On-Demand Tailoring between Brittle and Ductile of Poly(methyl methacrylate) (PMMA) via High Temperature Stretching

Abstract

:1. Introduction

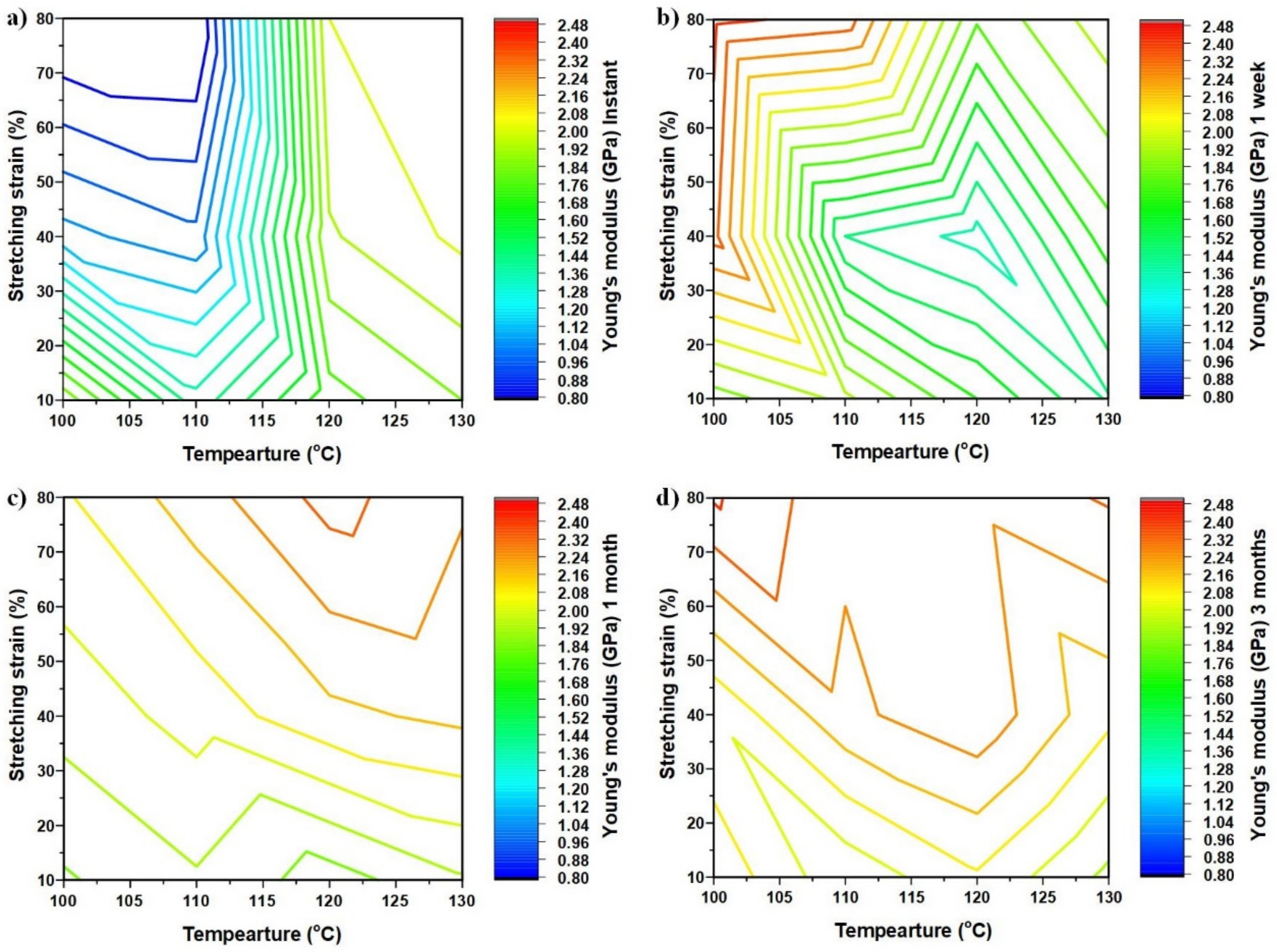

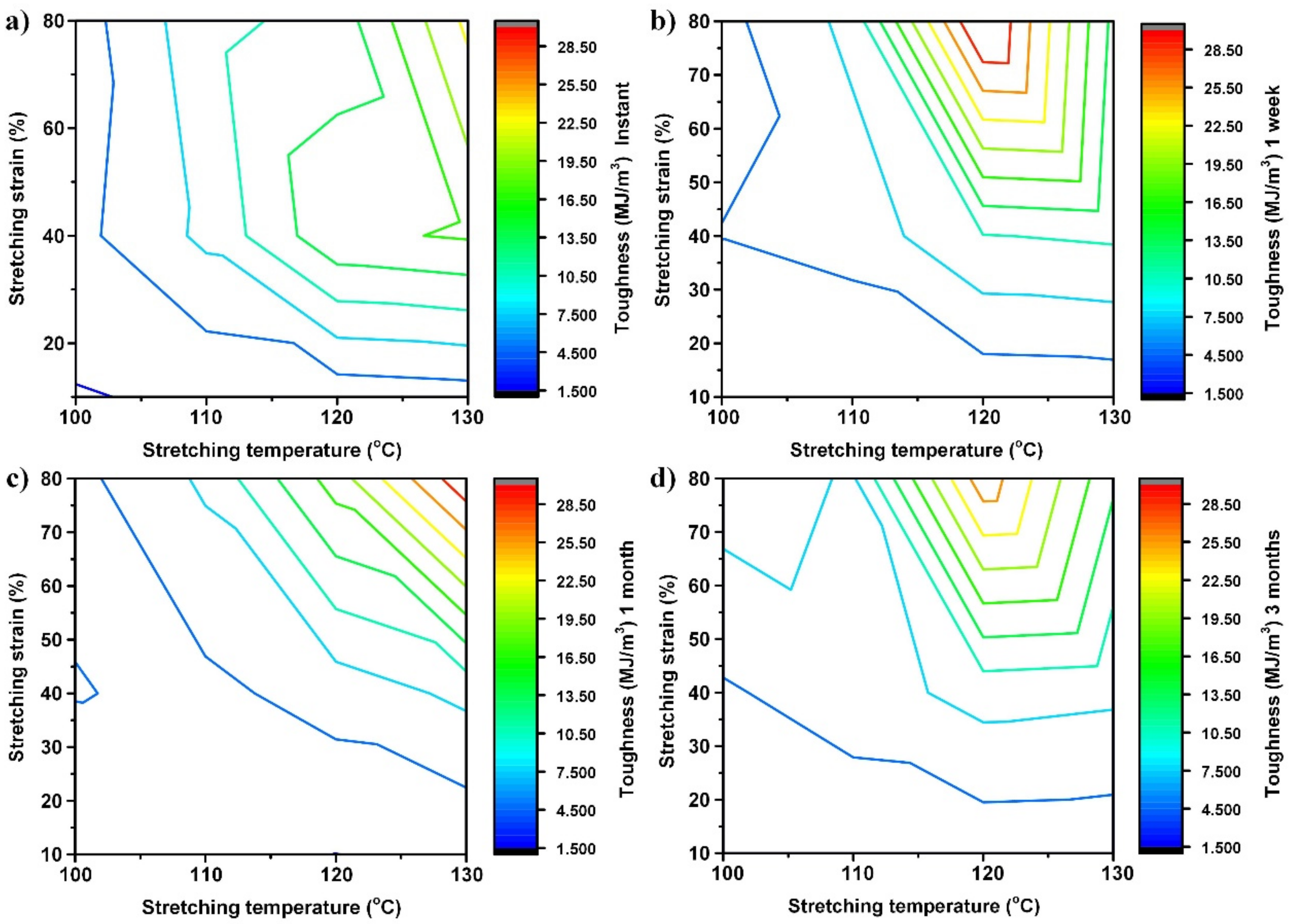

2. Material, Sample Preparation and Experimental

2.1. Material and Samples Preparation

