Degradation Performance Investigation of Hydrothermally Stressed Epoxy Micro and Nanocomposites for High Voltage Insulation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Fabrication of Epoxy Composites

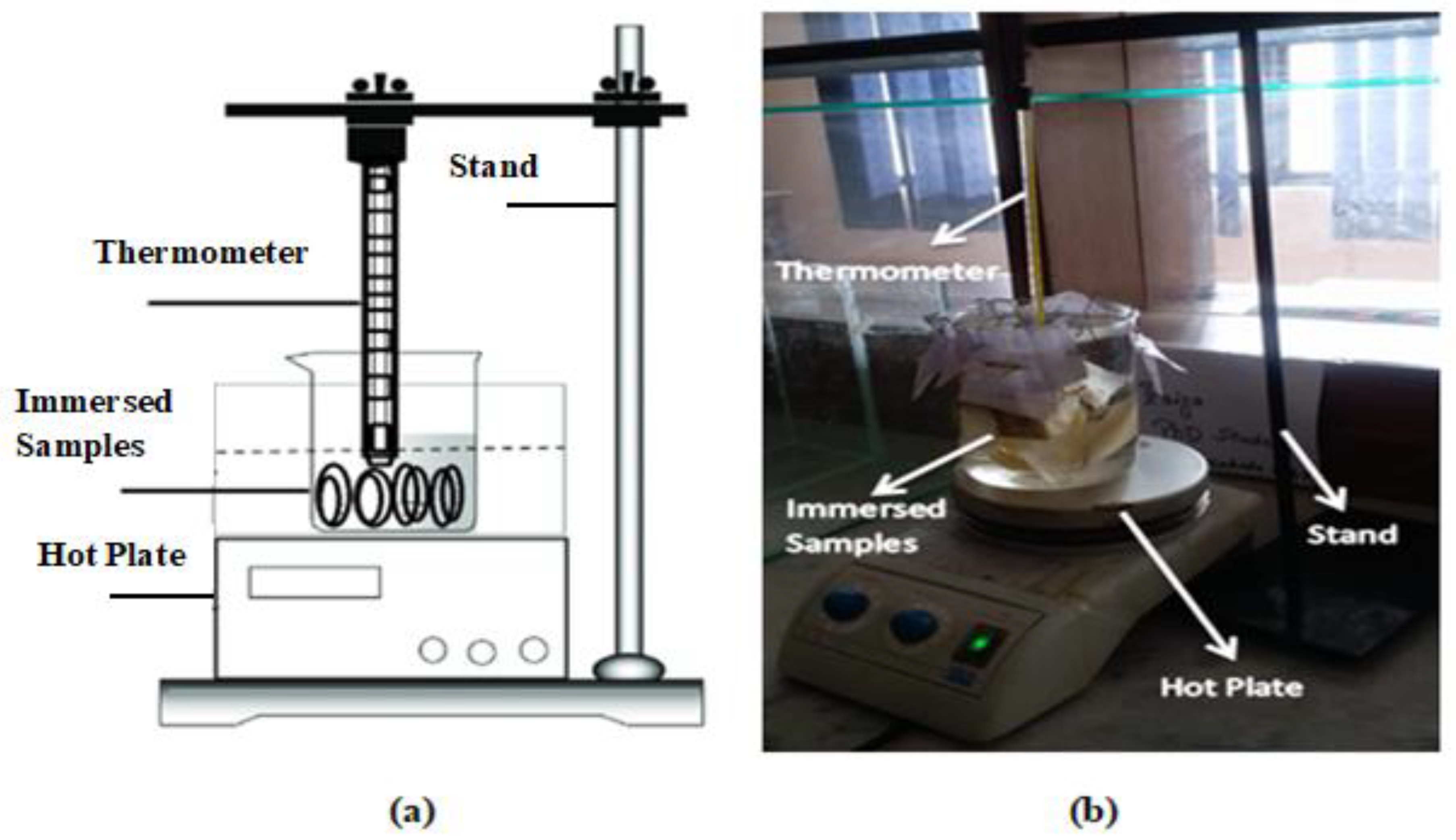

