Comparative Study on the Stiffness of Poly(lactic acid) Reinforced with Untreated and Bleached Hemp Fibers

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Biocomposites

2.3. Characterization of Biocomposites

2.4. Modeling and Calculation

3. Results and Discussion

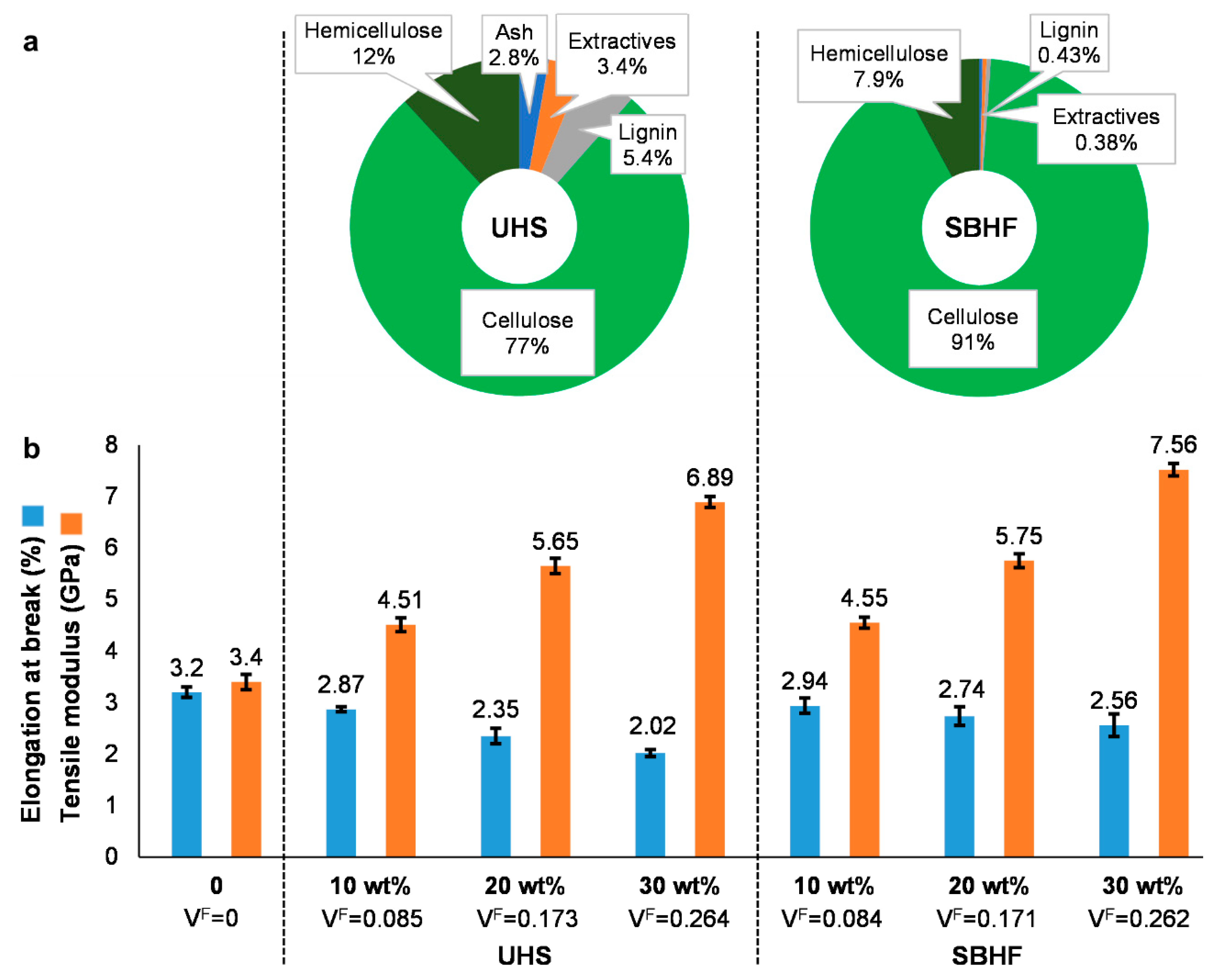

3.1. Stiffness of PLA/UHS and PLA/SBHF

3.2. Empirical Assessment of the Constituents

