Assessment of Functional Performance, Self-Healing Properties and Degradation Resistance of Poly-Lactic Acid and Polyhydroxyalkanoates Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Healing Agents

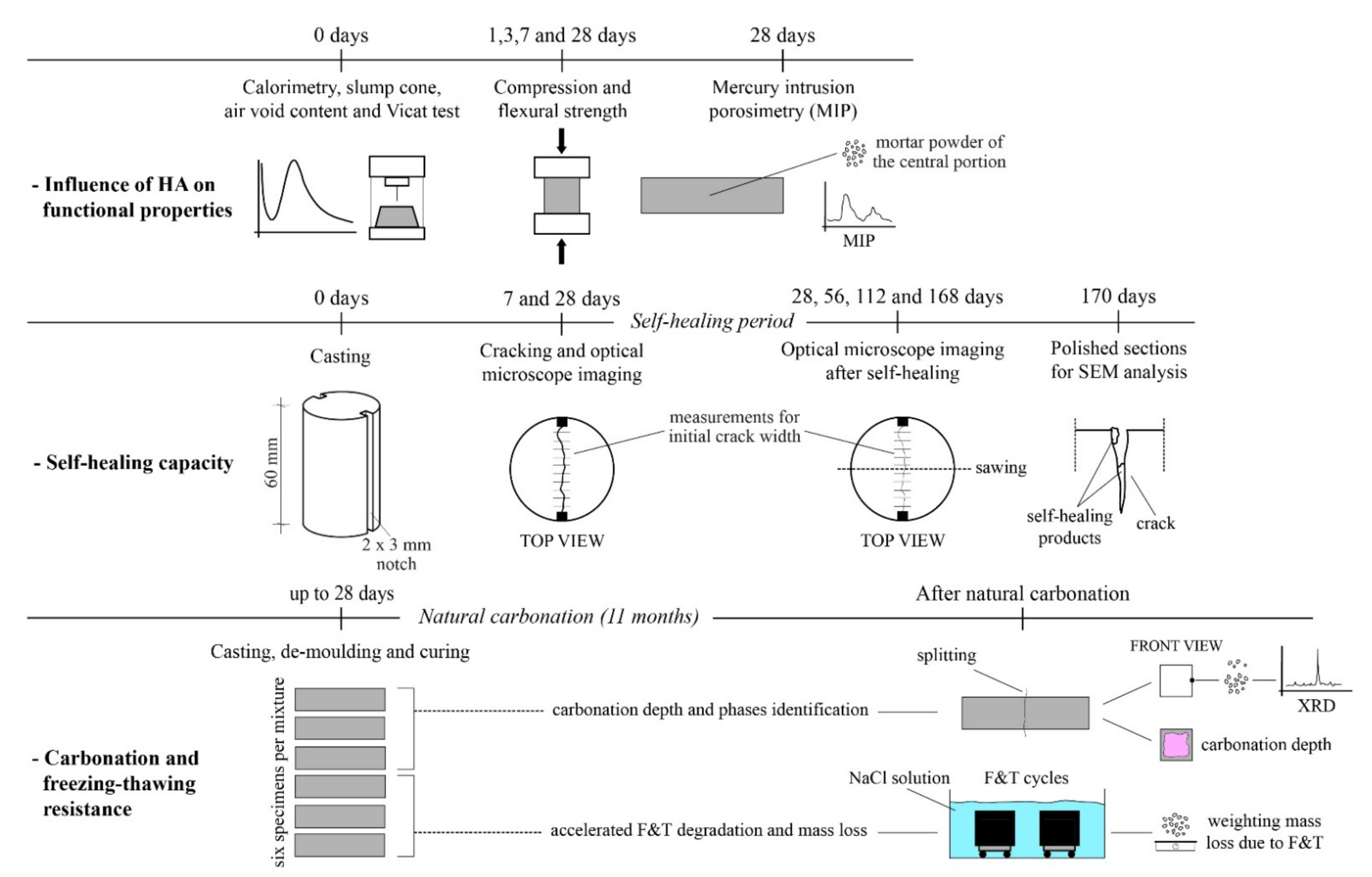

2.2. Assessment of Mortar Functional Properties

2.3. Assessment of Self-Healing Capacity through Microscopy Analysis

2.4. Freezing–Thawing Resistance of Carbonated Specimens

3. Results

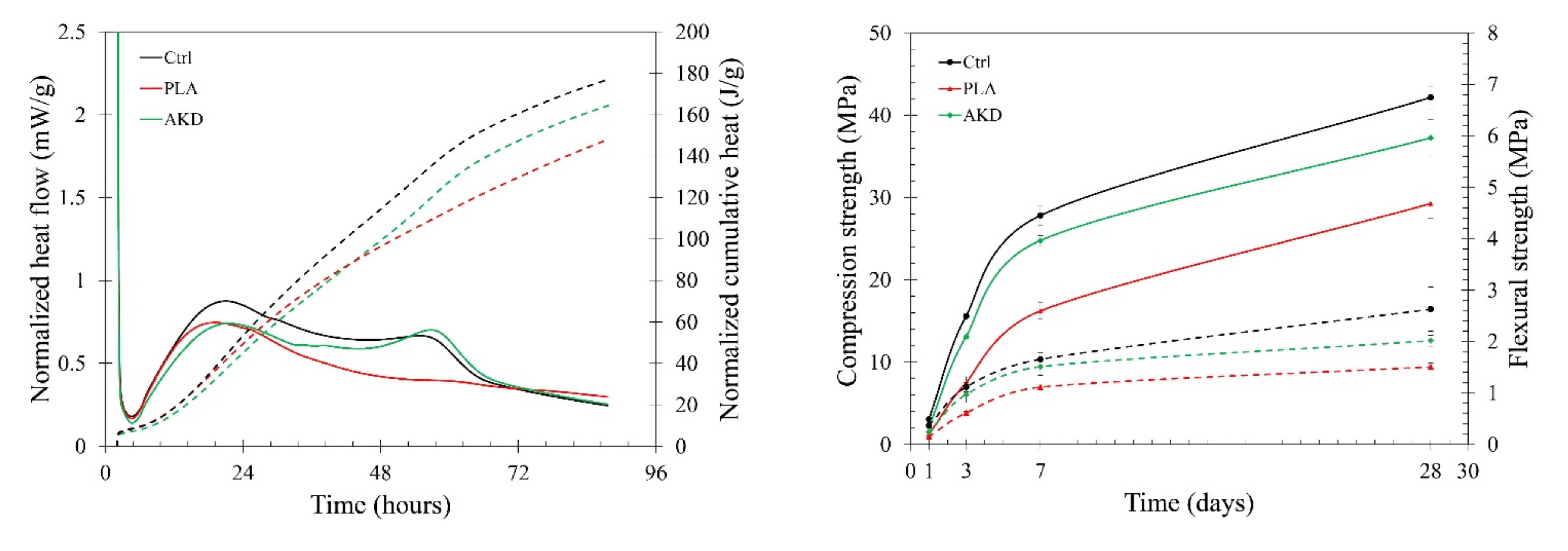

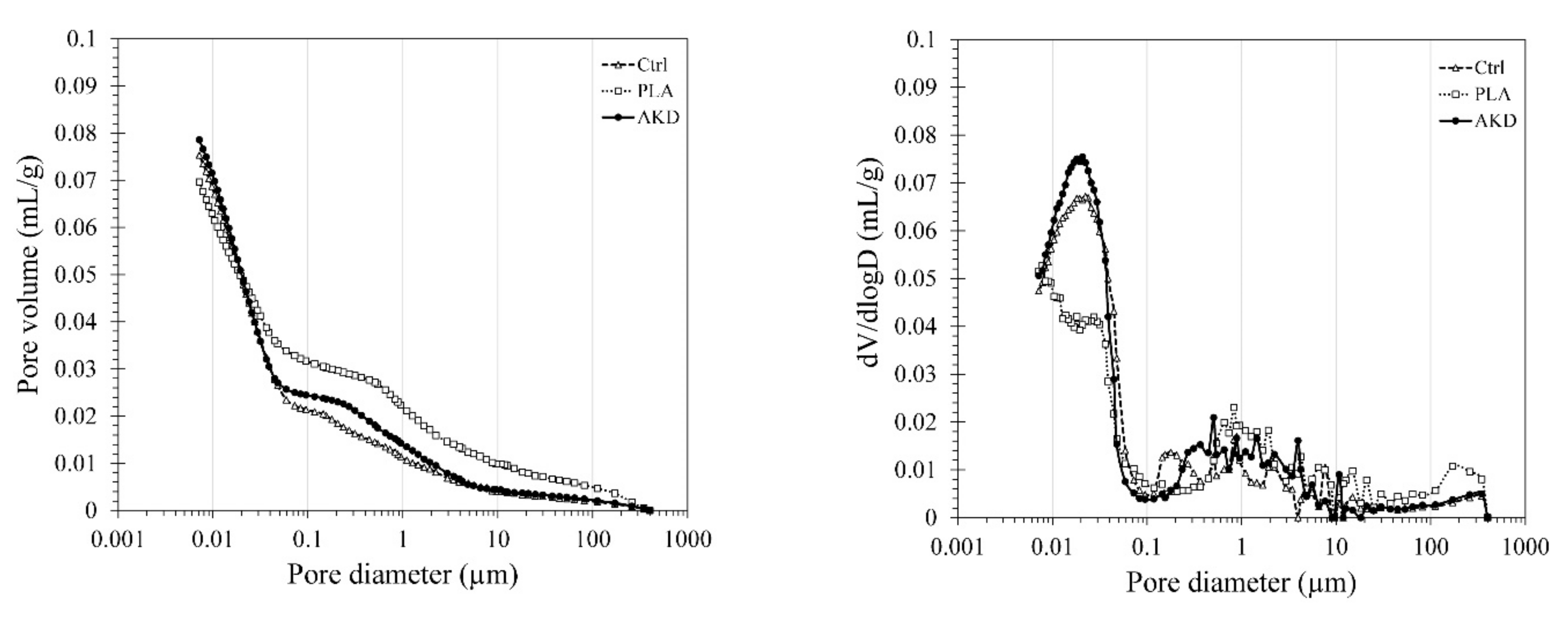

3.1. Effect of Healing Agents on Mortar Functional Properties

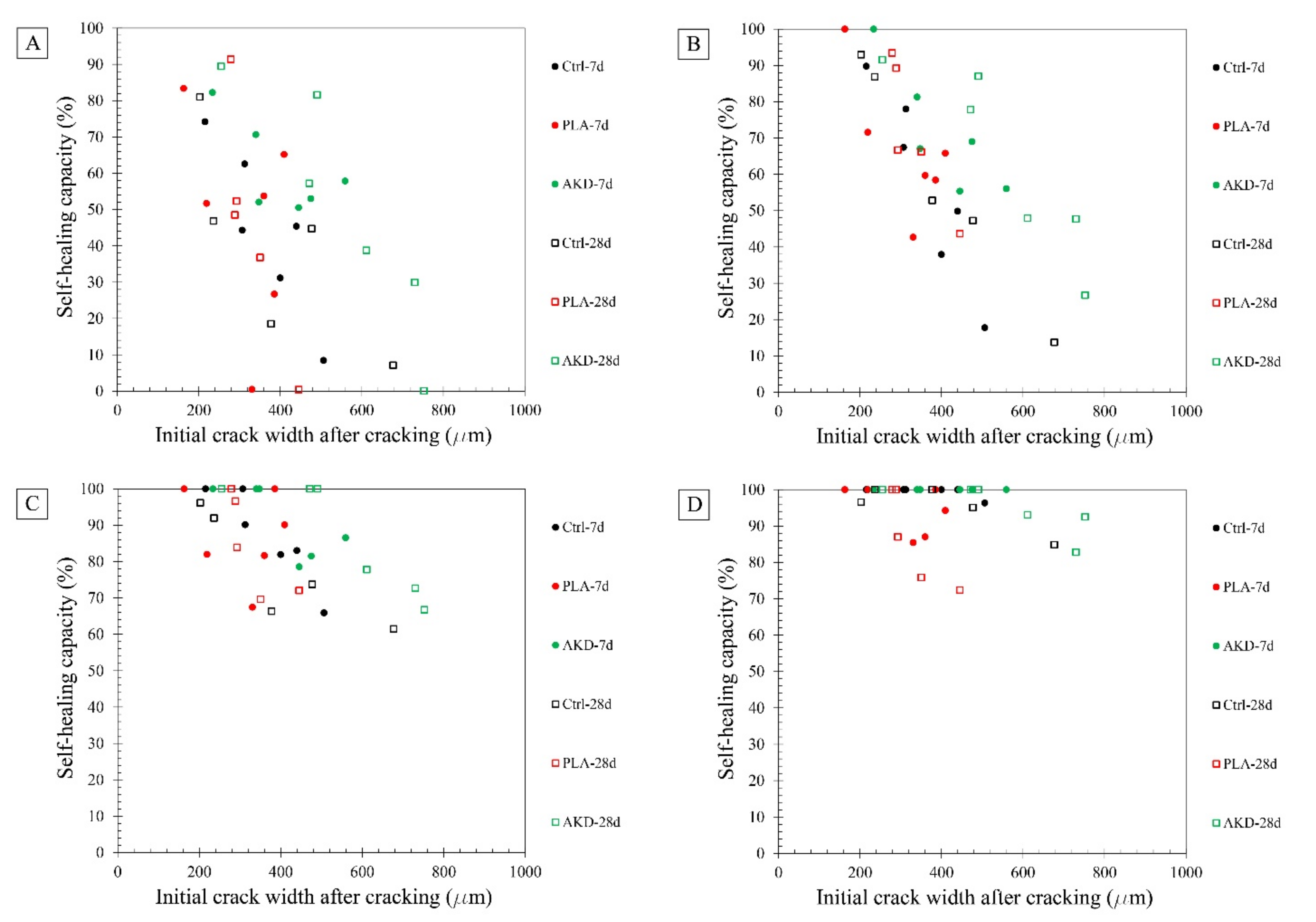

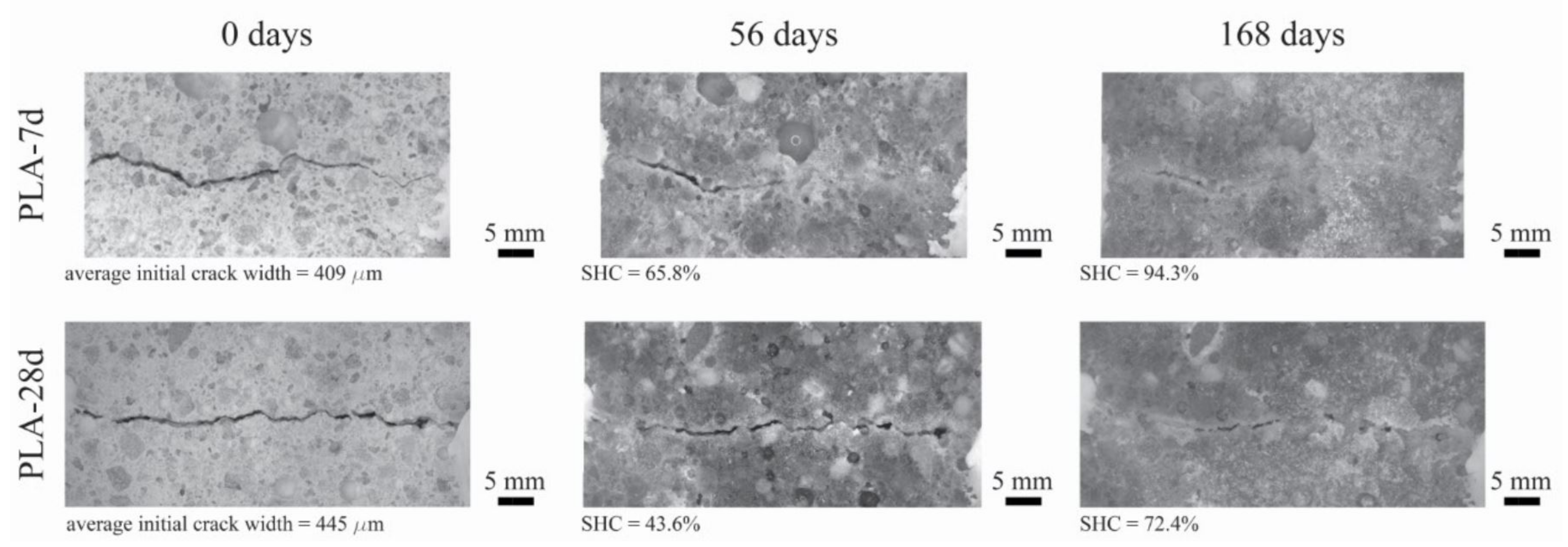

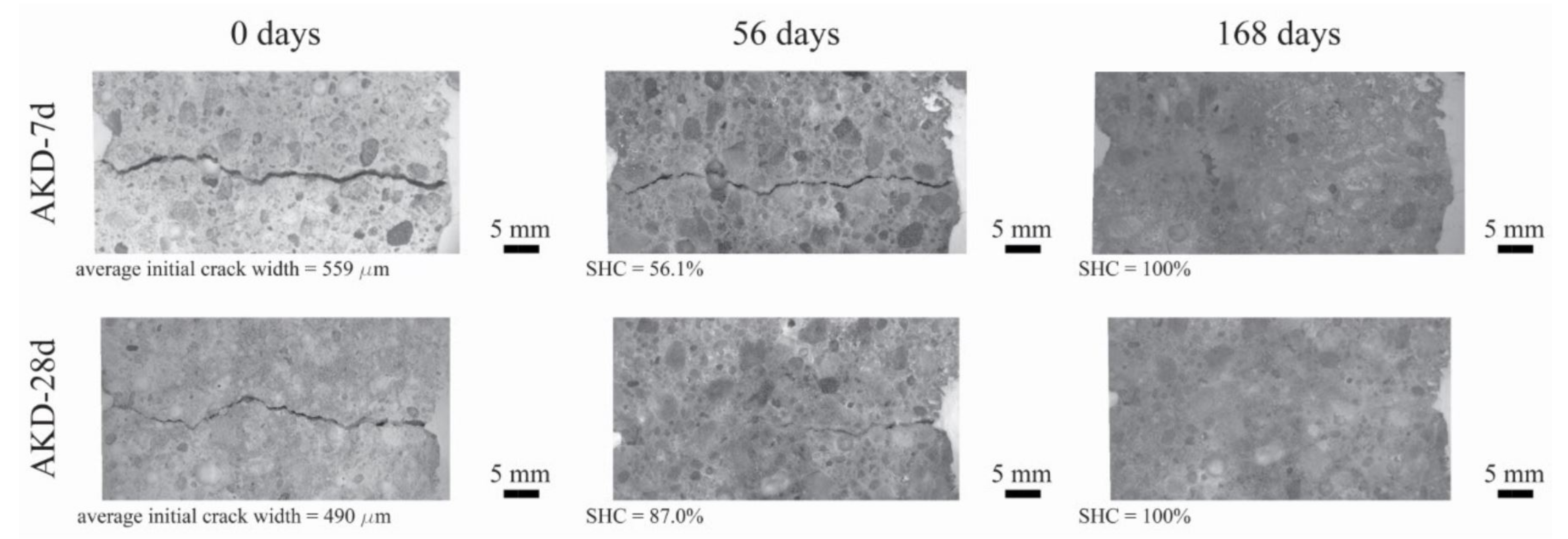

3.2. Self-Healing Capacity

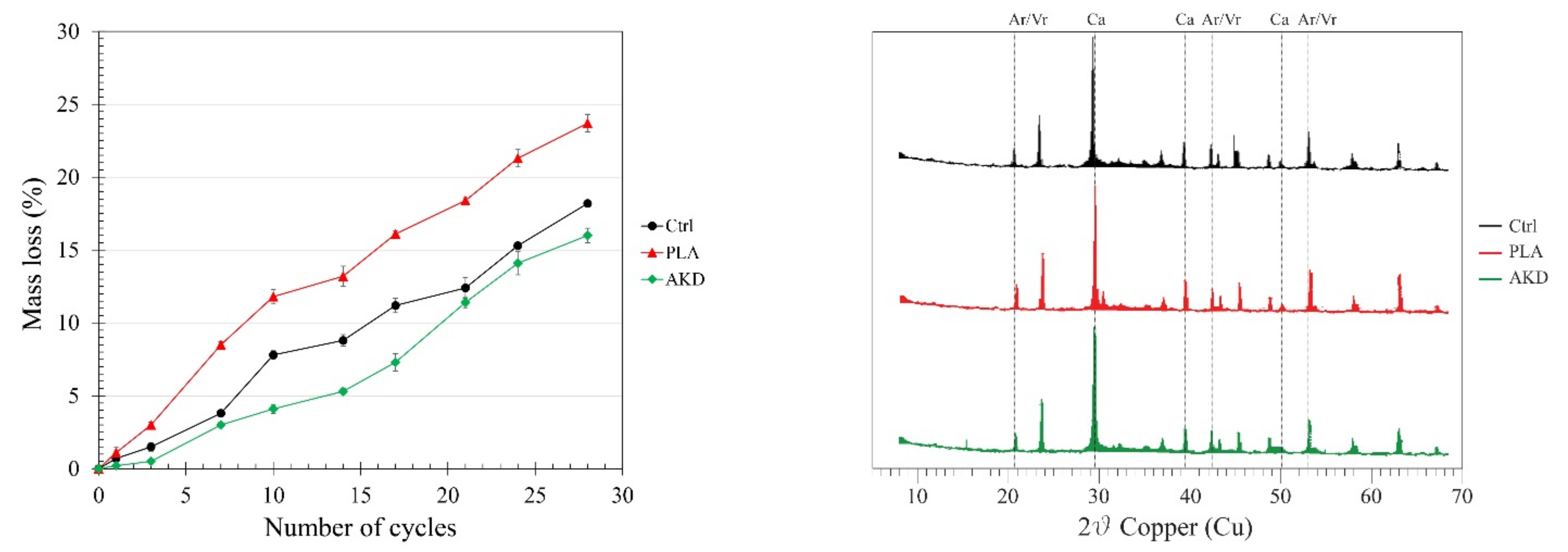