2.3. Experimental Setup for Degradation

2.3.1. Short Term Aging Setup

2.3.2. Long Term Aging Setup

2.4. Analysis Techniques

2.4.1. Swedish Transmission Research Institute (STRI) Classification Method

2.4.2. Contact Angle Measurements

2.4.3. Optical Microscopy

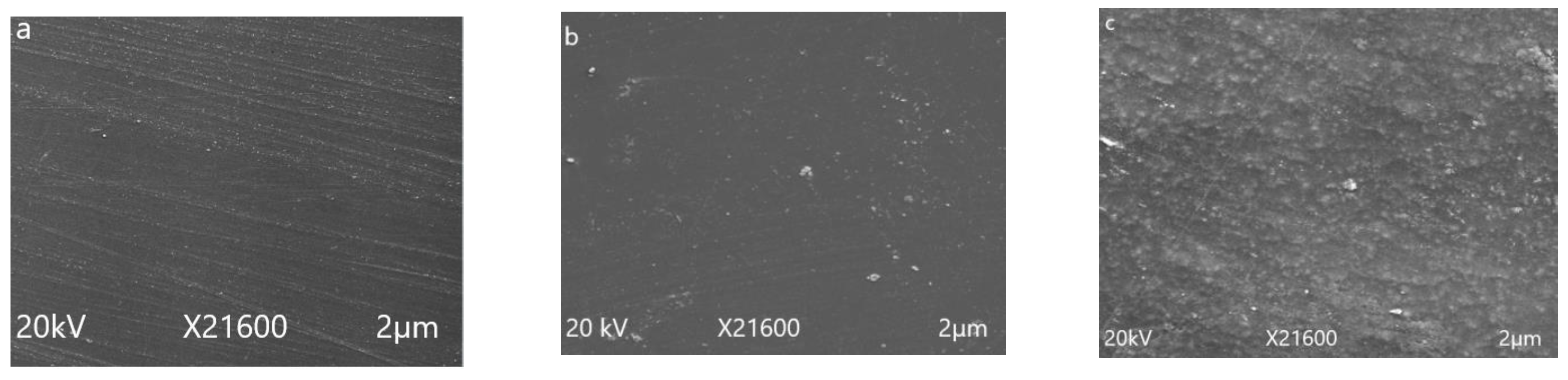

2.4.4. Scanning Electron Microscopy (SEM)

2.4.5. Fourier Transform Infrared Spectroscopy (FTIR)

3. Results and Discussion

3.1. Hydrophobicity Analysis

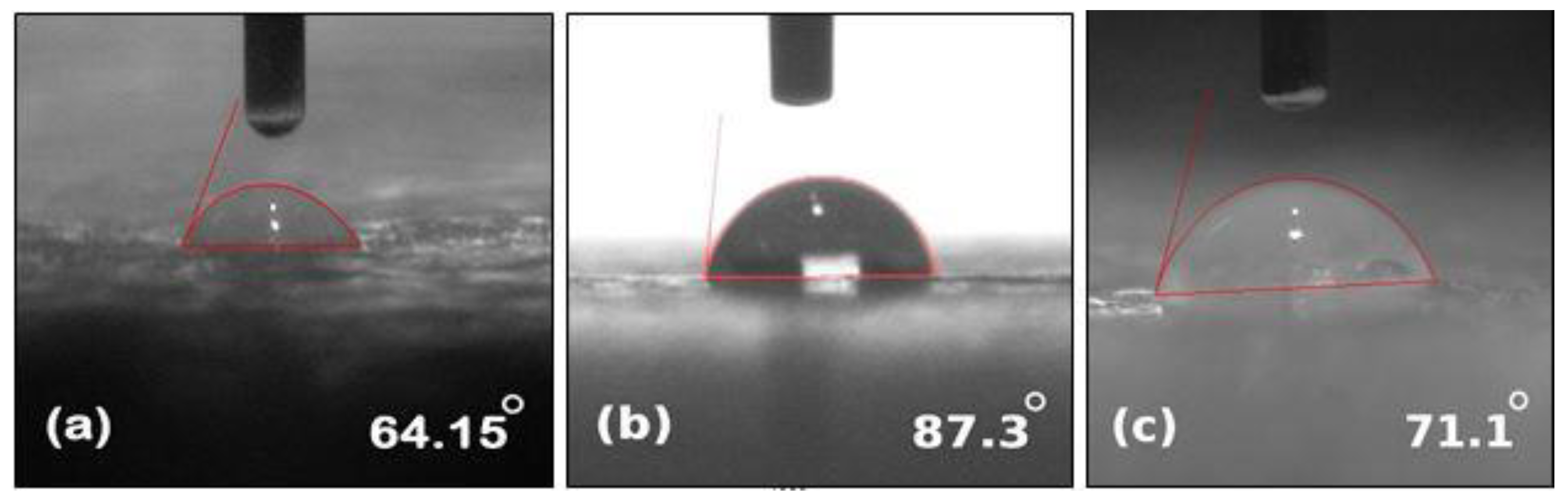

