Multilateral Assessment of Anchorage Bond Characteristics in Steel Fibre Reinforced Concrete

Abstract

:1. Introduction

1.1. State of Knowledge

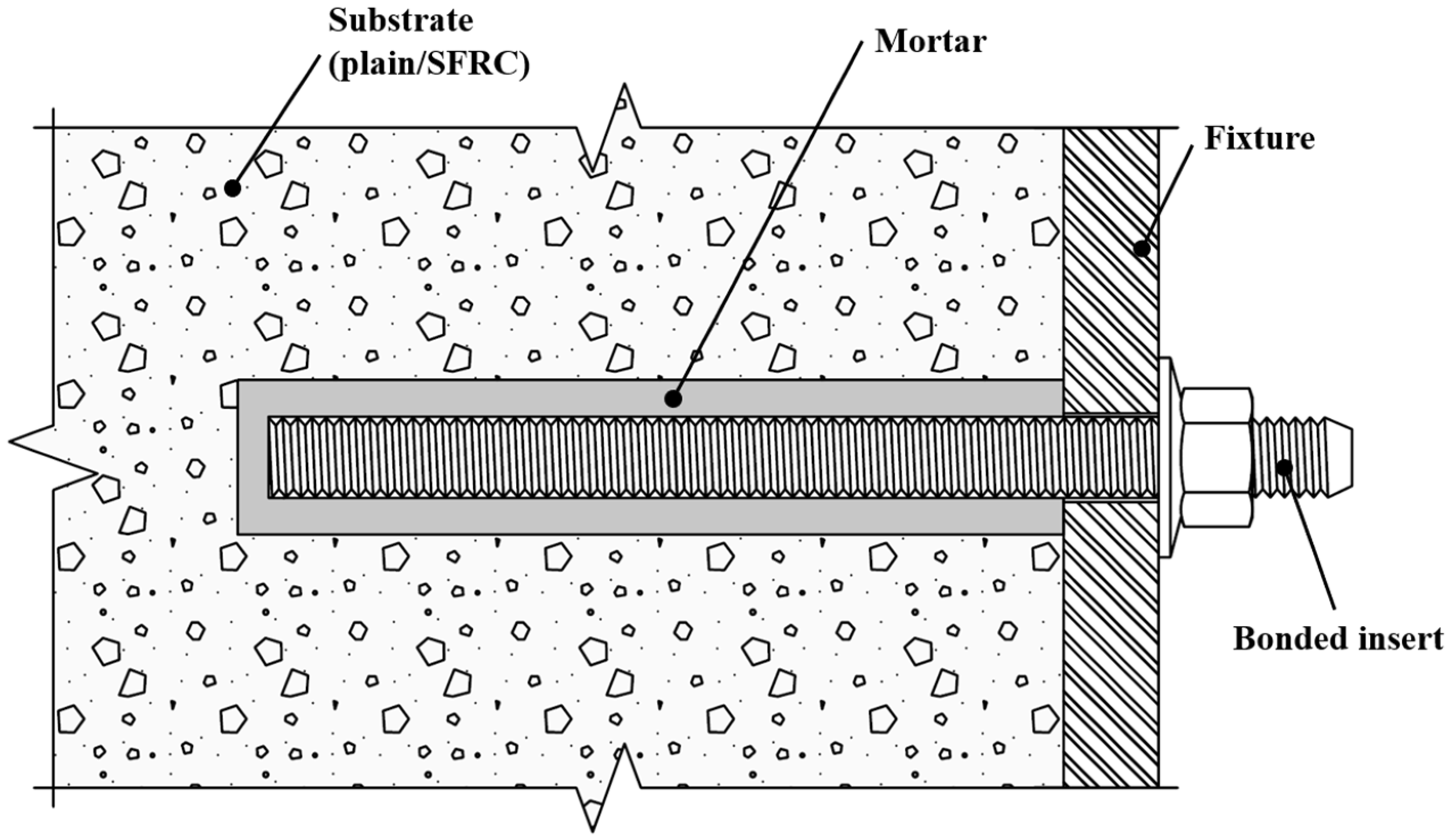

1.1.1. Basics of Fastenings Engineering for Bonded Anchors

1.1.2. Previous Research

1.1.3. Research Gap, Novelty, and Overview of the Study

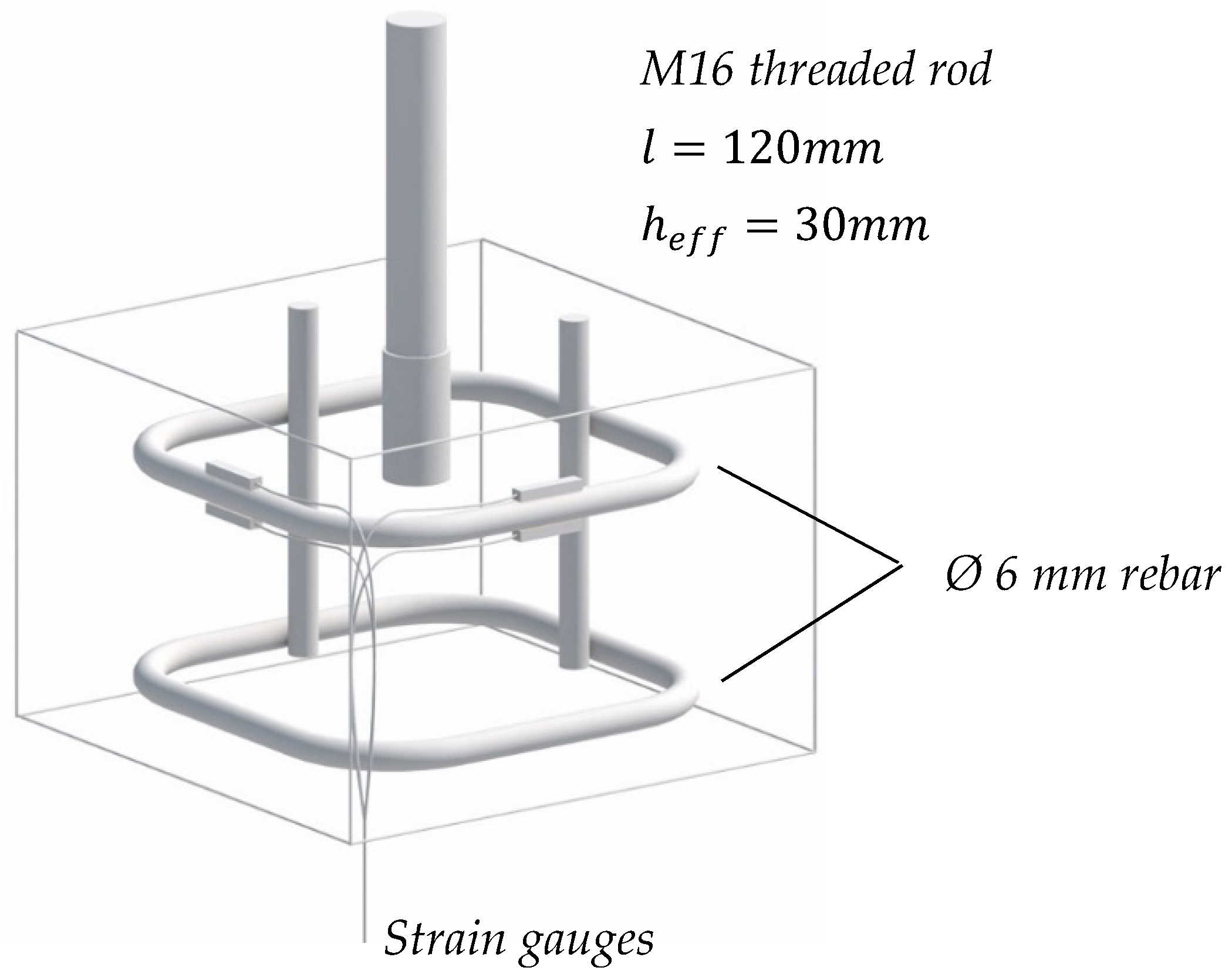

2. Materials

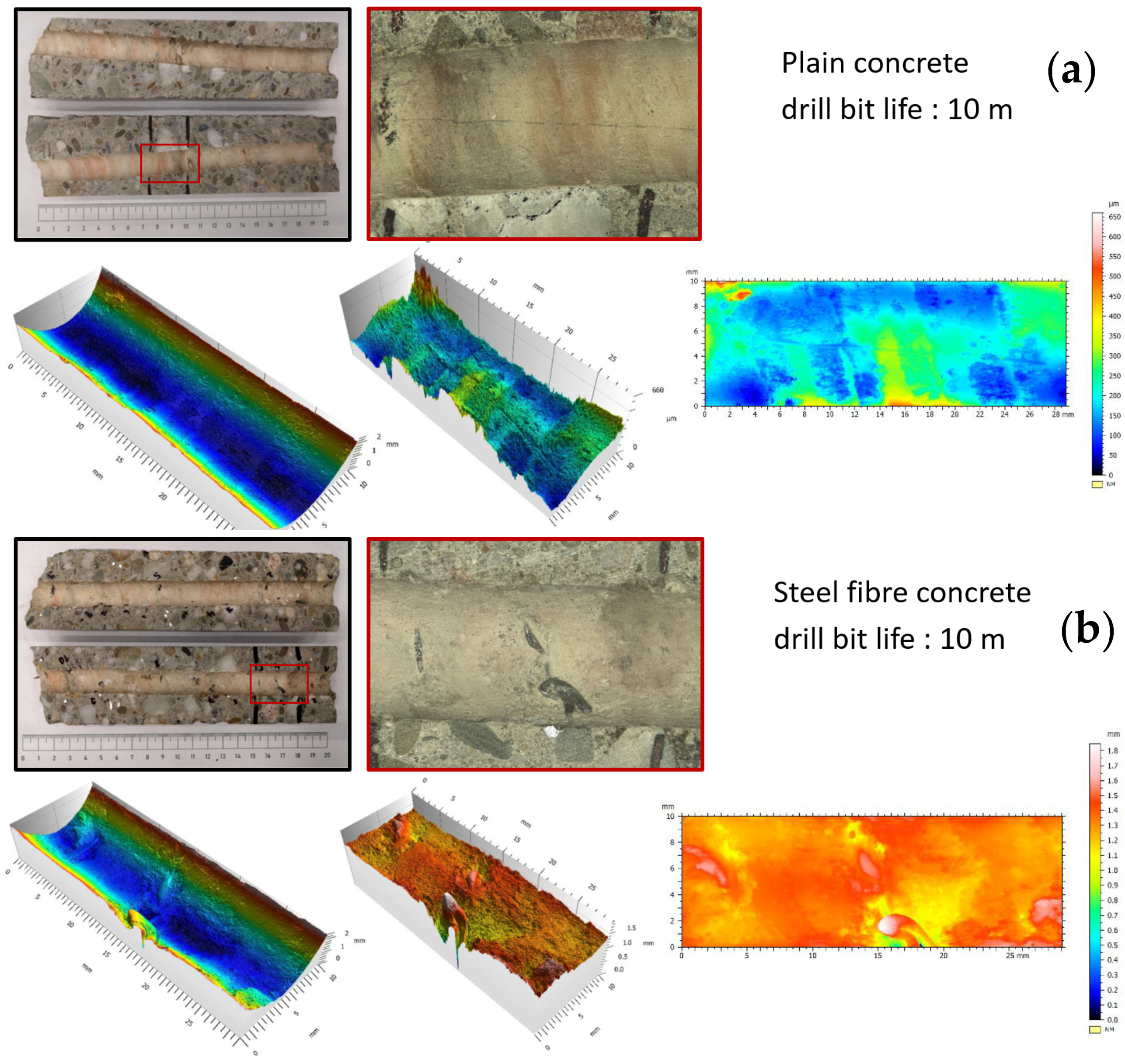

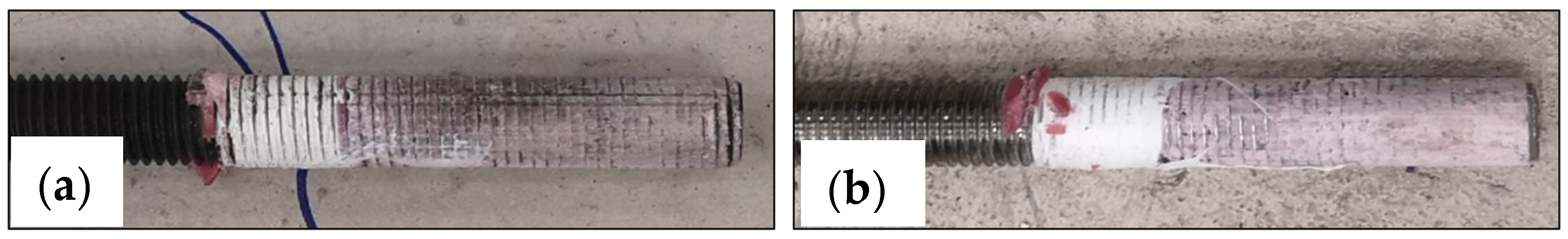

3. Borehole Examinations

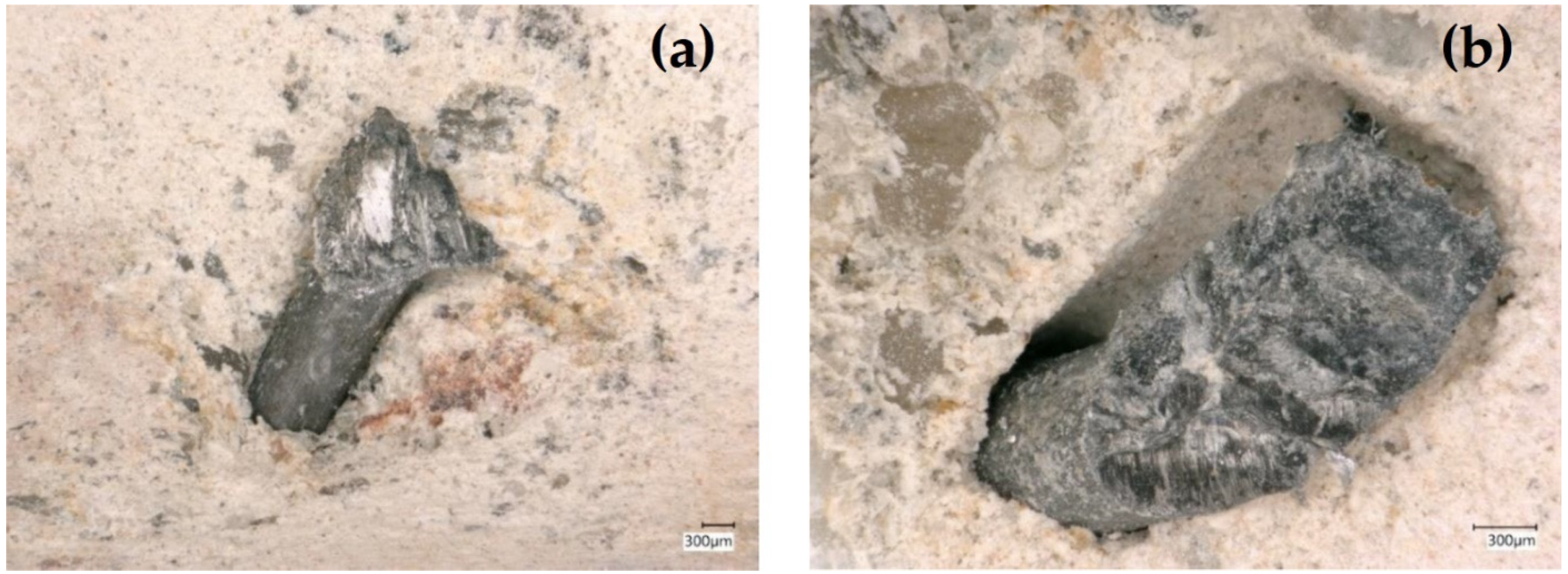

3.1. High-Level Qualitative Analysis

3.2. Microscopic Roughness Analysis

