Wave Attenuation in Additively Manufactured Polymer Acoustic Black Hole Structures Considering the Viscoelastic Effect

Abstract

1. Introduction

2. Materials and Methods

2.1. Prony Series Model of Viscoelastic Material

2.2. Viscoelastic Material Properties of Additively Manufactured ABH

2.3. Calibration of Prony Series

3. Experimental Verification of Material Characterization

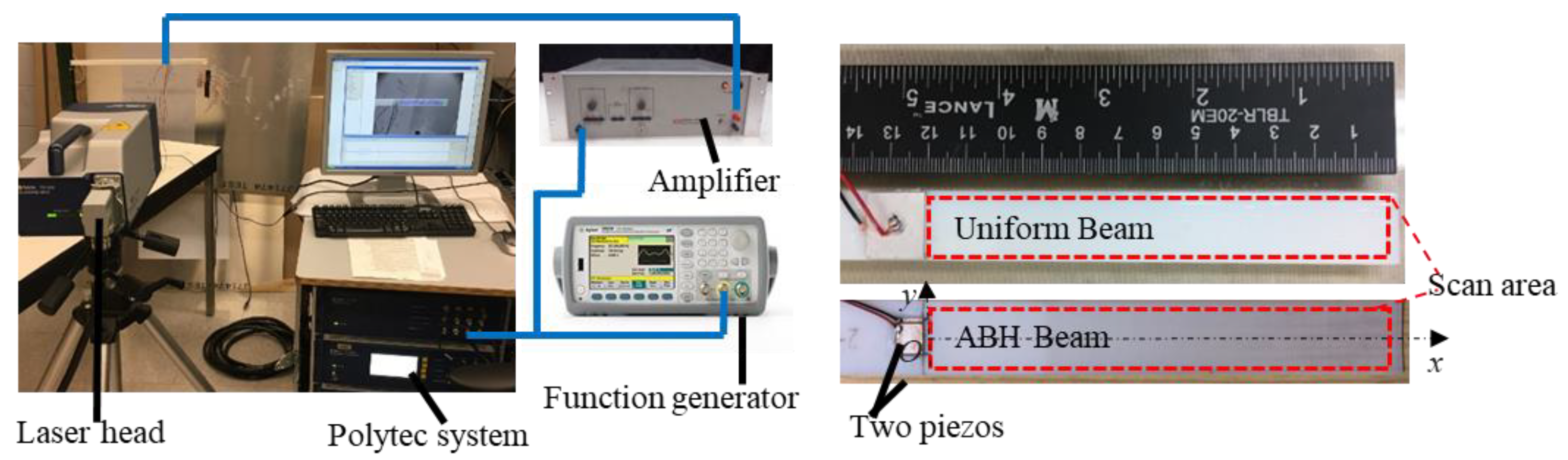

3.1. Experimental Set-Up and Finite Element Model

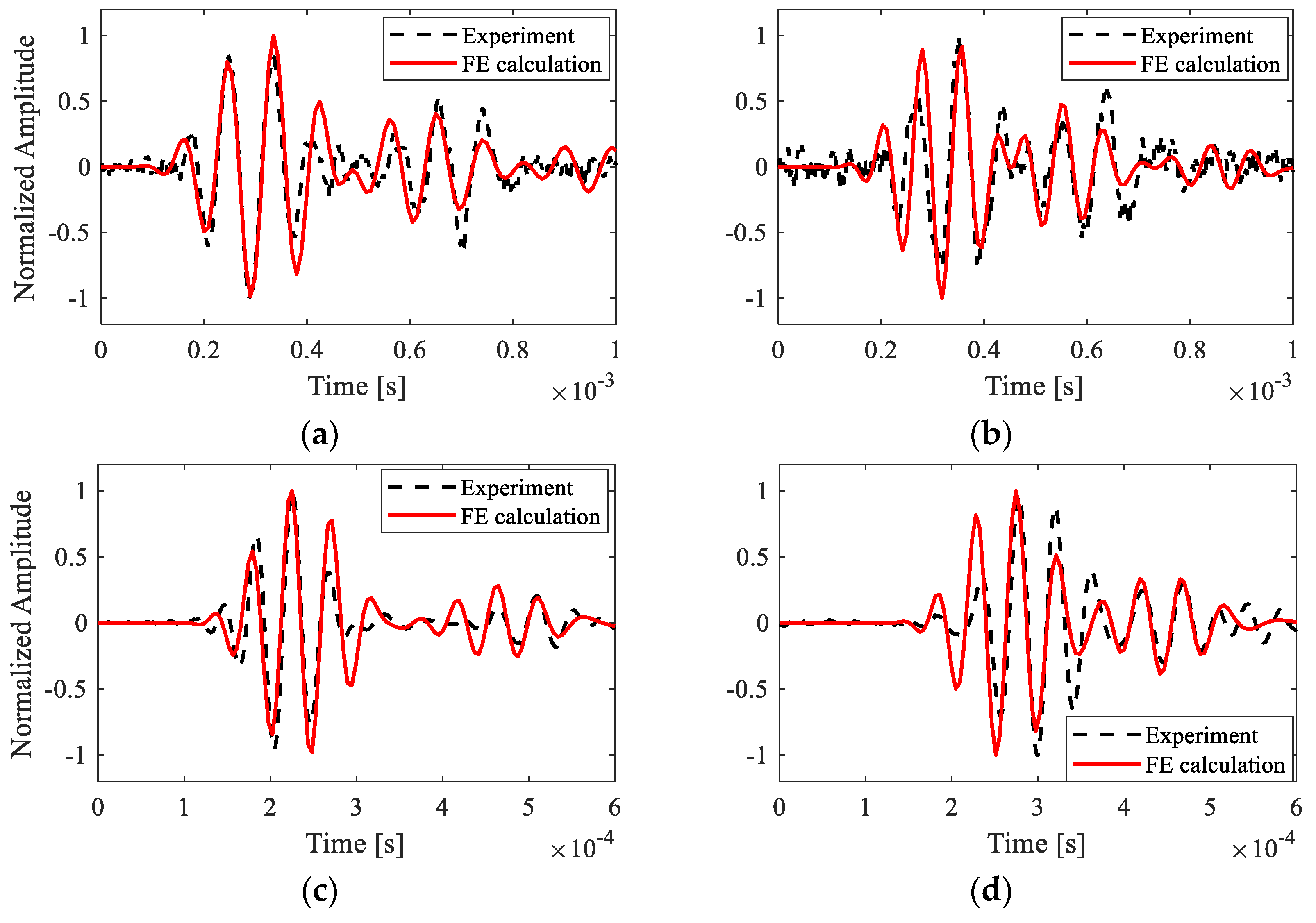

3.2. Verification of Material Characterization

4. Results and Discussion

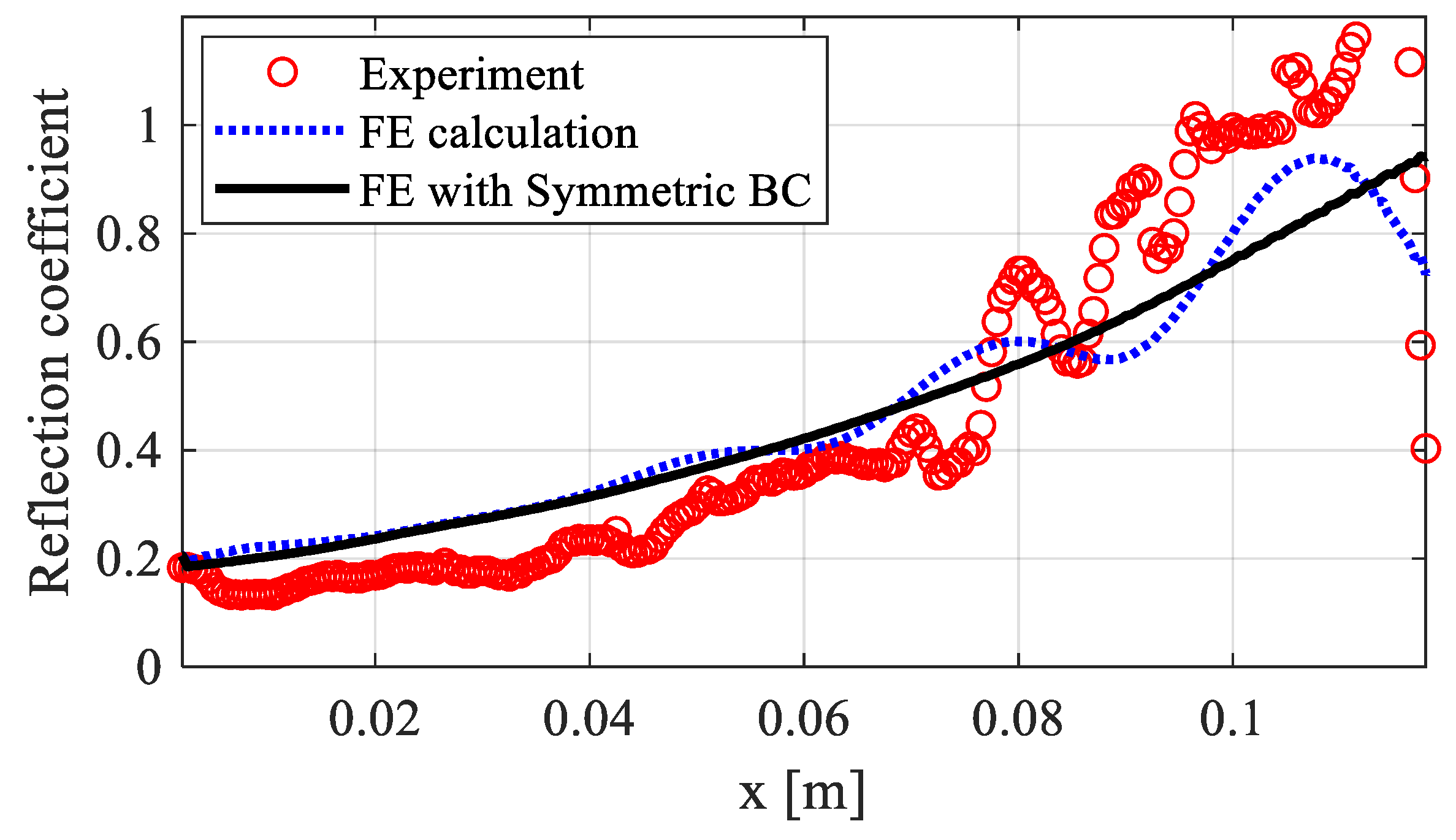

4.1. Wave Reflection Coefficient in Printed Specimen

4.2. Wave Attenuation and Influence of Load Frequency in Printed ABH Beam

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Pelat, A.; Gautier, F.; Conlon, S.C.; Semperlotti, F. The acoustic black hole: A review of theory and applications. J. Sound Vib. 2020, 476, 115316. [Google Scholar] [CrossRef]

