Experimental Study on Effects of Additional Prestressing Using Fiber Reinforced Polymers and Strands on Deterioration of PSC Bridge Structure

Abstract

:1. Introduction

2. Materials and Methods

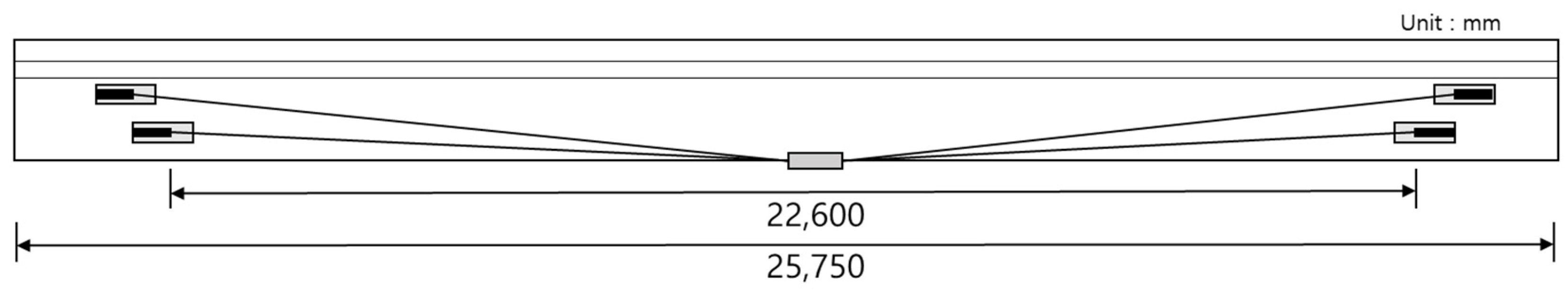

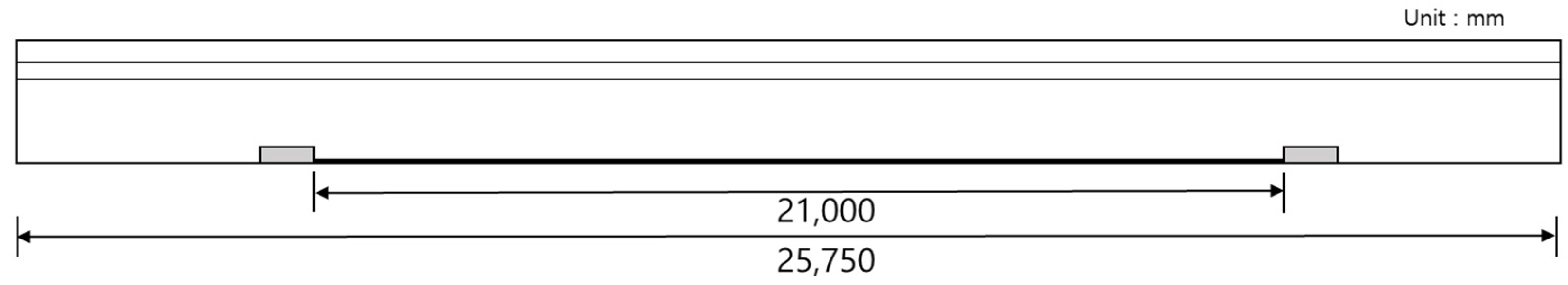

2.1. Strengthening Methods

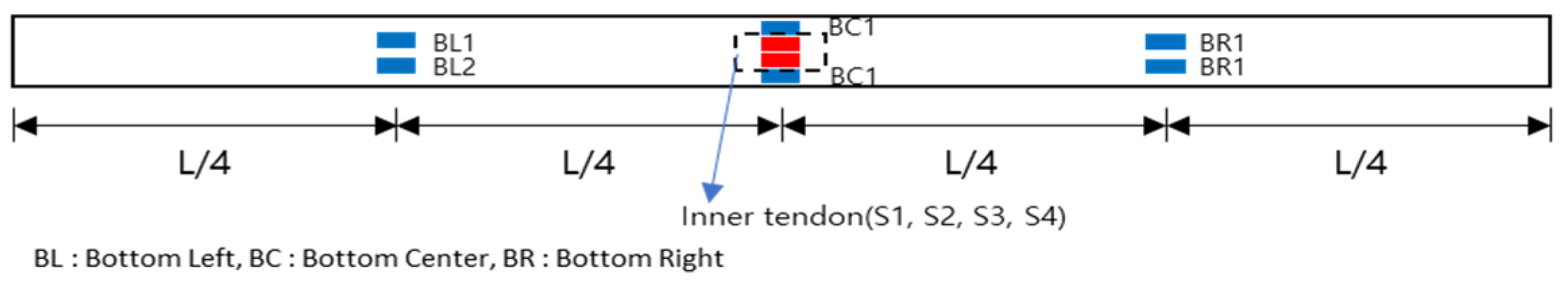

2.2. Specification of Specimens

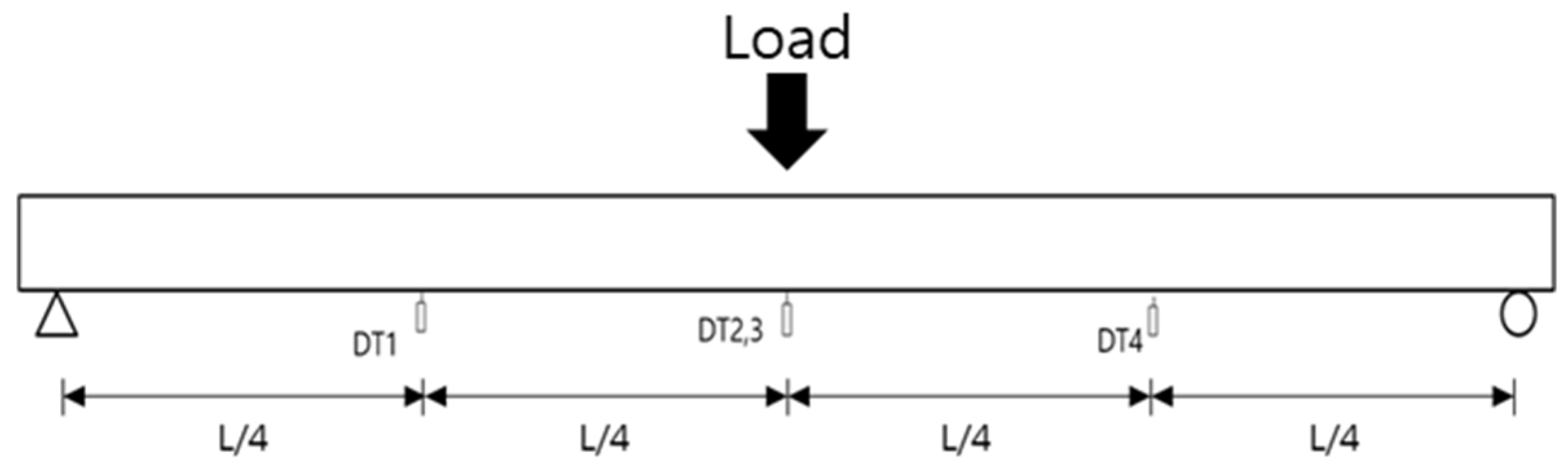

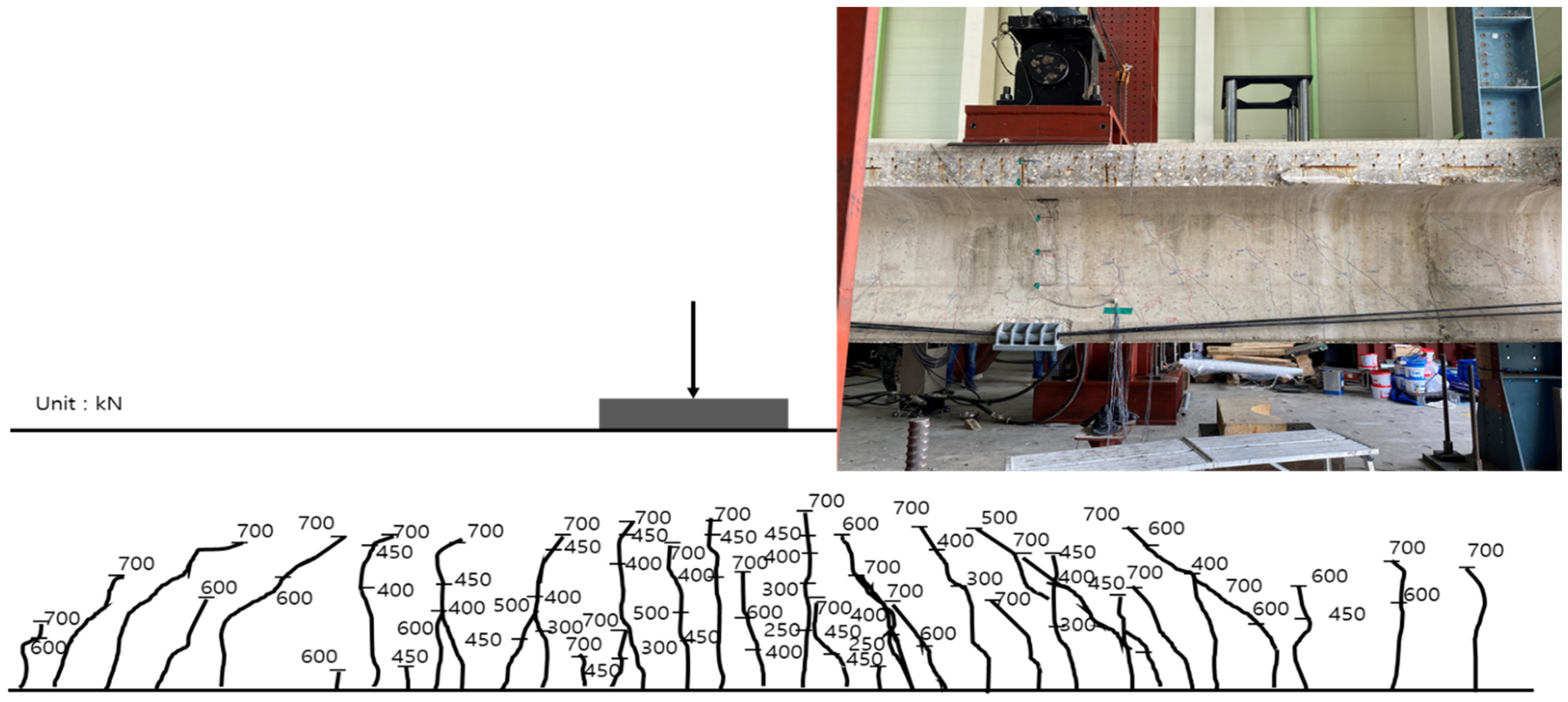

2.3. Flexural Test Setup

2.4. Concrete Strength

3. Flexural Test Results and Discussion

3.1. Additional Prestressing

3.1.1. Prestressing in EP Method

3.1.2. Prestressing in NSM Method

3.2. Load–Displacement