3.3. Freezing–Thawing Resistance of Carbonated Specimens

4. Discussion

4.1. Effect of Healing Agents on Mortar Functional Properties

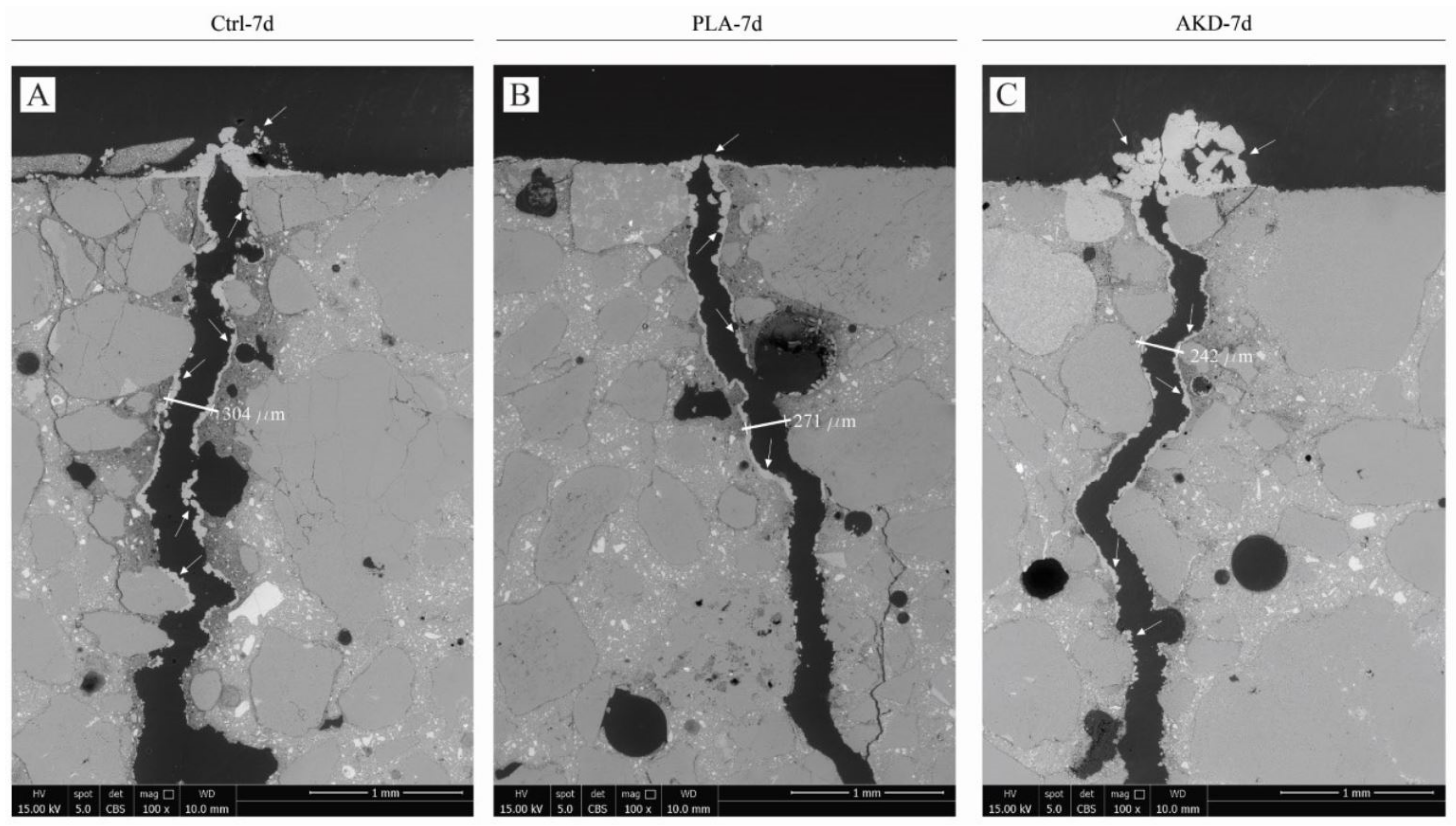

4.2. Effect of Healing Agents on Self-Healing Capacity

4.3. Freezing–Thawing Resistance of Carbonated Specimens

5. Conclusions

- The inclusion of PLA influences the hydration of BFS cement, compromising the slag reaction of the paste. As a consequence, the compression and flexural strength drop. At 28 days, the compression and flexural strength values were 13 MPa and 1.4 MPa lower than those of the Ctrl mixture. On the other hand, the inclusion of AKD only slightly influenced the heat development during hydration of the mixture, with a consequent strength drop of