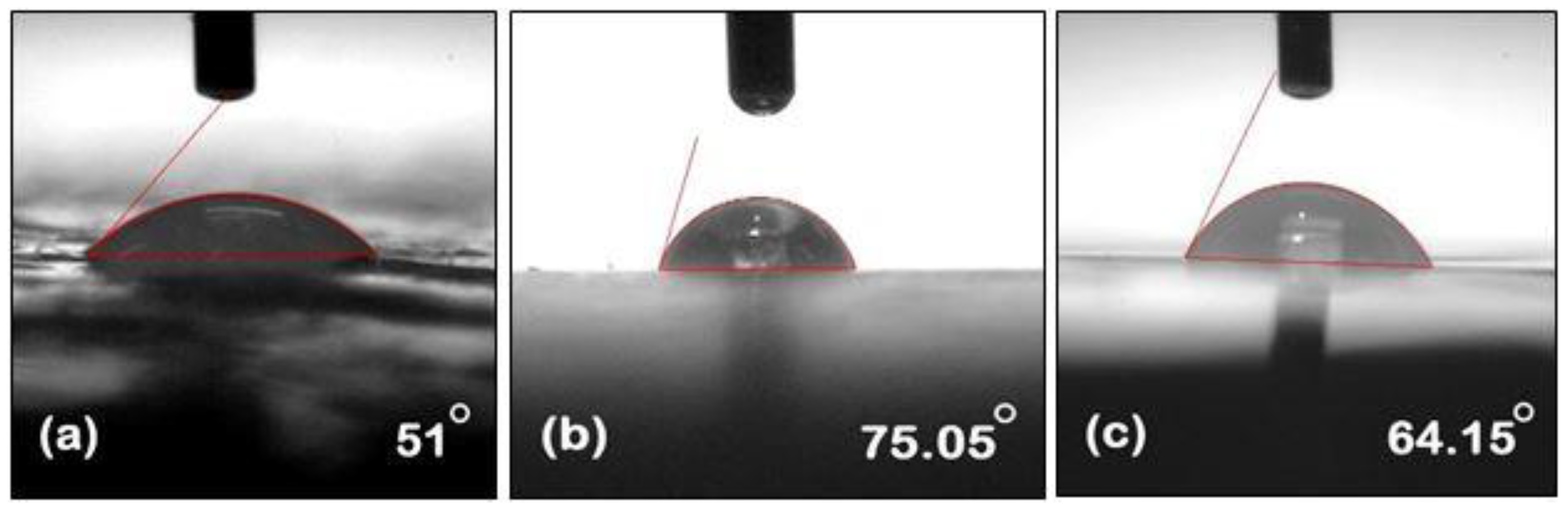

3.1.1. Contact Angle Measurement

3.1.2. STRI Analysis

3.2. Structural Analysis

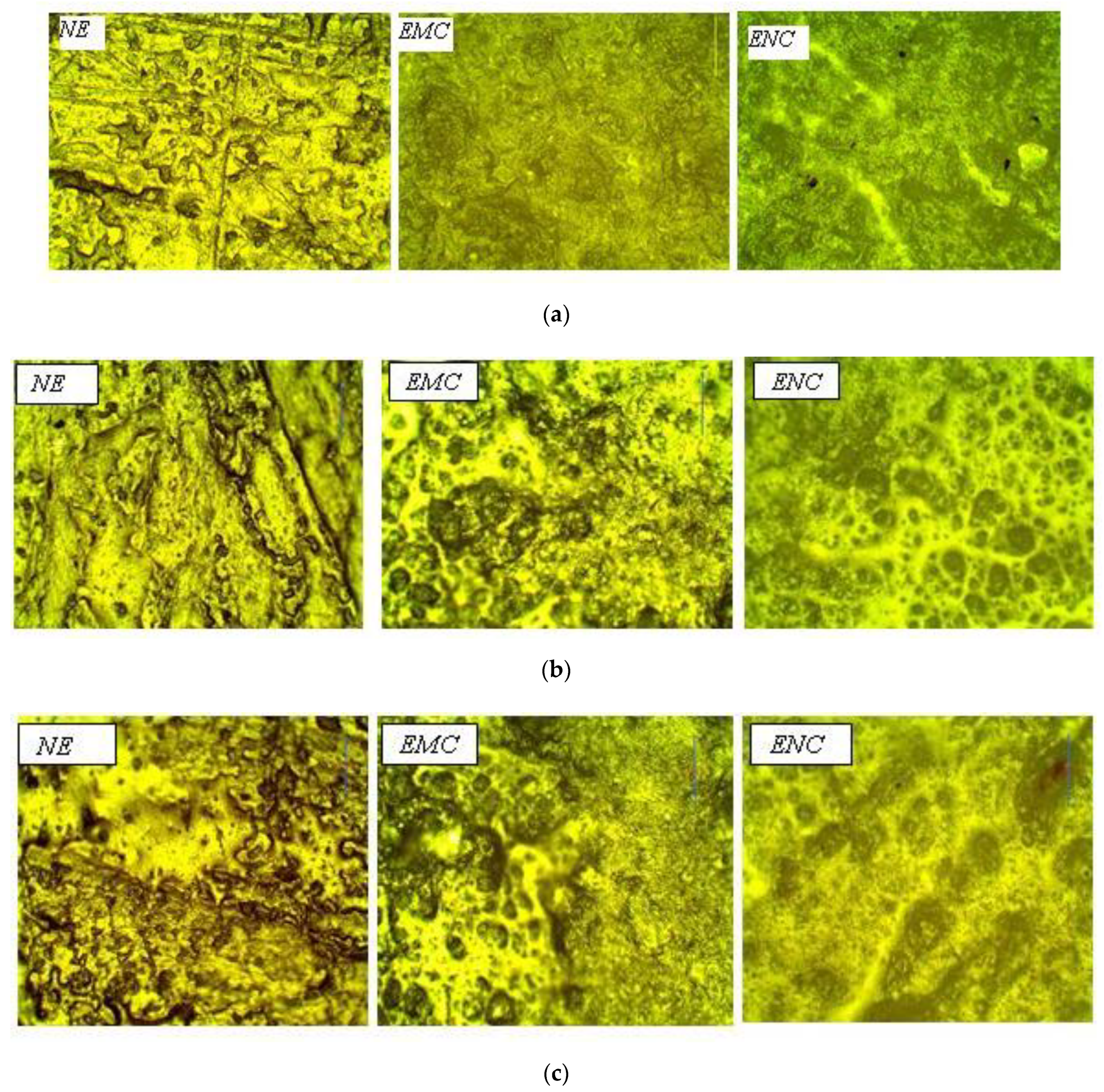

3.2.1. Optical Microscopy

3.2.2. Scanning Electron Microscopy (SEM)

