An Ordinary State-Based Peridynamic Model of Unidirectional Carbon Fiber Reinforced Polymer Material in the Cutting Process

Abstract

1. Introduction

2. Modeling of Machining of UD-CFRP Materials

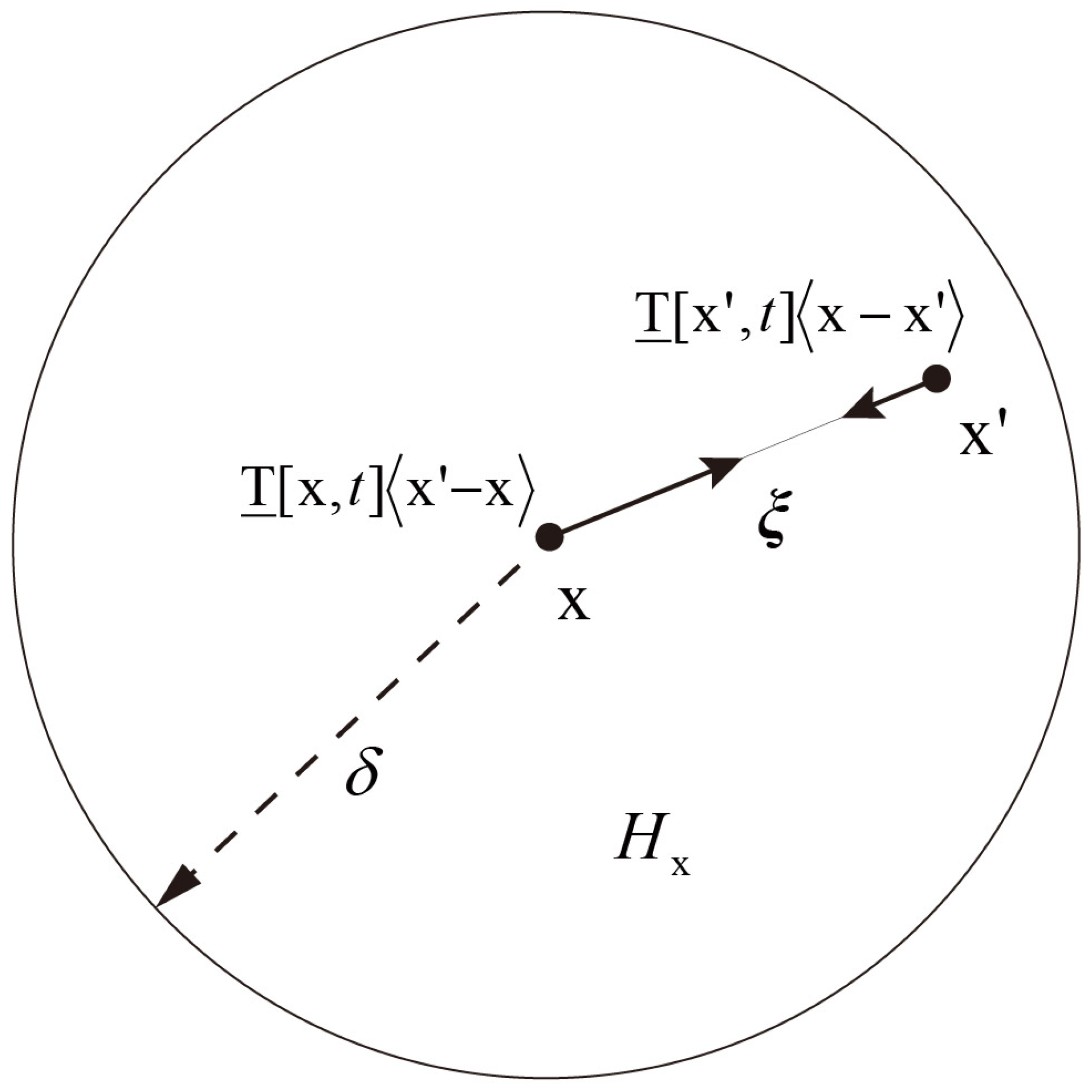

2.1. A Brief Review of the OSB-PD Model

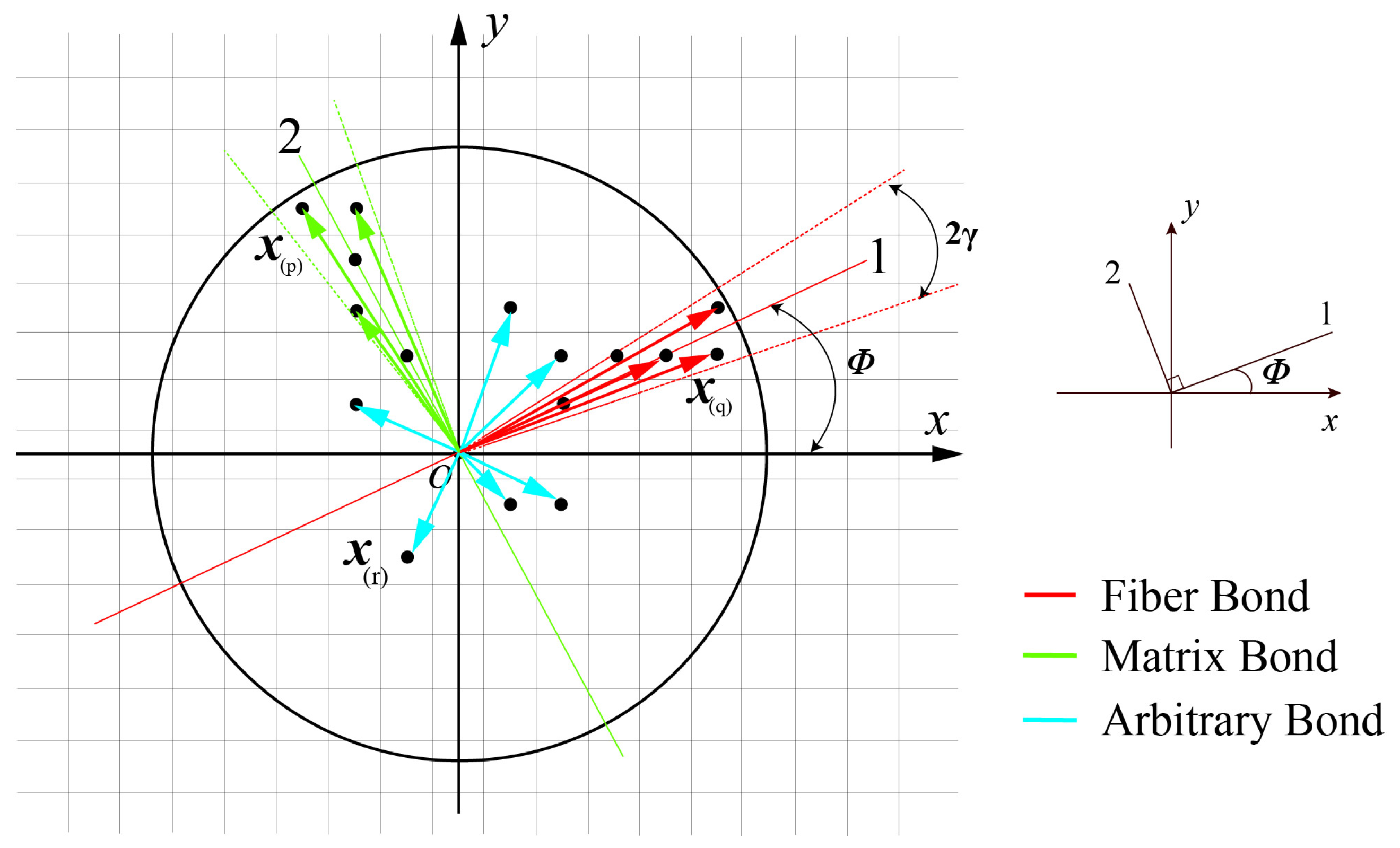

2.2. PD Laminated Composite Theory

2.3. Failure Criterion

2.4. Contact Algorithm

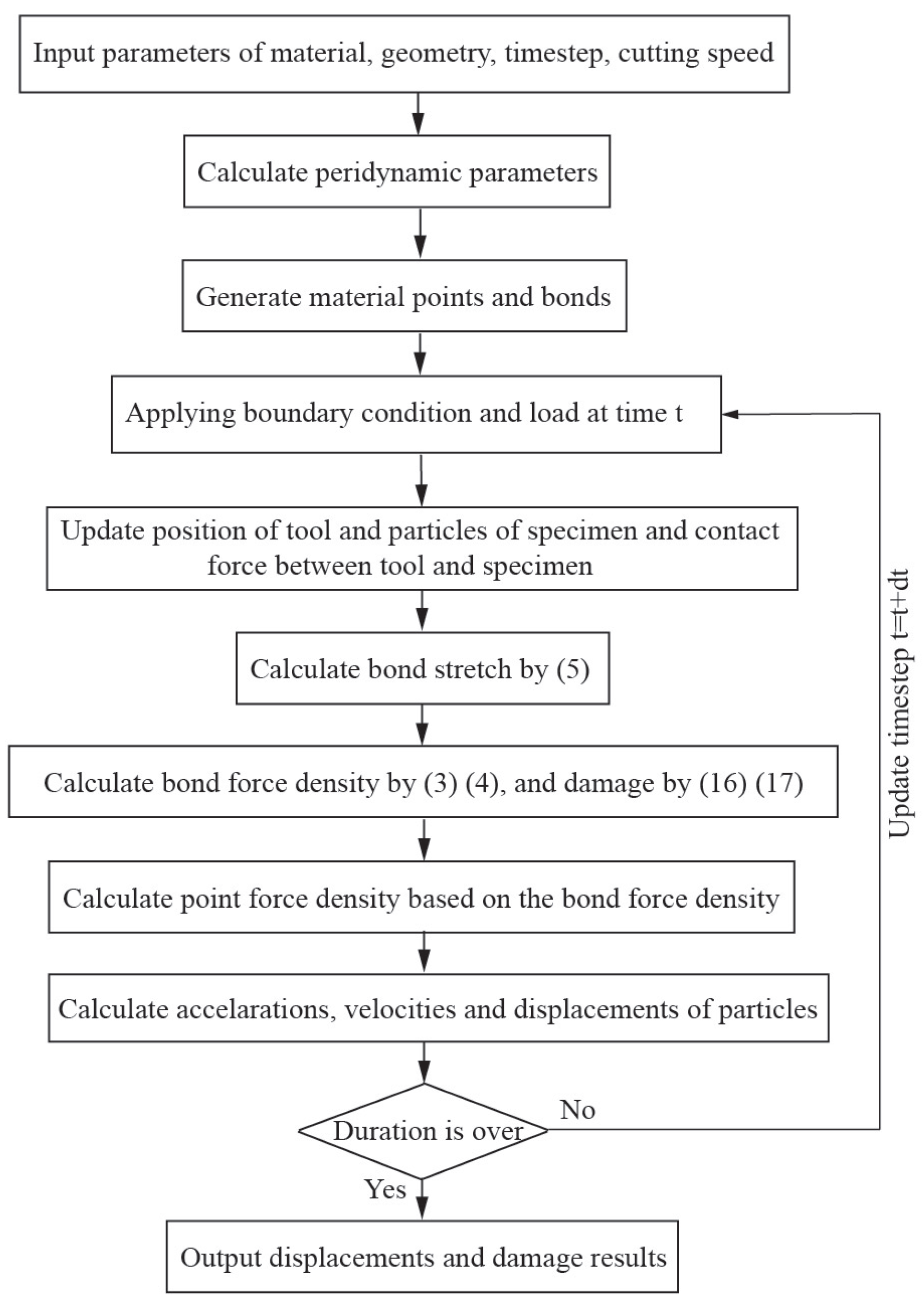

2.5. Numerical Implementation

3. Results and Discussion

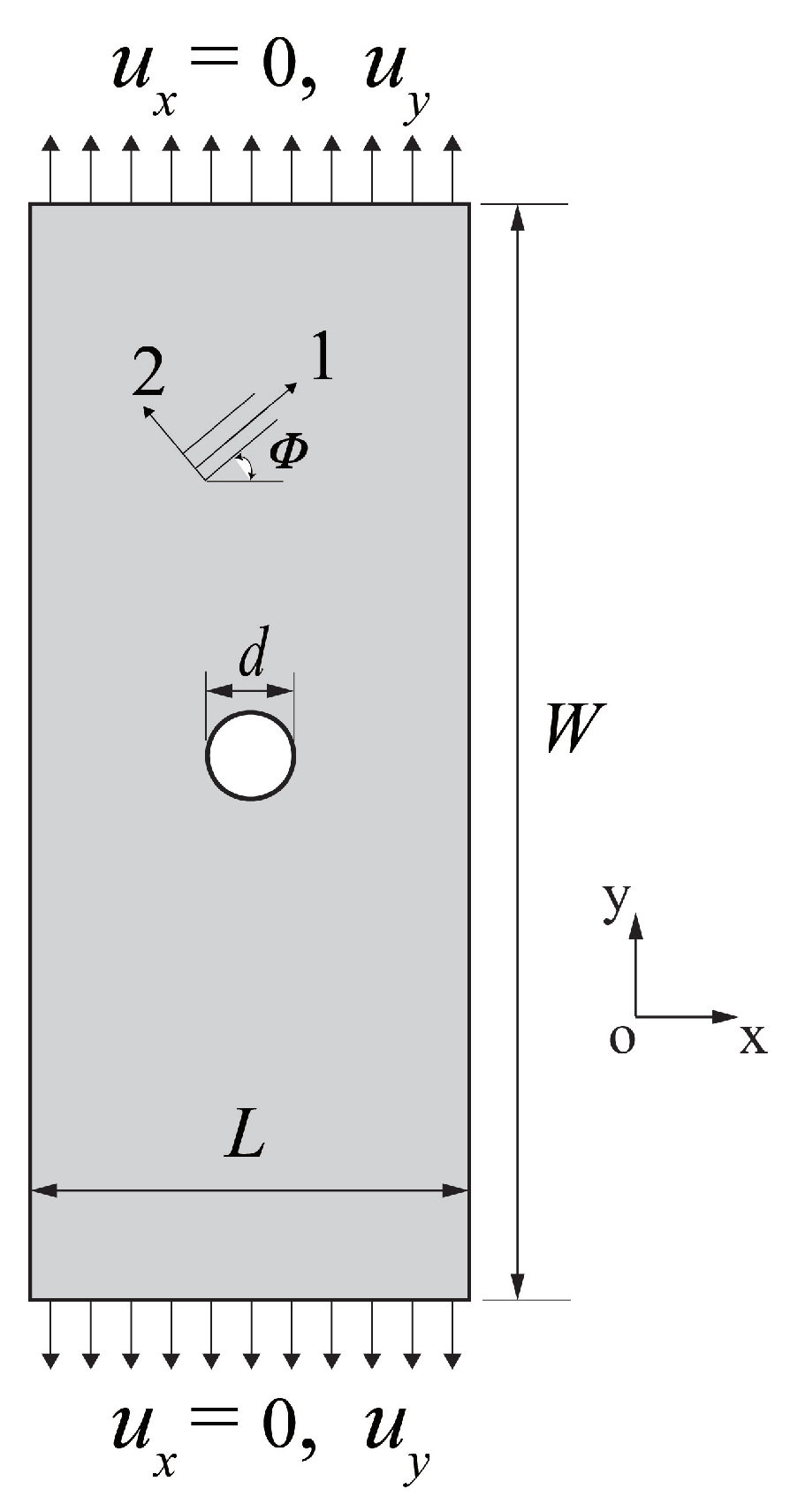

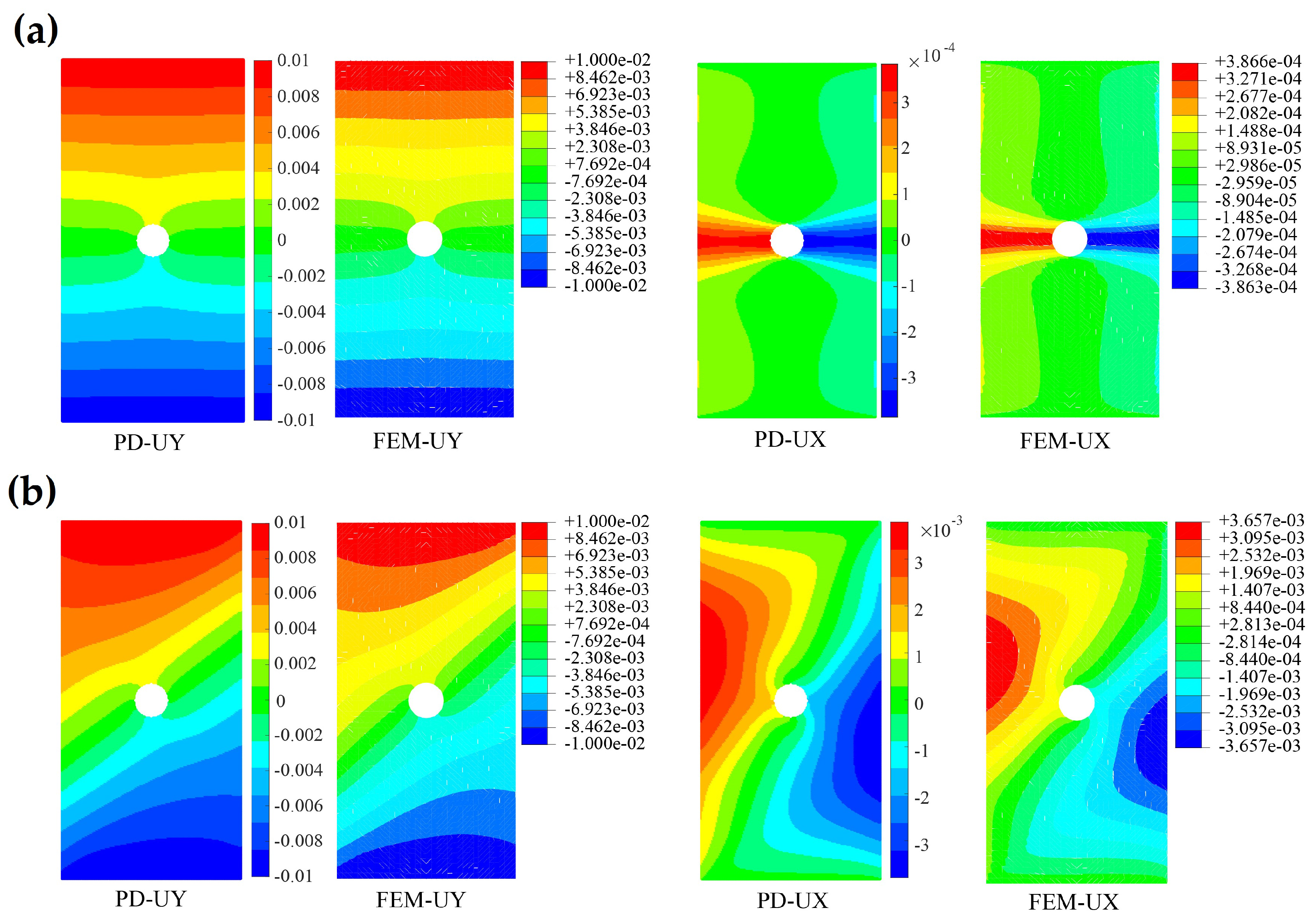

3.1. Tension Simulation

3.2. Cutting Process for CFRP Lamina

3.2.1. Experimental and Simulation Setup

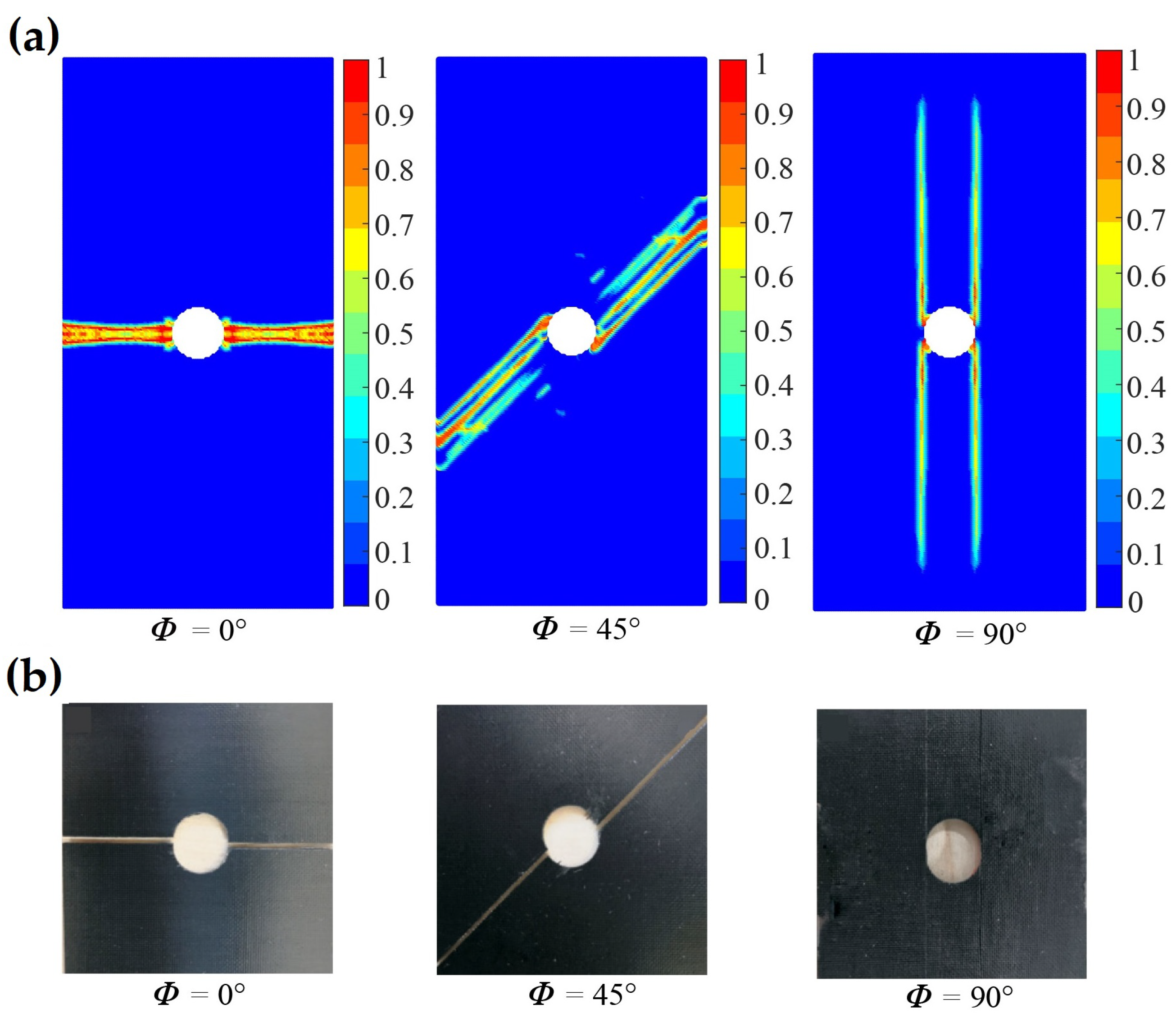

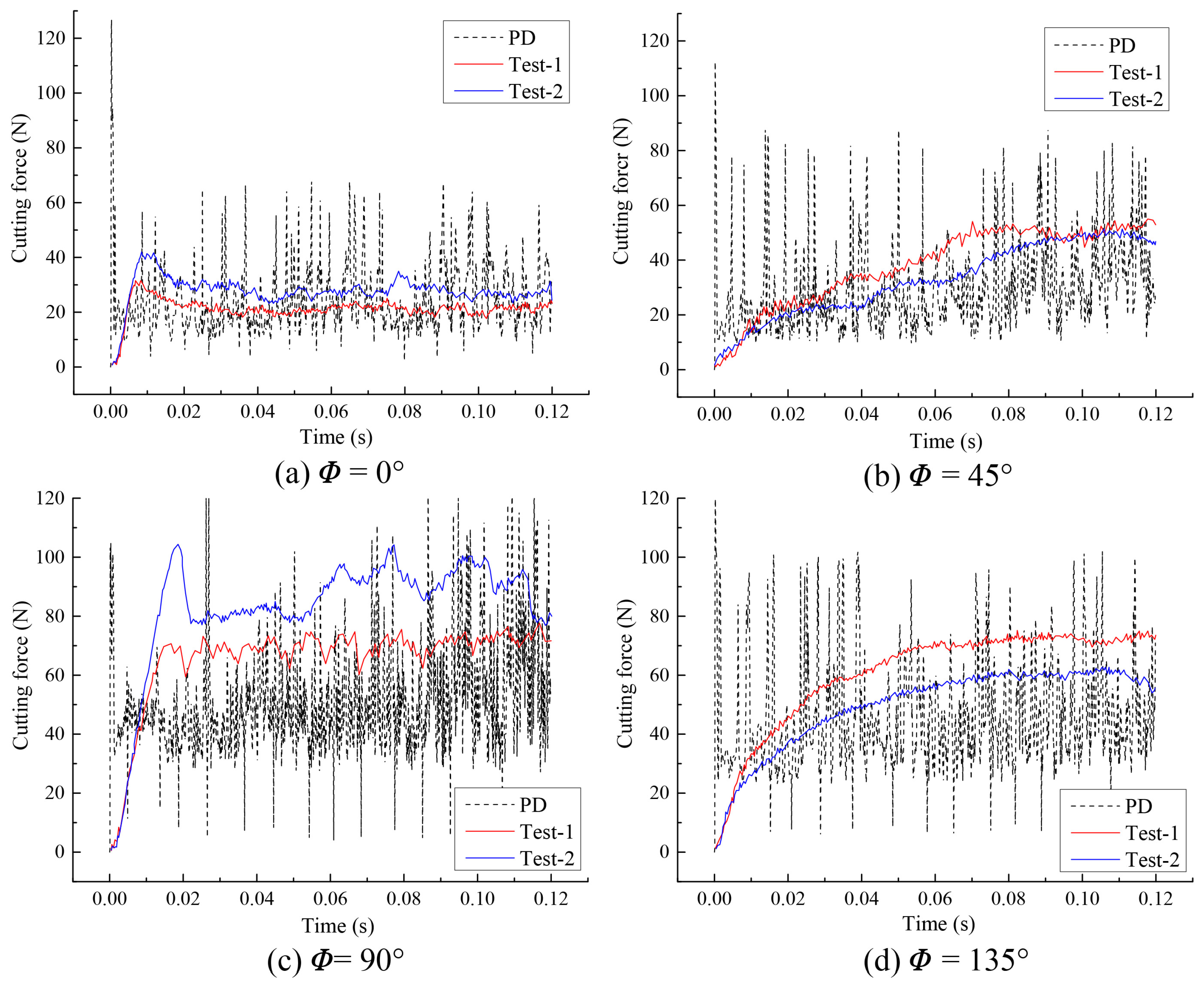