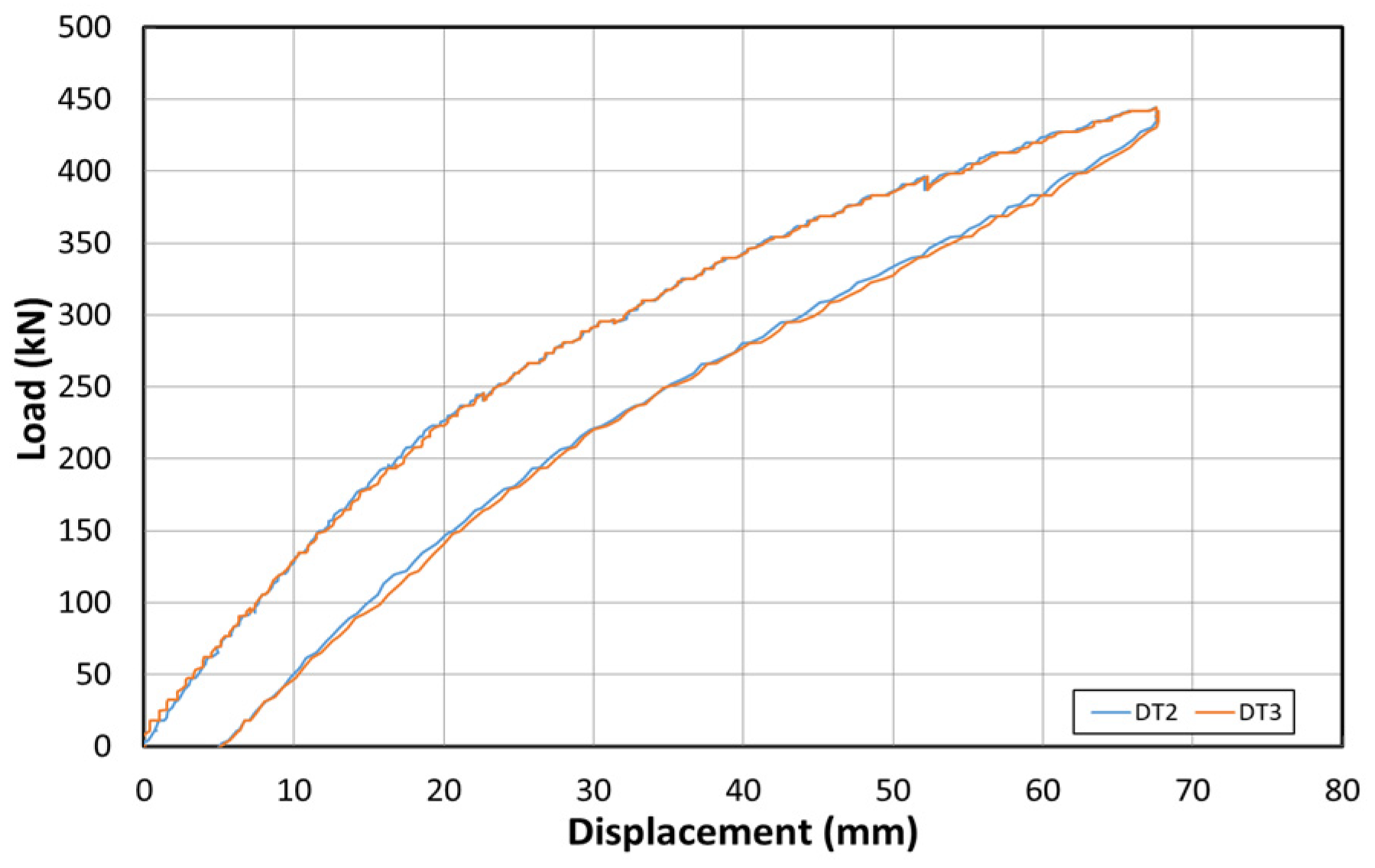

3.2.1. Analysis before Applying EP Method

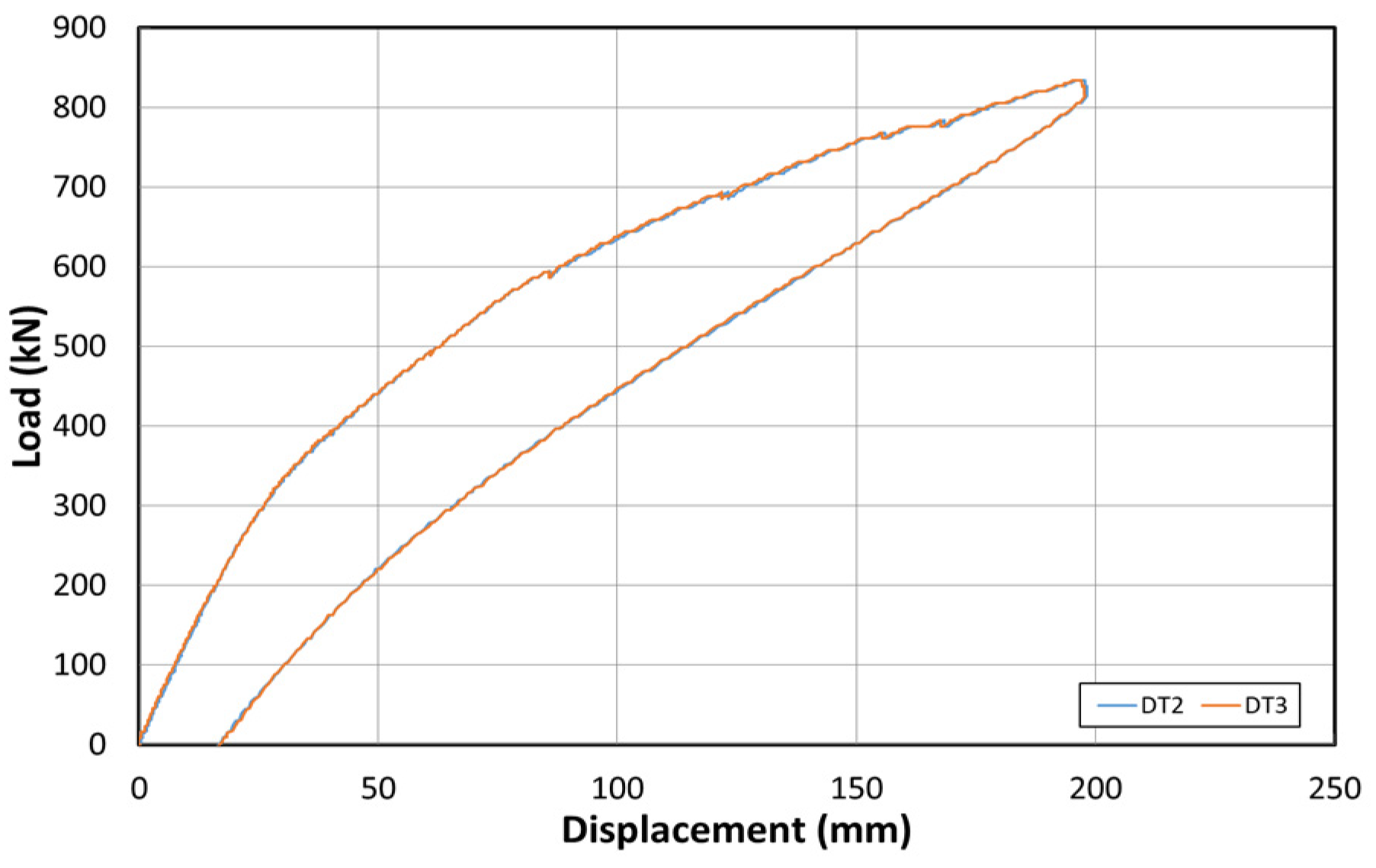

3.2.2. Analysis after Reinforcement via EP Method

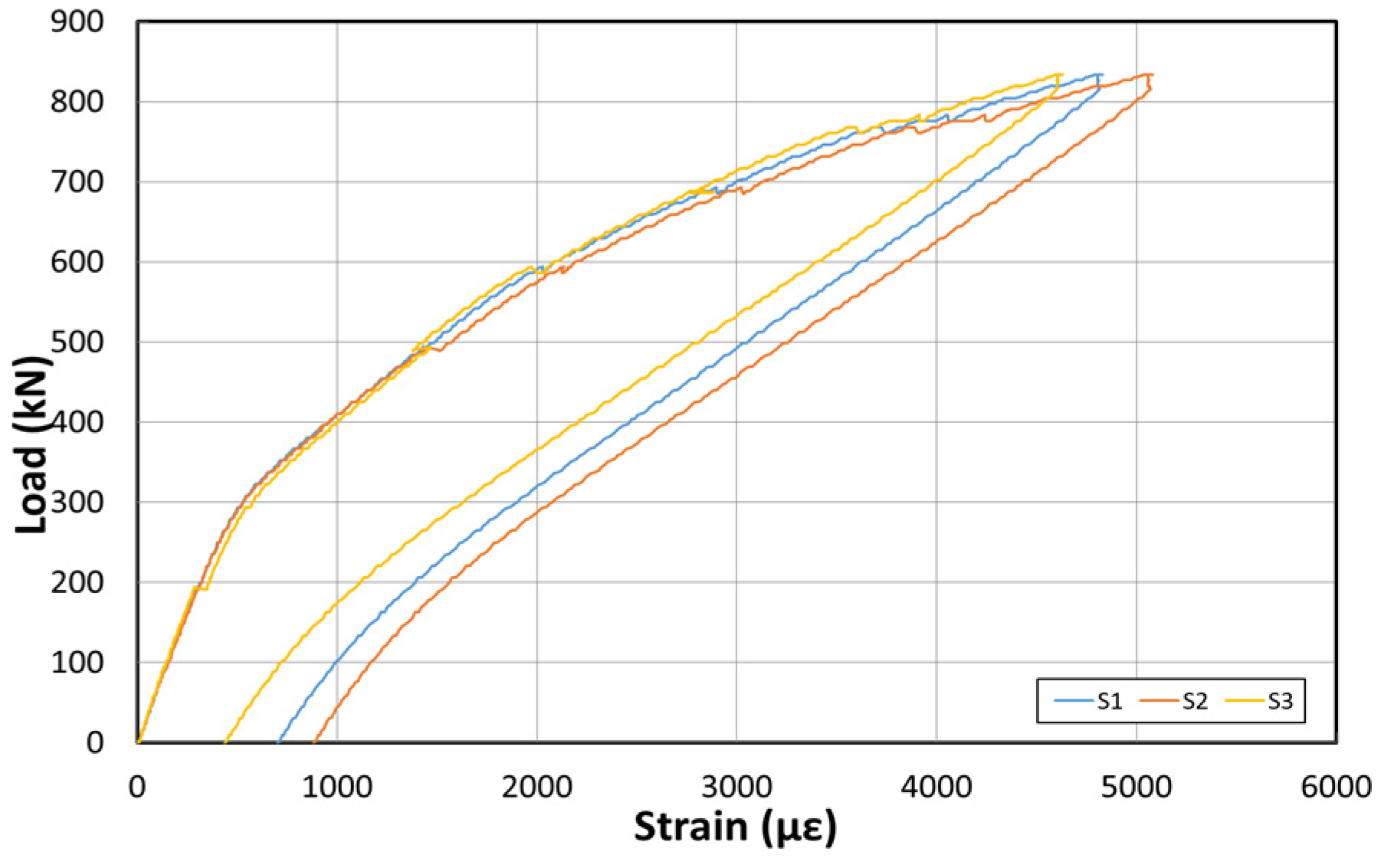

3.2.3. Analysis after Reinforcement via NSM Method

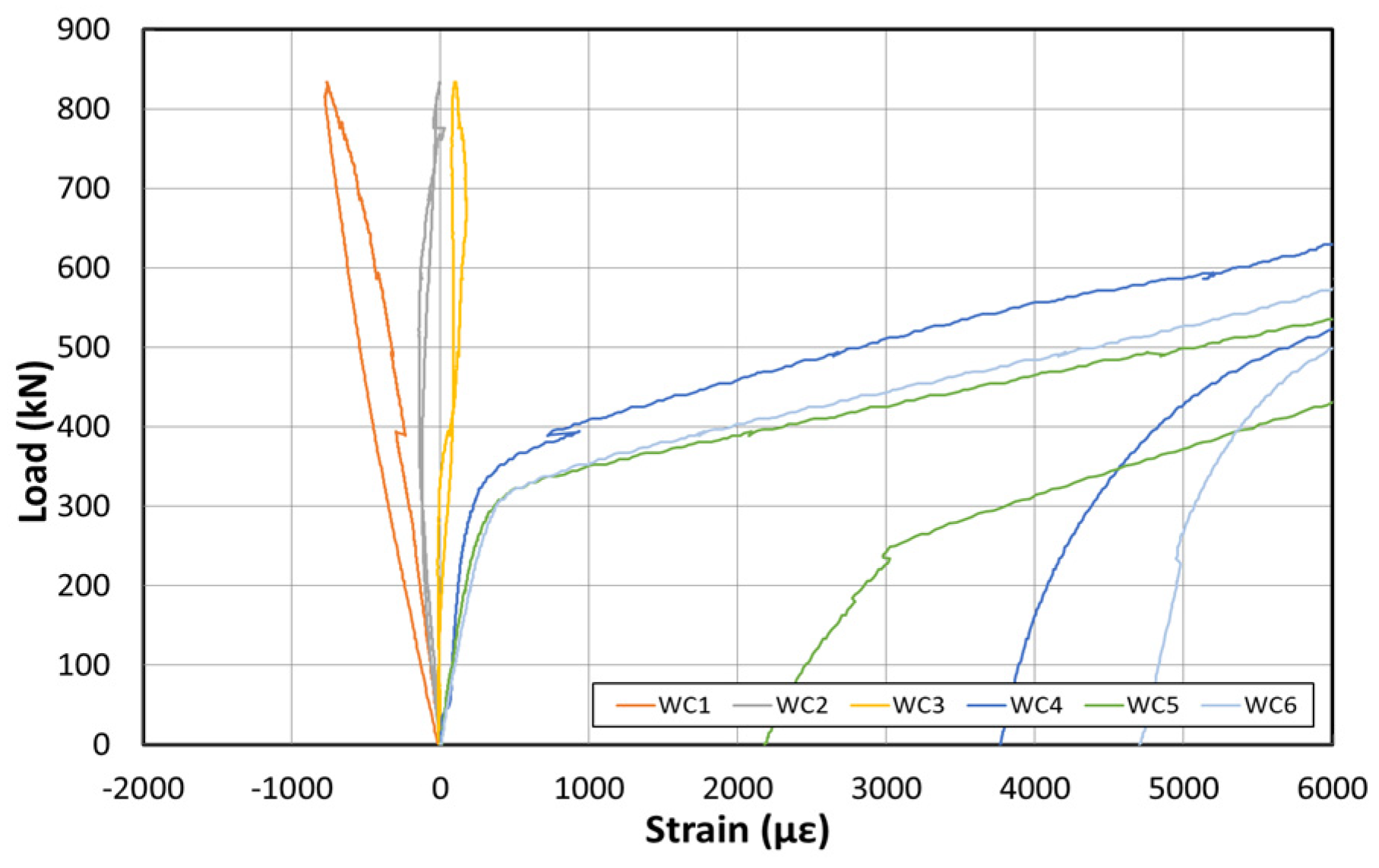

3.3. Comparison of Strengthening Methods

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shin, H.M.; Lee, J.H. Reinforced Concrete, 11th ed.; Dong Myeong: Paju City, Korea, 2013. [Google Scholar]

- Shin, H.M. Prestressed Concrete, 10th ed.; Dong Myeong: Paju City, Korea, 2012. [Google Scholar]

- Mehta, P.K.; Paulo, J.M.M. Concrete (Microstructure, Properties, and Materials), 3rd ed.; McGraw Hill: New York, NY, USA, 2006. [Google Scholar]

