Partial Biodegradable Blend for Fused Filament Fabrication: In-Process Thermal and Post-Printing Moisture Resistance

Abstract

:1. Introduction

| Blend | Minimum Percentage of PP | Properties | 3D Printing | Moisture-Based Degradation of 3D-Printed Blend |

|---|---|---|---|---|

| Non-compatibilized PP and PLA [19] | 30 | Viscosity Non-Newtonian index Tensile stress and strain | No | No |

| Compatibilized PP and PLA PP-g-MAH SEBS-g-MAH [17] | 80 | Tensile strength Impact strength Morphology Complex viscosity | No | No |

| Non-compatibilized PP and PLA fibers (not bulk) [21] | 20 | Breaking tenacity AFM-based morphology X-ray diffraction graphs | No | No |

| Compatibilized rPP, PLA, n-(6-aminohexyl) aminomethyltriethoxysilane [22] | 10 | Phase morphology TGA, DSC, Impact strength Tensile strength | No | No |

| Compatibilized PP, PLA, Toughening modifier Hybrid compatibilizer of following PP-g-MAH PE-g-GMA [18] | 60 | Tensile strength Flexural strength Impact strength Viscosity Relaxation time analysis | No | No |

| Compatibilized PP, PLA, EBA-GMA [23] | 10 | TGA, DSC, SEM Viscosity | No | No |

| Compatibilized PLA, PP, PP-g-MAH [24] | 64 | No | No | |

| Compatibilized PLA, PP, PP-g-MAH [25] | 80 | TGA Viscosity Thermal degradation activation energy | No | No |

| Compatibilized PP, PLA, PP-g-MAH, OMMT [26] | 25 | TGA SEM Impact testing Tensile testing | No | No |

