Fused-Filament Fabrication of Short Carbon Fiber-Reinforced Polyamide: Parameter Optimization for Improved Performance under Uniaxial Tensile Loading

Abstract

:1. Introduction

2. Materials and Methods

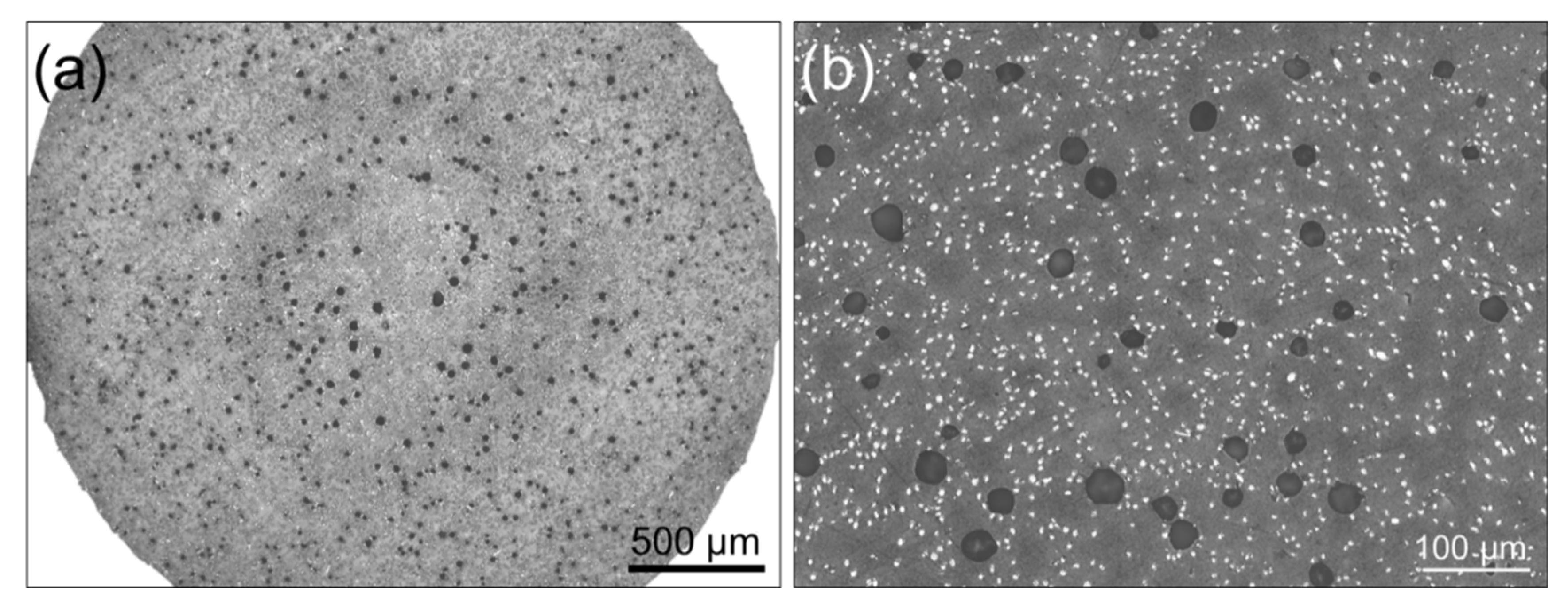

2.1. Filament Material

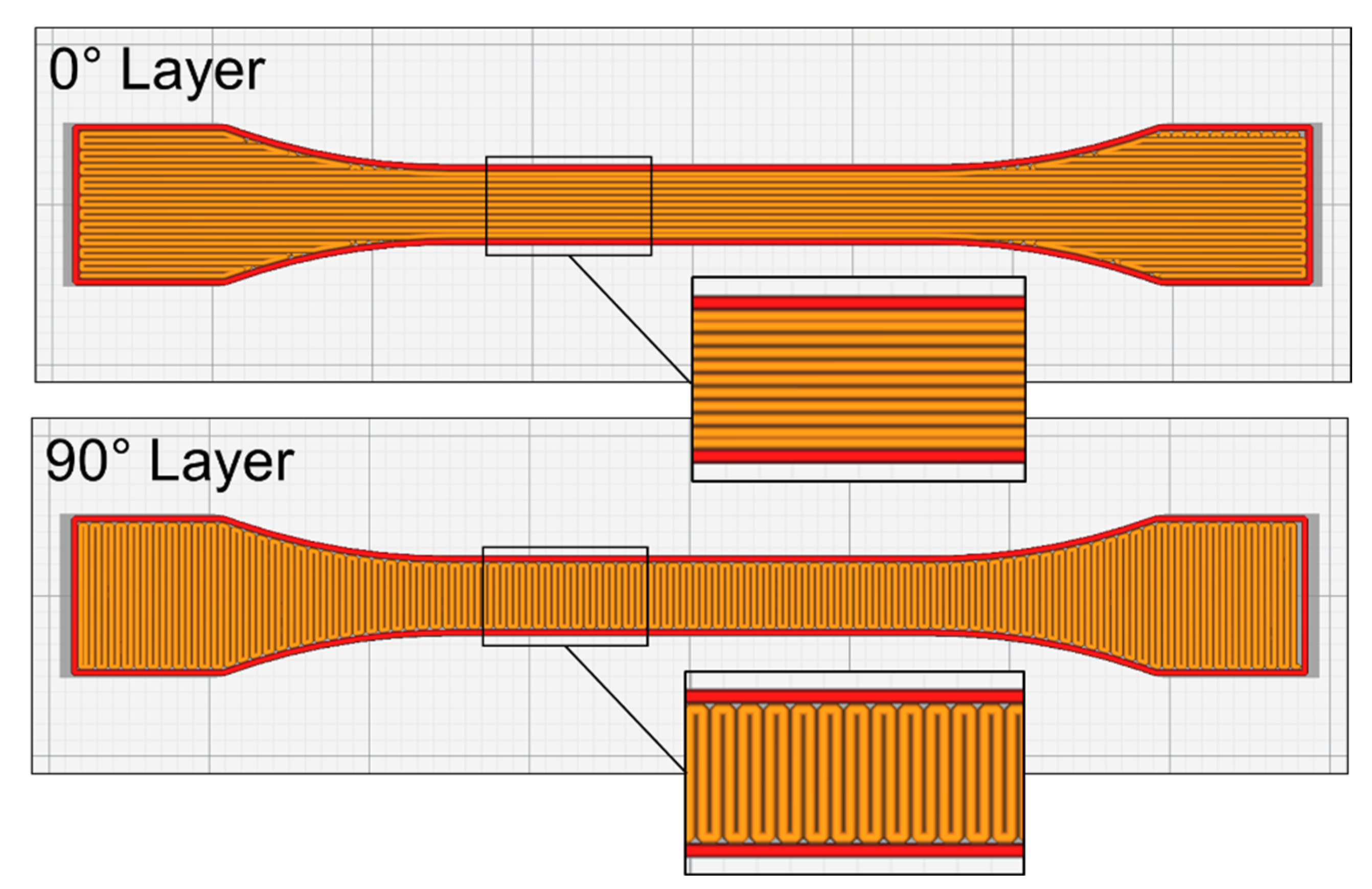

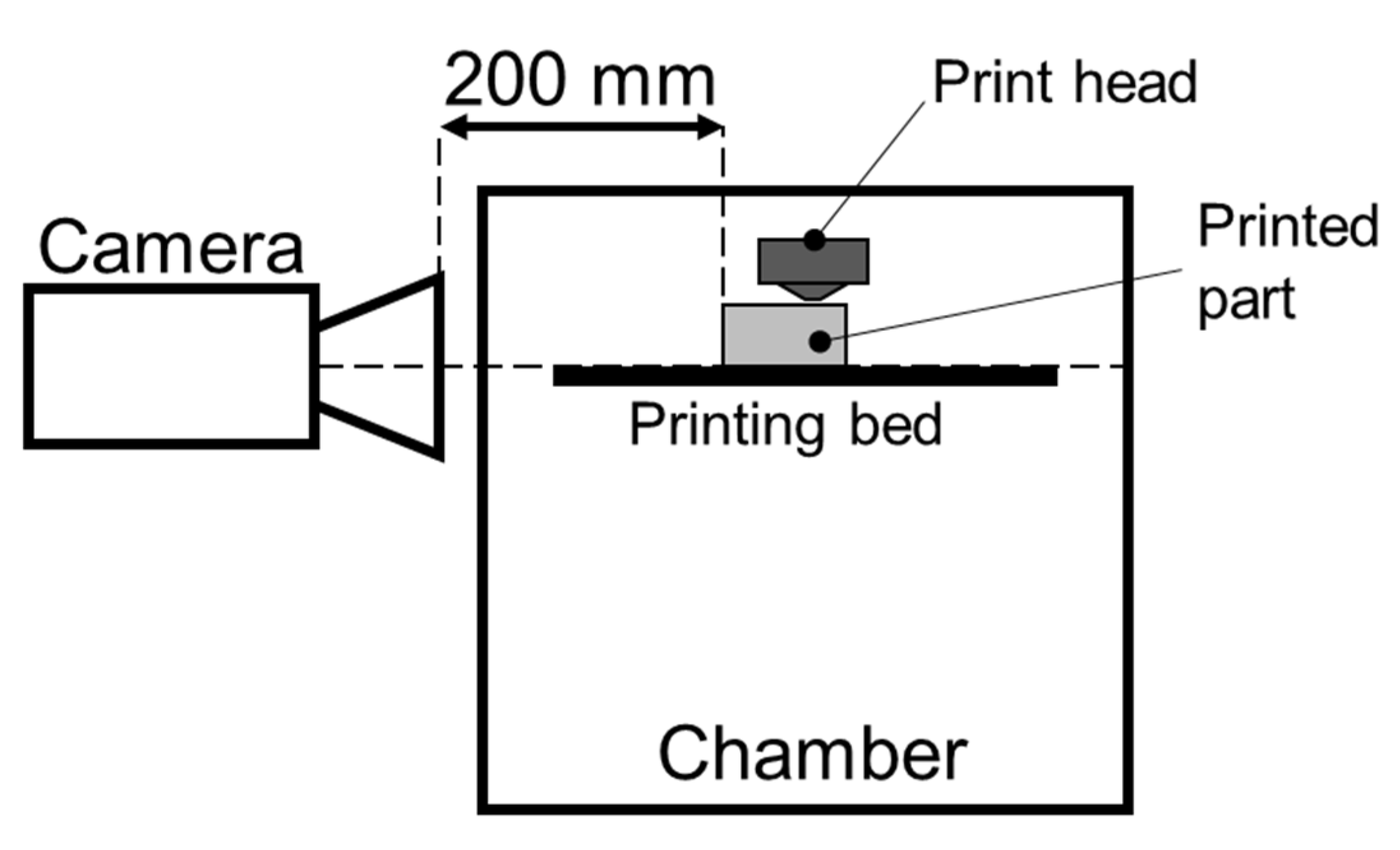

2.2. Process Setup, Specimen Geometry and Mechanical Testing

2.3. Process Parameters and Data Analysis

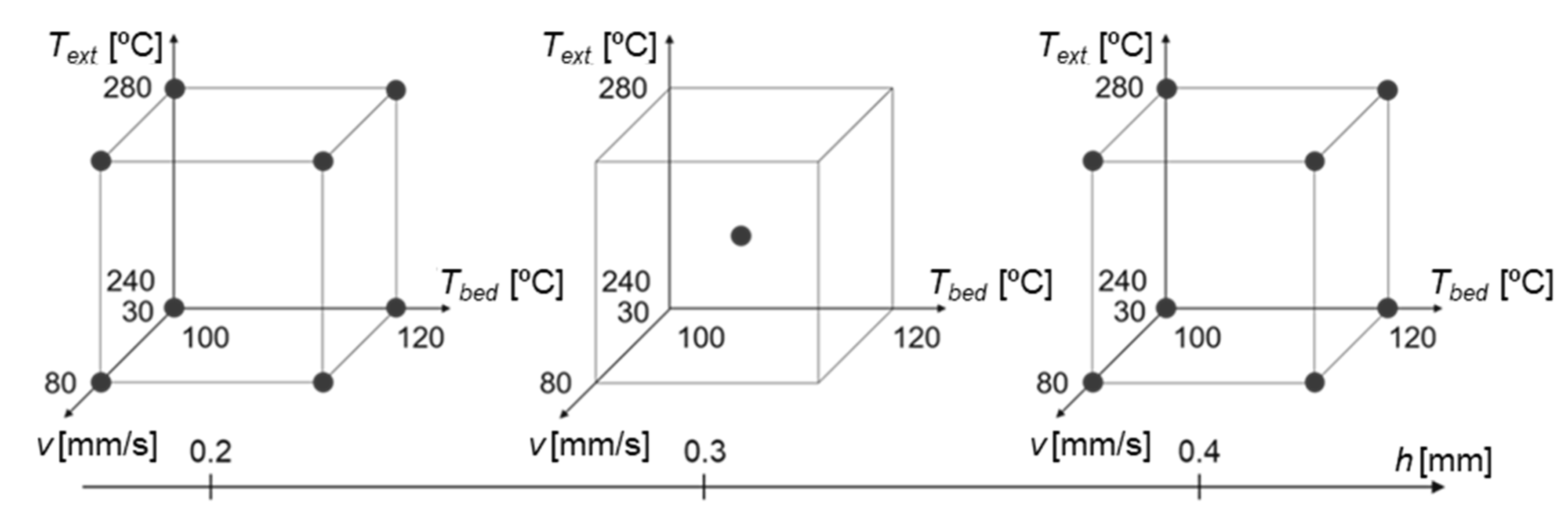

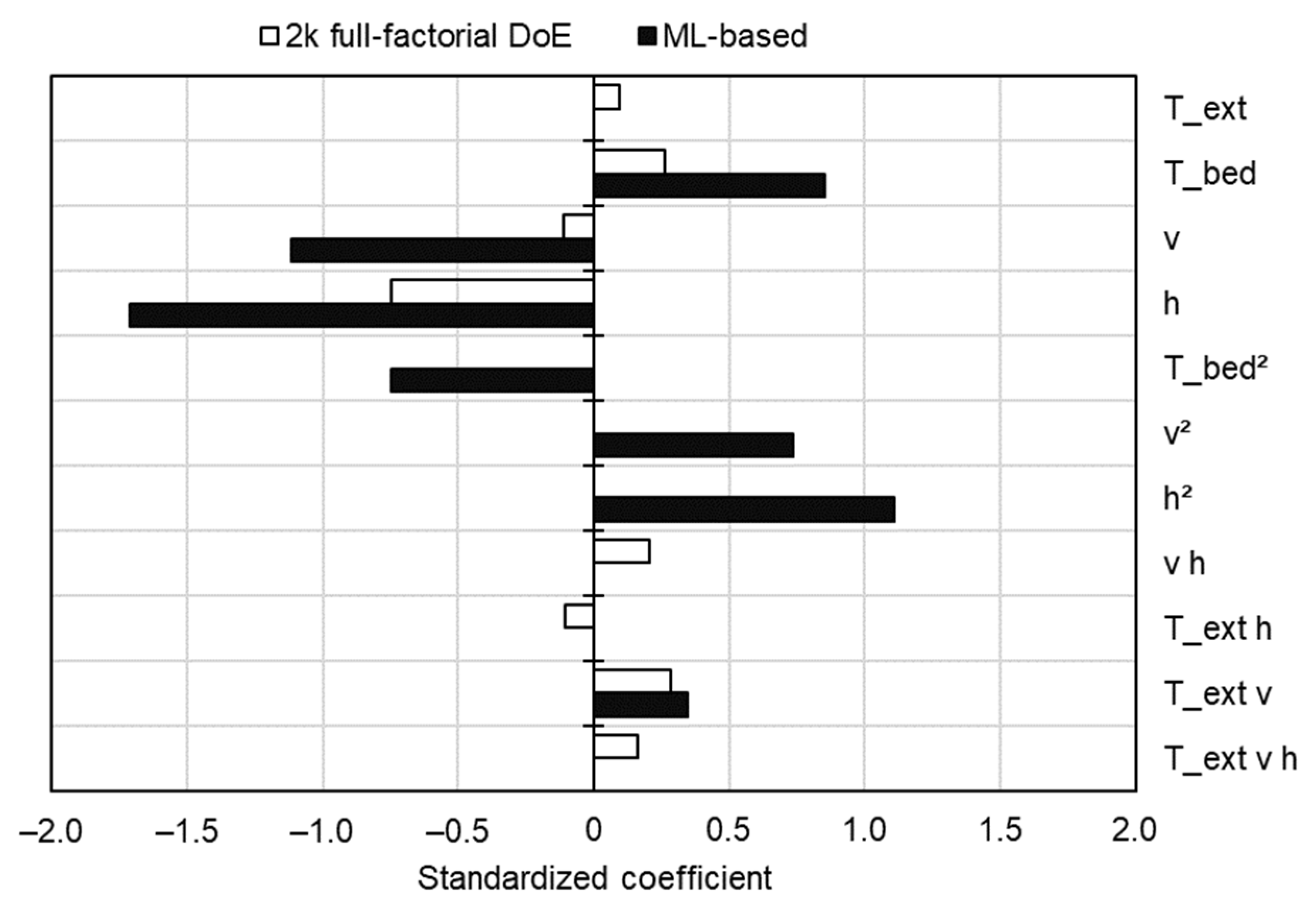

2.3.1. Prediction Model Based on 2k Full Factorial DoE

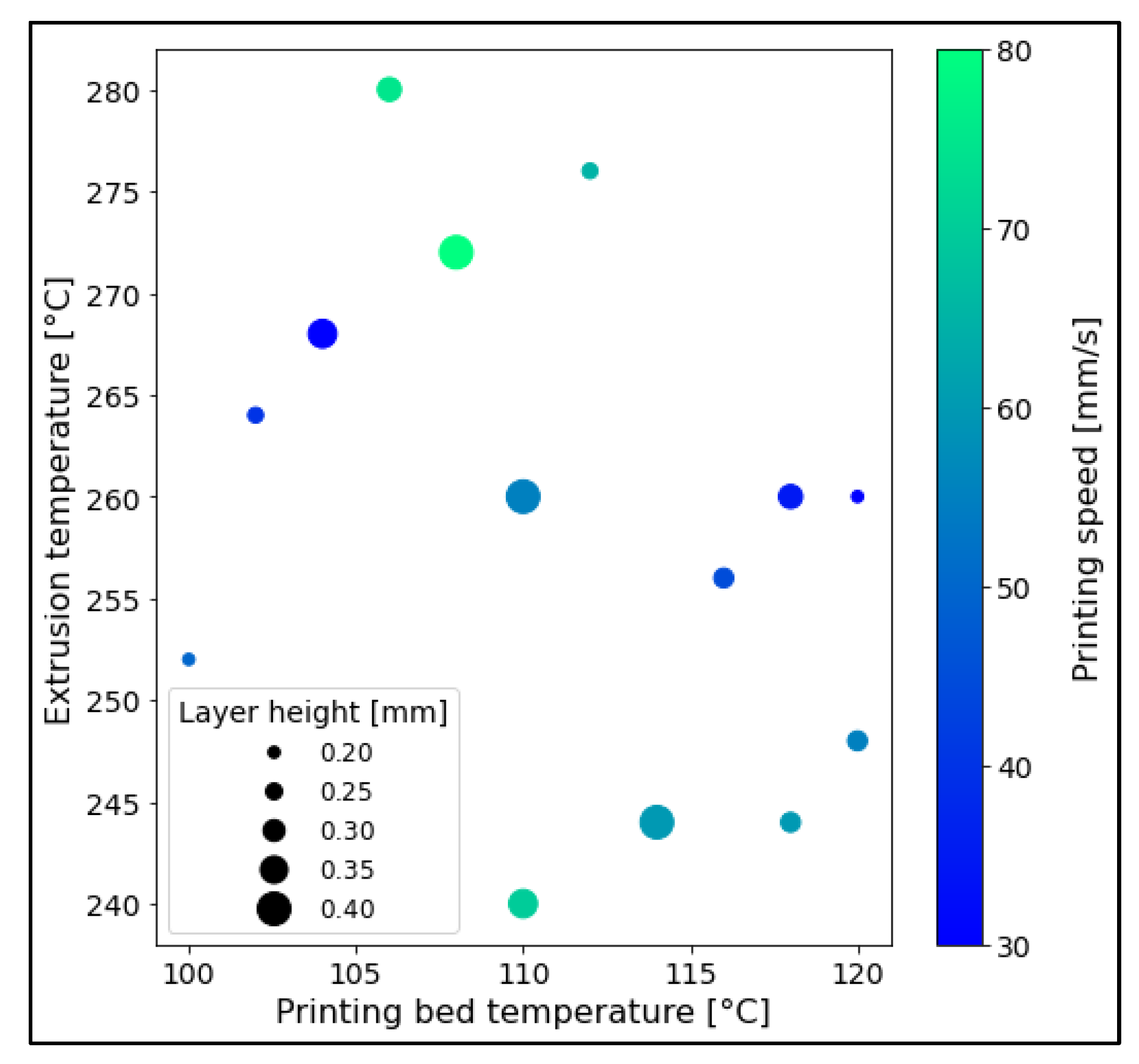

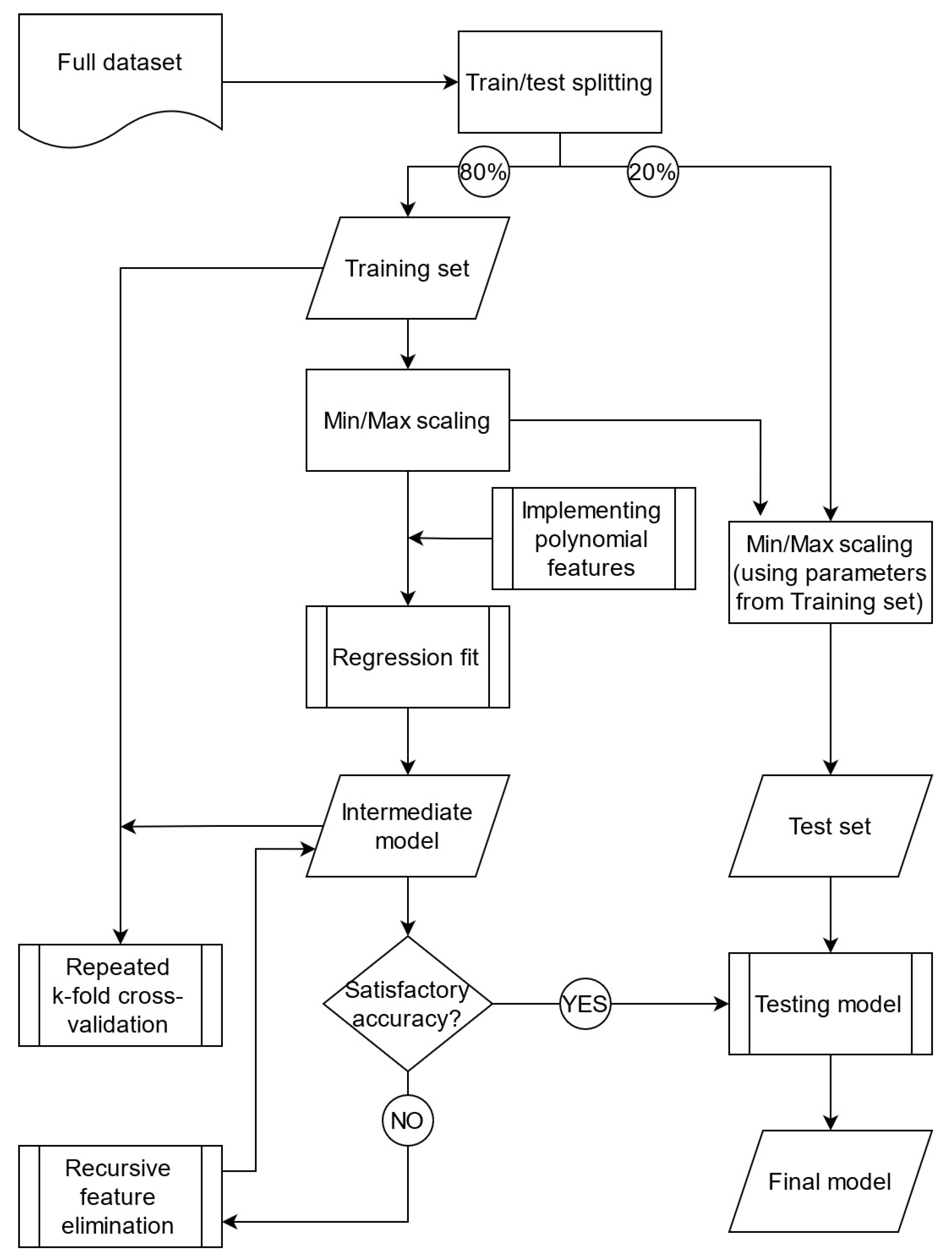