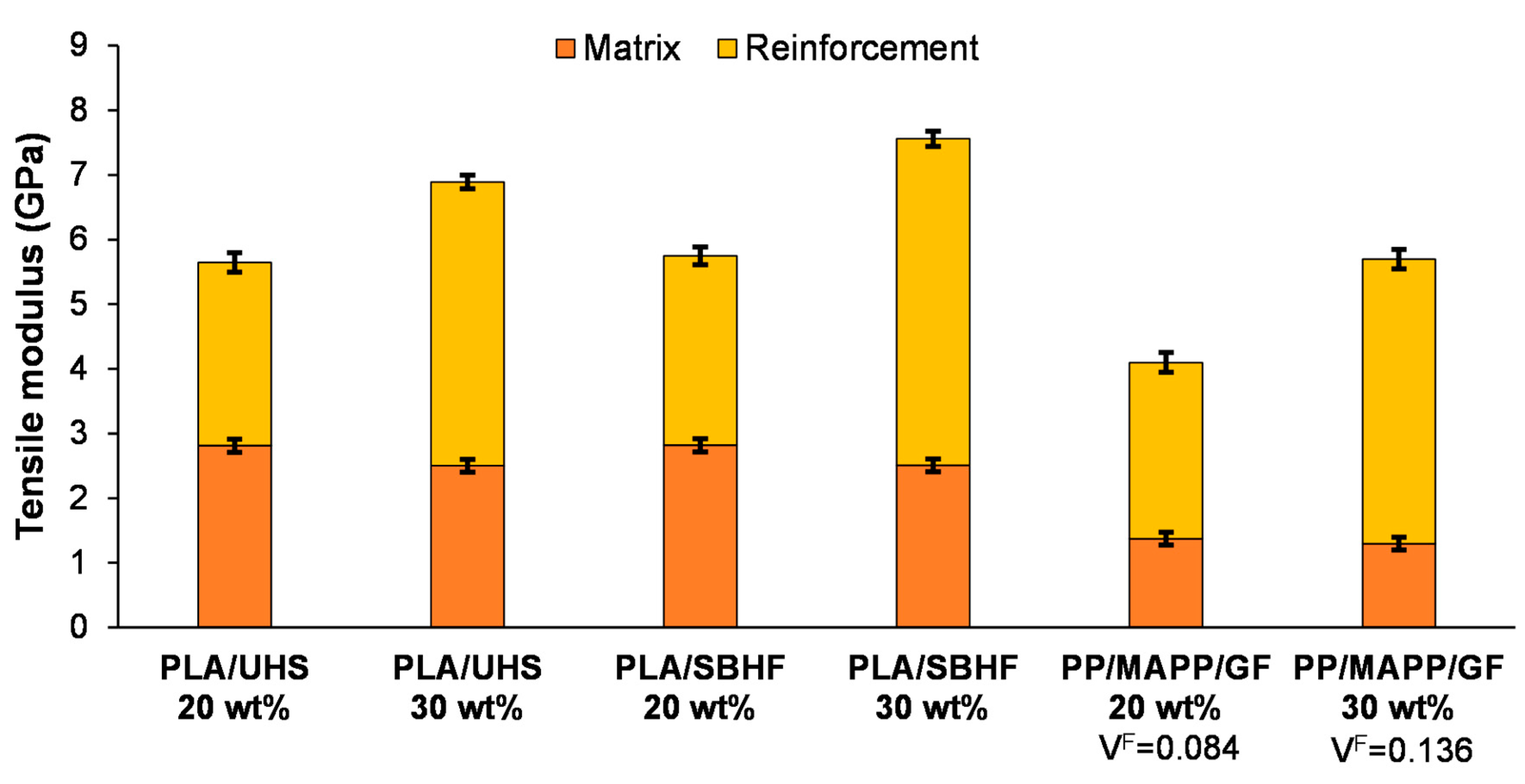

3.3. Micromechanics of the Tensile Modulus

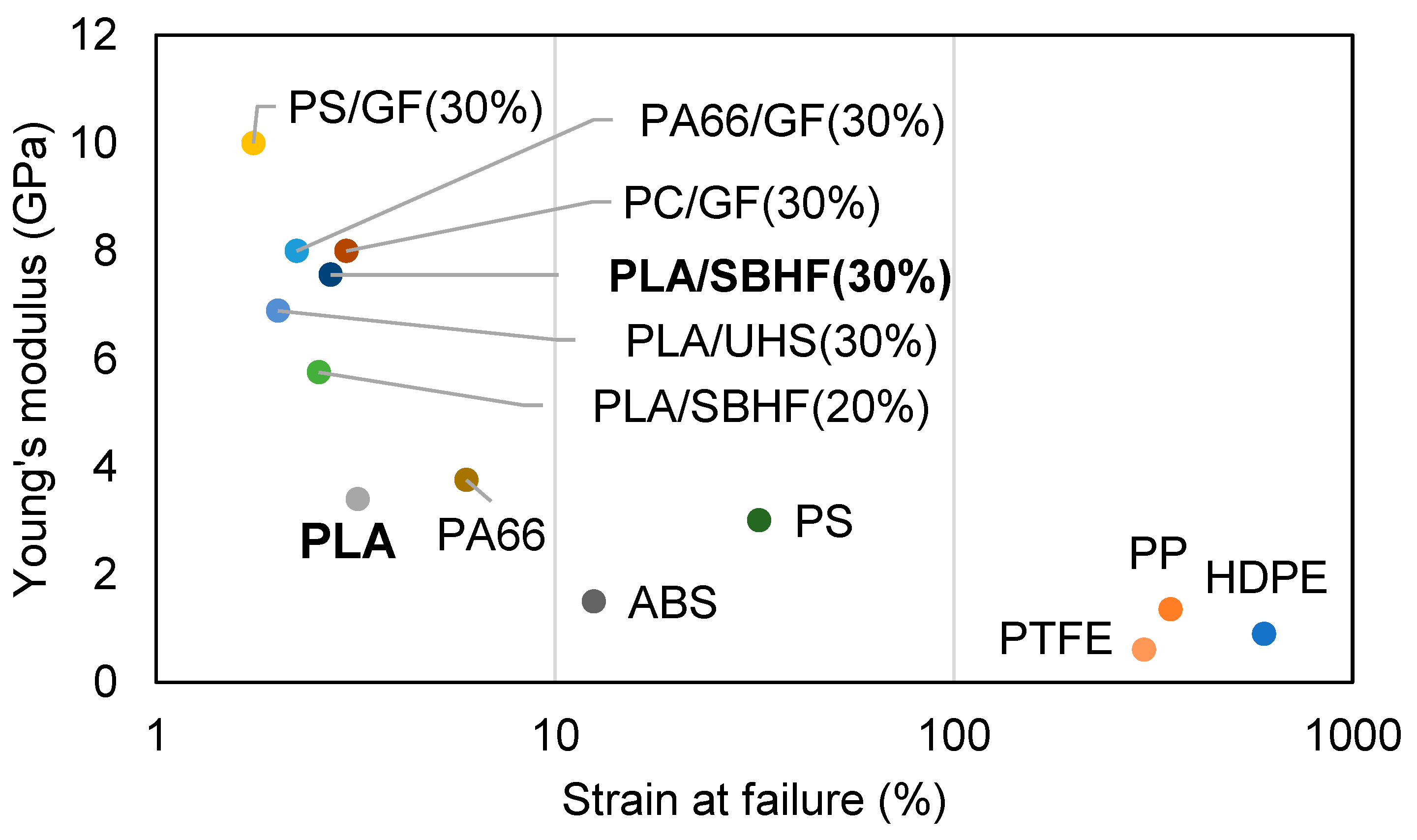

3.4. Comparison of PLA/Hemp and More Conventional Options

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Precedence Research. Bioplastic Composites Market (By Type: Biodegradable, Non-Biodegradable; By Fiber Type: Wood Fiber Composites, Non-Wood Fiber Composites. Available online: https://www.precedenceresearch.com/bioplastic-composites-market (accessed on 15 November 2022).

- Markets and Markets. Biocomposites Market by Fiber Type (Wood-Fiber and Non-Wood-Fiber), Polymer Type (Synthetic and Natural), Product. Available online: https://www.marketsandmarkets.com/Market-Reports/biocomposite-market-258097936.html (accessed on 15 November 2022).

