Properties of Composites Based on Recycled Polypropylene and Silico-Aluminous Industrial Waste

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Composites

2.3. Characterization

2.3.1. Fourier Transform Infrared Spectroscopy Analysis (FTIR)

2.3.2. Thermal Characterization

2.3.3. Dynamic Mechanical Analysis (DMA)

2.3.4. X-ray Diffraction Analysis (XRD)

2.3.5. Mechanical Properties Analysis

2.3.6. Nanomechanical Analysis

2.3.7. Scanning Electron Microscopy (SEM)

3. Results

3.1. Characterization of Modified Ashes Compositions

3.1.1. SEM and EDX Analysis

3.1.2. X-ray Diffraction Analysis

3.1.3. FTIR Analysis

3.1.4. Thermogravimetric Analysis

3.2. Characterization of PP Composites

3.2.1. X-ray Diffraction Analysis

3.2.2. FTIR Analysis

3.2.3. Thermogravimetric Analysis

3.2.4. Differential Scanning Analysis

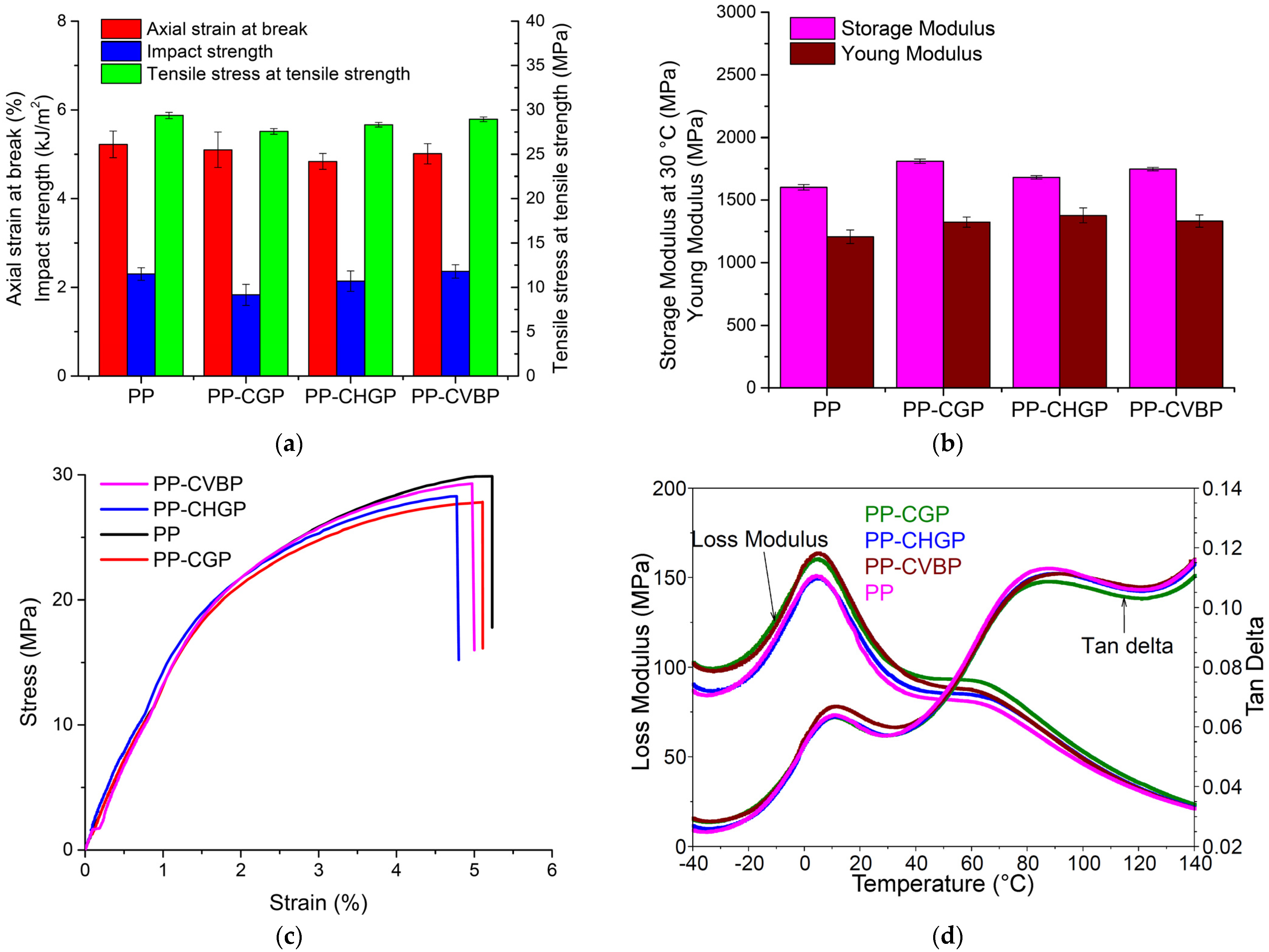

3.2.5. Mechanical and Dynamic Mechanical Analysis

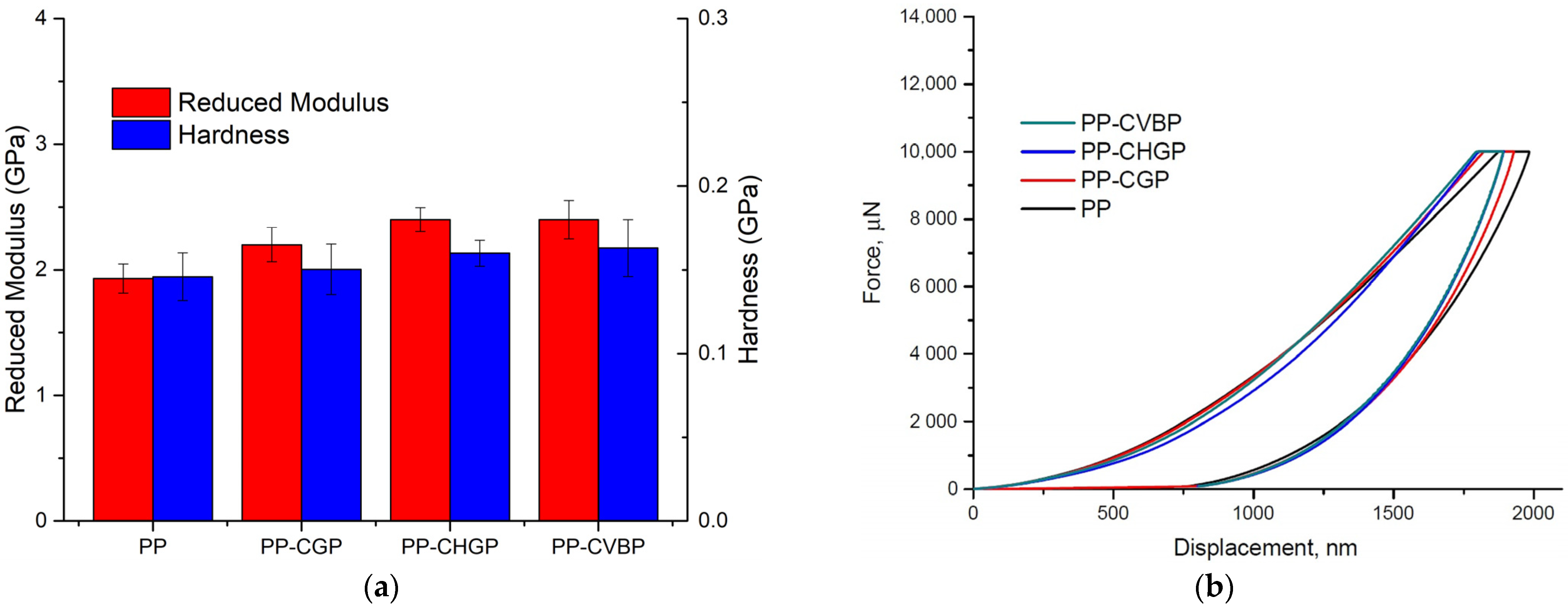

3.2.6. Nanomechanical Analysis

3.2.7. SEM and EDX Analysis

4. Conclusions

5. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Selvaranjan, K.; Navaratnam, S.; Rajeev, P.; Ravintherakumaran, N. Environmental challenges induced by extensive use of face masks during COVID-19: A review and potential solutions. Environ. Chall. 2021, 3, 100039. [Google Scholar] [CrossRef]

