Green Composites Based on Hedysarum coronarium with Outstanding FDM Printability and Mechanical Performance

Abstract

:1. Introduction

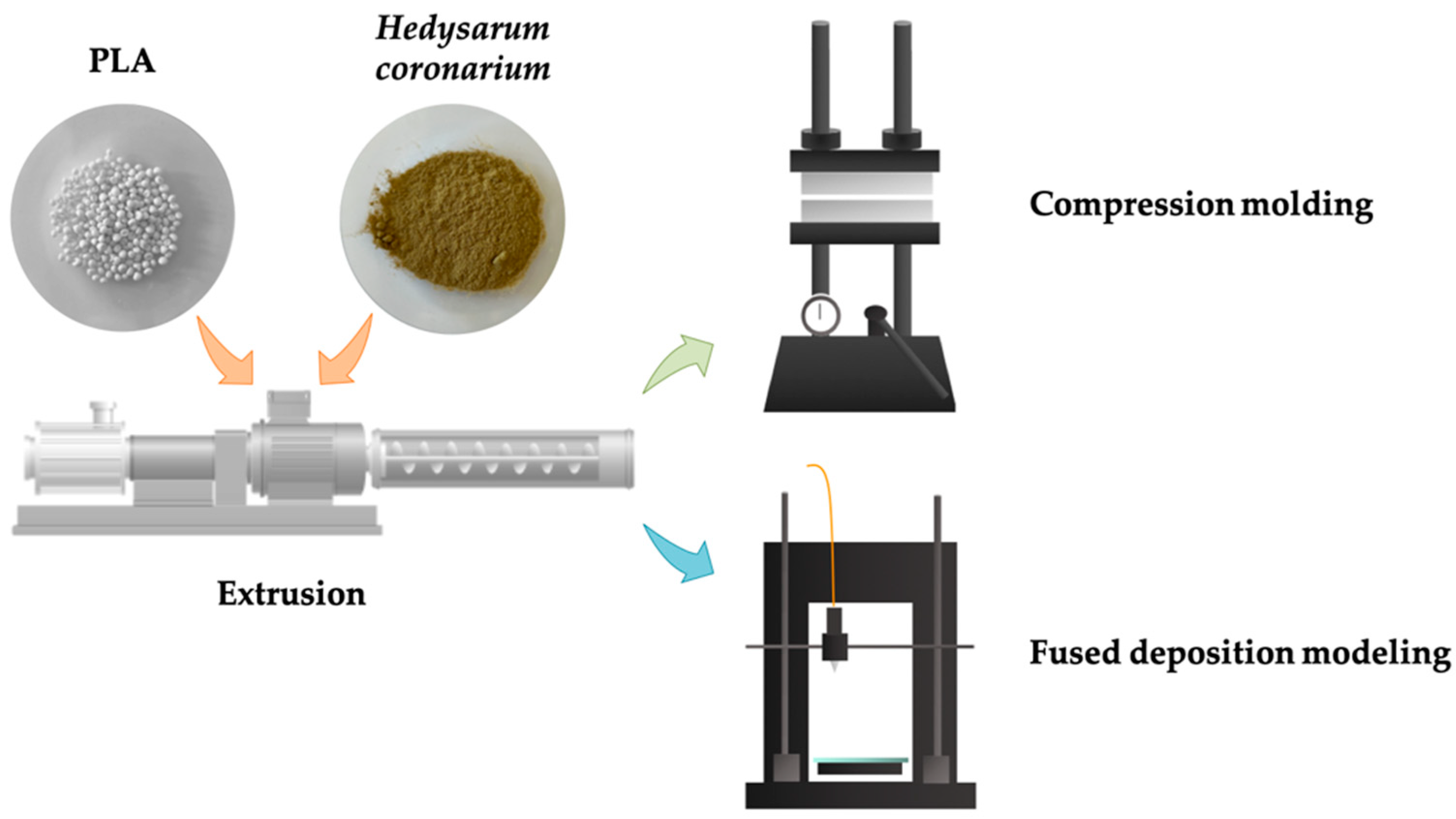

2. Materials and Methods

2.1. Materials

2.2. Preparation of Composites

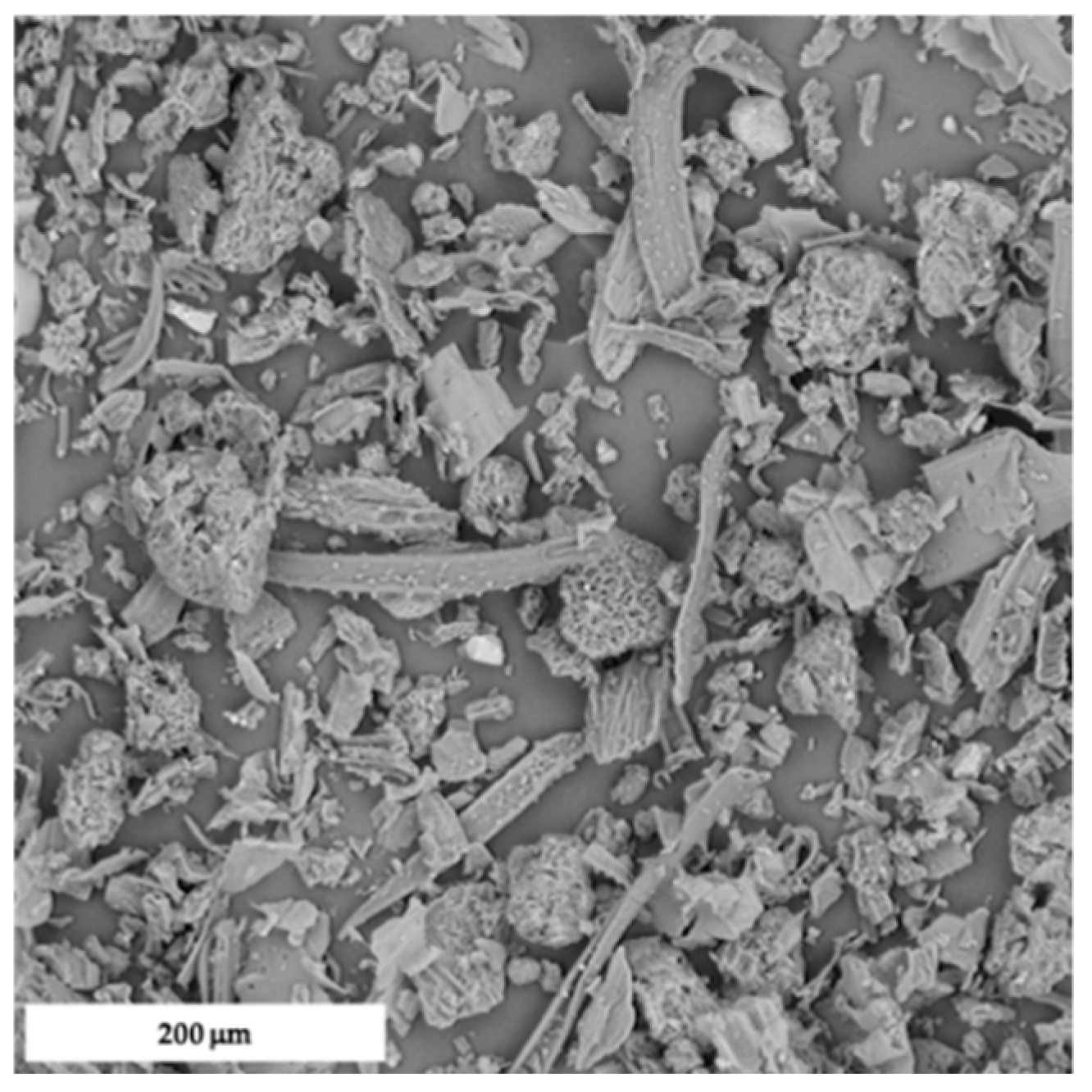