- Murariu, M.; Dubois, P. PLA Composites: From Production to Properties. Adv. Drug Deliv. Rev. 2016, 107, 17–46. [Google Scholar] [CrossRef] [PubMed]

- Singh, S.; Patel, M.; Schwendemann, D.; Zaccone, M.; Geng, S.; Maspoch, M.L.; Oksman, K. Effect of Chitin Nanocrystals on Crystallization and Properties of Poly(lactic acid)-Based Nanocomposites. Polymers 2020, 12, 726. [Google Scholar] [CrossRef] [PubMed]

- Zhao, W.; Lee, J.; Kim, H.; Jang, H.; Nam, J.; Kim, K.; Suhr, J. Semi-Empirical Investigation of the Interfacial Shear Strength of Short Fiber Polymer Composites. Polym. Test. 2019, 74, 99–103. [Google Scholar] [CrossRef]

- Teixeira, D.; Giovanela, M.; Gonella, L.B.; Crespo, J.S. Influence of Flow Restriction on the Microstructure and Mechanical Properties of Long Glass Fiber-Reinforced Polyamide 6.6 Composites for Automotive Applications. Mater. Des. 2013, 47, 287–294. [Google Scholar] [CrossRef]

- Chen, T.; Mansfield, C.D.; Ju, L.; Baird, D.G. The Influence of Mechanical Recycling on the Properties of Thermotropic Liquid Crystalline Polymer and Long Glass Fiber Reinforced Polypropylene. Compos. Part B Eng. 2020, 200, 108316. [Google Scholar] [CrossRef]

- Joustra, J.; Flipsen, B.; Balkenende, R. Structural Reuse of Wind Turbine Blades through Segmentation. Compos. Part C Open Access 2021, 5, 100137. [Google Scholar] [CrossRef]

- Joshi, S.V.; Drzal, L.T.; Mohanty, A.K.; Arora, S. Are Natural Fiber Composites Environmentally Superior to Glass Fiber Reinforced Composites? Compos. Part A Appl. Sci. Manuf. 2004, 35, 371–376. [Google Scholar] [CrossRef]

- Koronis, G.; Silva, A.; Ong, M. Comparison of Structural Performance and Environmental Impact of Epoxy Composites Modified by Glass and Flax Fabrics. J. Compos. Sci. 2022, 6, 284. [Google Scholar] [CrossRef]

- Ahmad, H.; Chhipi-Shrestha, G.; Hewage, K.; Sadiq, R. A Comprehensive Review on Construction Applications and Life Cycle Sustainability of Natural Fiber Biocomposites. Sustainability 2022, 14, 15905. [Google Scholar] [CrossRef]

- Research and Markets. Composites Market by Fiber Type (Glass Fiber Composites, Carbon Fiber Composites, Natural Fiber Composites), Resin Type (Thermoset Composites, Thermoplastic Composites), Manufacturing Process, End-Use Industry and Region—Global Forecast to 2026. Available online: https://www.researchandmarkets.com/reports/5130343/composites-market-by-fiber-type-glass-fiber (accessed on 7 December 2022).

- Alao, P.F.; Marrot, L.; Kallakas, H.; Just, A.; Poltimäe, T.; Kers, J. Effect of Hemp Fiber Surface Treatment on the Moisture/Water Resistance and Reaction to Fire of Reinforced PLA Composites. Materials 2021, 14, 4332. [Google Scholar] [CrossRef] [PubMed]

- Zhou, L.; Ke, K.; Yang, M.-B.; Yang, W. Recent Progress on Chemical Modification of Cellulose for High Mechanical-Performance Poly(lactic acid)/Cellulose Composite: A Review. Compos. Commun. 2021, 23, 100548. [Google Scholar] [CrossRef]

- Sawpan, M.A.; Pickering, K.L.; Fernyhough, A. Effect of Fibre Treatments on Interfacial Shear Strength of Hemp Fibre Reinforced Polylactide and Unsaturated Polyester Composites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1189–1196. [Google Scholar] [CrossRef]

- López, J.P.; Boufi, S.; El Mansouri, N.E.; Mutjé, P.; Vilaseca, F. PP Composites Based on Mechanical Pulp, Deinked Newspaper and Jute Strands: A Comparative Study. Compos. Part B Eng. 2012, 43, 3453–3461. [Google Scholar] [CrossRef]

- Dong, Y.; Bhattacharyya, D. Investigation on the Competing Effects of Clay Dispersion and Matrix Plasticisation for Polypropylene/Clay Nanocomposites. Part II: Crystalline Structure and Thermo-Mechanical Behaviour. J. Mater. Sci. 2012, 47, 4127–4137. [Google Scholar] [CrossRef]

- Schaub, T. Efficient Industrial Organic Synthesis and the Principles of Green Chemistry. Chem.–A Eur. J. 2021, 27, 1865–1869. [Google Scholar] [CrossRef]

