Effect of Transfer Film on Tribological Properties of Anti-Friction PEI- and PI-Based Composites at Elevated Temperatures †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Fabrication of the Composites

2.3. Physical and Mechanical Properties

2.4. Tribological Characteristics

2.5. Structural Studies

3. Results and Discussion

3.1. The Structure, the Physical and Mechanical Properties of the PEI-Based Composites

3.2. The Tribological Properties of the PEI-Based Composites

3.3. High Temperature Tribological Tests of the PEI-Based Composites

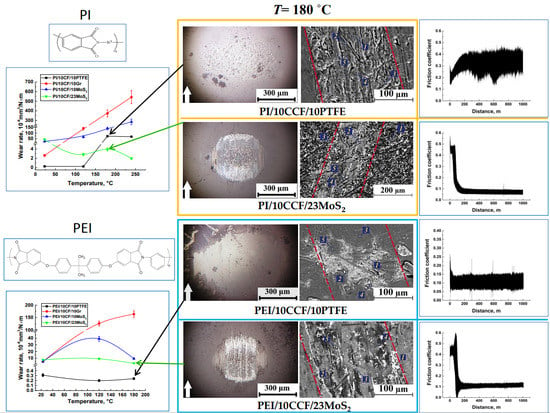

3.4. The Results of the Comparative Analysis of the High-Temperature Tribological Properties of the PEI- and PI-Based Composites

- For the PEI-based samples loaded with PTFE, the wearless mode (WR < 0.3 × 10−6 mm3/N m) was realized at low CoF levels (≤0.1) in the entire studied temperature range (T = 23–180 °C);

- For the PI-based ones identical in filling, PTFE ceased to play the role of a solid lubricant filler already at T = 180 °C, which corresponded to a sharp increase in CoF values (>0.3);

- For the PEI-based composites containing the lower MoS2 amount of 10 wt.%, these particles contributed to the solid lubricant mode only when the test temperature rose up to 180 °C, which corresponded to reducing the CoF values down to ~0.1;

- Enhancing the MoS2 content up to 23 wt.% in the PEI-based composites provided stable WR levels of <10 × 10−6 mm3/N m, although the CoF values reached ~0.1 only at T = 180 °C;

- The twofold change in the MoS2 content (10 and 23 wt.%) in the PEI-based composites contributed to equally low CoF values of about 0.1 at T = 180 °C, while WR levels of <(2–6) × 10−6 mm3/N·m also remained comparably negligible;

- The high MoS2 content of 23 wt.% in the PI-based samples was sufficient for providing low CoF levels of ~0.1 at all the elevated temperatures of the tribological tests (T = 120–240 °C), while ensuring negligible WR values of <(2–4) × 10−6 mm3/N·m;

- Loading both PEI- and PI-based composites with MoS2 solid lubricant particles did not contribute to ultra-low WF levels even when CoF values of 0.1 were reached, similar to the PTFE-containing composites based on the same polymers.

4. Discussion

5. Conclusions

- In the tribological tests of the ternary PEI-based composites at room temperature, the counterpart materials (steel or ceramic) did not significantly affect the tribological properties, namely their both CoF and WR.

- Loading the PEI- and PI-based composites with PTFE caused sliding in the ‘wearless’ mode due to the easy separation of PTFE flakes with the subsequent formation of the thin continuous transfer films on the composite friction surfaces at the CoF levels of 0.05–0.11 (at room temperature). With an increase in the test temperature, the average CoF level and the amplitude of its oscillations increased for both PEI- and PI-based composites. This prevented the transfer film from adhering to the wear track surfaces of the PTFE-containing PI-based samples at T = 180 °C. For the similar PEI-based ones, their more pliable matrix enabled to provide the extremely low wear at the levels of less than 0.2 × 10−6 mm3/N m with the increased CoF values of 0.11.

- Loading of MoS2 into the reinforced “PI-CCF” and “PEI-CCF” composites ensured the ‘solid lubricant’ sliding mode at the low CoF level of 0.1, which demanded for stimulating oxidation process (tougher friction conditions, primarily due to the increase in the test temperature and enlarging the CoF). However, it was not possible to reduce the WR values below 2 × 10−6 mm3/N m due to the difference in the solid lubrication mechanisms ensured by crystalline MoS2 compared to polymer PTFE.

- Raising the MoS2 content up to 23 wt.%, which was identical in volume to other used solid lubricant fillers (PTFE and Gr), made it possible to decrease the CoF levels for the PEI- (at T = 180 °C) and PI-based (at T = 120–240 °C) composites via the formation and adhering the transfer films. However, this effect was not realized at room temperature because of the low intensity of oxidative processes.

- Under the applied tribological conditions, colloidal graphite could not be considered as a solid lubricant filler for the studied ternary PEI- and PI-based composites, since the high interlayer shear energy did not ensure the formation of an anti-friction film on the wear track surfaces, maintaining the high both CoF and WR levels with rising the test temperature.

- The comparative analysis of the behavior of the PEI- and PI-based composites at the elevated temperatures showed that the WR values for the PEI-based samples were lower by 300 times than those for the PI-based ones at T = 180 °C.

