Preparation of a Ceramifiable Phenolic Foam and Its Ceramization Behavior

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.2.1. Synthesis of Phenolic Resin

2.2.2. LMG Pretreatment

2.2.3. Preparation of GC-PF

2.3. Measurements

3. Results and Discussion

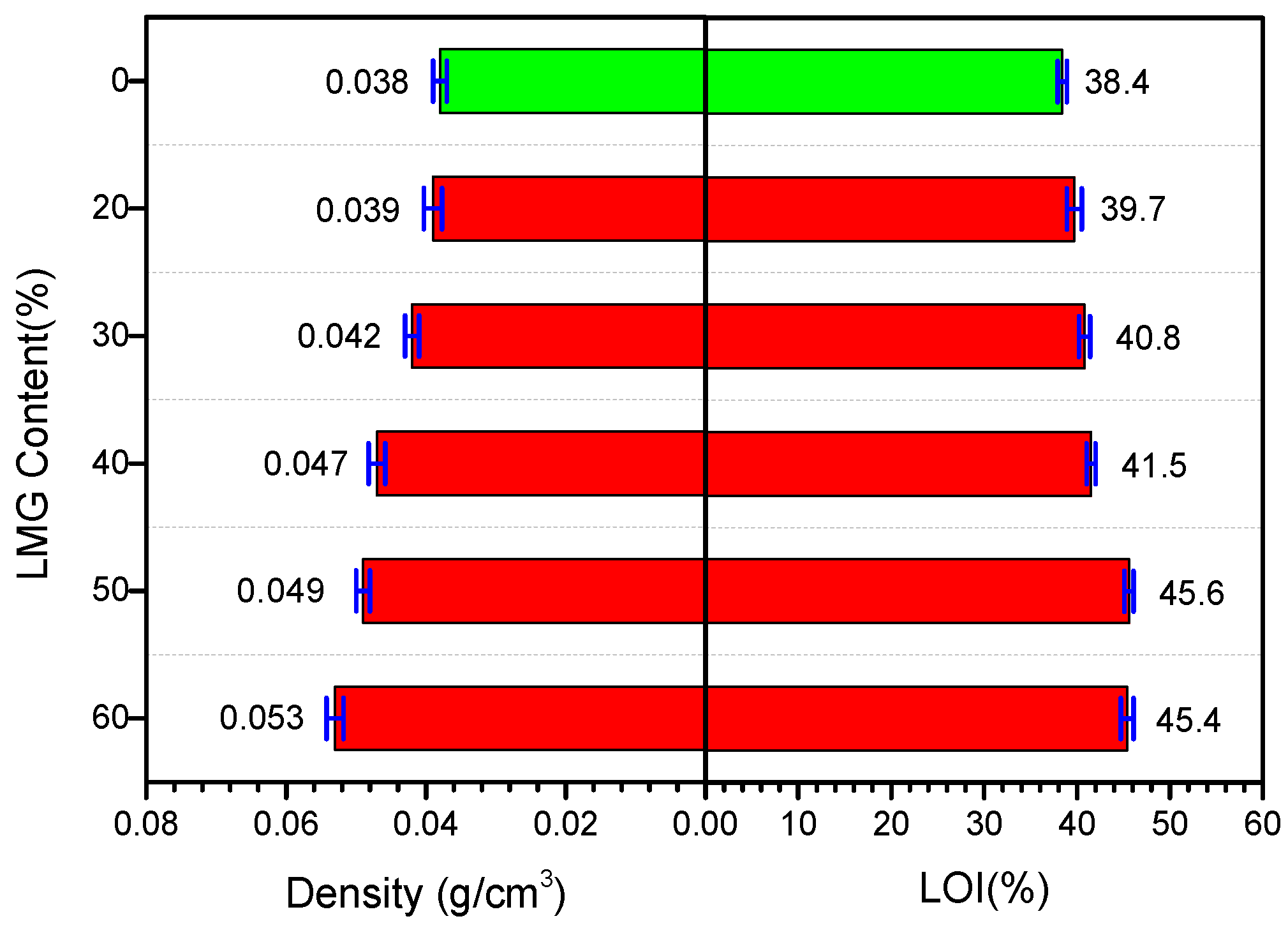

3.1. Apparent Density and LOI

3.2. Bending Strength and Compressive Strength

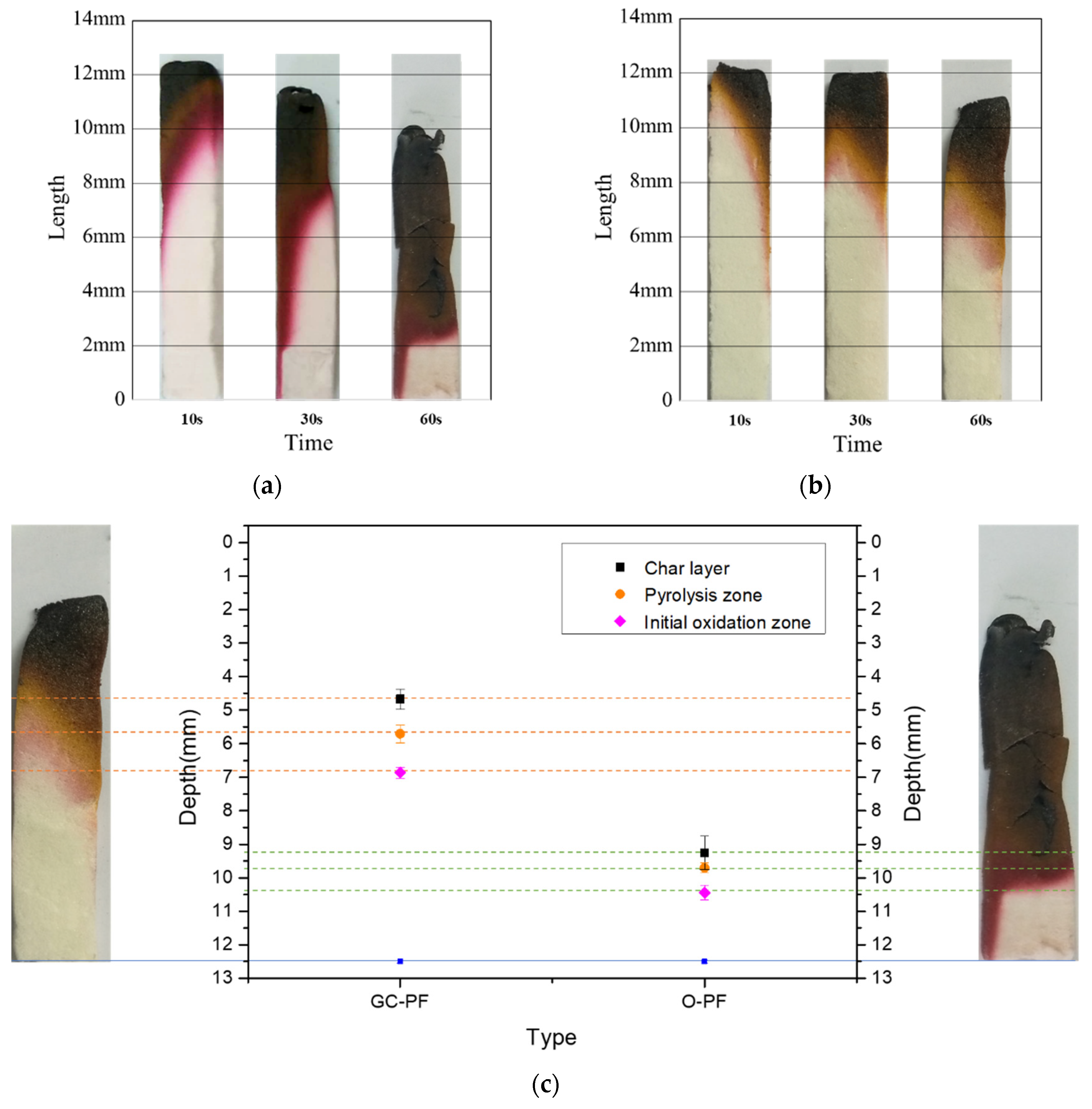

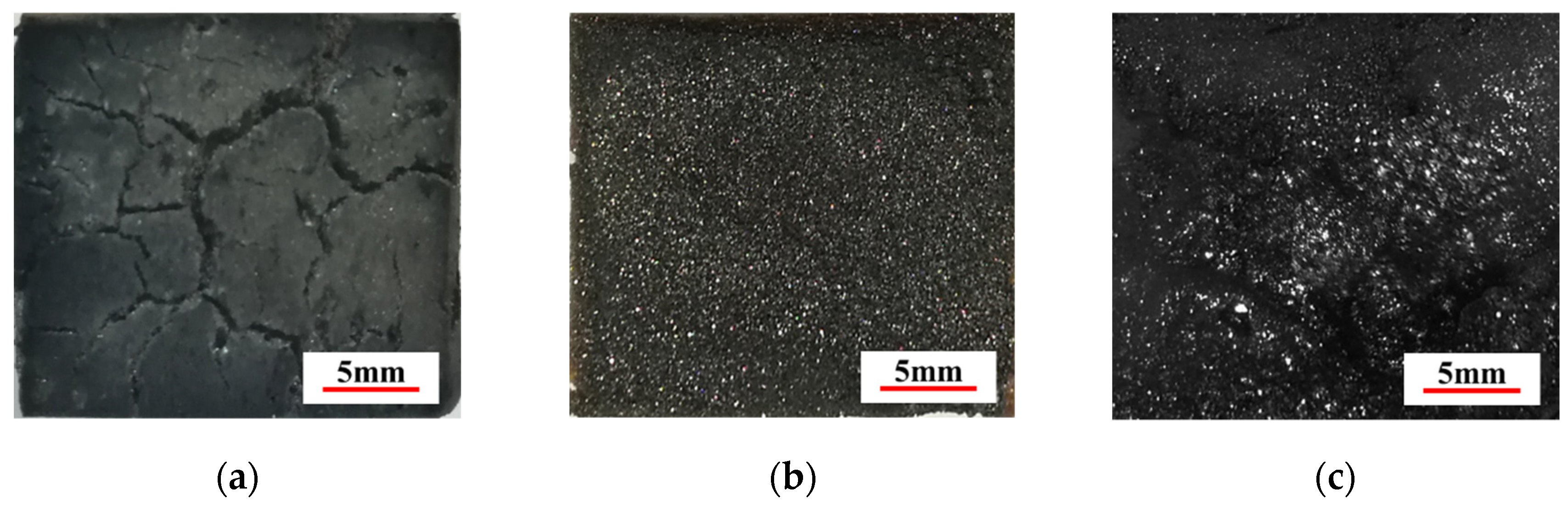

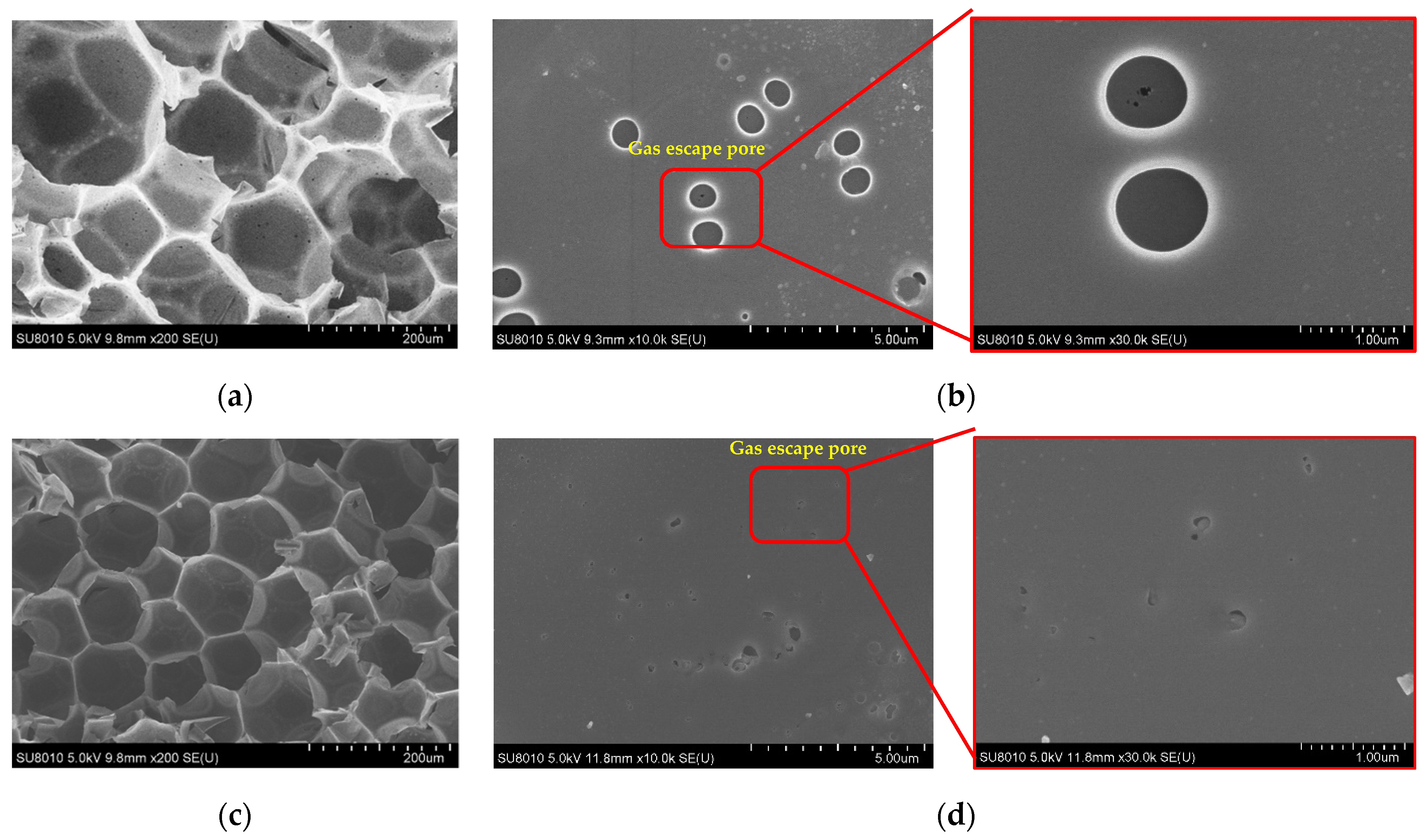

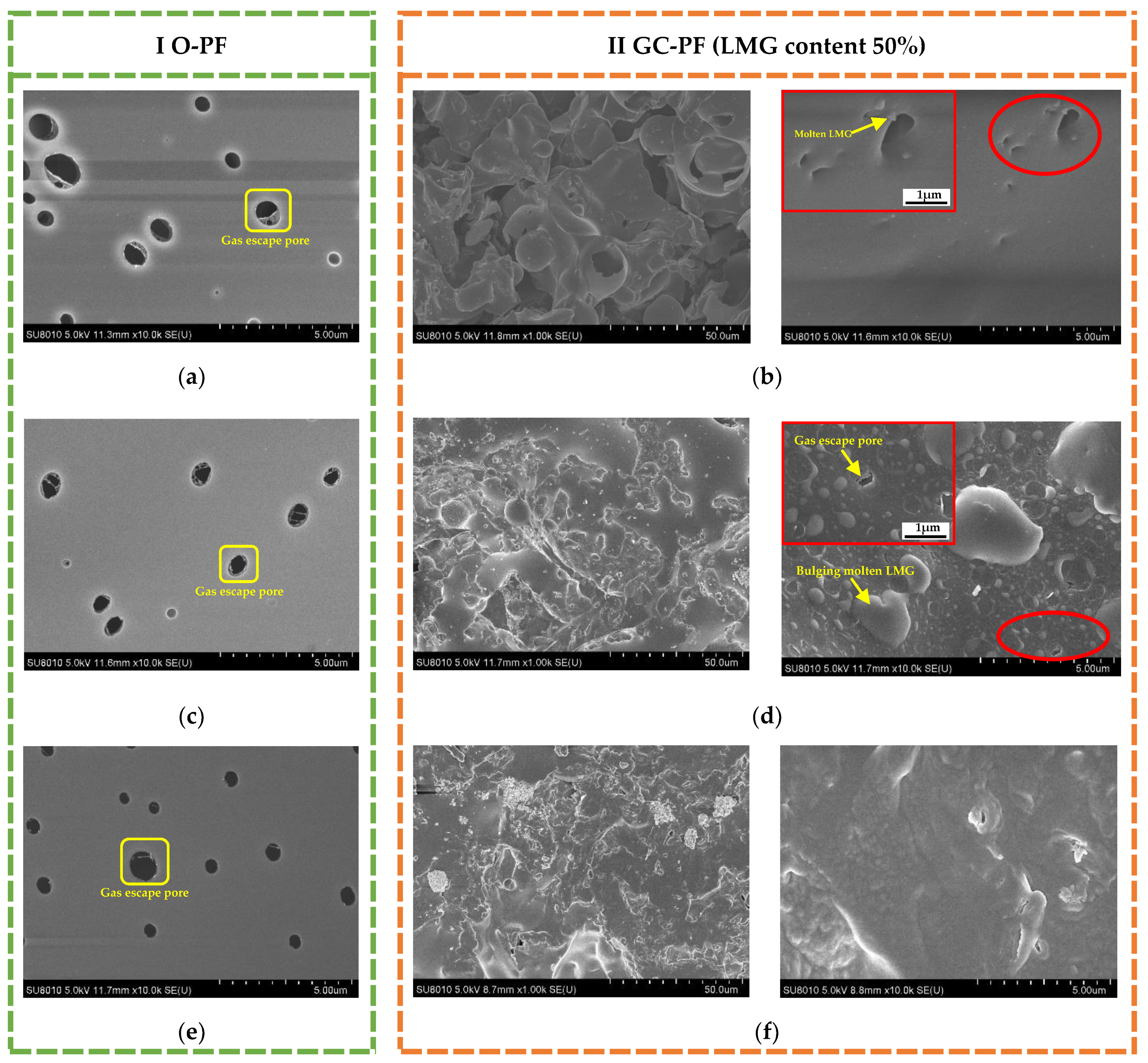

3.3. Surface Morphology of Foam after Combustion

