3D-Printed PLA Molds for Natural Composites: Mechanical Properties of Green Wax-Based Composites

Abstract

1. Introduction

2. Experimental Section

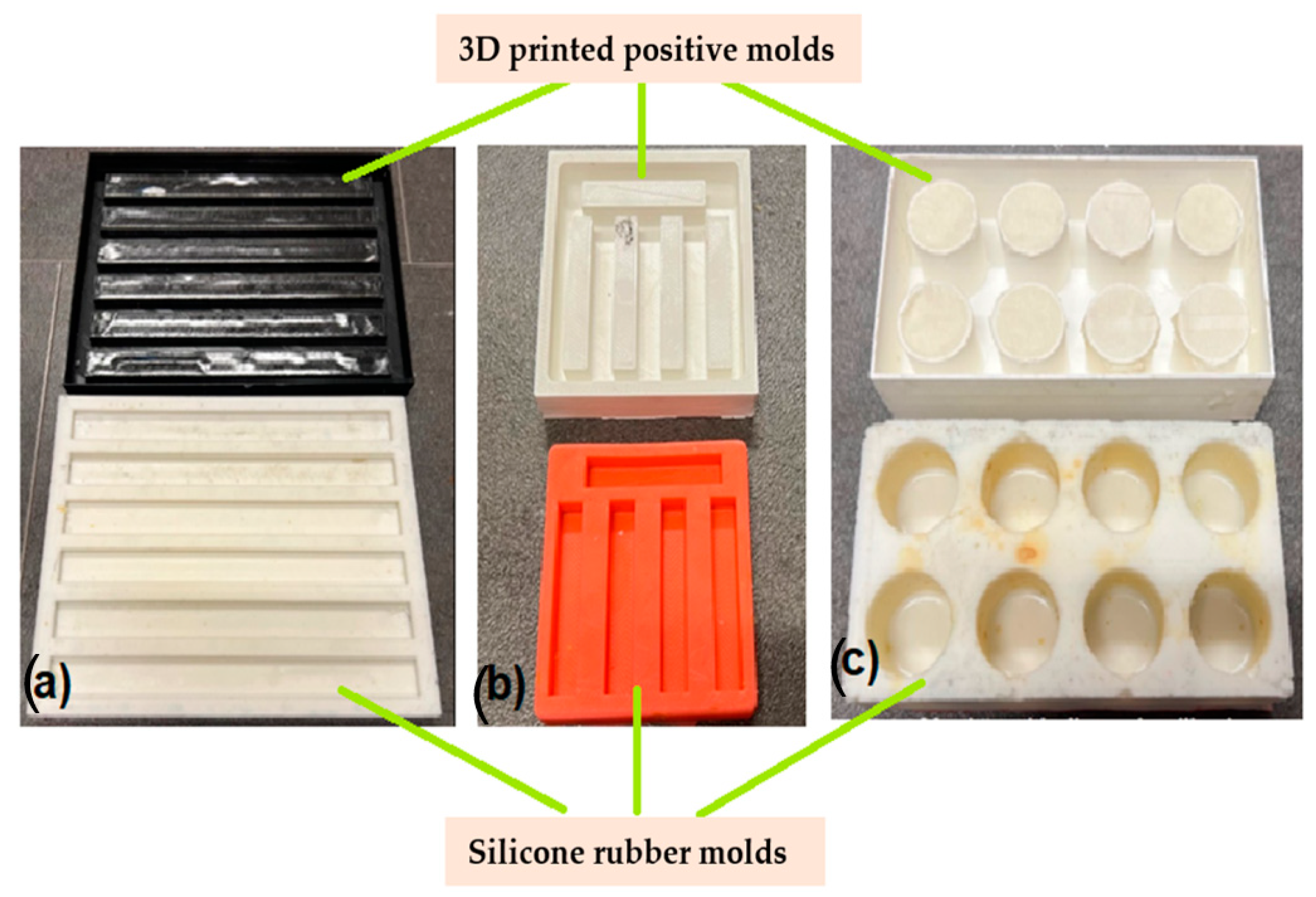

2.1. 3D-Printing Molds for Green Composite Development

- (a)

- Beeswax (Ca) and ground horsetail (Cc)—a total of 14 composite materials were obtained. Percent of ground horsetail between 0 and 39.4%.

- (b)

- Beeswax (Ca) and recycled paper (Hr)—a total of 18 composite materials were obtained. Percent of recycled paper was between 0 and 46%.

- (c)

- Beeswax (Ca) and ground rice (Or)—a total of 10 composite materials were obtained. Percent of ground rice was between 0 and 86.5%.

- (d)

- Beeswax (Ca) and ground fir needles (Abr)—a total of 10 composite materials were obtained. Percent of ground fir was between 0 and 86.5%.

- Recyclable paper 100% denoted as S1 (as base for comparison with new composites)