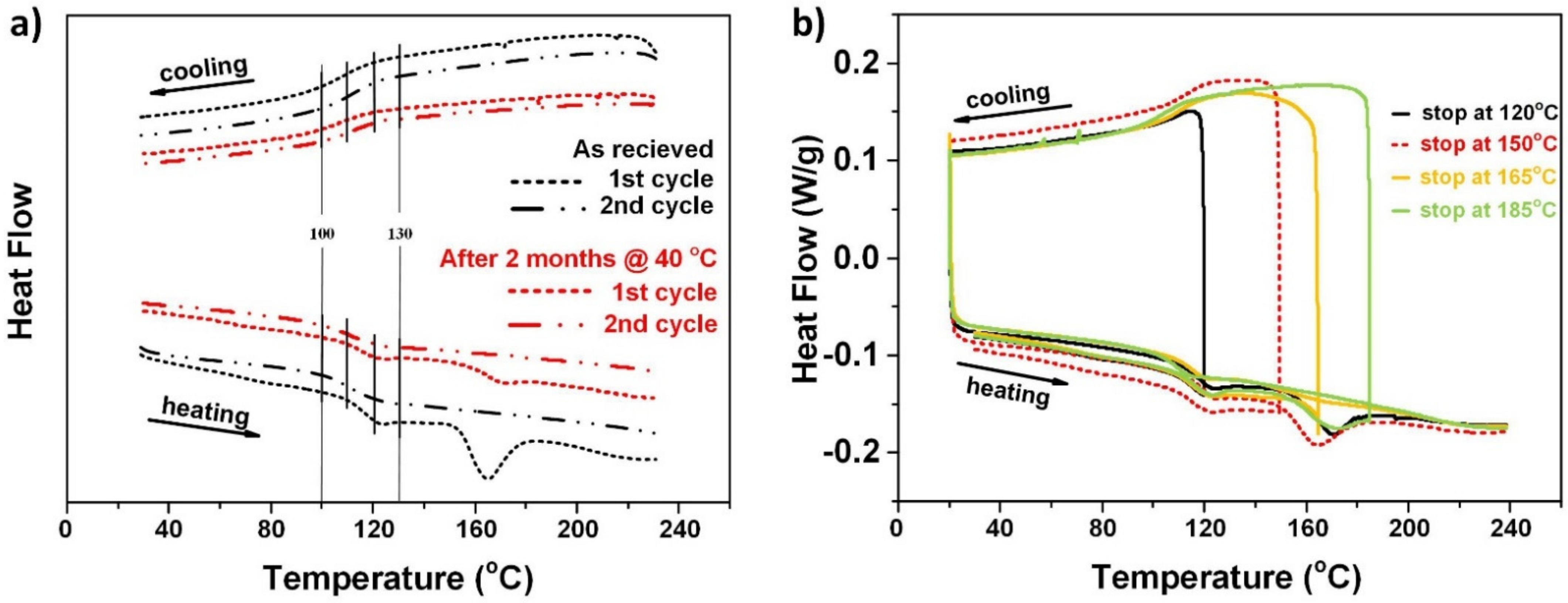

2.2. DSC Test

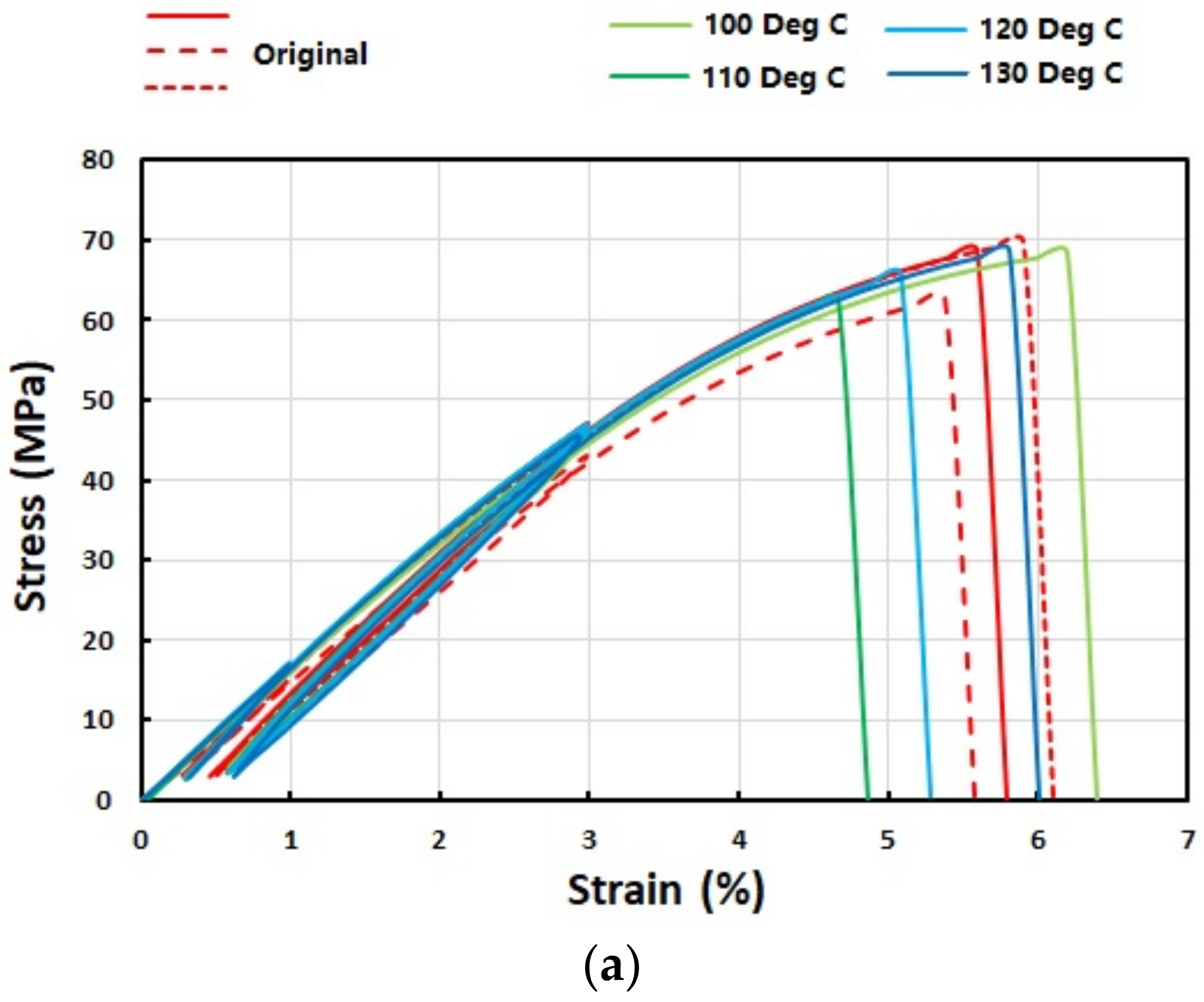

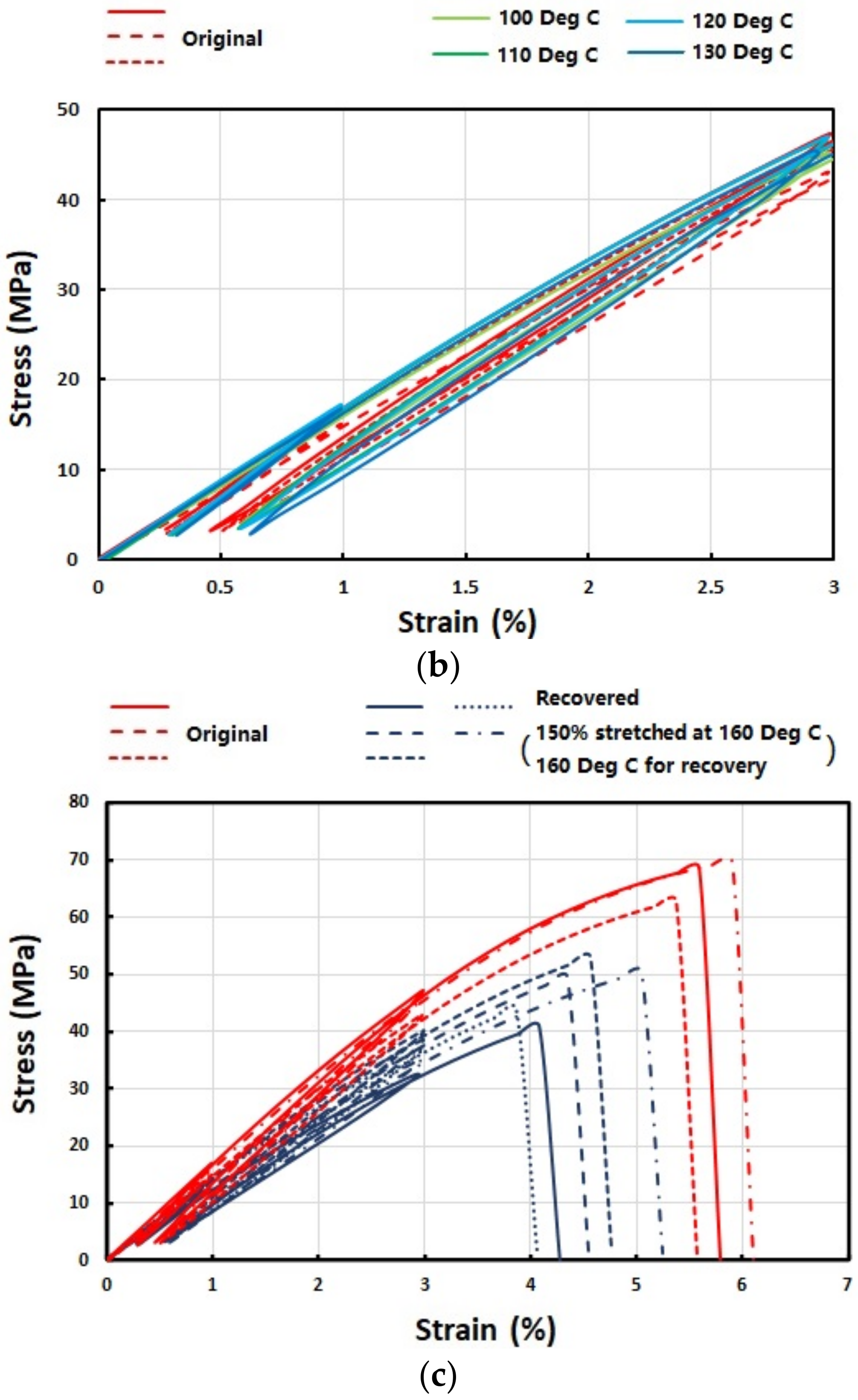

2.3. Pre-Stretching/Compression and Cyclic Uniaxial Tensile Tests

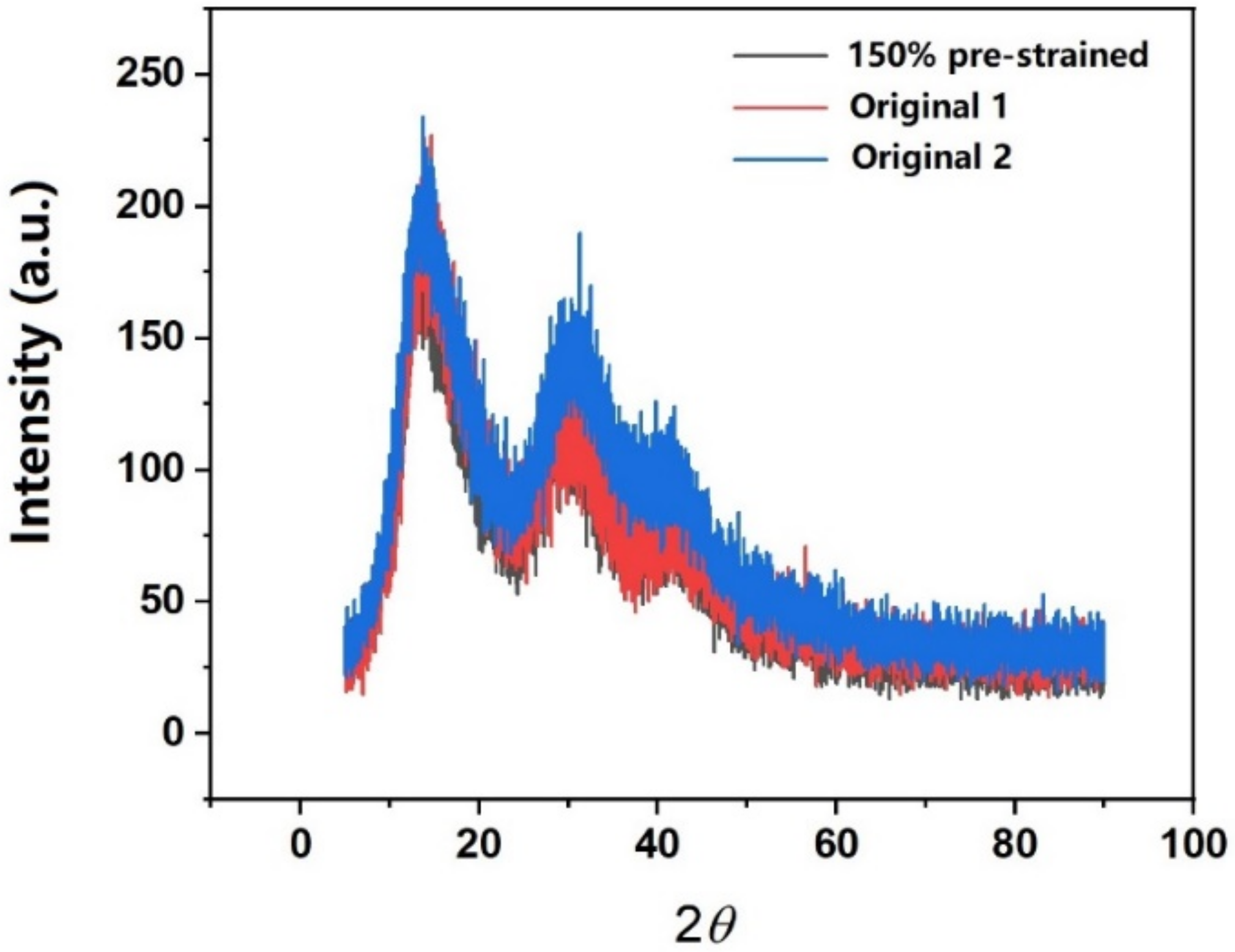

2.4. X-ray Diffraction (XRD) Test

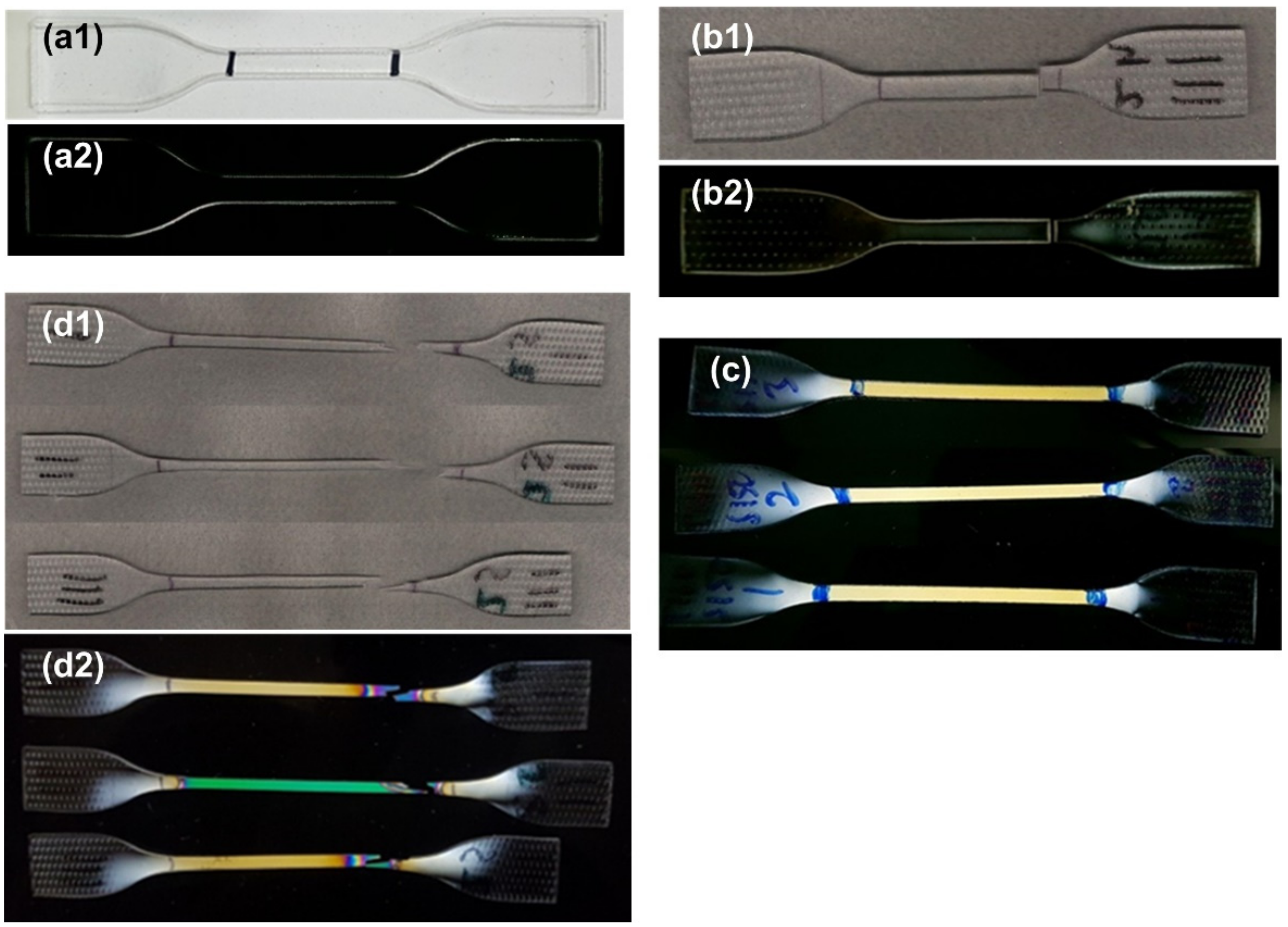