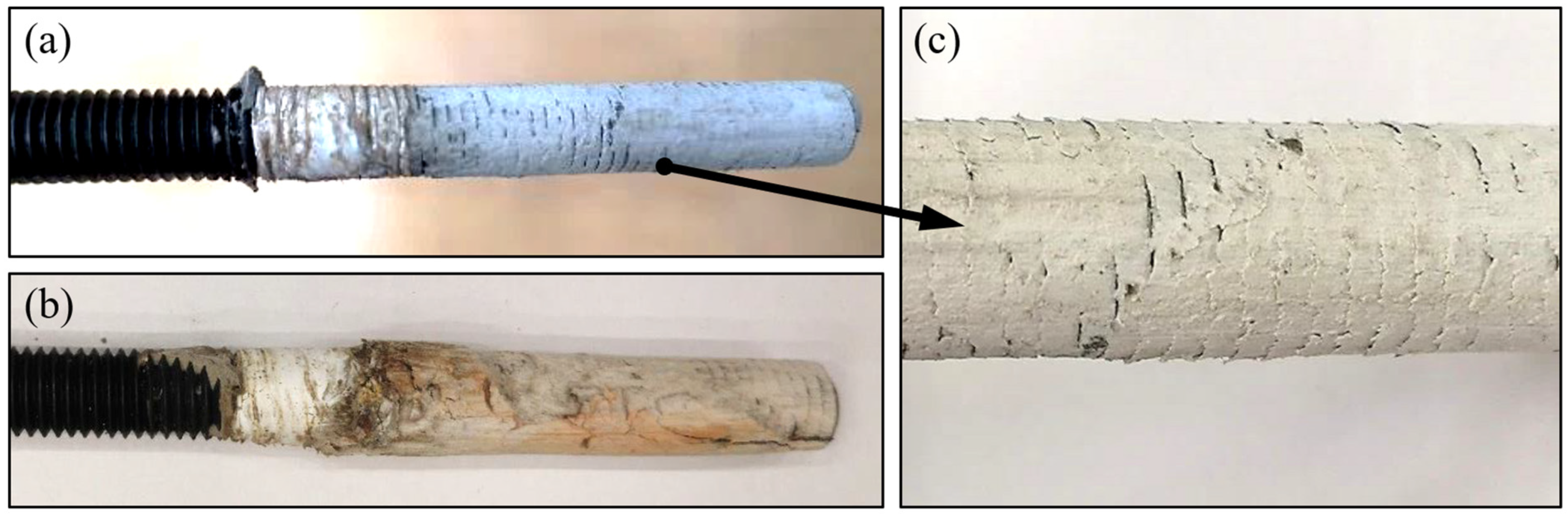

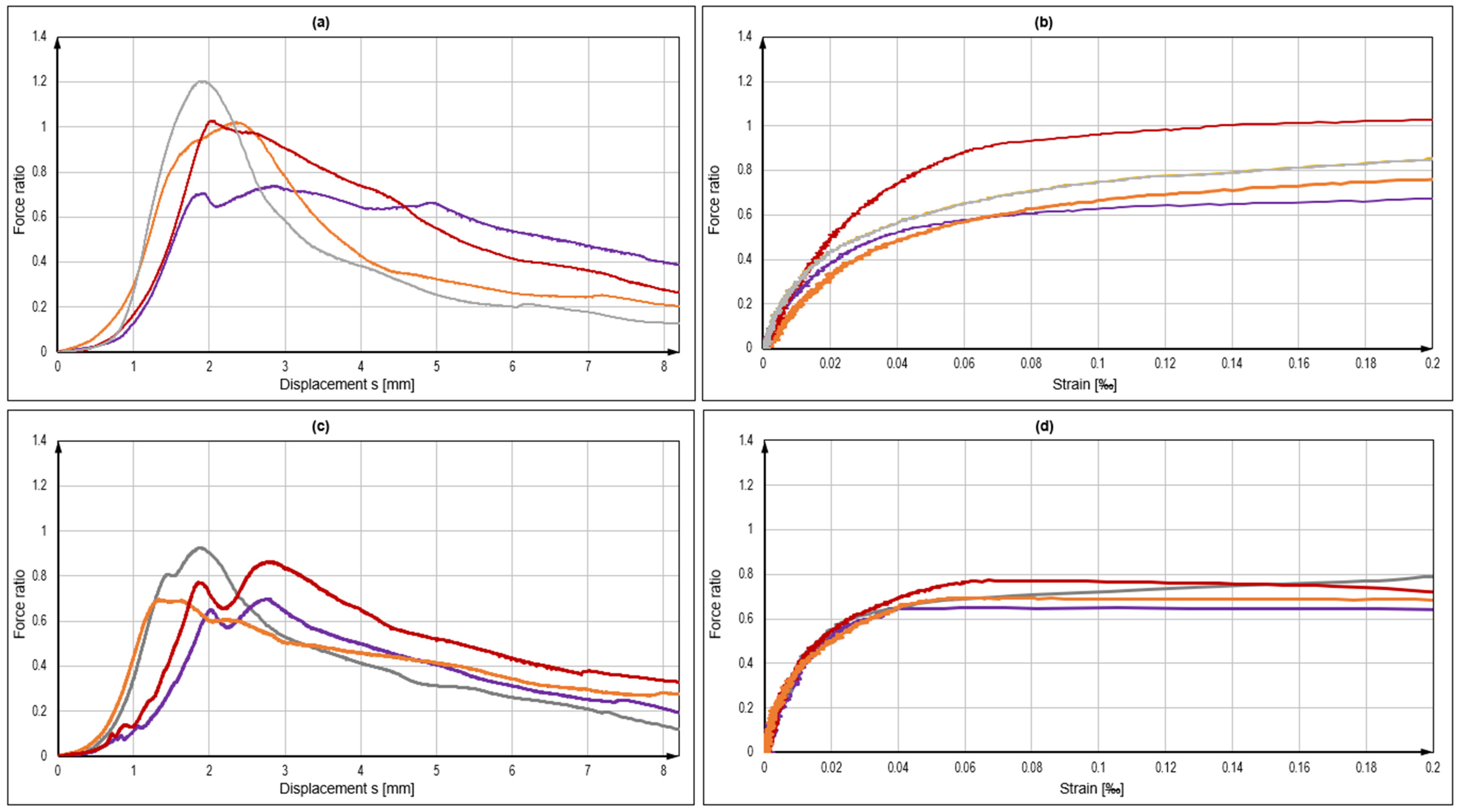

4. Pull-Out Tests at Fully Developed Bond Lengths

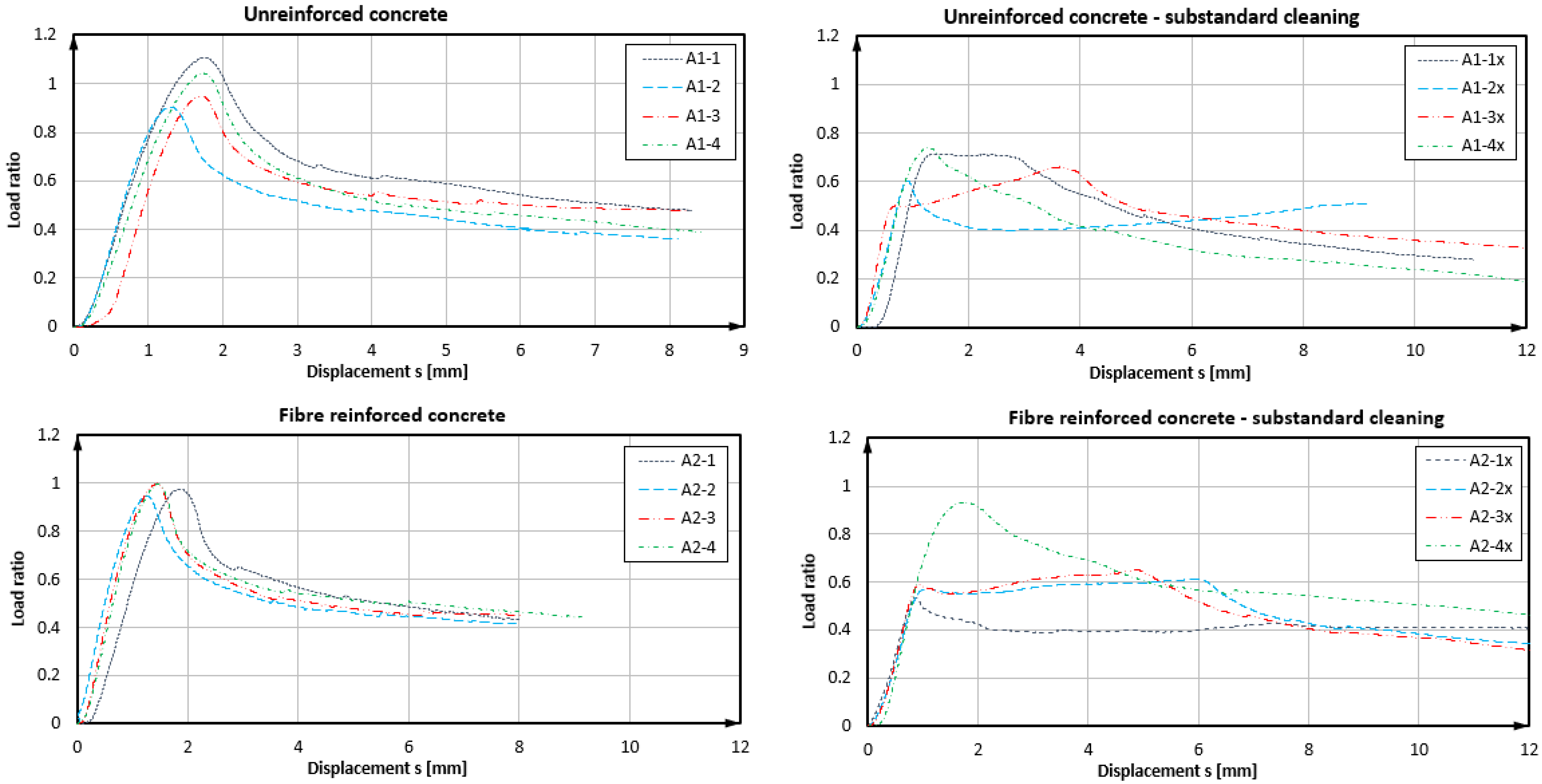

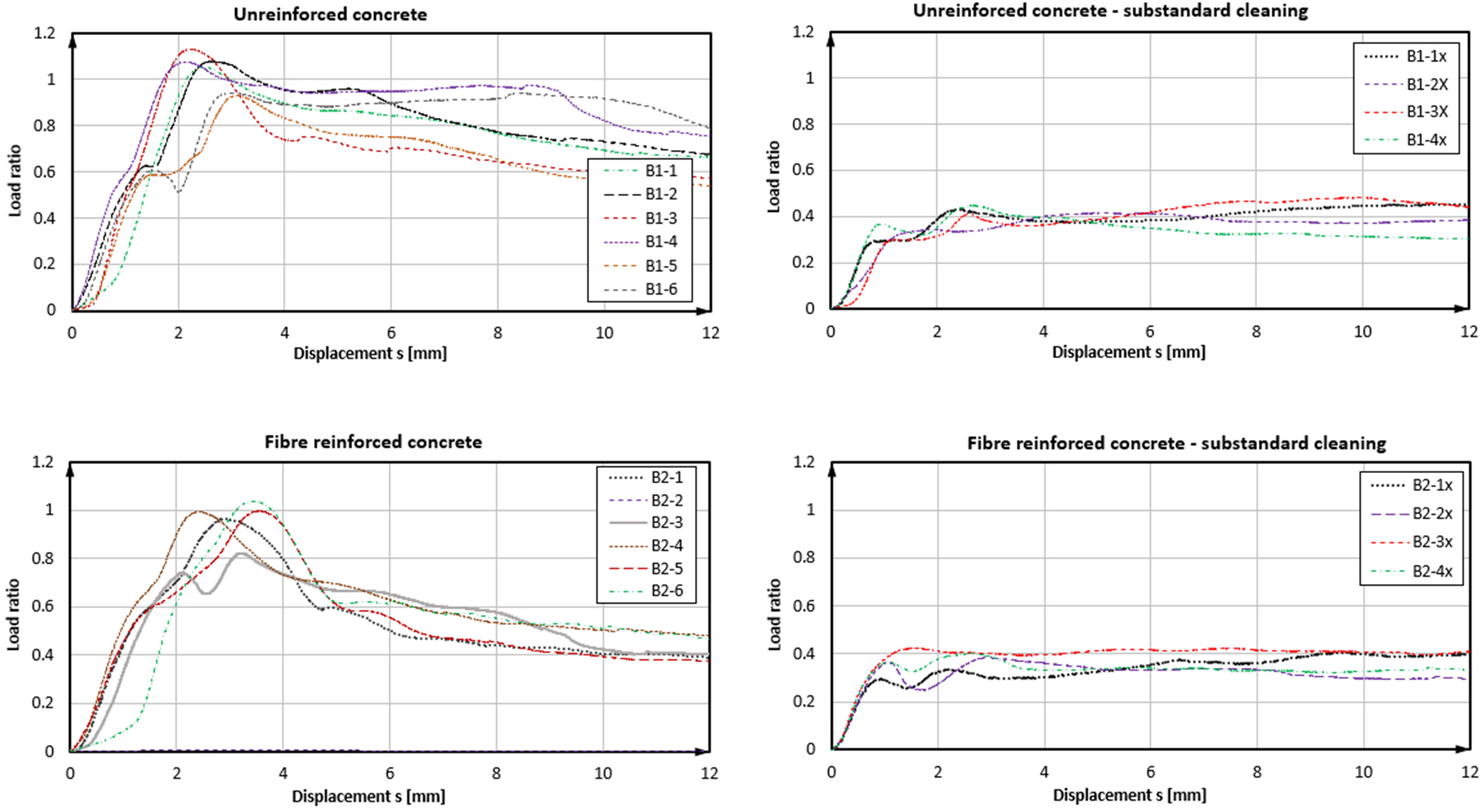

4.1. Results of Tests with Product A

4.2. Results of Tests with Product B

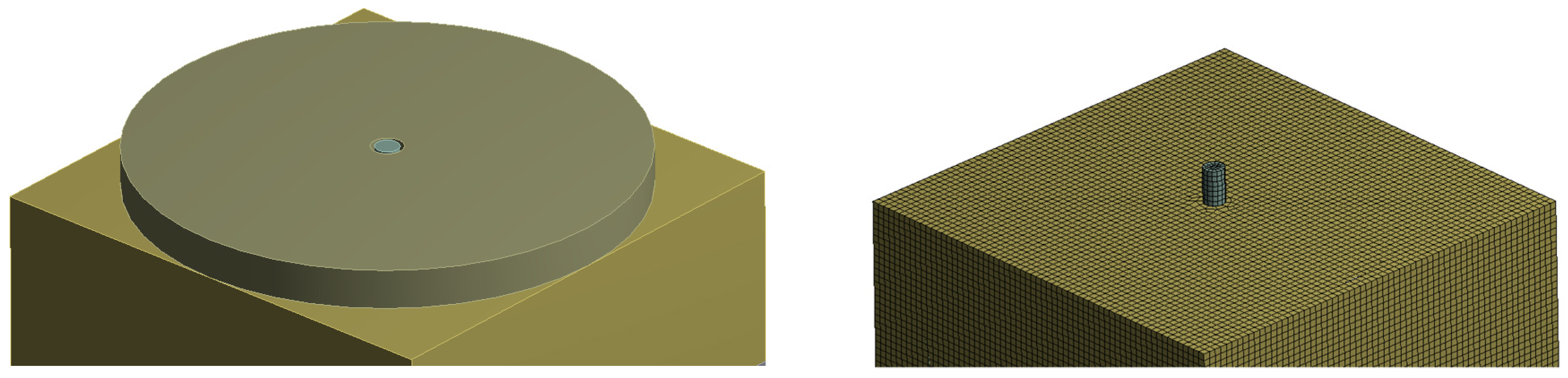

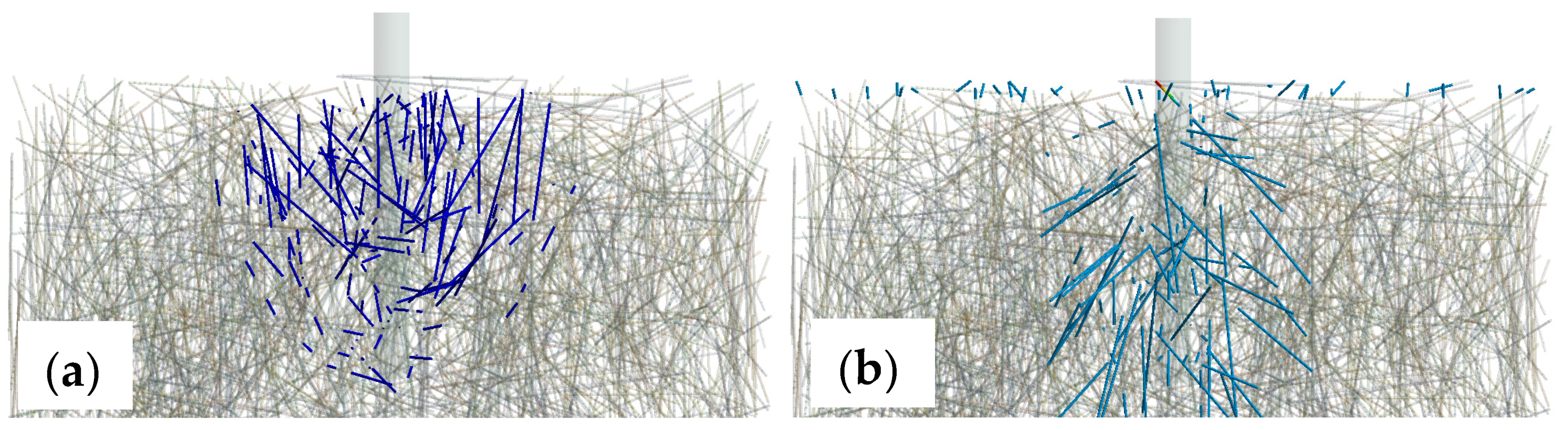

5. Finite Element Analysis of Fibre Contribution

6. Radial Stress Assessment

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Empelmann, M.; Teutsch, M.; Wichers, M. Baukonstruktionen aus Faserbeton. (Building