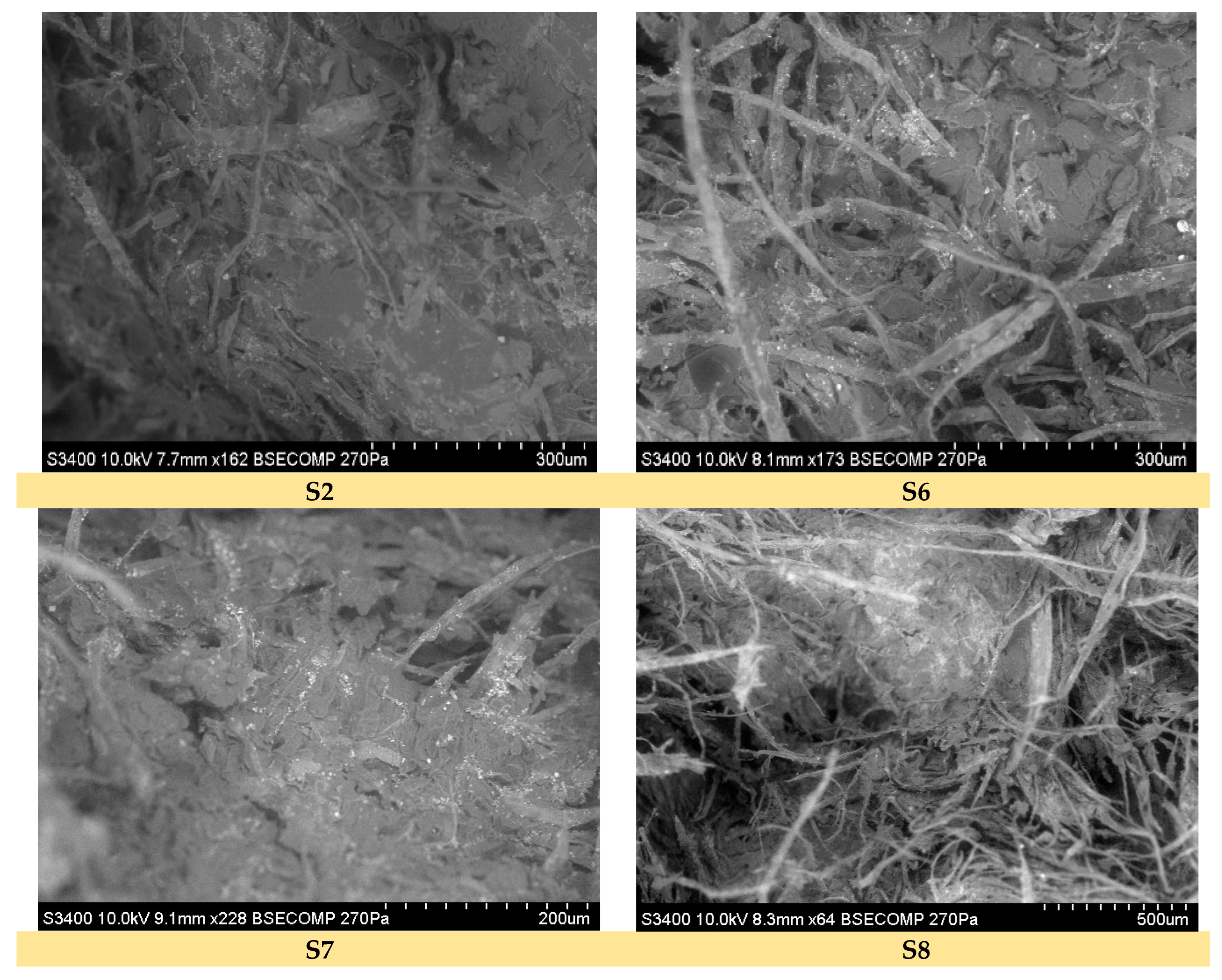

- Beeswax (50%) + fir resin (50%) denoted as S2

- Beeswax (62.5%) + horsetail (37.5%) denoted as S3

- Beeswax (55.56%) + recycled paper (44.44%) denoted as S4

- Beeswax (45.5%) + milled rice (54.5%) denoted as S5

- Beeswax (61.5%) + milled fir needles (38.5%) denoted as S6

- Beeswax (31.25%) + fir resin (31.25%) + horsetail (37.5%) denoted as S7

- Beeswax (27.78%) + fir resin (27.78%) + recycled paper (44.44%) denoted as S8

