Chemical Recycling of Fully Recyclable Bio-Epoxy Matrices and Reuse Strategies: A Cradle-to-Cradle Approach

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Virgin Epoxy Resin Formulation

2.3. Chemical Recycling Process

2.4. Epoxy Resin Formulation by Reusing the Recycled Polymer

2.5. Thermo-Mechanical Characterization

2.5.1. Thermal Analyses: Dynamic Mechanical Analysis (DMA) and Differential Scanning Calorimetry (DSC)

2.5.2. Mechanical Characterization: Flexural Test

2.6. Chemical Characterization

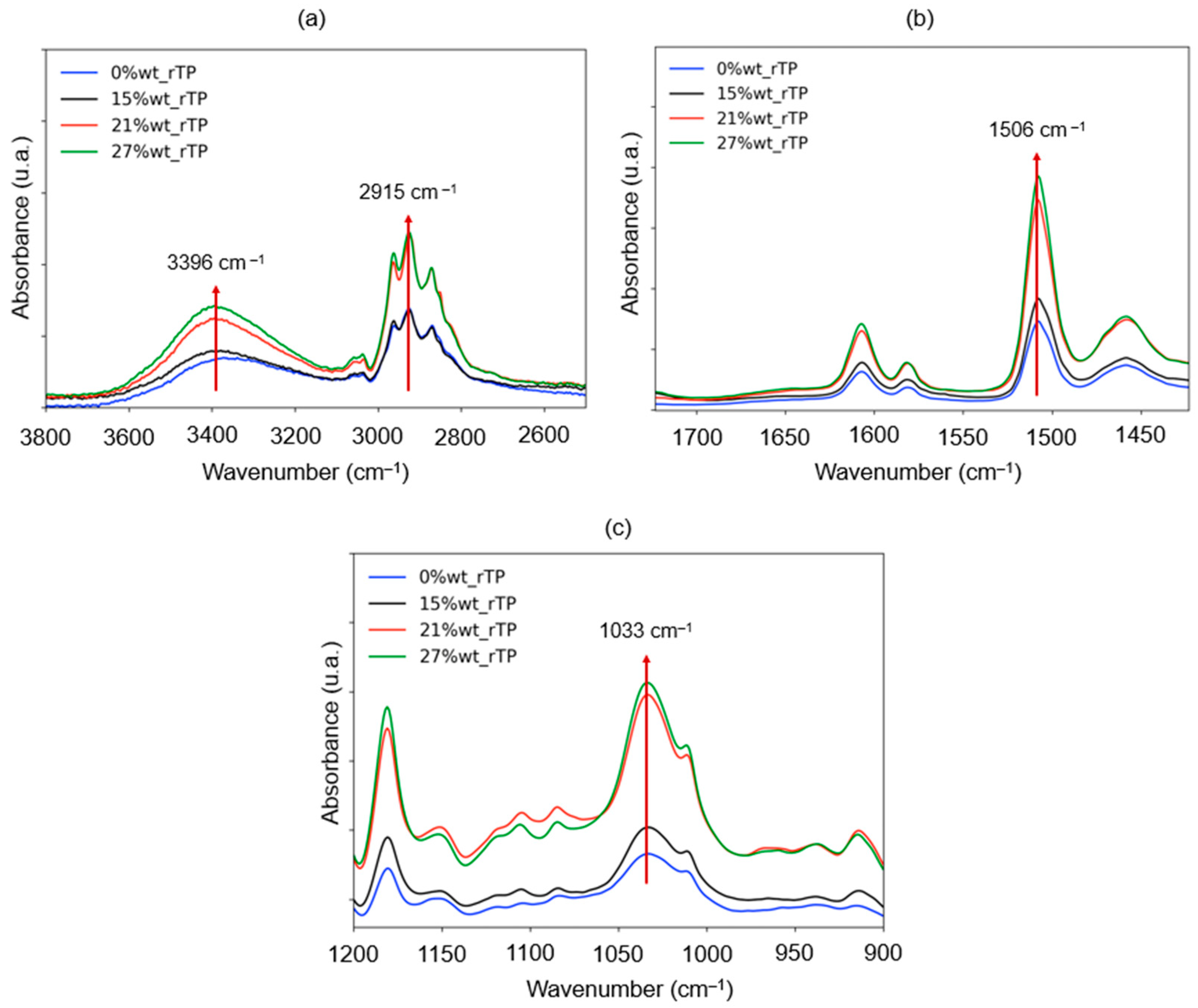

Fourier Transform Infrared Spectroscopy

