Investigation of the Warpage of a High-Density Polyethylene Pallet by Plastic Injection Compression Molding: Part I—Numerical Approach

Abstract

:1. Introduction

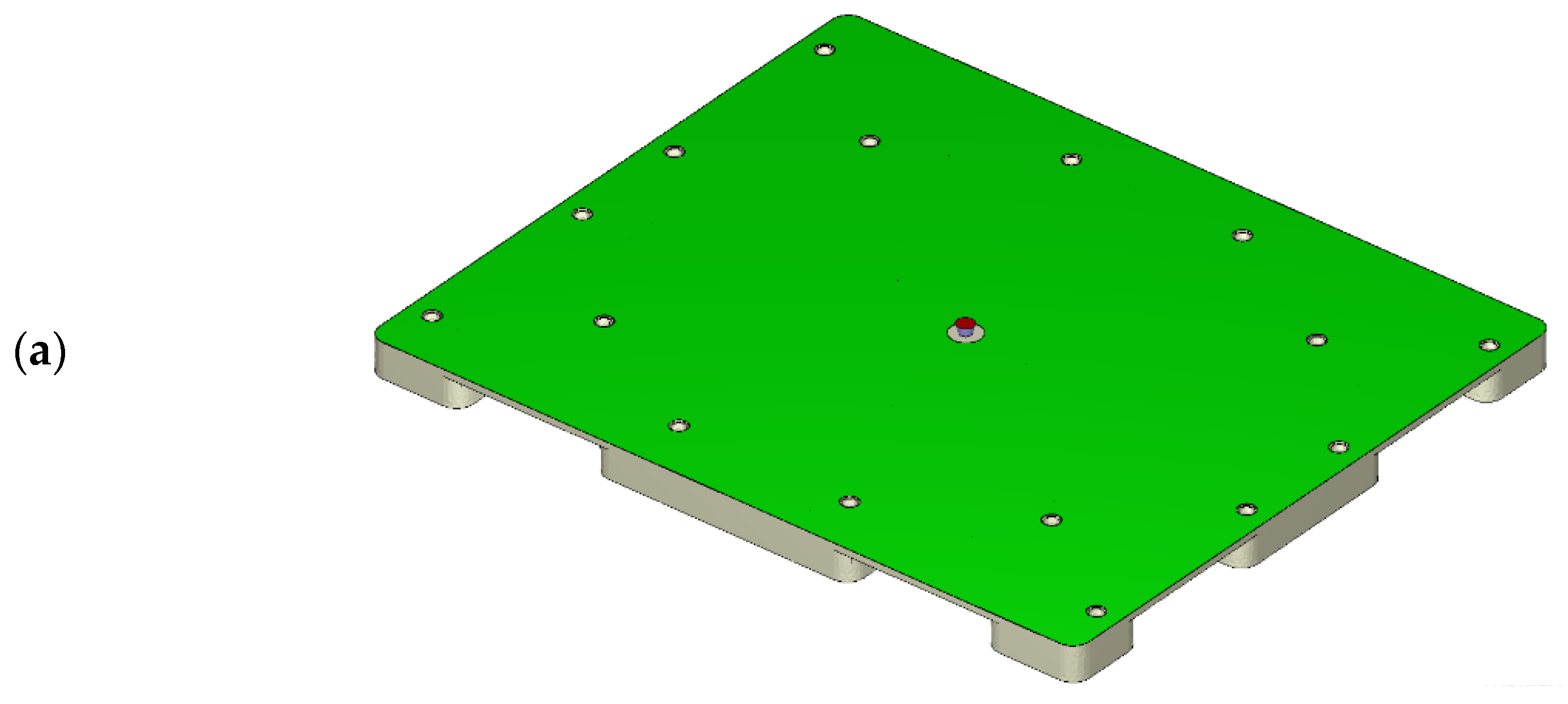

2. Materials and Methods

3. Results and Discussion

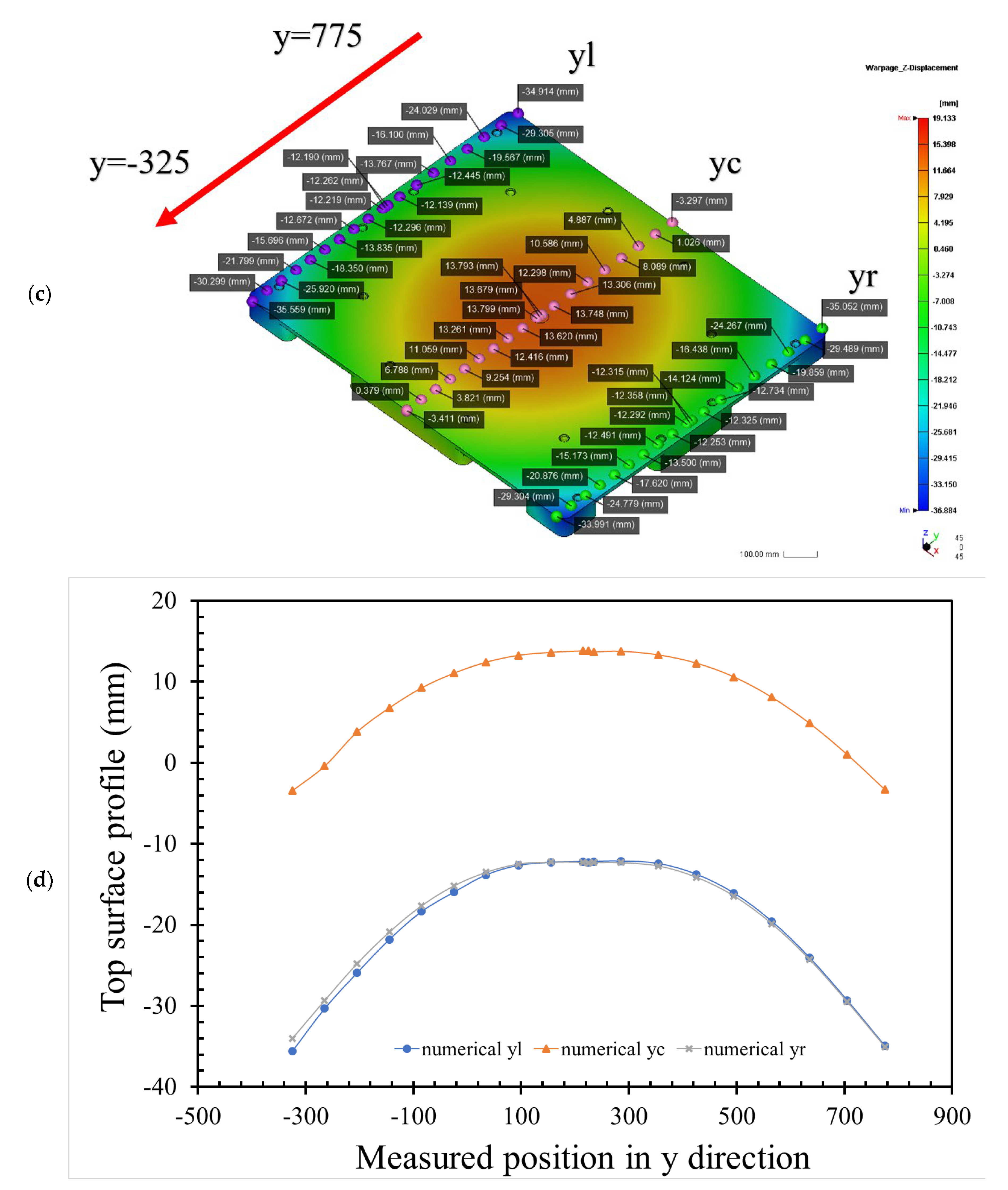

3.1. Molten HDPE Spreading during Filling and Compression

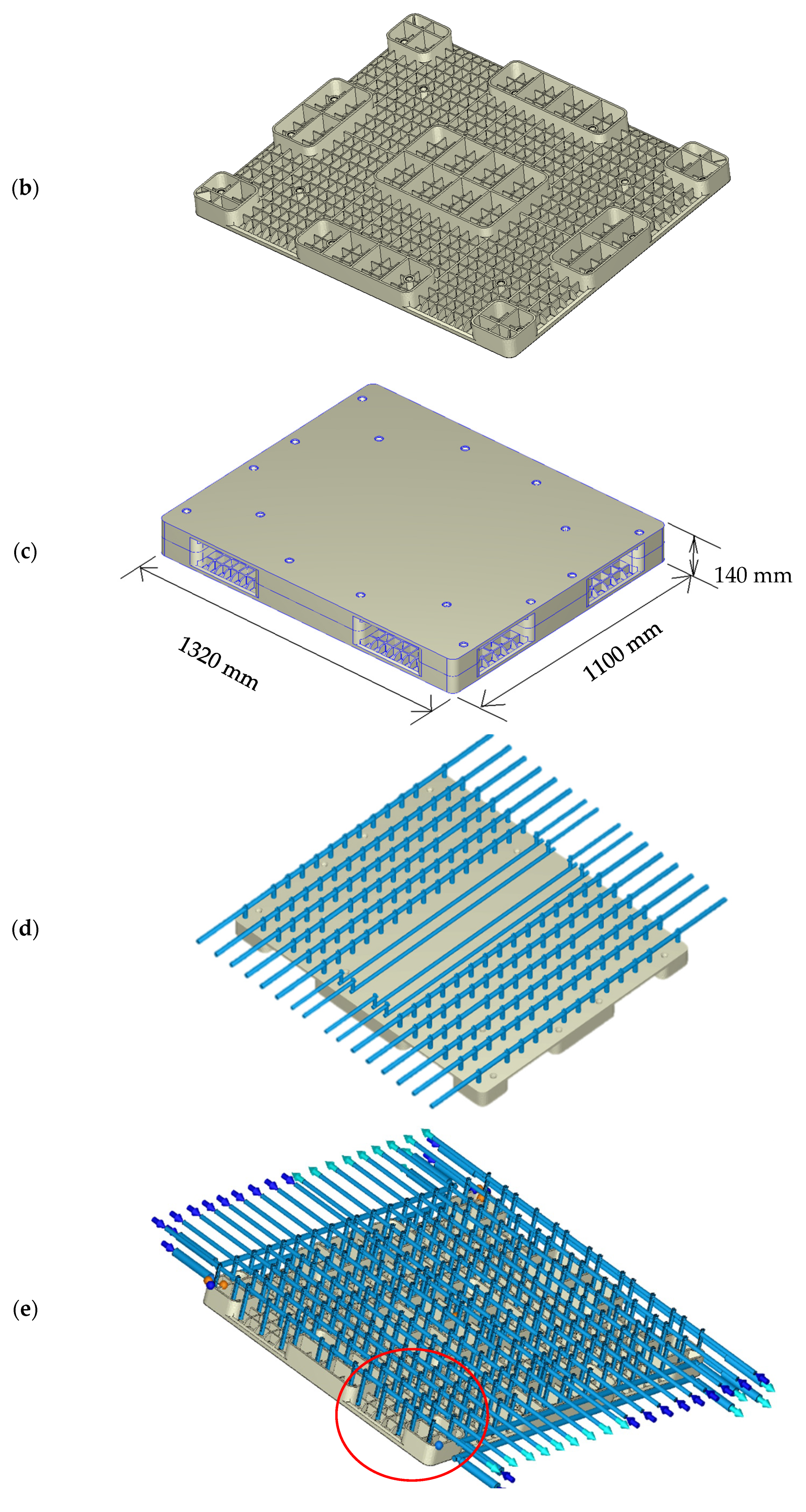

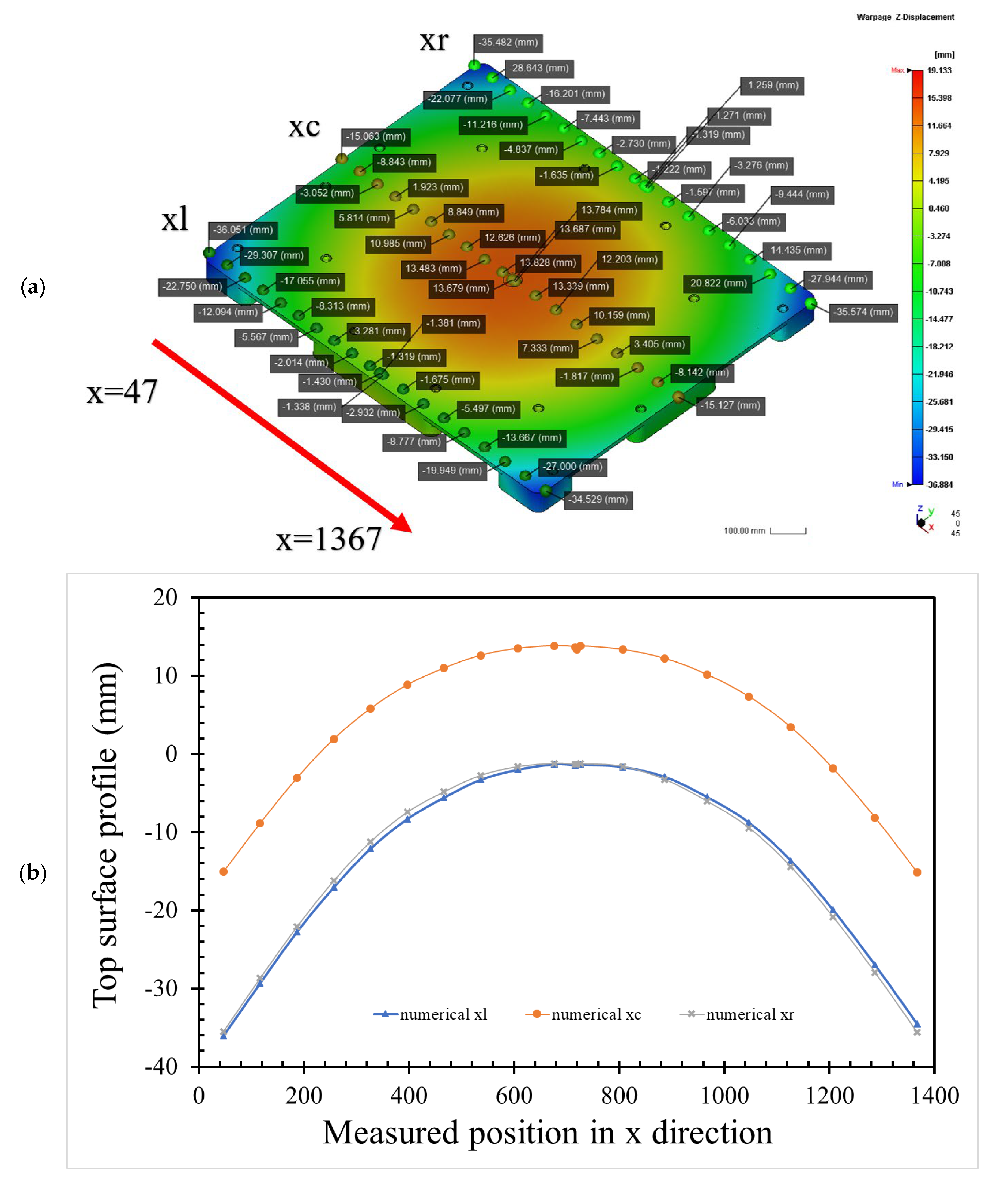

