Antimicrobial Activity of Cellulose Based Materials

Abstract

:1. Introduction

2. Materials and Methods

2.1. Obtaining and Characterizing Materials

2.2. Bacterial Culture Preparation

- (a)

- Microbial cultures preparation, in order to establish the optimal cellulose: extractant ratio

- (b)

- Microbial cultures preparation for further tests of antimicrobial effect of the synthesized materials on the reference strains

- UFCcontrol = number of colonies on the control plate

- UFCtest = the number of colonies on the test plate

3. Results and Discussion

3.1. Characterization of Materials Obtained by Cellulose Functionalizing

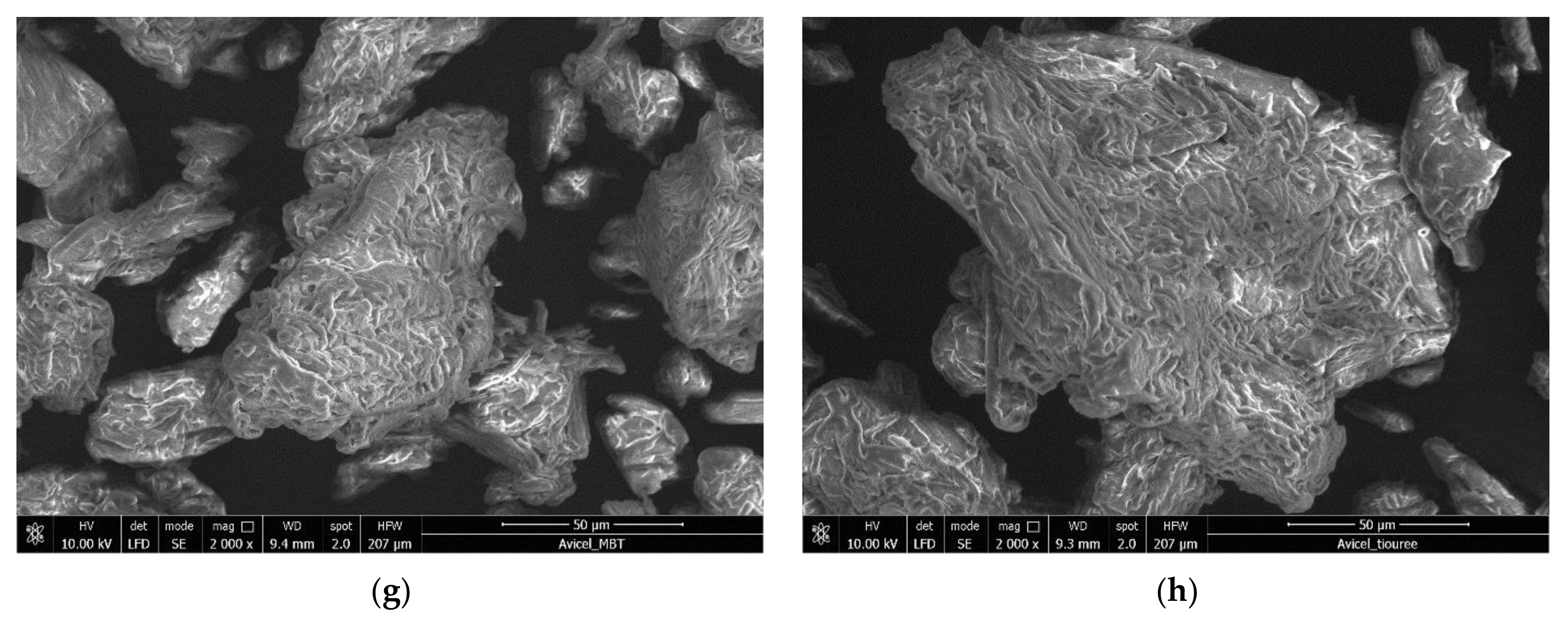

- Scanning electron microscopy, SEM

- b.