- Sidney, M.; Francis, Y.; David, D. Concrete, 2nd ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2003. [Google Scholar]

- Ministry of Land, Infrastructure, and Transport. Research of Longevity for Performance Evaluation of Aged Bridge; Report No. R&D/15RDPP-C102166-01; Korean Agency for Infrastructure Technology Advancement: Anyang-si, Korea, 2016. (In Korean)

- Kim, S.J.; Yoon, M.O. A study on the improvement program of bridge safety management through public–private governance. J. Korea Soc. 2018, 18, 145–156. (In Korean) [Google Scholar] [CrossRef]

- Korea Expressway Corporation. Techniques and Frameworks for Rapid Bridge Replacement after Extreme Events; Report No. 2016-35-534.9607; Korean Expressway Corporation Research Institute: Hwaseong-si, Korea, 2016. (In Korean) [Google Scholar]

- Kim, Y.J. Analysis of event in domestic bridge failures. J. Korea Inst. Concr. Struct. Maint. Insp. 2002, 6, 103–111. (In Korean) [Google Scholar]

- Ministry of Land, Infrastructure, and Transport. Detailed Guidelines on Safety Inspection and Precision Safety Diagnosis; Report No. RD-12-E6-024; Korean Authority of Land & Infrastructure Safety: Jinju, Korea, 2017. (In Korean)

- Wang, X.; Shi, J.; Wu, G.; Yang, L.; Wu, Z. Effectiveness of basalt FRP tendons for strengthening of RC beams through the external prestressing technique. Eng. Struct. 2015, 101, 34–44. [Google Scholar] [CrossRef]