- Torres, F.G.; De-la-Torre, G.E. Face mask waste generation and management during the COVID-19 pandemic: An overview and the Peruvian case. Sci. Total Environ. 2021, 786, 147628. [Google Scholar] [CrossRef]

- Sangkham, S. Face mask and medical waste disposal during the novel COVID-19 pandemic in Asia. Case Stud. Chem. Environ. Eng. 2020, 2, 100052. [Google Scholar] [CrossRef]

- Battegazzore, D.; Cravero, F.; Frache, A. Is it Possible to Mechanical Recycle the Materials of the Disposable Filtering Masks? Polymers 2020, 12, 2726. [Google Scholar] [CrossRef]

- Maderuelo-Sanz, R.; Acedo-Fuentes, P.; García-Cobos, F.J.; Sánchez-Delgado, F.J.; Mota-López, M.I.; Meneses-Rodríguez, J.M. The recycling of surgical face masks as sound porous absorbers: Preliminary evaluation. Sci. Total Environ. 2021, 786, 147461. [Google Scholar] [CrossRef]

- Saberian, M.; Li, J.; Kilmartin-Lynch, S.; Boroujeni, M. Repurposing of COVID-19 single-use face masks for pavements base/subbase. Sci. Total Environ. 2021, 769, 145527. [Google Scholar] [CrossRef]

- Pourebrahimi, S. Upcycling face mask wastes generated during COVID-19 into value-added engineering materials: A review. Sci. Total Environ. 2022, 851, 158396. [Google Scholar] [CrossRef]