- The PEI-based composites are recommended for use in tribological units both due to their high manufacturability because of the flexibility of polymer chains, and great wear resistance via the formation of fixed continuous transfer films on the wear track surfaces in the entire investigated temperature range of 23–180 °C. The PI-based composite containing 23 wt.% MoS2 (PI/10CF/23MoS2) might efficiently operate in tribological units at the elevated temperatures 180 ÷ 240 °C.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sethi, S.; Thakur, S.; Kaith, B.S.; Sharma, N.; Ansar, S.; Pandey, S.; Kuma, V. Biopolymer Starch-Gelatin Embedded with Silver Nanoparticle–Based Hydrogel Composites for Antibacterial Application. Biomass Conv. Bioref. 2022, 1–22. [Google Scholar] [CrossRef]

- Kumar, V.; Pandey, S. Microwave Synthesize Karaya Gum-Cu, Ni Nanoparticles Based Bionanocomposite as an Adsorbent for Malachite Green Dye: Kinetics and Thermodynamics. Front. Mater. 2022, 9, 1–11. [Google Scholar] [CrossRef]

- Murali, A.; Sakar, M.; Priya, S.; Vijayavarman, V.; Pandey, S.; Sai, R.; Katayama, Y.; Abdul Kader, M.; Ramanujam, K. Insights into the Emerging Alternative Polymer-Based Electrolytes for All Solid-State Lithium-Ion Batteries: A Review. Mater. Lett. 2022, 313, 131764. [Google Scholar] [CrossRef]

- Kricheldorf, H.R. Progress in Polyimide Chemistry I; Springer: Berlin/Heidelberg, Germany, 1999; pp. 107–136. [Google Scholar]

- Kricheldorf, H.R. Progress in Polyimide Chemistry II; Springer: Berlin/Heidelberg, Germany, 1999; pp. 1–43. [Google Scholar]

- Constantin, C.P.; Aflori, M.; Damian, R.F.; Rusu, R.D. Biocompatibility of Polyimides: A mini-review. Materials 2019, 12, 3166. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Revathi, R.; Prabunathan, P.; Alagar, M. Synthesis and studies on phosphazene core-based POSS-reinforced polyimide nanocomposites. Polym. Bull. 2019, 76, 387–407. [Google Scholar] [CrossRef]

- Fang, Q.; Wang, J.; Gu, S.; Kaspar, R.B.; Zhuang, Z.; Zheng, J.; Guo, H.; Qiu, S.; Yan, Y. 3D porous crystalline polyimide covalent organic frameworks for drug delivery. J. Am. Chem. Soc. 2015, 137, 8352–8355. [Google Scholar] [CrossRef] [PubMed]

- Jonson, R.O.; Burlhis, H.S. Polyetherimide: A new high-performance thermoplastic resin. J. Polym. Sci. Polym. Symp. 1983, 70, 129–143. [Google Scholar] [CrossRef]

- Parker, D.; Vussinr, J.; Grampel, H.T.; Weatey, G.W.; Dorf, E.U.; Ostlinning, E.; Reinking, K.; Schubert, F.; Jünger, O.; Wagener, R. Polymers, High-Temperature. In Ullmann’s Encyclopedia of Industrial Chemistry; John Wiley & Sons: Weinheim, Germany, 2012; pp. 1–40. [Google Scholar]

- Forés-Garriga, A.; Pérez, M.A.; Gómez-Gras, G.; Reyes-Pozo, G. Role of infill parameters on the mechanical performance and weight reduction of PEI Ultem processed by FFF. Mater. Des. 2020, 193, 108810. [Google Scholar] [CrossRef]

- Cai, C.L.; Wang, W.X.; Li, J. The Tribological Properties of Thermoplastic Polyetherimide Composites Filled with Kevlar Pulp. Appl. Mech. Mater. 2011, 66–68, 862–865. [Google Scholar] [CrossRef]

- Xian, G.J.; Zhang, Z. Sliding wear of polyetherimide matrix composites: I. Influence of short carbon fibre reinforcement. Wear 2005, 258, 776–782. [Google Scholar] [CrossRef]

- Li, B.; Wood, W.; Baker, L.; Sui, G.; Leer, C.; Zhong, W.H. Effectual dispersion of carbon nanofibers in polyetherimide composites and their mechanical and tribological properties. Polym. Eng. Sci. 2010, 50, 1914–1922. [Google Scholar] [CrossRef]

- Sun, Z.; Zhao, Z.K.; Zhang, Y.Y.; Li, Y.Q.; Fu, Y.Q.; Sun, B.G.; Shi, H.Q.; Huang, P.; Hu, N.; Fu, S.-Y. Mechanical, tribological and thermal properties of injection molded short carbon fiber/expanded graphite/polyetherimide composites. Compos. Sci. Technol. 2021, 201, 108498. [Google Scholar] [CrossRef]

- Bijwe, J.; Indumathi, J.; John Rajesh, J.; Fahim, M. Friction and wear behavior of polyetherimide composites in various wear modes. Wear 2011, 249, 715–726. [Google Scholar] [CrossRef]

- Lee, E.; Lee, C.; Chun, Y.S.; Han, C.; Lim, D.S. Effect of hydrogen plasma-mediated surface modification of carbon fibers on the mechanical properties of carbon-fiber-reinforced polyetherimide composites. Compos. Part B 2017, 116, 451–458. [Google Scholar] [CrossRef]

- Su, F.; Zhang, S. Tribological properties of polyimide coatings filled with PTFE and surface-modified nano-Si3N4. J. Appl. Polym. Sci. 2014, 131, 40410. [Google Scholar] [CrossRef]