Structures Made of Fibre-Reinforced Concrete) Beton-Kalender 2011: Schwerpunkte: Kraftwerke, Faserbeton; Ernst und Sohn: Berlin, Germany, 2010; pp. 89–139. [Google Scholar]

- Spyridis, P.; Nasekhian, A.; Skalla, G. Design of SCL structures in London. Geomech. Tunn. 2013, 6, 66–80. [Google Scholar] [CrossRef]

- di Prisco, M.S.F.; Failla, C.; Finazzi, P.; Siboni, A.; Bassani, A.; Nava, G.; Colombo, M. Innovative SFRC applications: An industrial building in Como. In Italian Concrete Days 2018; GWMAX srl: Erba, Italy, 2018; pp. 1–10. [Google Scholar]

- Holschemacher, K.; Dehn, F.; Müller, T.; Lobisch, F. Grundlagen des Faserbetons. (Fundamentals of fibre reinforced concrete). In Beton Kalender 2017: Schwerpunkte: Spannbeton, Spezialbetone; John Wiley & Sons: Hoboken, NJ, USA, 2016; Volume 106, pp. 381–472. [Google Scholar]

- Cascardi, A.; Leone, M.; Aiello, M.A. Transversal joining of multi-leaf masonry through different types of connector: Experimental and theoretical investigation. Constr. Build. Mater. 2020, 265, 120733. [Google Scholar] [CrossRef]

- Ahmed, L.T.; Braimah, A. Tensile behaviour of adhesive anchors under different strain rates. Eng. Struct. 2019, 192, 113–125. [Google Scholar] [CrossRef]