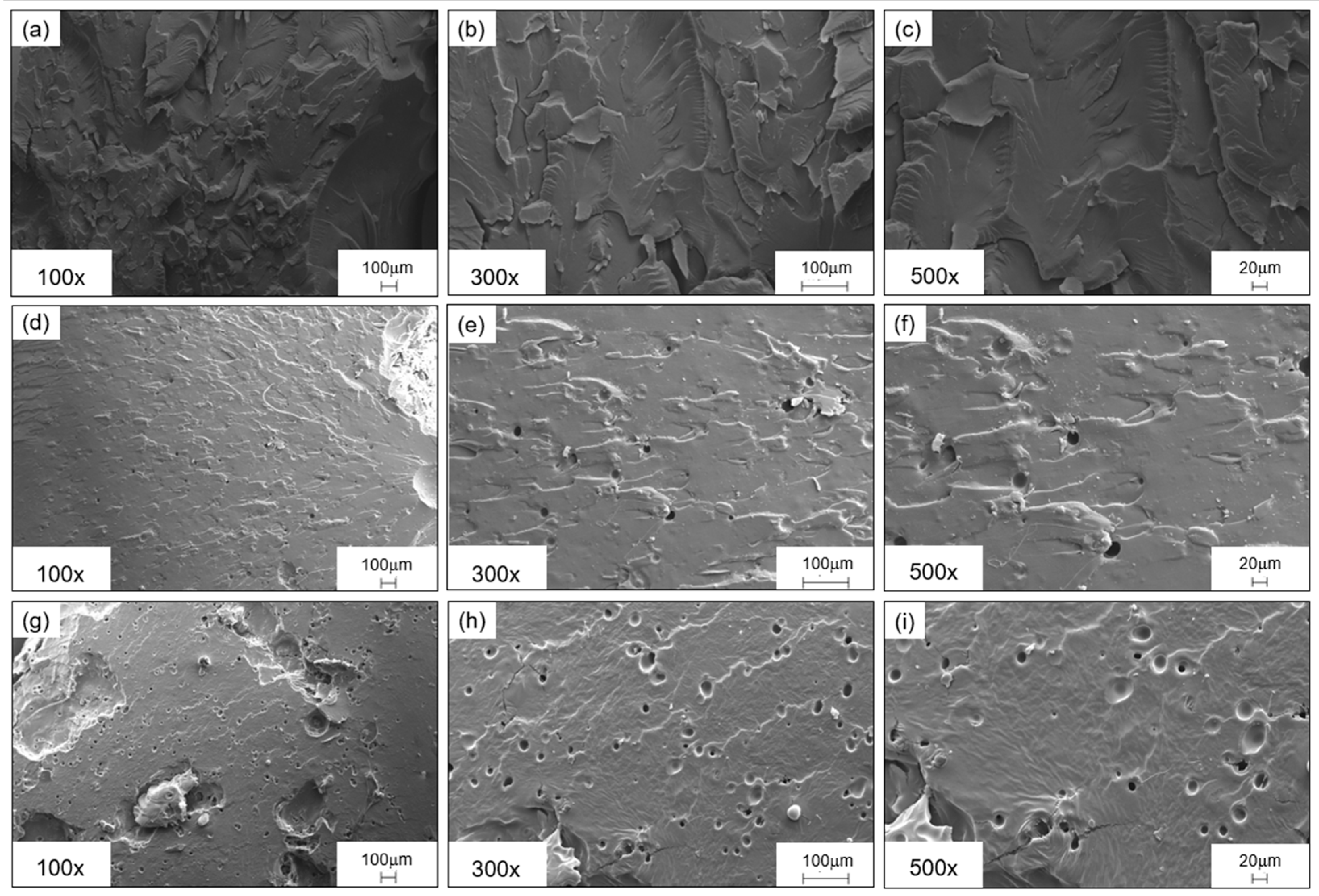

2.7. Morphological Characterization: Scanning Electron Microscopy

3. Results and Discussion

3.1. Thermal Characterization

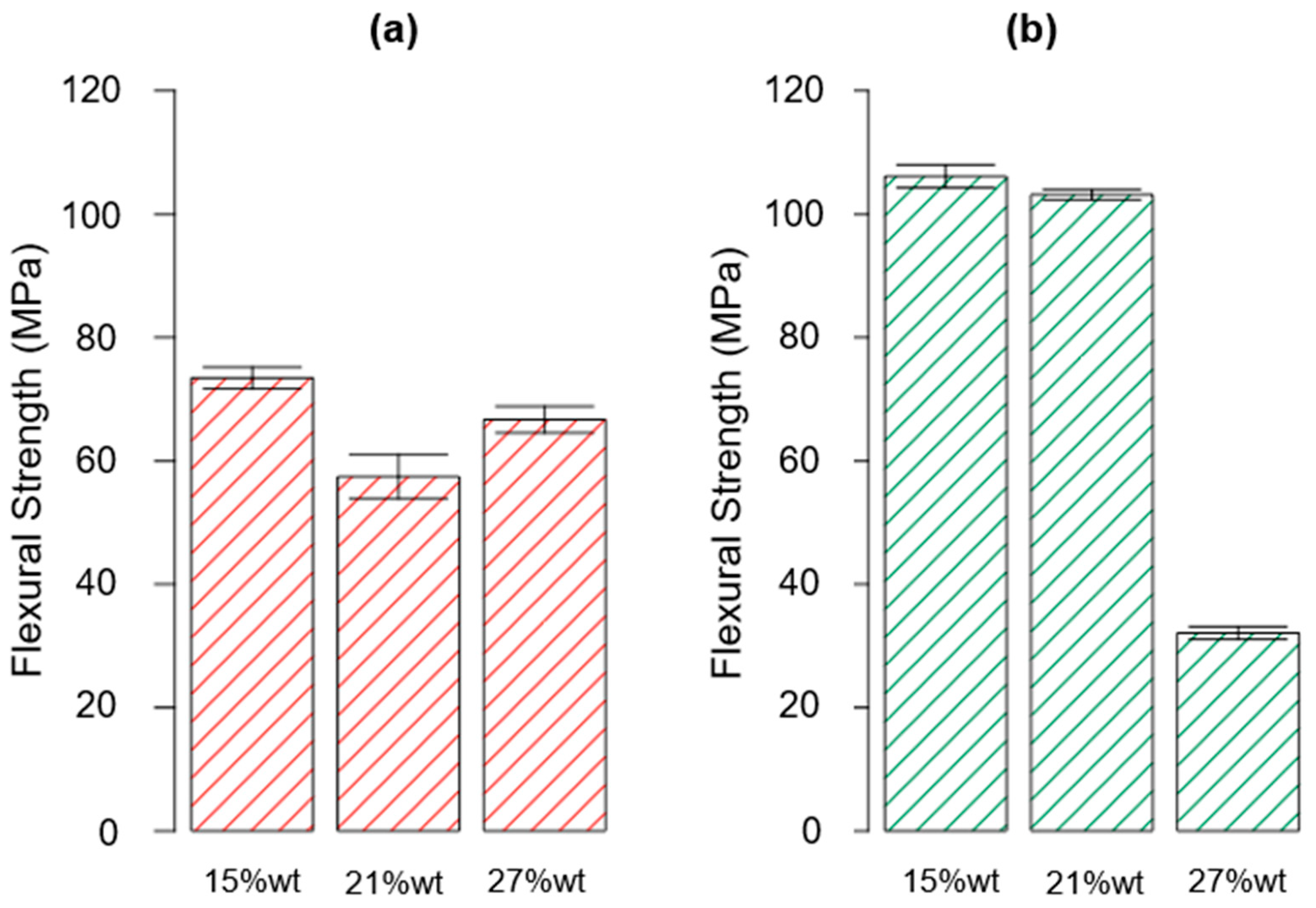

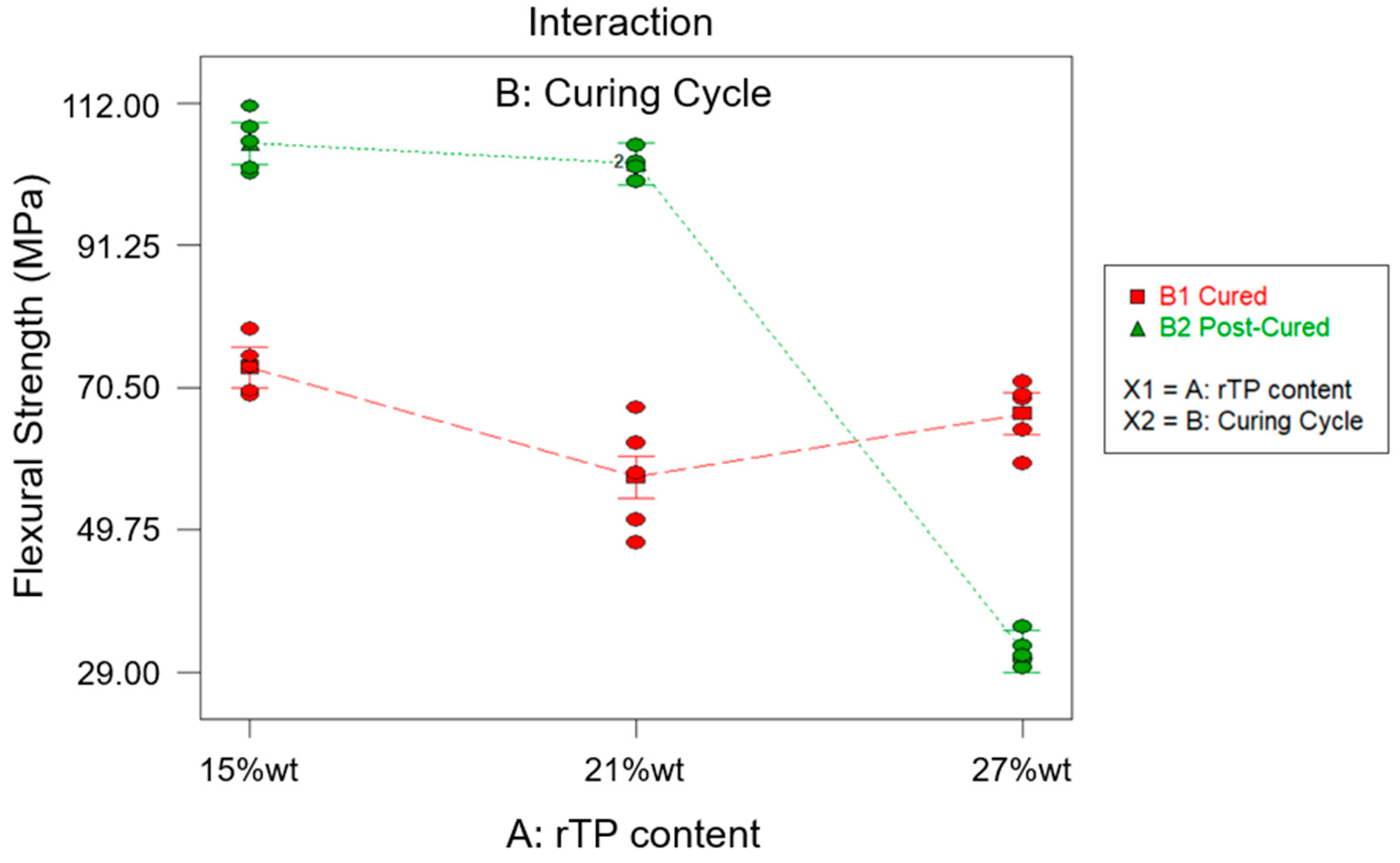

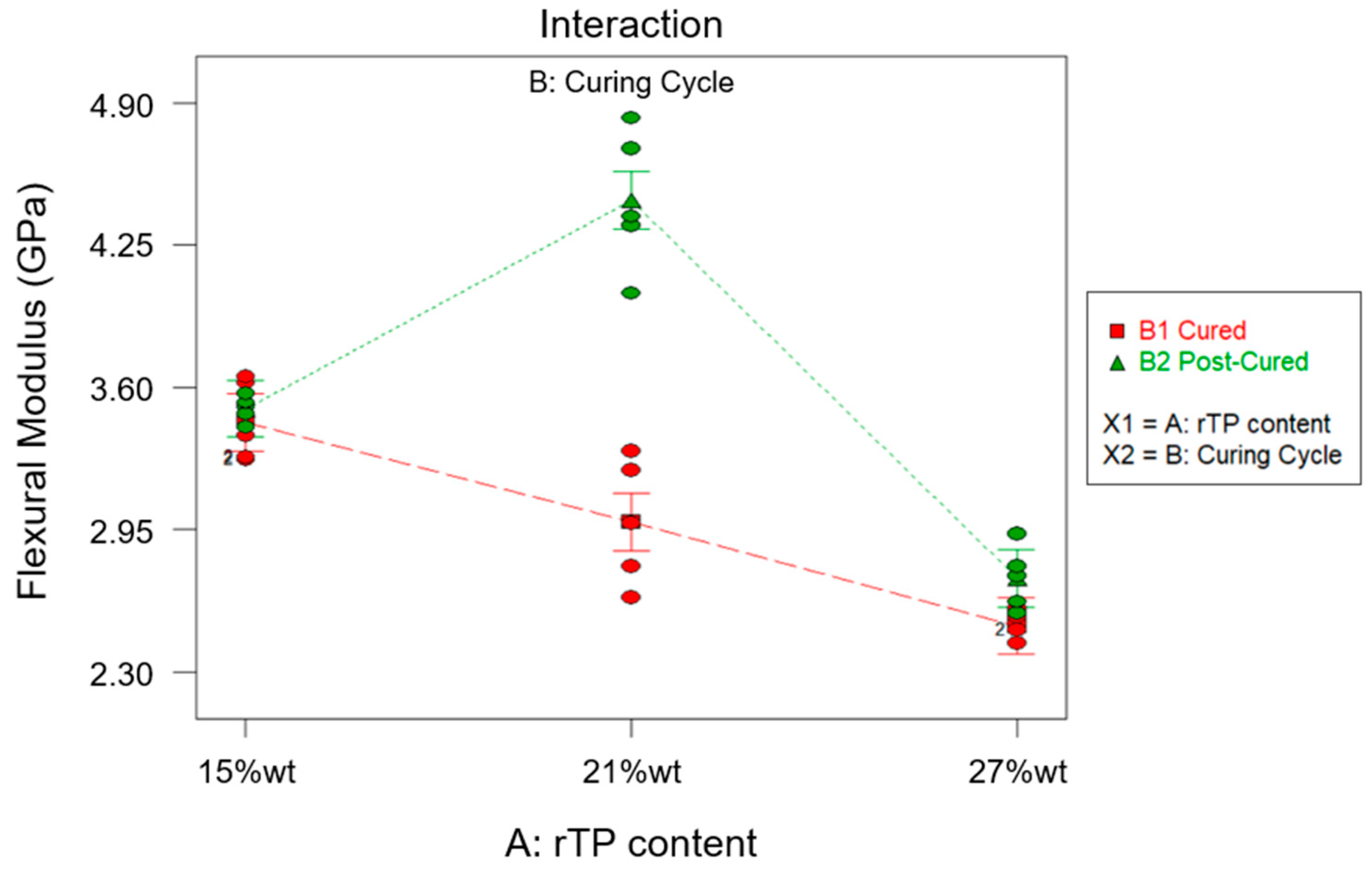