- Crespo, C.; Ibarz, G.; Sáenz-Ezquerro, C.; González Miguel, P.; Roche, S. Study of Recycling Potential of FFP2 Face Masks and Characterization of the Plastic Mix-Material Obtained. A Way of Reducing Waste in Times of Covid-19. Waste Biomass Valorization 2021, 12, 6423–6432. [Google Scholar] [CrossRef]

- George Varghese, P.J.; David, D.A.; Karuth, A.; Manamkeri Jafferali, J.F.; Begum, P.M.S.; George, J.J.; Rasulev, B.; Raghavan, P. Experimental and Simulation Studies on Nonwoven Polypropylene–Nitrile Rubber Blend: Recycling of Medical Face Masks to an Engineering Product. ACS Omega 2022, 7, 4791–4803. [Google Scholar] [CrossRef]

- Karian, H. Handbook of Polypropylene and Polypropylene Composites, 2nd ed.; Revised and Expanded; CRC Press: Boca Raton, FL, USA, 2003. [Google Scholar]

- Liu, J.; Wang, Z.; Xie, G.; Li, Z.; Fan, X.; Zhang, W.; Xing, F.; Tang, L.; Ren, J. Resource utilization of municipal solid waste incineration fly ash—Cement and alkali-activated cementitious materials: A review. Sci. Total Environ. 2022, 852, 158254. [Google Scholar] [CrossRef]

- Tariq, H.; Siddique, R.M.A.; Shah, S.A.R.; Azab, M.; Attiq-Ur-Rehman; Qadeer, R.; Ullah, M.K.; Iqbal, F. Mechanical Performance of Polymeric ARGF-Based Fly Ash-Concrete Composites: A Study for Eco-Friendly Circular Economy Application. Polymers 2022, 14, 1774. [Google Scholar] [CrossRef] [PubMed]