2.5. Photoelasticity Test

3. Results and Analysis

3.1. DSC

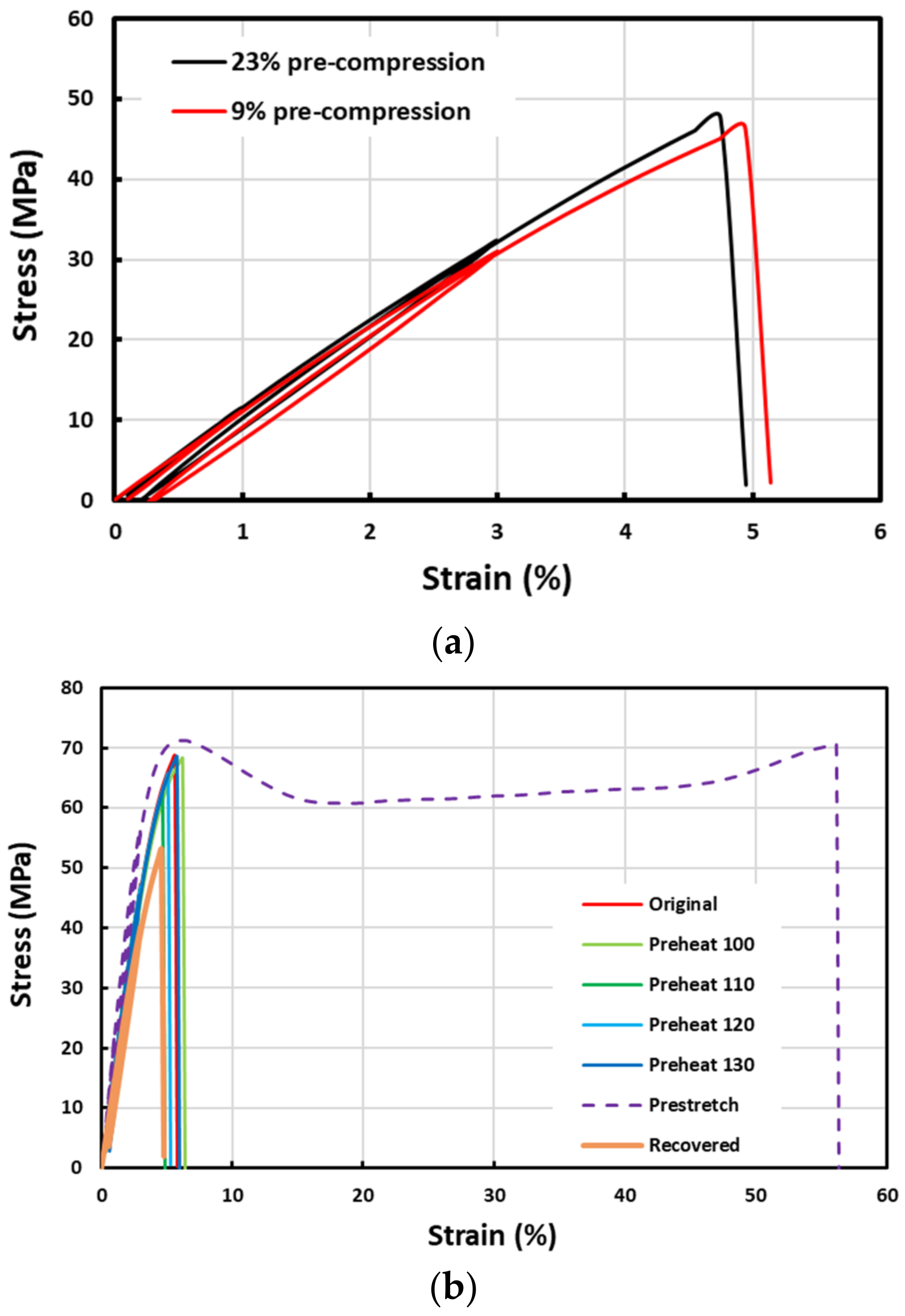

3.2. Cyclic Uniaxial Tension

3.3. XRD

3.4. Photoelasticity

3.5. Evolution after Storage at 40 °C

4. Mechanism of Brittle-Ductile Transition

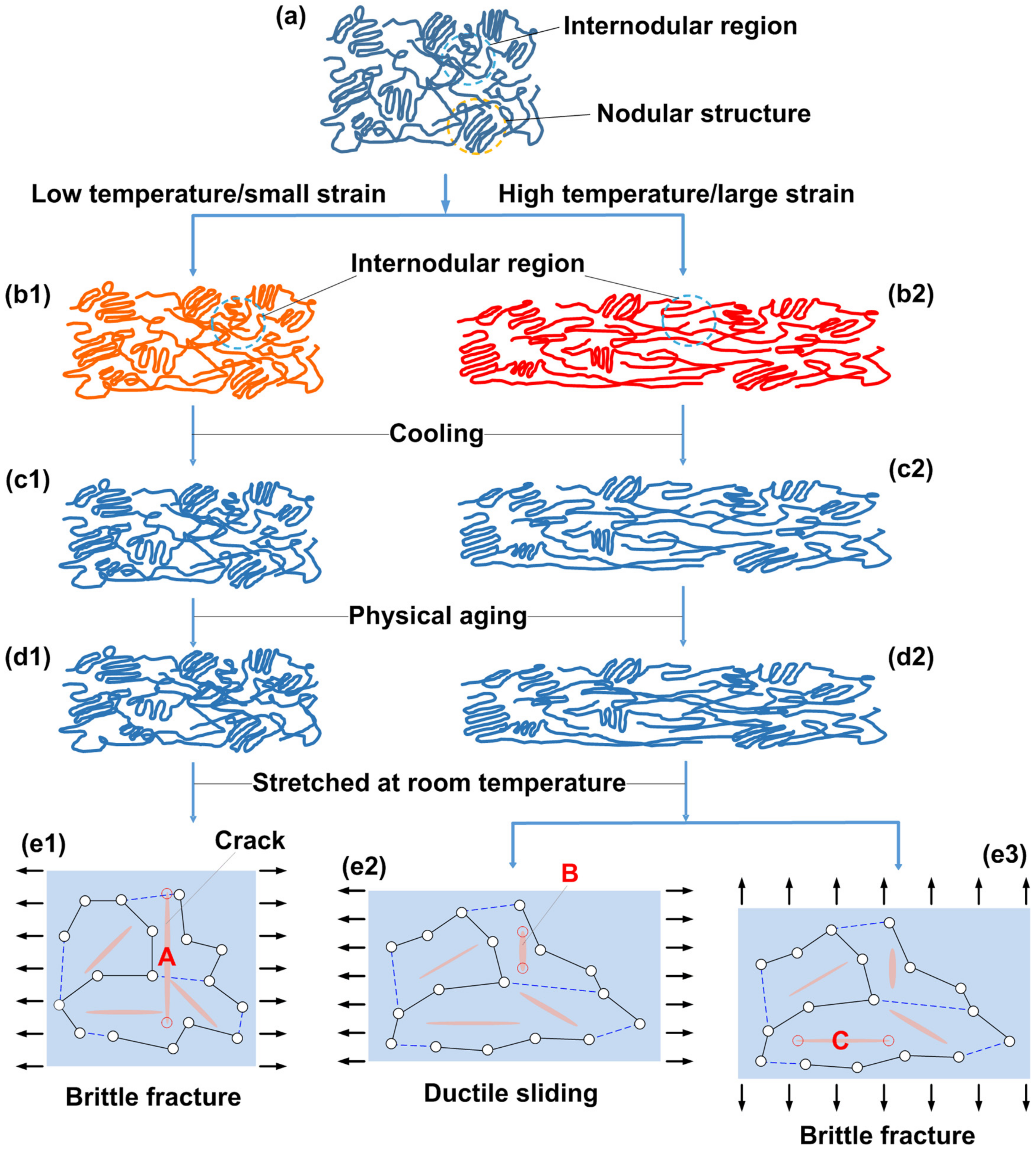

- If the temperature is low (Figure 10b1, the polymer is still relatively rigid) and the strain is small, the nodular structures are largely intact, while the internodular regions deform slightly to accommodate the required deformation. The tine cracks within the polymer mostly remain (similar to Figure 10e1).

- If the temperature is high (Figure 10b2, the polymer is much softer) and the strain is large, both the nodular structures and internodular regions deform remarkably to match the high strain requirement. During stretching, the molecular chains re-align and the cracks reshape (rotation, elongation in the stretching direction and shrinkage in the transverse direction of stretching) (similar to Figure 10e2,e3). Sliding is in favor to enable large stretching at high temperatures, and the polymer turns to be more packed. Given a polymer, there is always a stretching limit. Overstretching not only weakens the polymer network, but also limits the capability of the pre-stretched polymer to stretch further.