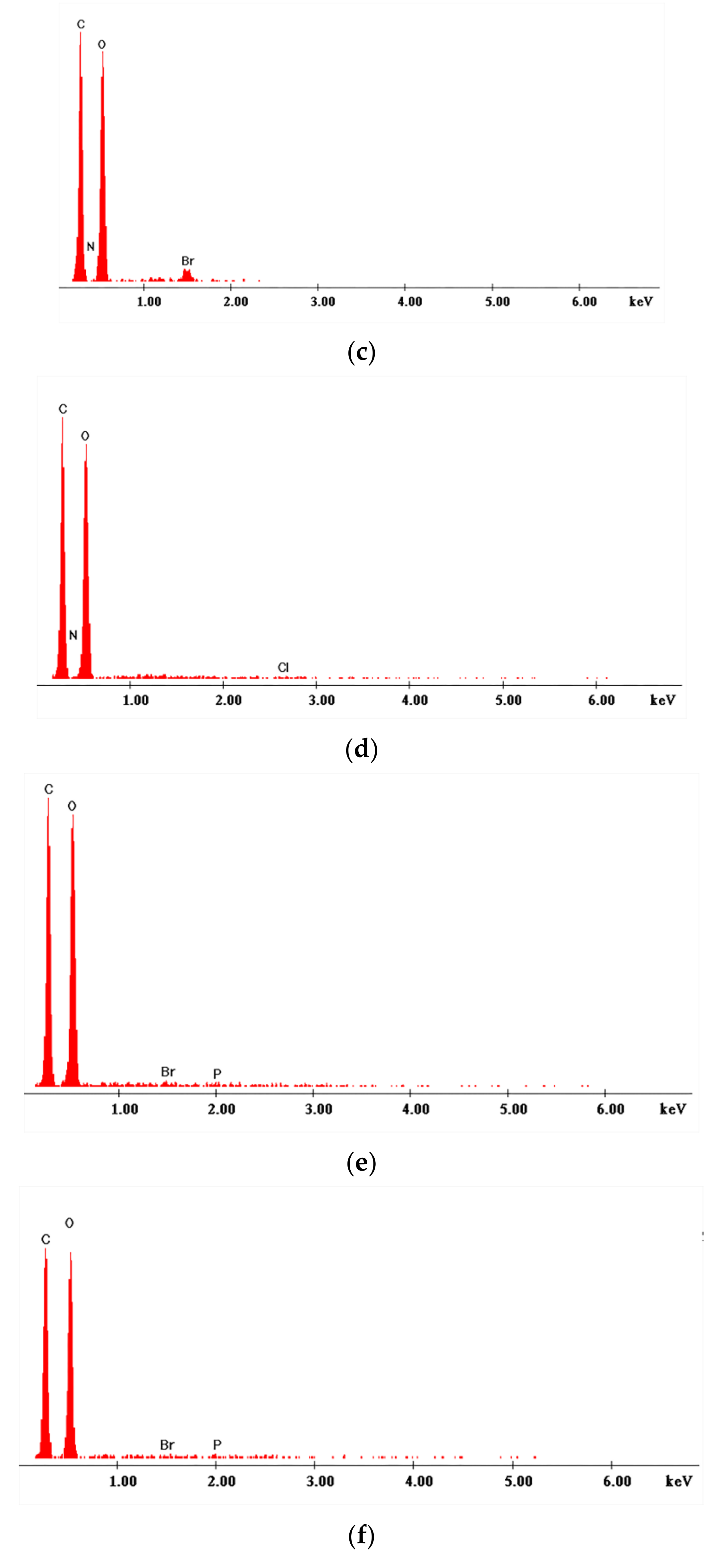

- X-ray energy dispersion, EDX

- c.