- Kishore; Kulkarni, S.M.; Sunil, D.; Sharathchandra, S. Effect of surface treatment on the impact behaviour of fly-ash filled polymer composites. Polym. Int. 2002, 51, 1378–1384. [Google Scholar] [CrossRef]

- Manikandan, V.; Richard, S.; Thanu, M.C.; Rajadurai, J.S. Effect of fly ash as filler on mechanical & frictional properties of jute fiber reinforced composite. Int. Res. J. Eng. Technol. 2015, 2, 154–158. [Google Scholar]

- Venkatachalam, G.; Sharma, S.; Kumar, A.; Prakasam, V.; Satonkar, N.; Chinnaiyan, P. Research Paper Investigations on Tensile and Flexural Characteristics of Fly Ash and Banana Fiber-Reinforced Epoxy Matrix Composites. Eng. Trans. 2020, 68, 89–101. [Google Scholar] [CrossRef]

- Kasar, A.K.; Gupta, N.; Rohatgi, P.K.; Menezes, P.L. A Brief Review of Fly Ash as Reinforcement for Composites with Improved Mechanical and Tribological Properties. JOM 2020, 72, 2340–2351. [Google Scholar] [CrossRef]

- Satheesh Raja, R.; Manisekar, K.; Manikandan, V. Study on mechanical properties of fly ash impregnated glass fiber reinforced polymer composites using mixture design analysis. Mater. Des. 2014, 55, 499–508. [Google Scholar] [CrossRef]

- Nath, D.C.D.; Bandyopadhyay, S.; Yu, A.; Zeng, Q.; Das, T.; Blackburn, D.; White, C. Structure–property interface correlation of fly ash–isotactic polypropylene composites. J. Mater. Sci. 2009, 44, 6078–6089. [Google Scholar] [CrossRef]

- Gummadi, J.; Kumar, G.; Gunti, R. Evaluation of Flexural Properties of Fly Ash Filled Polypropylene Composites. Int. J. Mod. Eng. Res. 2012, 2, 2584–2590. [Google Scholar]

- Chrissopoulou, K.; Anastasiadis, S.H. Polyolefin/layered silicate nanocomposites with functional compatibilizers. Eur. Polym. J. 2011, 47, 600–613. [Google Scholar] [CrossRef]

- Joseph, S.; Bambola, V.; Sherhtukade, V.; Mahanwar, P. Effect of Flyash Content, Particle Size of Flyash, and Type of Silane Coupling Agents on the Properties of Recycled Poly(ethylene terephthalate)/Flyash Composites. J. Appl. Polym. Sci. 2011, 119, 201–208. [Google Scholar] [CrossRef]

- Kutchko, B.G.; Kim, A.G. Fly ash characterization by SEM–EDS. Fuel 2006, 85, 2537–2544. [Google Scholar] [CrossRef]

- Hao, Y.-P.; Yang, H.-L.; Zhang, G.-B.; Zhang, H.-L.; Gao, G.; Dong, L.-S. Rheological, thermal and mechanical properties of biodegradable poly(propylene carbonate)/polylactide/Poly(1,2-propylene glycol adipate) blown films. Chin. J. Polym. Sci. 2015, 33, 1702–1712. [Google Scholar] [CrossRef]

- Zhao, Y.; Liang, H.; Wu, D.; Bian, J.; Hao, Y.; Zhang, G.; Liu, S.; Zhang, H.; Dong, L. Poly(1,2-propylene glycol adipate) as an Environmentally Friendly Plasticizer for Poly(vinyl chloride). Polym. Korea 2015, 39, 247–255. [Google Scholar] [CrossRef]

- Panaitescu, D.M.; Vuluga, Z.; Frone, A.N.; Gabor, A.R.; Nicolae, C.-A.; Usurelu, C.-D. Complex Effects of Hemp Fibers and Impact Modifiers in Multiphase Polypropylene Systems. Polymers 2023, 15, 409. [Google Scholar] [CrossRef] [PubMed]