- Kumar, R.; Malaval, B.; Antonov, M.; Zhao, G. Performance of polyimide and PTFE based composites under sliding, erosive and high stress abrasive conditions. Tribol. Int. 2020, 147, 106282. [Google Scholar] [CrossRef]

- Mu, L.; Zhu, J.; Fan, J.; Zhou, Z.; Shi, Y.; Feng, X.; Wang, H.; Lu, X. Self-Lubricating Polytetrafluoroethylene/Polyimide Blends Reinforced with Zinc Oxide Nanoparticles. J. Nanomater. 2015, 2015, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Shi, Y.; Mu, L.; Feng, X.; Lu, X. The tribological behavior of nanometer and micrometer TiO2 particle-filled polytetrafluoroethylene/polyimide. Mater. Des. 2011, 32, 964–970. [Google Scholar] [CrossRef]

- Gheisari, R.; Polycarpou, A.A. Tribological performance of graphite-filled polyimide and PTFE composites in oil-lubricated three-body abrasive conditions. Wear 2019, 436–437, 203044. [Google Scholar] [CrossRef]

- Panin, S.V.; Luo, J.; Alexenko, V.O.; Buslovich, D.G.; Kornienko, L.A.; Bochkareva, S.A.; Panov, I.L. The effect of annealing of milled carbon fibers on the mechanical and tribological properties of solid-lubricant thermoplastic polyimide-based composites. Polym. Eng. Sci. 2020, 60, 1–14. [Google Scholar] [CrossRef]

- Chen, B.; Li, X.; Jia, Y.; Li, X.; Yang, J.; Yan, F.; Li, C. MoS2 nanosheets-decorated carbon fiber hybrid for improving the friction and wear properties of polyimide composite. Compos. Part A 2018, 109, 232–238. [Google Scholar] [CrossRef]

- Li, J.; Bai, T. The effect of CNT modification on the mechanical properties of polyimide composites with and without MoS2. Mech. Compos. Mater. 2011, 47, 597–602. [Google Scholar] [CrossRef]

- Zhang, X.; Pei, X.; Wang, Q. Friction and wear properties of polyimide matrix composites reinforced with short basalt fibers. J. Appl. Polym. Sci. 2009, 111, 2980–2985. [Google Scholar] [CrossRef]

- Samyn, P.; Schoukens, G. Tribological properties of PTFE-filled thermoplastic polyimide at high load, velocity, and temperature. Polym. Compos. 2009, 30, 1631–1646. [Google Scholar] [CrossRef]

- Li, J. Tribological properties of polyimide composites filled with glass fibre and graphite. Plast. Rubber Compos. 2009, 38, 248–252. [Google Scholar] [CrossRef]

- Wu, J.; Liu, H.; Wang, H.; Ma, W.; Wang, T.; Wang, Q. Effects of TiO2 decorated reduced graphene oxide on mechanical and tribological properties of thermosetting polyimide. Compos. Interfaces 2021, 1–14. [Google Scholar] [CrossRef]

- Duan, C.; He, R.; Li, S.; Shao, M.; Yang, R.; Tao, L.; Wang, T.; Wang, Q. Exploring the friction and wear behaviors of Ag-Mo hybrid modified thermosetting polyimide composites at high temperature. Friction 2019, 8, 893–904. [Google Scholar] [CrossRef] [Green Version]

- Lisuzzo, L.; Cavallaro, G.; Milioto, S.; Lazzara, G. Effects of Halloysite Content on the Thermo-Mechanical Performances of Composite Bioplastics. Appl. Clay Sci. 2020, 185, 105416. [Google Scholar] [CrossRef] [Green Version]

- Xian, G.; Zhang, Z.; Friedrich, K. Tribological properties of micro- and nanoparticles-filled poly(etherimide) composites. J. Appl. Polym. Sci. 2006, 101, 1678–1686. [Google Scholar] [CrossRef]

- Duan, C.; Yuan, D.; Yang, Z.; Li, S.; Tao, L.; Wang, Q.; Wang, T. High wear-resistant performance of thermosetting polyimide reinforced by graphitic carbon nitride (g-C3N4) under high temperature. Compos. Part A 2018, 113, 200–208. [Google Scholar] [CrossRef]

- Panin, S.V.; Luo, J.; Buslovich, D.G.; Alexenko, V.O.; Kornienko, L.A.; Bochkareva, S.A.; Byakov, A.V. Experimental—FEM Study on Effect of Tribological Load Conditions on Wear Resistance of Three-Component High-Strength Solid-Lubricant PI-Based Composites. Polymers 2021, 13, 2837. [Google Scholar] [CrossRef] [PubMed]

- Panin, S.V.; Alexenko, V.O.; Buslovich, D.G. High Performance Polymer Composites: A Role of Transfer Films in Ensuring Tribological Properties—A Review. Polymers 2022, 14, 975. [Google Scholar] [CrossRef] [PubMed]

- Krasnov, A.P.; Askadskii, A.A.; Goroshkov, M.V.; Shaposhnikova, V.V.; Salazkin, S.N.; Naumkin, A.V.; Sorokin, A.E.; Solov’eva, V.A. Effect of the Chemical Structure of Heat-Resistant Thermoplastics on the Friction on Steel. Dokl. Chem. 2018, 479, 58–63. [Google Scholar] [CrossRef]