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sim, J.H.; Eom, S.; Lee, S.; Oh, C.; Lee, M.; Kim, S.; Lee, W.B.; Ryu, J.; Sohn, D.; Chung, H. 1D hypo-crystals: A novel concept for the crystallization of stereo-irregular polymers. Mater. Today 2020, 40, 26–37. [Google Scholar] [CrossRef]

- Galeski, A. Strength and toughness of crystalline polymer systems. Prog. Polym. Sci. 2003, 28, 1643–1699. [Google Scholar] [CrossRef]

- Argon, A.S.; Cohen, R.E. Toughenability of polymers. Polymer 2003, 44, 6013–6032. [Google Scholar] [CrossRef]

- Perkins, W.G. Polymer toughness and impact resistance. Polym. Eng. Sci. 1999, 39, 2445–2460. [Google Scholar] [CrossRef]

- Wada, H.; Seika, M.; Kennedy, T.C.; Calder, C.A.; Murase, K. Investigation of loading rate and plate thickness effects on dynamic fracture toughness of PMMA. Eng. Fract. Mech. 1996, 54, 805–811. [Google Scholar] [CrossRef]

- Drozdov, A.D. The effect of temperature on physical aging of classy polymers. J. Appl. Polym. Sci. 2001, 81, 3309–3320. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, X.; Paul, D.R. Physical aging of thin glassy polymer films: Free volume interpretation. J. Membr. Sci. 2006, 277, 219–229. [Google Scholar] [CrossRef]

- Choi, J.; Ortega, A.M.; Xiao, R.; Yakacki, C.M.; Nguyen, T.D. Effect of physical aging on the shape-memory behavior of amorphous networks. Polymer 2012, 53, 2453–2464. [Google Scholar] [CrossRef]

- Perez-De Eulate, N.G.; Cangialosi, D. The very long-term physical aging of glassy polymers. Phys. Chem. Chem. Phys. 2018, 20, 12356–12361. [Google Scholar] [CrossRef]

- Brady, T.E.; Yeh, G.S.Y. Effect of annealing cold-drawn polystyrene and polymethylmethacrylate below Tg. J. Macromol. Sci. Phys. 1973, B7, 243–252. [Google Scholar] [CrossRef]

- Hodge, I.M. Physical aging in polymer glasses. Science 1995, 267, 1945–1947. [Google Scholar] [CrossRef] [Green Version]

- Hutchinson, J.M. Physical aging of polymers. Prog. Polym. Sci. 1995, 20, 703–760. [Google Scholar] [CrossRef]

- Minguez, R.; Barrenetxea, L.; Solaberrieta, E.; Lizundia, E. A simple approach to understand the physical aging in polymers. Eur. J. Phys. 2019, 40, 015502. [Google Scholar] [CrossRef]

- Dorkenoo, K.D.; Pfromm, P.H. Experimental evidence and theoretical analysis of physical aging in thin and thick amorphous glassy polymer films. J. Polym. Sci. Part B-Polym. Phys. 1999, 37, 2239–2251. [Google Scholar] [CrossRef]

- Cangialosi, D.; Boucher, V.M.; Alegria, A.; Colmenero, J. Physical aging in polymers and polymer nanocomposites: Recent results and open questions. Soft Matter 2013, 9, 8619–8630. [Google Scholar] [CrossRef]

- Guo, J.; Xiao, R.; Tian, C.; Jiang, M. Optimizing physical aging in poly(ethylene terephthalate)-glycol (PETG). J. Non-Cryst. Solids 2018, 502, 15–21. [Google Scholar] [CrossRef]

- Guo, J.; Li, Z.; Long, J.; Xiao, R. Modeling the effect of physical aging on the stress response of amorphous polymers based on a two-temperature continuum theory. Mech. Mater. 2020, 143, 103335. [Google Scholar] [CrossRef]

- Mbarek, I.A.; Boumbimba, R.M.; Rusinek, A.; Voyiadjis, G.Z.; Gerard, P.; Samadi-Dooki, A. The dynamic behavior of poly (methyl methacrylate) based nano-rubbers subjected to impact and perforation: Experimental investigations. Mech. Mater. 2018, 122, 9–25. [Google Scholar] [CrossRef]

- Wang, G.; Zhao, J.; Mark, L.H.; Wang, G.; Yu, K.; Wang, C.; Park, C.B.; Zhao, G. Ultra-tough and super thermal-insulation nanocellular PMMA/TPU. Chem. Eng. J. 2017, 325, 632–646. [Google Scholar] [CrossRef]

- Andrew, J.J.; Srinivasan, S.M.; Arockiarajan, A.; Dhakal, H.N. Parameters influencing the impact response of fiber-reinforced polymer matrix composite materials: A critical review. Compos. Struct. 2019, 224. [Google Scholar] [CrossRef]

- Meng, Q.; Kuan, H.-C.; Araby, S.; Kawashima, N.; Saber, N.; Wang, C.H.; Ma, J. Effect of interface modification on PMMA/graphene nanocomposites. J. Mater. Sci. 2014, 49, 5838–5849. [Google Scholar] [CrossRef]

- Munch, E.; Launey, M.E.; Alsem, D.H.; Saiz, E.; Tomsia, A.P.; Ritchie, R.O. Tough, Bio-Inspired Hybrid Materials. Science 2008, 322, 1516–1520. [Google Scholar] [CrossRef] [Green Version]

- Zartman, G.D.; Cheng, S.; Li, X.; Lin, F.; Becker, M.L.; Wang, S.-Q. How melt-stretching affects mechanical behavior of polymer glasses. Macromolecules 2012, 45, 6719–6732. [Google Scholar] [CrossRef]

- Yan, Q.; Xu, T.; Zhang, W.; Lv, C.; Guo, H.; Tian, F.; Chen, W.; Li, L. Abnormal brittle-ductile transition for glassy polymers after free and constrained melt stretching: The role of molecular alignment. Polymer 2021, 233, 124199. [Google Scholar] [CrossRef]

- Huang, W.M.; Ding, Z.; Wang, C.C.; Wei, J.; Zhao, Y.; Purnawali, H. Shape memory materials. Mater. Today 2010, 13, 54–61. [Google Scholar] [CrossRef]