around 10%. AKD significantly increased the final setting time of the mixture by about 100 min. Compared to the Ctrl mixture, the inclusion of PLA and AKD healing agents increased the air void content by 0.7% and 0.9%, respectively;

- The self-healing capacity of each specimen was proportional to the self-healing duration. Furthermore, fewer wide cracks were healed more easily and quickly. On the contrary, no significant differences were observed regarding the self-healing capacity of specimens cracked at 7 or 28 days after casting, regardless of their composition. The performance of Ctrl and PLA specimens was similar up to 112 days of self-healing, after which most of the Ctrl specimens self-healed completely, while 6 out of 11 PLA specimens did not. On the other hand, the AKD specimens had better self-healing performance than the others overall. The maximum completely healed crack width of the AKD specimens was 234 µm after 56 days, 490 µm after 112 days and 559 µm after 168 days. The latter was 114 µm and 159 µm higher than the maximum healed crack width for Ctrl and PLA specimens, respectively.

- SEM analysis showed that the top of the crack of Ctrl-7d, AKD-7d and AKD-28d were completely self-healed. Because of the lower concentration of CO2 and lack of oxygen, only 20–50 µm thick layer of precipitates were observed at the sides deeper in the crack, demonstrating that the most significant self-healing precipitation occurs at the specimens’ surface;