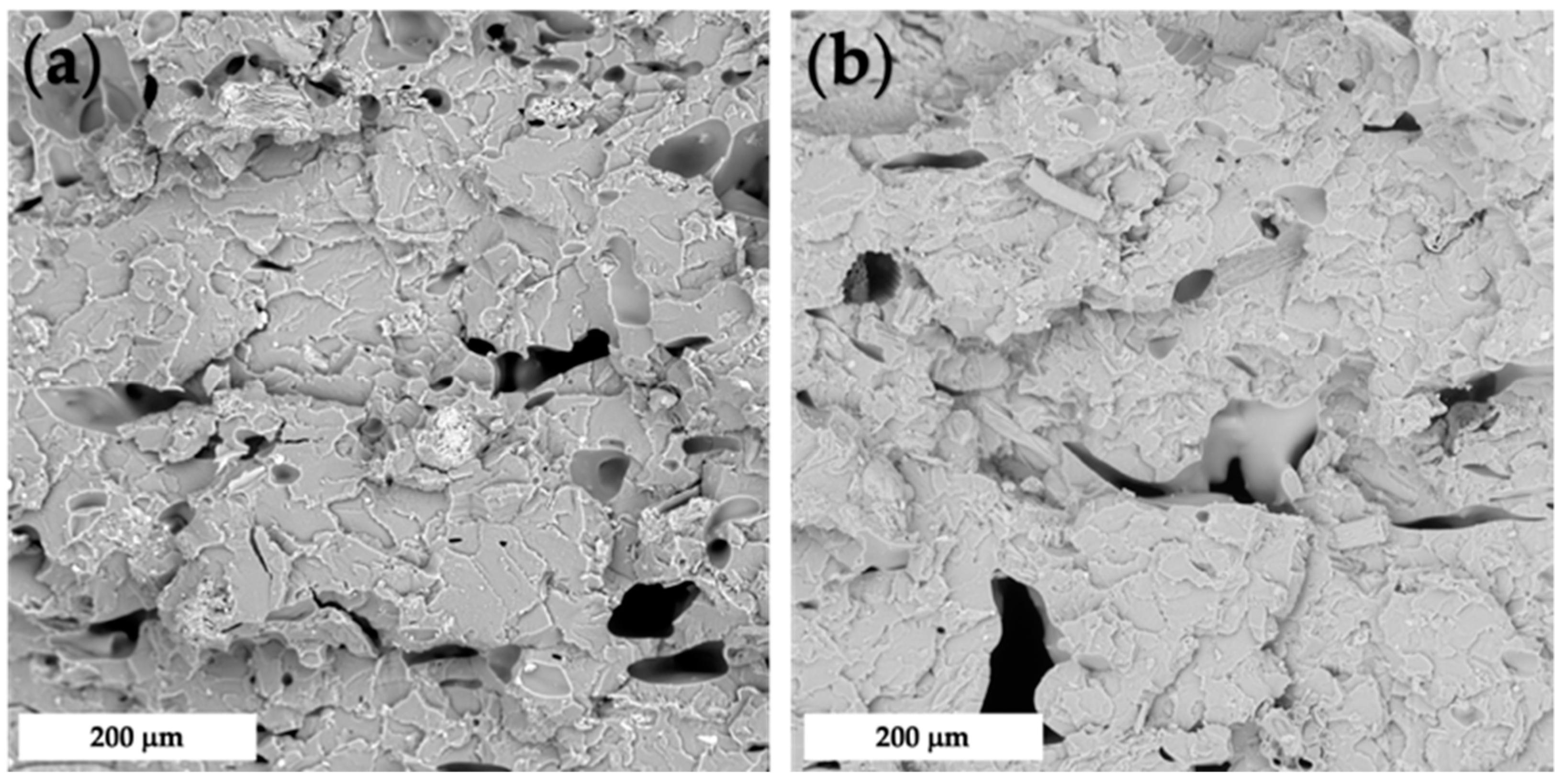

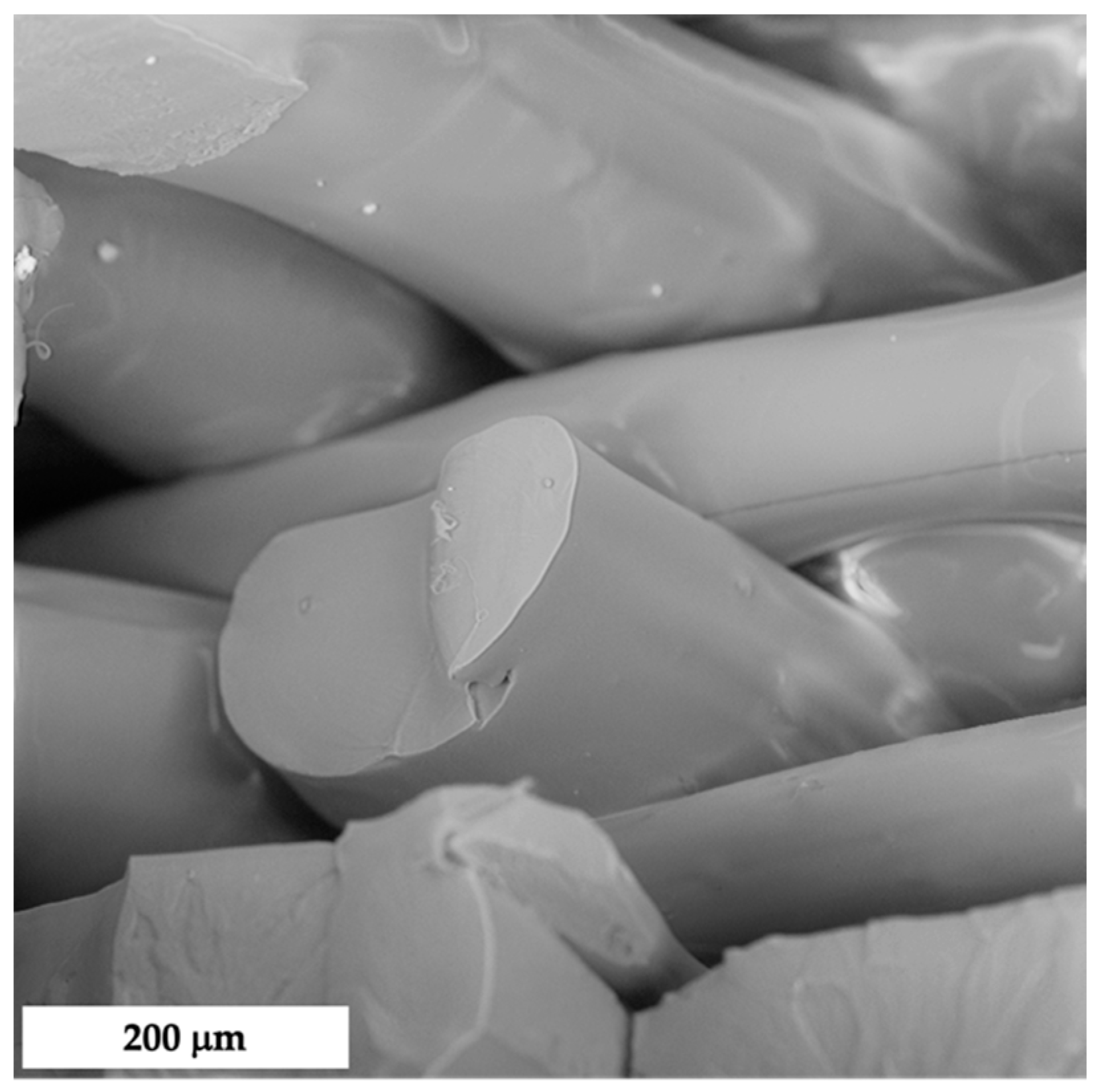

2.3. Morphological Analysis

2.4. Mechanical Characterization

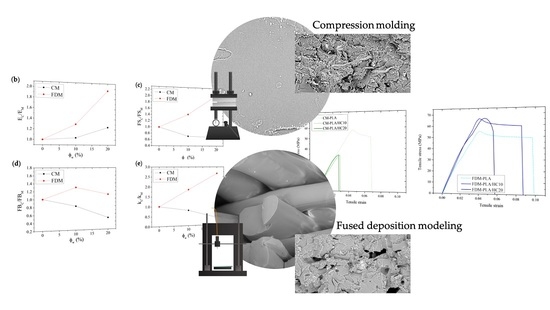

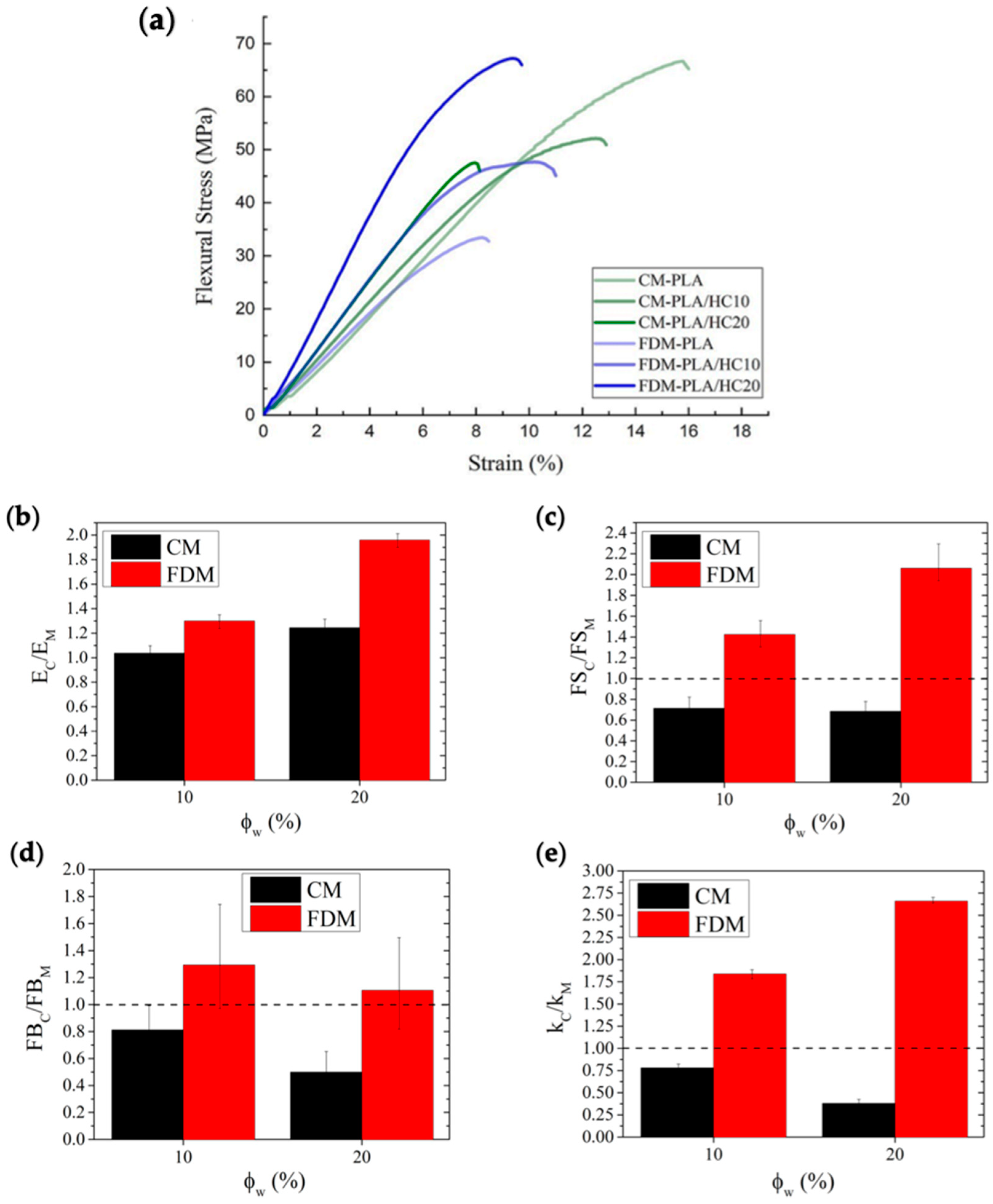

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tejyan, S.; Baliyan, N.K.; Patel, V.K.; Patnaik, A.; Singh, T. Polymer Green Composites Reinforced with Natural Fibers: A Comparative Study. Mater. Today Proc. 2020, 44, 4767–4769. [Google Scholar] [CrossRef]

- Scaffaro, R.; Maio, A.; Gulino, E.F.; Pitarresi, G. Lignocellulosic Fillers and Graphene Nanoplatelets as Hybrid Reinforcement for Polylactic Acid: Effect on Mechanical Properties and Degradability. Compos. Sci. Technol. 2020, 190, 108008. [Google Scholar] [CrossRef]

- Scaffaro, R.; Maio, A.; Sutera, F.; Gulino, E.F.; Morreale, M. Degradation and Recycling of Films Based on Biodegradable Polymers: A Short Review. Polymers 2019, 11, 651. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Re, G.L.; Morreale, M.; Scaffaro, R.; la Mantia, F.P. Biodegradation Paths of Mater-Bi®/Kenaf Biodegradable Composites. J. Appl. Polym. Sci. 2013, 129, 3198–3208. [Google Scholar] [CrossRef]