2.3.2. Prediction Model Based on Polynomial Regression Using Machine Learning Principles

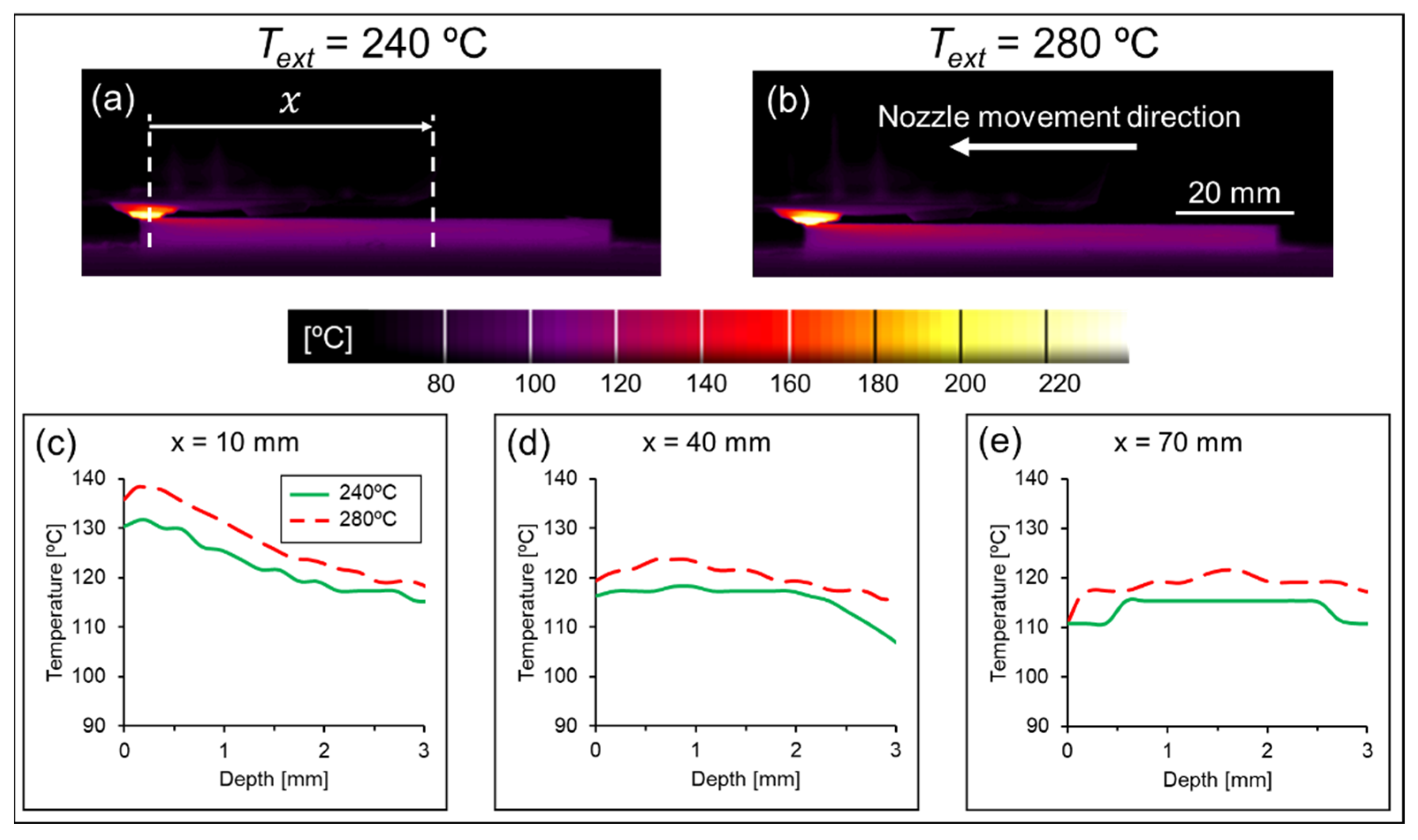

2.4. Temperature Measurements

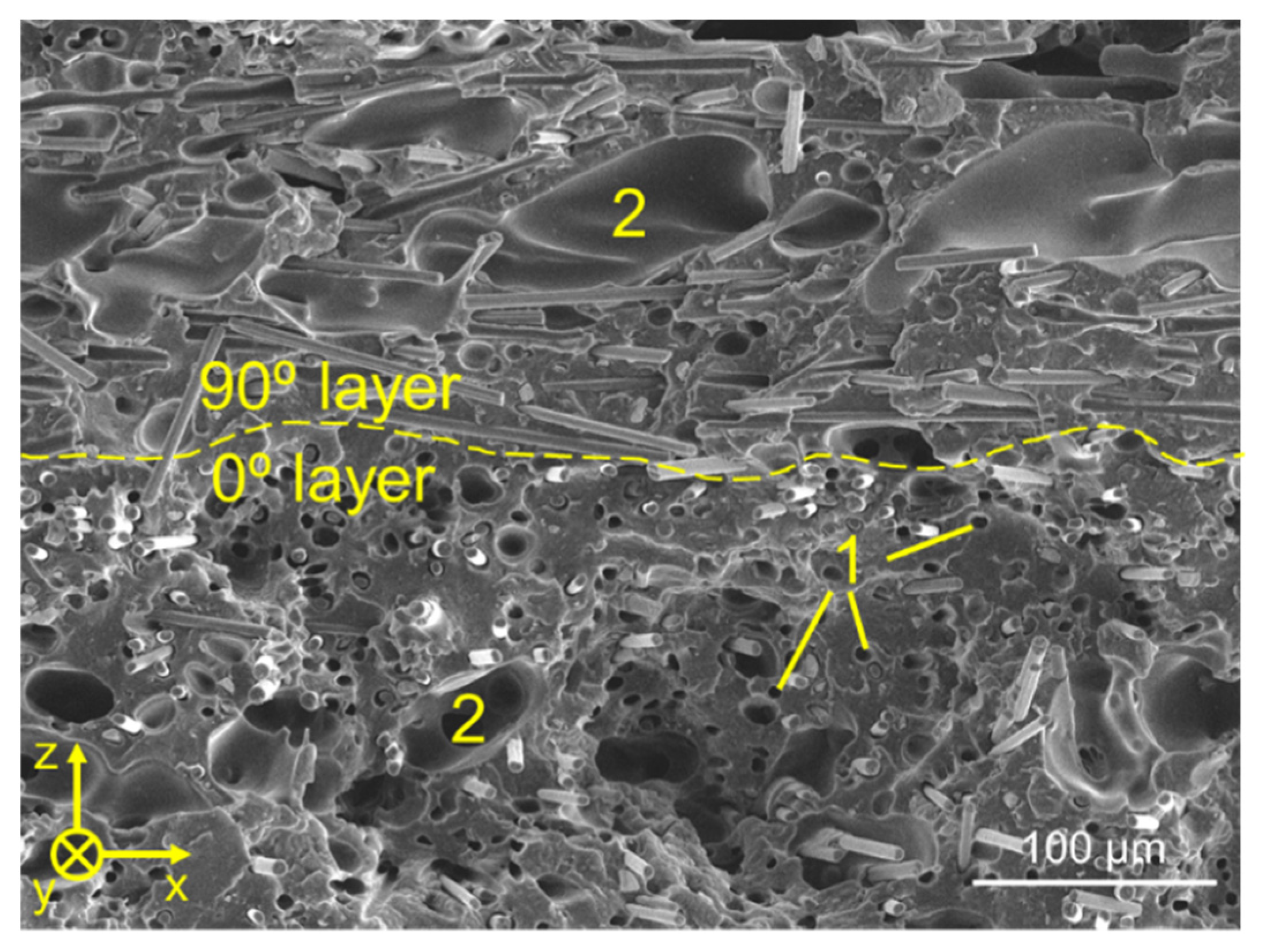

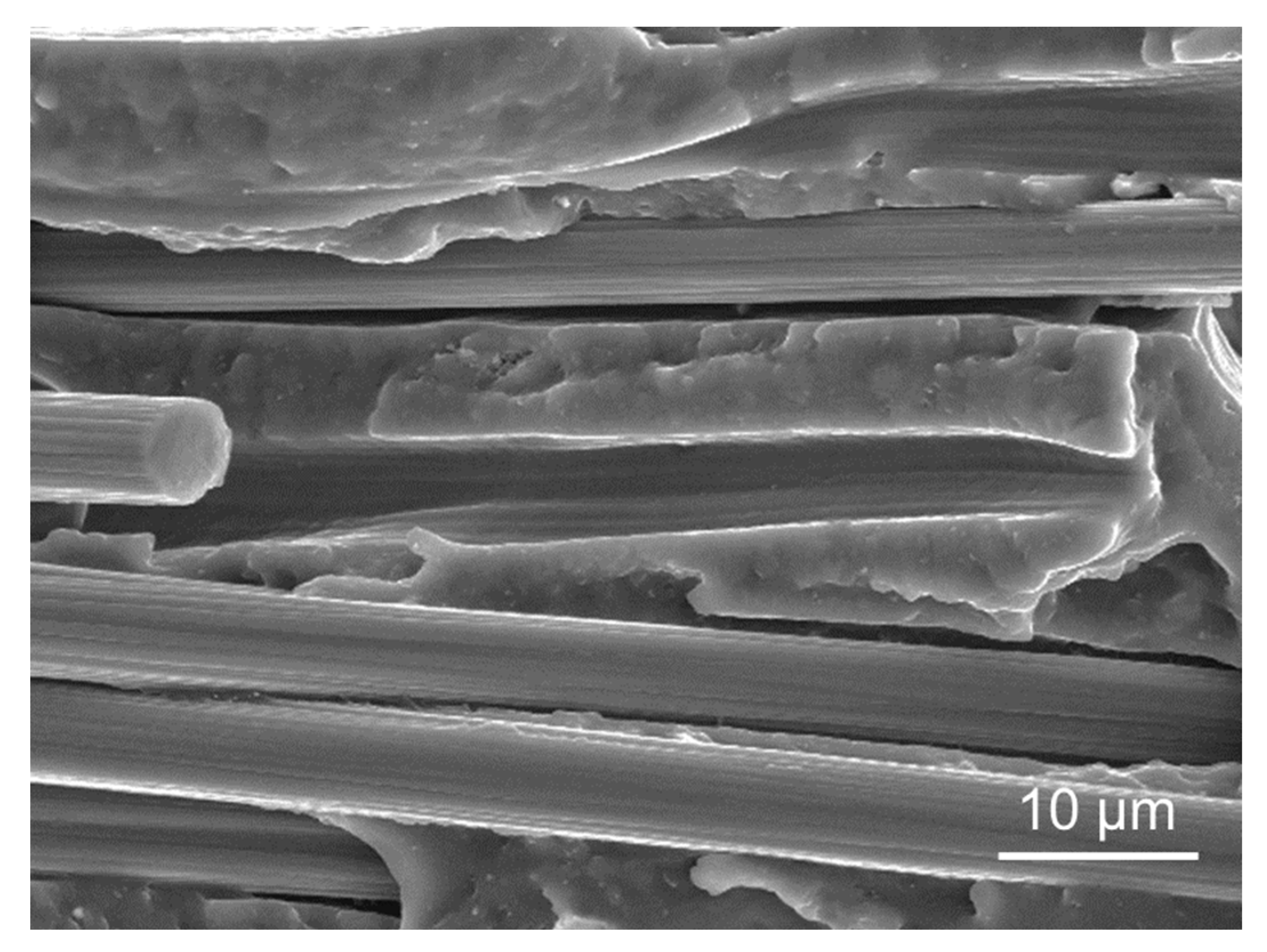

2.5. Microstructural Analysis and Fractography

3. Results and Discussion

3.1. Process Optimization

3.1.1. Prediction Model Based on the 2k Full Factorial DoE

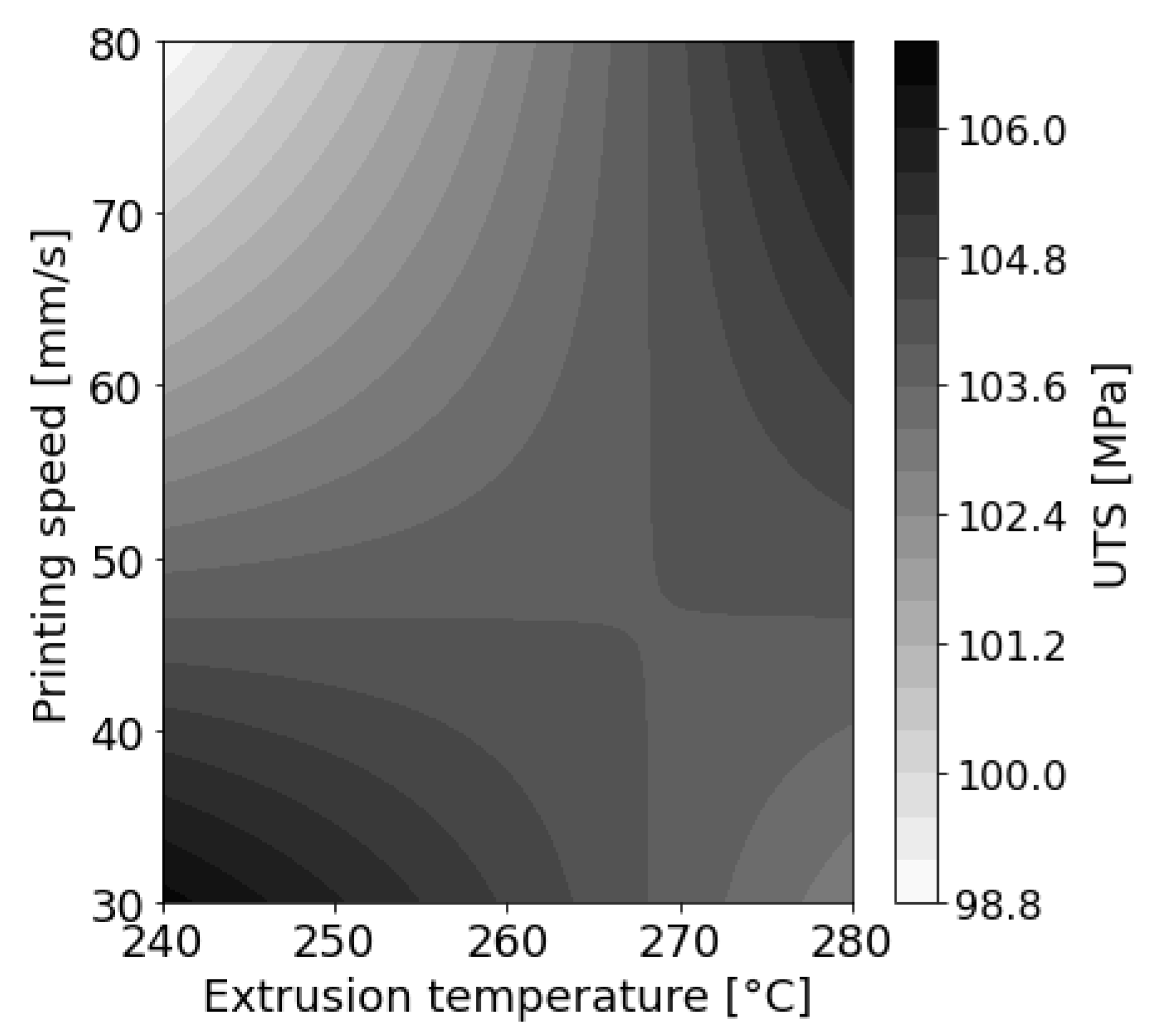

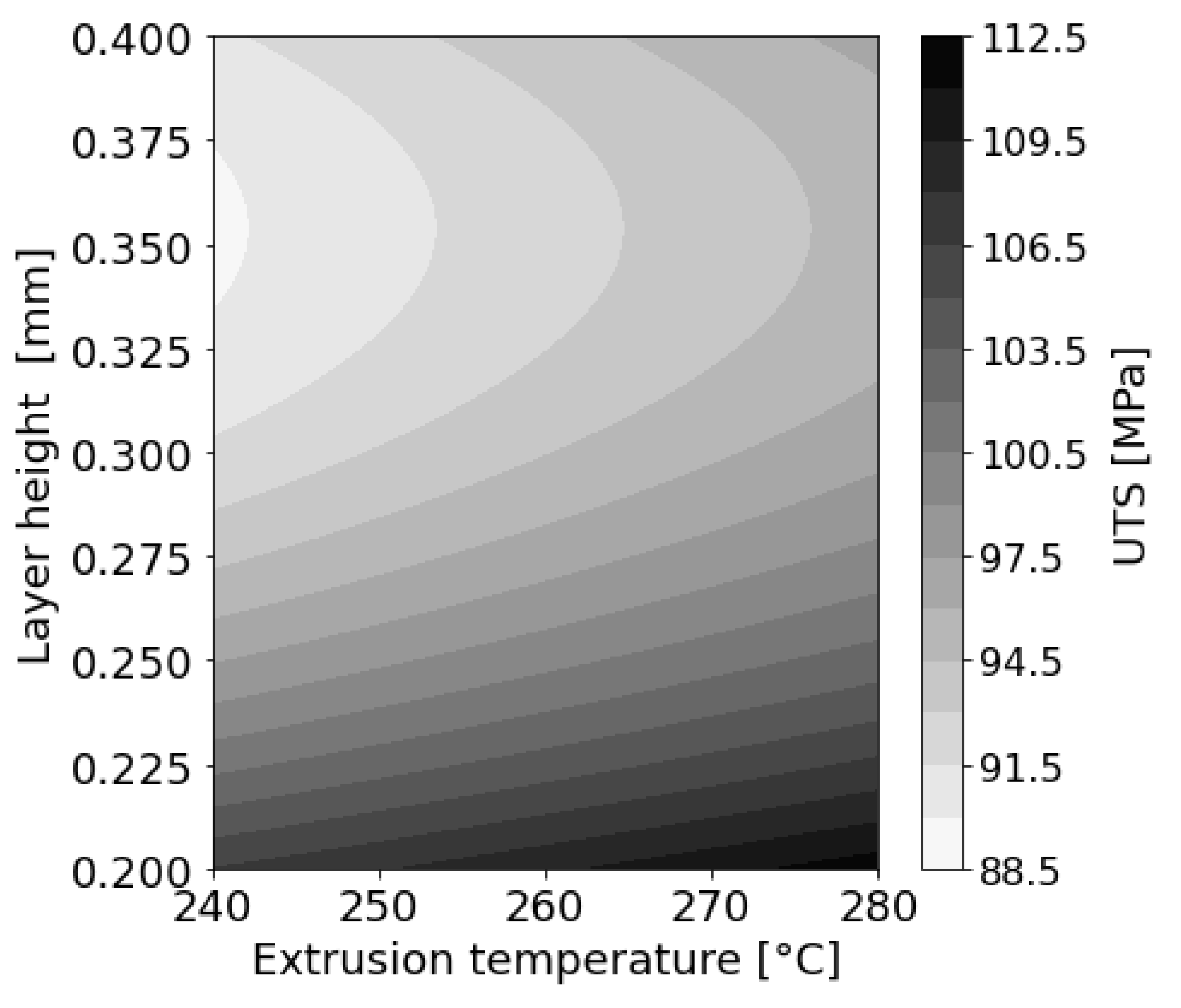

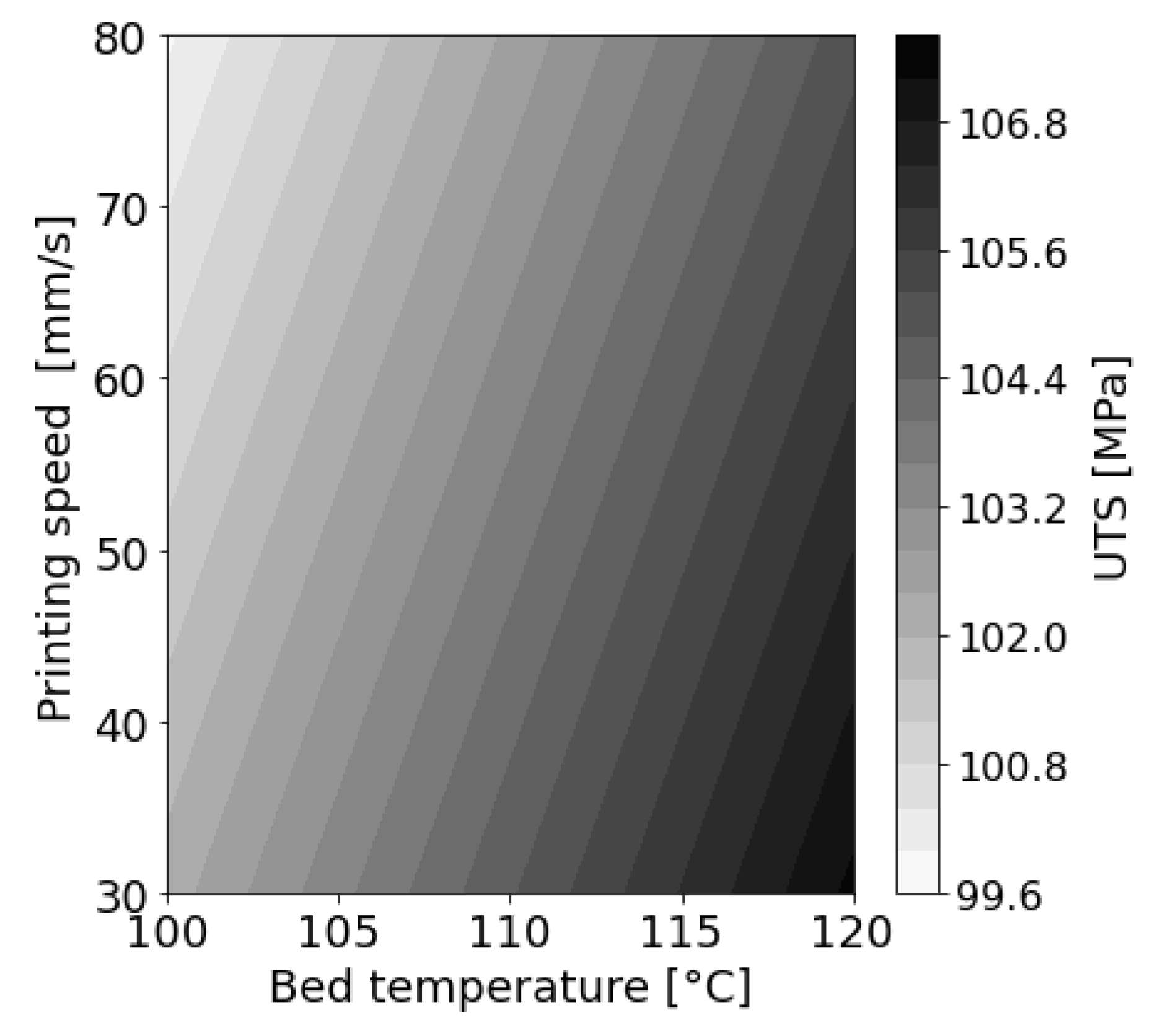

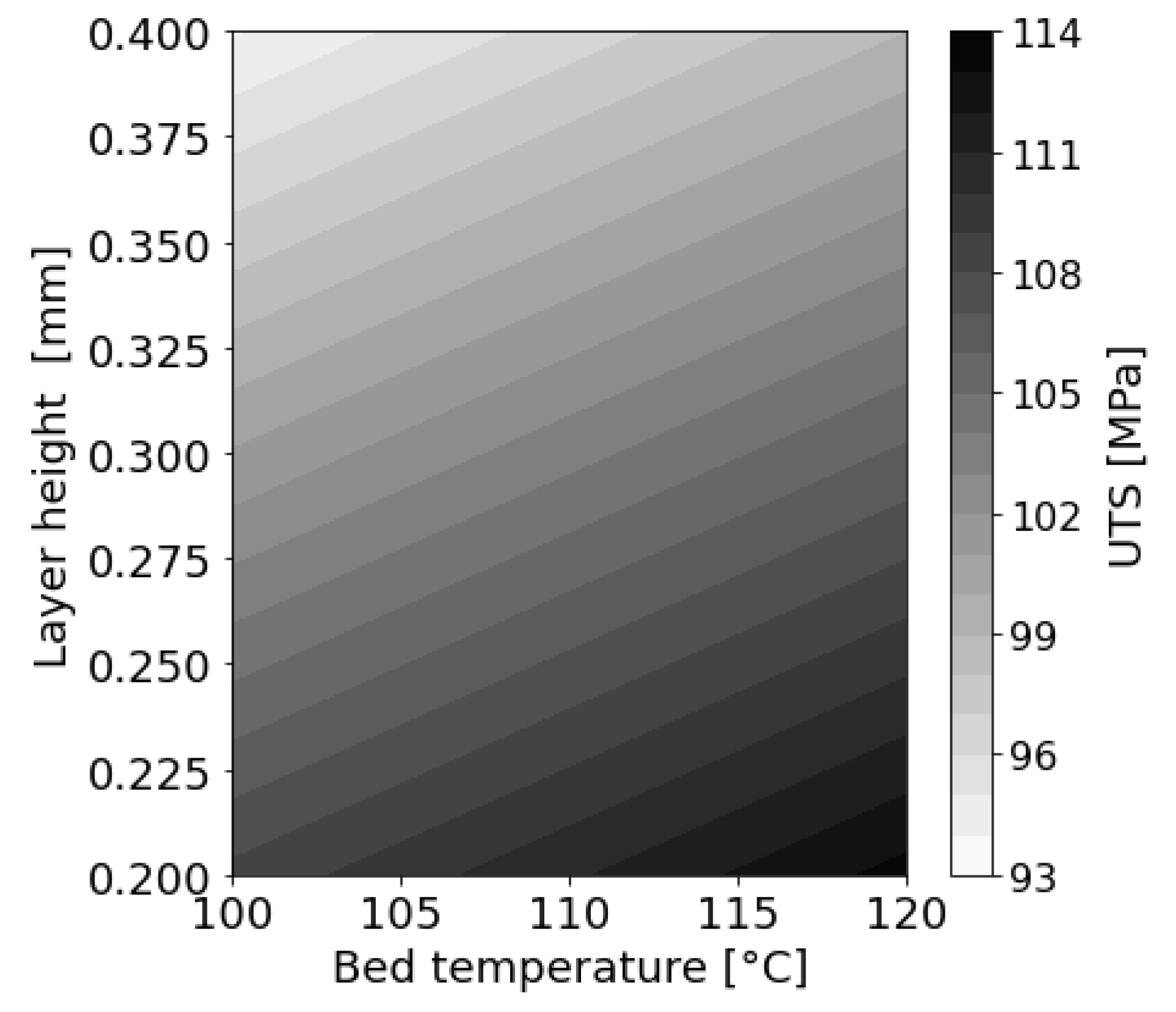

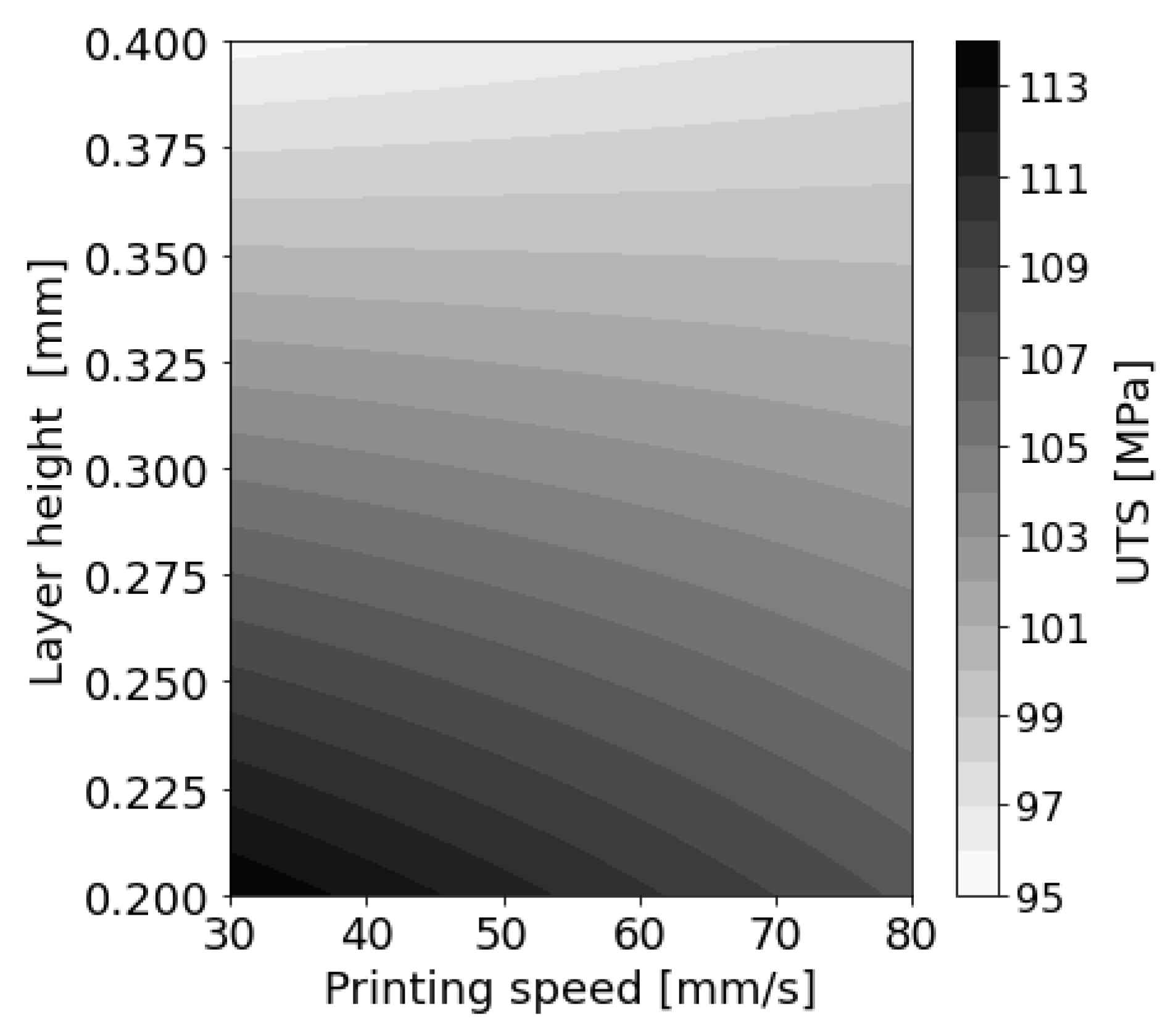

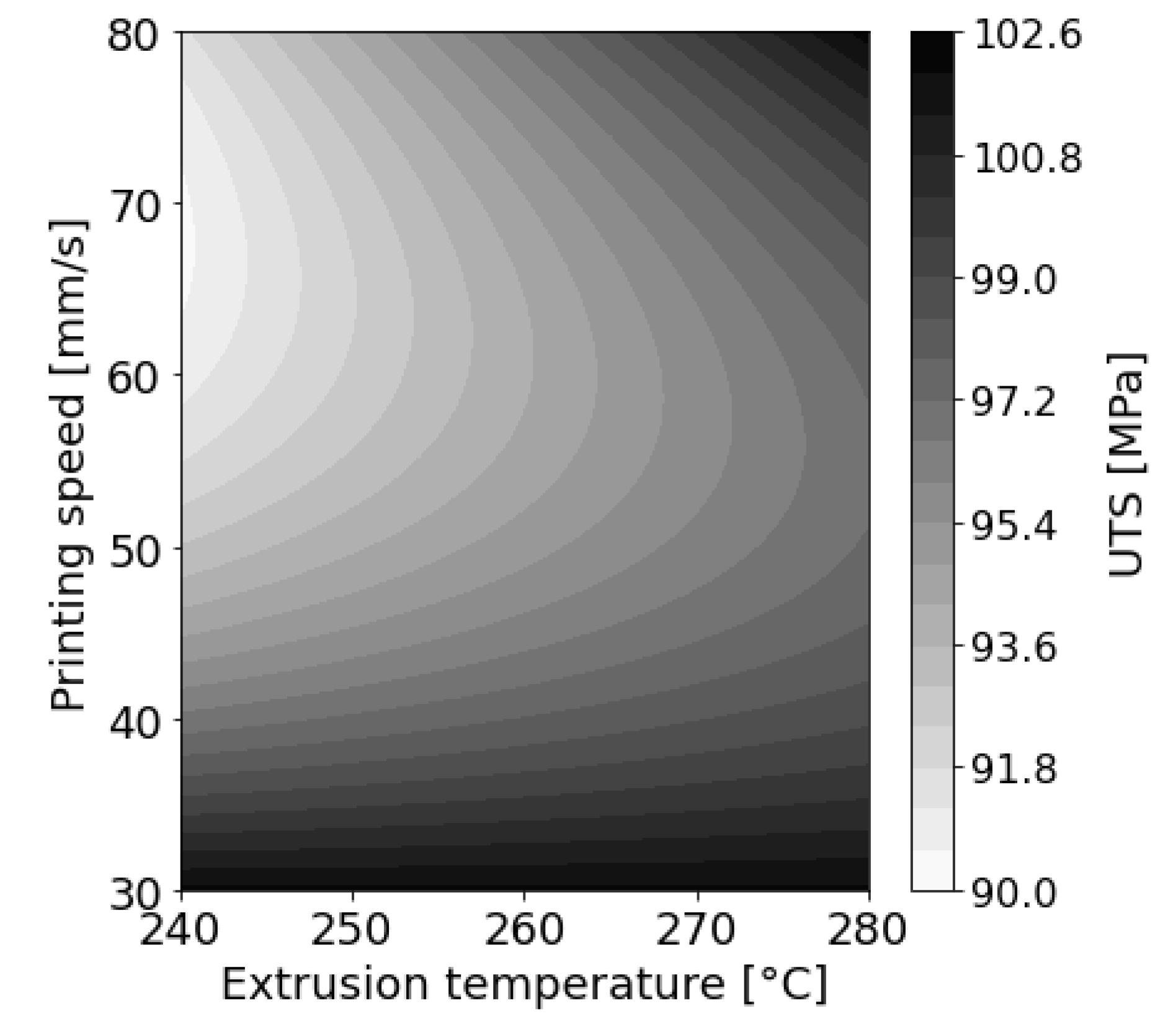

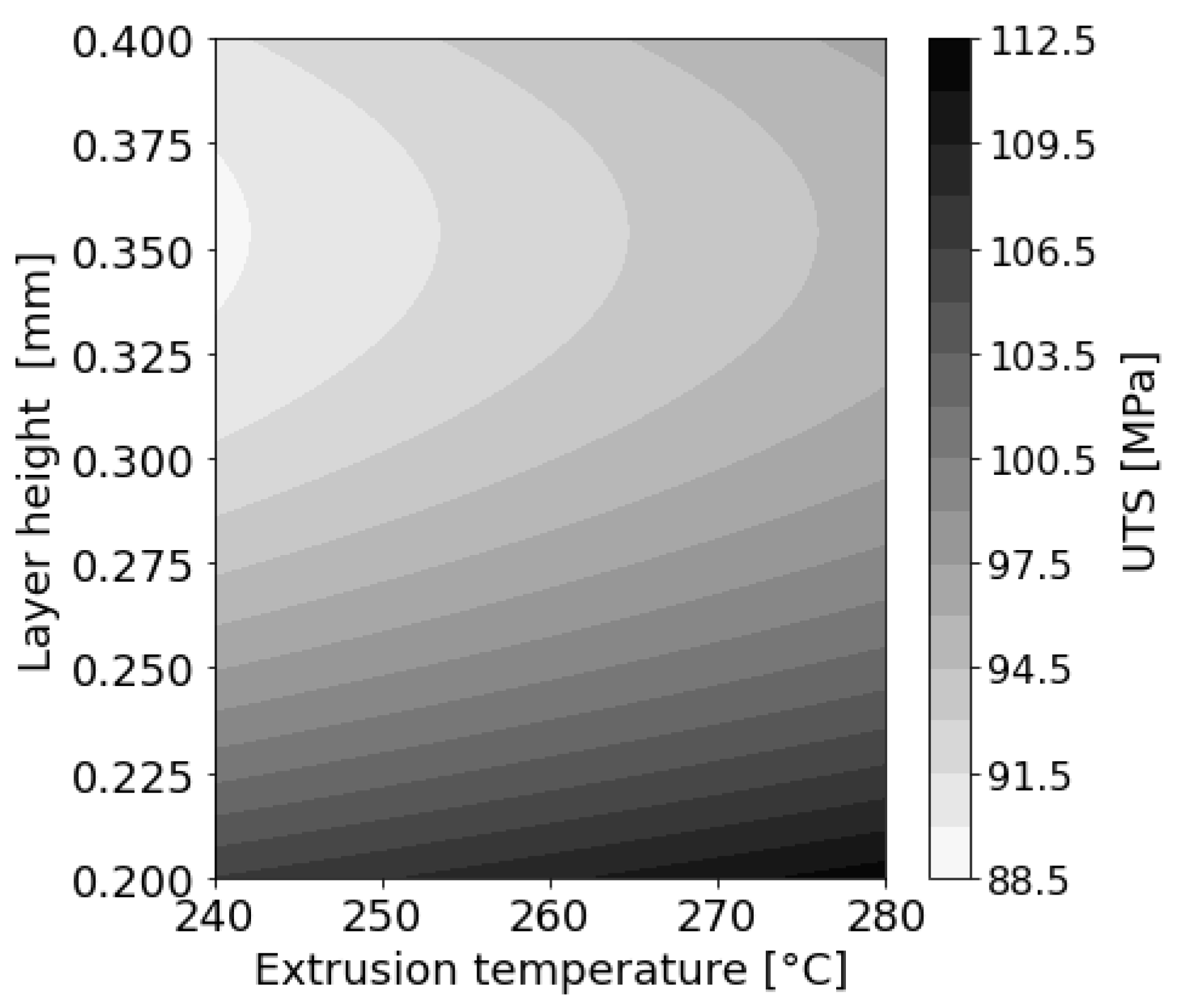

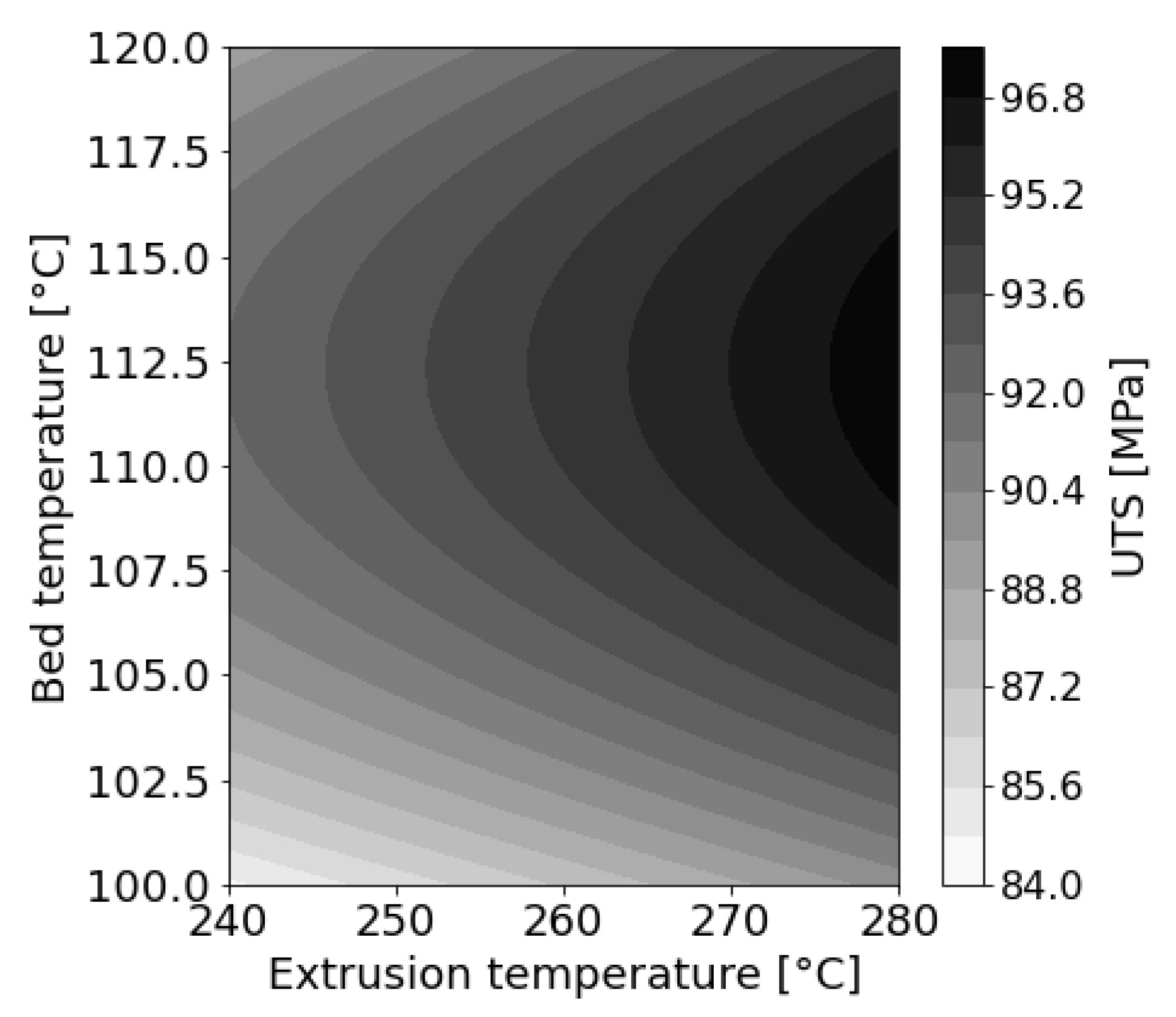