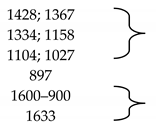

- Infrared spectroscopy with Fourier transform, FT-IR

3.2. Studies on the Antimicrobial Activity of Materials

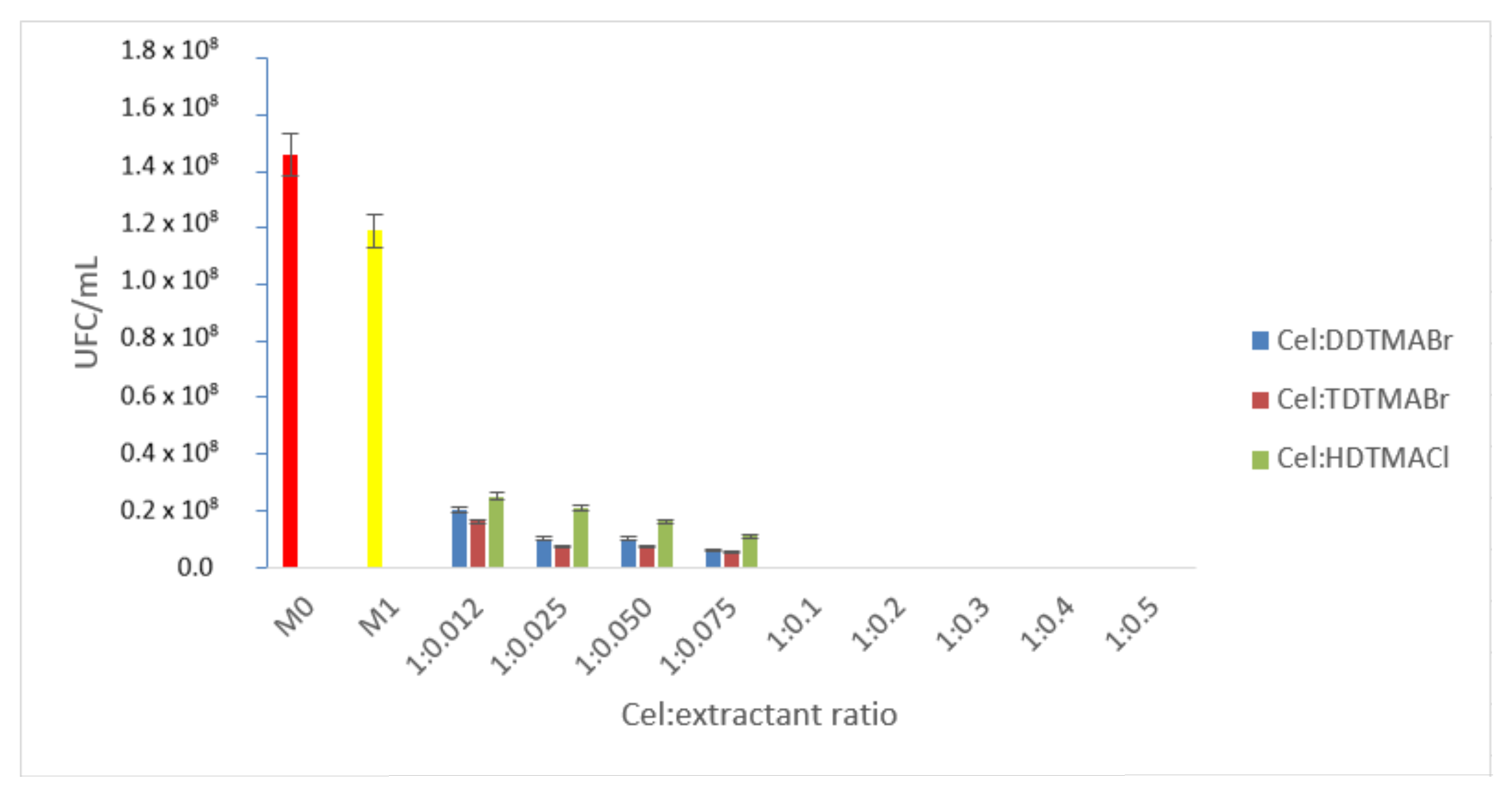

- Materials obtained by functionalizing cellulose with quaternary ammonium salts

- A.1.

- Studies to determine the optimal cellulose:extractant ratio

- A.2.

- Antimicrobial effect of ammonium materials on reference microbial strains

- B.

