A Magic Filter Filled with Waste Plastic Shavings, Loofah, and Iron Shavings for Wastewater Treatment

Abstract

:1. Introduction

2. Materials and Methods

2.1. Design Thought

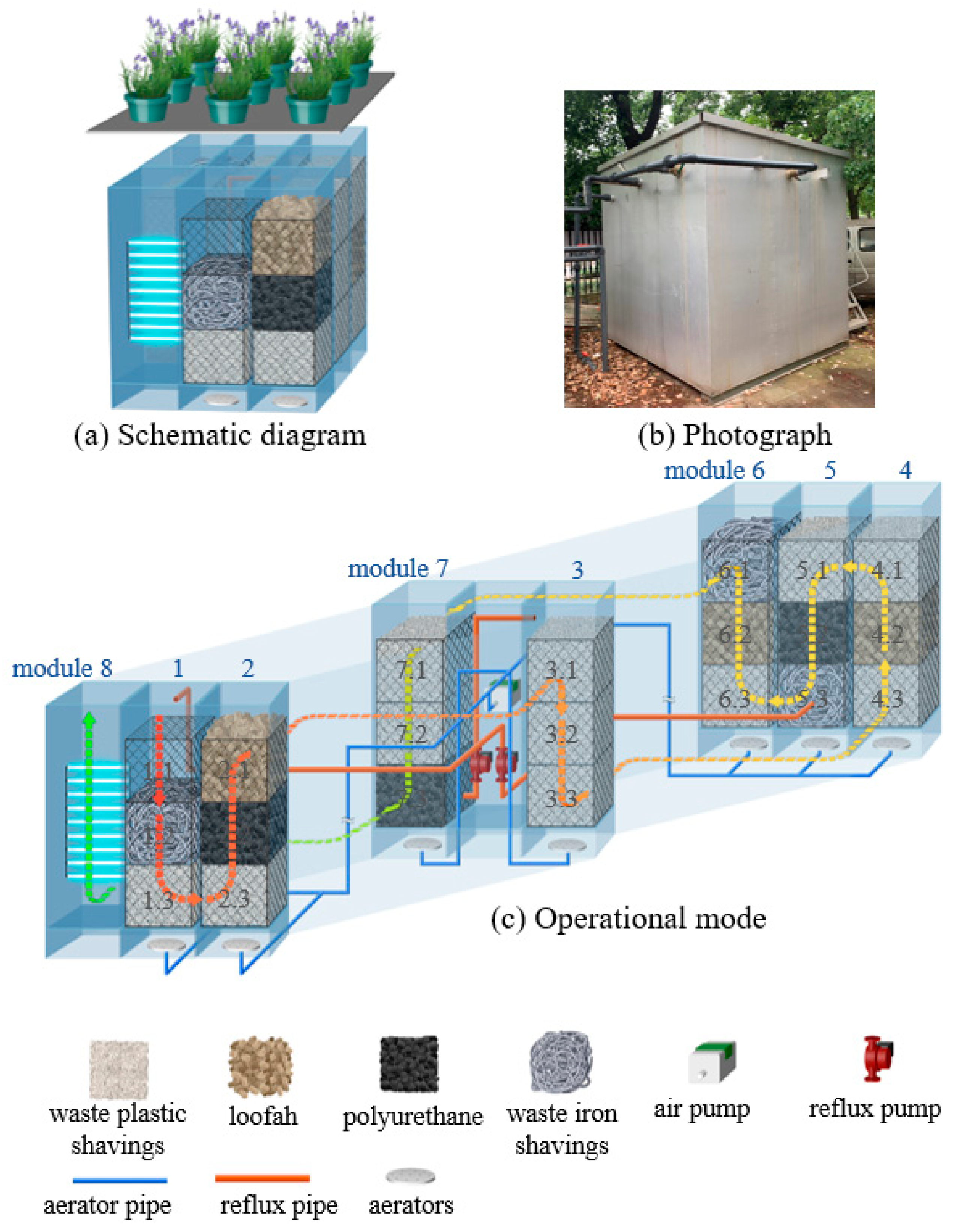

2.2. Reactor Setup and Operation

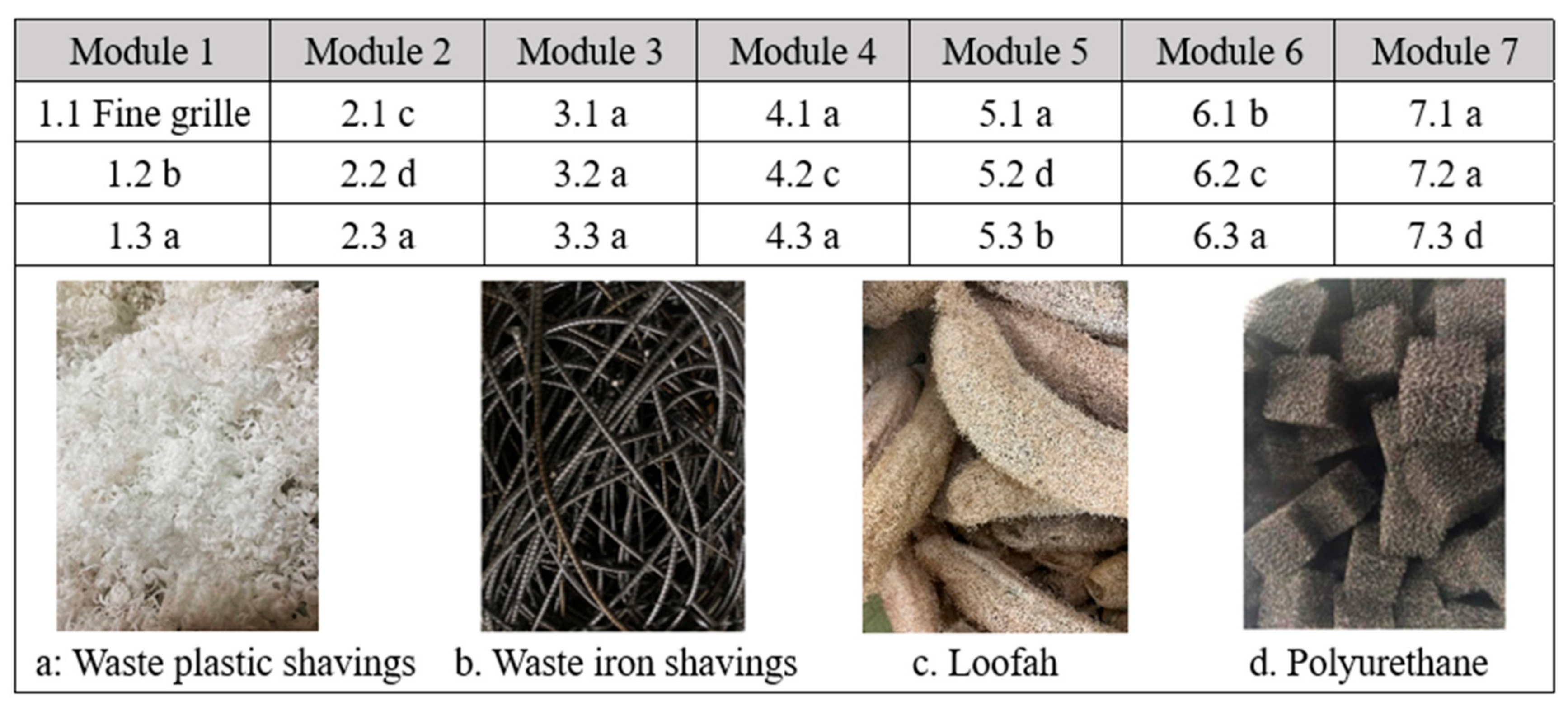

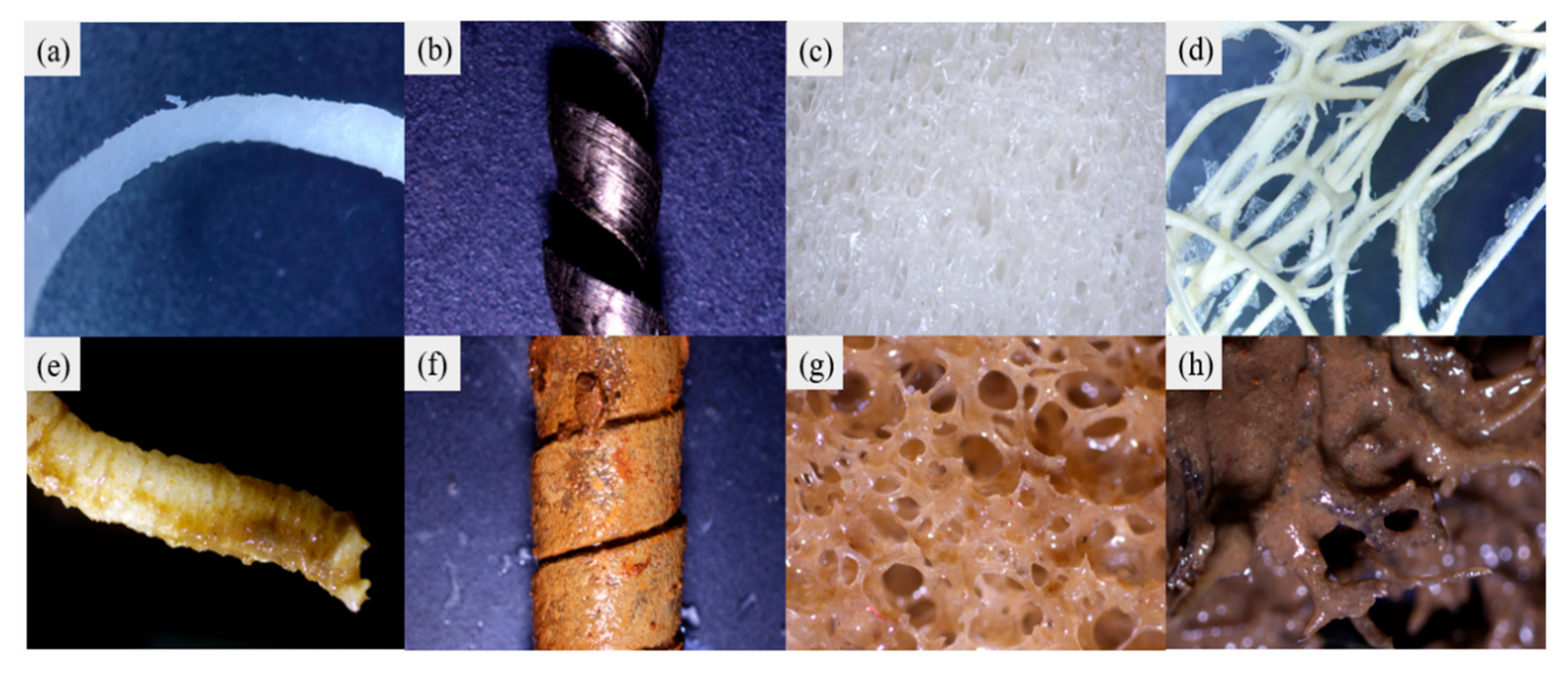