3.4. Ceramization of GC-PF

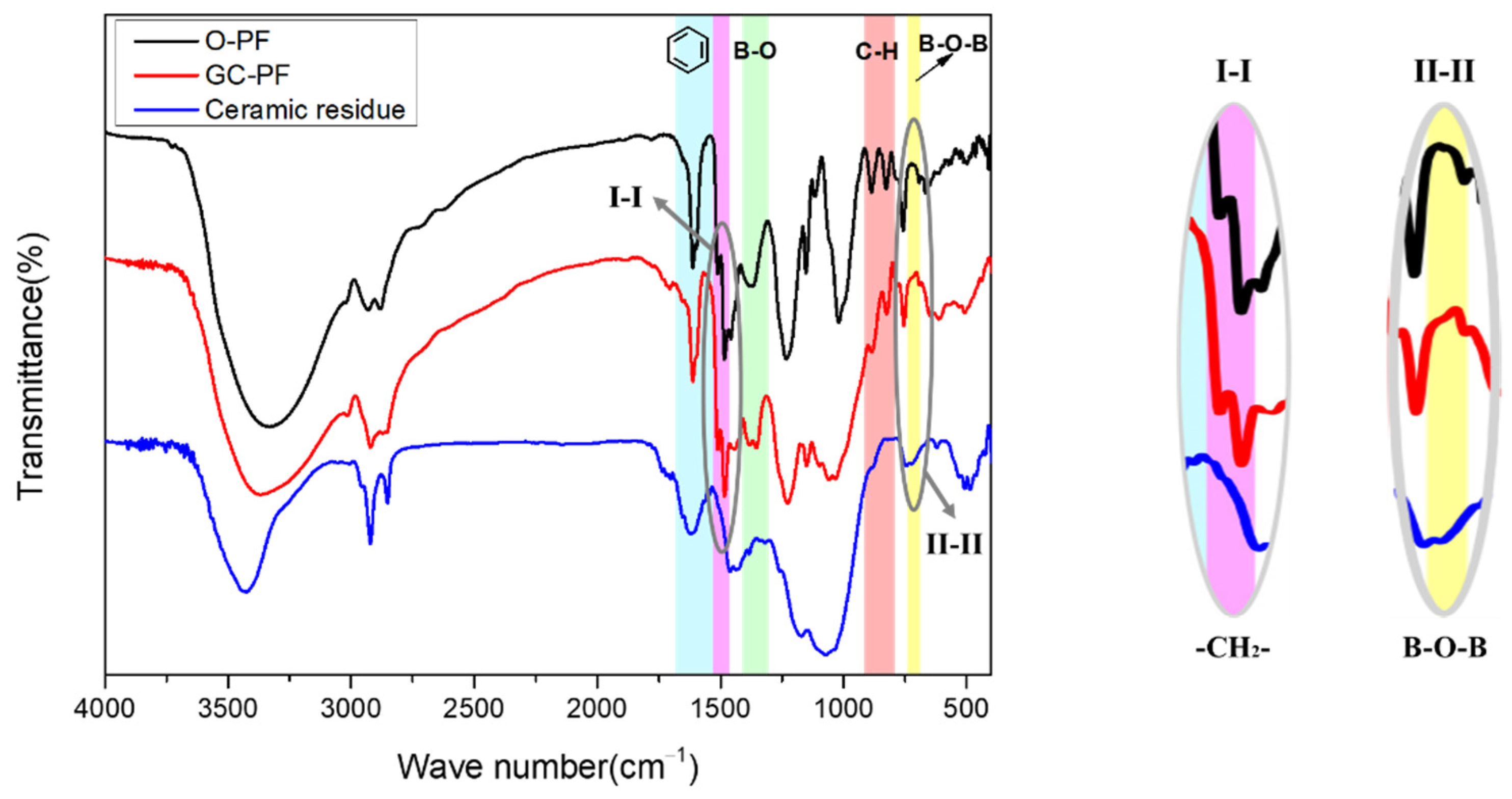

3.5. FTIR Analysis

3.6. XRD Analysis

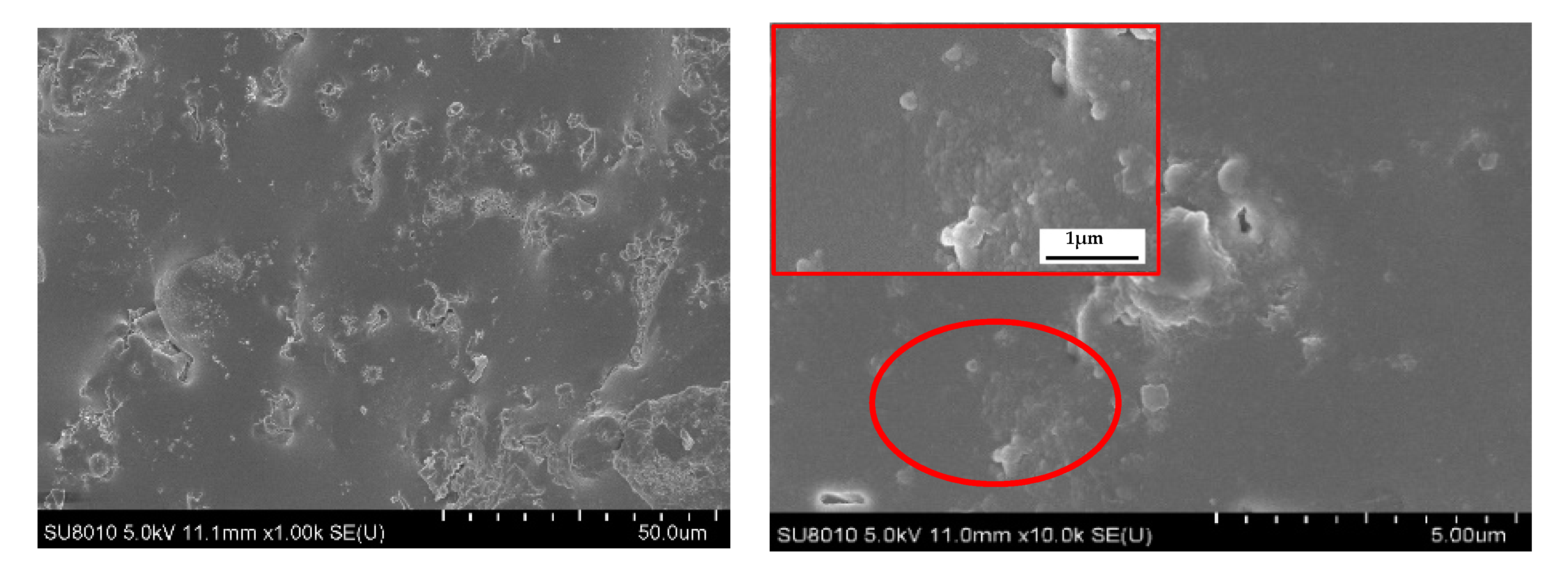

3.7. SEM Analysis

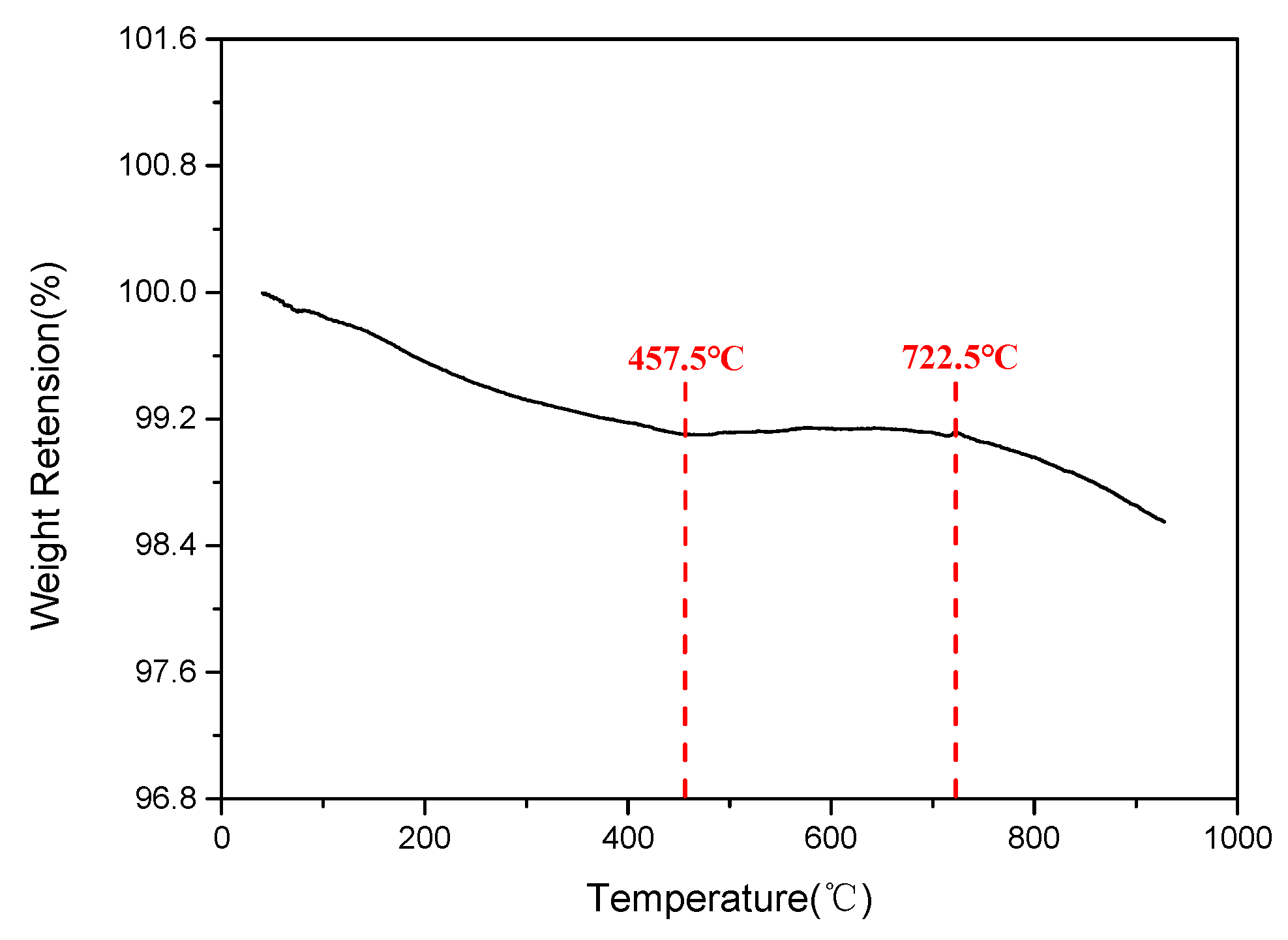

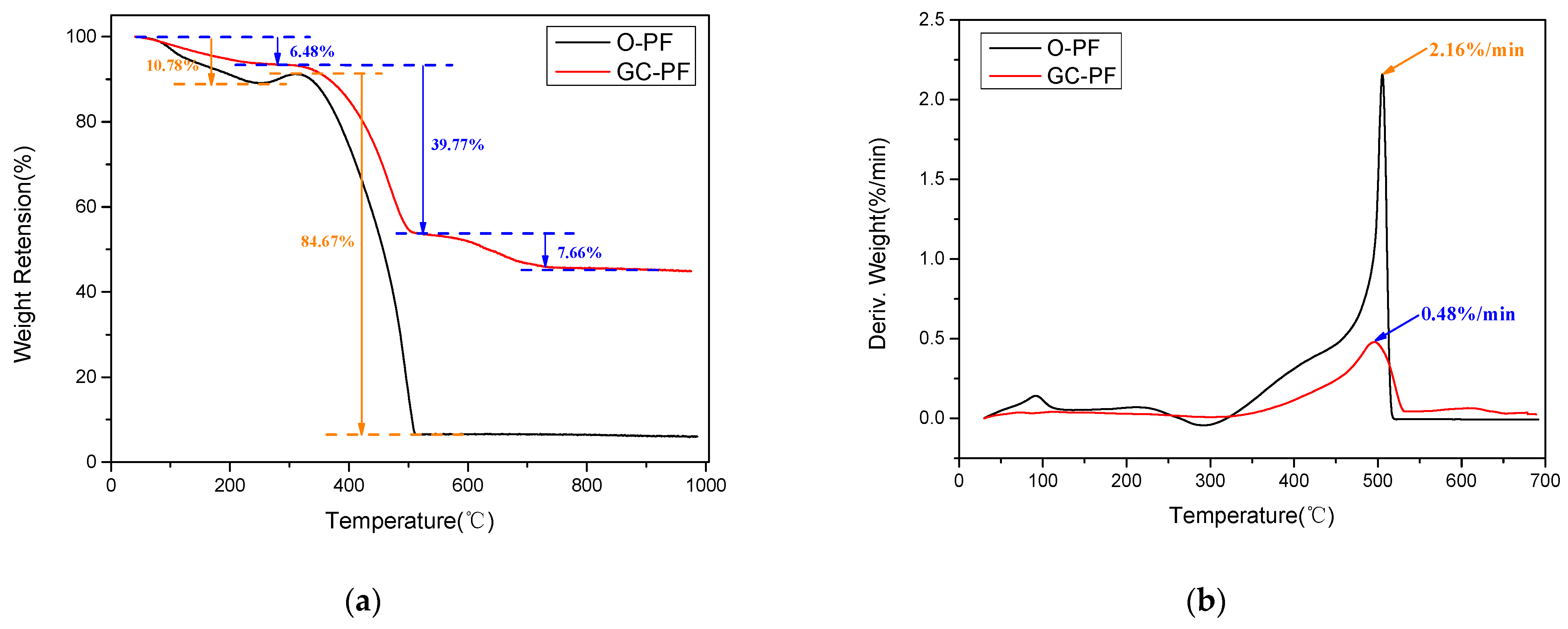

3.8. Thermogravimetric Analysis

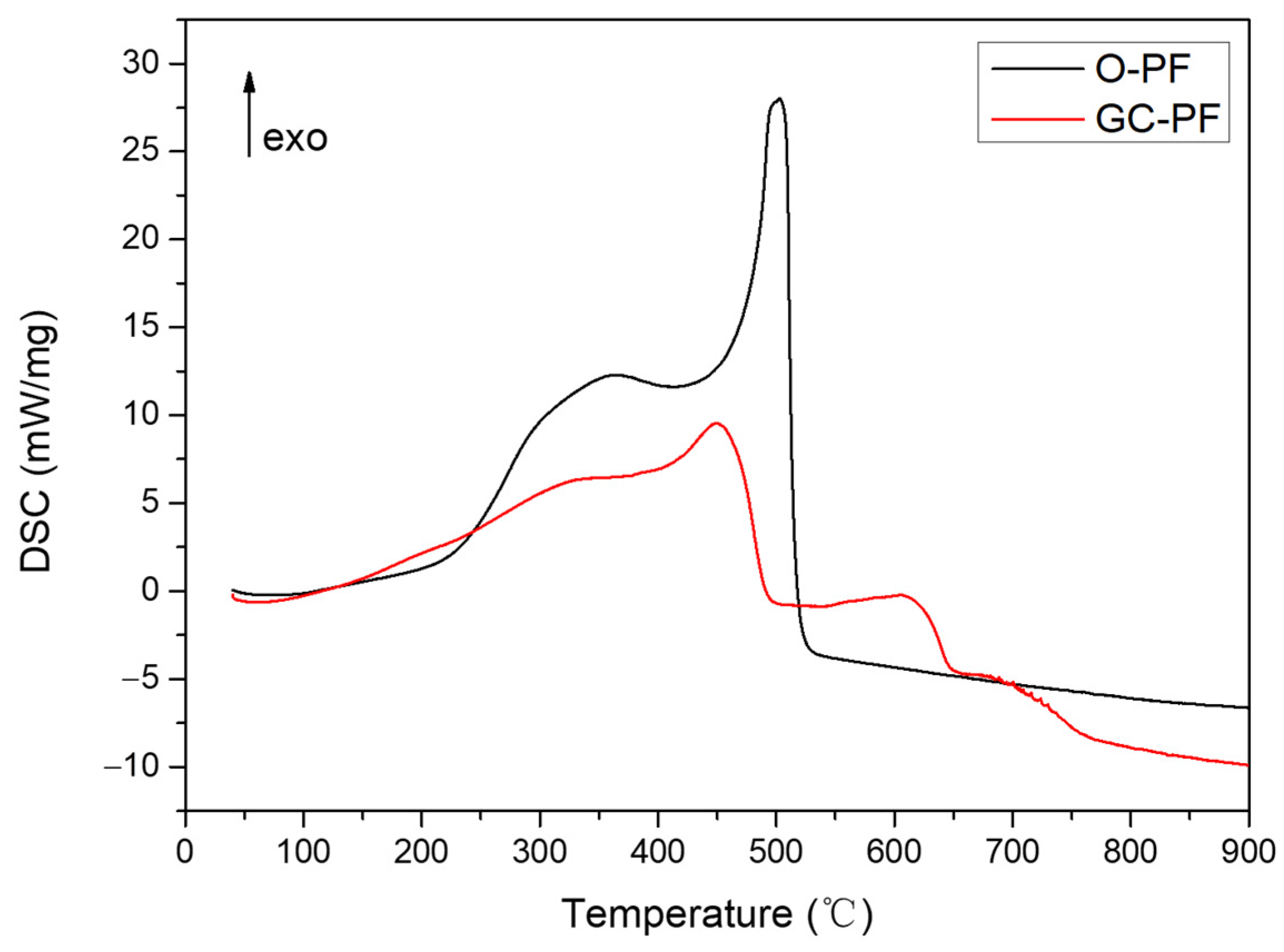

3.9. DSC Analysis

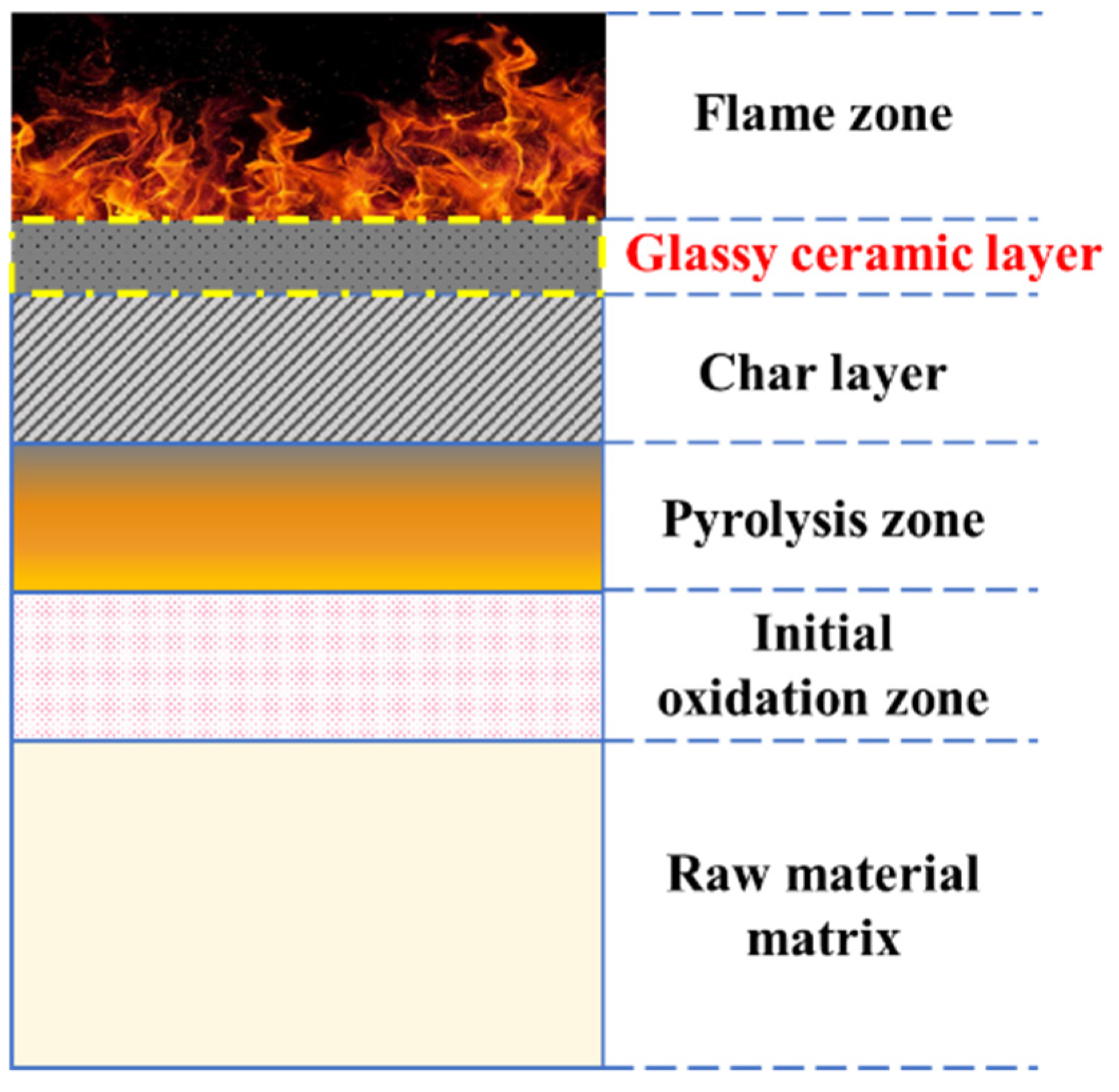

3.10. The Formation Mechanism of Glassy Ceramics Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Song, X.; Xiao, W.; Wang, P.; Liao, B.; Yan, K.; Zhang, J. Hollow glass microspheres-based ultralight non-combustible