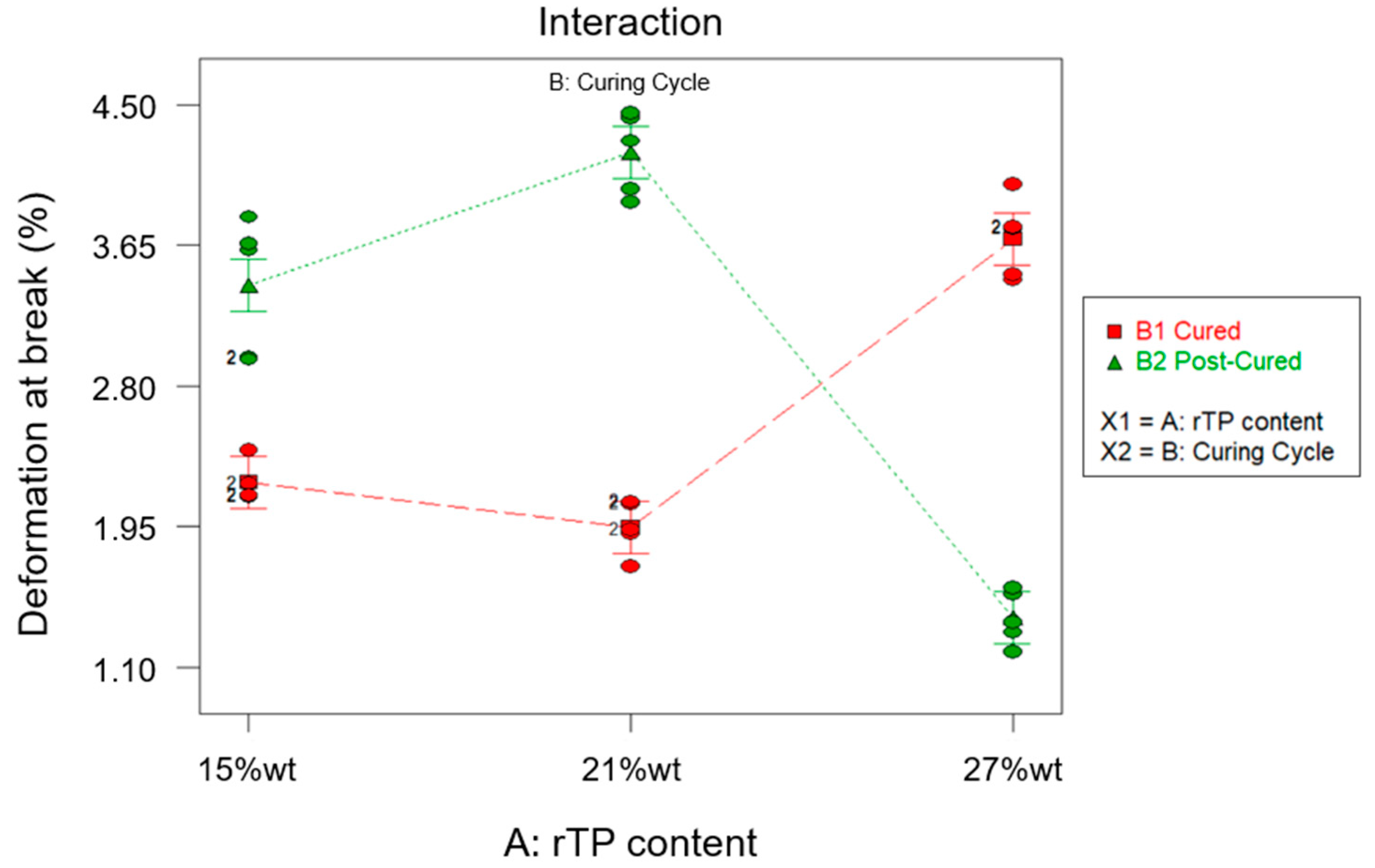

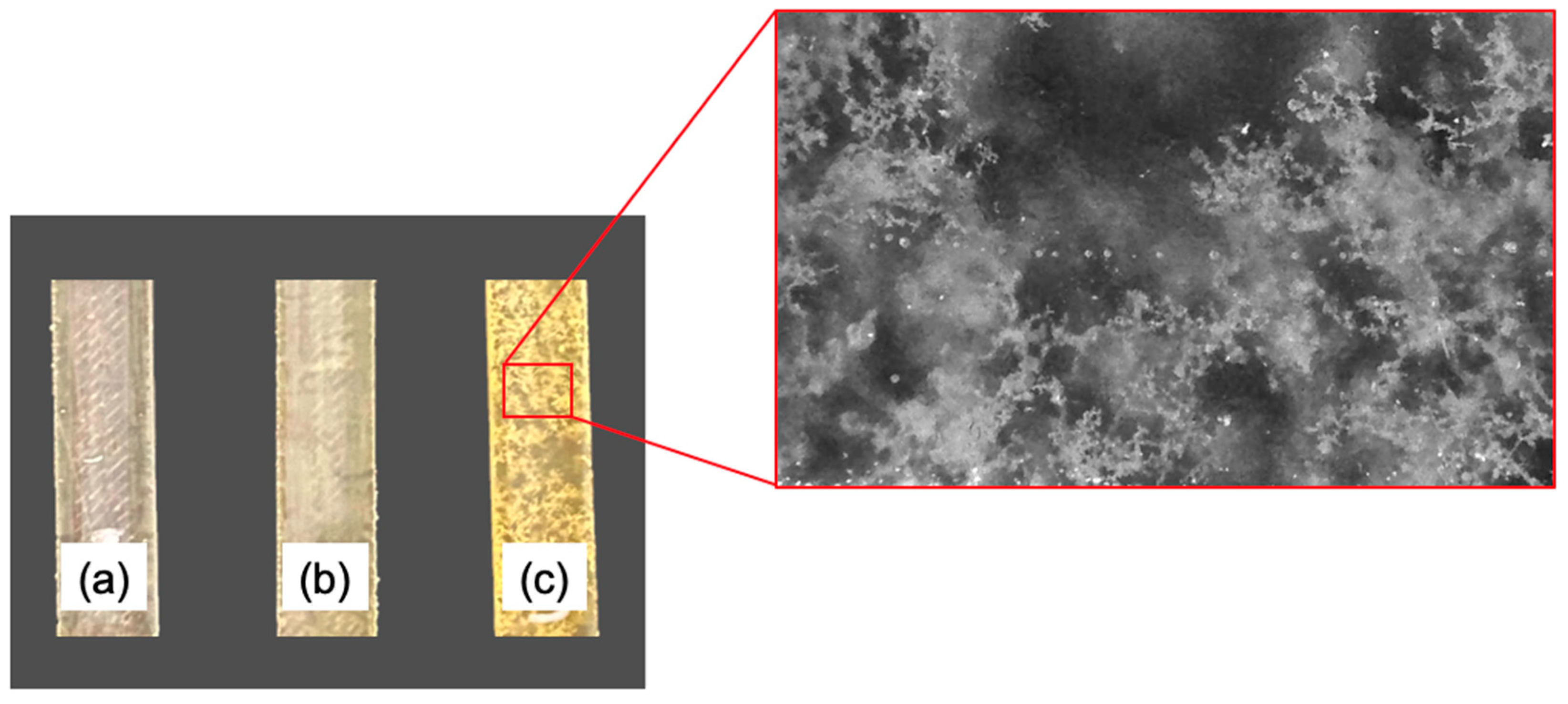

3.2. Mechanical Characterization

3.3. Optimization Process

4. Conclusions

- homogeneous epoxy/thermoplastic blends with good thermo-mechanical properties were obtained for an rTP content not exceeding a threshold value of 27%wt;