2.3. Filler Selection and Characteristic

2.4. Wastewater Characteristics and Seed Sludge

2.5. Analytical Methods

2.6. Statistical Analysis

3. Results and Discussion

3.1. Variation and Replacement of Fillers

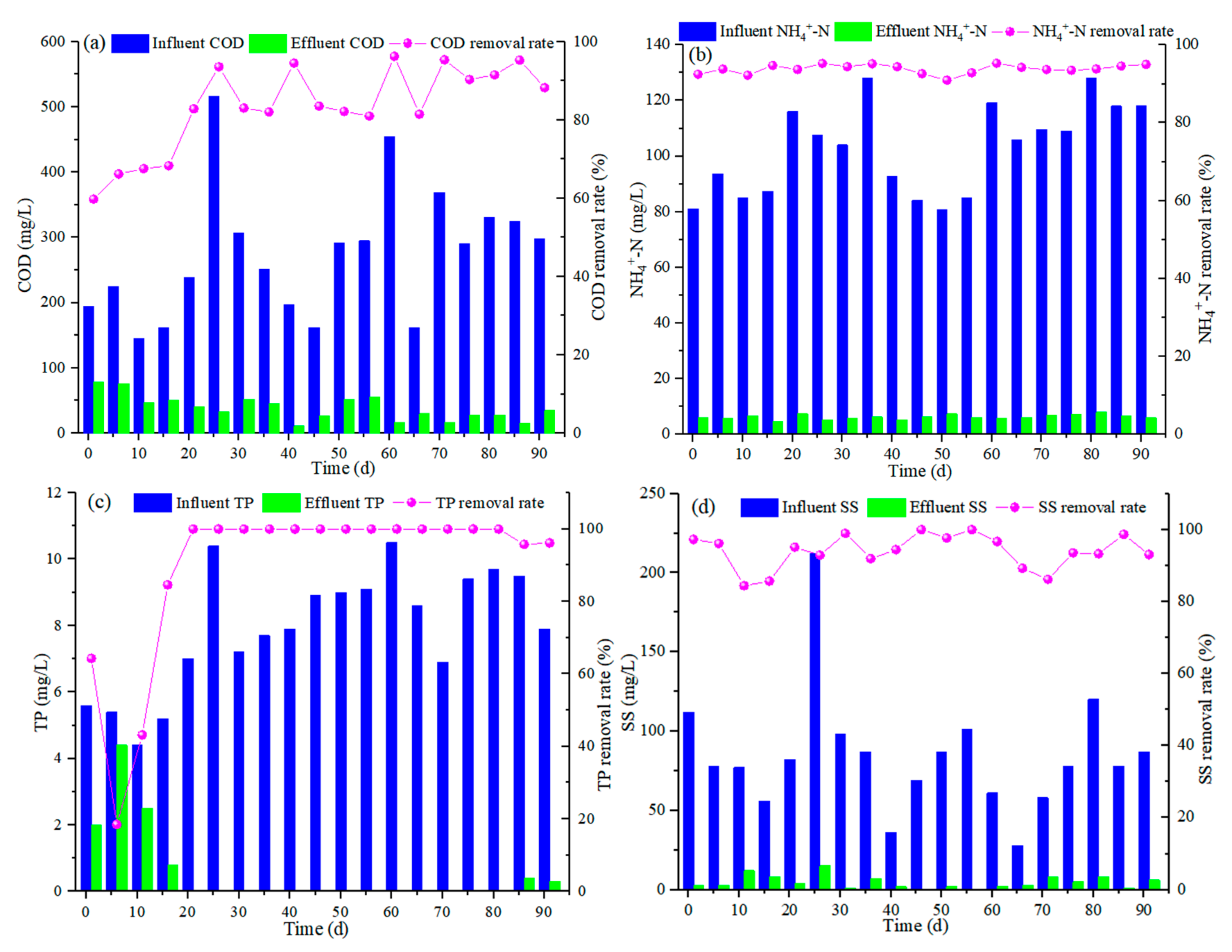

3.2. Pollutants Removal

3.3. Proposed Hypothesis of Pollutants Removal Path

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, J.; Liu, Y.-S.; Deng, W.-J.; Ying, G.-G. Removal of steroid hormones and biocides from rural wastewater by an integrated constructed wetland. Sci. Total Environ. 2019, 660, 358–365. [Google Scholar] [CrossRef]

- Gu, B.; Fan, L.; Ying, Z.; Xu, Q.; Luo, W.; Ge, Y.; Scott, S.; Chang, J. Socioeconomic constraints on the technological choices in rural sewage treatment. Environ. Sci. Pollut. Res. 2016, 23, 20360–20367. [Google Scholar] [CrossRef]

- Han, Y.; Ma, J.; Xiao, B.; Huo, X.; Guo, X. New Integrated Self-Refluxing Rotating Biological Contactor for rural sewage treatment. J. Clean. Prod. 2019, 217, 324–334. [Google Scholar] [CrossRef]