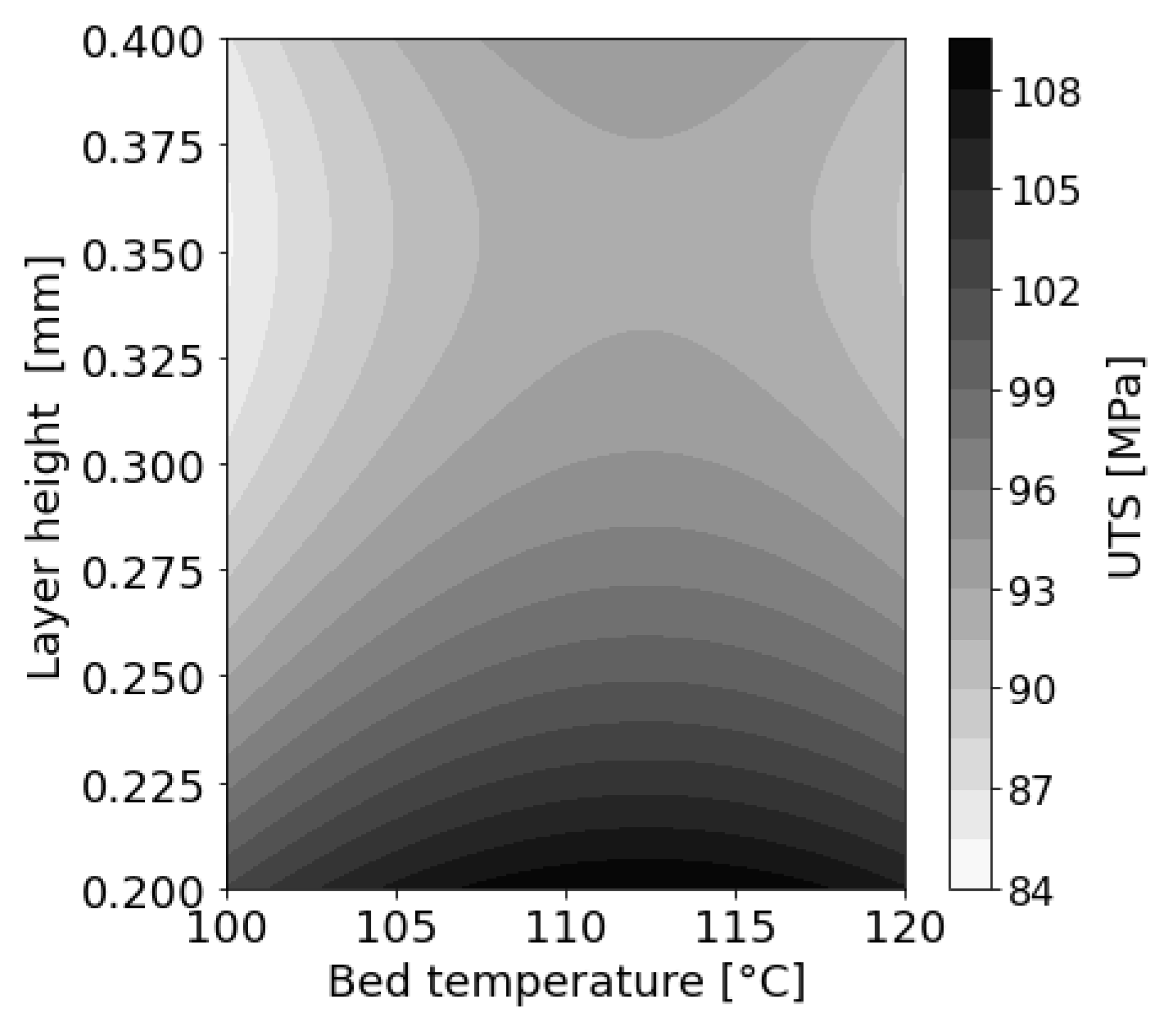

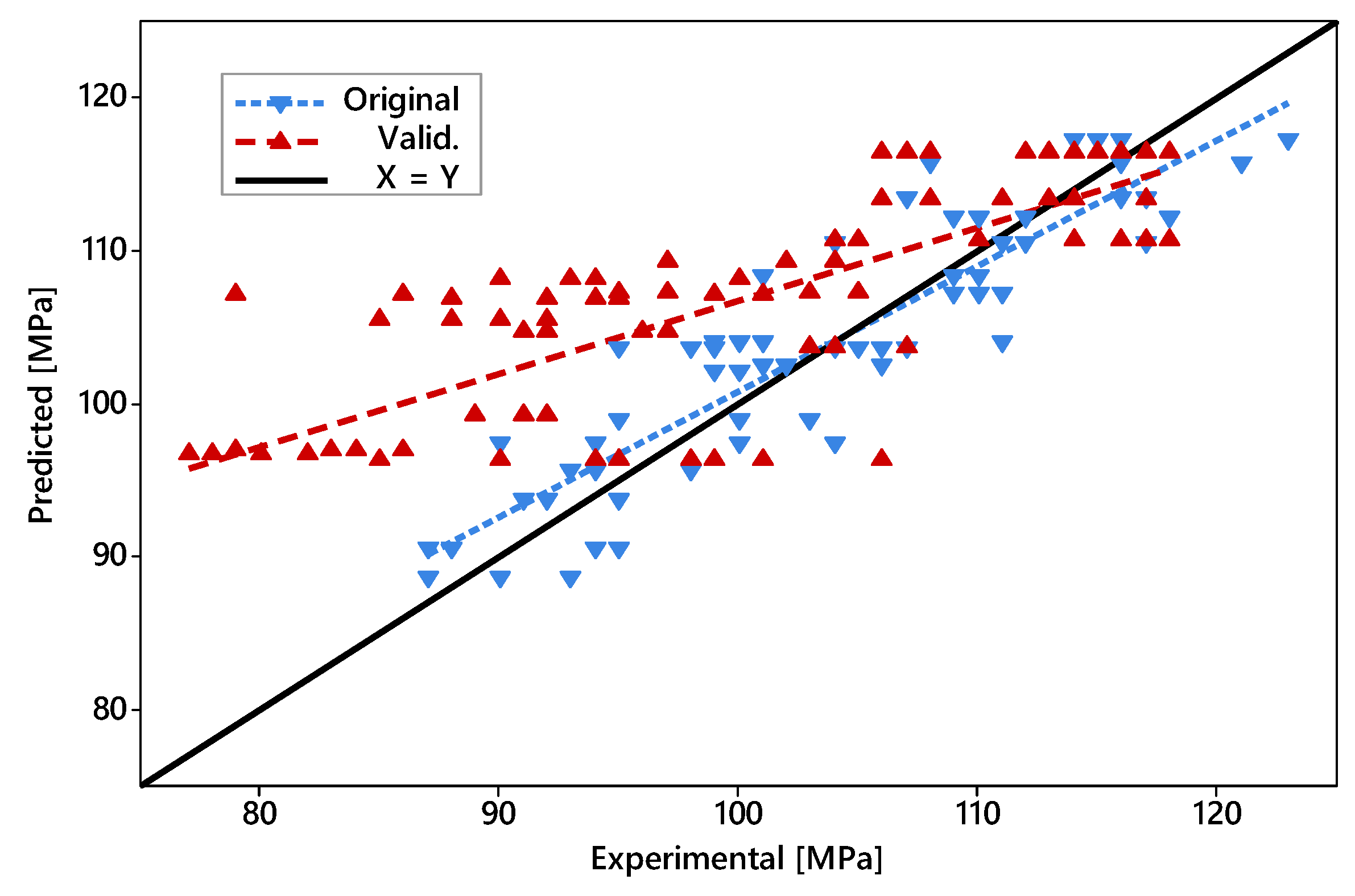

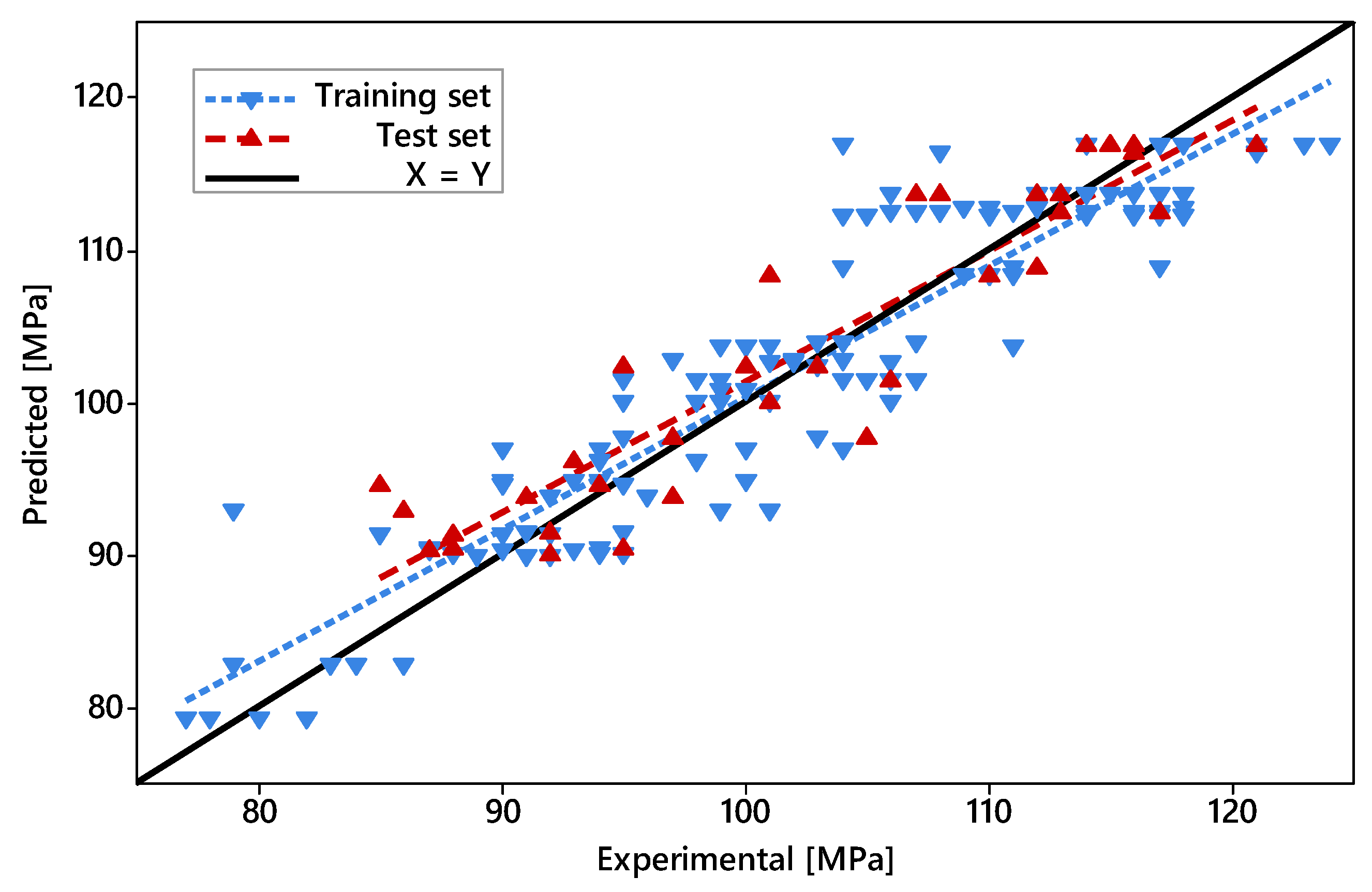

3.1.2. Prediction Model Based on Polynomial Regression Applying ML Principles

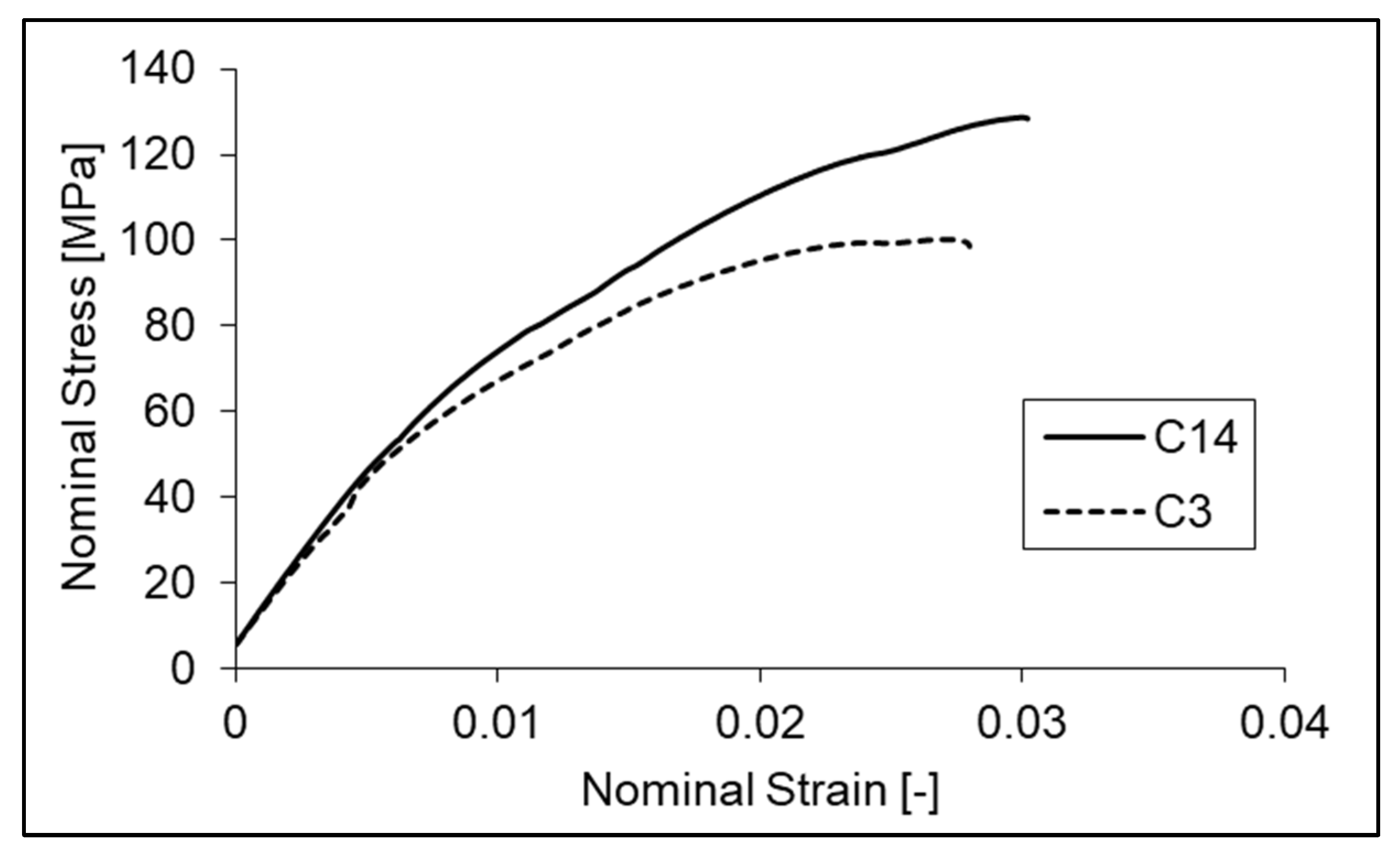

3.2. Material Behavior under Load: General Aspects

3.3. Influence of Process Parameters on the Mechanical Performance

3.3.1. Influence of Layer Height, h

3.3.2. Influence of Printing Bed Temperature, Tbed

3.3.3. Influence of Extrusion Temperature, Text, and Printing Speed, v

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Appendix B

References

- Zhu, L.; Li, N.; Childs, P.R.N. Light-Weighting in Aerospace Component and System Design. Propuls. Power Res. 2018, 7, 103–119. [Google Scholar] [CrossRef]