2. Materials and Methods

2.1. Materials

2.2. Melt Blending (Until Successful 3D Printing)

2.3. Pellet 3D Printing

2.4. Water Absorption (Moisture) Testing

2.5. In-Process (During 3D Printing) Thermal Testing

2.6. Tensile Testing

2.7. Scanning Electron Microscopy

2.8. Fourier Transform Infrared Spectroscopy

2.9. Differential Scanning Calorimetry

2.10. Thermogravimetric Analysis

3. Results

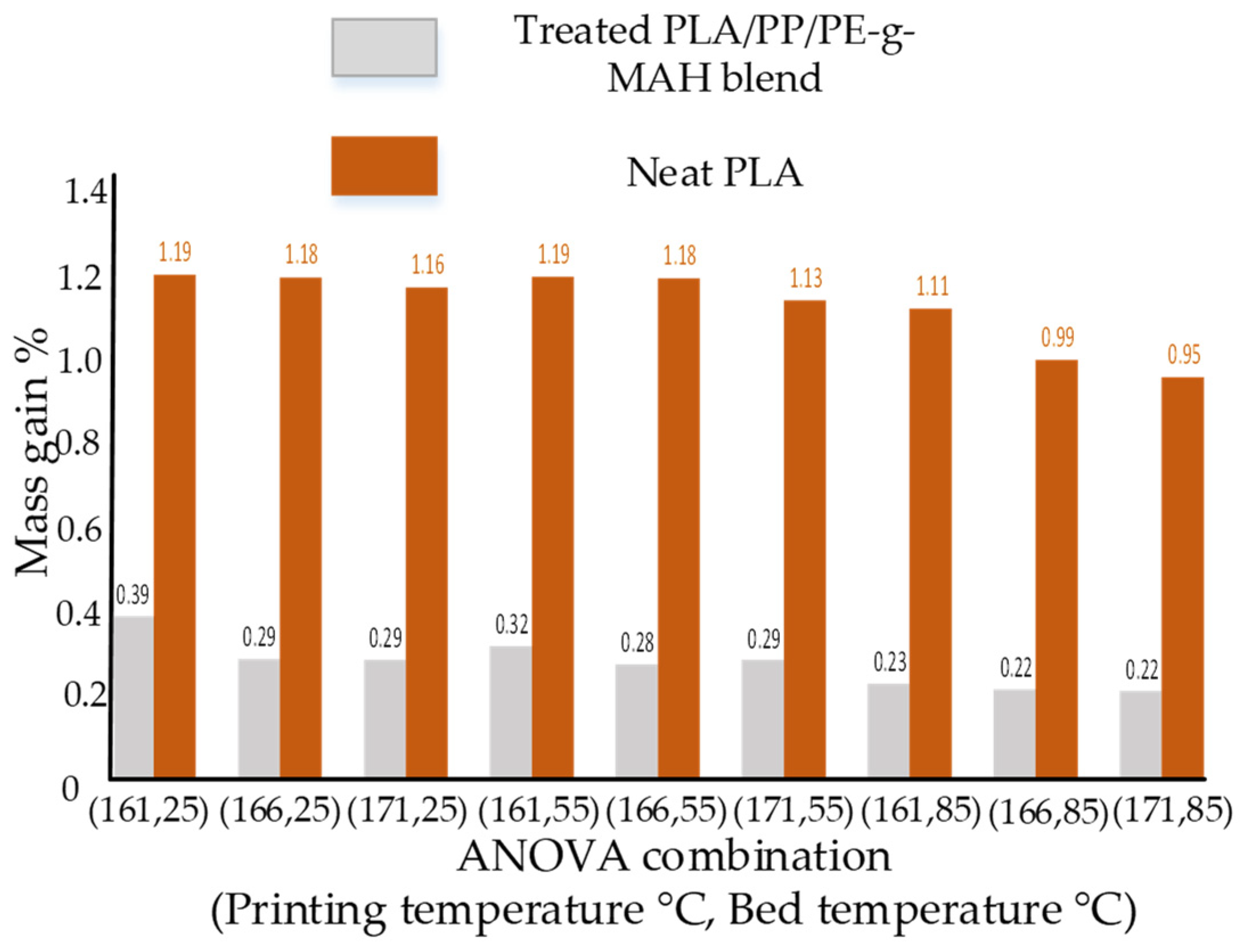

3.1. Water Absorption (Moisture-Based Degradation)

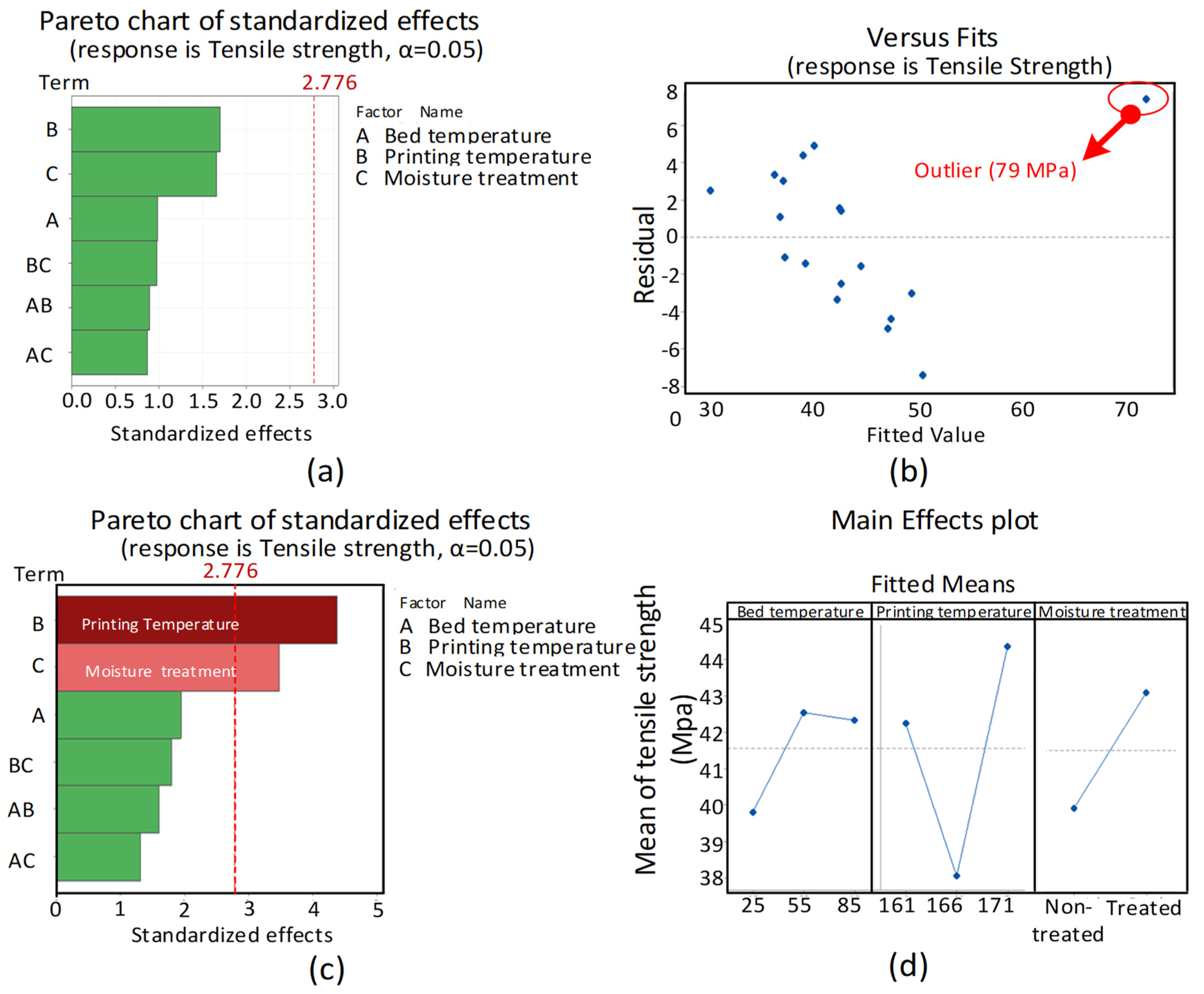

3.2. Tensile Testing

3.3. Effects of Bed and Printing Temperatures

4. Discussion

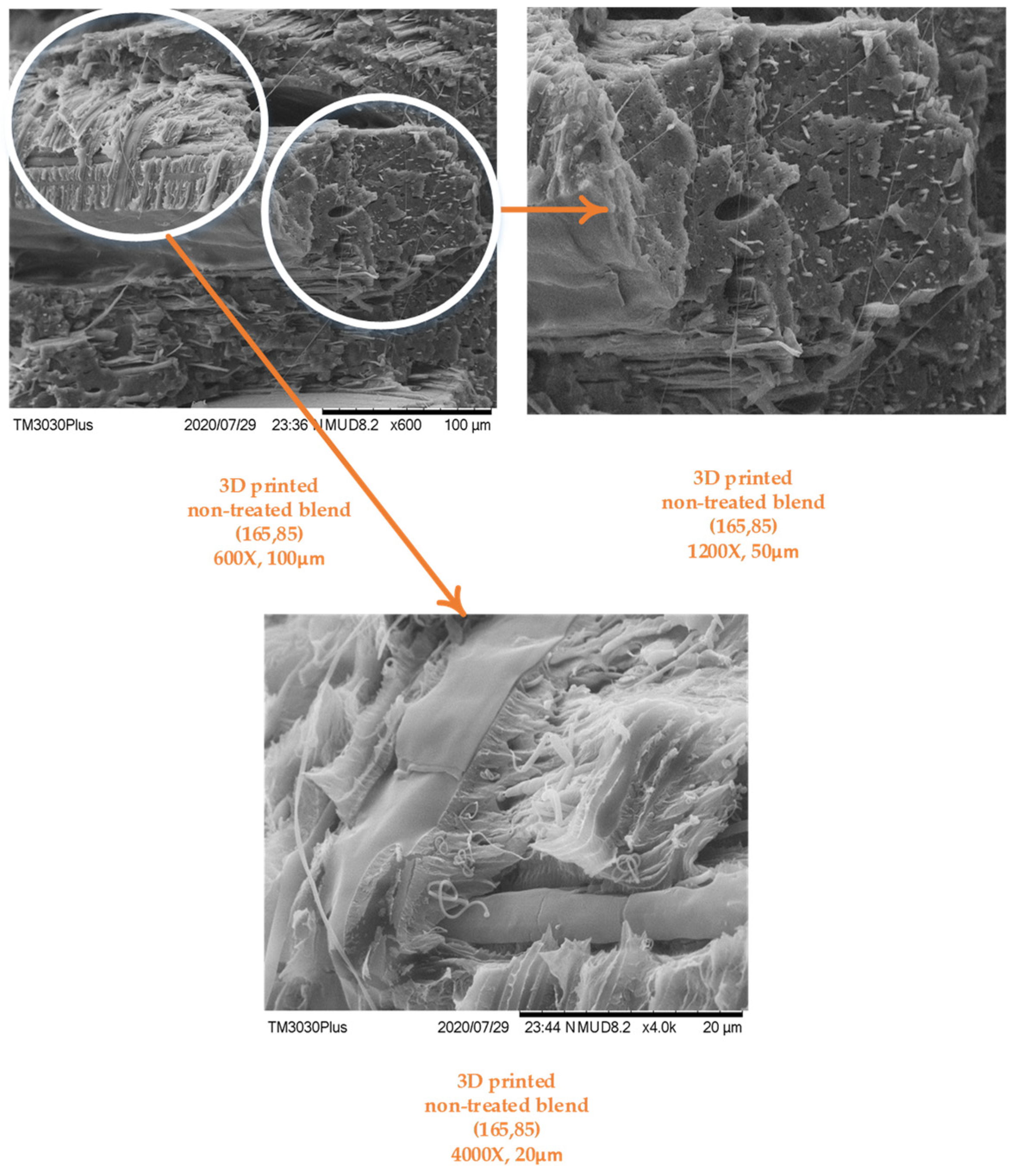

4.1. Microscopic Analysis of Melt Blending

4.2. Analysis for Intermolecular Interactions

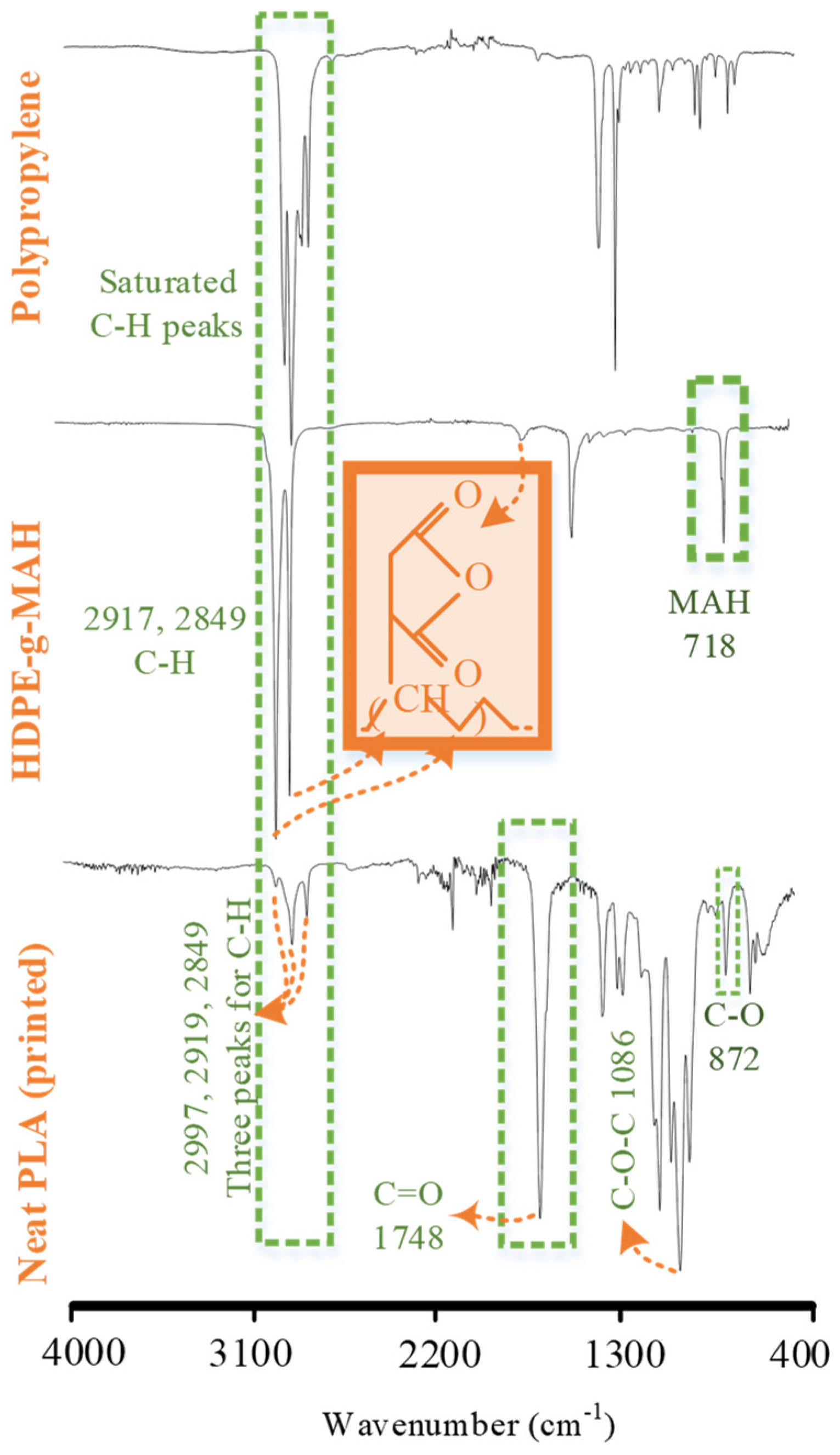

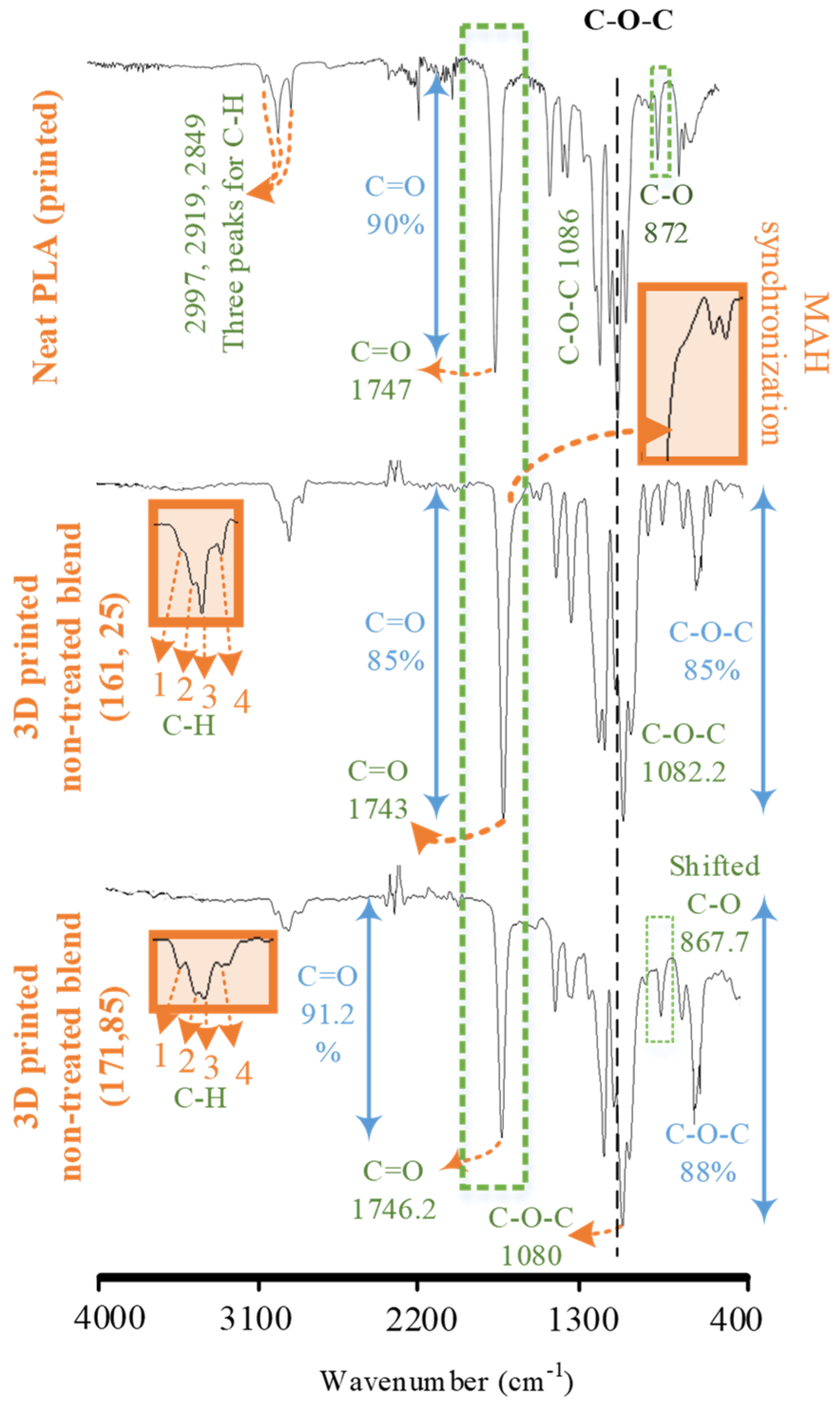

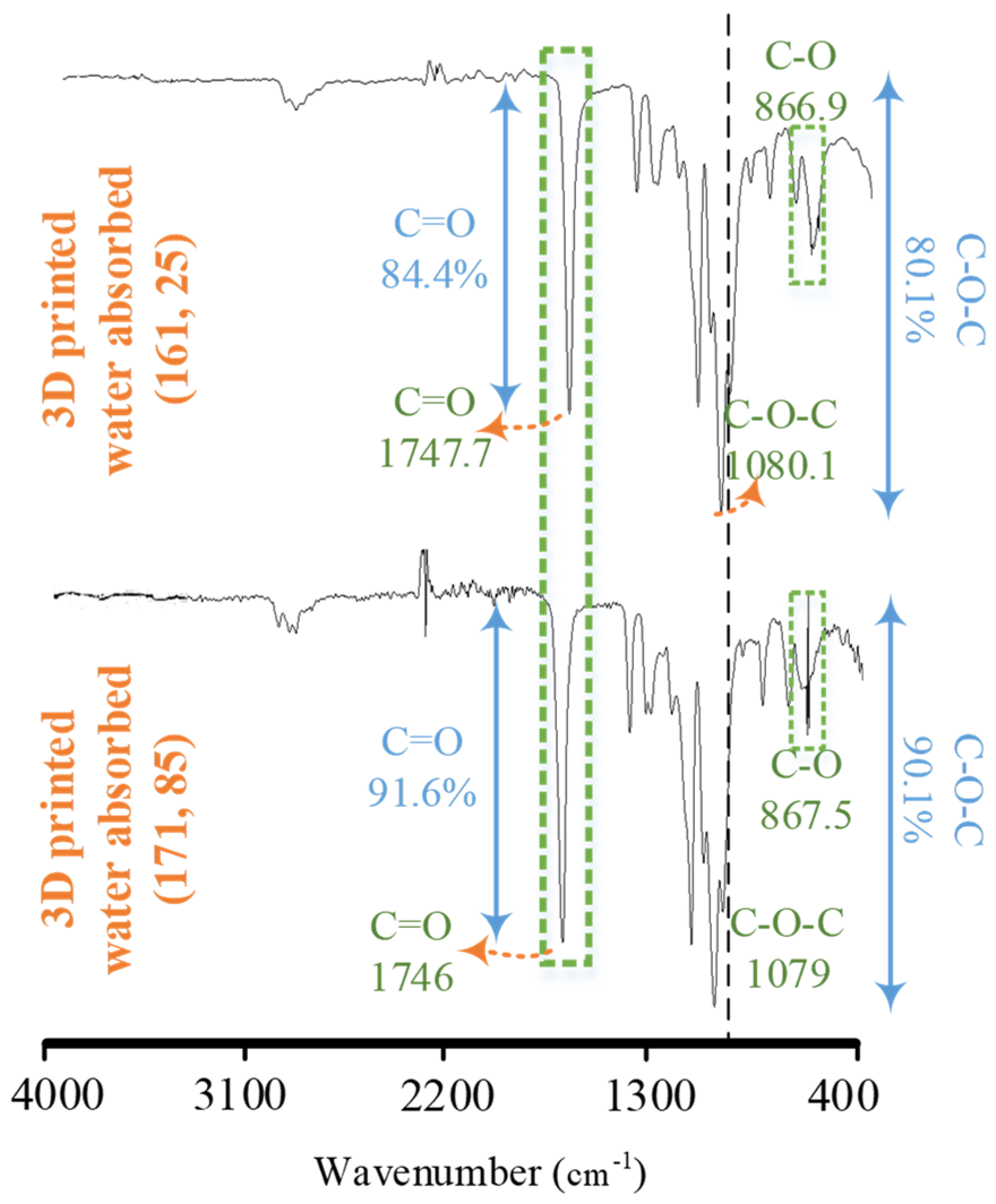

4.3. Analysis for Nature of Blending and Effects of Degradation Mechanisms

4.4. Measurement of Interlocking and Chemical Grafting