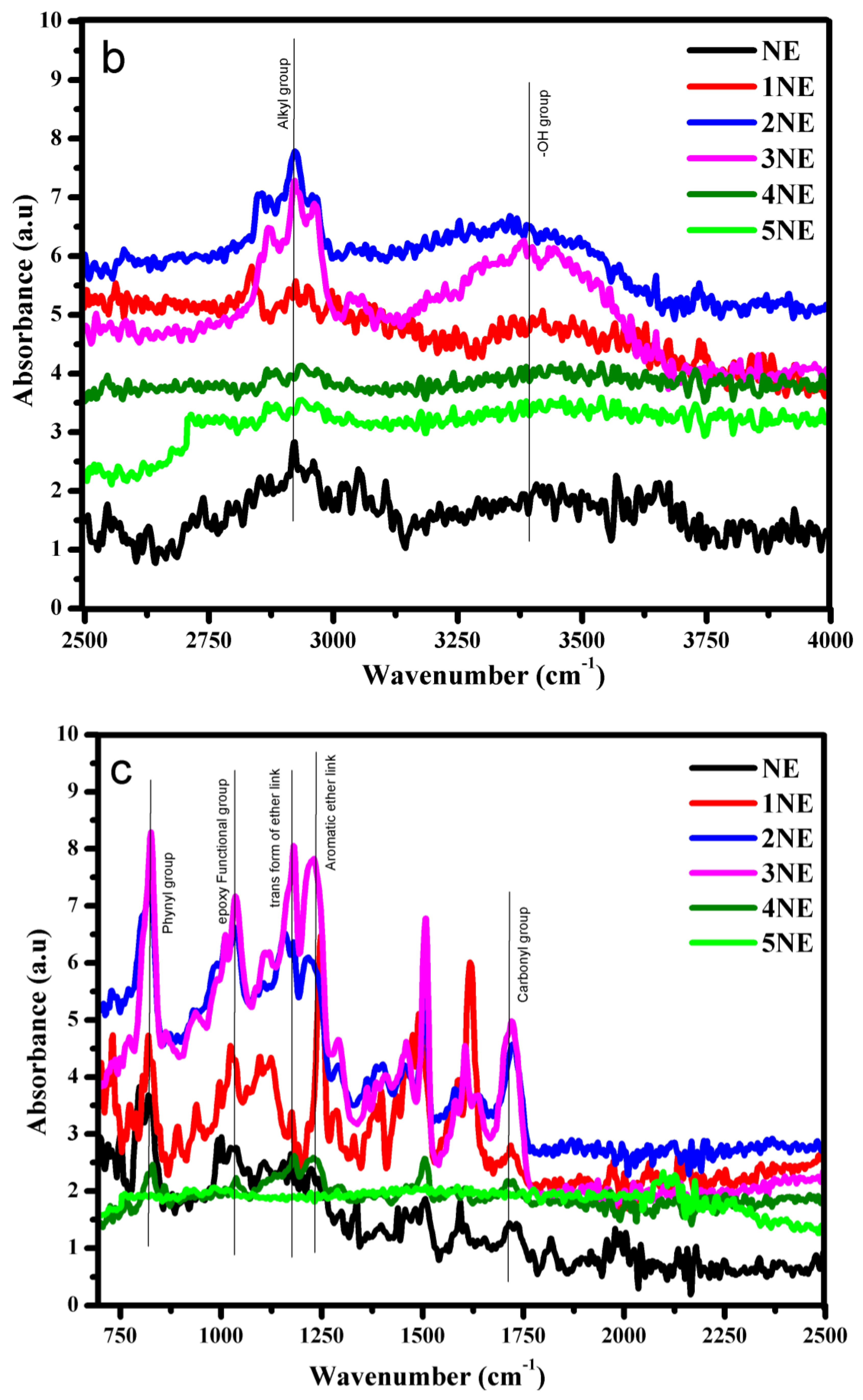

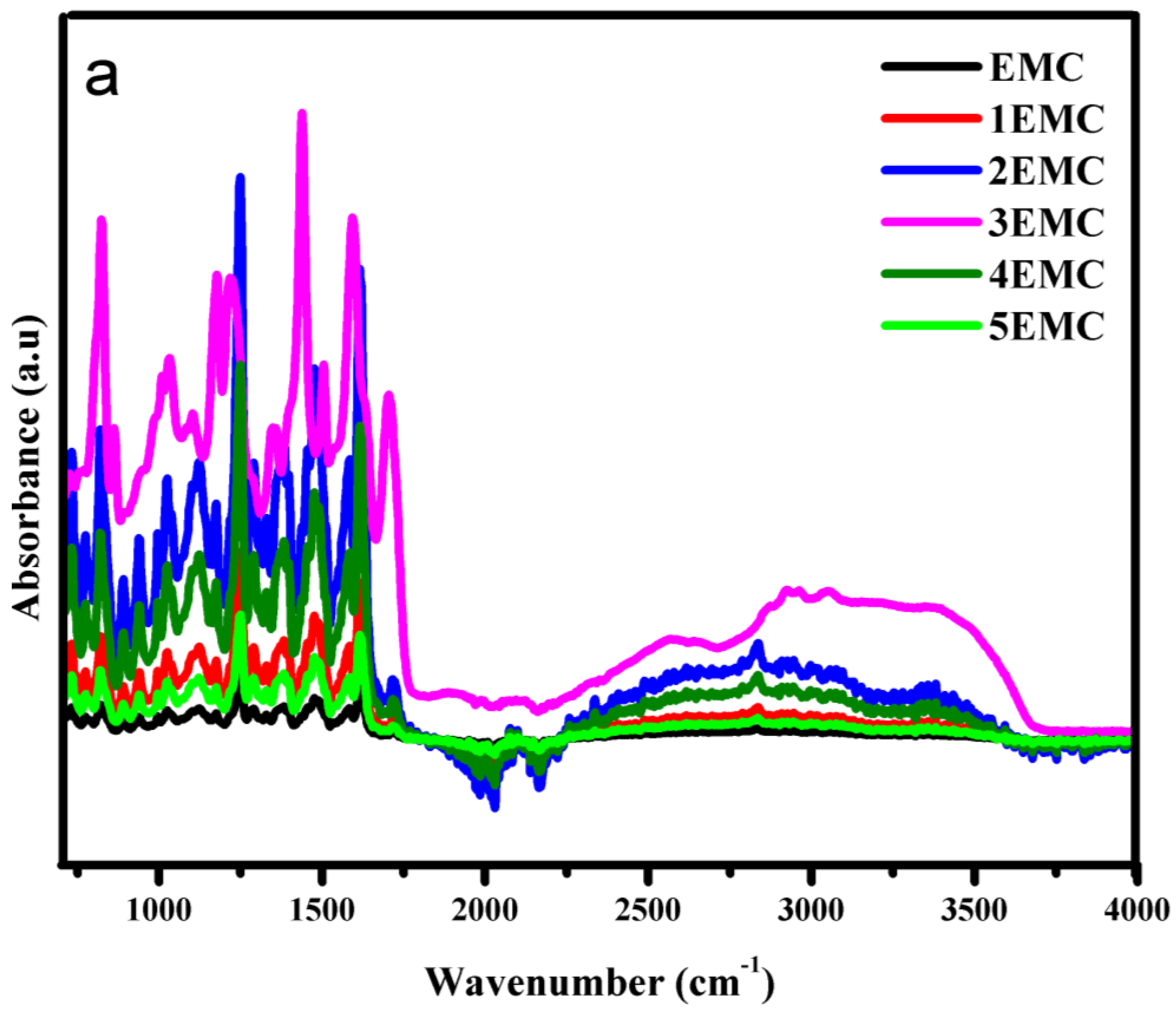

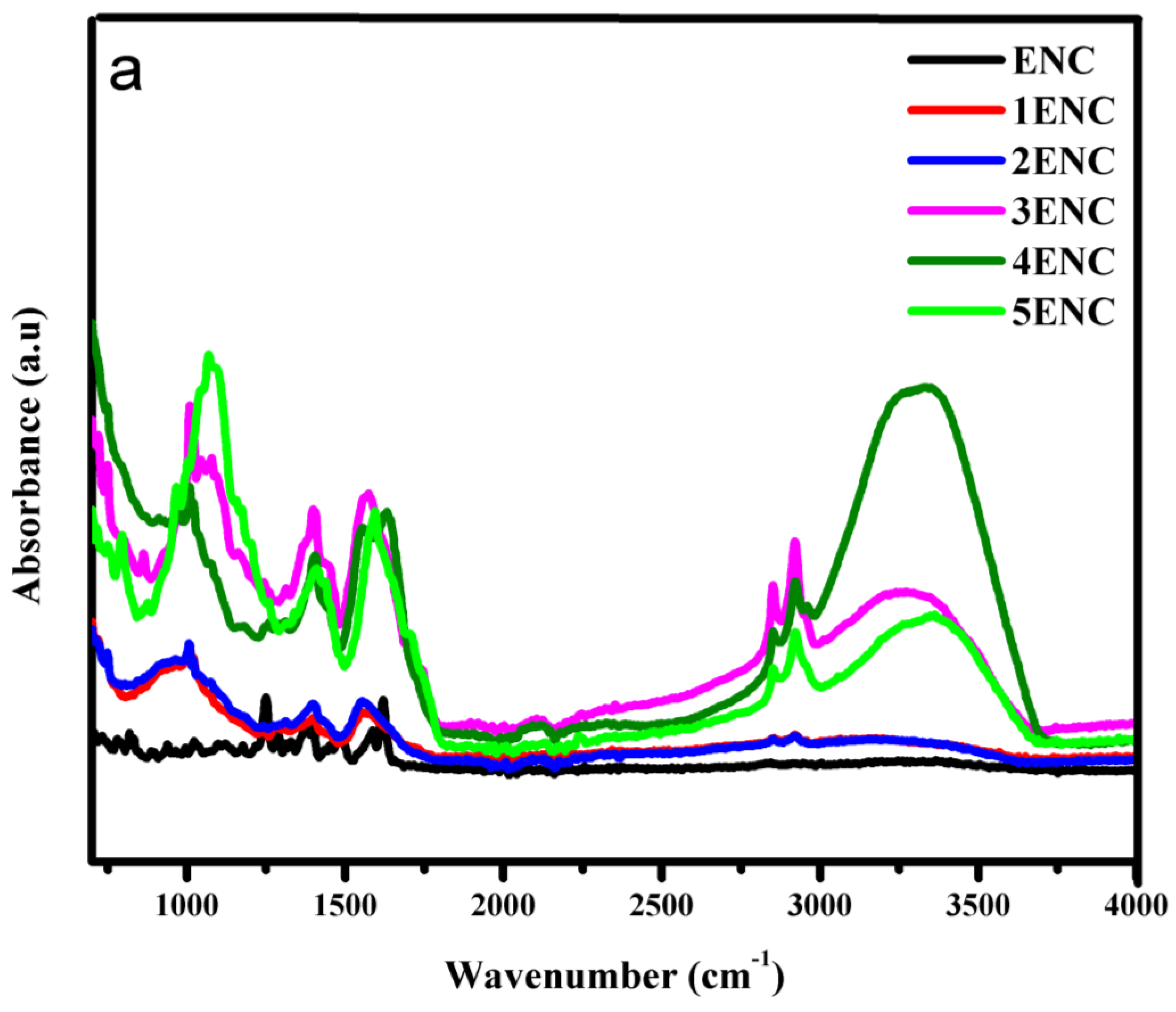

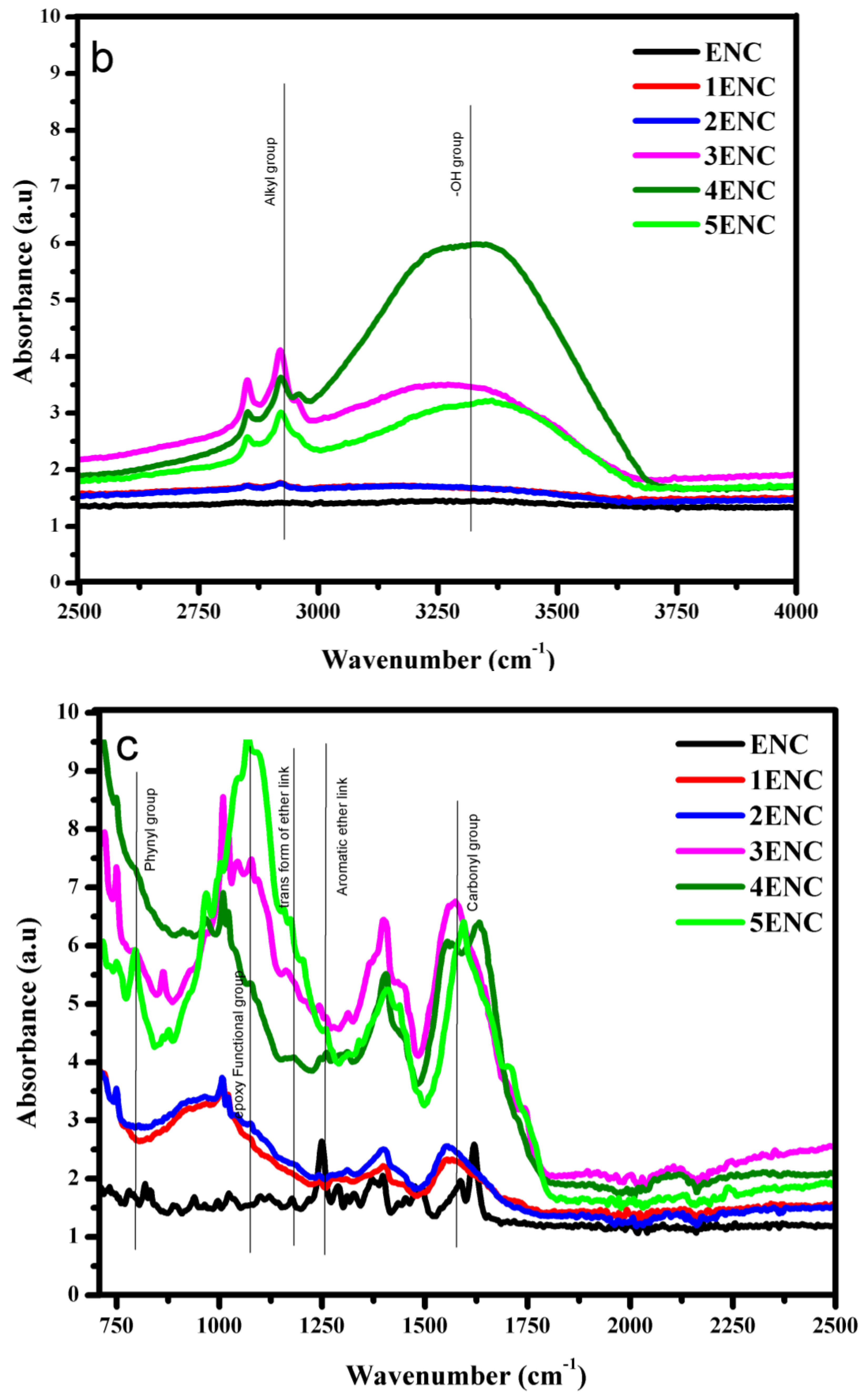

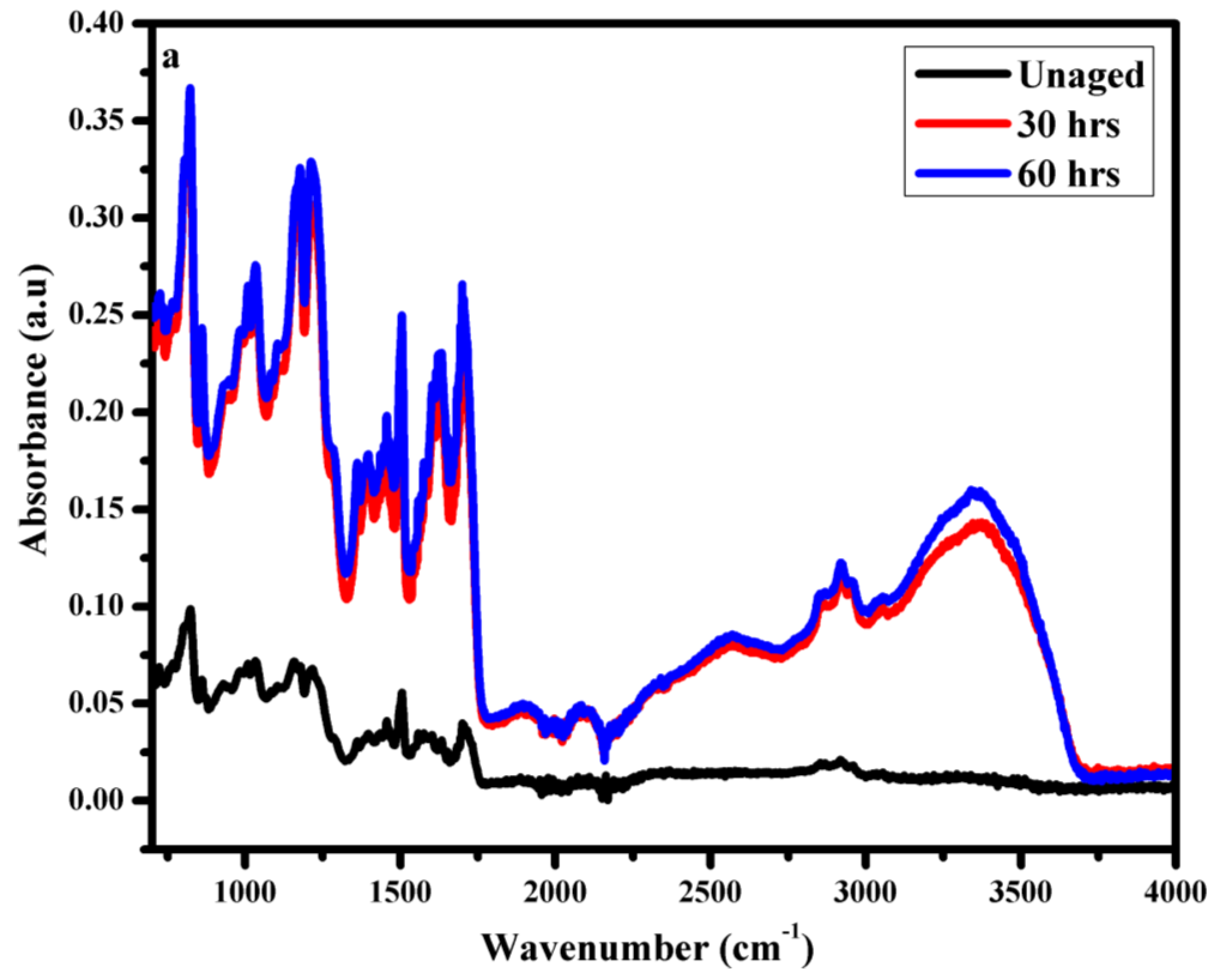

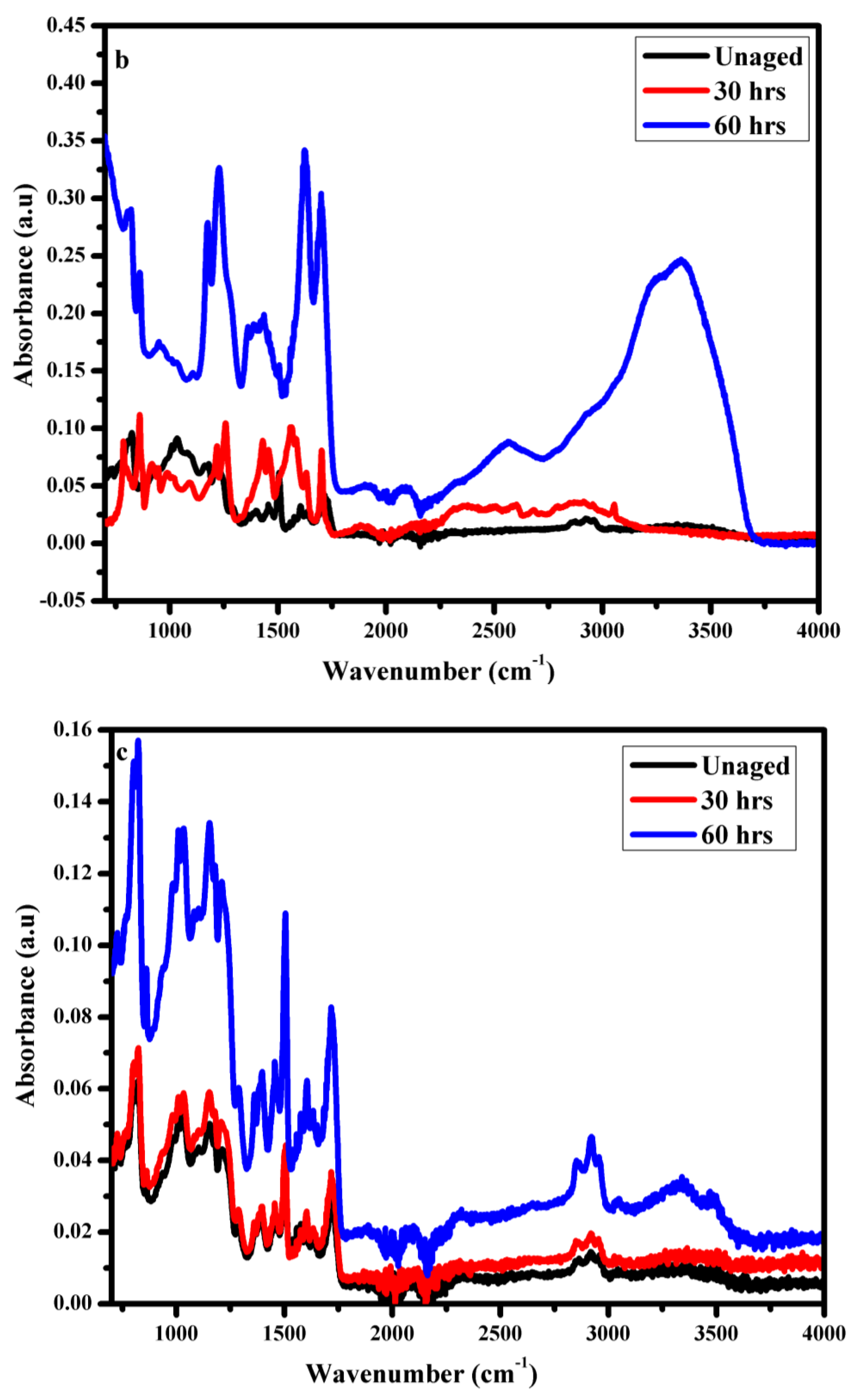

3.3. Fourier Transform Infrared Spectroscopy (FTIR)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kumara, S.; Fernando, M. Performance of outdoor insulators in tropical conditions of Sri Lanka. IEEE Electr. Insul. Mag. 2020, 36, 26–35. [Google Scholar] [CrossRef]