- Aguado, R.J.; Espinach, F.X.; Julián, F.; Tarrés, Q.; Delgado-Aguilar, M.; Mutjé, P. Tensile Strength of Poly(lactic acid)/Bleached Short Hemp Fiber Fully Green Composites as Replacement for Polypropylene/Glass Fiber. Polymers 2023, 15, 146. [Google Scholar] [CrossRef]

- Song, Y.; Liu, J.; Chen, S.; Zheng, Y.; Ruan, S.; Bin, Y. Mechanical Properties of Poly (Lactic Acid)/Hemp Fiber Composites Prepared with a Novel Method. J. Polym. Environ. 2013, 21, 1117–1127. [Google Scholar] [CrossRef]

- Song, Y.S.; Lee, J.T.; Ji, D.S.; Kim, M.W.; Lee, S.H.; Youn, J.R. Viscoelastic and Thermal Behavior of Woven Hemp Fiber Reinforced Poly(lactic acid) Composites. Compos. Part B Eng. 2012, 43, 856–860. [Google Scholar] [CrossRef]

- Serra-Parareda, F.; Tarrés, Q.; Espinach, F.X.; Vilaseca, F.; Mutjé, P.; Delgado-Aguilar, M. Influence of Lignin Content on the Intrinsic Modulus of Natural Fibers and on the Stiffness of Composite Materials. Int. J. Biol. Macromol. 2020, 155, 81–90. [Google Scholar] [CrossRef]

- TAPPI. TAPPI Standards, Technical Information Papers, and Useful Methods; Technical Association of the Pulp & Paper Industry: New York, NY, USA, 2020. [Google Scholar]

- Segal, L.; Creely, J.J.; Martin, A.E.; Conrad, C.M. An Empirical Method for Estimating the Degree of Crystallinity of Native Cellulose Using the X-ray Diffractometer. Text. Res. J. 1959, 29, 786–794. [Google Scholar] [CrossRef]

- ASTM D3039M-08; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International: Conshohocken, PA, USA, 2008.

- ASTM D618-21; Standard Practice for Conditioning Plastics for Testing. ASTM International: Conshohocken, PA, USA, 2021.

- ASTM D3379-75(1989)E1; Standard Test Method for Tensile Strength and Young’s Modulus for High-Modulus Single-Filament Materials (Withdrawn 1998). ASTM International: Conshohocken, PA, USA, 1989.

- Tham, M.W.; Fazita, M.R.N.; Abdul Khalil, H.P.S.; Mahmud Zuhudi, N.Z.; Jaafar, M.; Rizal, S.; Haafiz, M.K.M. Tensile Properties Prediction of Natural Fibre Composites Using Rule of Mixtures: A Review. J. Reinf. Plast. Compos. 2018, 38, 211–248. [Google Scholar] [CrossRef]

- Zhang, X.; Li, W.; Zhao, Z.; He, Y.; Dong, P.; Ma, Y.; Huang, J. A Theoretical Model for the Tensile Modulus of Polymer/CNT Nanocomposites over a Wide Temperature Range. Compos. Commun. 2021, 28, 100971. [Google Scholar] [CrossRef]

- Krenchel, H. Fibre Reinforcement: Theoretical and Practical Investigations of the Elasticity and Strength of Fibre-Reinforced Materials; Akademisk Forlag: Copenhagen, Denmark, 1964. [Google Scholar]

- Yan, J.; Demirci, E.; Gleadall, A. Are Classical Fibre Composite Models Appropriate for Material Extrusion Additive Manufacturing? A Thorough Evaluation of Analytical Models. Addit. Manuf. 2023, 62, 103371. [Google Scholar] [CrossRef]

- Hirsch, T.J. Modulus of Elasticity Iof Concrete Affected by Elastic Moduli of Cement Paste Matrix and Aggregate. ACI J. Proc. 1962, 59, 427–452. [Google Scholar] [CrossRef]

- López, J.P.; Mutjé, P.; Pèlach, M.À.; El Mansouri, N.-E.; Boufi, S.; Vilaseca, F. Analysis of the Tensile Modulus of Polypropylene Composites Reinforced with Stone Groundwood Fibers. BioResources 2012, 7, 1310–1323. [Google Scholar] [CrossRef]

- Espinach, F.X.; Julian, F.; Verdaguer, N.; Torres, L.; Pelach, M.A.; Vilaseca, F.; Mutje, P. Analysis of Tensile and Flexural Modulus in Hemp Strands/Polypropylene Composites. Compos. Part B Eng. 2013, 47, 339–343. [Google Scholar] [CrossRef]

- Halpin, J.C.; Pagano, N.J. The Laminate Approximation for Randomly Oriented Fibrous Composites. J. Compos. Mater. 1969, 3, 720–724. [Google Scholar] [CrossRef]

- Halpin, J.C. Effects of Environmental Factors on Composite Materials. Available online: https://apps.dtic.mil/sti/citations/ADA306357 (accessed on 17 April 2023).