5. Conclusions

- The in-process thermal variables during 3D printing for the non-treated blend significantly affected the overall tensile properties, i.e., 32.5 MPa to 44.9 MPa.

- Different types of thermochemical characterizations proved the partial blending with minimum grafting and excessive physical interlocking. For example, FTIR showed that the distinct fourth peak of C-H groups associated with PP in the blend’s spectrum. DSC revealed the phase separation in the melt crystallization thermal profile of PP in the PLA thermograph. TGA showed a distinct two-step degradation profile, with PP as the second step (6.3% to 6.7%).

- The novel blend showed statistically high stability against moisture degradation.

- After being treated with 45 days of water absorption, the ANOVA provided the printing temperature as a significant variable, followed by moisture treatment. However, instead of a decrease, the tensile strength increased after water absorption treatment.

- The FTIR of moisture-degraded samples revealed the scission of chemical chains at the C-O-C bond. This chemical degradation was ound in DSC in the form of ΔHM and ΔHD, and also in TGA as a decrease of onset temperatures.

- The study did not cover the hydrolytic degradation as a function of series of time. Instead, the moisture-based degradation was reported for a single duration of 45 days. Therefore, the complete potential of the blend is proposed for future research.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chaudhari, V.S.; Malakar, T.K.; Murty, U.S.; Banerjee, S. Extruded filaments derived 3D printed medicated skin patch to mitigate destructive pulmonary tuberculosis: Design to delivery. Expert Opin. Drug Deliv. 2021, 18, 301–313. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Q.; Zhang, M.; Mujumdar, A.S. Novel evaluation technology for the demand characteristics of 3D food printing materials: A review. Crit. Rev. Food Sci. Nutr. 2021, 1, 1–16. [Google Scholar] [CrossRef] [PubMed]