- Innocenzi, P.; Falcaro, P.; Grosso, D.; Babonneau, F. Order–Disorder Transitions and Evolution of Silica Structure in Self-Assembled Mesostructured Silica Films Studied through FTIR Spectroscopy. J. Phys. Chem. B 2003, 107, 4711–4717. [Google Scholar] [CrossRef]

- Ściubidło, A.; Nowak, W. Novel sorbents for flue gas purification. J. Power Technol. 2012, 92, 115–126. [Google Scholar]

- Foresta, T.; Piccarolo, S.; Goldbeck-Wood, G. Competition between α and γ phases in isotactic polypropylene: Effects of ethylene content and nucleating agents at different cooling rates. Polymer 2001, 42, 1167–1176. [Google Scholar] [CrossRef]

- Yang, J.; Gao, M.; Zhao, H.; Liu, S.; Hu, M.; Xie, S. Space Charge Characteristics of Polypropylene Modified by Rare Earth Nucleating Agent for b Crystallization. Materials 2019, 12, 42. [Google Scholar] [CrossRef]

- Roussel, M.D.; Guy, A.R.; Shaw, L.G.; Cara, J.E. The Use of Calcium Carbonate in Polyolefins Offers Significant Improvement in Productivity. Available online: https://www.tappi.org/content/enewsletters/eplace/2006/06-3rousselv1.pdf (accessed on 2 April 2023).

- Farahani, M.; Jahani, Y. An approach for prediction optimum crystallization conditions for formation of beta polypropylene by response surface methodology (RSM). Polym. Test. 2021, 93, 106921. [Google Scholar] [CrossRef]

- Caban, R. FTIR-ATR spectroscopic, thermal and microstructural studies on polypropylene-glass fiber composites. J. Mol. Struct. 2022, 1264, 133181. [Google Scholar] [CrossRef]

- Haris, N.I.N.; Ilyas, R.A.; Hassan, M.Z.; Sapuan, S.M.; Afdzaluddin, A.; Jamaludin, K.R.; Zaki, S.A.; Ramlie, F. Dynamic Mechanical Properties and Thermal Properties of Longitudinal Basalt/Woven Glass Fiber Reinforced Unsaturated Polyester Hybrid Composites. Polymers 2021, 13, 3343. [Google Scholar] [CrossRef] [PubMed]

- Sumita, M.; Tsukihi, H.; Miyasaka, K.; Ishikawa, K. Dynamic mechanical properties of polypropylene composites filled with ultrafine particles. J. Appl. Polym. Sci. 1984, 29, 1523–1530. [Google Scholar] [CrossRef]

- Joseph, P.V.; Mathew, G.; Joseph, K.; Groeninckx, G.; Thomas, S. Dynamic mechanical properties of short sisal fibre reinforced polypropylene composites. Compos. A Appl. Sci. Manuf. 2003, 34, 275–290. [Google Scholar] [CrossRef]

- Enrique-Jimenez, P.; Quiles-Díaz, S.; Salavagione, H.J.; Fernández-Blázquez, J.P.; Monclús, M.A.; Guzman de Villoria, R.; Gómez-Fatou, M.A.; Ania, F.; Flores, A. Nanoindentation mapping of multiscale composites of graphene-reinforced polypropylene and carbon fibres. Compos. Sci. Technol. 2019, 169, 151–157. [Google Scholar] [CrossRef]

