameur El Amine Hamami, Ferhat Benmahiddine, Sofiane Belhabib, Rafik Belarbi, and Sofiane Guessasma. 2023. "The Thermal and Mechanical Behaviour of Wood-PLA Composites Processed by Additive Manufacturing for Building Insulation" Polymers 15, no. 14: 3056. https://doi.org/10.3390/polym15143056

APA StyleBahar, A., Hamami, A. E. A., Benmahiddine, F., Belhabib, S., Belarbi, R., & Guessasma, S. (2023). The Thermal and Mechanical Behaviour of Wood-PLA Composites Processed by Additive Manufacturing for Building Insulation. Polymers, 15(14), 3056. https://doi.org/10.3390/polym15143056