- Krylov, V.V. Acoustic black holes: Recent developments in the theory and applications. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2014, 61, 1296–1306. [Google Scholar] [CrossRef]

- Krylov, V.V.; Tilman, F.J.B.S. Acoustic ‘black holes’ for flexural waves as effective vibration dampers. J. Sound Vib. 2004, 274, 605–619. [Google Scholar] [CrossRef]

- Ji, H.; Luo, J.; Qiu, J.; Cheng, L. Investigations on flexural wave propagation and attenuation in a modified one-dimensional acoustic black hole using a laser excitation technique. Mech. Syst. Signal Process. 2018, 104, 19–35. [Google Scholar] [CrossRef]

- Denis, V.; Gautier, F.; Pelat, A.; Poittevin, J. Measurement and modelling of the reflection coefficient of an Acoustic Black Hole termination. J. Sound Vib. 2015, 349, 67–79. [Google Scholar] [CrossRef]

- Huang, W.; Ji, H.; Qiu, J.; Cheng, L. Wave Energy Focalization in a Plate With Imperfect Two-Dimensional Acoustic Black Hole Indentation. J. Vib. Acoust. 2016, 138, 061004. [Google Scholar] [CrossRef]

- Huang, W.; Tao, C.; Ji, H.; Qiu, J. Enhancement of Wave Energy Dissipation in Two-Dimensional Acoustic Black Hole by Simultaneous Optimization of Profile and Damping Layer. J. Sound Vib. 2020, 491, 115764. [Google Scholar] [CrossRef]

- Bowyer, E.; Krylov, V. Damping of flexural vibrations in turbofan blades using the acoustic black hole effect. Appl. Acoust. 2014, 76, 359–365. [Google Scholar] [CrossRef]

- Leng, J.; Romero-García, V.; Pelat, A.; Picó, R.; Groby, J.-P.; Gautier, F. Interpretation of the Acoustic Black Hole effect based on the concept of critical coupling. J. Sound Vib. 2020, 471, 115199. [Google Scholar] [CrossRef]