2.2. Materials and Green Composite Preparation

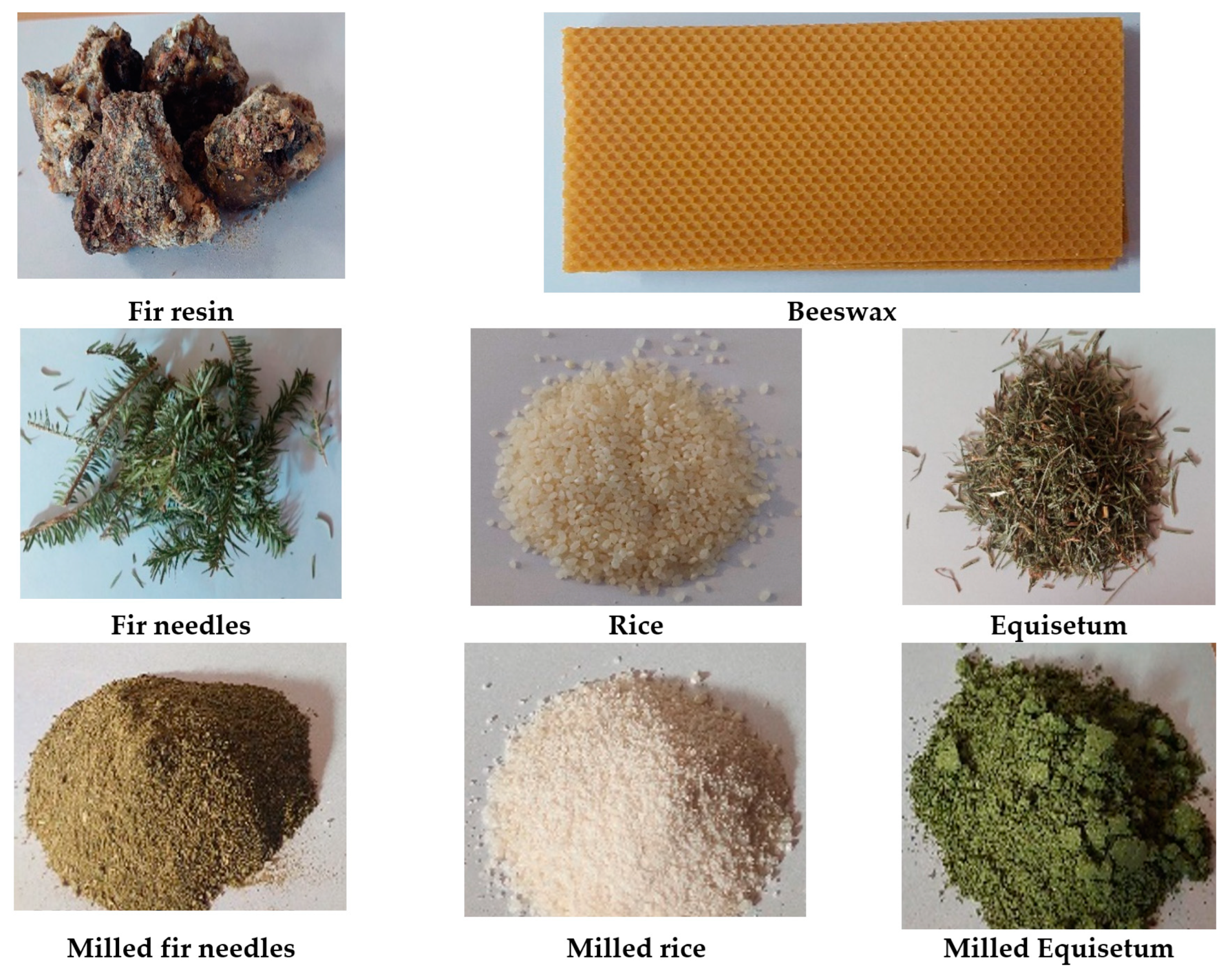

2.2.1. Materials

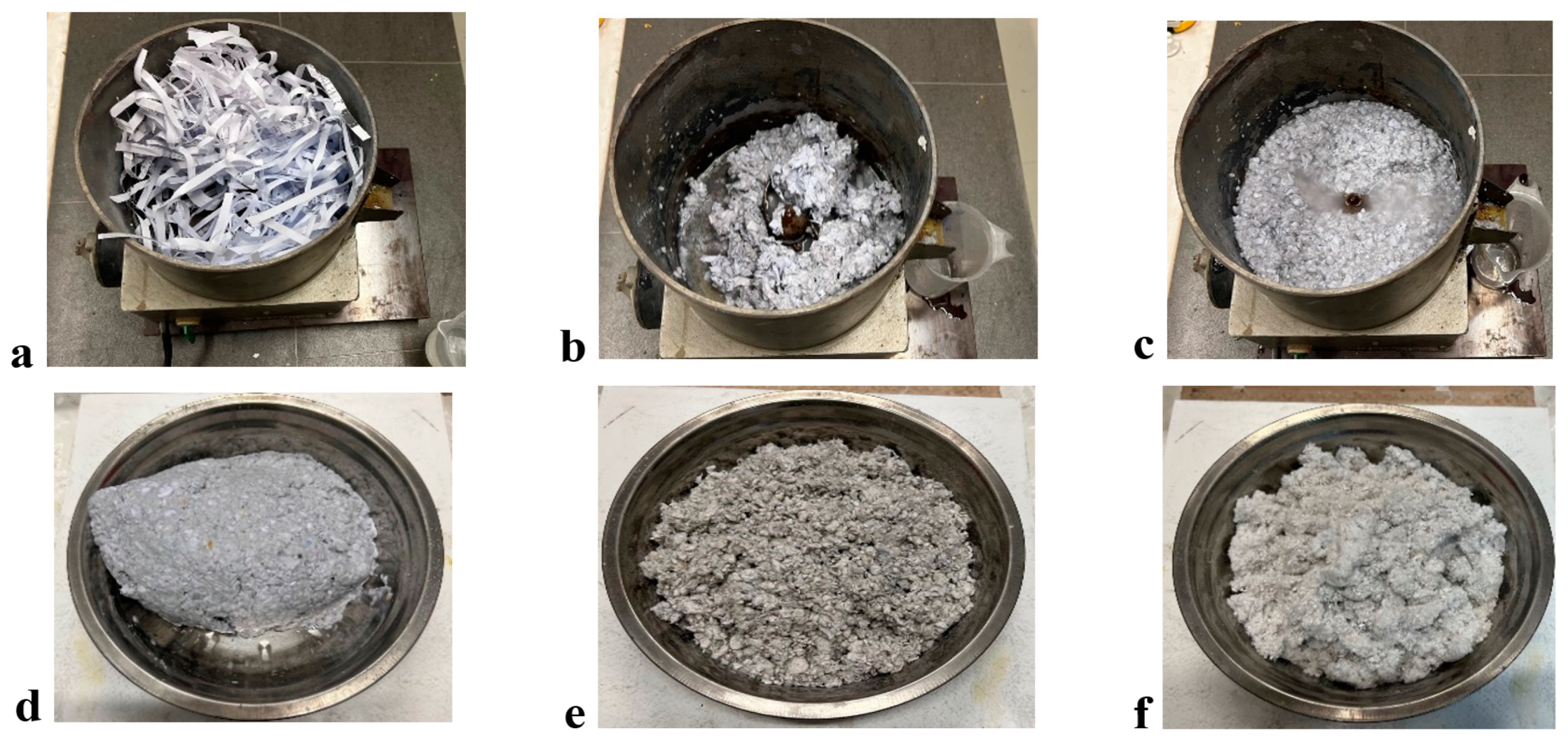

2.2.2. Obtaining Composites

- (1)

- The base natural materials (beeswax and/or fir resin) were melted at a temperature of approximately 80–100 °C.

- (2)

- The reinforcing natural filler powders (fir needles, rice, Equisetum arvense) were added in the proportions specified above.

- (3)

- The natural material blend was mixed thoroughly.

- (4)