- Nia, M.S.; Altimania, M.; Shamsi, P.; Ferdowsi, M. Comprehensive analysis for electric field and potential for polymeric and ceramic insulators. Am. J. Electr. Electron. Eng. 2020, 8, 26–34. [Google Scholar]

- Amin, M.; Mahmood, A.; Khattak, A. Accelerated multi stress aging and life estimation of polymeric insulators. In Proceedings of the 17th International Bhurban Conference on Applied Sciences and Technology (IBCAST), Islamabad, Pakistan, 12–16 January 2020. [Google Scholar]

- Murthy, K.R.; Rao, V.V.; Dixit, P.; Harikrishna, R.; Anand, T.; Chandrakala, P.C.; Kumar, S. Performance Evaluation of Naturally Aged Silicone Rubber Polymeric Insulating Filled Epoxy Specimen Coating with Nano TiO2. In Advances in Smart Grid Technology: Select Proceedings of PECCON 2019; Springer: Cham, Switzerland, 2020; Volume 1, p. 485. [Google Scholar]

- Chaipanit, N.; Rattanakhongviput, C.; Sundararajan, R. Accelerated multistress aging of polymeric insulators under San Francisco coastal environment. In Proceedings of the 2001 Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Kitchener, ON, Canada, 14–17 October 2001; pp. 636–639. [Google Scholar] [CrossRef]

- Amin, M.; Khattak, A.; Ali, M. Life estimation and investigation of dielectric strength of multistressed high-voltage epoxy micro and nanocomposites. Micro Nano Lett. 2016, 11, 765–768. [Google Scholar] [CrossRef]

- Amin, M.; Salman, M. Aging of polymeric insulators (an overview). Rev. Adv. Mater. Sci. 2006, 13, 93–116. [Google Scholar]

- Hackam, R. Outdoor high voltage polymeric insulators. In Proceedings of the 1998 International Symposium on Electrical Insulating Materials, 1998 Asian International Conference on Dielectrics and Electrical Insulation, Toyohashi, Japan, 13–17 September 1998; pp. 1–16. [Google Scholar] [CrossRef]

- Hall, J.F. History and bibliography of polymeric insulators for outdoor applications. IEEE Trans. Power Deliv. 1993, 8, 376–385. [Google Scholar] [CrossRef]

- Savadkoohi, E.M.; Mirzaie, M.; Seyyedbarzegar, S.; Mohammadi, M.; Khodsuz, M.; Pashakolae, M.G.; Ghadikolaei, M.B. Experimental investigation on composite insulators AC flashover performance with fan-shaped non-uniform pollution under electro-thermal stress. Int. J. Electr. Power Energy Syst. 2020, 121, 106142. [Google Scholar] [CrossRef]

- Ghosh, D.; Khastgir, D. Degradation and Stability of Polymeric High-Voltage Insulators and Prediction of Their Service Life through Environmental and Accelerated Aging Processes. ACS Omega 2018, 3, 11317–11330. [Google Scholar] [CrossRef]

- Wakhidin, M. Effects of Artificial Tropical Climate Aging on Insulation Performance of Silicone Rubber Polymeric Insulators. In Proceedings of the 2019 2nd International Conference on High Voltage Engineering and Power Systems (ICHVEPS), Denpasar, Indonesia, 1–4 October 2019. [Google Scholar]

- Ashwini, A.V.; Ravi, K.N.; Vasudev, N. Study on Aging of Polymeric Insulators by Dip Method. In Proceedings of the 2019 International Conference on High Voltage Engineering and Technology (ICHVET), Hyderabad, India, 7–8 February 2019. [Google Scholar]

- Verma, A.R.; Chakraborty, R. Multistress aging studies on polymeric insulators. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 524–532. [Google Scholar] [CrossRef]

- Adnan, M.M.; Tveten, E.G.; Glaum, J.; Ese, M.-H.G.; Hvidsten, S.; Glomm, W.; Einarsrud, M.-A. Epoxy-Based Nanocomposites for High-Voltage Insulation: A Review. Adv. Electron. Mater. 2018, 5, 1800505. [Google Scholar] [CrossRef]

- Balguri, P.K.; Samuel, D.H.; Thumu, U. A review on mechanical properties of epoxy nanocomposites. Mater. Today Proc. 2020, 44, 346–355. [Google Scholar] [CrossRef]

- Messerer, F.; Boeck, W. High resistance surface coating of solid insulating components for HVDC metal enclosed equipment. In Proceedings of the 1999 Eleventh International Symposium on High Voltage Engineering, London, UK, 23–27 August 1999; Volume 4, pp. 63–66. [Google Scholar]

- Li, C.; Hu, J.; Lin, C.; He, J. The control mechanism of surface traps on surface charge behavior in alumina-filled epoxy composites. J. Phys. D Appl. Phys. 2016, 49, 445304. [Google Scholar] [CrossRef]

- Cha, J.; Kim, J.; Ryu, S.; Hong, S.H. Comparison to mechanical properties of epoxy nanocomposites reinforced by functionalized carbon nanotubes and graphene nanoplatelets. Compos. Part B Eng. 2018, 162, 283–288. [Google Scholar] [CrossRef]

- Shao, T.; Zhou, Y.; Zhang, C.; Yang, W.; Niu, Z.; Ren, C. Surface modification of polymethyl-methacrylate using atmospheric pressure argon plasma jets to improve surface flashover performance in vacuum. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 1747–1754. [Google Scholar] [CrossRef]

- Shao, T.; Liu, F.; Hai, B.; Ma, Y.; Wang, R.; Ren, C. Surface modification of epoxy using an atmospheric pressure dielectric barrier discharge to accelerate surface charge dissipation. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 1557–1565. [Google Scholar] [CrossRef]