- The inclusion of PLA and AKD increased the air void content of BFSC mortar by 0.7% and 0.9%, respectively, compared to the Ctrl mixture. For the AKD mixture, this leads to higher resistance to freezing–thawing cycles in terms of mass loss. On the other hand, even though the air void content of PLA was higher than that of the Ctrl, the mass loss for PLA was 5.4% higher than that of the Ctrl mixture, likely because of the coarser microstructure caused by the inclusion of poly-lactic acid healing agents.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Darquennes, A.; Roziere, E.; Khokhar, M.I.A.; Turcry, P.; Loukili, A.; Grondin, F. Long-term deformations and cracking risk of concrete with high content of mineral additions. Mater. Struct. 2012, 45, 1705–1716. [Google Scholar] [CrossRef]

- Luo, R.; Cai, Y.; Wang, C.; Huang, X. Study of chloride binding and diffusion in GGBS concrete. Cem. Concr. Res. 2003, 33, 1–7. [Google Scholar] [CrossRef]

- Dhir, R.K.; El-Mohr, M.A.K.; Dyer, T.D. Chloride binding in GGBS concrete. Cem. Concr. Res. 1996, 26, 1767–1773. [Google Scholar] [CrossRef]

- Itim, A.; Ezziane, K.; Kadri, E.H. Compressive strength and shrinkage of mortar containing various amounts of mineral additions. Constr. Build. Mater. 2011, 25, 3603–3609. [Google Scholar] [CrossRef]

- Dubovoy, V.S.; Gebler, S.H.; Klieger, P.; Whiting, D.A. Effects of ground granulated blast-furnace slags on some properties of pastes, mortars and concretes. In Blended Cements; Frohnsdorff, G., Ed.; ASTM International: West Conshohocken, PA, USA, 1986. [Google Scholar]