- Pisani, M.A. Behaviour under long-term loading of externally prestressed concrete beams. Eng. Struct. 2018, 160, 24–33. [Google Scholar] [CrossRef]

- Fan, Y.; Chen, L.; Fang, Q.; Wang, T. Blast resistance of externally prestressed RC Beam: A theoretical approach. Eng. Struct. 2019, 179, 211–224. [Google Scholar] [CrossRef]

- Senthil, R.; Manisekar, R. Ultimate flexural behaviour of externally prestressed new beams and distressed beams. J. Eng. Sci. Technol. 2015, 10, 461–484. [Google Scholar]

- Kaur, H.; Singh, J.A. Review on external prestressing in concrete. Int. Res. J. Eng. Technol. 2017, 4, 1801–1805. [Google Scholar]

- Coelho, M.R.; Sena-Cruz, J.M.; Neves, L.A. A review on the bond behavior of FRP NSM systems in concrete. Constr. Build. Mater. 2015, 93, 1157–1169. [Google Scholar] [CrossRef] [Green Version]

- Bilotta, A.; Ceroni, F.; Nigro, E.; Pecce, M. Efficiency of CFRP NSM strips and EBR plates for flexural strengthening of RC beams and loading pattern influence. Compos. Struct. 2015, 124, 163–175. [Google Scholar] [CrossRef]

- Jumaat, M.Z.; Shukri, A.A.; Obaydullah, M.; Huda, M.; Hosen, M.; Hoque, N. Strengthening of RC beams using externally bonded reinforcement combined with near-surface mounted technique. Polymers 2016, 8, 261. [Google Scholar]