- Al-Mansouri, O.; Mège, R.; Pinoteau, N.; Guillet, T.; Piccinin, R.; McBride, K.; Abate, M.; Rémond, S. Design Recommendations for Bonded Anchors under Fire Conditions Using the Resistance Integration Method. Appl. Sci. 2021, 11, 7810. [Google Scholar] [CrossRef]

- Boumakis, I.; Marcon, M.; Ninčević, K.; Czernuschka, L.M.; Wan-Wendner, R. Concrete creep and shrinkage effect in adhesive anchors subjected to sustained loads. Eng. Struct. 2018, 175, 790–805. [Google Scholar] [CrossRef]

- Vita, N.; Sharma, A. Behaviour of single bonded anchors in non-cracked and cracked steel fiber reinforced concrete under short-time tensile loading. Eng. Struct. 2021, 245, 112900. [Google Scholar] [CrossRef]

- Spyridis, P. Fastening technology as an interface and integration element of architectural, structural, and building engineering. In Structures and Architecture: Bridging the Gap and Crossing Borders; CRC Press: Boca Raton, FL, USA, 2019; pp. 296–303. [Google Scholar] [CrossRef]

- EN 1992-4:2018; Design of Concrete Structures. Design of Fastenings for Use in Concrete (Eurocode 2–Part 4). CEN-European Committee for Standardization: Brussels, Belgium, 2018.