- Lanser, P.A.; Burger, A.M. Carbon dioxide as a stimulus for life cycle thinking in cement and carbon neutral concrete building. Concr. Prod. 2008, 53–58. [Google Scholar]

- Darquennes, A.; Staquet, S.; Espion, B. Behaviour of slag cement concrete under restraint conditions. Eur. J. Environ. Civ. Eng. 2011, 15, 787–798. [Google Scholar] [CrossRef]

- Briffaut, M.; Benboudjema, F.; D’aloia, L.; Bahrami, B.; Bonnet, A. Analysis of cracking due to shrinkage restraint in a concrete tunnel. In Proceedings of the Numerical Modeling Strategies for Sustainable Concrete Structures, Aix-en-Provence, France, 29 May–1 June 2012. [Google Scholar]

- Darquennes, A.; Olivier, K.; Benboudjema, F.; Gagné, R. Self-healing at early-age, a way to improve the chloride resistance of blast-furnace slag cementitious materials. Constr. Build. Mater. 2016, 113, 1017–1028. [Google Scholar] [CrossRef]

- De Belie, N.; Gruyaert, E.; Al-Tabbaa, A.; Antonaci, P.; Baera, C.; Bajare, D.; Jonkers, H.M. A review of self-healing concrete for damage management of structures. Adv. Mater. Interfaces 2018, 5, 1800074. [Google Scholar] [CrossRef]

- Hearn, N. Self-sealing, autogenous healing and continued hydration: What is the difference? Mater. Struct. 1998, 31, 563–567. [Google Scholar] [CrossRef]

- Yoon, I.S.; Schlangen, E. Experimental examination on chloride penetration through micro-crack in concrete. KSCE J. Civ. Eng. 2014, 18, 188–198. [Google Scholar] [CrossRef]

- Ismail, M.; Toumi, A.; François, R.; Gagné, R. Effect of crack opening on the local diffusion of chloride in cracked mortar samples. Cem. Concr. Res. 2008, 38, 1106–1111. [Google Scholar] [CrossRef]

- Sahmaran, M. Effect of flexure induced transverse crack and self-healing on chloride diffusivity of reinforced mortar. J. Mater. Sci. 2007, 42, 9131–9136. [Google Scholar] [CrossRef]

- Wang, J.; Soens, H.; Verstraete, W.; De Belie, N. Self-healing concrete by use of microencapsulated bacterial spores. Cem. Concr. Res. 2014, 56, 139–152. [Google Scholar] [CrossRef]

- Wang, J.Y.; Snoeck, D.; Van Vlierberghe, S.; Verstraete, W.; De Belie, N. Application of hydrogel encapsulated carbonate precipitating bacteria for approaching a realistic self-healing in concrete. Constr. Build. Mater. 2014, 68, 110–119. [Google Scholar] [CrossRef]

- Wang, J.; Mignon, A.; Trenson, G.; Van Vlierberghe, S.; Boon, N.; De Belie, N. A chitosan based pH-responsive hydrogel for encapsulation of bacteria for self-sealing concrete. Cem. Concr. Compos. 2018, 93, 309–322. [Google Scholar] [CrossRef]

- Xu, H.; Lian, J.; Gao, M.; Fu, D.; Yan, Y. Self-healing concrete using rubber particles to immobilize bacterial spores. Materials 2019, 12, 2313. [Google Scholar] [CrossRef] [Green Version]

- Palin, D. A Cost-Effective Bacteria-Based Self-Healing Cementitious Composite for Low-Temperature Marine Applications. Ph.D. Thesis, Technical University of Delft, Delft, The Netherlands, 2017. [Google Scholar]

- Palin, D.; Wiktor, V.; Jonkers, H. Autogenous healing of marine exposed concrete: Characterization and quantification through visual crack closure. Cem. Concr. Res. 2015, 73, 17–24. [Google Scholar] [CrossRef]

- Palin, D.; Wiktor, V.; Jonkers, H. A bacteria-based self-healing cementitious composite for application in low temperature marine environments. Biomimetics 2017, 2, 13. [Google Scholar] [CrossRef] [Green Version]

- Mors, R.M.; Jonkers, H.M. Feasibility of lactate derivative based agent as additive for concrete for regain of crack water tightness by bacterial metabolism. Ind. Crops Prod. 2017, 106, 97–104. [Google Scholar] [CrossRef]

- Mors, R. and Jonkers, H. Effect on concrete surface water absorption upon addition of lactate derived agent. Coatings 2017, 7, 51. [Google Scholar] [CrossRef]

- Vermeer, C.M.; Rossi, E.; Tamis, J.; Jonkers, H.M.; Kleerebezem, R. From waste to self-healing concrete: A proof-of-concept of a new application for polyhydroxyalkanoate. Resour. Conserv. Recycl. 2021, 164, 105206. [Google Scholar] [CrossRef]

- Rossi, E.; Vermeer, C.M.; Mors, R.M.; Kleerebezem, R.; Copuroglu, O.; Jonkers, H.M. On the applicability of a precursor derived from organic waste streams for bacteria-based self-healing concrete. Front. Built Environ. 2021, 7, 632921. [Google Scholar] [CrossRef]

- Rossi, E.; Roy, R.; Copuroglu, O.; Jonkers, H.M. Influence of self-healing induced by polylactic-acid and alkanoates-derivates precursors on transport properties and chloride penetration resistance of sound and cracked mortar specimens. Constr. Build. 2022, 319, 126081. [Google Scholar] [CrossRef]

- EN 196-1; Methods of Testing Cement—Part 1: Determination of Strength. European Standard: Brussels, Belgium, 2009.