- Kim, T.K.; Kim, S.H.; Park, J.S.; Park, H.B. Experimental evaluation of PSC structures from FRP with a prestressing strengthening method. Materials 2021, 14, 1265. [Google Scholar] [CrossRef] [PubMed]

- Alwash, D.; Kalfat, R.; Al-Mahaidi, R.; Du, H. Shear strengthening of RC beams using NSM CFRP bonded using cement-based adhesive. Constr. Build. Mater. 2021, 301, 124365. [Google Scholar] [CrossRef]

- El-Hacha, R.; Awassa, O. Strengthening of Concrete Structures Using Prestressed FRP–A Review. Int. Conf. FRP Compos. Civ. Eng. 2021, 198, 2209–2221. [Google Scholar]

- Jahangir, H.; Khatibinia, M.; Masinaei, M.M. Damage Detection in Prestressed Concrete Slabs Using Wavelet Analysis of Vibration Responses in the Time Domain. J. Rehabil. Civ. Eng. 2022, 10, 37–63. [Google Scholar]

- Slaitas, J.; Valivonis, J. Full moment-deflection response and bond stiffness reduction of RC elements strengthened with prestressed FRP materials. Compos. Struct. 2021, 260, 113265. [Google Scholar] [CrossRef]

- Kim, T.K.; Park, J.S.; Kim, S.H.; Jung, W.T. Structural behavior evaluation of reinforced concrete using the fiber-reinforced polymer strengthening method. Polymers 2021, 13, 780. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.S.; Ke, Y.; Chen, E.; Biscaia, H.; Li, W.G. Effect of load distribution on the behaviour of RC beams strengthened in flexure with near-surface mounted (NSM) FRP. Compos. Struct. 2021, 279, 114782. [Google Scholar] [CrossRef]

- Jahani, Y.; Baena, M.; Gómez, J.; Barris, C.; Torres, L. Experimental study of the effect of high service temperature on the flexural performance of near-surface mounted (NSM) carbon fiber-reinforced polymer (CFRP)-Strengthened concrete beams. Polymers 2021, 13, 920. [Google Scholar] [CrossRef]

- Abdallah, M.; Al Mahmoud, F.; Boissiere, R.; Khelil, A.; Mercier, J. Experimental study on strengthening of RC beams with side near surface mounted technique-CFRP bars. Compos. Struct. 2020, 234, 111716. [Google Scholar] [CrossRef]

- Le, T.D.; Pham, T.M.; Hao, H.; Li, H. Behavior of precast segmental concrete beams prestressed with external steel and CFRP tendons. J. Compos. Constr. 2020, 24, 04020053. [Google Scholar] [CrossRef]

- Zou, J.; Huang, Y.; Feng, W.; Chen, Y.; Huang, Y. Experimental study on flexural behavior of concrete T-beams strengthened with externally prestressed tendons. Math. Biosci. Eng. 2019, 16, 6962–6974. [Google Scholar] [CrossRef] [PubMed]

- Guo, R.; Xian, G.; Li, C.; Huang, X.; Xin, M. Effect of fiber hybridization types on the mechanical properties of carbon/glass fiber reinforced polymer composite rod. Mech. Adv. Mater. Struct. 2021, 1–13. [Google Scholar] [CrossRef]

- Li, C.; Xian, G. Novel wedge-shaped bond anchorage system for pultruded CFRP plates. Mater. Struct. 2018, 51, 162. [Google Scholar] [CrossRef]

- Sun, W.; Lou, T.; Achintha, M. A novel strong and durable near-surface mounted (NSM) FRP method with cost-effective fillers. Compos. Struct. 2021, 255, 112952. [Google Scholar] [CrossRef]

- Korea Standards Association (KSA). Standard Test Method for Compressive Strength of Concrete; KS F 2405; Korea Agency for Technology and Standards: Seoul, Korea, 2017.

- Korea Standards Association (KSA). Standard Test Method for Tensile Splitting Strength of Concrete; KS F 2423; Korea Agency for Technology and Standards: Seoul, Korea, 2016.