- Zhou, X.; Yu, D. Elastic wave propagation energy dissipation characteristics analysis on the viscoelastic damping material structures embedded with acoustic black hole based on semi-analytical homogeneous asymptotic method. Appl. Math. Model. 2019, 70, 221–245. [Google Scholar] [CrossRef]

- Du, X.; Huang, D.; Fu, Q.; Zhang, J. Effects of Acoustic Black Hole Parameters and Damping Layer on Sound Insulation Performance of ABH Circular Plate. Appl. Sci. 2019, 9, 5366. [Google Scholar] [CrossRef]

- Feurtado, P.A.; Conlon, S.C. An Experimental Investigation of Acoustic Black Hole Dynamics at Low, Mid, and High Frequencies. J. Vib. Acoust. 2016, 138, 061002. [Google Scholar] [CrossRef]

- Park, S.; Lee, J.Y.; Jeon, W. Vibration damping of plates using waveguide absorbers based on spiral acoustic black holes. J. Sound Vib. 2022, 521, 116685. [Google Scholar] [CrossRef]

- Deng, J.; Guasch, O.; Maxit, L.; Zheng, L. Transmission loss of plates with multiple embedded acoustic black holes using statistical modal energy distribution analysis. Mech. Syst. Signal Process. 2021, 150, 107262. [Google Scholar] [CrossRef]

- Feurtado, P.A.; Conlon, S.C.; Semperlotti, F. A normalized wave number variation parameter for acoustic black hole design. J. Acoust. Soc. Am. 2014, 136, EL148–EL152. [Google Scholar] [CrossRef]

- Hook, K.; Cheer, J.; Daley, S. A parametric study of an acoustic black hole on a beam. J. Acoust. Soc. Am. 2019, 145, 3488–3498. [Google Scholar] [CrossRef]

- Huang, W.; Tao, C.; Ji, H.; Qiu, J. Optimization of profile and damping layer of plates embedded with acoustic black hole indentations for broadband energy dissipation. J. Intell. Mater. Syst. Struct. 2022, 33, 1947–1959. [Google Scholar] [CrossRef]

- Ma, L.; Cheng, L. Topological optimization of damping layout for minimized sound radiation of an acoustic black hole plate. J. Sound Vib. 2019, 458, 349–364. [Google Scholar] [CrossRef]

- Krylov, V.; Winward, R. Experimental investigation of the acoustic black hole effect for flexural waves in tapered plates. J. Sound Vib. 2007, 300, 43–49. [Google Scholar] [CrossRef]

- Tang, L.; Cheng, L. Enhanced Acoustic Black Hole effect in beams with a modified thickness profile and extended platform. J. Sound Vib. 2017, 391, 116–126. [Google Scholar] [CrossRef]

- Bikas, H.; Stavropoulos, P.; Chryssolouris, G. Additive manufacturing methods and modelling approaches: A critical review. Int. J. Adv. Manuf. Technol. 2016, 83, 389–405. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, Y. 3D Printed Auxetic Mechanical Metamaterial with Chiral Cells and Re-entrant Cores. Sci. Rep. 2018, 8, 2397. [Google Scholar] [CrossRef] [PubMed]

- Reichl, K.K.; Avci, O.; Inman, D.J. Temperature Dependent Damping in Additively Manufactured Polymer Structures. J. Appl. Comput. Mech. 2021, 7, 993–1008. [Google Scholar] [CrossRef]

- Huang, W.; Zhang, H.; Inman, D.J.; Qiu, J.; Cesnik, C.E.; Ji, H. Low reflection effect by 3D printed functionally graded acoustic black holes. J. Sound Vib. 2019, 450, 96–108. [Google Scholar] [CrossRef]

- Chong, B.M.P.; Tan, L.B.; Lim, K.M.; Lee, H.P. A review on acoustic black-holes (ABH) and the experimental and numerical study of ABH-featured 3D printed beams. Int. J. Appl. Mech. 2017, 9, 1750078. [Google Scholar] [CrossRef]

- Lakes, R.; Lakes, R.S. Viscoelastic Materials; Cambridge University Press: Cambridge, UK, 2009. [Google Scholar]