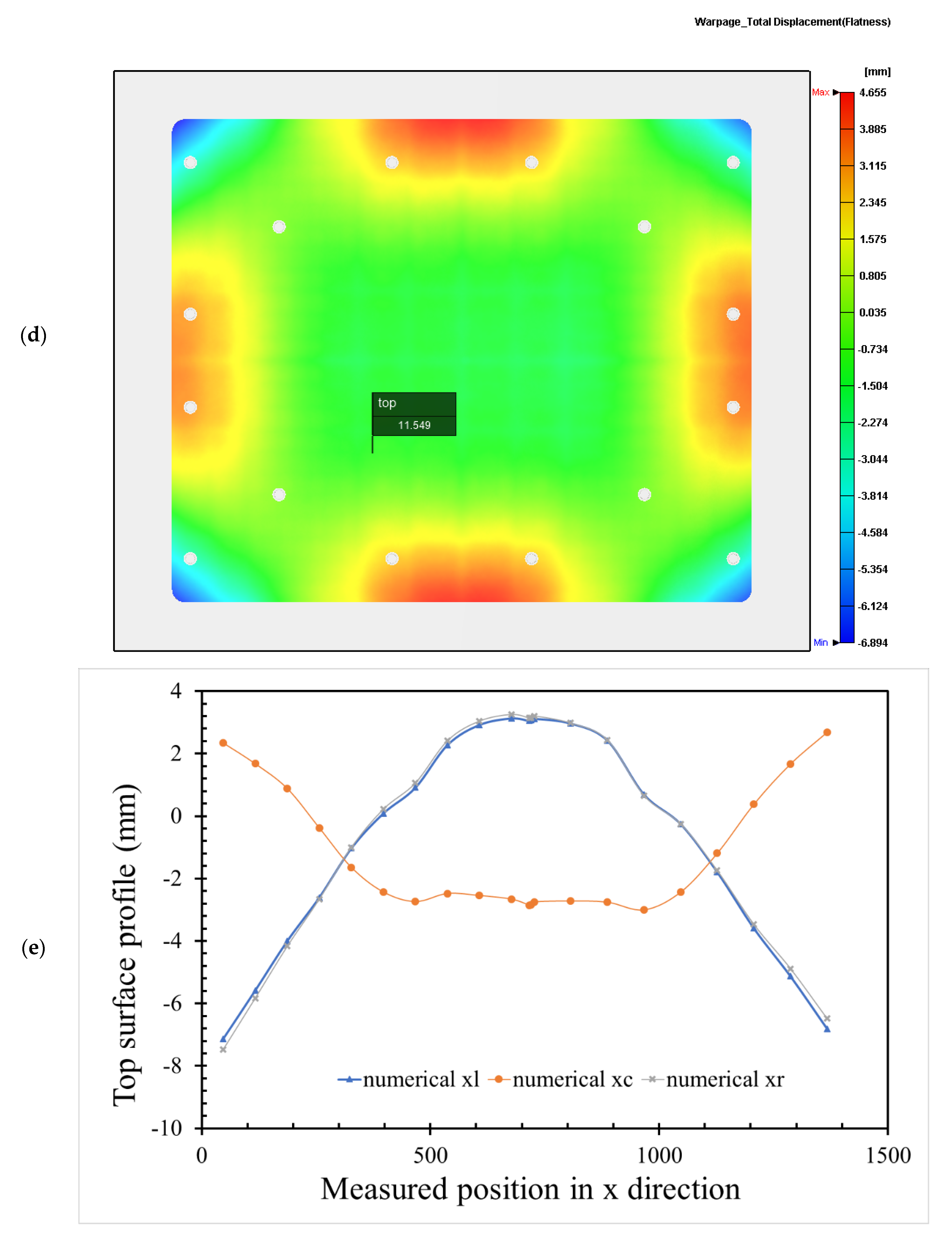

3.2. Pallet Profiles by Pre-Setting Molding Parameters

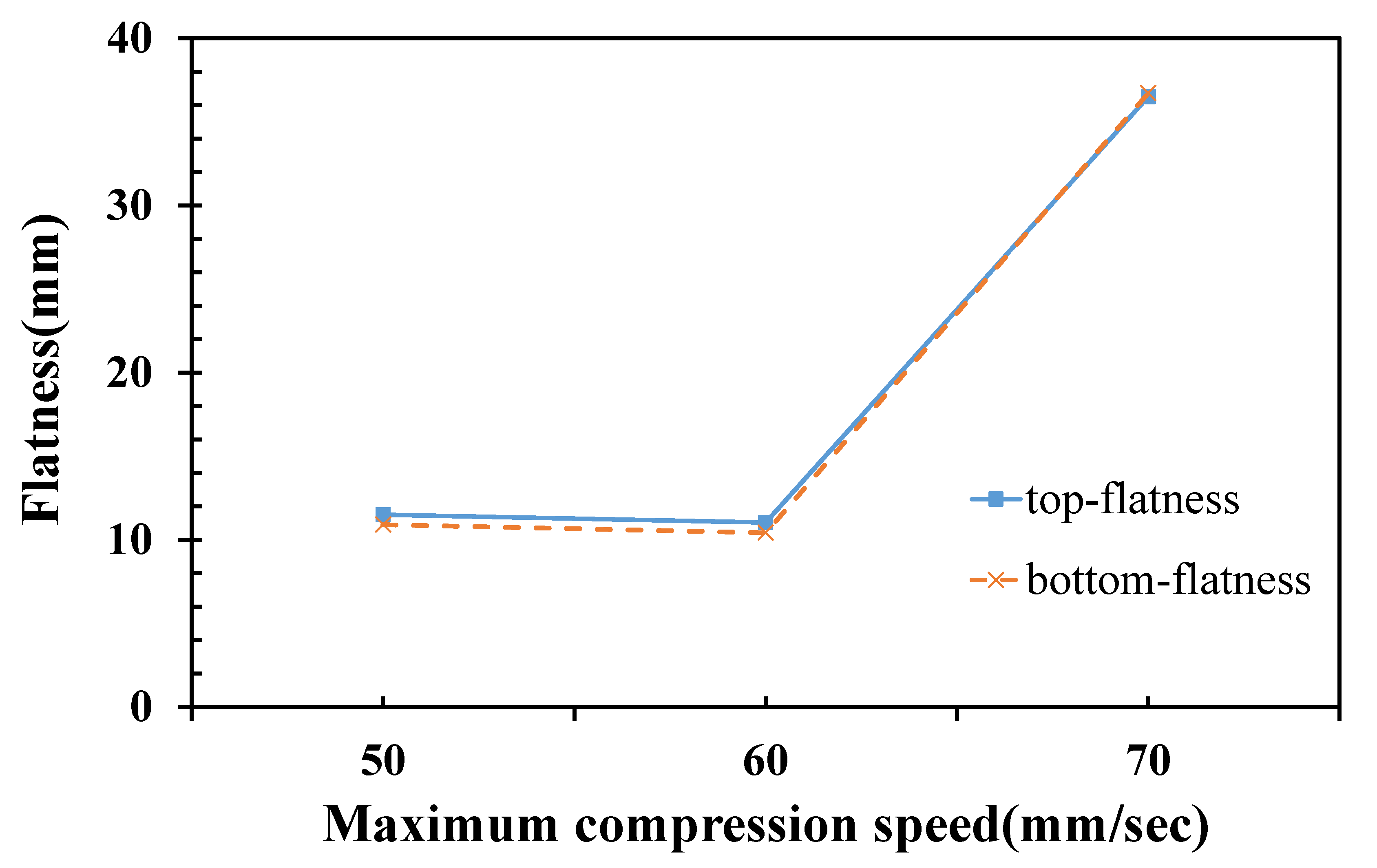

3.3. Proposed ICM Parameters for Lowering the Pallet’s Flatness

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- SFS-EN ISO 445 Pallets for Materials Handling. Vocabulary. 2013. Available online: https://www.iso.org/standard/61915.html (accessed on 15 February 2022).