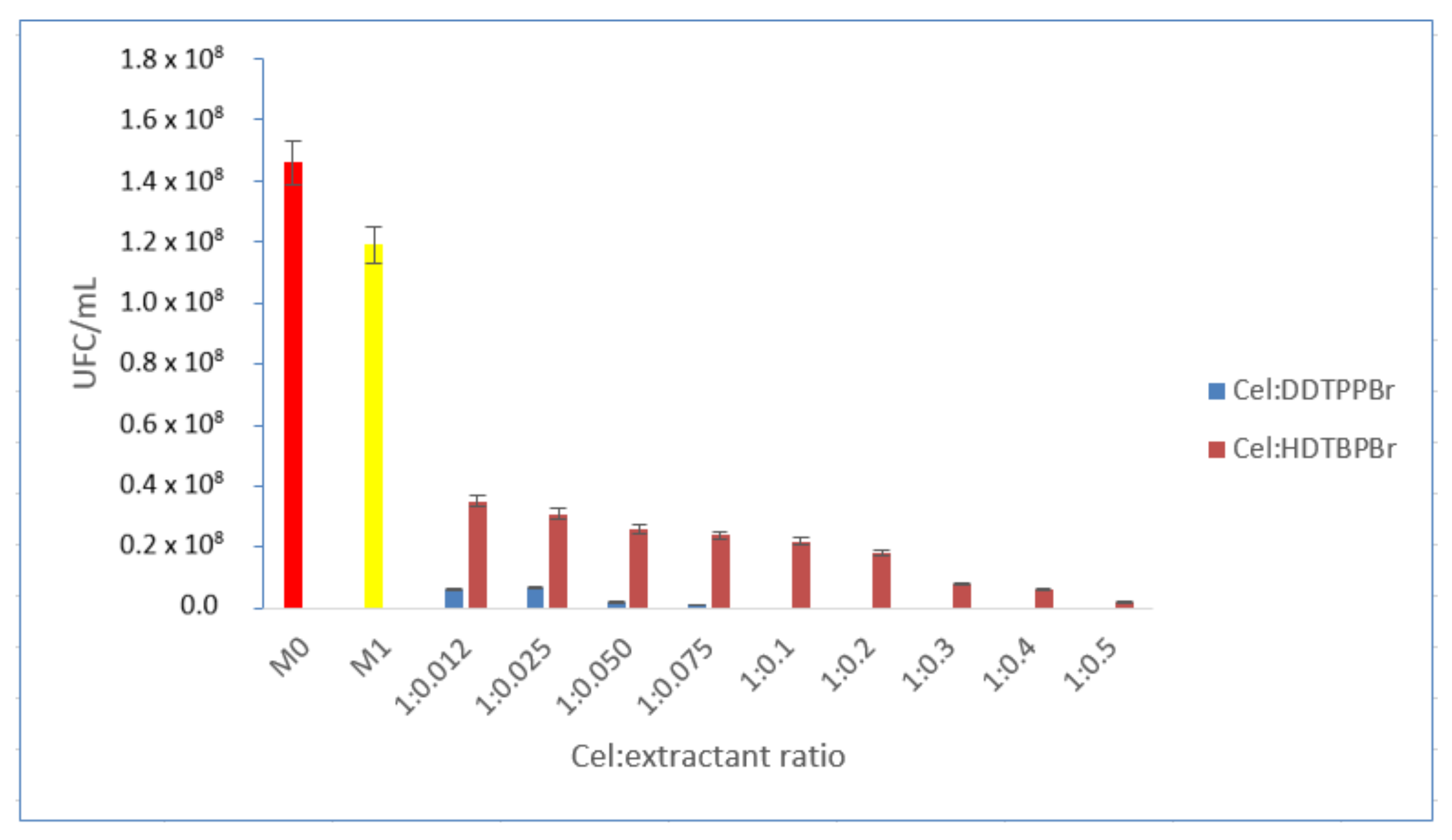

- Materials obtained by functionalization of cellulose with extractants containing phosphonium salts

- B.1.

- Studies to determine the optimal cellulose:extractant ratio

- B.2.

- Antimicrobial effect of phosphonium materials on reference microbial strains

- C.