- Zhai, Z.; Feng, L.; Li, G.; Liu, Z.; Chang, X. The anti-ultraviolet light (UV) aging property of aluminium particles/epoxy composite. Prog. Org. Coat. 2016, 101, 305–308. [Google Scholar] [CrossRef]

- Gorur, R.; Montesinos, J. Electrical performance of cycloaliphatic epoxy materials and insulators for outdoor use. IEEE Trans. Power Deliv. 2000, 15, 1274–1278. [Google Scholar] [CrossRef]

- Iyer, G.; Gorur, R.; Richert, R.; Krivda, A.; Schmidt, L. Evaluation of epoxy based nanodielectrics for high voltage outdoor insulation. In Proceedings of the 2010 IEEE International Symposium on Electrical Insulation, San Diego, CA, USA, 6–9 June 2010; pp. 1–5. [Google Scholar]

- Tanaka, T.; Montanari, G.C.; Mulhaupt, R. Polymer nanocomposites as dielectrics and electrical insulation-perspectives for processing technologies, material characterization and future applications. IEEE Trans. Dielectr. Electr. Insul. 2004, 11, 763–784. [Google Scholar]

- Faiza, F.; Khattak, A.; Butt, S.; Imran, K.; Ulasyar, A.; Ali, A.; Khan, Z.; Mahmood, A.; Ullah, N.; Alahmadi, A.; et al. Investigation of Hydrothermally Stressed Silicone Rubber/Silica Micro and Nanocomposite for the Coating High Voltage Insulation Applications. Materials 2021, 14, 3567. [Google Scholar] [CrossRef]

- Cheng, L.; Shao, S.; Zhang, S.; Liao, R.; Yang, L.; Guo, C. Research on the long-time operation performance of composite insulator shed hydrophobicity under hydrothermal conditions. High Volt. 2018, 3, 67–72. [Google Scholar] [CrossRef]

- Roggendorf, C.; Schnettler, A. Accelerated hydrothermal aging of epoxy resin based syntactic foams with polymeric microspheres. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 973–980. [Google Scholar] [CrossRef]

- Wang, Y.; Feng, C.; Fei, R.; Luo, Y. Thermal-ageing characteristics of dry-type transformer epoxy composite insulation. High Perform. Polym. 2020, 32, 741–752. [Google Scholar] [CrossRef]

- Xie, Y.; Liu, W.; Liang, L.; Liu, C.; He, S.; Zhang, F.; Shi, H.; Yang, M. Enhancement of anticorrosion property and hydrophobicity of modified epoxy coatings with fluorinated polyacrylate. Colloids Surf. A Physicochem. Eng. Asp. 2019, 579, 123659. [Google Scholar] [CrossRef]

- Hameed, N.; Guo, Q.; Hanley, T.; Mai, Y.W. Hydrogen bonding interactions, crystallization, and surface hydrophobicity in nanostructured epoxy/block copolymer blends. J. Polym. Sci. Part B Polym. Phys. 2010, 48, 790–800. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, X.; Zhang, H.J.; Wang, Z.P. Effects of hydrothermal aging on epoxy-based anisotropic conductive film. Mater. Lett. 2006, 60, 2958–2963. [Google Scholar] [CrossRef]

- Cherdoud-Chihani, A.; Mouzali, M.; Abadie, M.J.M. Study of crosslinking AMS/DGEBA system by FTIR. J. Appl. Polym. Sci. 1998, 69, 1167–1178. [Google Scholar] [CrossRef]

| Groups Name | Wavenumber (cm−1) |

|---|---|

| –CH3 Group Asymmetrical Stretching (Methyl) | ~2965 |

| –CH2 Group Asymmetric Stretching | ~2928 |

| EWA-CH2 Group Symmetric Stretching | ~2871 |

| C=O Vibration Stretching | ~1725 |

| Aromatic Ring C=C Stretching | ~1605 |

| Aromatic Ring C-C Stretching | ~1506 |

| Stretching of Symmetrical aromatic C-O-C | ~1033–1050 |

| Deformation in Aromatic –CH bending | ~829 |

| Rocking of –CH2 | ~724 |

| Neat Epoxy | EMC | ENC | ||||||

|---|---|---|---|---|---|---|---|---|

| Stat | df | p | Stat | df | p | Stat | df | p |

| 0.964 | 6 | 0.853 | 0.933 | 6 | 0.601 | 0.795 | 6 | 0.052 |

| N | Mean | Std. Deviation | Std. Error | 95% Confidence Interval for Mean | |||

|---|---|---|---|---|---|---|---|

| Lower Bound | Upper Bound | ||||||

| absorbance | NE | 6 | 1.3067 | 0.96926 | 0.39570 | 0.2895 | 2.3238 |

| ENC | 6 | 1.4333 | 0.70333 | 0.28713 | 0.6952 | 2.1714 | |

| EMC | 6 | 1.3667 | 0.70899 | 0.28944 | 0.6226 | 2.1107 | |

| ANOVA | |||||

|---|---|---|---|---|---|

| Absorbance | |||||

| Sum of Squares | df | Mean Square | F | Sig. | |

| Between Groups | 0.048 | 2 | 0.024 | 0.037 | 0.963 |

| Within Groups | 9.684 | 15 | 0.646 | ||

| Total | 9.732 | 17 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Faiza; Khattak, A.; Alahamdi, A.A.; Iqbal, M.B. Degradation Performance Investigation of Hydrothermally Stressed Epoxy Micro and Nanocomposites for High Voltage Insulation. Polymers 2022, 14, 1094. https://doi.org/10.3390/polym14061094

Faiza, Khattak A, Alahamdi AA, Iqbal MB. Degradation Performance Investigation of Hydrothermally Stressed Epoxy Micro and Nanocomposites for High Voltage Insulation. Polymers. 2022; 14(6):1094. https://doi.org/10.3390/polym14061094

Chicago/Turabian StyleFaiza, Abraiz Khattak, Ahmad Aziz Alahamdi, and Muhammad Bilal Iqbal. 2022. "Degradation Performance Investigation of Hydrothermally Stressed Epoxy Micro and Nanocomposites for High Voltage Insulation" Polymers 14, no. 6: 1094. https://doi.org/10.3390/polym14061094

APA StyleFaiza, Khattak, A., Alahamdi, A. A., & Iqbal, M. B. (2022). Degradation Performance Investigation of Hydrothermally Stressed Epoxy Micro and Nanocomposites for High Voltage Insulation. Polymers, 14(6), 1094. https://doi.org/10.3390/polym14061094