thermal insulation foam with point-to-point binding structure using solvent evaporation method. Constr. Build. Mater. 2021, 292, 123415. [Google Scholar] [CrossRef]

- Mougel, C.; Garnier, T.; Cassagnau, P.; Sintes-Zydowicz, N. Phenolic foams: A review of mechanical properties, fire resistance and new trends in phenol substitution. Polymer 2018, 164, 86–117. [Google Scholar] [CrossRef]

- Pintus, V.; Piccolo, A.; Vetter, W.; Moretto, L.M.; Sterflinger, K.; Schreiner, M. What about phenol formaldehyde (PF) foam in modern-contemporary art? Insights into the unaged and naturally aged material by a multi-analytical approach. Polymers 2021, 13, 1964. [Google Scholar] [CrossRef]

- Jalalian, M.; Jiang, Q.; Coulon, A.; Storb, M.; Woodward, R.; Bismarck, A. Mechanically whipped phenolic froths as versatile templates for manufacturing phenolic and carbon foams. Mater. Des. 2019, 168, 107658. [Google Scholar] [CrossRef]

- Hidalgo, J.P.; Torero, J.L.; Welch, S. Fire performance of charring closed-cell polymeric insulation materials: Polyisocyanurate and phenolic foam. Fire Mater. 2018, 42, 358–373. [Google Scholar] [CrossRef]