- Gong, H.; Yu, C.; Zhang, L.; Xie, G.; Guo, D.; Luo, J. Intelligent lubricating materials: A review. Compos. Part B 2020, 202, 108450. [Google Scholar] [CrossRef]

- Ye, J.; Haidar, D.; Burris, D. Polymeric Solid Lubricant Transfer Films: Relating Quality to Wear Performance. In Self-Lubricating Composites, 1st ed.; Menezes, P., Rohatgi, P., Omrani, E., Eds.; Springer: Berlin/Heidelberg, Germany, 2018; pp. 155–180. [Google Scholar]

- Onodera, T.; Nunoshige, J.; Kawasaki, K.; Adachi, K.; Kurihara, K.; Kubo, M. Structure and Function of Transfer Film Formed from PTFE/PEEK Polymer Blend. J. Phys. Chem. C 2017, 121, 14589–14596. [Google Scholar] [CrossRef]

- Omrani, E.; Rohatgi, P.K.; Menezes, P.L. Tribology and Applications of Self-Lubricating Materials, 1st ed.; CRC Press: Boca Raton, FL, USA, 2018; p. 206. [Google Scholar]

- Ye, J.; Burris, D.L.; Xie, T. A Review of Transfer Films and Their Role in Ultra-Low-Wear Sliding of Polymers. Lubricants 2016, 4, 4. [Google Scholar] [CrossRef] [Green Version]

- Friedrich, K.; Zhang, Z.; Schlarb, A.K. Effects of various fillers on the sliding wear of polymer composites. Compos. Sci. Technol. 2005, 65, 2329–2343. [Google Scholar] [CrossRef]

- Bahadur, S. The development of transfer layers and their role in polymer tribology. Wear 2000, 245, 92–99. [Google Scholar] [CrossRef]

- Gao, J. Tribochemical effects in formation of polymer transfer film. Wear 2000, 245, 100–106. [Google Scholar]

- Zuo, Z.; Liang, L.; Bao, Q.; Yan, P.; Jin, X.; Yang, Y. Molecular Dynamics Calculation on the Adhesive Interaction Between the Polytetrafluoroethylene Transfer Film and Iron Surface. Front. Chem. 2021, 9, 740447. [Google Scholar] [CrossRef]

- Scharf, T.W.; Prasad, S.V. Solid lubricants: A review. J. Mater. Sci. 2013, 48, 511–531. [Google Scholar] [CrossRef]

- Singer, I.L.; Pollock, H.M. Fundamentals of Friction: Macroscopic and Microscopic Processes; Springer: Dordrecht, Germany, 1992; p. 621. [Google Scholar]

- Benedict, L.X.; Chopra, N.G.; Cohen, M.L.; Zettl, A.; Louie, S.G.; Crespi, V.H. Microscopic determination of the interlayer binding energy in graphite. Chem. Phys. Lett. 1998, 286, 490. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, J.Z.; Cheng, Y.; Li, Z.; Wang, L.; Zheng, Q. Interlayer binding energy of graphite: A mesoscopic determination from deformation. Phys. Rev. B 2012, 85, 205418. [Google Scholar] [CrossRef] [Green Version]

- Fang, Z.; Li, X.; Shi, W.; Li, Z.; Guo, Y.; Chen, Q.; Peng, L.; Wei, X. Interlayer Binding Energy of Hexagonal MoS2 as Determined by an In Situ Peeling-to-Fracture Method. J. Phys. Chem. C 2020, 124, 23419–23425. [Google Scholar] [CrossRef]

- Abdelbary, A. Chapter 1—Polymer Tribology. In Wear of Polymers and Composites, 1st ed.; Abdelbary, A., Ed.; Elsevier: Amsterdam, The Netherlands, 2014; pp. 1–36. [Google Scholar]

- Fusaro, R.L. Effect of Atmosphere and Temperature on Wear, Friction, and Transfer of Polyimide Films. Asle Trans. 1978, 21, 125–133. [Google Scholar] [CrossRef] [Green Version]

- Samyn, P.; Vancraenenbroeck, J.; Verpoort, F.; De Baets, P. Postmortem Raman Spectroscopy Explaining Friction and Wear Behavior of Sintered Polyimide at High Temperature. J. Mater. Eng. Perform. 2006, 15, 750–757. [Google Scholar] [CrossRef]

- Ma, J.; Qi, X.; Zhao, Y.; Zhang, Q.; Yang, Y. Effects of Elevated Temperature on Tribological Behavior of Polyimide and Polyimide/Mesoporous Silica Nanocomposite in Dry Sliding against GCr15 Steel. Wear 2017, 374–375, 142–151. [Google Scholar] [CrossRef]

- Chang, L.; Zhang, Z.; Ye, L.; Friedrich, K. Tribological Properties of High Temperature Resistant Polymer Composites with Fine Particles. Tribol. Int. 2007, 40, 1170–1178. [Google Scholar] [CrossRef]

- Dong, F.; Hou, G.; Cao, F.; Yan, F.; Liu, L.; Wang, J. The Lubricity and Reinforcement of Carbon Fibers in Polyimide at High Temperatures. Tribol. Int. 2016, 101, 291–300. [Google Scholar] [CrossRef]