- Lam, M.J.; Inman, D.J.; Saunders, W.R. Hybrid damping models using the Golla-Hughes-McTavish method with internally balanced model reduction and output feedback. Smart Mater. Struct. 2000, 9, 362. [Google Scholar] [CrossRef]

- Martin, L.A.; Inman, D.J. A Novel Viscoelastic Material Modulus Function for Modifying the Golla-Hughes-McTavish Method. Int. J. Acoust. Vib. 2013, 18, 102–108. [Google Scholar] [CrossRef]

- Bagley, R.L.; Torvik, P.J. Fractional calculus—A different approach to the analysis of viscoelastically damped structures. AIAA J. 1983, 21, 741–748. [Google Scholar] [CrossRef]

- Vasques, C.M.A.; Moreira, R.A.S.; Rodrigues, J.D. Viscoelastic Damping Technologies-Part I: Modeling and Finite Element Implementation. J. Adv. Res. Mech. Eng. 2010, 1, 76–95. [Google Scholar]

- Park, S.; Schapery, R. Methods of interconversion between linear viscoelastic material functions. Part I—A numerical method based on Prony series. Int. J. Solids Struct. 1999, 36, 1653–1675. [Google Scholar] [CrossRef]

- Ghoreishy, M.H.R. Determination of the parameters of the Prony series in hyper-viscoelastic material models using the finite element method. Mater. Des. 2012, 35, 791–797. [Google Scholar] [CrossRef]

- Chen, T. Determining a Prony Series for a Viscoelastic Material from Time Varying Strain Data; NASA/TM-2000-210123, ARL-TR-2206; US Army Research Laboratory: Adelphi, MD, USA, 2000. [Google Scholar]

- Shil’ko, S.V.; Gavrilenko, S.L.; Panin, S.V.; Alexenko, V.O. Method of rheological characterization of polymer materials by identification of the prony viscoelastic model according to data of static and dynamic accelerated tests. In Proceedings of the AIP Conference Proceedings, Tomsk, Russia, 9–13 October 2017; Volume 1909, p. 020194. [Google Scholar]

- Endo, V.T.; Pereira, J.C.D.C. Linear orthotropic viscoelasticity model for fiber reinforced thermoplastic material based on Prony series. Mech. Time-Depend. Mater. 2017, 21, 199–221. [Google Scholar] [CrossRef]

- Johannesmann, S.; Claes, L.; Henning, B. Lamb wave based approach to the determination of elastic and viscoelastic material parameters. TM Tech. Mess. 2021, 88, s28–s33. [Google Scholar] [CrossRef]

- Barrientos, E.; Pelayo, F.; Noriega, Á.; Lamela, M.J.; Fernández-Canteli, A.; Tanaka, E. Optimal discrete-time Prony series fitting method for viscoelastic materials. Mech. Time-Depend. Mater. 2019, 23, 193–206. [Google Scholar] [CrossRef]

- Cui, Z.; Brinson, L.C. A combination optimisation method for the estimation of material parameters for viscoelastic solids. Int. J. Comput. Sci. Math. 2014, 5, 325–335. [Google Scholar] [CrossRef]

- Reichl, K.; Inman, D. Dynamic Mechanical and Thermal Analyses of Objet Connex 3D Printed Materials. Exp. Tech. 2018, 42, 19–25. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, W.; Ji, H.; Ding, Y.; Qiu, J. Wave Attenuation in Additively Manufactured Polymer Acoustic Black Hole Structures Considering the Viscoelastic Effect. Polymers 2023, 15, 2457. https://doi.org/10.3390/polym15112457

Huang W, Ji H, Ding Y, Qiu J. Wave Attenuation in Additively Manufactured Polymer Acoustic Black Hole Structures Considering the Viscoelastic Effect. Polymers. 2023; 15(11):2457. https://doi.org/10.3390/polym15112457

Chicago/Turabian StyleHuang, Wei, Hongli Ji, Ye Ding, and Jinhao Qiu. 2023. "Wave Attenuation in Additively Manufactured Polymer Acoustic Black Hole Structures Considering the Viscoelastic Effect" Polymers 15, no. 11: 2457. https://doi.org/10.3390/polym15112457

APA StyleHuang, W., Ji, H., Ding, Y., & Qiu, J. (2023). Wave Attenuation in Additively Manufactured Polymer Acoustic Black Hole Structures Considering the Viscoelastic Effect. Polymers, 15(11), 2457. https://doi.org/10.3390/polym15112457