- Zhang, L.; Liang, S.; Chen, Z. Influence of particle size and addition of recycling phenolic foam on mechanical and flame retardant properties of wood-phenolic composites. Constr. Build. Mater. 2018, 168, 1–10. [Google Scholar] [CrossRef]

- Ma, Y.; Gong, X.; Liao, C.; Geng, X.; Wang, C.; Chu, F. Preparation and characterization of DOPO-ITA modified ethyl cellulose and its application in phenolic foams. Polymers 2018, 10, 1049. [Google Scholar] [CrossRef] [Green Version]

- Lei, L.; Wang, Z. Facile synthesis of a novel magnesium amino-tris-(methylenephosphonate)-reduced graphene oxide hybrid and its high performance in mechanical strength, thermal stability, smoke suppression and flame retardancy in phenolic foam. J. Hazard. Mater. 2018, 357, 89–99. [Google Scholar] [CrossRef]

- Yang, H.; Jiang, Y.; Liu, H.; Xie, D.; Wan, C.; Pan, H.; Jiang, S. Mechanical, thermal and fire performance of an inorganic-organic insulation material composed of hollow glass microspheres and phenolic resin. J. Colloid Interface Sci. 2018, 530, 163–170. [Google Scholar] [CrossRef]

- Kumar, S.A.; Kumar, S.; Nagaraja, B.K. Thermal stability and flammability characteristics of phenolic syntactic foam core sandwich composites. J. Sandw. Struct. Mater. 2020, 23, 3234–3249. [Google Scholar] [CrossRef]