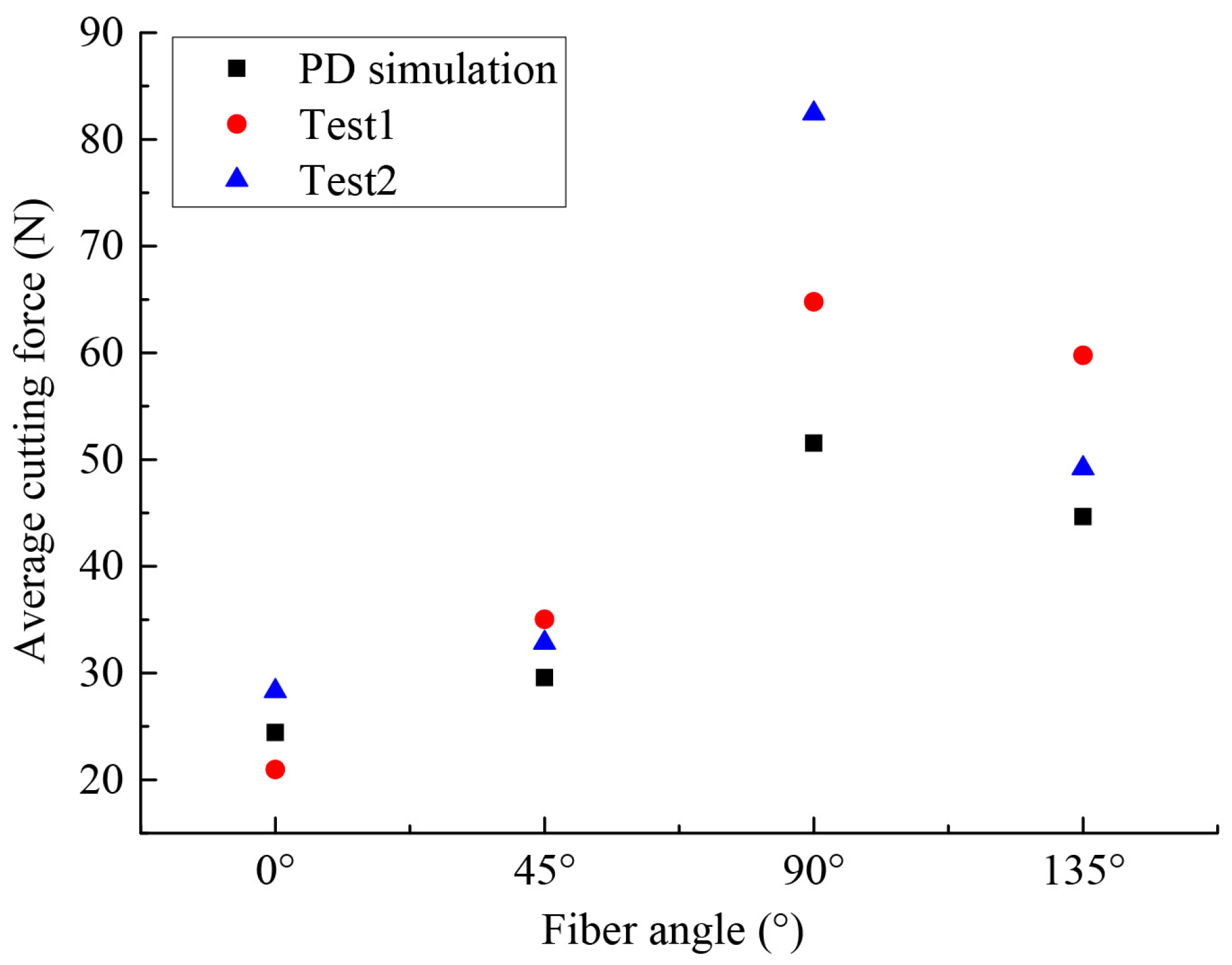

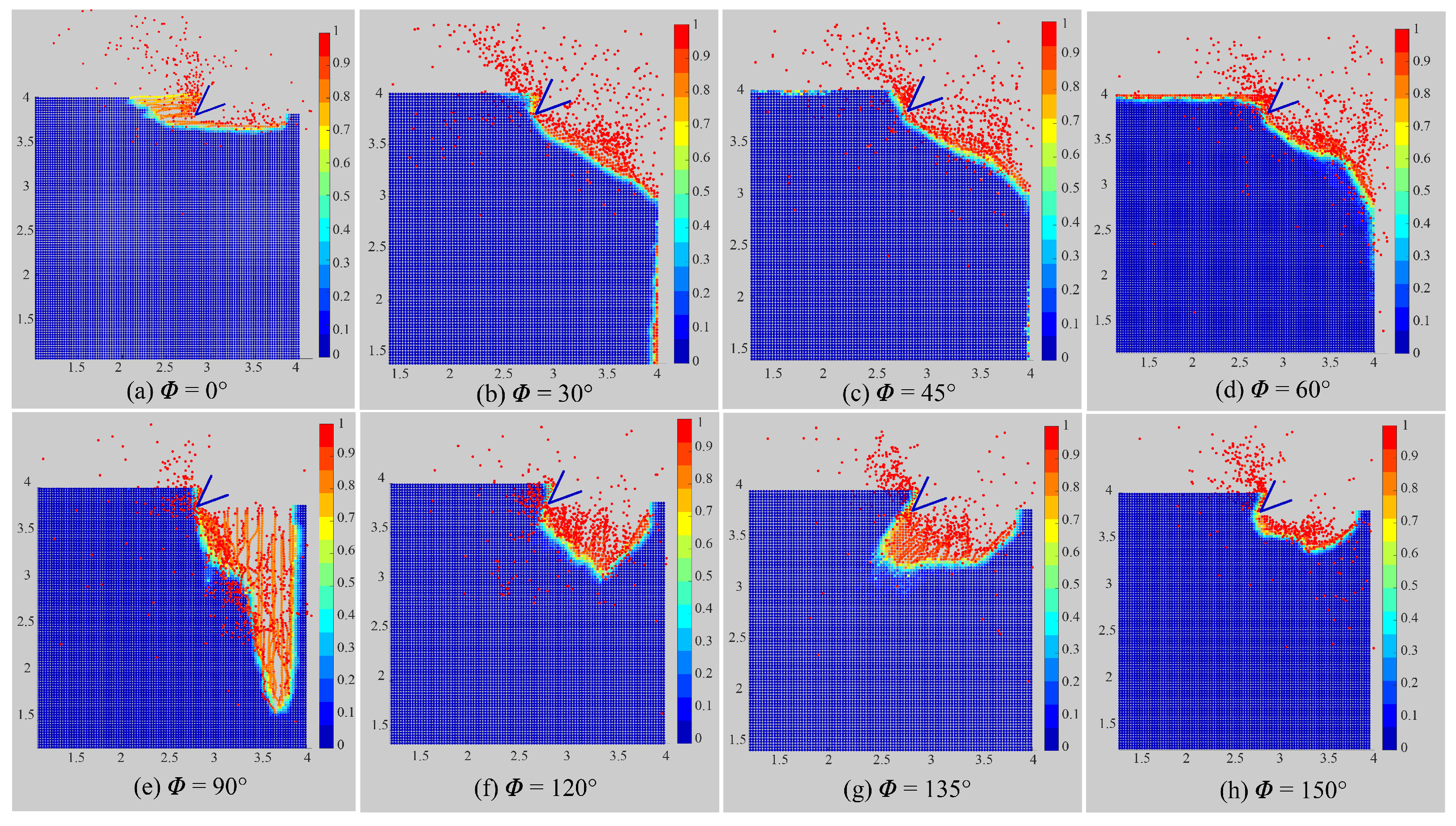

3.2.2. Cutting Process under General Fiber Orientations

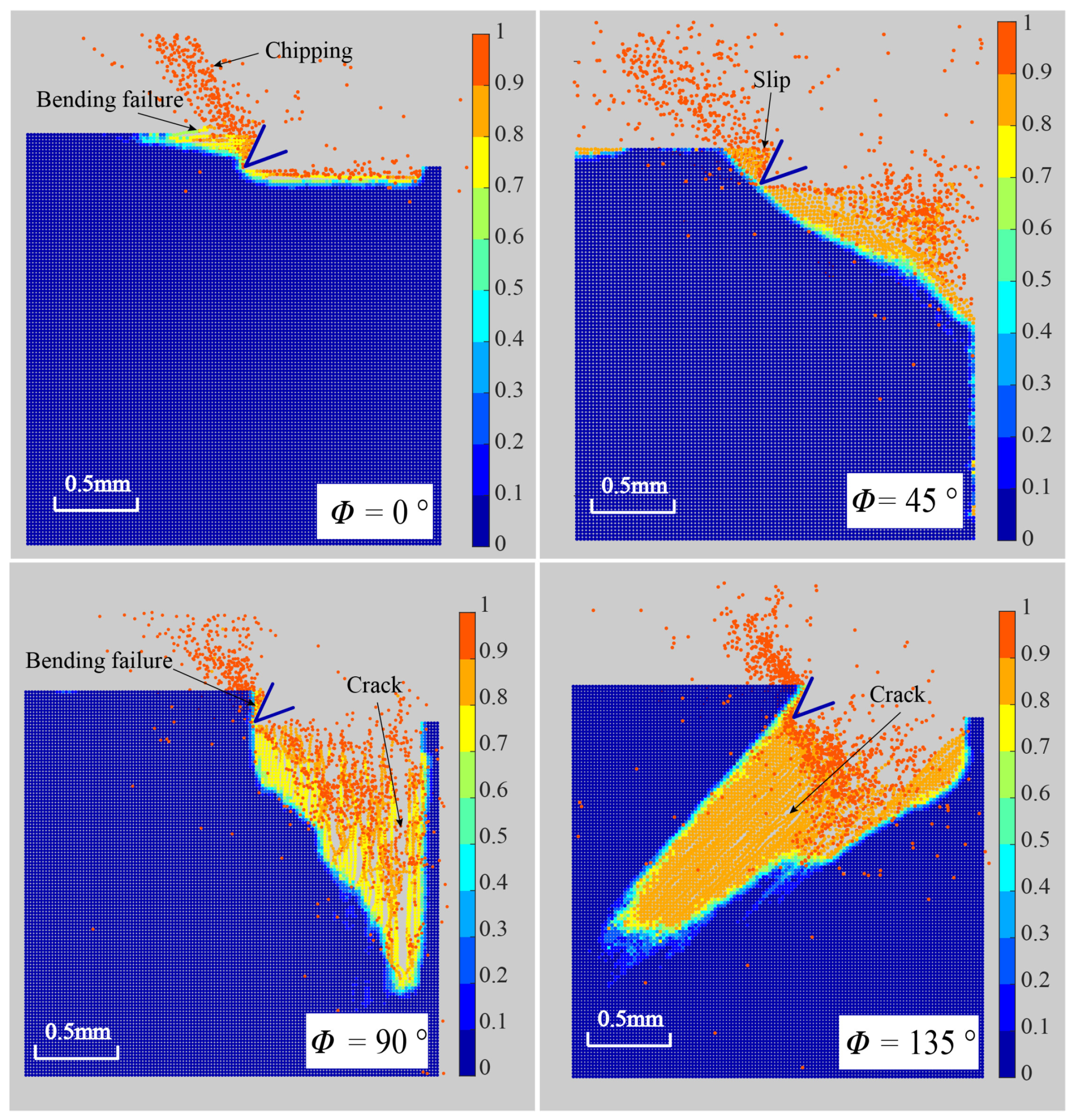

3.2.3. Cutting Process for Different Fiber Orientations

4. Conclusions

- (1)

- (2)

- Fiber direction has a great influence on the quality of the machining surface. In this study, the quality of the machined surface of the plate with is the best, whereas the plate with is the worst, according to the depth of cutting damage.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Camanho, P.; Lambert, M. A design methodology for mechanically fastened joints in laminated composite materials. Compos. Sci. Technol. 2006, 66, 3004–3020. [Google Scholar] [CrossRef]