- Alateyah, A. Nano indentation and morphology study of the polypropylene and high density polyethylene nanocomposites based on exfoliated graphite Nano platelets/Nano- magnesium oxide. Int. J. Eng. Technol. 2018, 7, 891. [Google Scholar] [CrossRef]

| Characteristic | CHG | CVB | CG |

|---|---|---|---|

| Oxidic Chemical Component, (%) | |||

| Loss on ignition (LOI) | 7.85 | 12.35 | 3.08 |

| SiO2 | 50.76 | 40.19 | 56.24 |

| Al2O3 | 22.87 | 3.4 | 22.44 |

| Fe2O3 | 6.49 | 6 | 8.03 |

| CaO | 4.49 | 1.5 | 5.65 |

| MgO | 2.40 | 7.8 | 0.08 |

| SO3 | 0.08 | 1 | 1.33 |

| Na2O | 0.40 | 8.92 | 0.56 |

| K2O | 2.15 | 18.05 | 2.22 |

| SiO2 reactive | 40.25 | 39.74 | 48.11 |

| Physical Characteristics | |||

| Average diameter for 50% of particles, (d50), μm | 12.72 | 6.7 | 23.6 |

| Density, g/cm3 | 2.24 | 1.97 | 2.08 |

| Specific surface area (Blaine value), cm2/g | 8519 | 14,492 | 4650 |

| R009, % | 0.0 | 0.0 | 6.0 |

| Sample Name | 2θ | d-Value (Å) | Height (cps) | FWHM (°) | Size (Å) | h k l Planes |

|---|---|---|---|---|---|---|

| CG | 20.77 | 4.27 | 1542.94 | 0.60 | 133.79 | 1 0 0 |

| 26.55 | 3.35 | 7756.41 | 0.35 | 232.16 | 1 0 1 | |

| 36.53 | 2.46 | 963.36 | 0.50 | 168.04 | 1 1 0 | |

| 50.16 | 1.82 | 1197.79 | 0.48 | 181.01 | 1 1 2 | |

| CGP | 20.77 | 4.27 | 1541.54 | 0.35 | 229.14 | 1 0 0 |

| 26.56 | 3.35 | 8263.79 | 0.35 | 231.82 | 1 0 1 | |

| 36.46 | 2.46 | 717.41 | 0.24 | 349.9 | 1 1 0 | |

| 50.08 | 1.82 | 790.14 | 0.40 | 217.4 | 1 1 2 | |

| CHG | 20.77 | 4.27 | 1799.27 | 0.36 | 226.66 | 1 0 0 |

| 26.57 | 3.35 | 9902.87 | 0.35 | 234.71 | 1 0 1 | |

| 36.52 | 2.46 | 529.48 | 0.30 | 277.53 | 1 1 0 | |

| 50.11 | 1.82 | 1067.70 | 0.40 | 221.47 | 1 1 2 | |

| CHGP | 20.79 | 4.27 | 1915.11 | 0.33 | 246.67 | 1 0 0 |

| 26.65 | 3.34 | 9497.51 | 0.31 | 260.64 | 1 0 1 | |

| 36.58 | 2.45 | 672 | 0.38 | 218.55 | 1 1 0 | |

| 50.11 | 1.82 | 900.90 | 0.41 | 216.54 | 1 1 2 |

| Sample Name | 2θ | d-Value (Å) | Height (cps) | FWHM (°) | Size (Å) | h k l Planes |