- Morreale, M.; Scaffaro, R.; Maio, A.; la Mantia, F.P. Mechanical Behaviour of Mater-Bi®/Wood Flour Composites: A Statistical Approach. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1537–1546. [Google Scholar] [CrossRef]

- Scaffaro, R.; Citarrella, M.C.; Gulino, E.F.; Morreale, M. Hedysarum Coronarium-Based Green Composites Prepared by Compression Molding and Fused Deposition Modeling. Materials 2022, 15, 465. [Google Scholar] [CrossRef]

- Rafiee, K.; Schritt, H.; Pleissner, D.; Kaur, G.; Brar, S.K. Biodegradable Green Composites: It’s Never Too Late to Mend. Curr. Opin. Green Sustain. Chem. 2021, 30, 100482. [Google Scholar] [CrossRef]

- Bordón, P.; Paz, R.; Peñalva, C.; Vega, G.; Monzón, M.; García, L. Biodegradable Polymer Compounds Reinforced with Banana Fiber for the Production of Protective Bags for Banana Fruits in the Context of Circular Economy. Agronomy 2021, 11, 242. [Google Scholar] [CrossRef]

- lo Re, G.; Morreale, M.; Scaffaro, R.; la Mantia, F.P. Kenaf-Filled Biodegradable Composites: Rheological and Mechanical Behaviour. Polym. Int. 2012, 61, 1542–1548. [Google Scholar] [CrossRef]

- la Mantia, F.P.; Morreale, M. Improving the Properties of Polypropylene-Wood Flour Composites by Utilization of Maleated Adhesion Promoters. Compos. Interfaces 2007, 14, 685–698. [Google Scholar] [CrossRef]

- Kopparthy, S.D.S.; Netravali, A.N. Review: Green Composites for Structural Applications. Compos. Part C Open Access 2021, 6, 100169. [Google Scholar] [CrossRef]

- Scaffaro, R.; Maio, A.; Gulino, E.F.; Megna, B. Structure-Property Relationship of PLA-Opuntia Ficus Indica Biocomposites. Compos. Part B Eng. 2019, 167, 199–206. [Google Scholar] [CrossRef]

- Scaffaro, R.; Lopresti, F.; Botta, L. PLA Based Biocomposites Reinforced with Posidonia Oceanica Leaves. Compos. Part B Eng. 2018, 139, 1–11. [Google Scholar] [CrossRef]

- Benito-González, I.; López-Rubio, A.; Martínez-Sanz, M. Potential of Lignocellulosic Fractions from Posidonia Oceanica to Improve Barrier and Mechanical Properties of Bio-Based Packaging Materials. Int. J. Biol. Macromol. 2018, 118, 542–551. [Google Scholar] [CrossRef]

- Boudjema, H.L.; Bendaikha, H.; Maschke, U. Green Composites Based on Atriplex Halimus Fibers and PLA Matrix. J. Polym. Eng. 2020, 40, 693–702. [Google Scholar] [CrossRef]

- Scaffaro, R.; Maio, A.; Lopresti, F. Physical Properties of Green Composites Based on Poly-Lactic Acid or Mater-Bi® Filled with Posidonia Oceanica Leaves. Compos. Part A Appl. Sci. Manuf. 2018, 112, 315–327. [Google Scholar] [CrossRef]

- Scaffaro, R.; Maio, A.; Gulino, E.F. Hydrolytic Degradation of PLA/Posidonia Oceanica Green Composites: A Simple Model Based on Starting Morpho-Chemical Properties. Compos. Sci. Technol. 2021, 213, 108930. [Google Scholar] [CrossRef]

- Seggiani, M.; Cinelli, P.; Mallegni, N.; Balestri, E.; Puccini, M.; Vitolo, S.; Lardicci, C.; Lazzeri, A. New Bio-Composites Based on Polyhydroxyalkanoates and Posidonia Oceanica Fibres for Applications in a Marine Environment. Materials 2017, 10, 326. [Google Scholar] [CrossRef] [Green Version]