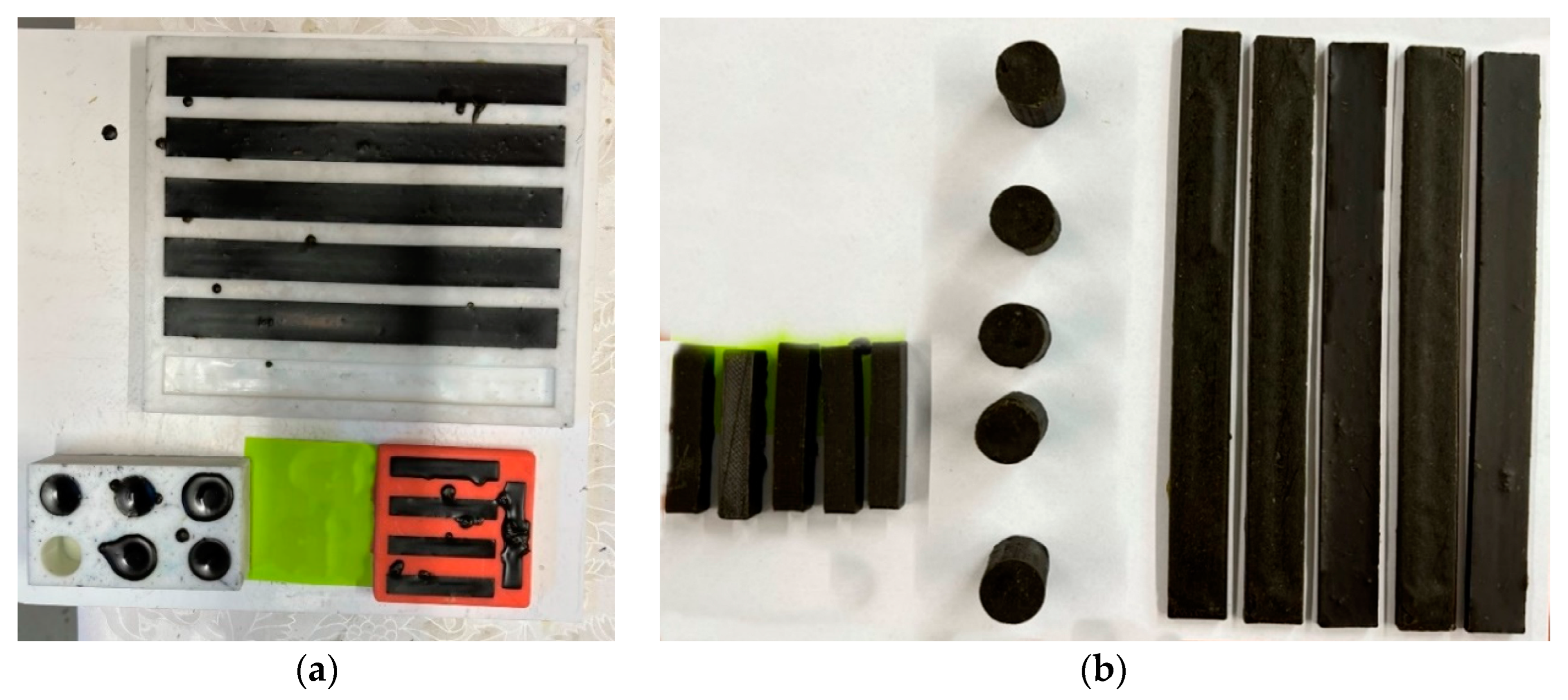

- The blend was poured into silicone rubber molds, as shown in Figure 1, over the recyclable paper.

2.3. Characterization Techniques

2.3.1. Mechanical Tests

2.3.2. Surface Morphology Analysis

2.3.3. Optical Microscope

3. Results and Disscusion

3.1. Mechanical Tests

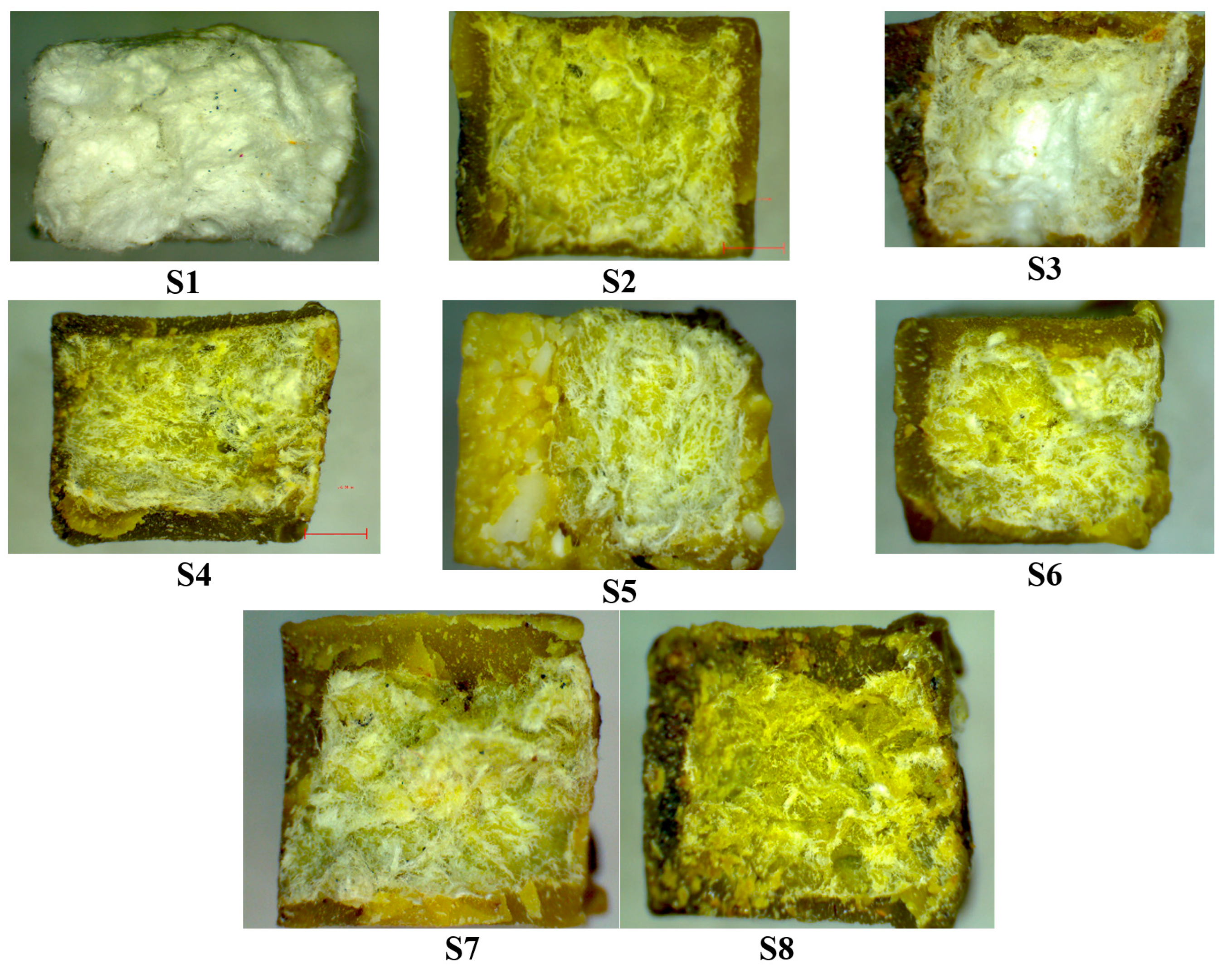

3.2. Light Microscopy

3.3. Surface Morphlogy and Internal Structure

4. Conclusions

- This paper presents the steps involved in obtaining 3D-printed PLA molds for natural composites made of recyclable paper, beeswax, fir resin, needles, rice, and Equisetum arvense, and it assesses the mechanical properties of the green composites;