- Belarbi, A.; Dawood, M.; Acun, B. 20—Sustainability of Fiber-Reinforced Polymers (FRPs) as a Construction Material. In Sustainability of Construction Materials, 2nd ed.; Khatib, J.M., Ed.; Woodhead Publishing Series in Civil and Structural Engineering; Woodhead Publishing: Cambridge, UK, 2016; pp. 521–538. ISBN 978-0-08-100995-6. [Google Scholar]

- Ziehl, P.; Anay, R.; Myers, J.J. 6—Durability of Fiber-Reinforced Plastics for Infrastructure Applications. In Durability of Composite Systems; Reifsnider, K.L., Ed.; Woodhead Publishing Series in Composites Science and Engineering; Woodhead Publishing: Cambridge, UK, 2020; pp. 271–288. ISBN 978-0-12-818260-4. [Google Scholar]

- Liang, R.; Hota, G. 16—Fiber-Reinforced Polymer (FRP) Composites in Environmental Engineering Applications. In Developments in Fiber-Reinforced Polymer (FRP) Composites for Civil Engineering; Uddin, N., Ed.; Woodhead Publishing Series in Civil and Structural Engineering; Woodhead Publishing: Cambridge, UK, 2013; pp. 410–468. ISBN 978-0-85709-234-2. [Google Scholar]

- Dmitruk, A.; Kaczmar, J. Application of Polymer Based Composite Materials in Transportation. Prog. Rubber Plast. Recycl. Technol. 2016, 32, 1–24. [Google Scholar] [CrossRef]

- Zhang, J.; Chevali, V.S.; Wang, H.; Wang, C.-H. Current Status of Carbon Fibre and Carbon Fibre Composites Recycling. Compos. Part B Eng. 2020, 193, 108053. [Google Scholar] [CrossRef]

- Thermoset Composites Market by Manufacturing Process (Lay-Up, Filament Winding, Injection Molding, Pultrusion), Fiber Type (Glass, Carbon), Resin Type (Polyester, Epoxy, Vinyl Ester), End-Use Industry, and Region—Global Forecast to 2021. Available online: https://www.researchandmarkets.com/reports/4091266/thermoset-composites-market-by-manufacturing (accessed on 12 February 2022).

- Thermoplastic Composites Market—Growth, Trends, COVID-19 Impact, and Forecasts (2021–2026). Available online: https://www.researchandmarkets.com/reports/4622426/thermoplastic-composites-market-growth-trends (accessed on 12 February 2022).