- ACI-318-19; Building Code Requirements for Structural Concrete and Commentary. ACI—Amercian Concrete Institute: Farmington Hills, MI, USA, 2019.

- Cook, R.A.; Kunz, J.; Fuchs, W.; Konz, R.C. Behavior and design of single adhesive anchors under tensile load in uncracked concrete. ACI Struct. J. 1998, 95, 9–26. [Google Scholar]

- McCarter, W.J.; Emerson, M.; Ezirim, H. Properties of concrete in the cover zone: Developments in monitoring techniques. Mag. Concr. Res. 1995, 47, 243–251. [Google Scholar] [CrossRef]

- Long, A.E.; Henderson, G.D.; Montgomery, F.R. Why assess the properties of near-surface concrete? Constr. Build. Mater. 2001, 15, 65–79. [Google Scholar] [CrossRef]

- Tóth, M.; Bokor, B.; Sharma, A. Anchorage in steel fibre reinforced concrete–concept, experimental evidence and design recommendations for concrete cone and concrete edge breakout failure modes. Eng. Struct. 2019, 181, 60–75. [Google Scholar] [CrossRef]

- Appl, J.J. Tragverhalten von Verbunddübeln unter Zugbelastung [Load-Bearing Behavior of Bonded Anchors under Tensile Load]. Ph.D. Thesis, University of Stuttgart, Stuttgart, Germany, 2009. [Google Scholar]

- Cattaneo, S.; Muciaccia, G. Adhesive anchors in high performance concrete. Mater. Struct. 2016, 49, 2689–2700. [Google Scholar] [CrossRef]

- Eligehausen, R.; Mallée, R.; Silva, J.F. Anchorage in Concrete Construction; John Wiley & Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

- Boumakis, I.; Ninčević, K.; Marcon, M.; Vorel, J.; Wan-Wendner, R. Bond stress distribution in adhesive anchor systems: Interplay of concrete and mortar creep. Eng. Struct. 2022, 250, 113293. [Google Scholar] [CrossRef]

- Boumakis, I.; Ninčević, K.; Vorel, J.; Wan-Wendner, R. Creep rate based time-to-failure prediction of adhesive anchor systems under sustained load. Compos. Part B Eng. 2019, 178, 107389. [Google Scholar] [CrossRef] [Green Version]

- Stierschneider, E.; Tamparopoulos, A.E.; McBride, K.E.; Bergmeister, K. Influencing factors on creep displacement assessment of bonded fasteners in concrete. Eng. Struct. 2021, 241, 112448. [Google Scholar] [CrossRef]

- EOTA-European Organisation for Technical Assessment. EAD 330499-01-0601: Bonded Fasteners for Use in Concrete, EU Decision 2020/1574; OJEU: Brussels, Belgium, 2018. [Google Scholar]

- ACI Committee 355. Qualification of Post-Installed Adhesive Anchors in Concrete (ACI 355.4-19) and Commentary; ACI: Farmington Hills, MI, USA, 2020. [Google Scholar]

- Cronin, B. Industry Fears over Fixings. New Civil Engineer. 2015. Available online: www.newcivilengineer.com/latest/industry-fears-over-fixings-10-09-2015 (accessed on 1 March 2022).

- González, F.; Fernández, J.; Agranati, G.; Villanueva, P. Influence of construction conditions on strength of post installed bonded anchors. Constr. Build. Mater. 2018, 165, 272–283. [Google Scholar] [CrossRef]

- Grosser, P.R. Load-Bearing Behavior and Design of Anchorages Subjected to Shear and Torsion Loading in Uncracked Concrete. Ph.D.Thesis, University of Stuttgart, Stuttgart, Germany, 2012. [Google Scholar]

- Alhaidary, H.; Al-Tamimi, A.K. Importance of performance certification for post-installed anchors: An experimental assessment. In Structures; Elsevier: Amsterdam, The Netherlands, 2021; Volume 29, pp. 273–285. [Google Scholar]

- Kudszus, R.; Klemencic, R.; Spyridis, P. Basic Concepts of Engineering Risk Management for Fastenings and Risk Register Based on Industry Survey. CivilEng 2020, 1, 275–290. [Google Scholar] [CrossRef]

- Cattaneo, S.; Locatelli, A.; Rago, D. Reliability of bonded anchors with different installation techniques: Experimental assessment. Asian J. Civ. Eng. 2019, 20, 681–692. [Google Scholar] [CrossRef]

- Mattis, L.; Silva, J. Inspecting adhesive anchors. Concr. Int. 2017, 39, 59–64. [Google Scholar]

- Gerber, B.; Ekenel, M. Building code requirements for inspection of adhesive anchors in concrete. J. Constr. Eng. Manag. 2013, 139, 06013001. [Google Scholar] [CrossRef]

- ACI-American Concrete Institute. Adhesive Anchor Installer Workbook; ACI: Farmington Hills, MI, USA, 2012. [Google Scholar]

- German Institute for Construction Engineering. Instructions for the Installation of Dowel Anchors; DIBt: Berlin, Germany, 2010. [Google Scholar]

- BS 8539:2012; Code of Practice for the Selection and Installation of Post-Installed Anchors in Concrete and Masonry. BSI—Bristish Standards Institute: London, UK, 2012.

- Kawahara, S.; Shirato, M.; Kajifusa, N.; Kutsukake, T. Investigation of the tunnel ceiling collapse in the central expressway in Japan. In Transportation Research Board 93rd Annual Meeting; Transportation Research Board: Washington, DC, USA, 2014. [Google Scholar]

- NTSB-National Transportation Safety Board. Highway Accident Report: Ceiling Collapse in the Interstate 90 Connector Tunnel at Boston, Massachusetts, July 10, 2006; NTSB: Washington, DC, USA, 2007.