- Deviatkin, I.; Khan, M.; Ernst, E.; Horttanainen, M. Wooden and Plastic Pallets: A Review of Life Cycle Assessment (LCA) Studies. Sustainability 2019, 11, 5750. [Google Scholar] [CrossRef] [Green Version]

- Gahleitner, M.; Tranninger, C.; Doshev, P. Polypropylene copolymers. In Polypropylene Handbook: Morphology, Blends and Composites; Karger-Kocsis, J., Ed.; Springer International: Berlin, Germany, 2019. [Google Scholar]

- Yilmaz, G.; Ellingham, T.; Turng, L.S. Improved Processability and the Processing-Structure-Properties Relationship of Ultra-High Molecular Weight Polyethylene via Supercritical Nitrogen and Carbon Dioxide in Injection Molding. Polymers 2018, 10, 36. [Google Scholar] [CrossRef] [Green Version]

- Xu, M.M.; Huang, G.Y.; Feng, S.S.; McShane, G.J.; Stronge, W.J. Static and dynamic properties of semi-crystalline polyethylene. Polymers 2016, 8, 77. [Google Scholar] [CrossRef]

- Mejia, E.; Cherupurakal, N.; Mourad, A.-H.I.; Al Hassanieh, S.; Rabia, M. Effect of Processing Techniques on the Microstructure and Mechanical Performance of High-Density Polyethylene. Polymers 2021, 13, 3346. [Google Scholar] [CrossRef]

- Amjadi, M.; Fatemi, A. Tensile Behavior of High-Density Polyethylene Including the Effects of Processing Technique, Thickness, Temperature, and Strain Rate. Polymers 2020, 12, 1857. [Google Scholar] [CrossRef]

- Huang, C.T.; Chen, L.J.; Chien, T.Y. Investigation of the Viscoelastic Behavior Variation of Glass Mat Thermoplastics (GMT) in Compression Molding. Polymers 2019, 11, 335. [Google Scholar] [CrossRef] [Green Version]

- Stokes, V.K. Experiments on the hot-tool welding of three dissimilar thermoplastics. Polymer 1998, 39, 2469–2477. [Google Scholar] [CrossRef]