- Yao, S.-S.; Jin, F.-L.; Rhee, K.Y.; Hui, D.; Park, S.-J. Recent Advances in Carbon-Fiber-Reinforced Thermoplastic Composites: A Review. Compos. Part B Eng. 2018, 142, 241–250. [Google Scholar] [CrossRef]

- Ma, Y.; Yang, Y.; Sugahara, T.; Hamada, H. A Study on the Failure Behavior and Mechanical Properties of Unidirectional Fiber Reinforced Thermosetting and Thermoplastic Composites. Compos. Part B Eng. 2016, 99, 162–172. [Google Scholar] [CrossRef]

- Reis, J.P.; de Moura, M.; Samborski, S. Thermoplastic Composites and Their Promising Applications in Joining and Repair Composites Structures: A Review. Materials 2020, 13, 5832. [Google Scholar] [CrossRef]

- Ning, F.; Cong, W.; Qiu, J.; Wei, J.; Wang, S. Additive Manufacturing of Carbon Fiber Reinforced Thermoplastic Composites Using Fused Deposition Modeling. Compos. Part B Eng. 2015, 80, 369–378. [Google Scholar] [CrossRef]

- Valino, A.D.; Dizon, J.R.C.; Espera, A.H.; Chen, Q.; Messman, J.; Advincula, R.C. Advances in 3D Printing of Thermoplastic Polymer Composites and Nanocomposites. Prog. Polym. Sci. 2019, 98, 101162. [Google Scholar] [CrossRef]

- Chacón, J.M.; Caminero, M.A.; Núñez, P.J.; García-Plaza, E.; García-Moreno, I.; Reverte, J.M. Additive Manufacturing of Continuous Fibre Reinforced Thermoplastic Composites Using Fused Deposition Modelling: Effect of Process Parameters on Mechanical Properties. Compos. Sci. Technol. 2019, 181, 107688. [Google Scholar] [CrossRef]

- Dickson, A.N.; Abourayana, H.M.; Dowling, D.P. 3D Printing of Fibre-Reinforced Thermoplastic Composites Using Fused Filament Fabrication—A Review. Polymers 2020, 12, 2188. [Google Scholar] [CrossRef]

- Hu, Q.; Duan, Y.; Zhang, H.; Liu, D.; Yan, B.; Peng, F. Manufacturing and 3D Printing of Continuous Carbon Fiber Prepreg Filament. J. Mater. Sci. 2018, 53, 1887–1898. [Google Scholar] [CrossRef]

- Matsuzaki, R.; Ueda, M.; Namiki, M.; Jeong, T.-K.; Asahara, H.; Horiguchi, K.; Nakamura, T.; Todoroki, A.; Hirano, Y. Three-Dimensional Printing of Continuous-Fiber Composites by in-Nozzle Impregnation. Sci. Rep. 2016, 6, 23058. [Google Scholar] [CrossRef] [PubMed]

- Yang, C.; Tian, X.; Liu, T.; Cao, Y.; Li, D. 3D Printing for Continuous Fiber Reinforced Thermoplastic Composites: Mechanism and Performance. Rapid Prototyp. J. 2017, 23, 209–215. [Google Scholar] [CrossRef]

- Aburaia, M.; Bucher, C.; Lackner, M.; Gonzalez-Gutierrez, J.; Zhang, H.; Lammer, H. A Production Method for Standardized Continuous Fiber Reinforced FFF Filament. Biomater. Med. Appl. 2020, 4. [Google Scholar] [CrossRef]

- Ye, W.; Lin, G.; Wu, W.; Geng, P.; Hu, X.; Gao, Z.; Zhao, J. Separated 3D Printing of Continuous Carbon Fiber Reinforced Thermoplastic Polyimide. Compos. Part A Appl. Sci. Manuf. 2019, 121, 457–464. [Google Scholar] [CrossRef]

- Mark, G.T.; Gozdz, A.S. Three Dimensional Printer with Composite Filament Fabrication. U.S. Patent 9,156,205, 13 October 2015. [Google Scholar]

- Sanei, S.H.R.; Popescu, D. 3D-Printed Carbon Fiber Reinforced Polymer Composites: A Systematic Review. J. Compos. Sci. 2020, 4, 98. [Google Scholar] [CrossRef]

- Naranjo-Lozada, J.; Ahuett-Garza, H.; Orta-Castañón, P.; Verbeeten, W.M.H.; Sáiz-González, D. Tensile Properties and Failure Behavior of Chopped and Continuous Carbon Fiber Composites Produced by Additive Manufacturing. Addit. Manuf. 2019, 26, 227–241. [Google Scholar] [CrossRef]

- Isobe, T.; Tanaka, T.; Nomura, T.; Yuasa, R. Comparison of Strength of 3D Printing Objects Using Short Fiber and Continuous Long Fiber. In IOP Conference Series: Materials Science and Engineering, Proceedings of the 13th International Conference on Textile Composites (TEXCOMP-13), Milan, Italy, 17–19 September 2018; IOP Publishing: Bristol, UK, 2018; Volume 406, p. 012042. [Google Scholar] [CrossRef]

- Zhang, X.; Fan, W.; Liu, T. Fused Deposition Modeling 3D Printing of Polyamide-Based Composites and Its Applications. Compos. Commun. 2020, 21, 100413. [Google Scholar] [CrossRef]

- Rahimizadeh, A.; Kalman, J.; Fayazbakhsh, K.; Lessard, L. Mechanical and Thermal Study of 3D Printing Composite Filaments from Wind Turbine Waste. Polym. Compos. 2021, 42, 2305–2316. [Google Scholar] [CrossRef]

- Rangisetty, S.; Peel, L. The Effect of Infill Patterns and Annealing on Mechanical Properties of Additively Manufactured Thermoplastic Composites. In Proceedings of the Smart Materials, Adaptive Structures and Intelligent Systems 2017, Snowbird, UT, USA, 18–20 September 2017. [Google Scholar]

- Ferreira, I.; Machado, M.; Alves, F.; Torres Marques, A. A Review on Fibre Reinforced Composite Printing via FFF. Rapid Prototyp. J. 2019, 25, 972–988. [Google Scholar] [CrossRef]

- Penumakala, P.K.; Santo, J.; Thomas, A. A Critical Review on the Fused Deposition Modeling of Thermoplastic Polymer Composites. Compos. Part B Eng. 2020, 201, 108336. [Google Scholar] [CrossRef]

- Pratama, J.; Cahyono, S.I.; Suyitno, S.; Muflikhun, M.A.; Salim, U.A.; Mahardika, M.; Arifvianto, B. A Review on Reinforcement Methods for Polymeric Materials Processed Using Fused Filament Fabrication (FFF). Polymers 2021, 13, 4022. [Google Scholar] [CrossRef] [PubMed]

- Liao, G.; Li, Z.; Cheng, Y.; Xu, D.; Zhu, D.; Jiang, S.; Guo, J.; Chen, X.; Xu, G.; Zhu, Y. Properties of Oriented Carbon Fiber/Polyamide 12 Composite Parts Fabricated by Fused Deposition Modeling. Mater. Des. 2018, 139, 283–292. [Google Scholar] [CrossRef]

- Badini, C.; Padovano, E.; Camillis, R.D.; Lambertini, V.G.; Pietroluongo, M. Preferred Orientation of Chopped Fibers in Polymer-Based Composites Processed by Selective Laser Sintering and Fused Deposition Modeling: Effects on Mechanical Properties. J. Appl. Polym. Sci. 2020, 137, 49152. [Google Scholar] [CrossRef]

- Pei, S.; Wang, K.; Chen, C.-B.; Li, J.; Li, Y.; Zeng, D.; Su, X.; Yang, H. Process-Structure-Property Analysis of Short Carbon Fiber Reinforced Polymer Composite via Fused Filament Fabrication. J. Manuf. Processes 2021, 64, 544–556. [Google Scholar] [CrossRef]

- Peng, X.; Zhang, M.; Guo, Z.; Sang, L.; Hou, W. Investigation of Processing Parameters on Tensile Performance for FDM-Printed Carbon Fiber Reinforced Polyamide 6 Composites. Compos. Commun. 2020, 22, 100478. [Google Scholar] [CrossRef]

- Handwerker, M.; Wellnitz, J.; Marzbani, H.; Tetzlaff, U. Annealing of Chopped and Continuous Fibre Reinforced Polyamide 6 Produced by Fused Filament Fabrication. Compos. Part B Eng. 2021, 223, 109119. [Google Scholar] [CrossRef]

- Dul, S.; Fambri, L.; Pegoretti, A. High-Performance Polyamide/Carbon Fiber Composites for Fused Filament Fabrication: Mechanical and Functional Performances. J. Mater. Eng. Perform. 2021, 30, 5066–5085. [Google Scholar] [CrossRef]

- Toro, E.; Coello, J.; Martínez, A.; Eguía, V.; Ayllon, J. Investigation of a Short Carbon Fibre-Reinforced Polyamide and Comparison of Two Manufacturing Processes: Fused Deposition Modelling (FDM) and Polymer Injection Moulding (PIM). Materials 2020, 13, 672. [Google Scholar] [CrossRef] [Green Version]

- Abderrafai, Y.; Hadi Mahdavi, M.; Sosa-Rey, F.; Hérard, C.; Otero Navas, I.; Piccirelli, N.; Lévesque, M.; Therriault, D. Additive Manufacturing of Short Carbon Fiber-Reinforced Polyamide Composites by Fused Filament Fabrication: Formulation, Manufacturing and Characterization. Mater. Des. 2022, 214, 110358. [Google Scholar] [CrossRef]

- Ferreira, I.; Madureira, R.; Villa, S.; de Jesus, A.; Machado, M.; Alves, J.L. Machinability of PA12 and Short Fibre–Reinforced PA12 Materials Produced by Fused Filament Fabrication. Int. J. Adv. Manuf. Technol. 2020, 107, 885–903. [Google Scholar] [CrossRef]

- Ultrafuse PAHT CF15. Available online: https://www.ultrafusefff.com/product-category/innopro/paht-cf/ (accessed on 10 September 2021).

- Rtayli, N.; Enneya, N. Enhanced Credit Card Fraud Detection Based on SVM-Recursive Feature Elimination and Hyper-Parameters Optimization. J. Inf. Secur. Appl. 2020, 55, 102596. [Google Scholar] [CrossRef]

- Wang, C.; Pan, Y.; Chen, J.; Ouyang, Y.; Rao, J.; Jiang, Q. Indicator Element Selection and Geochemical Anomaly Mapping Using Recursive Feature Elimination and Random Forest Methods in the Jingdezhen Region of Jiangxi Province, South China. Appl. Geochem. 2020, 122, 104760. [Google Scholar] [CrossRef]

- Lepoivre, A.; Boyard, N.; Levy, A.; Sobotka, V. Heat Transfer and Adhesion Study for the FFF Additive Manufacturing Process. Procedia Manuf. 2020, 47, 948–955. [Google Scholar] [CrossRef]

- Rudolph, N.; Chen, J.; Dick, T. Understanding the Temperature Field in Fused Filament Fabrication for Enhanced Mechanical Part Performance. AIP Conf. Proc. 2019, 2055, 140003. [Google Scholar] [CrossRef]

- Richhariya, B.; Tanveer, M.; Rashid, A.H. Diagnosis of Alzheimer’s Disease Using Universum Support Vector Machine Based Recursive Feature Elimination (USVM-RFE). Biomed. Signal Process. Control 2020, 59, 101903. [Google Scholar] [CrossRef]

- Arif, M.; Ali, F.; Ahmad, S.; Kabir, M.; Ali, Z.; Hayat, M. Pred-BVP-Unb: Fast Prediction of Bacteriophage Virion Proteins Using Un-Biased Multi-Perspective Properties with Recursive Feature Elimination. Genomics 2020, 112, 1565–1574. [Google Scholar] [CrossRef]

- Li, X.; Liu, T.; Tao, P.; Wang, C.; Chen, L. A Highly Accurate Protein Structural Class Prediction Approach Using Auto Cross Covariance Transformation and Recursive Feature Elimination. Comput. Biol. Chem. 2015, 59, 95–100. [Google Scholar] [CrossRef]

- Martin, B.; Addona, V.; Wolfson, J.; Adomavicius, G.; Fan, Y. Methods for Real-Time Prediction of the Mode of Travel Using Smartphone-Based GPS and Accelerometer Data. Sensors 2017, 17, 2058. [Google Scholar] [CrossRef] [Green Version]

- Wang, P.; Zou, B.; Ding, S.; Huang, C.; Shi, Z.; Ma, Y.; Yao, P. Preparation of Short CF/GF Reinforced PEEK Composite Filaments and Their Comprehensive Properties Evaluation for FDM-3D Printing. Compos. Part B Eng. 2020, 198, 108175. [Google Scholar] [CrossRef]

- Papon, E.A.; Haque, A. Fracture Toughness of Additively Manufactured Carbon Fiber Reinforced Composites. Addit. Manuf. 2019, 26, 41–52. [Google Scholar] [CrossRef]

- Quan, Z.; Larimore, Z.; Wu, A.; Yu, J.; Qin, X.; Mirotznik, M.; Suhr, J.; Byun, J.-H.; Oh, Y.; Chou, T.-W. Microstructural Design and Additive Manufacturing and Characterization of 3D Orthogonal Short Carbon Fiber/Acrylonitrile-Butadiene-Styrene Preform and Composite. Compos. Sci. Technol. 2016, 126, 139–148. [Google Scholar] [CrossRef]

- Tekinalp, H.L.; Kunc, V.; Velez-Garcia, G.M.; Duty, C.E.; Love, L.J.; Naskar, A.K.; Blue, C.A.; Ozcan, S. Highly Oriented Carbon Fiber–Polymer Composites via Additive Manufacturing. Compos. Sci. Technol. 2014, 105, 144–150. [Google Scholar] [CrossRef] [Green Version]

- Brenken, B.; Barocio, E.; Favaloro, A.; Kunc, V.; Pipes, R.B. Fused Filament Fabrication of Fiber-Reinforced Polymers: A Review. Addit. Manuf. 2018, 21, 1–16. [Google Scholar] [CrossRef]

- Monticeli, F.M.; Neves, R.M.; Ornaghi, H.L., Jr.; Almeida, J.H.S., Jr. A Systematic Review on High-Performance Fiber-Reinforced 3D Printed Thermoset Composites. Polym. Compos. 2021, 42, 3702–3715. [Google Scholar] [CrossRef]

- Greenhalgh, E.; Hiley, M.J.; Meeks, C.B. Failure Analysis and Fractography of Polymer Composites; Woodhead Publishing: Cambridge, UK, 2009; ISBN 978-1-4200-7964-7. [Google Scholar]

- Karsli, N.G.; Aytac, A. Tensile and Thermomechanical Properties of Short Carbon Fiber Reinforced Polyamide 6 Composites. Compos. Part B Eng. 2013, 51, 270–275. [Google Scholar] [CrossRef]

- Ma, Y.; Yan, C.; Xu, H.; Liu, D.; Shi, P.; Zhu, Y.; Liu, J. Enhanced Interfacial Properties of Carbon Fiber Reinforced Polyamide 6 Composites by Grafting Graphene Oxide onto Fiber Surface. Appl. Surf. Sci. 2018, 452, 286–298. [Google Scholar] [CrossRef]