- Komal, U.K.; Lila, M.K.; Singh, I. PLA/Banana Fiber Based Sustainable Biocomposites: A Manufacturing Perspective. Compos. Part B Eng. 2020, 180, 107535. [Google Scholar] [CrossRef]

- Tava, A.; Biazzi, E.; Ronga, D.; Mella, M.; Doria, F.; D’Addabbo, T.; Candido, V.; Avato, P. Chemical Identification of Specialized Metabolites from Sulla (Hedysarum coronarium L.) Collected in Southern Italy. Molecules 2021, 26, 4606. [Google Scholar] [CrossRef]

- Squartini, A.; Struffi, P.; Do, H.; Selenska-pobell, S.; Tola, E.; Giacomini, A.; Vendramin, E.; Mateos, P.F.; Martı, E. Rhizobium Sullae, the Root-Nodule Microsymbiont of Hedysarum coronarium L. Int. J. Syst. Evol. Microbiol. 2002, 52, 1267–1276. [Google Scholar] [PubMed] [Green Version]

- Gholampour, A.; Ozbakkaloglu, T. A Review of Natural Fiber Composites: Properties, Modification and Processing Techniques, Characterization, Applications. Journal of Materials Science 2020, 55, 829–892. [Google Scholar] [CrossRef]

- Scaffaro, R.; Maio, A.; Gulino, E.F.; Alaimo, G.; Morreale, M. Green Composites Based on Pla and Agricultural or Marine Waste Prepared by Fdm. Polymers 2021, 13, 1361. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Lei, Q.; Xing, S. Mechanical Characteristics of Wood, Ceramic, Metal and Carbon Fiber-Based PLA Composites Fabricated by FDM. J. Mater. Res. Technol. 2019, 8, 3743–3753. [Google Scholar] [CrossRef]

- Prabhu, R.; Devaraju, A. Recent Review of Tribology, Rheology of Biodegradable and FDM Compatible Polymers. Mater. Today Proc. 2020, 39, 781–788. [Google Scholar] [CrossRef]

- Rajendran Royan, N.R.; Leong, J.S.; Chan, W.N.; Tan, J.R.; Shamsuddin, Z.S.B. Current State and Challenges of Natural Fibre-Reinforced Polymer Composites as Feeder in Fdm-Based 3d Printing. Polymers 2021, 13, 2289. [Google Scholar] [CrossRef]

- Mazzanti, V.; Malagutti, L.; Mollica, F. FDM 3D Printing of Polymers Containing Natural Fillers: A Review of Their Mechanical Properties. Polymers 2019, 11, 1094. [Google Scholar] [CrossRef] [Green Version]

- Alvarez, C.K.L.; Lagos, C.R.F.; Aizpun, M. Investigating the Influence of Infill Percentage on the Mechanical Properties of Fused Deposition Modelled ABS Parts. Ingenieria e Investigacion 2016, 36, 110–116. [Google Scholar] [CrossRef] [Green Version]

- Mahmood, S.; Qureshi, A.J.; Goh, K.L.; Talamona, D. Tensile Strength of Partially Filled FFF Printed Parts: Experimental Results. Rapid Prototyp. J. 2017, 23, 122–128. [Google Scholar] [CrossRef]

- Dave, H.K.; Patadiya, N.H.; Prajapati, A.R.; Rajpurohit, S.R. Effect of Infill Pattern and Infill Density at Varying Part Orientation on Tensile Properties of Fused Deposition Modeling-Printed Poly-Lactic Acid Part. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2021, 235, 1811–1827. [Google Scholar] [CrossRef]

- Živković, I.; Fragassa, C.; Pavlović, A.; Brugo, T. Influence of Moisture Absorption on the Impact Properties of Flax, Basalt and Hybrid Flax/Basalt Fiber Reinforced Green Composites. Compos. Part B Eng. 2017, 111, 148–164. [Google Scholar] [CrossRef]

- Hassanin, A.H.; Hamouda, T.; Candan, Z.; Kilic, A.; Akbulut, T. Developing High-Performance Hybrid Green Composites. Compos. Part B Eng. 2016, 92, 384–394. [Google Scholar] [CrossRef]