- Huang, W.M.; Zhao, Y.; Wang, C.C.; Ding, Z.; Purnawali, H.; Tang, C.; Zhang, J.L. Thermo/chemo-responsive shape memory effect in polymers: A sketch of working mechanisms, fundamentals and optimization. J. Polym. Res. 2012, 19, 9952. [Google Scholar] [CrossRef]

- Wu, X.; Wang, T.; Huang, W.; Zhao, Y. Thermo-Responsive Shape-Memory Effect and Surface Features in Polycarbonate (PC). Appl. Sci. 2017, 7, 848. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.; Dai, Y.; Kou, B.; Huang, W.M. Influence of long-term storage on shape memory performance and mechanical behavior of pre-stretched commercial poly (methyl methacrylate) (PMMA). Polymers 2019, 11, 1978. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhao, Q.; Wang, Y.; Cui, H.; Du, X. Bio-inspired sensing and actuating materials. J. Mater. Chem. C 2019, 7, 6493–6511. [Google Scholar] [CrossRef]

- Bradley, W.; Kobayashi, A. An investigation of propagating cracks by dynamic photoelasticity. Exp. Mech. 1970, 10, 106–113. [Google Scholar] [CrossRef]

- Yang, W.G.; Lu, H.B.; Huang, W.M.; Qi, H.J.; Wu, X.L.; Sun, K.Y. Advanced shape memory technology to reshape product design, manufacturing and recycling. Polymers 2014, 6, 2287–2308. [Google Scholar] [CrossRef]

- Lagasse, R. Improved calorimetric procedure for monitoring the approach to thermodynamic equilibrium in glassy polymers. J. Polym. Sci. Polym. Phys. Ed. 1982, 20, 279–295. [Google Scholar] [CrossRef]

- Ribelles, J.G.; Greus, A.R.; Calleja, R.D. A phenomenological study of the structural relaxation of poly (methyl methacrylate). Polymer 1990, 31, 223–230. [Google Scholar] [CrossRef]

- Boucher, V.M.; Cangialosi, D.; Alegría, A.; Colmenero, J. Enthalpy recovery of glassy polymers: Dramatic deviations from the extrapolated liquidlike behavior. Macromolecules 2011, 44, 8333–8342. [Google Scholar] [CrossRef]

- Andreozzi, L.; Faetti, M.; Giordano, M.; Zulli, F. Molecular-weight dependence of enthalpy relaxation of PMMA. Macromolecules 2005, 38, 6056–6067. [Google Scholar] [CrossRef]

- Hodge, I.M. Effects of annealing and prior history on enthalpy relaxation in glassy polymers. 4. Comparison of five polymers. Macromolecules 1983, 16, 898–902. [Google Scholar] [CrossRef]

- Yeh, G.S.Y. Order in amorphous polystyrenes as revealed by electron-diffraction and diffraction microscopy. J. Macromol. Sci.-Phys. 1972, B6, 451–463. [Google Scholar] [CrossRef]

- Weber, H.; Paul, W.; Kob, W.; Binder, K. Small-angle excess scattering: Glassy freezing or local orientational ordering? Phys. Rev. Lett. 1997, 78, 2136–2139. [Google Scholar] [CrossRef] [Green Version]

- Uhlmann, D.R. Electron-microscopy and SAXS studies of amorphous polymers. Faraday Discuss. Chem. Soc. 1979, 68, 87–95. [Google Scholar] [CrossRef]

- Geil, P.H. Amorphous polymers—Additional remark. Faraday Discuss. Chem. Soc. 1979, 68, 141–144. [Google Scholar] [CrossRef]

- Lee, S.; Miyaji, H.; Geil, P.H. Morphology of amprphous polyethylene terephthalate. J. Macromol. Sci. Phys. 1983, B22, 489–496. [Google Scholar] [CrossRef]

- Sun, L.; Wang, T.; Huang, W. Monitoring minor over-heating/cooling temperature based on the temperature memory effect in shape memory materials via DSC. J. Therm. Anal. Calorim. 2018, 133, 1649–1661. [Google Scholar] [CrossRef]

- Hertzberg, R.W.; Vinci, R.P.; Hertzberg, J.L. Deformation and Fracture Mechanics of Engineering Materials; John Wiley & Sons: Hoboken, NJ, USA, 2020. [Google Scholar]

- Struik, L.C.E. On the rejuvenation of physically aged polymers by mechanical deformation. Polymer 1997, 38, 4053–4057. [Google Scholar] [CrossRef]

- Oleynik, E. Plastic deformation and mobility in glassy polymers. In Relaxation in Polymers; Springer: Berlin/Heidelberg, Germany, 1989; pp. 140–150. [Google Scholar]

- Klassen-Neklyudova, M.V. Mechanical Twinning of Crystals; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, C.; Pek, J.X.; Chen, H.M.; Huang, W.M. On-Demand Tailoring between Brittle and Ductile of Poly(methyl methacrylate) (PMMA) via High Temperature Stretching. Polymers 2022, 14, 985. https://doi.org/10.3390/polym14050985

Wang C, Pek JX, Chen HM, Huang WM. On-Demand Tailoring between Brittle and Ductile of Poly(methyl methacrylate) (PMMA) via High Temperature Stretching. Polymers. 2022; 14(5):985. https://doi.org/10.3390/polym14050985

Chicago/Turabian StyleWang, Changchun, Jia Xi Pek, Hong Mei Chen, and Wei Min Huang. 2022. "On-Demand Tailoring between Brittle and Ductile of Poly(methyl methacrylate) (PMMA) via High Temperature Stretching" Polymers 14, no. 5: 985. https://doi.org/10.3390/polym14050985

APA StyleWang, C., Pek, J. X., Chen, H. M., & Huang, W. M. (2022). On-Demand Tailoring between Brittle and Ductile of Poly(methyl methacrylate) (PMMA) via High Temperature Stretching. Polymers, 14(5), 985. https://doi.org/10.3390/polym14050985