- Zhang, T.; Xu, Y.; Li, H.; Zhang, B. Interfacial Adhesion between Carbon Fibers and Nylon 6: Effect of Fiber Surface Chemistry and Grafting of Nano-SiO2. Compos. Part A Appl. Sci. Manuf. 2019, 121, 157–168. [Google Scholar] [CrossRef]

- Zhang, T.; Zhao, Y.; Li, H.; Zhang, B. Effect of Polyurethane Sizing on Carbon Fibers Surface and Interfacial Adhesion of Fiber/Polyamide 6 Composites. J. Appl. Polym. Sci. 2018, 135, 46111. [Google Scholar] [CrossRef]

- Sang, L.; Wang, Y.; Chen, G.; Liang, J.; Wei, Z. A Comparative Study of the Crystalline Structure and Mechanical Properties of Carbon Fiber/Polyamide 6 Composites Enhanced with/without Silane Treatment. RSC Adv. 2016, 6, 107739–107747. [Google Scholar] [CrossRef]

- van de Werken, N.; Tekinalp, H.; Khanbolouki, P.; Ozcan, S.; Williams, A.; Tehrani, M. Additively Manufactured Carbon Fiber-Reinforced Composites: State of the Art and Perspective. Addit. Manuf. 2020, 31, 100962. [Google Scholar] [CrossRef]

- Goh, G.D.; Dikshit, V.; Nagalingam, A.P.; Goh, G.L.; Agarwala, S.; Sing, S.L.; Wei, J.; Yeong, W.Y. Characterization of Mechanical Properties and Fracture Mode of Additively Manufactured Carbon Fiber and Glass Fiber Reinforced Thermoplastics. Mater. Des. 2018, 137, 79–89. [Google Scholar] [CrossRef]

- Huang, Y.; Young, R.J. Interfacial Micromechanics in Thermoplastic and Thermosetting Matrix Carbon Fibre Composites. Compos. Part A Appl. Sci. Manuf. 1996, 27, 973–980. [Google Scholar] [CrossRef]

- Walter, R.; Selzer, R.; Gurka, M.; Friedrich, K. Effect of Filament Quality, Structure, and Processing Parameters on the Properties of Fused Filament Fabricated Short Fiber-Reinforced Thermoplastics. In Structure and Properties of Additive Manufactured Polymer Components; Friedrich, K., Walter, R., Soutis, C., Advani, S.G., Fiedler, I.H.B., Eds.; Woodhead Publishing Series in Composites Science and Engineering; Woodhead Publishing: Cambridge, UK, 2020; pp. 253–302. ISBN 978-0-12-819535-2. [Google Scholar]

- Siegel, A.F. Chapter 12—Multiple Regression: Predicting One Variable From Several Others. In Practical Business Statistics, 7th ed.; Siegel, A.F., Ed.; Academic Press: Cambridge, MA, USA, 2016; pp. 355–418. ISBN 978-0-12-804250-2. [Google Scholar]

- Bring, J. How to Standardize Regression Coefficients. Am. Stat. 1994, 48, 209–213. [Google Scholar] [CrossRef]

- Kuznetsov, V.E.; Solonin, A.N.; Urzhumtsev, O.D.; Schilling, R.; Tavitov, A.G. Strength of PLA Components Fabricated with Fused Deposition Technology Using a Desktop 3D Printer as a Function of Geometrical Parameters of the Process. Polymers 2018, 10, 313. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Y.; Chen, Y.; Zhou, Y. Novel Mechanical Models of Tensile Strength and Elastic Property of FDM AM PLA Materials: Experimental and Theoretical Analyses. Mater. Des. 2019, 181, 108089. [Google Scholar] [CrossRef]

- Garzon-Hernandez, S.; Garcia-Gonzalez, D.; Jérusalem, A.; Arias, A. Design of FDM 3D Printed Polymers: An Experimental-Modelling Methodology for the Prediction of Mechanical Properties. Mater. Des. 2020, 188, 108414. [Google Scholar] [CrossRef]

- Nomani, J.; Wilson, D.; Paulino, M.; Mohammed, M.I. Effect of Layer Thickness and Cross-Section Geometry on the Tensile and Compression Properties of 3D Printed ABS. Mater. Today Commun. 2020, 22, 100626. [Google Scholar] [CrossRef]

- Rinaldi, M.; Ghidini, T.; Cecchini, F.; Brandao, A.; Nanni, F. Additive Layer Manufacturing of Poly (Ether Ether Ketone) via FDM. Compos. Part B Eng. 2018, 145, 162–172. [Google Scholar] [CrossRef]

- Wang, P.; Zou, B.; Ding, S.; Li, L.; Huang, C. Effects of FDM-3D Printing Parameters on Mechanical Properties and Microstructure of CF/PEEK and GF/PEEK. Chin. J. Aeronaut. 2020, 34, 236–349. [Google Scholar] [CrossRef]

- Blok, L.; Longana, M.; Yu, H.; Woods, B. An Investigation into 3D Printing of Fibre Reinforced Thermoplastic Composites. Addit. Manuf. 2018, 22, 176–186. [Google Scholar] [CrossRef]

- Sun, Q.; Rizvi, G.M.; Bellehumeur, C.T.; Gu, P. Effect of Processing Conditions on the Bonding Quality of FDM Polymer Filaments. Rapid Prototyp. J. 2008, 14, 72–80. [Google Scholar] [CrossRef]

- Skaskevich, A.; Sudan, A.; Dzhendov, D. Influence of Technological Parameters of FDM-Print on the Strength Characteristics of Samples of Polyamide. Mach. Technol. Mater. 2020, 14, 210–212. [Google Scholar]

- Ding, S.; Zou, B.; Wang, P.; Ding, H. Effects of Nozzle Temperature and Building Orientation on Mechanical Properties and Microstructure of PEEK and PEI Printed by 3D-FDM. Polym. Test. 2019, 78, 105948. [Google Scholar] [CrossRef]

- Benwood, C.; Anstey, A.; Andrzejewski, J.; Misra, M.; Mohanty, A.K. Improving the Impact Strength and Heat Resistance of 3D Printed Models: Structure, Property, and Processing Correlationships during Fused Deposition Modeling (FDM) of Poly(Lactic Acid). ACS Omega 2018, 3, 4400–4411. [Google Scholar] [CrossRef]

- Klein, J. The Self-Diffusion of Polymers. Contemp. Phys. 1979, 20, 611–629. [Google Scholar] [CrossRef]

- Zhang, J.; Neeckx, J.; Van Hooreweder, B.; Ferraris, E. Measurement, Characterisation and Influence of the Air Temperature above the Build Plate in Fused Filament Fabrication. Addit. Manuf. Lett. 2021, 1, 100013. [Google Scholar] [CrossRef]

- Spoerk, M.; Arbeiter, F.; Raguž, I.; Traxler, G.; Schuschnigg, S.; Cardon, L.; Holzer, C. The Consequences of Different Printing Chamber Temperatures in Extrusion-Based Additive Manufacturing. In Proceedings of the International Conference on Polymers and Moulds Innovations-PMI 2018, Braga, Portugal, 19–21 September 2018. [Google Scholar]

- Rodzeń, K.; Harkin-Jones, E.; Wegrzyn, M.; Sharma, P.K.; Zhigunov, A. Improvement of the Layer-Layer Adhesion in FFF 3D Printed PEEK/Carbon Fibre Composites. Compos. Part A Appl. Sci. Manuf. 2021, 149, 106532. [Google Scholar] [CrossRef]

- Kurzynowski, T.; Stopyra, W.; Gruber, K.; Ziółkowski, G.; Kuźnicka, B.; Chlebus, E. Effect of Scanning and Support Strategies on Relative Density of SLM-Ed H13 Steel in Relation to Specimen Size. Materials 2019, 12, 239. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z.Y.; Li, C.; Fang, X.Y.; Guo, Y.B. Energy Consumption in Additive Manufacturing of Metal Parts. Procedia Manuf. 2018, 26, 834–845. [Google Scholar] [CrossRef]

- Caiazzo, F.; Alfieri, V.; Casalino, G. On the Relevance of Volumetric Energy Density in the Investigation of Inconel 718 Laser Powder Bed Fusion. Materials 2020, 13, 538. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Flores Ituarte, I.; Wiikinkoski, O.; Jansson, A. Additive Manufacturing of Polypropylene: A Screening Design of Experiment Using Laser-Based Powder Bed Fusion. Polymers 2018, 10, 1293. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Drummer, D.; Wudy, K.; Drexler, M. Influence of Energy Input on Degradation Behavior of Plastic Components Manufactured by Selective Laser Melting. Phys. Procedia 2014, 56, 176–183. [Google Scholar] [CrossRef] [Green Version]

| Parameter | Value |

|---|---|

| Extrusion temperature (Text) | 240–280 °C |

| Printing bed temperature (Tbed) | 100–120 °C |

| Printing speed (v) | 30–80 mm/s |

| Layer height (h) | 0.2–0.4 mm |

| Nozzle diameter | 0.6 mm (constant) |

| Bead width | 0.4 mm (constant) |

| Air gap | 0.4 mm (constant) |

| Condition | v [mm/s] | Tbed [°C] | Text [°C] | h [mm] | UTS [MPa] |

|---|---|---|---|---|---|

| C1 | 30 | 100 | 240 | 0.4 | 97.0 ± 5.4 |

| C2 | 30 | 120 | 240 | 0.4 | 102.8 ± 1.9 |

| C3 | 80 | 100 | 240 | 0.4 | 91.0 ± 3.5 |

| C4 | 80 | 120 | 240 | 0.4 | 95.0 ± 2.2 |

| C5 | 30 | 100 | 280 | 0.4 | 89.2 ± 2.5 |

| C6 | 30 | 120 | 280 | 0.4 | 92.7 ± 1.7 |

| C7 | 80 | 100 | 280 | 0.4 | 100.2 ± 3.3 |

| C8 | 80 | 120 | 280 | 0.4 | 102.8 ± 4.8 |

| C9 | 30 | 100 | 240 | 0.2 | 111.0 ± 4.6 |

| C10 | 30 | 120 | 240 | 0.2 | 115.0 ± 5.4 |

| C11 | 80 | 100 | 240 | 0.2 | 99.3 ± 0.5 |

| C12 | 80 | 120 | 240 | 0.2 | 110.0 ± 0.8 |

| C13 | 30 | 100 | 280 | 0.2 | 112.3 ± 3.5 |

| C14 | 30 | 120 | 280 | 0.2 | 117.0 ± 3.5 |

| C15 | 80 | 100 | 280 | 0.2 | 107.5 ± 3.8 |

| C16 | 80 | 120 | 280 | 0.2 | 114.2 ± 4.2 |

| C17 | 55 | 110 | 260 | 0.3 | 102.5 ± 4.2 |

| S [MPa] | R² | R² (Adjusted) | R² (Predicted) | Curvature (p-Value) | Lack-of-Fit (p-Value) |

|---|---|---|---|---|---|

| 4.13 | 0.820 | 0.795 | 0.761 | 0.486 | 0.757 |

| Condition | v [mm/s] | Tbed [°C] | Text [°C] | h [mm] | UTS [MPa] |

|---|---|---|---|---|---|

| E1 | 75 | 106 | 280 | 0.32 | 100.0 ± 9.5 |

| E2 | 30 | 120 | 259 | 0.2 | 112.7 ± 3.0 |

| E3 | 50 | 100 | 252 | 0.2 | 94.3 ± 4.2 |

| E4 | 40 | 102 | 264 | 0.24 | 100.0 ± 4.8 |

| E5 | 30 | 104 | 268 | 0.36 | 91.0 ± 4.5 |

| E6 | 55 | 110 | 260 | 0.2 | 112.8 ± 5.7 |

| E7 | 35 | 118 | 260 | 0.32 | 94.0 ± 2.9 |

| E8 | 45 | 116 | 256 | 0.28 | 91.3 ± 10.5 |

| E9 | 55 | 120 | 248 | 0.28 | 92.3 ± 3.1 |

| E10 | 65 | 112 | 276 | 0.24 | 101.3 ± 3.0 |

| E11 | 60 | 118 | 244 | 0.28 | 88.8 ± 3.0 |

| E12 | 55 | 110 | 260 | 0.4 | 99.9 ± 3.2 |

| E13 | 60 | 114 | 244 | 0.4 | 83.0 ± 2.9 |

| E14 | 80 | 108 | 272 | 0.4 | 90.8 ± 1.2 |

| E15 | 70 | 110 | 240 | 0.36 | 79.3 ± 2.2 |

| Condition | v [mm/s] | Tbed [°C] | Text [°C] | h [mm] | Predicted UTS [MPa] | 95% CI [MPa] | 95% PI [MPa] |

|---|---|---|---|---|---|---|---|

| C-opt | 30 | 120 | 280 | 0.2 | 117.4 | (114.3, 120.6) | (108.2, 126.7) |

| S (Train) [MPa] | S (Test) [MPa] | R² (Train) | R² (Test) | CV Accuracy |

|---|---|---|---|---|

| 6.16 | 5.88 | 0.682 | 0.688 | 0.612 ± 0.078 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Belei, C.; Joeressen, J.; Amancio-Filho, S.T. Fused-Filament Fabrication of Short Carbon Fiber-Reinforced Polyamide: Parameter Optimization for Improved Performance under Uniaxial Tensile Loading. Polymers 2022, 14, 1292. https://doi.org/10.3390/polym14071292

Belei C, Joeressen J, Amancio-Filho ST. Fused-Filament Fabrication of Short Carbon Fiber-Reinforced Polyamide: Parameter Optimization for Improved Performance under Uniaxial Tensile Loading. Polymers. 2022; 14(7):1292. https://doi.org/10.3390/polym14071292

Chicago/Turabian StyleBelei, Carlos, Jana Joeressen, and Sergio T. Amancio-Filho. 2022. "Fused-Filament Fabrication of Short Carbon Fiber-Reinforced Polyamide: Parameter Optimization for Improved Performance under Uniaxial Tensile Loading" Polymers 14, no. 7: 1292. https://doi.org/10.3390/polym14071292

APA StyleBelei, C., Joeressen, J., & Amancio-Filho, S. T. (2022). Fused-Filament Fabrication of Short Carbon Fiber-Reinforced Polyamide: Parameter Optimization for Improved Performance under Uniaxial Tensile Loading. Polymers, 14(7), 1292. https://doi.org/10.3390/polym14071292