- Soussia, A.; Mkaddem, A.; Mansori, M. Rigorous treatment of dry cutting of FRP-Interface consumption concept: A review. Int. J. Mech. Sci. 2014, 83, 1–29. [Google Scholar] [CrossRef]

- Li, S.; Thouless, M.; Waas, A.; Schroeder, J.; Zavattieri, P. Use of mode-I cohesive-zone models to describe the fracture of an adhesively-bonded polymer-matrix composite. Compos. Sci. Technol. 2005, 65, 281–293. [Google Scholar] [CrossRef]

- Hou, Y.; Tie, Y.; Li, C.; Meng, L.; Sapanathan, T.; Rachik, M. On the damage mechanism of high-speed ballast impact and compression after impact for CFRP laminates. Compos. Struct. 2019, 229, 111435. [Google Scholar] [CrossRef]

- Calzada, K.A.; Kapoor, S.G.; DeVor, R.E.; Samuel, J.; Srivastava, A.K. Modeling and interpretation of fiber orientation-based failure mechanisms in machining of carbon fiber-reinforced polymer composites. J. Manuf. Process. 2012, 14, 141–149. [Google Scholar] [CrossRef]

- Zhou, W.; Liu, D.; Liu, N. Analyzing dynamic fracture process in fiber-reinforced composite materials with a peridynamic model. Eng. Fract. Mech. 2017, 178, 60–76. [Google Scholar] [CrossRef]

- Silling, S. Reformulation of elasticity theory for discontinuities and long-range forces. J. Mech. Phys. Solids 2000, 48, 175–209. [Google Scholar] [CrossRef]

- Silling, S.; Askari, E. A meshfree method based on the peridynamic model of solid mechanics. Comput. Struct. 2005, 83, 1526–1535. [Google Scholar] [CrossRef]

- Silling, S.; Epton, M.; Weckner, O.; Xu, J.; Askari, W. Peridynamic states and constitutive modeling. J. Elast. 2007, 88, 151–184. [Google Scholar] [CrossRef]