- Laine, J.; Stenius, P.; Carlsson, G.; Strom, G. The Effect of ECF and TCF Bleaching on the Surface Chemical Composition of Kraft Pulp as Determined by ESCA. Nord. Pulp Pap. Res. J. 1996, 11, 201–210. [Google Scholar] [CrossRef]

- Zouari, M.; Devallance, D.B.; Marrot, L. Effect of Biochar Addition on Mechanical Properties, Thermal Stability, and Water Resistance of Hemp-Polylactic Acid (PLA) Composites. Materials 2022, 15, 2271. [Google Scholar] [CrossRef]

- Ganesh, S.; Keerthiveettil Ramakrishnan, S.; Palani, V.; Sundaram, M.; Sankaranarayanan, N.; Ganesan, S.P. Investigation on the Mechanical Properties of Ramie/Kenaf Fibers under Various Parameters Using GRA and TOPSIS Methods. Polym. Compos. 2022, 43, 130–143. [Google Scholar] [CrossRef]

- Šturcová, A.; Davies, G.R.; Eichhorn, S.J. Elastic Modulus and Stress-Transfer Properties of Tunicate Cellulose Whiskers. Biomacromolecules 2005, 6, 1055–1061. [Google Scholar] [CrossRef] [PubMed]

- Carvalho, M.G.; Ferreira, P.J.; Figueiredo, M.M. Cellulose Depolymerisation and Paper Properties in E. globulus Kraft Pulps. Cellulose 2000, 7, 359–368. [Google Scholar] [CrossRef]

- Ham, C.H.; Youn, H.J.; Lee, H.L. Influence of Fiber Composition and Drying Conditions on the Bending Stiffness of Paper. BioResources 2020, 15, 9197–9211. [Google Scholar] [CrossRef]

- Delgado-Aguilar, M.; Oliver-Ortega, H.; Alberto Méndez, J.; Camps, J.; Espinach, F.X.; Mutjé, P. The Role of Lignin on the Mechanical Performance of Polylactic Acid and Jute Composites. Int. J. Biol. Macromol. 2018, 116, 299–304. [Google Scholar] [CrossRef] [PubMed]

- The Engineering Toolbox Thermoplastics—Physical Properties. Available online: https://www.engineeringtoolbox.com/physical-properties-thermoplastics-d_808.html (accessed on 25 June 2023).

- Omnexus Modulus of Elasticity. Available online: https://omnexus.specialchem.com/polymer-properties/properties/young-modulus (accessed on 26 June 2023).

- Omnexus Elongation at Break. Available online: https://omnexus.specialchem.com/polymer-properties/properties/elongation-at-break (accessed on 26 June 2023).

- Alonso-Montemayor, F.J.; Tarrés, Q.; Oliver-Ortega, H.; Espinach, F.X.; Narro-Céspedes, R.I.; Castañeda-Facio, A.O.; Delgado-Aguilar, M. Enhancing the Mechanical Performance of Bleached Hemp Fibers Reinforced Polyamide 6 Composites: A Competitive Alternative to Commodity Composites. Polymers 2020, 12, 1041. [Google Scholar] [CrossRef]

- Duval, A.; Bourmaud, A.; Augier, L.; Baley, C. Influence of the Sampling Area of the Stem on the Mechanical Properties of Hemp Fibers. Mater. Lett. 2011, 65, 797–800. [Google Scholar] [CrossRef]

- Sunny, T.; Pickering, K.L. Improving Polypropylene Matrix Composites Reinforced with Aligned Hemp Fibre Mats Using High Fibre Contents. Materials 2022, 15, 5587. [Google Scholar] [CrossRef]

- Sangeetha, V.H.; Deka, H.; Varghese, T.O.; Nayak, S.K. State of the Art and Future Prospectives of Poly(lactic acid) Based Blends and Composites. Polym. Compos. 2018, 39, 81–101. [Google Scholar] [CrossRef]