- Bhayana, M.; Singh, J.; Singh, B.; Singh, J. Investigation of Fused Deposition Modeling (FDM) Process Parameters Influencing the Additively Manufactured Part Characteristics: A Review Paper. Recent Trends Ind. Prod. Eng. 2022, 1, 109–118. [Google Scholar] [CrossRef]

- Duty, C.E.; Kunc, V.; Compton, B.; Post, B.; Erdman, D.; Smith, R.; Lind, R.; Lloyd, P.; Love, L. Structure and mechanical behavior of Big Area Additive Manufacturing (BAAM) materials. Rapid Prototyp. J. 2017, 23, 1355–2546. [Google Scholar] [CrossRef]

- Greer, C.; Nycz, A.; Noakes, M.; Richardson, B.; Post, B.; Kurfess, T.; Love, L. Introduction to the design rules for metal big area additive manufacturing. Addit. Manuf. 2019, 27, 159–166. [Google Scholar] [CrossRef]

- Post, B.K.; Chesser, P.C.; Lind, R.F.; Roschli, A.; Love, L.J.; Gaul, K.T.; Sallas, M.; Blue, F.; Wu, S. Using Big Area Additive Manufacturing to directly manufacture a boat hull mould. Virtual Phys. Prototyp. 2019, 14, 123–129. [Google Scholar] [CrossRef]