- Dong, F.; Hou, G.; Liu, H.; Liu, L.; Cao, F.; Wang, J.; Yan, F. An Investigation on the Mechanical and Tribological Properties of Carbon Fiber/Polyimide Composites at Elevated Temperatures. Polym. Compos. 2018, 39, E869–E882. [Google Scholar] [CrossRef]

- Zhao, G.; Hussainova, I.; Antonov, M.; Wang, Q.; Wang, T.; Yung, D.-L. Effect of Temperature on Sliding and Erosive Wear of Fiber Reinforced Polyimide Hybrids. Tribol. Int. 2015, 82, 525–533. [Google Scholar] [CrossRef]

- Duan, C.; Gao, C.; Li, S.; Yang, R.; Yang, Z.; Zhang, Y.; Tao, L.; Zhang, X.; Wang, Q.; Wang, T. Tailoring Polyimide Composites with Low Friction and Wear at High Temperatures. J. Appl. Polym. Sci. 2022, 139, 51736. [Google Scholar] [CrossRef]

- Samyn, P.; De Baets, P.; Schoukens, G. Role of Internal Additives in the Friction and Wear of Carbon-Fiber-Reinforced Polyimide. J. Appl. Polym. Sci. 2010, 116, 1146–1156. [Google Scholar] [CrossRef]

- Nunez, E.E.; Polycarpou, A.A. The Effect of Surface Roughness on the Transfer of Polymer Films under Unlubricated Testing Conditions. Wear 2015, 326–327, 74–83. [Google Scholar] [CrossRef]

- Liu, G.; Zhang, L.; Li, G.; Zhao, F.; Che, Q.; Wang, C.; Zhang, G. Tuning the Tribofilm Nanostructures of Polymer-on-Metal Joint Replacements for Simultaneously Enhancing Anti-Wear Performance and Corrosion Resistance. Acta Biomater. 2019, 87, 285–295. [Google Scholar] [CrossRef] [PubMed]

- Hu, C.; Qi, H.; Yu, J.; Zhang, G.; Zhang, Y.; He, H. Significant Improvement on Tribological Performance of Polyimide Composites by Tuning the Tribofilm Nanostructures. J. Mater. Process. Technol. 2020, 281, 116602. [Google Scholar] [CrossRef]

- Qi, H.; Li, G.; Zhang, G.; Wang, T.; Wang, Q. Impact of Counterpart Materials and Nanoparticles on the Transfer Film Structures of Polyimide Composites. Mater. Des. 2016, 109, 367–377. [Google Scholar] [CrossRef]

- Haidar, D.R.; Ye, J.; Moore, A.C.; Burris, D.L. Assessing Quantitative Metrics of Transfer Film Quality as Indicators of Polymer Wear Performance. Wear 2017, 380–381, 78–85. [Google Scholar] [CrossRef] [Green Version]

- Yu, L.; He, R.; Zhang, Y.; Gao, J. Effect of Surface Treatment on Flexural and Tribological Properties of Poly(p-phenylene Benzobisoxazole)/Polyimide Composites under Normal and Elevated Temperature. Materials 2018, 11, 2131. [Google Scholar] [CrossRef] [Green Version]

- Allam, I.M. Solid Lubricants for Applications at Elevated Temperatures. J. Mater. Sci. 1991, 26, 3977–3984. [Google Scholar] [CrossRef]

| Sample | Crystallinity, % |

|---|---|

| PEI ROOH | 32 |

| PI 1600 | 21 |

| Filler Content, vol.% | Tg, °C | Filler Content, wt.% | Designation |

|---|---|---|---|

| PI | 259 | PI | PI |

| PI + 8.3%CF | 265 | PI + 10%CF | PI/10CCF |

| PI + 8.3%CF + 6.6%PTFE | 266 | PI + 10%CF + 10%PTFE | PI/10CCF/10PTFE |

| PI + 8.3%CF + 6.6%Gr | 259 | PI + 10%CF + 10%Gr | PI/10CCF/10Gr |

| PI + 8.3%CF + 3.0%MoS2 | 256 | PI + 10%CF + 10%MoS2 | PI/10CCF/10MoS2 |

| PI + 8.3%CF + 6.6%MoS2 | 256 | PI + 10%CF + 23%MoS2 | PI/10CCF/23MoS2 |

| PEI | 211 | PEI | PEI |

| PEI + 8.3%CF | 212 | PEI + 10%CF | PEI/10CCF |

| PEI + 8.3%CF + 6.6%PTFE | 211 | PEI + 10%CF + 10%PTFE | PEI/10CCF/10PTFE |

| PEI + 8.3%CF + 6.6%Gr | 215 | PEI + 10%CF + 10%Gr | PEI/10CCF/10Gr |

| PEI + 8.3%CF + 3.0%MoS2 | 215 | PEI + 10%CF + 10%MoS2 | PEI/10CCF/10MoS2 |

| PEI + 8.3%CF + 6.6%MoS2 | 215 | PEI + 10%CF + 23%MoS2 | PEI/10CCF/23MoS2 |

| No. | Filler Composition (wt.%) | Density ρ, (g/cm3) | Shore D Hardness | Elastic Modulus E (GPa) | Ultimate Tensile Strength σU (MPa) | Elongation at Break ε (%) | Stored Energy (kJ/m3) |