- by implementing an additional post-curing process at 100 °C for 3 h, it was possible to enhance the thermo-mechanical properties;

- the best-performing epoxy system in terms of thermo-mechanical properties, as determined by an optimization process relying on the approach of desirability functions, was the one containing 21%wt rTP which was cured exploiting the C2 curing cycles.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Epoxy Composite Market Size, Share & Trends Analysis Report by Fiber Type (Glass, Carbon), by End-Use (Automotive & Transportation, Wind Energy), by Region (APAC, North America), and Segment Forecasts, 2021–2028; Rep ID GVR-4-68039-095-9; 2021; p. 133. Available online: https://www.researchandmarkets.com/reports/5440519/epoxy-composite-market-size-share-and-trends (accessed on 19 May 2023).

- Pompidou, S.; Prinçaud, M.; Perry, N.; Leray, D. Recycling of carbon fiber. Identification of bases for a synergy between recyclers and designers. In Proceedings of the ASME 2012 11th Biennial Conference on Engineering Systems Design and Analysis, Nantes, France, 2–4 July 2012; Volume 3, pp. 551–560. [Google Scholar] [CrossRef]

- Mohan, P. A Critical Review: The Modification, Properties, and Applications of Epoxy Resins. Polym.-Plast. Technol. Eng. 2013, 52, 107–125. [Google Scholar] [CrossRef]

- Epoxy Resin Market Size, Share & Trends Analysis Report by Application (Adhesives, Electrical & Electronics, Paints & Coatings, Wind Turbines, Composites, Construction), by Region, and Segment Forecasts, 2022–2030; Report ID: 978-1-68038-171-9, Marke Analysis Report, Grand View Research; Research and Markets: Dublin, Ireland, 2022.

- Rani, M.; Choudhary, P.; Krishnan, V.; Zafar, S. A Review on Recycling and Reuse Methods for Carbon Fiber/Glass Fiber Composites Waste from Wind Turbine Blades. Compos. B Eng. 2021, 215, 108768. [Google Scholar] [CrossRef]

- Khalid, M.Y.; Arif, Z.U.; Ahmed, W.; Arshad, H. Recent Trends in Recycling and Reusing Techniques of Different Plastic Polymers and Their Composite Materials. Sustain. Mater. Technol. 2022, 31, e00382. [Google Scholar] [CrossRef]

- Mishnaevsky, L. Sustainable end-of-life management of wind turbine blades: Overview of current and coming solutions. Materials 2021, 14, 1124. [Google Scholar] [CrossRef]

- Oliveux, G.; Dandy, L.O.; Leeke, G.A. Current status of recycling of fibre reinforced polymers: Review of technologies, reuse and resulting properties. Prog. Mater. Sci. 2015, 72, 61–99. [Google Scholar] [CrossRef]

- Krauklis, A.E.; Karl, C.W.; Gagani, A.I.; Jørgensen, J.K. Composite Material Recycling Technology—State-of-the-Art and Sustainable Development for the 2020s. J. Compos. Sci. 2021, 5, 28. [Google Scholar] [CrossRef]

- Rani, M.; Choudhary, P.; Krishnan, V.; Zafar, S. Development of Sustainable Microwave-Based Approach to Recover Glass Fibers for Wind Turbine Blades Composite Waste. Resour. Conserv. Recycl. 2022, 179, 106107. [Google Scholar] [CrossRef]

- Khalid, M.Y.; Arif, Z.U.; Hossain, M.; Umer, R. Recycling of Wind Turbine Blades through Modern Recycling Technologies: A Road to Zero Waste. Renew. Energy Focus 2023, 44, 373–389. [Google Scholar] [CrossRef]

- Liang, B. Data RUSA. Patent Application Publication Pub No. US 2013/0245204 A1, 17 October 2013. [Google Scholar]

- La Rosa, A.D.; Blanco, I.; Banatao, D.R.; Pastine, S.J.; Björklund, A.; Cicala, G. Innovative chemical process for recycling thermosets cured with recyclamines® by converting bio-epoxy composites in reusable thermoplastic-an LCA study. Materials 2018, 11, 353. [Google Scholar] [CrossRef]

- Dattilo, S.; Cicala, G.; Riccobene, P.M.; Puglisi, C.; Saitta, L. Full Recycling and Re-Use of Bio-Based Epoxy Thermosets: Chemical and Thermomechanical Characterization of the Recycled Matrices. Polymers 2022, 14, 4828. [Google Scholar] [CrossRef]

- Arif, Z.U.; Khalid, M.Y.; Ahmed, W.; Arshad, H.; Ullah, S. Recycling of the glass/carbon fibre reinforced polymer composites: A step towards the circular economy. Polym.-Plast. Technol. Mater. 2022, 61, 761–788. [Google Scholar] [CrossRef]

- McDonough, W.; Braungart, M. Cradle to Cradle: Remaking the Way We Make Things, 1st ed.; North Point Press: New York, NY, USA, 2002. [Google Scholar]

- Lieder, M.; Rashid, A. Towards circular economy implementation: A comprehensive review in context of manufacturing industry. J. Clean. Prod. 2016, 115, 36–51. [Google Scholar] [CrossRef]

- Brennan, G.; Tennant, M.; Blomsma, F. Business and Production Solutions: Closing the Loop, 1st ed.; Routledge: New York, NY, USA, 2015. [Google Scholar]

- Sun, B.; Zhang, J.; Wang, M.; Yu, S.; Xu, Y.; Tian, S.; Gao, Z.; Xiao, D.; Liu, G.; Zhou, W.; et al. Valorization of Waste Biodegradable Polyester for Methyl Methacrylate Production. Nat. Sustain. 2023, 6, 712–719. [Google Scholar] [CrossRef]

- Sultan, J.N.; Mcgarry, F.J. Effect of Rubber Particle Size on Deformation Mechanisms in Glassy Epoxy. Polym. Eng. Sci. 1973, 13, 29–34. [Google Scholar] [CrossRef]

- Manzione, L.T.; Gillham, J.K. Rubber-Modified Epoxies. II. Morphology and Mechanical Properties. J. Appl. Polym. Sci. 1981, 26, 907–919. [Google Scholar] [CrossRef]