- Li, Z.; Hu, X.; Zhang, X.; Gong, L.; Jiang, Z.; Xing, Y.; Ding, J.; Tian, J.; Huang, J. Distributed treatment of rural environmental wastewater by artificial ecological geographic information system. J. King Saud Univ.-Sci. 2022, 34, 101806. [Google Scholar] [CrossRef]

- Li, H.; Liu, F.; Luo, P.; Xie, G.; Xiao, R.; Hu, W.; Peng, J.; Wu, J. Performance of integrated ecological treatment system for decentralized rural wastewater and significance of plant harvest management. Ecol. Eng. 2018, 124, 69–76. [Google Scholar] [CrossRef]

- Xu, D.; Liu, J.; Ma, T.; Zhao, X.; Ma, H. Coupling of sponge fillers and two-zone clarifiers for granular sludge in an integrated oxidation ditch. Environ. Technol. Innov. 2022, 26, 102264. [Google Scholar] [CrossRef]

- Yang, F.; Zhang, H.; Zhang, X.; Zhang, Y.; Li, J.; Jin, F.; Zhou, B. Performance analysis and evaluation of the 146 rural decentralized wastewater treatment facilities surrounding the Erhai Lake. J. Clean. Prod. 2021, 315, 128159. [Google Scholar] [CrossRef]

- Bassin, J.P.; Rachid, C.T.; Vilela, C.; Cao, S.M.; Peixoto, R.S.; Dezotti, M. Revealing the bacterial profile of an anoxic-aerobic moving-bed biofilm reactor system treating a chemical industry wastewater. Int. Biodeterior. Biodegrad. 2017, 120, 152–160. [Google Scholar] [CrossRef]

- Dong, J.; Wang, Y.; Wang, L.; Wang, S.; Li, S.; Ding, Y. The performance of porous ceramsites in a biological aerated filter for organic wastewater treatment and simulation analysis. J. Water Process Eng. 2020, 34, 101134. [Google Scholar] [CrossRef]

- Gidstedt, S.; Betsholtz, A.; Falås, P.; Cimbritz, M.; Davidsson, Å.; Micolucci, F.; Svahn, O. A comparison of adsorption of organic micropollutants onto activated carbon following chemically enhanced primary treatment with microsieving, direct membrane filtration and tertiary treatment of municipal wastewater. Sci. Total Environ. 2021, 811, 152225. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; Deng, Y.; Dai, M.; Wu, Y.; Ali, I.; Peng, C. Preparation of super-hydrophobic/super-oleophilic quartz sand filter for the application in oil-water separation. J. Water Process Eng. 2022, 46, 102561. [Google Scholar] [CrossRef]

- Vítězová, M.; Jančiková, S.; Dordević, D.; Vítěz, T.; Elbl, J.; Hanišáková, N.; Jampílek, J.; Kushkevych, I. The Possibility of Using Spent Coffee Grounds to Improve Wastewater Treatment Due to Respiration Activity of Microorganisms. Appl. Sci. 2019, 9, 3155. [Google Scholar] [CrossRef] [Green Version]

- Dahlbo, H.; Poliakova, V.; Mylläri, V.; Sahimaa, O.; Anderson, R. Recycling potential of post-consumer plastic packaging waste in Finland. Waste Manag. 2018, 71, 52–61. [Google Scholar] [CrossRef] [PubMed]

- Ragaert, K.; Delva, L.; Van Geem, K. Mechanical and chemical recycling of solid plastic waste. Waste Manag. 2017, 69, 24–58. [Google Scholar] [CrossRef] [PubMed]

- Demets, R.; Van Kets, K.; Huysveld, S.; Dewulf, J.; De Meester, S.; Ragaert, K. Addressing the complex challenge of understanding and quantifying substitutability for recycled plastics. Resour. Conserv. Recycl. 2021, 174, 105826. [Google Scholar] [CrossRef]

- Shamsuyeva, M.; Endres, H.-J. Plastics in the context of the circular economy and sustainable plastics recycling: Comprehensive review on research development, standardization and market. Compos. Part C Open Access 2021, 6, 100168. [Google Scholar] [CrossRef]