- Scaffaro, R.; Maio, A. Integrated Ternary Bionanocomposites with Superior Mechanical Performance via the Synergistic Role of Graphene and Plasma Treated Carbon Nanotubes. Compos. Part B Eng. 2019, 168, 550–559. [Google Scholar] [CrossRef]

| FDM Operating Parameter | Value |

|---|---|

| Nozzle temperature | 230 °C |

| Bed temperature | 60 °C |

| Infill rate | 100% |

| Infill pattern | Rectilinear |

| Raster angle | ±45° |

| Layer thickness of tensile samples | 0.1 mm |

| Layer thickness of flexural/impact samples | 0.2 mm |

| Extrusion width | 0.4 mm |

| Printing speed | 20 mm/s |

| Perimeter shells | 1 |

| Sample Orientation | flat |

| Sample Code Name | PLA Content (wt%) | HC Content (wt%) | HC Mesh Size (μm) | Production Technique |

|---|---|---|---|---|

| CM-PLA | 100 | 0 | - | CM |

| CM-PLA/HC10 | 90 | 10 | <150 | CM |

| CM-PLA/HC20 | 80 | 20 | <150 | CM |

| FDM-PLA | 100 | 0 | - | FDM |

| FDM-PLA/HC10 | 90 | 10 | <150 | FDM |

| FDM-PLA/HC20 | 80 | 20 | <150 | FDM |

| Sample | E (MPa) | TS (MPa) | EB (%) | k (MJ/m3) |

|---|---|---|---|---|

| CM-PLA | 1580 ± 19 | 54 ± 2 | 5.6 ± 0.4 | 2.64 ± 0.01 |

| CM-PLA/HC10 | 1730 ± 15 | 32 ± 3 | 2.5 ± 0.4 | 0.55 ± 0.01 |

| CM-PLA/HC20 | 1830 ± 22 | 34 ± 2 | 2.4 ± 0.2 | 0.55 ± 0.01 |

| FDM-PLA | 1260 ± 13 | 56 ± 4 | 10 ± 0.3 | 4.09 ± 0.02 |

| FDM-PLA/HC10 | 1843 ± 20 | 63 ± 4 | 9 ± 0.5 | 3.60 ± 0.02 |

| FDM-PLA/HC20 | 2070 ± 31 | 62 ± 3 | 7 ± 0.1 | 2.43 ± 0.01 |

| Sample | E (MPa) | FS (MPa) | FB (%) | k (MJ/m3) |

|---|---|---|---|---|

| CM-PLA | 530 ± 10 | 70 ± 3 | 16 ± 2.0 | 5.12 ± 0.04 |

| CM-PLA/HC10 | 550 ± 10 | 50 ± 5 | 13 ± 1.1 | 3.99 ± 0.04 |

| CM-PLA/HC20 | 660 ± 25 | 48 ± 3 | 8 ± 1.3 | 1.93 ± 0.02 |

| FDM-PLA | 500 ± 10 | 33 ± 2 | 8.5 ± 1.2 | 1.44 ± 0.01 |

| FDM-PLA/HC10 | 650 ± 10 | 47 ± 1 | 11 ± 1.6 | 2.65 ± 0.01 |

| FDM-PLA/HC20 | 980 ± 20 | 68 ± 3 | 9.4 ± 1.5 | 3.83 ± 0.02 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Scaffaro, R.; Gulino, E.F.; Citarrella, M.C.; Maio, A. Green Composites Based on Hedysarum coronarium with Outstanding FDM Printability and Mechanical Performance. Polymers 2022, 14, 1198. https://doi.org/10.3390/polym14061198

Scaffaro R, Gulino EF, Citarrella MC, Maio A. Green Composites Based on Hedysarum coronarium with Outstanding FDM Printability and Mechanical Performance. Polymers. 2022; 14(6):1198. https://doi.org/10.3390/polym14061198

Chicago/Turabian StyleScaffaro, Roberto, Emmanuel Fortunato Gulino, Maria Clara Citarrella, and Andrea Maio. 2022. "Green Composites Based on Hedysarum coronarium with Outstanding FDM Printability and Mechanical Performance" Polymers 14, no. 6: 1198. https://doi.org/10.3390/polym14061198

APA StyleScaffaro, R., Gulino, E. F., Citarrella, M. C., & Maio, A. (2022). Green Composites Based on Hedysarum coronarium with Outstanding FDM Printability and Mechanical Performance. Polymers, 14(6), 1198. https://doi.org/10.3390/polym14061198