- Asséko, A.C.A.; Cosson, B.; Schmidt, F.; Maoult, Y.L.; Lafranche, E. Laser transmission welding of composites-Part A: Thermo-physical and optical characterization of materials. Infrared Phys. Technol. 2015, 72, 293–299. [Google Scholar] [CrossRef] [Green Version]

- Huang, M.-C.; Tai, C.C. The effective factors in the warpage problem of an injection-molded part with a thin shell feature. J. Mater. Process. Technol. 2001, 110, 1–9. [Google Scholar] [CrossRef]

- Wang, C.; Huang, M.; Shen, C.; Zhao, Z. Warpage prediction of the injection-molded strip-like plastic parts. Chin. J. Chem. Eng. 2016, 24, 665–670. [Google Scholar] [CrossRef]

- Cheng, C.D.; Tsai, H.H.; Liao, Y.L. Investigation of the Large-Scale Pallet by Recycled Polypropylene and the Sequential Valve Gate System during the Injection Molding. Adv. Polymer Technol. 2021, 19, 6692133. [Google Scholar] [CrossRef]

- Liparoti, S.; Speranza, V.; Sorrentino, A.; Titomanlio, G. Mechanical Properties Distribution within Polypropylene Injection Molded Samples: Effect of Mold Temperature under Uneven Thermal Conditions. Polymers 2017, 9, 585. [Google Scholar] [CrossRef] [Green Version]

- Liparoti, S.; Speranza, V.; Titomanlio, G.; Pantani, R. Effect of Rapid Mold Heating on the Structure and Performance of Injection-Molded Polypropylene. Polymers 2020, 12, 341. [Google Scholar] [CrossRef] [Green Version]

- Park, K.; Kim, Y.S. Effect of Mold Temperature on Mechanical Properties of an Injection-Molded Part with Microfeatures. J. Polym. Eng. 2009, 29, 135–154. [Google Scholar] [CrossRef]

- Fan, B.F.; Kazmer, D.O.; Bushko, W.C.; Theriault, R.P.; Poslinski, A.J. Warpage prediction of optical media. J. Polym. Sci. Part B 2003, 41, 859–872. [Google Scholar] [CrossRef]

- Chen, S.C.; Chen, Y.C.; Peng, H.S. Simulation of injection compression molding process. II. Influence of process characteristics on part shrinkage. J. Appl. Polym. Sci. 2000, 75, 1640–1654. [Google Scholar] [CrossRef]

- Lee, S.H.; Kim, S.Y.; Youn, J.R.; Kim, B.J. Warpage of a large-sized orthogonal stiffened plate produced by injection molding and injection compression molding. J. Appl. Polym. Sci. 2010, 116, 3460–3467. [Google Scholar] [CrossRef]

- Ho, J.Y.; Park, J.M.; Kang, T.G.; Park, S.J. Three-dimensional numerical analysis of injection compression molding process. Polym. Eng. Sci. 2012, 52, 901–911. [Google Scholar] [CrossRef]

- Cao, W.; Min, Z.Y.; Zhang, S.X.; Wang, T.; Jiang, J.; Li, H.M.; Wang, Y.M.; Shen, C.Y. Numerical simulation for flow-induced stress in injection compression molding. Polym. Eng. Sci. 2016, 56, 287–298. [Google Scholar] [CrossRef]

- Baldi-Boleda, T.; Sadeghi, E.; Colominas, C.; García-Granada, A. Simulation Approach for Hydrophobicity Replication via Injection Molding. Polymers 2021, 13, 2069. [Google Scholar] [CrossRef]

- Jiang, B.; Peng, H.; Wu, W.; Jia, Y.; Zhang, Y. Numerical Simulation and Experimental Investigation of the Viscoelastic Heating Mechanism in Ultrasonic Plasticizing of Amorphous Polymers for Micro Injection Molding. Polymers 2016, 8, 199. [Google Scholar] [CrossRef]

- Zink, B.; Szabó, F.; Hatos, I.; Suplicz, A.; Kovács, N.K.; Hargitai, H.; Tábi, T.; Kovács, J.G. Enhanced Injection Molding Simulation of Advanced Injection Molds. Polymers 2017, 9, 77. [Google Scholar] [CrossRef] [Green Version]

- Krebelj, K.; Krebelj, A.; Halilovič, M.; Mole, N. Modeling Injection Molding of High-Density Polyethylene with Crystallization in Open-Source Software. Polymers 2021, 13, 138. [Google Scholar] [CrossRef]