- Holschemacher, K.; Klug, Y.; Wittmann, F. Experimental Investigations on Fastenings in Steel Fibre Reinforced Concrete; LACER-Leipzig Annual Civil Engineering Report; Univ. Leipzig, Institut für Massivbau und Baustofftechnologie-IMB (Hrgs.): Leipzig, Germany, 2002; pp. 145–158. [Google Scholar]

- Gesoglu, M.; Ozturan, T.; Ozel, M.; Guneyisi, E. Tensile behavior of post-installed anchors in plain and steel fibre-reinforced normal-and high-strength concretes. ACI Struct. J. 2005, 102, 224. [Google Scholar]

- Dengg, F.; Zeman, O.; Voit, K.; Bergmeister, K. Fastening application in concrete using recycled tunnel excavation material. Struct. Concr. 2018, 19, 374–386. [Google Scholar] [CrossRef]

- Randl, N.; Kunz, J. Post-installed reinforcement connections at ultimate and serviceability limit states. Struct. Concr. 2014, 15, 563–574. [Google Scholar] [CrossRef]

- Delhomme, F.; Brun, M. Pullout Tests on Post-installed Bonded Anchors in Ultra-high Performance Fibre Reinforced Concrete. Struct. Eng. Int. 2019, 29, 417–424. [Google Scholar] [CrossRef]

- Schwenn, M.; Voit, K.; Zeman, O.; Bergmeister, K. Post-installed mechanical fasteners in high strength and ultra-high strength performance concrete. Civ. Eng. Des. 2019, 1, 161–167. [Google Scholar] [CrossRef]

- Toth, M.; Bokor, B.; Sharma, A. Anchorages in Steel Fibre Reinforced Concrete in the case of concrete breakout failure-State of the art and design concept. Bauingenieur 2021, 96, 254–265. [Google Scholar] [CrossRef]

- Spyridis, P.; Mellios, N. Tensile performance of headed anchors in steel fiber reinforced and conventional concrete in uncracked and cracked state. Materials 2022, 15, 1886. [Google Scholar] [CrossRef]

- Unterweger, R.; Bergmeister, K. Experimentelle und numerische Untersuchungen von Injektionsankern-Bohrverfahren, Haftspannungen, Materialmodell. Beton-Und Stahlbetonbau 1999, 94, 524–536. [Google Scholar] [CrossRef]

- Schwenn, M.; Zeman, O.; Schorn, J.; Bergmeister, K. Influence of different drilling methods on the behavior of post-installed mechanical fasteners in uncracked and cracked concrete. Struct. Concr. 2021, 22, 1600–1611. [Google Scholar] [CrossRef]

- Liu, H.; Zhao, J.; Davis, T. Novel adhesive anchoring system through engineered adhesive-concrete interface. In Structures; Elsevier: Amsterdam, The Netherlands, 2021; Volume 33, pp. 947–956. [Google Scholar]

- Meszaros, J. Tragverhalten von Einzelverbunddübeln unter zentrischer Kurzzeitbelastung. [Load Bearing Behavior of Single Bonded Anchors under Shortterm Centric Loading]. Ph.D. Thesis, University of Stuttgart, Stuttgart, Germany, 2002. [Google Scholar]

- Mellios, N.; Oesch, T.; Spyridis, P. Finite element modelling of UHPC under pulsating load using X-ray computed tomography based fiber distributions. Mater. Struct. 2022, 55, 1. [Google Scholar] [CrossRef]

- Gettu, R.; Gardner, D.R.; Saldivar, H.; Barragán, B.E. Study of the distribution and orientation of fibres in SFRC specimens. Mater. Struct. 2005, 38, 31–37. [Google Scholar] [CrossRef]

- Zerbino, R.; Tobes, J.M.; Bossio, M.E.; Giaccio, G. On the orientation of fibres in structural members fabricated with self compacting fibre reinforced concrete. Cem. Concr. Compos. 2012, 34, 191–200. [Google Scholar] [CrossRef]

| Test ID | Bonding Mortar | Borehole Cleaning | Substrate Concrete | Sample Size (-) |

|---|---|---|---|---|

| A1 | Product A | Yes | Plain | 4 |

| A1x | Product A | No | Plain | 4 |

| A2 | Product A | Yes | SFRC | 4 |

| A2x | Product A | No | SFRC | 4 |

| B1 | Product B | Yes | Plain | 6 |

| B1x | Product B | No | Plain | 4 |

| B2 | Product B | Yes | SFRC | 5 + 1 outlier |

| B2x | Product B | No | SFRC | 4 |

| Test ID | Mean Failure Load Normalized (-) | Coefficient of Variation (-) | Characteristic Resistance Normalized (-) | Mean Displacement at Peak Load (mm) | Mean Displacement at Loss of Adhesion (mm) |

|---|---|---|---|---|---|

| A1 | 1.00 | 0.091 | 1.00 | 1.6 | 1.6 |

| A1x | 0.68 | 0.089 | 0.68 | 1.8 | 1.8 |

| A2 | 0.98 | 0.025 | 1.12 | 1.5 | 1.5 |

| A2x | 0.68 | 0.250 | 0.44 | 3.4 | 3.4 |

| B1 | 1.00 | 0.075 | 1.00 | 2.7 | 2.7 |

| B1x | 0.44 | 0.074 | 0.44 | 8.5 | 8.5 |

| B2 | 1.10 | 0.026 | 1.22 | 3.0 | 3.0 |

| B2x | 0.47 | 0.088 | 0.46 | 11.0 | 11.0 |

| Test ID | Substrate Concrete | Sample Size (-) | Mean Failure Load (-) | Coef. of Variation (-) | Mean Displacement (mm) |

|---|---|---|---|---|---|

| H1 | Plain | 4 | 1.00 | 0.146 | 2.3 |

| H2 | SFRC | 4 | 1.25 | 0.193 | 2.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Spyridis, P.; Dreier, J.; Mellios, N.; Walter, L.; Biermann, D. Multilateral Assessment of Anchorage Bond Characteristics in Steel Fibre Reinforced Concrete. Polymers 2022, 14, 1411. https://doi.org/10.3390/polym14071411

Spyridis P, Dreier J, Mellios N, Walter L, Biermann D. Multilateral Assessment of Anchorage Bond Characteristics in Steel Fibre Reinforced Concrete. Polymers. 2022; 14(7):1411. https://doi.org/10.3390/polym14071411

Chicago/Turabian StyleSpyridis, Panagiotis, Julia Dreier, Nikolaos Mellios, Lars Walter, and Dirk Biermann. 2022. "Multilateral Assessment of Anchorage Bond Characteristics in Steel Fibre Reinforced Concrete" Polymers 14, no. 7: 1411. https://doi.org/10.3390/polym14071411

APA StyleSpyridis, P., Dreier, J., Mellios, N., Walter, L., & Biermann, D. (2022). Multilateral Assessment of Anchorage Bond Characteristics in Steel Fibre Reinforced Concrete. Polymers, 14(7), 1411. https://doi.org/10.3390/polym14071411