- Kilic, B.; Madenci, E. An adaptive dynamic relaxation method for quasi-static simulations using the peridynamic theory. Theor. Appl. Fract. Mech. 2010, 53, 194–204. [Google Scholar] [CrossRef]

- Sau, N.; Medina, J.; Borbon, A. Peridynamic modelling of reinforced concrete structures. Eng. Fail. Anal. 2019, 103, 266–274. [Google Scholar] [CrossRef]

- Chen, Z.; Jafarzadeh, S.; Zhao, J.; Bobaru, F. A coupled mechano-chemical peridynamic model for pit-to-crack transition in stress-corrosion cracking. J. Mech. Phys. Solids 2021, 146, 104203. [Google Scholar] [CrossRef]

- Kilic, B.; Agwai, A.; Madenci, E. Peridynamic theory for progressive damage prediction in center-cracked composite laminates. Compos. Struct. 2009, 90, 141–151. [Google Scholar] [CrossRef]

- Oterkus, E.; Madenci, E. Peridynamic analysis of fiber-reinforced composite materials. J. Mech. Mater. Struct. 2015, 7, 45–84. [Google Scholar] [CrossRef]

- Askari, A.; Azdoud, Y.; Han, F.; Lubineau, G.; Silling, S. 12—Peridynamics for analysis of failure in advanced composite materials. In Numerical Modelling of Failure in Advanced Composite Materials; Woodhead Publishing Series in Composites Science and Engineering; Elsevier: Amsterdam, The Netherlands, 2015; pp. 331–350. [Google Scholar] [CrossRef]

- Hu, Y.; Madenci, E. Peridynamics for fatigue life and residual strength prediction of composite laminates. Compos. Struct. 2017, 160, 169–184. [Google Scholar] [CrossRef]

- Askari, E.; Xu, J.; Silling, S. Peridynamic Analysis of Damage and Failure in Composites. In Proceedings of the 44th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 9–12 January 2006. [Google Scholar]

- Ghajari, M.; Iannucci, L.; Curtis, P. A peridynamic material model for the analysis of dynamic crack propagation in orthotropic media. Comput. Methods Appl. Mech. Eng. 2014, 276, 431–452. [Google Scholar] [CrossRef]

- Hu, Y.; Yu, Y.; Madenci, E. Peridynamic modeling of composite laminates with material coupling and transverse shear deformation. Compos. Struct. 2020, 253, 112760. [Google Scholar] [CrossRef]

- Madenci, E.; Yaghoobi, A.; Barut, A.; Dorduncu, M.; Phan, N.D. A peridynamic approach for modeling composite laminates. In Proceedings of the AIAA Scitech 2021 Forum, Virtual Event, 11–15 & 19–21 January 2021. [Google Scholar]