- Salifu, S.; Desai, D.; Ogunbiyi, O.; Mwale, K. Recent development in the additive manufacturing of polymer-based composites for automotive structures—A review. Int. J. Adv. Manuf. Technol. 2022, 119, 6877–6891. [Google Scholar] [CrossRef]

- Chesser, P.; Post, B.; Roschli, A.; Carnal, C.; Lind, R.; Borish, M.; Love, L. Extrusion control for high quality printing on Big Area Additive Manufacturing (BAAM) systems. Addit. Manuf. 2019, 28, 445–455. [Google Scholar] [CrossRef]

- Blanco, I. The use of composite materials in 3D printing. J. Compos. Sci. 2020, 4, 42. [Google Scholar] [CrossRef] [Green Version]

- Jamshidian, M.; Tehrany, E.A.; Imran, M.; Jacquot, M.; Desobry, S. Poly-lactic acid: Production, applications, nanocomposites, and release studies. Compr. Rev. Food Sci. Food Saf. 2010, 9, 552–571. [Google Scholar] [CrossRef]

- Cicala, G.; Giordano, D.; Tosto, C.; Filippone, G.; Recca, A.; Blanco, I. Polylactide (PLA) filaments a biobased solution for additive manufacturing: Correlating rheology and thermomechanical properties with printing quality. Materials 2018, 11, 1191. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Harris, M.; Potgieter, J.; Archer, R.; Arif, K.M. In-process thermal treatment of polylactic acid in fused deposition modelling. Mater. Manuf. Process. 2019, 34, 701–713. [Google Scholar] [CrossRef]

- Harris, M.; Potgieter, J.; Ray, S.; Archer, R.; Arif, K.M. Polylactic acid and high-density polyethylene blend: Characterization and application in additive manufacturing. J. Appl. Polym. Sci. 2020, 137, 49602. [Google Scholar] [CrossRef]

- Nwabunma, D.; Kyu, T. Polyolefin Blends, 1st ed.; John Wiley & Sons: Hoboken, NJ, USA, 2008. [Google Scholar] [CrossRef]

- Rasselet, D.; Caro-Bretelle, A.-S.; Taguet, A.; Lopez-Cuesta, J.-M. Reactive Compatibilization of PLA/PA11 Blends and Their Application in Additive Manufacturing. Materials 2019, 12, 485. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Long, H.; Wu, Z.; Dong, Q.; Shen, Y.; Zhou, W.; Luo, Y.; Zhang, C.; Dong, X. Mechanical and thermal properties of bamboo fiber reinforced polypropylene/polylactic acid composites for 3D printing. Polym. Eng. Sci. 2019, 59, E247–E260. [Google Scholar] [CrossRef]

- Yoo, T.W.; Yoon, H.G.; Choi, S.J.; Kim, M.S.; Kim, Y.H.; Kim, W.N. Effects of compatibilizers on the mechanical properties and interfacial tension of polypropylene and poly (lactic acid) blends. Macromol. Res. 2010, 18, 583–588. [Google Scholar] [CrossRef]

- Lee, H.S.; Kim, J.D. Effect of a hybrid compatibilizer on the mechanical properties and interfacial tension of a ternary blend with polypropylene, poly (lactic acid), and a toughening modifier. Polym. Compos. 2012, 33, 1154–1161. [Google Scholar] [CrossRef]

- Hamad, K.; Kaseem, M.; Deri, F. Rheological and mechanical characterization of poly (lactic acid)/polypropylene polymer blends. J. Polym. Res. 2011, 18, 1799–1806. [Google Scholar] [CrossRef]

- Harris, M.; Potgieter, J.; Mohsin, H.; Chen, J.Q.; Ray, S.; Arif, K.M. Partial Polymer Blend for Fused Filament Fabrication with High Thermal Stability. Polymers 2021, 13, 3353. [Google Scholar] [CrossRef]

- Reddy, N.; Nama, D.; Yang, Y. Polylactic acid/polypropylene polyblend fibers for better resistance to degradation. Polym. Degrad. Stab. 2008, 93, 233–241. [Google Scholar] [CrossRef]

- Abay, A.K.; Gebeyehu, M.B.; Lin, H.K.; Lin, P.C.; Lee, J.-Y.; Wu, C.-M.; Murakami, R.-I.; Chiang, T.-C. Preparation and characterization of poly (lactic acid)/recycled polypropylene blends with and without the coupling agent, n-(6-aminohexyl) aminomethyltriethoxysilane. J. Polym. Res. 2016, 23, 1–12. [Google Scholar] [CrossRef]

- Kang, H.; Lu, X.; Xu, Y. Properties of immiscible and ethylene-butyl acrylate-glycidyl methacrylate terpolymer compatibilized poly (lactic acid) and polypropylene blends. Polym. Test. 2015, 43, 173–181. [Google Scholar] [CrossRef]

- Bai, Z.-f.; Dou, Q. Non-isothermal crystallization kinetics of polypropylene/poly (lactic acid)/maleic anhydride-grafted polypropylene blends. J. Therm. Anal. Calorim. 2016, 126, 785–794. [Google Scholar] [CrossRef]

- Rajan, K.P.; Thomas, S.P.; Gopanna, A.; Al-Ghamdi, A.; Chavali, M. Rheology, mechanical properties and thermal degradation kinetics of polypropylene (PP) and polylactic acid (PLA) blends. Mater. Res. Express 2018, 5, 085304. [Google Scholar] [CrossRef]

- Zawawi, E.; Hafizah, A.N.; Romli, A.; Yuliana, N.; Bonnia, N. Effect of nanoclay on mechanical and morphological properties of poly (lactide) acid (PLA) and polypropylene (PP) blends. Mater. Today Proc. 2021, 46, 1778–1782. [Google Scholar] [CrossRef]