- Ma, Y.; Dai, W.; Zheng, P.; Zheng, X.; He, S.; Zhao, M. Iron scraps enhance simultaneous nitrogen and phosphorus removal in subsurface flow constructed wetlands. J. Hazard. Mater. 2020, 395, 122612. [Google Scholar] [CrossRef]

- Pan, Z.; Guo, T.; Sheng, J.; Feng, H.; Yan, A.; Li, J. Adding waste iron shavings in reactor to develop aerobic granular sludge and enhance removal of nitrogen and phosphorus. J. Environ. Chem. Eng. 2021, 9, 106620. [Google Scholar] [CrossRef]

- Akhtar, N.; Saeed, A.; Iqbal, M. Chlorella sorokiniana immobilized on the biomatrix of vegetable sponge of Luffa cylindrica: A new system to remove cadmium from contaminated aqueous medium. Bioresour. Technol. 2003, 88, 163–165. [Google Scholar] [CrossRef]

- Bai, Y.; Su, J.; Ali, A.; Wen, Q.; Chang, Q.; Gao, Z.; Wang, Y. Efficient removal of nitrate, manganese, and tetracycline in a novel loofah immobilized bioreactor: Performance, microbial diversity, and functional genes. Bioresour. Technol. 2021, 344, 126228. [Google Scholar] [CrossRef]

- Zhang, C.; Yuan, B.; Liang, Y.; Yang, L.; Bai, L.; Yang, H.; Wei, D.; Wang, F.; Wang, Q.; Wang, W.; et al. Carbon nanofibers enhanced solar steam generation device based on loofah biomass for water purification. Mater. Chem. Phys. 2021, 258, 123998. [Google Scholar] [CrossRef]

- Apha, A. Standard Methods for the Examination of Water and Wastewater, 9th ed.; American Public Health Association: Washington, DC, USA, 2005. [Google Scholar]

- ATV-DVWK-A 131. Dimensioning of Single-Stage Activated Sludge Plants; GFA Publishing Company of ATV-DVWK Water: Hennef, Germany, 2000. [Google Scholar]

- Hu, S.; He, S.; Wang, Y.; Wu, Y.; Shou, T.; Yin, D.; Mu, G.; Zhao, X.; Gao, Y.; Liu, J.; et al. Self-Repairable, Recyclable and Heat-Resistant Polyurethane for High-Performance Automobile Tires. Nano Energy 2022, 95, 107012. [Google Scholar] [CrossRef]

- Pedrazzoli, D.; Manas-Zloczower, I. Understanding phase separation and morphology in thermoplastic polyurethanes nanocomposites. Polymer 2016, 90, 256–263. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, Z.; Sheng, J.; Qiu, C.; Wei, H.; Yang, Q.; Pan, J.; Li, J. A Magic Filter Filled with Waste Plastic Shavings, Loofah, and Iron Shavings for Wastewater Treatment. Polymers 2022, 14, 1410. https://doi.org/10.3390/polym14071410

Pan Z, Sheng J, Qiu C, Wei H, Yang Q, Pan J, Li J. A Magic Filter Filled with Waste Plastic Shavings, Loofah, and Iron Shavings for Wastewater Treatment. Polymers. 2022; 14(7):1410. https://doi.org/10.3390/polym14071410

Chicago/Turabian StylePan, Zengrui, Jianlong Sheng, Chong Qiu, Hongtang Wei, Qianjin Yang, Jinbo Pan, and Jun Li. 2022. "A Magic Filter Filled with Waste Plastic Shavings, Loofah, and Iron Shavings for Wastewater Treatment" Polymers 14, no. 7: 1410. https://doi.org/10.3390/polym14071410

APA StylePan, Z., Sheng, J., Qiu, C., Wei, H., Yang, Q., Pan, J., & Li, J. (2022). A Magic Filter Filled with Waste Plastic Shavings, Loofah, and Iron Shavings for Wastewater Treatment. Polymers, 14(7), 1410. https://doi.org/10.3390/polym14071410