|---|---|---|---|---|---|---|

| CVB | 27.32 | 3.26 | 1030.58 | 0.42 | 194.26 | 1 1 1 |

| 31.67 | 2.82 | 11,722.75 | 0.32 | 259.69 | 2 0 0 | |

| 45.43 | 1.99 | 6298.4 | 0.32 | 272.23 | 2 2 0 | |

| 56.44 | 1.63 | 1824.69 | 0.32 | 280.6 | 2 2 2 | |

| CVBP | 27.36 | 3.26 | 777.68 | 0.26 | 311.94 | 1 1 1 |

| 31.71 | 2.82 | 9139.36 | 0.31 | 266.74 | 2 0 0 | |

| 45.42 | 2.00 | 4856.34 | 0.31 | 279.61 | 2 2 0 | |

| 56.43 | 1.63 | 1336.63 | 0.35 | 260.88 | 2 2 2 |

| Sample | RT-100 °C | RT-230 °C | Onset Point | Tmax | Residue | |

|---|---|---|---|---|---|---|

| Wt. | Wt. | Temp | Weight | 700 °C | ||

| % | % | °C | % | °C | % | |

| CG | 99.81 | 99.61 | 509.2 | 99.26 | 562.2 | 98.25 |

| CGP | 99.74 | 97.26 | 326.6 | 97.51 | 359.2 | 76.06 |

| CHG | 99.25 | 98.74 | 515.3 | 97.64 | 666.5 | 92.99 |

| CHGP | 99.4 | 97.04 | 320.2 | 96.26 | 353.4 | 73.23 |

| CVB | 99.17 | 97.39 | 512.3 | 98.55 | 612.3 | 94.44 |

| CVBP | 99.37 | 96.37 | 299.4 | 95.47 | 336.7 | 74.28 |

| P | 97.83 | 93.37 | 350.3 | 91.45 | 386.6 | 1.24 |

| αPP (110) | βPP (300) | αPP (040) | αPP (120) | CaCO3 (104) | Kβ | ||

|---|---|---|---|---|---|---|---|

| PP | 2θ | 14.043 | 16.043 | 16.821 | 18.491 | 29.4246 | 10.35% |

| d (Å) | 6.302 | 5.520 | 5.266 | 4.794 | 3.0331 | ||

| Height (cps) | 65,583 | 19,394 | 76,309 | 26,078 | 16,058.84 | ||

| Size (Å) | 126.5 | 180 | 156.5 | 120.3 | 221.76 | ||

| PP–CVBP | 2θ | 14.016 | 16.048 | 16.828 | 18.488 | 29.4110 | 9.64% |

| d (Å) | 6.313 | 5.518 | 5.264 | 4.795 | 3.0344 | ||

| Height (cps) | 39,992 | 10,827 | 45,682 | 15,803 | 5835.20 | ||

| Size (Å) | 128.9 | 173 | 152.9 | 117 | 240.8 | ||

| PP–CHGP | 2θ | 14.047 | 16.29 | 16.844 | 18.498 | 29.4270 | 4.79% |

| d (Å) | 6.299 | 5.438 | 5.259 | 4.7957 | 3.03283 | ||

| Height (cps) | 35,982 | 5800 | 59,088 | 20,134 | 7376.68 | ||

| Size (Å) | 130.8 | 120 | 163.8 | 122.1 | 218.64 | ||

| PP–CGP | 2θ | 14.026 | 16.2 | 16.827 | 18.486 | 29.4018 | 4.05% |

| d (Å) | 6.309 | 5.467 | 5.260 | 4.795 | 3.0354 | ||

| Height (cps) | 47,331 | 4956 | 51,750 | 18,166 | 6864.91 | ||

| Size (Å) | 128.8 | 137 | 158.1 | 117.8 | 192.99 | ||

| Sample | RT-230 °C Wt. Loss % | 230–500 °C | 500–700 °C | Residue 700 °C | Temp for Wt. Loss 5% °C | |||

|---|---|---|---|---|---|---|---|---|

| Wt. Loss % | Tmax °C | Wt. Loss % | Tmax °C | (N2) % | (Air) % | |||

| PP | 0.52 | 97.71 | 441.6 | 0.69 | 606.3 | 1.09 | 1.07 | 371.3 |

| PP–CGP | 0.46 | 93.63 | 442.6 | 0.63 | 617.0 | 5.28 | 5.28 | 370.0 |

| PP–CHGP | 0.58 | 92.97 | 442.0 | 0.87 | 621.3 | 5.57 | 5.57 | 368.7 |

| PP–CVBP | 0.64 | 92.92 | 441.5 | 0.77 | 590.9 | 5.38 | 5.37 | 368.0 |

| Sample | 1st Heating | Cooling | 2nd Heating | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Melting | Crystallization | Melting | ||||||||||

| Onset | Tmax | ΔHm | Xc | Onset | Tmax | ΔHc | Xc | Onset | Tmax | ΔHm | Xc | |