- Kelly, A.L.; Brown, E.C.; Coates, P.D. The effect of screw geometry on melt temperature profile in single screw extrusion. Polym. Eng. Sci. 2006, 46, 1706–1714. [Google Scholar] [CrossRef]

- Harris, M.; Potgieter, J.; Ray, S.; Archer, R.; Arif, K.M. Acrylonitrile Butadiene Styrene and Polypropylene Blend with Enhanced Thermal and Mechanical Properties for Fused Filament Fabrication. Materials 2019, 12, 4167. [Google Scholar] [CrossRef] [Green Version]

- Vrsaljko, D.; Macut, D.; Kovačević, V. Potential role of nanofillers as compatibilizers in immiscible PLA/LDPE Blends. J. Appl. Polym. Sci. 2015, 132., 41414. [Google Scholar] [CrossRef]

- Kumar, K.A.; Soundararajan, S. Studies on Mechanical, Barrier, Optical and Physical Properties of LDPE/PLA Blend for Packaging Films. J. Polym. Mater. 2016, 33, 491–502. [Google Scholar]

- Hwang, K.-J.; Park, J.-W.; Kim, I.; Ha, C.-S.; Kim, G.-H. Effect of a compatibilizer on the microstructure and properties of partially biodegradable LDPE/aliphatic polyester/organoclay nanocomposites. Macromol. Res. 2006, 14, 179–186. [Google Scholar] [CrossRef]

- Yu, G.; Ji, J.; Zhu, H.; Shen, J. Poly (D, L-lactic acid)-block-(ligand-tethered poly (ethylene glycol)) copolymers as surface additives for promoting chondrocyte attachment and growth. J. Biomed. Mater. Res. B. 2006, 76, 64–75. [Google Scholar] [CrossRef] [PubMed]

- Supri, A.G.; Ismail, H.; Shuhadah, S. Effect of polyethylene-grafted maleic anhydride (PE-g-MAH) on properties of low density polyethylene/eggshell powder (LDPE/ESP) composites. Polym. Plast. Technol. Eng. 2010, 49, 347–353. [Google Scholar] [CrossRef]

- Whyman, S.; Arif, K.M.; Potgieter, J. Design and development of an extrusion system for 3D printing biopolymer pellets. Int. J. Adv. Manuf. Technol. 2018, 96, 3417–3428. [Google Scholar] [CrossRef]

- Wallis, M.D.; Bhatia, S.K. Thermal degradation of high density polyethylene in a reactive extruder. Polym. Degrad. Stab. 2007, 92, 1721–1729. [Google Scholar] [CrossRef]

- Harris, M.; Potgieter, J.; Archer, R.; Arif, K.M. Effect of Material and Process Specific Factors on the Strength of Printed Parts in Fused Filament Fabrication: A Review of Recent Developments. Materials 2019, 12, 1664. [Google Scholar] [CrossRef] [Green Version]

- ASTM International. D638-10. In Standard Test Methods for Tensile Properties of Plastics; ASTM International: West Conshohocken, PA, USA, 2010. [Google Scholar]

- Wu, C.S.; Liao, H.T.; Cai, Y.X. Characterisation, biodegradability and application of palm fibre-reinforced polyhydroxyalkanoate composites. Polym. Degrad. Stab. 2017, 140, 55–63. [Google Scholar] [CrossRef]

- Codou, A.; Anstey, A.; Misra, M.; Mohanty, A.K. Novel compatibilized nylon-based ternary blends with polypropylene and poly (lactic acid): Morphology evolution and rheological behaviour. RSC Adv. 2018, 8, 15709–15724. [Google Scholar] [CrossRef] [Green Version]

- Ma, P.; Jiang, L.; Ye, T.; Dong, W.; Chen, M. Melt free-radical grafting of maleic anhydride onto biodegradable poly (lactic acid) by using styrene as a comonomer. Polymers 2014, 6, 1528–1543. [Google Scholar] [CrossRef] [Green Version]

- Birnin-Yauri, A.U.; Ibrahim, N.A.; Zainuddin, N.; Abdan, K.; Then, Y.Y.; Chieng, B.W. Effect of maleic anhydride-modified poly (lactic acid) on the properties of its hybrid fiber biocomposites. Polymers 2017, 9, 165. [Google Scholar] [CrossRef] [Green Version]

- Morent, R.; De Geyter, N.; Leys, C.; Gengembre, L.; Payen, E. Comparison between XPS-and FTIR-analysis of plasma-treated polypropylene film surfaces: An International Journal devoted to the development and application of techniques for the analysis of surfaces, interfaces and thin films. Surf. Interface Anal. 2008, 40, 597–600. [Google Scholar] [CrossRef]

- Coates, J. Interpretation of infrared spectra, a practical approach. In Encyclopedia of Analytical Chemistry; Meyers, R.A., Ed.; John Wiley & Sons Ltd.: Chichester, UK, 2000; pp. 10815–10837. [Google Scholar]

- Gajria, A.M.; Dave, V.; Gross, R.A.; McCarthy, S.P. Miscibility and biodegradability of blends of poly (lactic acid) and poly (vinyl acetate). Polymer 1996, 37, 437–444. [Google Scholar] [CrossRef]