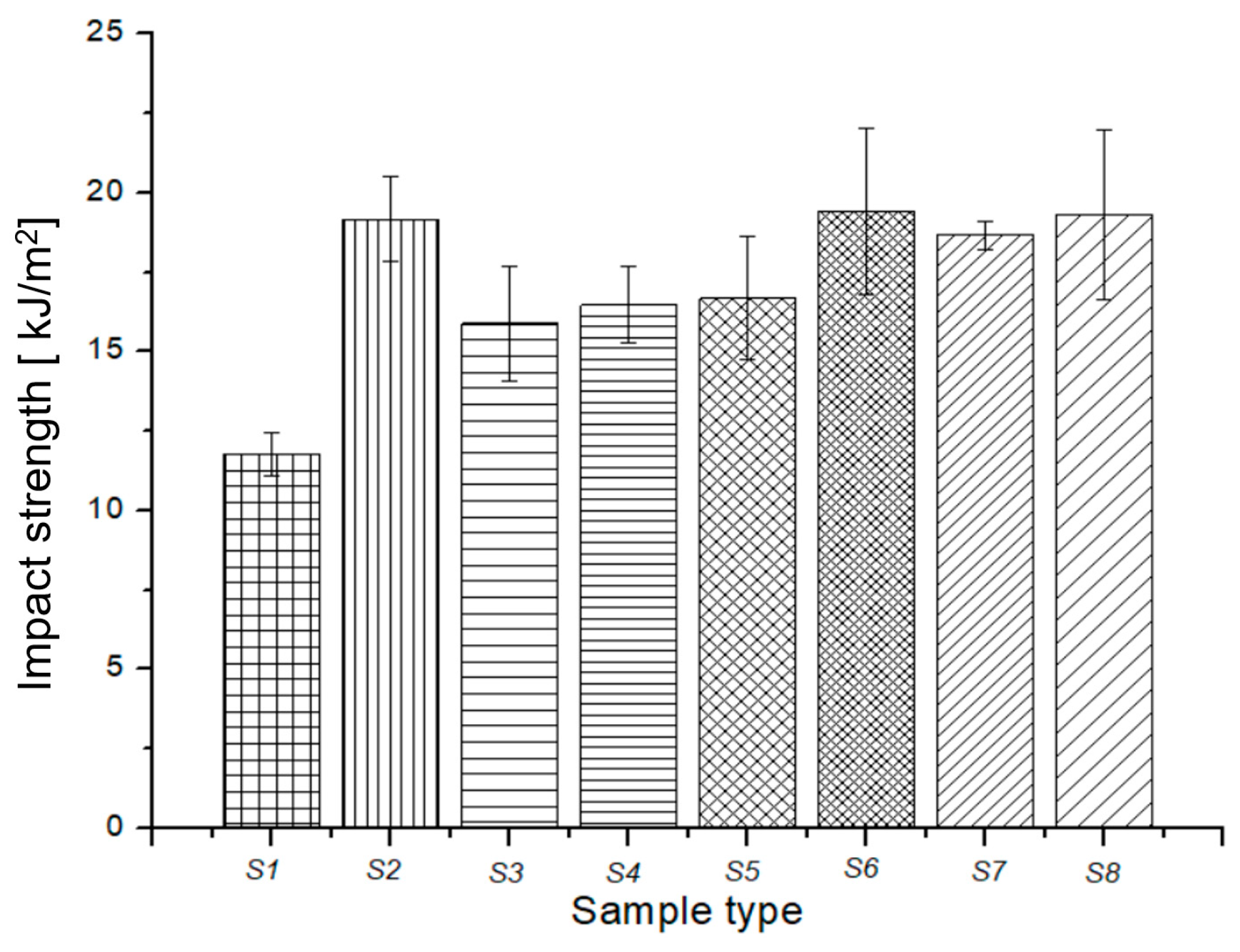

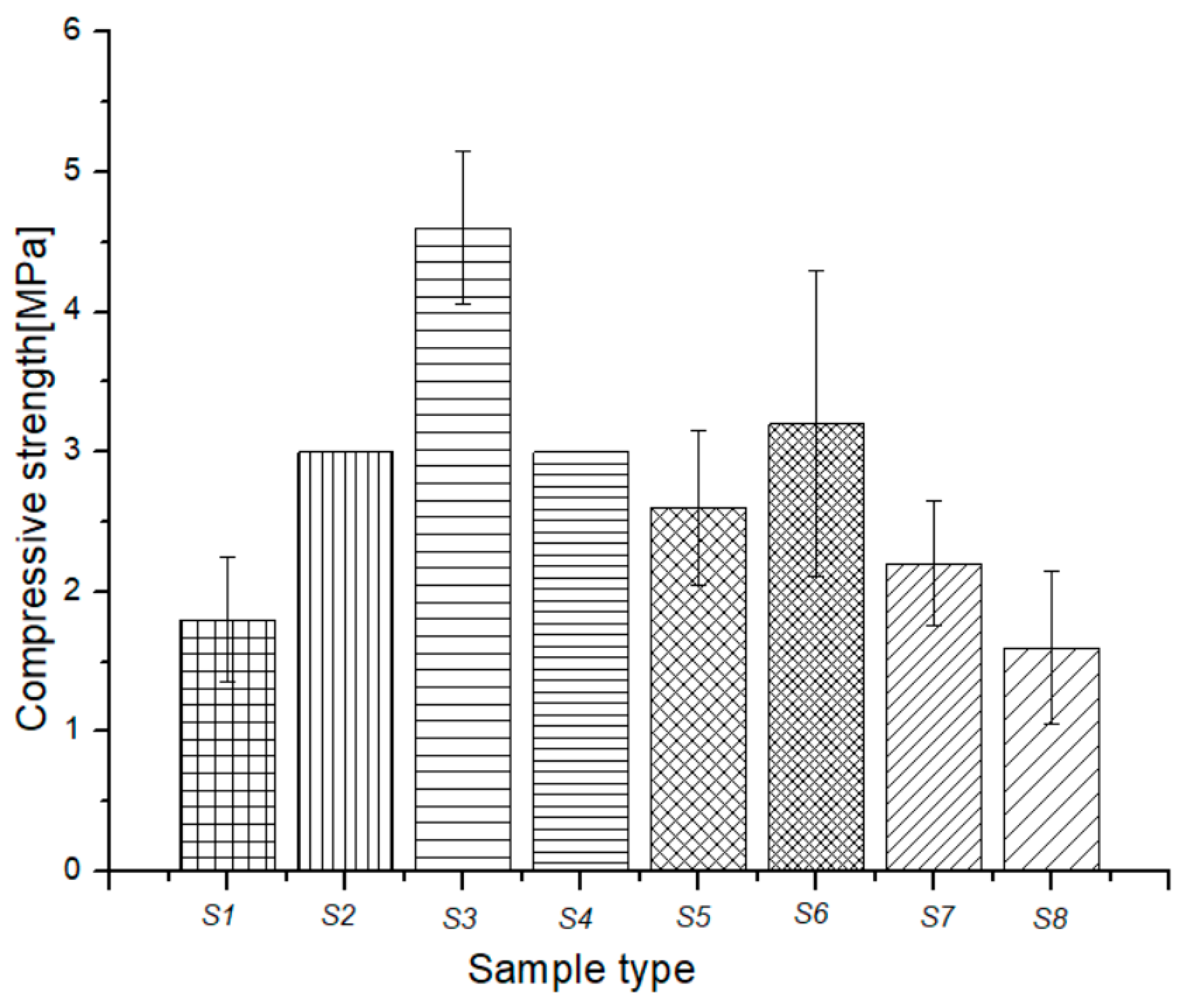

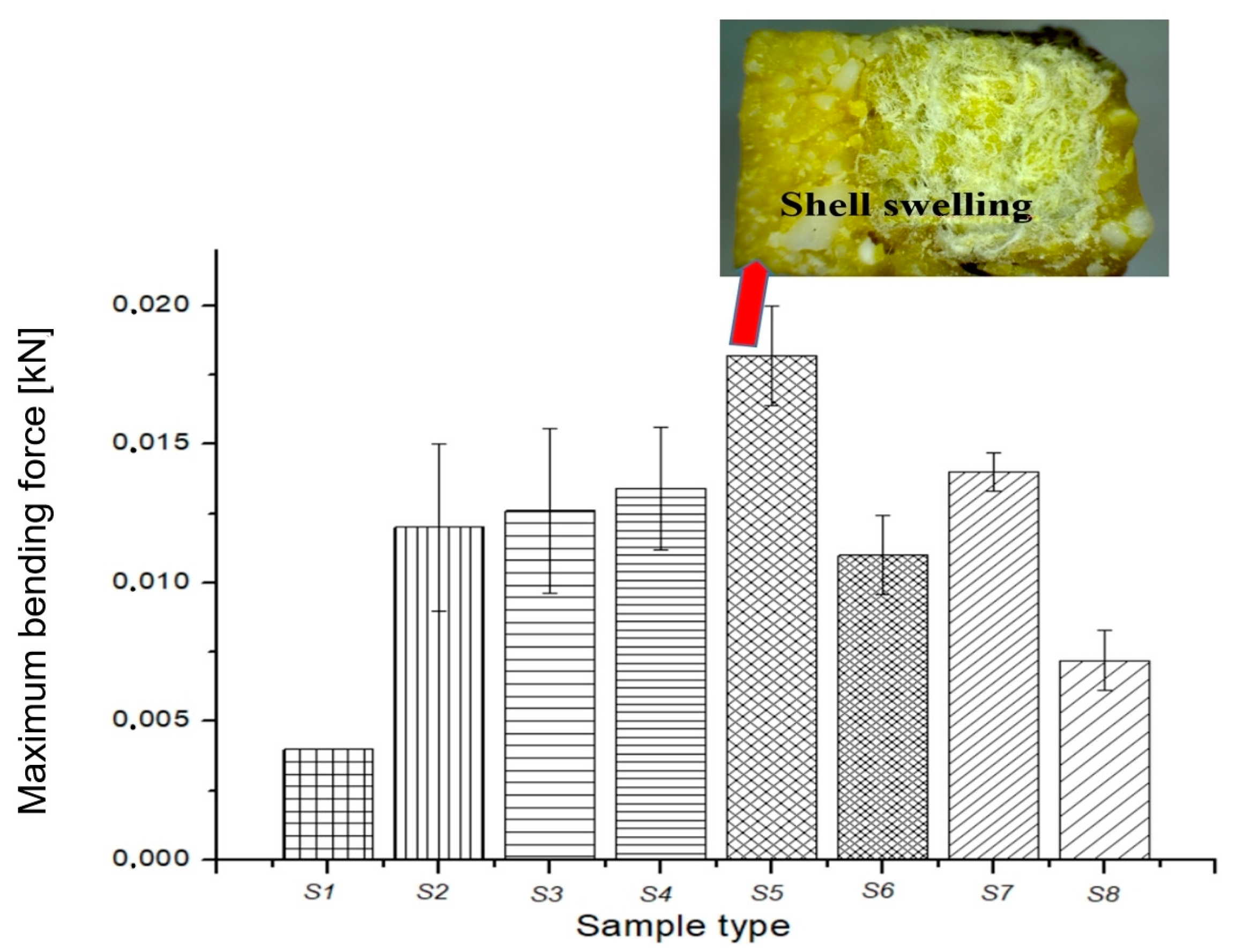

- The highest impact strengths, provided mainly by fir resin and cellulose, were attributed to the samples with beeswax and fir needles S6 and beeswax fir resin and recyclable paper S8, 19.42 and 19.32 kJ/m2, respectively, while the highest compressive strength was 4 MPa for the S3 sample. The rice fibers positively influenced the maximum bending for the S5 sample;

- The superiority of the green composites’ mechanical properties was proved, considering the core materials for the final green products over similar commercial products from the automotive sector;

- The green composites exhibited over 60% higher mechanical properties compared to similar products from the market used as sound-absorbing core materials in the automotive industry;

- The physico-mechanical properties were directly influenced by the wetting degree of the powders for the beeswax and the fir resin and through the interaction between the complementary chemical groups from the fillers and the matrices (possibly silicates, phenolic carboxylic acids, resinic acids, and so on);

- Further research is ongoing to determine the thermal and sound-absorbing properties of these composites, as well as finding new solutions to enhance their physical–mechanical properties. One possible solution is combining the benefits of eco-friendly filament printing, such as polylactic acid, with the sound-absorbing properties of these new materials.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hoang, A.T.; Varbanov, P.S.; Nižetić, S.; Sirohi, R.; Pandey, A.; Luque, R.; Ng, K.H.; Pham, V.V. Perspective review on Municipal Solid Waste-to-energy route: Characteristics, management strategy, and role in circular economy. J. Clean. Prod. 2022, 359, 131897. [Google Scholar] [CrossRef]