- Carlos, D.J.; Saz-Orozco, B.D.; Oliet, M.; Virginia, A.M.; Rodriguez, F. Thermal degradation kinetics of a lignin particle-reinforced phenolic foam. J. Cell. Plast. 2021, 57, 176–192. [Google Scholar] [CrossRef]

- Song, F.; Li, Z.; Jia, P.; Bo, C.; Zhang, M.; Hu, L.; Zhou, Y. Phosphorus-containing tung oil-based siloxane toughened phenolic foam with good mechanical properties, fire performance and low thermal conductivity. Mater. Des. 2020, 192, 108668. [Google Scholar] [CrossRef]

- Delgado-Sanchez, C.; Sarazin, J.; Santiago-Medina, F.J.; Fierro, V.; Pizzi, A.; Bourbigot, S.; Celzard, A. Impact of the formulation of biosourced phenolic foams on their fire properties. Polym. Degrad. Stab. 2018, 153, 1–14. [Google Scholar] [CrossRef]

- Sarika, P.R.; Nancarrow, P.; Khansaheb, A.; Ibrahim, T. Bio-Based Alternatives to Phenol and Formaldehyde for the Production of Resins. Polymers 2020, 12, 2237. [Google Scholar] [CrossRef]

- Issaoui, H.; Hoyos-Martinez, P.L.D.; Pellerin, V.; Dourges, M.A.; Bouhtoury, C.E. Effect of catalysts and curing temperature on the properties of biosourced phenolic foams. ACS Sustain. Chem. Eng. 2021, 9, 6209–6223. [Google Scholar] [CrossRef]

- Lazar, S.T.; Kolibaba, T.J.; Grunlan, J.C. Flame-retardant surface treatments. Nat. Rev. Mater. 2020, 5, 259–275. [Google Scholar] [CrossRef]

- Hanua, L.G.; Simon, G.P.; Mansouri, J.; Burford, R.P.; Cheng, Y.B. Development of polymer-ceramic composites for improved fire resistance. J. Mater. Process. Tech. 2004, 153–154, 401–407. [Google Scholar] [CrossRef]

- Liu, W.; Zhao, D.; Pan, Z.; Shen, Y.; Wang, T. Enhanced residue stability and strength of epoxy-based coating for fire protection via ceramifiable strategy. Prog. Org. Coat. 2021, 154, 106211. [Google Scholar] [CrossRef]

- Zhao, D.; Xia, M.; Shen, Y.; Wang, T. Three-dimensional cross-linking structures in ceramifiable EVA composites for improving self-supporting property and ceramifiable properties at high temperature. Polym. Degrad. Stab. 2019, 162, 94–101. [Google Scholar] [CrossRef]

- Al-Hassany, Z.; Genovese, A.; Shanks, R.A. Fire-retardant and fire-barrier poly(vinyl acetate) composites for sealant application. Express Polym. Lett. 2010, 4, 79–93. [Google Scholar] [CrossRef]

- Du, W.; Yin, C.; Huang, H.; Ge, X. Vinyl-functionalized polyborosiloxane for improving mechanical and flame retardancy performances of silicone rubber foam composites. Polym. Int. 2022, 71, 124–131. [Google Scholar] [CrossRef]

- Wang, Y.; Lai, X.; Li, H.; Liu, T.; Zeng, X. Significantly improve fire safety of silicone rubber by efficiently catalyzing ceramization on fluorophlogopite. Compos. Commun. 2021, 25, 100683. [Google Scholar] [CrossRef]

- Yang, J.; Xu, Y.; Jiang, W.; Jiang, B.; Huang, Y. The thermal transformation process and mechanical strength evolution of ceramifiable silicone composites. Ceram. Int. 2021, 47, 21276–21284. [Google Scholar] [CrossRef]

- Ferdous, W.; Ngo, T.D.; Nguyen, K.T.Q.; Ghazlan, A.; Mendis, P.; Manalo, A. Effect of fire-retardant ceram powder on the properties of phenolic-based GFRP composites. Compos. Part B Eng. 2018, 155, 414–424. [Google Scholar] [CrossRef]

- He, D.; Shi, M.; Yang, Y.; Huang, Z. Effect of inorganic components on properties of ceramizable phenolic resin matrix composites. In IOP Conference Series Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 472, pp. 414–424. [Google Scholar] [CrossRef]

- Yang, W.; Xu, B.; Qi, M.; Chen, D.; Ding, J.; Huang, Z.; Wang, Y. Improving ablation properties of ceramifiable vitreous silica fabric reinforced boron phenolic resin composites via an incorporation of MoSi2. Plast. Rubber Compos. 2020, 49, 456–469. [Google Scholar] [CrossRef]

- Li, Z.; Zou, Z.; Qin, Y.; Qi, M.; Ren, J.; Peng, Z. The effect of fibre content on properties of ceramifiable composites. Plast. Rubber Compos. 2020, 49, 230–236. [Google Scholar] [CrossRef]

- Chiang, C.L.; Ma, C.C.M. Synthesis, characterization, thermal properties and flame retardance of novel phenolic resin/silica nanocomposites. Polym. Degrad. Stab. 2004, 83, 207–214. [Google Scholar] [CrossRef]

- Babu, T.G.; Bhuvaneswari, S.; Devasia, R. Synthesis and ceramic conversion of novel silazane modified phenol formaldehyde resin. Mater. Chem. Phys. 2018, 212, 175–186. [Google Scholar] [CrossRef]

- Shi, M.; Tang, Q.; Fan, S.; Dong, C.; Huang, Z. Ceramification of composites of MgO-Al2O3-SiO2/boron phenolic resin with different calcine time. J. Wuhan Univ. Technol. 2021, 36, 174–182. [Google Scholar] [CrossRef]

- Imiela, M.; Anyszka, R.; Bieliński, D.M.; Pędzich, Z.; Zarzecka-Napierała, M.; Szumera, M. Effect of carbon fibers on thermal properties and mechanical strength of ceramizable composites based on silicone rubber. J. Therm. Anal. Calorim. 2015, 124, 197–203. [Google Scholar] [CrossRef] [Green Version]

- Dong, Z.; Shen, Y.; Wang, T. Ceramifiable EVA/APP/SGF composites for improved ceramifiable properties. Polym. Degrad. Stab. 2018, 150, 140–147. [Google Scholar] [CrossRef]

- Zou, Z.; Qin, Y.; Liu, L.; Huang, Z. Effect of the flux on the fire-resistance properties of cerami-fiable epdm rubber composites. Adv. Compos. Lett. 2018, 27, 89–95. [Google Scholar] [CrossRef] [Green Version]

- Jiang, G.; Zhou, H.; Liao, K. Effect of benzotriazole-protected platinum catalyst on flame retardancy and ceramic-forming property of ceramifiable silicone rubber. Polym. Adv. Technol. 2020, 31, 1–14. [Google Scholar] [CrossRef]

- Song, J.; Huang, Z.; Qin, Y.; Yang, G.; Wang, X. Ceramifiable and mechanical properties of silicone rubber foam composite with frit and high silica glass fiber. IOP Conf. Ser. Mater. Sci. Eng. 2018, 423, 012168. [Google Scholar] [CrossRef]