| Girder | ||||

|---|---|---|---|---|

| Number | Compressive | Splitting Tensile | ||

| Load (kN) | Strength (MPa) | Load (kN) | Strength (MPa) | |

| 1 | 238.00 | 30.30 | 65.70 | 3.29 |

| 2 | 227.00 | 28.90 | 52.70 | 2.64 |

| 3 | 209.70 | 26.70 | 69.90 | 3.50 |

| 4 | 267.80 | 34.10 | 62.40 | 3.12 |

| 5 | 246.60 | 31.40 | 69.60 | 3.48 |

| Average | 237.82 ± 19.4 | 30.28 ± 2.5 | 64.06 ± 6.3 | 3.21 ± 0.32 |

| Slab | ||||

|---|---|---|---|---|

| Number | Compressive | Splitting Tensile | ||

| Load (kN) | Strength (MPa) | Load (kN) | Strength (MPa) | |

| 1 | 285.10 | 36.30 | 81.80 | 4.09 |

| 2 | 317.30 | 40.40 | 108.30 | 5.42 |

| 3 | - | - | 107.10 | 5.36 |

| Average | 301.20 ± 16.1 | 38.35 ± 2.1 | 99.07 ± 12.2 | 4.96 ± 0.6 |

| Prestressing (kN) | T1-L | T1-R | T3-L | T3-R |

|---|---|---|---|---|

| (kN) | (kN) | (kN) | (kN) | |

| 0 | 0 | 0 | 0 | 0 |

| 30 | 21.34 | 21.09 | 20.56 | 23.26 |

| 60 | 46.71 | 47.77 | 43.80 | 49.79 |

| 90 | 71.66 | 74.74 | 66.95 | 76.46 |

| 120 | 97.84 | 103.19 | 87.02 | 100.06 |

| 150 | 124.28 | 131.72 | 111.77 | 126.45 |

| 180 | 147.02 | 156.23 | 129.85 | 126.21 |

| Final | 135.17 | 144.27 | 116.14 | 108.77 |

| Prestressing losses | 44.83 | 35.73 | 63.86 | 71.23 |

| Prestressing (kN) | T2-L | T2-R | T4-L | T4-R |

|---|---|---|---|---|

| (kN) | (kN) | (kN) | (kN) | |

| 0 | 0 | 0 | 0 | 0 |

| 30 | 14.99 | 14.76 | 12.32 | 14.04 |

| 60 | 40.42 | 39.28 | 39.67 | 43.69 |

| 90 | 66.22 | 64.36 | 63.67 | 69.19 |

| 120 | 89.36 | 87.88 | 87.88 | 94.45 |

| 150 | 117.18 | 113.60 | 111.16 | 120.12 |

| 180 | 138.67 | 134.73 | 132.43 | 143.72 |

| Final | 134.73 | 128.43 | 127.52 | 135.81 |

| Prestressing losses | 45.27 | 51.57 | 52.48 | 44.19 |

| Prestressing (kN) | T1-(Avg) (kN) | T2-Avg (kN) | T3-Avg (kN) | T4-Avg (kN) |

|---|---|---|---|---|

| 0 | 0 | 0 | 0 | 0 |

| 30 | 21.23 | 14.88 | 21.92 | 13.18 |

| 60 | 47.24 | 39.83 | 46.24 | 41.66 |

| 90 | 73.19 | 65.28 | 71.69 | 66.45 |

| 120 | 100.50 | 88.60 | 93.54 | 91.18 |

| 150 | 128.00 | 115.38 | 119.10 | 115.63 |

| 180 | 151.62 | 136.70 | 128.02 | 138.06 |

| Final | 139.72 | 131.57 | 112.45 | 131.65 |

| Prestressing losses | 40.28 | 48.43 | 67.55 | 48.35 |

| DT1 (mm) | DT2 (mm) | DT3 (mm) | DT4 (mm) | L/2Avg (mm) |

|---|---|---|---|---|

| 4.3 | 6.2 | 5.9 | 5.4 | 6.05 |

| DT-A1 (mm) | DT-A2 (mm) | DT-A3 (mm) | DT-A4 (mm) | DT-A5 (mm) | DT-A6 (mm) | DT-A7 (mm) | DT-A8 (mm) |

|---|---|---|---|---|---|---|---|

| 0.005 | 0.084 | 0.055 | −0.014 | 0.018 | 0.005 | 0.05 | 0.005 |

| Load Cell-1 (kN) | Load Cell-2 (kN) | Load Cell-3 (kN) |

|---|---|---|

| 87.5 | 77.3 | 74.2 |

| FC1 (με) | FC2 (με) | FC5 (με) | FC6 (με) | FC3 (με) | FC4 (με) |

|---|---|---|---|---|---|

| 4245 | 4300 | 4395 | 4440 | 4169 | 4139 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, T.-K.; Jung, W.-T.; Park, J.-S.; Park, H.-B. Experimental Study on Effects of Additional Prestressing Using Fiber Reinforced Polymers and Strands on Deterioration of PSC Bridge Structure. Polymers 2022, 14, 1115. https://doi.org/10.3390/polym14061115

Kim T-K, Jung W-T, Park J-S, Park H-B. Experimental Study on Effects of Additional Prestressing Using Fiber Reinforced Polymers and Strands on Deterioration of PSC Bridge Structure. Polymers. 2022; 14(6):1115. https://doi.org/10.3390/polym14061115

Chicago/Turabian StyleKim, Tae-Kyun, Woo-Tai Jung, Jong-Sup Park, and Hee-Beom Park. 2022. "Experimental Study on Effects of Additional Prestressing Using Fiber Reinforced Polymers and Strands on Deterioration of PSC Bridge Structure" Polymers 14, no. 6: 1115. https://doi.org/10.3390/polym14061115

APA StyleKim, T.-K., Jung, W.-T., Park, J.-S., & Park, H.-B. (2022). Experimental Study on Effects of Additional Prestressing Using Fiber Reinforced Polymers and Strands on Deterioration of PSC Bridge Structure. Polymers, 14(6), 1115. https://doi.org/10.3390/polym14061115