- Yee, A.F.; Pearson, R.A. Toughening mechanisms in elastomer-modified epoxies. J. Mater. Sci. 1986, 21, 2462–2474. [Google Scholar] [CrossRef]

- Kinloch, A.J.; Shaw, S.J.; Tod, D.A.; Hunston, D.L. Deformation and fracture behaviour of a and fracture studies. Polymer 1983, 24, 1341–1354. [Google Scholar] [CrossRef]

- Maloney, A.C.; Kausch, H.H.; Kaiser, T.; Beer, H.R. Parameters determining the strength and toughness of particulate filled epoxide resins. J. Mater. Sci. 1987, 22, 381–393. [Google Scholar] [CrossRef]

- Hsia, H.C.; Ma, C.C.M.; Li, M.S.; Li, Y.S.; DSChen, J. Glycidyl-Terminated Polyurethane Modified Epoxy Resins: Mechanical Properties, Adhesion Properties, and morphology. Appl. Polym. Sci. 1994, 52, 1137–1151. [Google Scholar] [CrossRef]

- Nakamura, Y.; Yamaguchi, M.; Iko, K.; Okubo, M.; Matsumoto, T. Effect of Particle Size on Mechanical Properties of Epoxy Resin Filled with Angular-Shaped Silica. J. Mater. Sci. 1990, 52, 2711. [Google Scholar] [CrossRef]

- Bucknall, C.B.; Partridge, L.K. Effects of morphology in the epoxy/PES matrix on the fatigue behaviour of uniaxial CFRP. Composites 1984, 15, 129–133. [Google Scholar] [CrossRef]

- Zhuo, H.; He, Z.; Liu, J.; Ma, G.; Ren, Z.; Zeng, Y.; Chen, S. Bulk Polymerization of Thermoplastic Shape Memory Epoxy Polymer for Recycling Applications. Polymers 2023, 15, 809. [Google Scholar] [CrossRef]

- Cara, F.; Dumon, M.; Pascault, J.P. Porous Epoxy Thermosets Obtained by a Polymerization-Induced Phase Separation Process of a Degradable Thermoplastic Polymer. Macromolecules 2002, 35, 6291–6297. [Google Scholar]

- Liu, X.; Jiang, Y.; Tang, Z.; Zhang, C.; Zhu, J. Bio-based epoxy resin from itaconic acid and its thermosets cured with anhydride and comonomers. Green Chem. 2013, 15, 245–254. [Google Scholar] [CrossRef]

- Llevot, A.; Grau, E.; Carlotti, S.; Grelier, S.; Cramail, H. From Lignin-derived Aromatic Compounds to Novel Biobased Polymers. Macromol. Rapid Commun. 2015, 37, 9–28. [Google Scholar] [CrossRef]

- Tan, S.G.; Chow, W.S. Biobased Epoxidized Vegetable Oils and Its Greener Epoxy Blends: A Review Biobased Epoxidized Vegetable Oils and Its Greener Epoxy Blends: A Review. Polym.-Plast. Technol. Eng. 2010, 49, 1581–1590. [Google Scholar] [CrossRef]

- Kalita, D.J.; Tarnavchyk, I.; Chisholm, B.J.; Webster, D.C. Novel Bio-Based Epoxy Resins from Eugenol as an Alternative to BPA Epoxy and High Throughput Screening of the Cured Coatings. Polymer 2021, 233, 124191. [Google Scholar] [CrossRef]

- Kalita, D.J.; Tarnavchyk, I.; Kalita, H.; Chisholm, B.J.; Webster, D.C. Novel Bio-Based Epoxy Resins from Eugenol Derived Copolymers as an Alternative to DGEBA Resin. Prog. Org. Coat. 2023, 178, 107471. [Google Scholar] [CrossRef]

- Saitta, L.; Prasad, V.; Tosto, C.; Murphy, N.; Ivankovic, A.; Cicala, G.; Scarselli, G. Characterization of biobased epoxy resins to manufacture eco-composites showing recycling properties. Polym. Compos. 2022, 43, 9179–9192. [Google Scholar] [CrossRef]

- Cicala, G.; Pergolizzi, E.; Piscopo, F.; Carbone, D.; Recca, G. Hybrid composites manufactured by resin infusion with a fully recyclable bioepoxy resin. Compos. Part B Eng. 2018, 132, 69–76. [Google Scholar] [CrossRef]

- Cicala, G.; Mannino, S.; La Rosa, A.D.; Banatao, D.R.; Pastine, S.J.; Kosinski, S.T.; Scarpa, F. Hybrid Biobased Recyclable Epoxy Composites for Mass Production. Polym. Compos. 2017, 39, E2217–E22252017. [Google Scholar] [CrossRef]

- Daniela, A.; Rosa, L.; Greco, S.; Tosto, C.; Cicala, G. LCA and LCC of a chemical recycling process of waste CF-thermoset composites for the production of novel CF-thermoplastic composites. Open loop and closed loop scenarios. J. Clean. Prod. 2021, 304, 127158. [Google Scholar] [CrossRef]

- Qin, J.; Woloctt, M.; Zhang, J. Use of Polycarboxylic Acid Derived from Partially Depolymerized Lignin As a Curing Agent for Epoxy Application. ACS Sustain. Chem. Eng. 2014, 2, 188–193. [Google Scholar] [CrossRef]

- Zhang, J.; Guo, Q.; Fox, B. Thermal and Mechanical Properties of a Dendritic Hydroxyl-Functional Hyperbranched Polymer and Tetrafunctional Epoxy Resin Blends. J. Polym. Sci. Part B Polym. Phys. 2010, 48, 417–424. [Google Scholar] [CrossRef]

- Yang, Y.; Xian, G.; Li, H.; Sui, L. Thermal aging of an anhydride-cured epoxy resin. Polym. Degrad. Stab. 2015, 118, 111–119. [Google Scholar] [CrossRef]

- Samper, M.D.; Fombuena, V.; Boronat, T.; García-Sanoguera, D.; Balart, R. Thermal and Mechanical Characterization of Epoxy Resins (ELO and ESO) Cured with Anhydrides. J. Am. Oil Chem. Soc. 2012, 89, 1521–1528. [Google Scholar] [CrossRef]

- Ding, C.; Matharu, A.S. Recent Developments on Biobased Curing Agents: A Review of Their Preparation and Use. ACS Sustain. Chem. Eng. 2014, 2, 2217–2236. [Google Scholar] [CrossRef]

- Jin, F.; Li, X.; Park, S. Synthesis and application of epoxy resins: A review. J. Ind. Eng. Chem. 2015, 29, 1–11. [Google Scholar] [CrossRef]

- Cicala, G.; La Spina, R.; Recca, A.; Sturiale, S. Influence of Copolymer’s End Groups and Molecular Weights on the Rheological and Thermomechanical Properties of Blends of Novel Thermoplastic Copolymers and Epoxy Resins. J. Appl. Polym. Sci. 2006, 101, 250–257. [Google Scholar] [CrossRef]