- Isitman, N.A.; Kaynak, C. Nanoclay and carbon nanotubes as potential synergists of an organophosphorus flame-retardant in poly(methyl methacrylate). Polym. Degrad. Stab. 2010, 95, 1523–1532. [Google Scholar] [CrossRef]

- Gay, D. Matériaux Composites; Hermes: Paris, France, 1991. [Google Scholar]

- Stefanescu, F.; Neagu, G.; Mihai, A. Materiale Composite; Publishing house “Didactica si Pedagogica”: Bucuresti, Romania, 1996. [Google Scholar]

- Abraham, T.; Bryant, R.W.; Mooney, P.J. The Prospects for Advanced Polymer-, Metal- and Ceramic-Matrix Composites. JOM 1988, 40, 46–48. [Google Scholar] [CrossRef]

- Chawla, K.K. The high-temperature application of ceramic-matrix composites. JOM 1995, 47, 19–21. [Google Scholar] [CrossRef]

- Baltes, L. Materiale Amorfe—Materiale Compozite; Publishing House “Transilvania” University: Brasov, Romania, 2003. [Google Scholar]

- Sumesh, G.; Mailadil, T.S. Three-phase polymer–ceramic–metal composite for embedded capacitor applications. Compos. Sci. Technol. 2009, 69, 1298–1302. [Google Scholar]

- Usmani, Z.; Sharma, M.; Awasthi, A.K.; Sivakumar, N.; Lukk, T.; Pecoraro, L.; Thakur, V.K.; Roberts, D.; Newbold, J.; Gupta, V.K. Bioprocessing of waste biomass for sustainable product development and minimizing environmental impact. Bioresour. Technol. 2021, 322, 124548. [Google Scholar] [CrossRef]

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef]

- Ismail, S.O.; Akpan, E.; Dhakal, H.N. Review on natural plant fibres and their hybrid composites for structural applications: Recent trends and future perspectives. Compos. Part C Open Access 2022, 9, 100322. [Google Scholar] [CrossRef]

- Mueller, D.H.; Krobjilowski, A. New Discovery in the Properties of Composites Reinforced with Natural Fibers. J. Ind. Text. 2003, 33, 111–130. [Google Scholar] [CrossRef]

- Rodríguez, E.; Petrucci, R.; Puglia, D.; Kenny, J.M.; Vázquez, A. Characterization of Composites Based on Natural and Glass Fibers Obtained by Vacuum Infusion. J. Compos. Mater. 2005, 39, 265–282. [Google Scholar] [CrossRef]

- Mann, G.S.; Singh, L.P.; Kumar, P.; Singh, S. Green composites: A review of processing technologies and recent applications. J. Thermoplast. Compos. Mater. 2018, 33, 1145–1171. [Google Scholar] [CrossRef]

- Syduzzaman, M.; Al Faruque, M.A.; Bilisik, K.; Naebe, M. Plant-Based Natural Fibre Reinforced Composites: A Review on Fabrication, Properties and Applications. Coatings 2020, 10, 973. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Progress Report on Natural Fiber Reinforced Composites. Macromol. Mater. Eng. 2014, 299, 9–26. [Google Scholar] [CrossRef]

- Ates, B.; Koytepe, S.; Ulu, A.; Gurses, C.; Thakur, V.K. Chemistry, Structures, and Advanced Applications of Nanocomposites from Biorenewable Resources. Chem. Rev. 2020, 120, 9304–9362. [Google Scholar] [CrossRef] [PubMed]

- Sharath Shekar, H.S.; Ramachandra, M. Green Composites: A Review. Mater. Today Proc. 2018, 5, 2518–2526. [Google Scholar] [CrossRef]

- Islam, M.Z.; Sarker, M.E.; Rahman, M.M.; Islam, M.R.; Ahmed, A.; Mahmud, M.S.; Syduzzaman, M. Green composites from natural fibers and biopolymers: A review on processing, properties, and applications. J. Reinf. Plast. Compos. 2022, 41, 526–557. [Google Scholar] [CrossRef]

- Ntimugura, F.; Vinai, R.; Harper, A.; Walker, P. Mechanical, thermal, hygroscopic and acoustic properties of bio-aggregates—lime and alkali—Activated insulating composite materials: A review of current status and prospects for miscanthus as an innovative resource in the South West of England. Sustain. Mater. Technol. 2020, 26, e00211. [Google Scholar] [CrossRef]

- Núñez-Decap, M.; Wechsler-Pizarro, A.; Vidal-Vega, M. Mechanical, physical, thermal and morphological properties of polypropylene composite materials developed with particles of peach and cherry stones. Sustain. Mater. Technol. 2021, 29, e00300. [Google Scholar] [CrossRef]

- Kumar, A.; Gupta, V.; Singh, S.; Saini, S.; Gaikwad, K.K. Pine needles lignocellulosic ethylene scavenging paper impregnated with nanozeolite for active packaging applications. Ind. Crop. Prod. 2021, 170, 113752. [Google Scholar] [CrossRef]

- Farid, M.; Purniawan, A.; Rasyida, A.; Ramadhani, M.; Komariyah, S. Improvement of acoustical characteristics: Wideband bamboo based polymer composite. IOP Conf. Ser. Mater. Sci. Eng. 2017, 223, 012021. [Google Scholar] [CrossRef]

- Paul, P.; Ahirwar, M.; Behera, B.K. Acoustic behaviour of needle punched nonwoven structures produced from various natural and synthetic fibers. Appl. Acoust. 2022, 199, 109043. [Google Scholar] [CrossRef]

- Atabani, A.; Ali, I.; Naqvi, S.R.; Badruddin, I.A.; Aslam, M.; Mahmoud, E.; Almomani, F.; Juchelková, D.; Atelge, M.; Khan, T.Y. A state-of-the-art review on spent coffee ground (SCG) pyrolysis for future biorefinery. Chemosphere 2022, 286, 131730. [Google Scholar] [CrossRef] [PubMed]

- Bhatia, S.K.; Palai, A.K.; Kumar, A.; Bhatia, R.K.; Patel, A.K.; Thakur, V.K.; Yang, Y.-H. Trends in renewable energy production employing biomass-based biochar. Bioresour. Technol. 2021, 340, 125644. [Google Scholar] [CrossRef]

- Moscariello, C.; Matassa, S.; Pirozzi, F.; Esposito, G.; Papirio, S. Valorisation of industrial hemp (Cannabis sativa L.) biomass residues through acidogenic fermentation and co-fermentation for volatile fatty acids production. Bioresour. Technol. 2022, 355, 127289. [Google Scholar] [CrossRef]