- Mourad, A.-H.; Akkad, R.O.; Soliman, A.; Madkour, T. Characterisation of thermally treated and untreated polyethylene–polypropylene blends using DSC, TGA and IR techniques. Plast. Rubber Compos. 2009, 38, 265–278. [Google Scholar] [CrossRef]

| Blend | PLA | PP | HDPE-g-MAH |

|---|---|---|---|

| 1 | 75 | 20 | 5 |

| 2 | 92 | 7.5 | 0.5 |

| Parameter | Set Value |

|---|---|

| Layer thickness | 0.2 mm [35] |

| Extrusion width | 0.3 mm |

| Multiplier | 5 |

| Nozzle diameter | 0.4 mm [12] |

| Printing speed | 15 m/min |

| Bed temperature | 25 °C, 55 °C, 85 °C |

| Printing temperature | 161 °C, 166 °C, 171 °C |

| Infill density | 100% [35] |

| Infill pattern | 45°/−45° [35] |

| Factor (Parameter) | Level 1 | Level 2 | Level 3 |

|---|---|---|---|

| Bed temperature (°C) | 25 | 55 | 85 |

| Printing temperature (°C) | 161 | 166 | 171 |

| Moisture absorption (Days) | 0 | 45 |

| RunOrder | PtType | Blocks | Bed Temperature | Printing Temperature | Moisture Treatment | Tensile Strength |

|---|---|---|---|---|---|---|

| 1 | 1 | 1 | 25 | 171 | Treated | 43.00672 |

| 2 | 1 | 1 | 55 | 171 | Non-treated | 40.01403 |

| 3 | 1 | 1 | 55 | 166 | Non-treated | 37.71559 |

| 4 | 1 | 1 | 25 | 166 | Non-treated | 36.12446 |

| 5 | 1 | 1 | 85 | 166 | Treated | 40.15167 |

| 6 | 1 | 1 | 85 | 171 | Non-treated | 43.10712 |

| 7 | 1 | 1 | 55 | 171 | Treated | 46.4119 |

| 8 | 1 | 1 | 25 | 161 | Treated | 39.565995 |

| 9 | 1 | 1 | 25 | 171 | Non-treated | 43.37669 |

| 10 | 1 | 1 | 55 | 166 | Treated | 44.06397 |

| 11 | 1 | 1 | 25 | 166 | Treated | 37.79949 |

| 12 | 1 | 1 | 85 | 161 | Treated | 43 |

| 13 | 1 | 1 | 55 | 161 | Treated | 44.06397 |

| 14 | 1 | 1 | 55 | 161 | Non-treated | 42.99 |

| 15 | 1 | 1 | 85 | 171 | Treated | 50.3 |

| 16 | 1 | 1 | 85 | 161 | Non-treated | 44.9 |

| 17 | 1 | 1 | 25 | 161 | Non-treated | 38.92701 |

| 18 | 1 | 1 | 85 | 166 | Non-treated | 32.49289 |

| Material | Saturated C-H | C=O | CH2 and CH3 Bending Vibrations | Aromatic Styrene Ring | C-O-H | C-O-C | C-O | C-H | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| WN | I | WN | I | WN | I | WN | I | WN | I | WN | I | WN | I | WN | I | |

| Neat PLA | 2997 2919 2849 | 1747 | 90 | 1185 | 1086 | 872 | 729 755 | |||||||||

| Water absorption blend (161, 25) | 2993 2950 2919 2873 2838 | 97.7 97.3 97.6 98.1 98.2 | 1747.7 | 84.4 | 1451.2 | 93.8 | 1182.3 | 84.7 | 1080.1 | 80.1 | 866.9 | 93.5 | 675.6 750.3 | 91.4 93.3 | ||

| Water absorption blend (171, 85) | 2994 2949.8 2919 2849 | 98.7 98.6 98.6 99.1 | 1746 | 91.6 | 1451.2 | 96.3 | 1180.6 | 91.5 | 1079 | 90.1 | 867.5 | 96.9 | 664 754.5 | 96.4 96.9 | ||

| Material | Onset Temperature °C | End Temperature °C | First Mass Loss % (MA) | Second Mass Loss % (MB) | Total Mass Loss in Two Steps % (MT = MA + MB) | Mass Remained (100%-MT) % |

|---|---|---|---|---|---|---|

| PLA | 351 | 393 | 96.73 | 0 | 96.73 | 3.27 |

| Pellets | 348 | 380 | 90.24 | 6.7 | 96.97 | 3.03 |

| Moisture (161 °C, 25 °C) | 329.4 | 370.4 | 90.62 | 6.26 | 96.88 | 3.12 |

| Moisture (171 °C, 85 °C) | 335.3 | 374.9 | 89.78 | 6.65 | 96.43 | 3.57 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Harris, M.; Mohsin, H.; Naveed, R.; Potgieter, J.; Ishfaq, K.; Ray, S.; Guen, M.-J.L.; Archer, R.; Arif, K.M. Partial Biodegradable Blend for Fused Filament Fabrication: In-Process Thermal and Post-Printing Moisture Resistance. Polymers 2022, 14, 1527. https://doi.org/10.3390/polym14081527

Harris M, Mohsin H, Naveed R, Potgieter J, Ishfaq K, Ray S, Guen M-JL, Archer R, Arif KM. Partial Biodegradable Blend for Fused Filament Fabrication: In-Process Thermal and Post-Printing Moisture Resistance. Polymers. 2022; 14(8):1527. https://doi.org/10.3390/polym14081527

Chicago/Turabian StyleHarris, Muhammad, Hammad Mohsin, Rakhshanda Naveed, Johan Potgieter, Kashif Ishfaq, Sudip Ray, Marie-Joo Le Guen, Richard Archer, and Khalid Mahmood Arif. 2022. "Partial Biodegradable Blend for Fused Filament Fabrication: In-Process Thermal and Post-Printing Moisture Resistance" Polymers 14, no. 8: 1527. https://doi.org/10.3390/polym14081527

APA StyleHarris, M., Mohsin, H., Naveed, R., Potgieter, J., Ishfaq, K., Ray, S., Guen, M.-J. L., Archer, R., & Arif, K. M. (2022). Partial Biodegradable Blend for Fused Filament Fabrication: In-Process Thermal and Post-Printing Moisture Resistance. Polymers, 14(8), 1527. https://doi.org/10.3390/polym14081527