- Anyszka, R.; Bieliński, D.M.; Pędzich, Z.; Szumera, M. Influence of surface-modified montmorillonites on properties of silicone rubber-based ceramizable composites. J. Therm. Anal. Calorim. 2015, 119, 111–121. [Google Scholar] [CrossRef] [Green Version]

- Liu, R.; Xia, W.; Otitoju, T.A.; Wu, W.; Wang, S.; Li, S.; Zhang, A.; Chen, X.; Tang, T.; Liu, J. Effect of oleic acid on improving flame retardancy of brucite in low-density polyethylene composite. J. Appl. Polym. Sci. 2021, 139, 51862. [Google Scholar] [CrossRef]

- Li, Y.; Deng, C.; Wang, Y. A novel high-temperature-resistant polymeric material for cables and insulated wires via the ceramization of mica-based ceramifiable EVA composites. Compos. Sci. Technol. 2016, 132, 116–122. [Google Scholar] [CrossRef]

- Li, Z.; Liang, W.; Shan, Y.; Wang, X.; Yang, K.; Cui, Y. Study of flame-retarded silicone rubber with ceramifiable property. Fire Mater. 2020, 44, 487–496. [Google Scholar] [CrossRef]

- Marosi, G.; Marton, A.; Anna, P. Ceramic precursor in flame retardant systems. Polym. Degrad. Stab. 2002, 77, 259–265. [Google Scholar] [CrossRef]

- Li, Y.; Deng, C.; Long, J.; Huang, S.; Zhao, Z.; Wang, Y. Improving fire retardancy of ceramifiable polyolefin system via a hybrid of zinc borate@melamine cyanurate—ScienceDirect. Polym. Degrad. Stab. 2018, 153, 325–332. [Google Scholar] [CrossRef]

- Imiela, M.; Anyszka, R.; Bieliński, D.M.; Lipińska, M.; Rybiński, P.; Syrek, B. Synergistic effect of mica, glass frit, and melamine cyanurate for improving fire resistance of styrene-butadiene rubber composites destined for ceramizable coatings. Coatings 2019, 9, 170. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Deng, C.; Shi, X.; Xu, B.; Chen, H.; Wang, Y. Simultaneously improved flame retardance and ceramifiable properties of polymer-based composites via the formed crystalline phase at high temperature. ACS Appl. Mater. Inter. 2019, 11, 7459–7471. [Google Scholar] [CrossRef] [PubMed]

- Ge, T.; Tang, K.; Zhang, A. Toughened Phenolic Foams. In Phenolic Based Foams; Sandhya, P.K., Sreekala, M.S., Sabu, T., Eds.; Springer: Singapore, 2022; pp. 81–101. [Google Scholar] [CrossRef]

- Yasin, S. Large amplitude oscillatory rheology of silica and cellulose nanocrystals filled natural rubber compounds. J. Colloid Interface Sci. 2020, 588, 602–610. [Google Scholar] [CrossRef] [PubMed]

- Hussain, M.; Yasin, S.; Akram, M.A.; Xu, H.; Song, Y.; Zheng, Q. Influence of ionic liquids on structure and rheological behaviors of silica-filled butadiene rubber. Ind. Eng. Chem. Res. 2019, 58, 18205–18212. [Google Scholar] [CrossRef]

- Guo, J.; Wei, G.; Yu, W.; Dong, L.; Li, H.; Xin, Z. Effect of glass frit with low softening temperature on the properties, microstructure and formation mechanism of polysiloxane elastomer-based ceramizable composites. Polym. Degrad. Stab. 2017, 136, 71–79. [Google Scholar] [CrossRef]

- Shi, M.; Fan, S.; Luo, W.; Huang, Z. Pyrolysis Behaviour of boron phenolic resin-based ceramicable composites by introducing of MgO-Al2O3-SiO2. Adv. Mater. Res. 2017, 1142, 138–145. [Google Scholar] [CrossRef]

- Chen, X.; Yu, W.; Ma, L.; Zhou, S.; Liu, X. Mechanical properties and thermal characteristics of different-density phenolic foams. J. Therm. Anal. Calorim. 2021, 144, 393–401. [Google Scholar] [CrossRef]

- Grange, N.; Manescau, B.; Chetehouna, K.; Gascoin, N.; Reynaud, I. Fire resistance of carbon-based composite materials under both ideal and realistic normative configurations. Appl. Therm. Eng. 2019, 159, 113834. [Google Scholar] [CrossRef]

- Sheng, H.; Chen, F.; Li, J.; Shen, Q.; Huang, Z.; Zhang, L. The ceramifying process and mechanical properties of silicone rubber/ammonium polyphosphate/aluminium hydroxide/mica composites. Polym. Degrad. Stab. 2016, 126, 196–203. [Google Scholar] [CrossRef]

- Gild, J.; Zhang, Y.; Harrington, T.; Jiang, S.; Hu, T.; Quinn, M.C.; Mellor, W.M.; Zhou, N.; Vecchio, K.; Luo, J. High-entropy metal diborides: A new class of high-entropy materials and a new type of ultrahigh temperature ceramics. Sci. Rep. 2016, 6, 37946. [Google Scholar] [CrossRef]

| Samples | Resole Resin (phr a) | LMG (phr) | Surfactant (phr) | Foaming Agent (phr) | Curing Agent (phr) |

|---|---|---|---|---|---|

| O-PF b | 100 | - | 6 | 10 | 15 |

| GC-PF c-1 | 100 | 20 | 6 | 10 | 15 |

| GC-PF-2 | 100 | 30 | 6 | 10 | 15 |

| GC-PF-3 | 100 | 40 | 6 | 10 | 15 |

| GC-PF-4 | 100 | 50 | 6 | 10 | 15 |

| GC-PF-5 | 100 | 60 | 6 | 10 | 15 |

| O-PF | GC-PF | ||

|---|---|---|---|

| TG | T5% * (°C) | 124.9 | 188.3 |

| residues at 900 °C (wt.%) | 6.14 | 45.25 | |

| DTG | First decomposition temperature region (°C) | 30~124.9 | - |

| Second decomposition temperature region (°C) | 303.4~519.3 | 323.1~515.9 | |

| Third decomposition temperature region (°C) | - | 535.9~700.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, K.; Yu, Y.; Xu, G.; Tang, X.; Zhang, A.; Ge, T.; Li, Y. Preparation of a Ceramifiable Phenolic Foam and Its Ceramization Behavior. Polymers 2022, 14, 1591. https://doi.org/10.3390/polym14081591

Tang K, Yu Y, Xu G, Tang X, Zhang A, Ge T, Li Y. Preparation of a Ceramifiable Phenolic Foam and Its Ceramization Behavior. Polymers. 2022; 14(8):1591. https://doi.org/10.3390/polym14081591

Chicago/Turabian StyleTang, Kaihong, Yang Yu, Guiqiu Xu, Xiaojun Tang, Ailing Zhang, Tiejun Ge, and Yongjiang Li. 2022. "Preparation of a Ceramifiable Phenolic Foam and Its Ceramization Behavior" Polymers 14, no. 8: 1591. https://doi.org/10.3390/polym14081591

APA StyleTang, K., Yu, Y., Xu, G., Tang, X., Zhang, A., Ge, T., & Li, Y. (2022). Preparation of a Ceramifiable Phenolic Foam and Its Ceramization Behavior. Polymers, 14(8), 1591. https://doi.org/10.3390/polym14081591