- Shechter, L.; Wynstra, J. Glycidyl Ether Reactions with Alcohols, Phenols, Carboxylic Acids. Ind. Eng. Chem. 1956, 48, 86–93. [Google Scholar] [CrossRef]

- Bowen, D.O.; Whiteside, R.C. Effect of Hydroxyl Compounds on Reactivity of Epoxy Resins; ACS Publications: Washington, DC, USA, 1970; pp. 48–59. [Google Scholar]

- Montgomery, D.C. Design and Analysis of Experiments, 8th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Gabbot, P. Principles and Applications of Thermal Analysis; John Wiley & Sons: Hoboken, NJ, USA, 2008. [Google Scholar]

- Paul, D.R. Control of Phase Structure in Polymer Blends. In Functional Polymers; Bergbreiter, D.E., Martin, C.R., Eds.; Springer US: Boston, MA, USA, 1989; pp. 1–18. [Google Scholar] [CrossRef]

- Grohens, Y.; George, B.; Touyeras, F.; Vebrel, J.; Laude, B. Experimental Design as a Route for Improving the Performances of Formulated Epoxy Adhesives. Polym. Test. 1997, 16, 417–427. [Google Scholar] [CrossRef]

- Zucchi, I.A.; Galante, M.J.; Williams, R.J.J. Comparison of morphologies and mechanical properties of crosslinked epoxies modified by polystyrene and poly(methyl methacrylate)) or by the corresponding block copolymer polystyrene-b-poly(methyl methacrylate). Polymer 2005, 46, 2603–2609. [Google Scholar] [CrossRef]

- Poncet, S.; Boiteux, G.; Pascault, J.P.; Sautereau, H.; Seytre, G.; Rogozinski, J.; Kranbuehl, D. Monitoring phase separation and reaction advancement in situ in thermoplastic/epoxy blends. Polymer 1999, 40, 6811–6820. [Google Scholar] [CrossRef]

- Rodríguez, M.T.; García, S.J.; Cabello, R.; Naber, J.J.G. Effect of Plasticizer on the Thermal, Mechanical, and Anticorrosion Properties Of an Epoxy Primer. JCT Res. 2005, 2, 557–564. [Google Scholar] [CrossRef]

- Blanco, I.; Cicala, G.; Motta, O.; Recca, A. Influence of a Selected Hardener on the Phase Separation in Epoxy/Thermoplastic Polymer Blends. J. Appl. Polym. Sci. 2004, 94, 361–371. [Google Scholar] [CrossRef]

- Wu, J.; Li, C.; Hailatihan, B.; Mi, L.; Baheti, Y.; Yan, Y. Effect of the Addition of Thermoplastic Resin and Composite on Mechanical and Thermal Properties of Epoxy Resin. Polymers 2022, 14, 1087. [Google Scholar] [CrossRef]

- Giannotti, M.I.; Galante, M.J.; Oyanguren, P.A.; Vallo, C.I. Role of intrinsic flaws upon flexural behaviour of a thermoplastic modified epoxy resin. Polym. Test. 2003, 22, 429–437. [Google Scholar] [CrossRef]

- Essmeister, J.; Taublaender, M.J.; Thomas Koch Cerròn-Infantes, D.A.; Unterlass, M.M.; Konegger, T. High modulus polyimide particle-reinforcement of epoxy composites. Mater. Adv. 2021, 2, 2278–2288. [Google Scholar] [CrossRef]

- Carolina, S.; Carolina, S. Raman and Near-Infrared Studies of an Epoxy Resin. Appl. Spectrosc. 1993, 47, 1631–1635. [Google Scholar]

- Hay, M.B.; Myneni, S.C.B. Structural environments of carboxyl groups in natural organic molecules from terrestrial systems. Part 1: Infrared spectroscopy. Geochim. Cosmochim. Acta 2007, 71, 3518–3532. [Google Scholar] [CrossRef]

- Stevens, G.C. Cure kinetics of a low epoxide/hydroxyl group-ratio bisphenol a epoxy resin–anhydride system by infrared absorption spectroscopy. J. Appl. Polym. Sci. 1981, 26, 4259–4278. [Google Scholar] [CrossRef]

- Wang, J.; Liu, R.; Jian, X. Introduction to Epoxy/Thermoplastic Blends. In Handbook of Epoxy Blends; Springer: Cham, Switzerland, 2016. [Google Scholar] [CrossRef]

- Yu, Y.F.; Cui, J.; Chen, W.J.; Li, S.J. Pure and Applied Chemistry Studies on the Phase Separation of Polyetherimide Modified Tetrafunctional Epoxy Resin. II. Effects of the Molecular Weight. J. Macromol. Sci. Part A 1998, 35, 121–135. [Google Scholar] [CrossRef]

| Response | Factor | Symbol | Type | Unit | Level (−1) | Level (0) | Level (+1) |

|---|---|---|---|---|---|---|---|

| Tg | rTP content | A | Categorical | (%wt) | 15 | 21 | 27 |

| Curing cycle | B | Categorical | (-) | C1 | - | C2 | |

| Flexural strength | rTP content | A | Categorical | (%wt) | 15 | 21 | 27 |

| Curing cycle | B | Categorical | (-) | C1 | - | C2 | |

| Flexural modulus | rTP content | A | Categorical | (%wt) | 15 | 21 | 27 |

| Curing cycle | B | Categorical | (-) | C1 | - | C2 | |

| Deformation at break | rTP content | A | Categorical | (%wt) | 15 | 21 | 27 |

| Curing cycle | B | Categorical | (-) | C1 | - | C2 |

| Parameter | Goal | Lower Limit | Upper Limit | Lower Weight | Upper Weight | Importance |

|---|---|---|---|---|---|---|

| rTP content | In range | 15%wt | 27%wt | 1 | 1 | 3 |

| Curing cycle | In range | C1 | C2 | 1 | 1 | 3 |

| Tg | Maximize | Lowest value collected | Highest value collected | 1 | 1 | 3 |

| Flexural strength | Maximize | Lowest value collected | Highest value collected | 1 | 1 | 3 |

| Flexural modulus | Maximize | Lowest value collected | Highest value collected | 1 | 1 | 3 |

| Deformation at break | Maximize | Lowest value collected | Highest value collected | 1 | 1 | 3 |