- Hasan, K.M.F.; Horváth, P.G.; Markó, G.; Alpár, T. Thermomechanical Characteristics of Flax-Woven-Fabric-Reinforced Poly(lactic acid) and Polypropylene Biocomposites. Green Mater. 2022, 10, 1–10. [Google Scholar] [CrossRef]

- Feng, L.; Li, K.; Xue, B.; Fu, Q.; Zhang, L. Optimizing Matrix and Fiber/Matrix Interface to Achieve Combination of Strength, Ductility and Toughness in Carbon Nanotube-Reinforced Carbon/Carbon Composites. Mater. Des. 2017, 113, 9–16. [Google Scholar] [CrossRef]

- Mazumder, S.; Zhang, N. Cellulose–Hemicellulose–Lignin Interaction in the Secondary Cell Wall of Coconut Endocarp. Biomimetics 2023, 8, 188. [Google Scholar] [CrossRef] [PubMed]

- RTP Company Glass Fiber Reinforced PLA Bioplastic. Available online: https://web.archive.org/web/20171215074618/ (accessed on 16 November 2022).

- Jaszkiewicz, A.; Bledzki, A.K.; Franciszczak, P. Improving the Mechanical Performance of PLA Composites with Natural, Man-Made Cellulose and Glass Fibers—A Comparison to PP Counterparts. Polymery 2013, 58, 435–443. [Google Scholar] [CrossRef]

- Wang, G.; Zhang, D.; Wan, G.; Li, B.; Zhao, G. Glass Fiber Reinforced PLA Composite with Enhanced Mechanical Properties, Thermal Behavior, and Foaming Ability. Polymer 2019, 181, 121803. [Google Scholar] [CrossRef]

| Load (wt%) | VF | lF (µm) | dF (µm) | Hirsch Model | Tsai-Pagano Model | ||

|---|---|---|---|---|---|---|---|

| EtF (GPa) | ηe | EtF (GPa) | ηe | ||||

| 10 | 0.085 | 353 | 20.5 | 32.4 | 0.522 | 31.2 | 0.544 |

| 20 | 0.171 | 318 | 20.5 | 32.1 | 0.524 | 30.3 | 0.563 |

| 30 | 0.262 | 295 | 20.4 | 33.0 | 0.542 | 30.5 | 0.578 |

| Load (wt%) | Hirsch Model | Tsai-Pagano Model | ||||

|---|---|---|---|---|---|---|

| ηl | ηo | α (°) | ηl | ηo | α (°) | |

| 10 | 0.848 | 0.616 | 45.9 | 0.853 | 0.650 | 43.2 |

| 20 | 0.861 | 0.609 | 46.5 | 0.865 | 0.642 | 43.7 |

| 30 | 0.874 | 0.621 | 45.5 | 0.877 | 0.655 | 42.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aguado, R.J.; Bastida, G.A.; Espinach, F.X.; Llorens, J.; Tarrés, Q.; Delgado-Aguilar, M.; Mutjé, P. Comparative Study on the Stiffness of Poly(lactic acid) Reinforced with Untreated and Bleached Hemp Fibers. Polymers 2023, 15, 2960. https://doi.org/10.3390/polym15132960

Aguado RJ, Bastida GA, Espinach FX, Llorens J, Tarrés Q, Delgado-Aguilar M, Mutjé P. Comparative Study on the Stiffness of Poly(lactic acid) Reinforced with Untreated and Bleached Hemp Fibers. Polymers. 2023; 15(13):2960. https://doi.org/10.3390/polym15132960

Chicago/Turabian StyleAguado, Roberto J., Gabriela A. Bastida, Francisco X. Espinach, Joan Llorens, Quim Tarrés, Marc Delgado-Aguilar, and Pere Mutjé. 2023. "Comparative Study on the Stiffness of Poly(lactic acid) Reinforced with Untreated and Bleached Hemp Fibers" Polymers 15, no. 13: 2960. https://doi.org/10.3390/polym15132960

APA StyleAguado, R. J., Bastida, G. A., Espinach, F. X., Llorens, J., Tarrés, Q., Delgado-Aguilar, M., & Mutjé, P. (2023). Comparative Study on the Stiffness of Poly(lactic acid) Reinforced with Untreated and Bleached Hemp Fibers. Polymers, 15(13), 2960. https://doi.org/10.3390/polym15132960