|---|---|---|---|---|---|---|---|

| 1 | Neat PEI | 1.26 | 79.9 ± 0.3 | 3.12 ± 0.15 | 123.1 ± 0.5 | 16.1 ± 1.2 | 14,700 |

| 2 | PEI/10CCF | 1.31 | 81.4 ± 0.3 | 6.54 ± 0.43 | 153.2 ± 12.5 | 3.7 ± 0.6 | 2900 |

| 3 | PEI/10CCF/10PTFE | 1.36 | 79.0 ± 0.3 | 6.17 ± 0.26 | 117.3 ± 8.0 | 3.1 ± 0.3 | 1900 |

| 4 | PEI/10CCF/10Gr | 1.36 | 80.6 ± 0.2 | 6.37 ± 0.16 | 101.4 ± 2.6 | 2.8 ± 0.1 | 1500 |

| 5 | PEI/10CCF/10MoS2 | 1.41 | 81.9 ± 0.1 | 6.26 ± 0.17 | 121.0 ± 5.0 | 3.5 ± 0.3 | 2200 |

| 6 | PEI/10CCF/23MoS2 | 1.56 | 81.9 ± 0.3 | 6.81 ± 0.14 | 101.4 ± 1.7 | 2.5 ± 0.1 | 1400 |

| Composite | Coefficient of Friction ƒ | Wear Rate (10−6 mm3/N · m) | ||

|---|---|---|---|---|

| Metal Counterpart | Ceramic Counterpart | Metal Counterpart | Ceramic Counterpart | |

| Neat PEI | 0.297 ± 0.026 | 0.342 ± 0.032 | 390.21 ± 20.51 | 443.72 ± 24.90 |

| PEI/10CCF | 0.286 ± 0.018 | 0.270 ± 0.009 | 30.39 ± 2.68 | 15.20 ± 1.23 |

| PEI/10CCF/10PTFE | 0.045 ± 0.005 | 0.048 ± 0.004 | 0.45 ± 0.04 | 0.31 ± 0.03 |

| PEI/10CCF/10Gr | 0.228 ± 0.016 | 0.245 ± 0.005 | 14.7 ± 1.35 | 4.83 ± 0.43 |

| PEI/10CCF/10MoS2 | 0.238 ± 0.014 | 0.253 ± 0.010 | 5.63 ± 0.52 | 5.04 ± 0.48 |

| PEI/10CCF/23MoS2 | 0.248 ± 0.012 | 0.261 ± 0.023 | 8.13 ± 0.87 | 7.52 ± 0.62 |

| Element | Spectrum 1 wt.%/at.% | Spectrum 2 wt.%/at.% | Spectrum 3 wt.%/at.% | Spectrum 4 wt.%/at.% | Spectrum 5 wt.%/at.% |

|---|---|---|---|---|---|

| PEI/10CCF/10PTFE | |||||

| C | 73.77/78.32 | 81.65/85.98 | 51.61/63.56 | 48.49/59.59 | 80.06/84.77 |

| O | 26.23/21.68 | 18.35/14.02 | 7.92/4.92 | 5.21/4.43 | 19.94/15.23 |

| F | 40.47/31.52 | 46.30/35.98 | 46.1/35.5 | ||

| PEI/10CCF/10Gr | |||||

| C | 81.16/85.16 | 81.58/85.51 | 85.11/89.47 | 79.17/83.51 | 78.79/83.19 |

| O | 18.84/14.84 | 18.42/14.49 | 14.89/10.53 | 20.83/16.49 | 21.21/16.81 |

| PEI/10CCF/10MoS2 | |||||

| C | 69.52/83.80 | 72.56/84.61 | 61.92/82.95 | 81.25/86.70 | 76.85/88.52 |

| O | 13.06/11.82 | 13.78/12.06 | 8.74/8.79 | 15.85/12.70 | 9.55/8.26 |

| Mo | 11.57/1.75 | 9.08/1.33 | 19.35/3.25 | 2.08/0.28 | 9.23/1.33 |

| S | 5.85/2.64 | 4.58/2.00 | 9.99/5.01 | 0.82/0.33 | 4.37/1.88 |

| T, °C | PEI/10CCF/10PTFE | PEI/10CCF/10Gr | PEI/10CCF/10MoS2 | PEI/10CCF/23MoS2 | ||||

|---|---|---|---|---|---|---|---|---|

| Coefficient of Friction | Wear Rate (10−6 mm3/N·m) | Coefficient of Friction | Wear Rate (10−6 mm3/N·m) | Coefficient of Friction | Wear Rate (10−6 mm3/N·m) | Coefficient of Friction | Wear Rate (10−6 mm3/N·m) | |

| 23 | 0.048 ± 0.004 | 0.31 ± 0.03 | 0.245 ± 0.005 | 4.83 ± 0.43 | 0.253 ± 0.010 | 5.04 ± 0.48 | 0.261 ± 0.023 | 7.52 ± 0.62 |

| 120 | 0.088 ± 0.009 | 0.20 ± 0.02 | 0.439 ± 0.015 | 126.35 ± 9.85 | 0.403 ± 0.030 | 39.07 ± 3.70 | 0.234 ± 0.017 | 9.13 ± 0.76 |

| 180 | 0.107 ± 0.012 | 0.24 ± 0.02 | 0.452 ± 0.031 | 163.98 ± 13.16 | 0.095 ± 0.011 | 9.36 ± 0.95 | 0.111 ± 0.009 | 2.15 ± 0.23 |