| °C | °C | J/(g) | (%) | °C | °C | J/(g) | (%) | °C | °C | J/(g) | (%) | |

| PP | 148.4 | 160.9 | 87.88 | 46.7 | 130.0 | 125.7 | 96.24 | 51.1 | 149.1 | 160.0 | 94.76 | 50.3 |

| PP–CGP | 149.7 | 160.0 | 82.23 | 43.7 | 131.1 | 127.0 | 91.32 | 48.5 | 147.4 | 159.9 | 88.54 | 47.0 |

| PP–CHGP | 149.6 | 159.6 | 79.57 | 42.2 | 129.4 | 125.2 | 91.51 | 48.6 | 148.0 | 159.8 | 88.78 | 47.1 |

| PP–CVBP | 147.6 | 160.9 | 81.47 | 43.3 | 129.4 | 125.2 | 90.73 | 48.2 | 149.8 | 159.9 | 87.98 | 46.7 |

| Sample | Loss Modulus, E″ | Loss Factor | ||||||

|---|---|---|---|---|---|---|---|---|

| Temp. | E″ Peak 1 | Temp. | E″ Peak 2 | Temp. | Tan Delta | Temp. | Tan Delta | |

| °C | MPa | °C | MPa | °C | Tan δ Peak 1 | °C | Tan δ Peak 2 | |

| PP | 4.61 | 150.0 | 59.56 | 80.37 | 11.15 | 0.06364 | 88.13 | 0.1127 |

| PP–CGP | 4.85 | 159.7 | 58.59 | 92.35 | 10.66 | 0.06298 | 87.4 | 0.1083 |

| PP–CHGP | 5.09 | 148.6 | 59.32 | 84.34 | 11.15 | 0.06319 | 90.31 | 0.111 |

| PP–CVBP | 5.3 | 163.1 | 59.16 | 87.07 | 11.15 | 0.06656 | 90.84 | 0.1109 |

| Sample | Roughness (Rms, nm) | µ | |

|---|---|---|---|

| Before Scratch | After Scratch | ||

| PP | 81.41 | 87.04 | 0.28 ± 0.01 |

| PP–CGP | 116.68 | 121.55 | 0.28 ± 0.01 |

| PP–CHGP | 209.8 | 227.27 | 0.29 ± 0.01 |

| PP–CVBP | 158.41 | 161.92 | 0.28 ± 0.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Teodorescu, G.-M.; Vuluga, Z.; Oancea, F.; Ionita, A.; Paceagiu, J.; Ghiurea, M.; Nicolae, C.-A.; Gabor, A.R.; Raditoiu, V. Properties of Composites Based on Recycled Polypropylene and Silico-Aluminous Industrial Waste. Polymers 2023, 15, 2545. https://doi.org/10.3390/polym15112545

Teodorescu G-M, Vuluga Z, Oancea F, Ionita A, Paceagiu J, Ghiurea M, Nicolae C-A, Gabor AR, Raditoiu V. Properties of Composites Based on Recycled Polypropylene and Silico-Aluminous Industrial Waste. Polymers. 2023; 15(11):2545. https://doi.org/10.3390/polym15112545

Chicago/Turabian StyleTeodorescu, George-Mihail, Zina Vuluga, Florin Oancea, Andreea Ionita, Jenica Paceagiu, Marius Ghiurea, Cristian-Andi Nicolae, Augusta Raluca Gabor, and Valentin Raditoiu. 2023. "Properties of Composites Based on Recycled Polypropylene and Silico-Aluminous Industrial Waste" Polymers 15, no. 11: 2545. https://doi.org/10.3390/polym15112545

APA StyleTeodorescu, G.-M., Vuluga, Z., Oancea, F., Ionita, A., Paceagiu, J., Ghiurea, M., Nicolae, C.-A., Gabor, A. R., & Raditoiu, V. (2023). Properties of Composites Based on Recycled Polypropylene and Silico-Aluminous Industrial Waste. Polymers, 15(11), 2545. https://doi.org/10.3390/polym15112545