- ASTM C143/C143M-20; Standard Test Method for Slump of Hydraulic-Cement Concrete. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM C185-20; Standard Test Method for Air Content of Hydraulic Cement Mortar. ASTM International: West Conshohocken, PA, USA, 2020.

- EN 196-3; Methods of Testing Cement—Part 3: Determination of Setting Times and Soundness. European Standard: Brussels, Belgium, 2009.

- Rodríguez, C.R.; de Mendonça Filho, F.F.; Mercuri, L.; Gan, Y.; Rossi, E.; Anglani, G.; Antonaci, P.; Schlangen, E.; Šavija, B. Chemo-physico-mechanical properties of the interface zone between bacterial PLA self-healing capsules and cement paste. Cem. Concr. Res. 2020, 138, 106228. [Google Scholar] [CrossRef]

- Niaounakis, M. Biopolymers: Applications and Trends; William Andrew: Norwich, NY, USA, 2015. [Google Scholar]

- Ferrara, L.; Van Mullem, T.; Alonso, M.C.; Antonaci, P.; Borg, R.P.; Cuenca, E.; De Belie, N. Experimental characterization of the self-healing capacity of cement based materials and its effects on the material performance: A state of the art report by COST Action SARCOS WG2. Constr. Build. Mater. 2018, 167, 115–142. [Google Scholar] [CrossRef] [Green Version]

- Winter, N.B. Understanding Cement: An Introduction to Cement Production, Cement Hydration and Deleterious Processes in Concrete; Microanalysis Consultants: Saint Ives, UK, 2012. [Google Scholar]

| Mixture | Cement Type | Water/Cement | HA (% by Mass of Cement) |

|---|---|---|---|

| Ctrl | CEM III/B 42.5 N | 0.5 | 0 |

| PLA | CEM III/B 42.5 N | 0.5 | 2.6 |

| AKD | CEM III/B 42.5 N | 0.5 | 2.6 |

| Ingredients | Weight (g) |

|---|---|

| CEM III/B 42.5 N | 220.9 |

| Water | 110.5 |

| Aggregates (0.125–2 mm) | 662.7 |

| Healing agent | 5.9 1 |

| 2–1 mm | 1–0.5 mm | 0.5–0.25 mm | 0.25–0.125 mm | |

|---|---|---|---|---|

| Percentage (%) | 33 | 34 | 21 | 12 |

| Quantity (g) | 218.7 | 225.3 | 139.2 | 79.5 |

| Workability (ASTM C143) | Air Void Content (ASTM C185) | Setting Time (EN 196-3) | ||

|---|---|---|---|---|

| Flow (mm) | Content (%) | Initial (min) | Final (min) | |

| Ctrl | 160 ± 10 | 4.1 | 165 ± 12 | 410 ± 18 |

| PLA | 182 ± 14 | 4.8 | 155 ± 15 | 435 ± 10 |

| AKD | 177 ± 10 | 5.0 | 185 ± 10 | 510 ± 15 |

| Ctrl | PLA | AKD | |

|---|---|---|---|

| Average CO2 depth (mm) | 2.76 | 2.87 | 2.61 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rossi, E.; Raghavan, A.; Copuroglu, O.; Jonkers, H.M. Assessment of Functional Performance, Self-Healing Properties and Degradation Resistance of Poly-Lactic Acid and Polyhydroxyalkanoates Composites. Polymers 2022, 14, 926. https://doi.org/10.3390/polym14050926

Rossi E, Raghavan A, Copuroglu O, Jonkers HM. Assessment of Functional Performance, Self-Healing Properties and Degradation Resistance of Poly-Lactic Acid and Polyhydroxyalkanoates Composites. Polymers. 2022; 14(5):926. https://doi.org/10.3390/polym14050926

Chicago/Turabian StyleRossi, Emanuele, Arjun Raghavan, Oguzhan Copuroglu, and Henk M. Jonkers. 2022. "Assessment of Functional Performance, Self-Healing Properties and Degradation Resistance of Poly-Lactic Acid and Polyhydroxyalkanoates Composites" Polymers 14, no. 5: 926. https://doi.org/10.3390/polym14050926

APA StyleRossi, E., Raghavan, A., Copuroglu, O., & Jonkers, H. M. (2022). Assessment of Functional Performance, Self-Healing Properties and Degradation Resistance of Poly-Lactic Acid and Polyhydroxyalkanoates Composites. Polymers, 14(5), 926. https://doi.org/10.3390/polym14050926