| Element | Spectrum 1 at.% | Spectrum 2 at.% | Spectrum 3 at.% | Spectrum 4 at.% | Spectrum 5 at.% |

|---|---|---|---|---|---|

| PEI/10CCF/10PTFE | |||||

| C | 43.93 | 61.55 | 62.23 | 61.72 | 65.49 |

| O | 12.38 | 22.17 | 27.55 | 18.31 | 21.45 |

| F | 43.69 | 16.28 | 10.22 | 19.97 | 13.06 |

| PEI/10CCF/10Gr | |||||

| C | 75.57 | 64.32 | 73.83 | 72.65 | 70.37 |

| O | 24.43 | 35.68 | 26.17 | 27.35 | 29.63 |

| PEI/10CCF/10MoS2 | |||||

| C | 77.24 | 69.45 | 70.40 | 68.68 | 82.17 |

| O | 8.90 | 26.54 | 26.39 | 9.95 | 14.69 |

| S | 9.67 | 2.65 | 2.16 | 15.08 | 2.10 |

| Mo | 4.19 | 1.36 | 1.04 | 6.30 | 1.05 |

| PEI/10CCF/23MoS2 | |||||

| C | 68.58 | 72.56 | 61.92 | 81.25 | 76.85 |

| O | 10.73 | 13.78 | 8.74 | 15.85 | 9.55 |

| S | 13.84 | 9.08 | 19.35 | 2.08 | 9.23 |

| Mo | 6.85 | 4.58 | 9.99 | 0.82 | 4.37 |

| T, °C | PI/10CCF/10PTFE | PI/10CCF/10Gr | PI/10CCF/10MoS2 | PI/10CCF/23MoS2 | ||||

|---|---|---|---|---|---|---|---|---|

| Coefficient of Friction | Wear Rate (10−6 mm3/N·m) | Coefficient of Friction | Wear Rate (10−6 mm3/N·m) | Coefficient of Friction | Wear Rate (10−6 mm3/N·m) | Coefficient of Friction | Wear Rate (10−6 mm3/N·m) | |

| 23 | 0.094 ± 0.007 | 0.27 ± 0.02 | 0.226 ± 0.023 | 2.60 ± 0.23 | 0.295 ± 0.021 | 23.71 ± 2.31 | 0.262 ± 0.022 | 43.66 ± 1.90 |

| 120 | 0.182 ± 0.019 | 0.25 ± 0.03 | 0.394 ± 0.040 | 141.79 ± 15.14 | 0.498 ± 0.045 | 65.96 ± 6.81 | 0.082 ± 0.011 | 2.82 ± 0.29 |

| 180 | 0.320 ± 0.050 | 72.49 ± 7.12 | 0.397 ± 0.099 | 372.30 ± 36.82 | 0.519 ± 0.046 | 140.27 ± 13.56 | 0.076 ± 0.013 | 3.93 ± 0.38 |

| 240 | 0.270 ± 0.077 | 68.35 ± 6.43 | 0.395 ± 0.165 | 542.88 ± 68.34 | 0.513 ± 0.060 | 284.92 ± 29.31 | 0.161 ± 0.069 | 1.95 ± 0.17 |

| Element | Spectrum 1 at.% | Spectrum 2 at.% | Spectrum 3 at.% | Spectrum 4 at.% | Spectrum 5 at.% |

|---|---|---|---|---|---|

| PI/10CCF/10PTFE | |||||

| C | 55.60 | 89.76 | 92.69 | 57.93 | 58.12 |

| O | 31.84 | 7.44 | 5.16 | 23.46 | 38.06 |

| F | 12.56 | 2.80 | 2.15 | 18.61 | 3.82 |

| PI/10CCF/10Gr | |||||

| C | 65.88 | 92.99 | 80.74 | 64.67 | 88.96 |

| O | 34.12 | 7.01 | 19.26 | 35.33 | 11.04 |

| PI/10CCF/10MoS2 | |||||

| C | 67.82 | 69.40 | 74.38 | 82.97 | 73.83 |

| O | 24.23 | 24.17 | 17.36 | 11.48 | 15.12 |

| S | 6.38 | 5.32 | 6.37 | 4.70 | 9.23 |

| Mo | 1.57 | 1.11 | 1.89 | 0.85 | 1.82 |

| PI/10CCF/23MoS2 | |||||

| C | 66.82 | - | - | 62.96 | 94.02 |

| O | 22.07 | 61.71 | 50.98 | 21.13 | 5.27 |

| S | 11.11 | 38.29 | 49.02 | 12.57 | 0.71 |

| Mo | - | - | - | 3.34 | - |

| Material | Contact Type and Counterpart Material | Working Conditions (TRt–Room Temperature) | Friction Coefficient | Specific Wear Rate [10−6 mm3/N · m] | Ref. | |

|---|---|---|---|---|---|---|

| 5 vol.% micro-CaSiO3/10 vol.% Gr/15 vol.% SCF/PEI | Pin-On-Disc, Metal counterpart (Ra = 0.1 μm) | P = 1 MPa V = 1 m/s | TRt T = 150 °C | ~0.18–0.22 ~0.12 | 0.20–0.29 1.67–1.74 | [32] |