- Huang, C.T.; Chen, X.W.; Fu, W.W. Investigation on the Fiber Orientation Distributions and Their Influence on the Mechanical Property of the Co-Injection Molding Products. Polymers 2020, 12, 24. [Google Scholar] [CrossRef] [Green Version]

- Chung, C.Y.; Hwang, S.S.; Chen, S.C.; Lai, M.C. Effects of Injection Molding Process Parameters on the Chemical Foaming Behavior of Polypropylene and Polystyrene. Polymers 2021, 13, 2331. [Google Scholar] [CrossRef]

- Guerrier, P.; Tosello, G.; Kirstein Nielsen, K.; Hattel, J.H. Three-dimensional numerical modeling of an induction heated injection molding tool with flow visualization. Int. J. Adv. Manuf. Technol. 2016, 85, 643–660. [Google Scholar] [CrossRef] [Green Version]

- Guerrier, P.; Tosello, G.; Hattel, J.H. Flow visualization and simulation of the filling process during injection moulding. CIRP J. Manuf. Sci. Technol. 2017, 16, 12–20. [Google Scholar] [CrossRef] [Green Version]

- Tsai, H.H.; Liao, Y.L. Feasibility Study of the Flatness of a Plastic Injection Molded Pallet by a Newly Proposed Sequential Valve Gate System. Polymers 2022, 14, 616. [Google Scholar] [CrossRef]

- Chang, R.Y.; Yang, W.H. Numerical simulation of mold filling in injection molding using a three-dimensional finite volume approach. Int. J. Numer. Meth. Fluids 2001, 37, 125–148. [Google Scholar] [CrossRef]

- Nian, S.C.; Wu, C.Y.; Huang, M.S. Warpage control of thin-walled injection molding using local mold temperatures. Int. Commun. Heat Mass Transf. 2015, 61, 102–110. [Google Scholar] [CrossRef]

- TAISOX® HDPE 8041 Resin. Available online: http://www.fpc.com.tw/fpcwuploads/pdocument/pdocument_150128095257.pdf (accessed on 23 February 2022).

- Shredder and Tank of EREMA, Ansfelden, Austria. Available online: https://www.erema.com/ (accessed on 21 February 2022).

- Advanced package on Injection Compression Molding of Moldex3D 2020. Available online: https://www.moldex3d.com/ (accessed on 24 February 2022).

| Parameters | Conditions |

|---|---|

| Melt temperature (°C) | 220 |

| Mold temperature (°C) | 60 |

| Filling pressure (max) (MPa) | 210 |

| Filling time (s) | 16.257 |

| Filling/compression overlap (s) | 1.007 |

| Filling volume (mm3) | 19,988,800 |

| Compression speed (mm/s) | 60 |

| Compression gap (mm) | 1 |

| Compression time (s) | 6 |

| Max. compression pressure (MPa) | 49.51 |

| Cooling time (s) | 148 |

| Cooling channels’ temperature (°C) | 30 |

| Mold opening time (s) | 10 |

| Cycle time (s) | 193.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, C.-D.; Liao, Y.-L.; Tsai, H.-H. Investigation of the Warpage of a High-Density Polyethylene Pallet by Plastic Injection Compression Molding: Part I—Numerical Approach. Polymers 2022, 14, 1437. https://doi.org/10.3390/polym14071437

Cheng C-D, Liao Y-L, Tsai H-H. Investigation of the Warpage of a High-Density Polyethylene Pallet by Plastic Injection Compression Molding: Part I—Numerical Approach. Polymers. 2022; 14(7):1437. https://doi.org/10.3390/polym14071437

Chicago/Turabian StyleCheng, Chun-Der, Yi-Ling Liao, and Hsi-Hsun Tsai. 2022. "Investigation of the Warpage of a High-Density Polyethylene Pallet by Plastic Injection Compression Molding: Part I—Numerical Approach" Polymers 14, no. 7: 1437. https://doi.org/10.3390/polym14071437

APA StyleCheng, C.-D., Liao, Y.-L., & Tsai, H.-H. (2022). Investigation of the Warpage of a High-Density Polyethylene Pallet by Plastic Injection Compression Molding: Part I—Numerical Approach. Polymers, 14(7), 1437. https://doi.org/10.3390/polym14071437