| Sample ID | Thermoset System | Curing Cycle | Tg (°C) |

|---|---|---|---|

| P_A_rTP15_C | Polar + R*101 + 15%wt rTP | C1 | 60.80 ± 0.56 |

| P_A_rTP15_PC | Polar + R*101 + 15%wt rTP | C2 | 85.10 ± 0.42 |

| P_A_rTP21_C | Polar + R*101 + 21%wt rTP | C1 | 59.42 ± 0.98 |

| P_A_rTP21_PC | Polar + R*101 + 21%wt rTP | C2 | 82.54 ± 0.21 |

| P_A_rTP27_C | Polar + R*101 + 27%wt rTP | C1 | 59.76 ± 0.57 |

| P_A_rTP27_PC | Polar + R*101 + 27%wt rTP | C2 | 81.34 ± 0.44 |

| Source | Sum of Squares | df | Mean Square | F Value | p-Value | |

|---|---|---|---|---|---|---|

| Model | 4007.42 | 5 | 801.48 | 2431.19 | <0.0001 | significant |

| A–rTP content | 33.05 | 2 | 16.52 | 50.12 | <0.0001 | |

| B–Curing Cycle | 3965.20 | 1 | 3965.20 | 12,027.91 | <0.0001 | |

| AB | 9.17 | 2 | 4.59 | 13.91 | <0.0001 | |

| Pure Error | 7.91 | 24 | 0.33 | |||

| Cor Total | 4015.33 | 29 | ||||

| Std. Dev. | 0.57 | R-Squared | 0.9980 | |||

| Mean | 71.50 | Adj R-Squared | 0.9976 |

| Sample ID | Thermoset System | Curing State | Onset (°C) | Endset (°C) | Peak (°C) | Heat (J/g) |

|---|---|---|---|---|---|---|

| P_A_rTP15 | Polar + R*101 + 15%wt rTP | Uncured | 82.26 | 157.84 | 120.19 | 226.83 |

| P_A_rTP21 | Polar + R*101 + 21%wt rTP | Uncured | 79.38 | 156.19 | 117.78 | 245.21 |

| P_A_rTP27 | Polar + R*101 + 27%wt rTP | Uncured | 77.94 | 153.17 | 116.91 | 179.38 |

| ID | Thermoset System | Flexural Strength (MPa) | Flexural Modulus (GPa) | Deformation at Break (%) |

|---|---|---|---|---|

| P_A_rTP15_C | Polar + R*101 + 15%wt rTP | 73.44 ± 3.93 | 3.44 ± 0.18 | 2.22 ± 0.11 |

| P_A_rTP15_PC | Polar + R*101 + 15%wt rTP | 106.11 ± 4.13 | 3.50 ± 0.06 | 3.41 ± 0.41 |

| P_A_rTP21_C | Polar + R*101 + 21%wt rTP | 57.44 ± 8.04 | 2.99 ± 0.28 | 1.95 ± 0.16 |

| P_A_rTP21_PC | Polar + R*101 + 21%wt rTP | 103.16 ± 1.86 | 4.45 ± 0.31 | 4.21 ± 0.25 |

| P_A_rTP27_C | Polar + R*101 + 27%wt rTP | 66.68 ± 4.82 | 2.51 ± 0.06 | 3.69 ± 0.24 |

| P_A_rTP27_PC | Polar + R*101 + 27%wt rTP | 31.09 ± 2.32 | 2.73 ± 0.14 | 1.40 ± 0.16 |

| Source | Sum of Squares | df | Mean Square | F Value | p-Value | |

|---|---|---|---|---|---|---|

| Model | 19,808.09 | 5 | 3961.62 | 184.02 | <0.0001 | significant |

| A–rTP content | 8921.93 | 2 | 4460.97 | 207.22 | <0.0001 | |

| B–Curing Cycle | 1598.85 | 1 | 1598.85 | 74.27 | <0.0001 | |

| AB | 9287.31 | 2 | 4643.66 | 215.70 | <0.0001 | |

| Pure Error | 516.67 | 24 | 21.52 | |||

| Cor Total | 20,324.76 | 29 | ||||

| Std. Dev. | 4.64 | R-Squared | 0.9746 | |||

| Mean | 73.16 | Adj R-Squared | 0.9693 |

| Source | Sum of Squares | df | Mean Square | F Value | p-Value | |

|---|---|---|---|---|---|---|

| Model | 12.18 | 5 | 2.44 | 60.92 | <0.0001 | significant |

| A—rTP content | 6.67 | 2 | 3.33 | 83.34 | <0.0001 | |

| B—Curing Cycle | 2.55 | 1 | 2.55 | 63.66 | <0.0001 | |

| AB | 2.97 | 2 | 1.48 | 37.12 | <0.0001 | |

| Pure Error | 0.96 | 24 | 0.04 | |||

| Cor Total | 13.14 | 29 | ||||

| Std. Dev. | 0.20 | R-Squared | 0.9270 | |||

| Mean | 3.27 | Adj R-Squared | 0.9117 |

| Source | Sum of Squares | df | Mean Square | F Value | p-Value | |

|---|---|---|---|---|---|---|

| Model | 30.86 | 5 | 6.17 | 105.67 | <0.0001 | significant |

| A—rTP content | 1.4 | 2 | 0.72 | 12.30 | 0.0002 | |

| B—Curing Cycle | 1.12 | 1 | 1.12 | 19.14 | 0.0002 | |

| AB | 28.30 | 2 | 14.15 | 242.31 | <0.0001 | |

| Pure Error | 1.40 | 24 | 0.06 | |||

| Cor Total | 32.26 | 29 | ||||

| Std. Dev. | 0.24 | R-Squared | 0.9566 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saitta, L.; Rizzo, G.; Tosto, C.; Cicala, G.; Blanco, I.; Pergolizzi, E.; Ciobanu, R.; Recca, G. Chemical Recycling of Fully Recyclable Bio-Epoxy Matrices and Reuse Strategies: A Cradle-to-Cradle Approach. Polymers 2023, 15, 2809. https://doi.org/10.3390/polym15132809

Saitta L, Rizzo G, Tosto C, Cicala G, Blanco I, Pergolizzi E, Ciobanu R, Recca G. Chemical Recycling of Fully Recyclable Bio-Epoxy Matrices and Reuse Strategies: A Cradle-to-Cradle Approach. Polymers. 2023; 15(13):2809. https://doi.org/10.3390/polym15132809

Chicago/Turabian StyleSaitta, Lorena, Giuliana Rizzo, Claudio Tosto, Gianluca Cicala, Ignazio Blanco, Eugenio Pergolizzi, Romeo Ciobanu, and Giuseppe Recca. 2023. "Chemical Recycling of Fully Recyclable Bio-Epoxy Matrices and Reuse Strategies: A Cradle-to-Cradle Approach" Polymers 15, no. 13: 2809. https://doi.org/10.3390/polym15132809

APA StyleSaitta, L., Rizzo, G., Tosto, C., Cicala, G., Blanco, I., Pergolizzi, E., Ciobanu, R., & Recca, G. (2023). Chemical Recycling of Fully Recyclable Bio-Epoxy Matrices and Reuse Strategies: A Cradle-to-Cradle Approach. Polymers, 15(13), 2809. https://doi.org/10.3390/polym15132809