| 5 vol.% nano-Gr/10 vol.% Gr/15 vol.% SCF/PEI | TRt T = 150 °C | ~0.2 ~0.05 | 0.29 0.95 | |||

| 5 vol.% Gr/15 vol.% SCF/PEI | Pin-On-Disc, Metal counterpart (Ra = 0.22 μm) | P ∈ [1,12] MPa V ∈ [1,3] m/s | TRt T ∈ (70,120) °C | 0.22–0.61 0.24–0.29 | 0.73–598.67 1.92–15.18 | [55] |

| 5 vol.% nano-TiO2/5 vol.% Gr/15 vol.% SCF/PEI | TRt T ∈ (70,120) °C | 0.09–0.36 0.09–0.26 | 0.30–2.99 1.08–29.27 | |||

| 5–20 vol.% SCF/PEI | Pin-On-Disc, Metal counterpart | P = 2 MPa V = 1 m/s | TRt T = 150 °C | ~0.35 ~0.15–0.25 | ~0.8 ~5 | [13] |

| 20 vol.% PBORES-treated /PI | Ball-On-Disc, Metal counterpart (Ra = 0.1 μm) | F = 6 N V = 0.5 m/s | TRt T = 210 °C | 0.35 0.2 | 5 22 | [66] |

| 1.5 wt.% SMPS/PI | Ball-On-Disc, Metal counterpart | F ∈ [5,15] N V = 0.08 m/s | TRt T ∈ (100,300) °C | ~0.13–0.40 ~0.15–0.42 | ~0.75–1.60 ~0.7–2.4 | [54] |

| 5–30 vol.% CF/PI | Ball-On-Disc, Metal counterpart (Ra = 0.02 μm) | F = 5 N V = 0.3 m/s | TRt T ∈ (100,260) °C | ~0.30–0.32 ~0.05–0.37 | ~5.7–9.1 ~3.4–29.5 | [57] |

| 15 vol.% CF/PI | Block-On-Ring, Metal counterpart (Ra = 0.1 μm) | F = 30 N V = 1 m/s | TRt T ∈ (50,200) °C | 0.30 0.32–0.35 | ~2.2 ~7.5–21 | [58] |

| 15 vol.% GF/PI | TRt T ∈ (50,200) °C | 0.43 0.47–0.53 | ~2.0 ~4–13 | |||

| 15 vol.% AF/PI | TRt T ∈ (50,200) °C | 0.34 0.30–0.38 | ~10 ~11–55 | |||

| 20 vol.% PTFE /PI | Cylinder-On-Plat, Metal counterpart (Ra = 0.05 μm) | F ∈ [50,200] N V ∈ [0.3, 1.2] m/s | TRt T ∈ (50,260) °C | ~0.12–0.30 ~0.10–0.22 | ~65–78 ~70–120 | [27] |

| 30 wt.% CF/PI | Cylinder-On-Plat, Metal counterpart (Ra = 0.05 μm) | F = 50 N V = 0.3 m/s | TRt T ∈ (60,260) °C | ~0.55 ~0.05–0.65 | ~40 ~80–600 | [60] |

| 15 wt.% PTFE/30 wt.% CF/PI | TRt T ∈ (60,260) °C | ~0.2 ~0.05–0.23 | ~15 ~102–700 | |||

| 15 wt.% silicon oil /30 wt.% CF/PI | TRt T ∈ (60,260) °C | ~0.7 ~0.24–0.92 | ~20 ~105–800 | |||

| 10 wt.% PTFE/10 wt.% CF/PEI | Ball-On-Disc, Ceramic counterpart (Ra = 0.02 μm) | F= 5 N V = 0.3 m/s | TRt T∈(120,180) °C | 0.05 0.09–0.11 | 0.31 0.20–0.24 | Present work |

| 23 wt.% MoS2/10 wt.% CF/PI | TRt T∈(120,240) °C | 0.262 0.08–0.16 | 44.0 2.0–4.0 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Panin, S.V.; Luo, J.; Buslovich, D.G.; Alexenko, V.O.; Berto, F.; Kornienko, L.A. Effect of Transfer Film on Tribological Properties of Anti-Friction PEI- and PI-Based Composites at Elevated Temperatures. Polymers 2022, 14, 1215. https://doi.org/10.3390/polym14061215

Panin SV, Luo J, Buslovich DG, Alexenko VO, Berto F, Kornienko LA. Effect of Transfer Film on Tribological Properties of Anti-Friction PEI- and PI-Based Composites at Elevated Temperatures. Polymers. 2022; 14(6):1215. https://doi.org/10.3390/polym14061215

Chicago/Turabian StylePanin, Sergey V., Jiangkun Luo, Dmitry G. Buslovich, Vladislav O. Alexenko, Filippo Berto, and Lyudmila A. Kornienko. 2022. "Effect of Transfer Film on Tribological Properties of Anti-Friction PEI- and PI-Based Composites at Elevated Temperatures" Polymers 14, no. 6: 1215. https://doi.org/10.3390/polym14061215

APA StylePanin, S. V., Luo, J., Buslovich, D. G., Alexenko, V. O., Berto, F., & Kornienko, L. A. (2022). Effect of Transfer Film on Tribological Properties of Anti-Friction PEI- and PI-Based Composites at Elevated Temperatures. Polymers, 14(6), 1215. https://doi.org/10.3390/polym14061215