- Rana, A.K.; Guleria, S.; Gupta, V.K.; Thakur, V.K. Cellulosic pine needles-based biorefinery for a circular bioeconomy. Bioresour. Technol. 2023, 367, 128255. [Google Scholar] [CrossRef]

- Sealy, C. Recyclable graphite-cellulose composite stronger than steel. Mater. Today 2019, 28, 7–8. [Google Scholar] [CrossRef]

- Dong, C. Review of natural fibre-reinforced hybrid composites. J. Reinf. Plast. Compos. 2018, 37, 331–348. [Google Scholar] [CrossRef]

- Khalid, M.Y.; Arif, Z.U.; Ahmed, W.; Arshad, H. Recent trends in recycling and reusing techniques of different plastic polymers and their composite materials. Sustain. Mater. Technol. 2022, 31, e00382. [Google Scholar] [CrossRef]

- Angin, N.; Caylak, S.; Ertas, M.; Cavdar, A.D. Effect of alkyl ketene dimer on chemical and thermal properties of polylactic acid (PLA) hybrid composites. Sustain. Mater. Technol. 2022, 32, e00386. [Google Scholar] [CrossRef]

- Patel, V.K.; Rawat, N. Physico-mechanical properties of sustainable Sagwan-Teak Wood Flour/Polyester Composites with/without gum rosin. Sustain. Mater. Technol. 2017, 13, 1–8. [Google Scholar] [CrossRef]

- AL-Oqla, F.M.; Hayajneh, M.T.; Al-Shrida, M.M. Mechanical performance, thermal stability and morphological analysis of date palm fiber reinforced polypropylene composites toward functional bio-products. Cellulose 2022, 29, 3293–3309. [Google Scholar] [CrossRef]

- Singh, M.K.; Tewari, R.; Zafar, S.; Rangappa, S.M.; Siengchin, S. A comprehensive review of various factors for application feasibility of natural fiber-reinforced polymer composites. Results Mater. 2023, 17, 100355. [Google Scholar] [CrossRef]

- Zhang, J.; Khatibi, A.A.; Castanet, E.; Baum, T.; Komeily-Nia, Z.; Vroman, P.; Wang, X. Effect of natural fibre reinforcement on the sound and vibration damping properties of bio-composites compression moulded by nonwoven mats. Compos. Commun. 2019, 13, 12–17. [Google Scholar] [CrossRef]

- Joseph-Leenose-Helen, J.; Noor, N.; Mushtaq, M.; Gani, A. Ultrasonics as a tool for development of pine-needle extract loaded bee wax edible packaging for value addition of Himalayan cheese. Ultrason. Sonochem. 2022, 82, 105914. [Google Scholar] [CrossRef]

- Kajjari, P.B.; Manjeshwar, L.S.; Aminabhavi, T.M. Novel blend microspheres of cellulose triacetate and bee wax for the controlled release of nateglinide. J. Ind. Eng. Chem. 2014, 20, 397–404. [Google Scholar] [CrossRef]

- Jakob, M.; Mahendran, A.R.; Gindl-Altmutter, W.; Bliem, P.; Konnerth, J.; Müller, U.; Veigel, S. The strength and stiffness of oriented wood and cellulose-fibre materials: A review. Prog. Mater. Sci. 2022, 125, 100916. [Google Scholar] [CrossRef]

- Bazli, M.; Heitzmann, M.; Hernandez, B.V. Durability of fibre-reinforced polymer-wood composite members: An overview. Compos. Struct. 2022, 295, 115827. [Google Scholar] [CrossRef]

- Taurino, R.; Bondioli, F.; Messori, M. Use of different kinds of waste in the construction of new polymer composites: Review. Mater. Today Sustain. 2023, 21, 100298. [Google Scholar] [CrossRef]

- Cosnita, M.; Cazan, C.; Duta, A. The influence of inorganic additive on the water stability and mechanical properties of recycled rubber, polyethylene terephthalate, high density polyethylene and wood composites. J. Clean. Prod. 2017, 165, 630–636. [Google Scholar] [CrossRef]

- Al-Oqla, F.M.; Sapuan, S.M. Natural fiber reinforced polymer composites in industrial applications: Feasibility of date palm fibers for sustainable automotive industry. J. Clean. Prod. 2014, 66, 347–354. [Google Scholar] [CrossRef]

- Butnaru, E.; Brebu, M. The Thermochemical Conversion of Forestry Residues from Silver Fir (Abies alba Mill.) by Torrefaction and Pyrolysis. Energies 2022, 15, 3483. [Google Scholar] [CrossRef]

| Mechanical Property/Commercial Automotive Sample/Green Composites | Impact Strength [kJ/m2] | Compressive Strength [MPa] | Bending Force [N] |

|---|---|---|---|

| 11.41 | <1 | <3 |

| 13.26 | <1 | <3 |

| Green composites’ mechanical properties | |||

| 19.42 | 4.60 | 18.20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pop, M.A.; Cosnita, M.; Croitoru, C.; Zaharia, S.M.; Matei, S.; Spîrchez, C. 3D-Printed PLA Molds for Natural Composites: Mechanical Properties of Green Wax-Based Composites. Polymers 2023, 15, 2487. https://doi.org/10.3390/polym15112487

Pop MA, Cosnita M, Croitoru C, Zaharia SM, Matei S, Spîrchez C. 3D-Printed PLA Molds for Natural Composites: Mechanical Properties of Green Wax-Based Composites. Polymers. 2023; 15(11):2487. https://doi.org/10.3390/polym15112487

Chicago/Turabian StylePop, Mihai Alin, Mihaela Cosnita, Cătălin Croitoru, Sebastian Marian Zaharia, Simona Matei, and Cosmin Spîrchez. 2023. "3D-Printed PLA Molds for Natural Composites: Mechanical Properties of Green Wax-Based Composites" Polymers 15, no. 11: 2487. https://doi.org/10.3390/polym15112487

APA StylePop, M. A., Cosnita, M., Croitoru, C., Zaharia, S. M., Matei, S., & Spîrchez, C. (2023). 3D-Printed PLA Molds for Natural Composites: Mechanical Properties of Green Wax-Based Composites. Polymers, 15(11), 2487. https://doi.org/10.3390/polym15112487