- Tian, D.; Zhou, X. A continuum-kinematics-inspired peridynamic model of anisotropic continua: Elasticity, damage, and fracture. Int. J. Mech. Sci. 2021, 199, 106413. [Google Scholar] [CrossRef]

- Wu, C.; Ren, B. A stabilized non-ordinary state-based peridynamics for the nonlocal ductile material failure analysis in metal machining process. Comput. Methods Appl. Mech. Eng. 2015, 291, 197–215. [Google Scholar] [CrossRef]

- Jiang, H.; He, L.; Fan, L.; Zhan, G. Numerical analysis method of cemented carbide turning tool’s micro breakage based on peridynamic theory. Int. J. Adv. Manuf. Technol. 2017, 88, 1–10. [Google Scholar] [CrossRef]

- Shang, S.; Qin, X.; Li, P.; Li, H.; Cao, X.; Li, Y. A bond-based peridynamic modeling of machining of unidirectional carbon fiber reinforced polymer material. Int. J. Adv. Manuf. Technol. 2019, 102, 4199–4211. [Google Scholar] [CrossRef]

- Shang, S.; Qin, X.; Li, H.; Cao, X. An application of non-ordinary state-based peridynamics theory in cutting process modelling of unidirectional carbon fiber reinforced polymer material. Compos. Struct. 2019, 226, 111194. [Google Scholar] [CrossRef]

- Madenci, E.; Oterkus, E. Peridynamic Theory and Its Applications; Springer: New York, NY, USA, 2014. [Google Scholar]

- Oterkus, E.; Oterkus, S.; Madenci, E. (Eds.) Peridynamic modeling, Numerical Techniques, and Applications; Springer: New York, NY, USA, 2021. [Google Scholar]

- Hu, W.; Ha, Y.; Bobaru, F. Peridynamic model for dynamic fracture in unidirectional fiber-reinforced composites. Comput. Methods Appl. Mech. Eng. 2012, 217–220, 247–261. [Google Scholar] [CrossRef]

- Zhang, H.; Qiao, P. A state-based peridynamic model for quantitative elastic and fracture analysis of orthotropic materials. Eng. Fract. Mech. 2019, 206, 147–171. [Google Scholar] [CrossRef]

- Madenci, E.; Yaghoobi, A.; Barut, A.; Phan, N. Peridynamic Modeling of Compression After Impact Damage in Composite Laminates. J. Peridynamics Nonlocal Model. 2021, 3, 327–347. [Google Scholar] [CrossRef]

- Hattori, G.; Trevelyan, J.; Coombs, W. A non-ordinary state-based peridynamics framework for anisotropic materials. Comput. Methods Appl. Mech. Eng. 2018, 339, 416–442. [Google Scholar] [CrossRef]

- Colavito, K.; Barut, A.; Madenci, E.; Phan, N. Residual Strength of Composite Laminates with a Hole by Using Peridynamic Theory. In Proceedings of the 54th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Boston, MA, USA, 8–11 April 2013. [Google Scholar]

- Hu, Y.; Yu, Y.; Wang, H. Peridynamic analytical method for progressive damage in notched composite laminates. Compos. Struct. 2014, 108, 801–810. [Google Scholar] [CrossRef]

- Hu, Y.; Carvalho, N.; Madenci, E. Peridynamic modeling of delamination growth in composite laminates. Compos. Struct. 2015, 132, 610–620. [Google Scholar] [CrossRef]

- Jiang, X.; Wang, H. Ordinary state-based peridynamics for open-hole tensile strength prediction of fiber-reinforced composite laminates. J. Mech. Mater. Struct. 2018, 13, 53–82. [Google Scholar] [CrossRef]

- Fang, G.; Liu, S.; Liang, J.; Fu, M.; Wang, B.; Meng, S. A stable non-ordinary state-based peridynamic model for laminated composite materials. Int. J. Numer. Methods Eng. 2021, 122. [Google Scholar] [CrossRef]

- Diyaroglu, C.; Oterkus, E.; Madenci, E.; Rabczuk, T.; Siddiq, A. Peridynamic modeling of composite laminates under explosive loading. Compos. Struct. 2016, 144, 14–23. [Google Scholar] [CrossRef]

- Li, H.; Qin, X.; He, G.; Jin, Y.; Sun, D.; Price, M. Investigation of chip formation and fracture toughness in orthogonal cutting of UD-CFRP. Int. J. Adv. Manuf. Technol. 2015, 82, 1079–1088. [Google Scholar] [CrossRef]

- Imachi, M.; Tanaka, S.; Bui, T.Q.; Oterkus, S.; Oterkus, E. A computational approach based on ordinary state-based peridynamics with new transition bond for dynamic fracture analysis. Eng. Fract. Mech. 2019, 206, 359–374. [Google Scholar] [CrossRef]

| Mechanical Property | Value |

|---|---|

| 133,000 | |

| 8000 | |

| v | 0.33 |

| 3700 | |

| 1900 | |

| 1300 | |

| 41 | |

| 170 | |

| 81 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qi, J.; Li, C.; Tie, Y.; Zheng, Y.; Cui, Z.; Duan, Y. An Ordinary State-Based Peridynamic Model of Unidirectional Carbon Fiber Reinforced Polymer Material in the Cutting Process. Polymers 2023, 15, 64. https://doi.org/10.3390/polym15010064

Qi J, Li C, Tie Y, Zheng Y, Cui Z, Duan Y. An Ordinary State-Based Peridynamic Model of Unidirectional Carbon Fiber Reinforced Polymer Material in the Cutting Process. Polymers. 2023; 15(1):64. https://doi.org/10.3390/polym15010064

Chicago/Turabian StyleQi, Jiaqi, Cheng Li, Ying Tie, Yanping Zheng, Zhen Cui, and Yuechen Duan. 2023. "An Ordinary State-Based Peridynamic Model of Unidirectional Carbon Fiber Reinforced Polymer Material in the Cutting Process" Polymers 15, no. 1: 64. https://doi.org/10.3390/polym15010064

APA StyleQi, J., Li, C., Tie, Y., Zheng, Y., Cui, Z., & Duan, Y. (2023). An Ordinary State-Based Peridynamic Model of Unidirectional Carbon Fiber Reinforced Polymer Material in the Cutting Process. Polymers, 15(1), 64. https://doi.org/10.3390/polym15010064