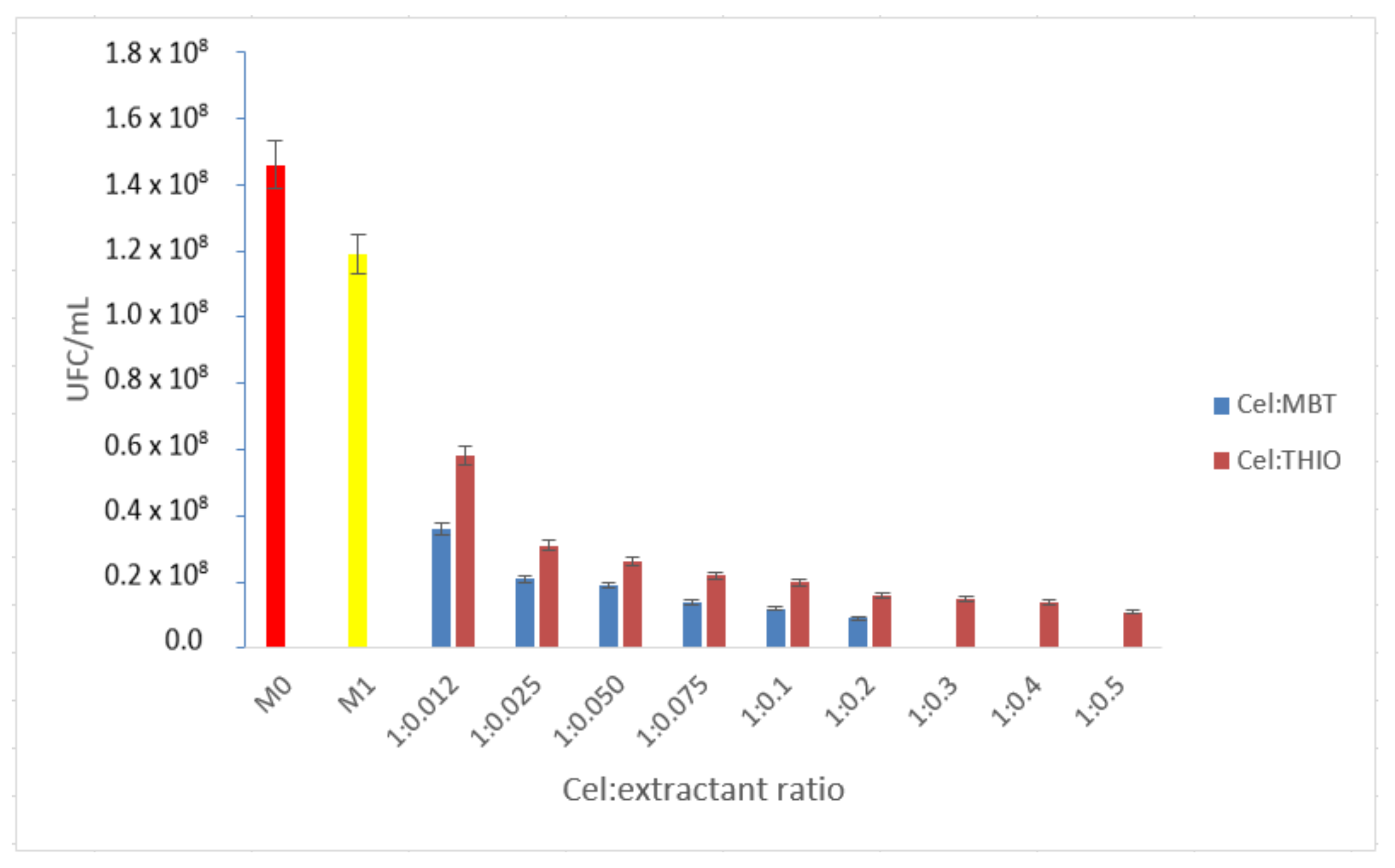

- Materials obtained by functionalizing cellulose with sulfur compounds

- C.1.

- Studies to determine the optimal cellulose:extractant ratio

- C.2.

- Antimicrobial effect of sulfur materials on reference microbial strains

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shanks, R.A. 2—Chemistry and structure of cellulosic fibres as reinforcements in natural fibre composites. In Natural Fibre Composites; Hodzic, A., Shanks, R., Eds.; Woodhead Publishing: Sawston, UK, 2014; pp. 66–83. [Google Scholar]

- Malmström, E.; Carlmark, A. Controlled grafting of cellulose fibres—An outlook beyond paper and cardboard. Polym. Chem. 2012, 3, 1702–1713. [Google Scholar] [CrossRef]

- Moriana, R.; Vilaplana, F.; Ek, M. Cellulose Nanocrystals from Forest Residues as Reinforcing Agents for Composites: A Study from Macro- to Nano-Dimensions. Carbohydr. Polym. 2016, 139, 139–149. [Google Scholar] [CrossRef] [PubMed]

- Malucelli, L.C.; Lacerda, L.G.; Dziedzic, M.; da Silva Carvalho Filho, M.A. Preparation, properties and futureperspectives of nanocrystals from agro-industrial residues: A review of recentresearch. Rev. Environ. Sci. Bio/Technol. 2017, 16, 131–145. [Google Scholar] [CrossRef]

- Khattak, S.; Wahid, F.; Liu, L.-P.; Jia, S.-R.; Chu, L.-Q.; Xie, Y.-Y.; Li, Z.-X.; Zhong, C. Applications of cellulose and chitin/chitosan derivatives and composites as antibacterial materials: Current state and perspectives. Appl. Microbiol. Biotechnol. 2019, 103, 1989–2006. [Google Scholar] [CrossRef] [PubMed]

- Kupnik, K.; Primožič, M.; Kokol, V.; Leitgeb, M. Nanocellulose in Drug Delivery and Antimicrobially Active Materials. Polymers 2020, 12, 2825. [Google Scholar] [CrossRef] [PubMed]

- Lavoine, N.; Desloges, I.; Dufresne, A.; Bras, J. Microfibrillated cellulose—Its barrier properties and applications in cellulosic materials: A review. Carbohydr. Polym. 2012, 90, 735–764. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Zheng, Y.; Song, W.; Luan, J.; Wen, X.; Wu, Z.; Chen, X.; Wang, Q.; Guo, S. In situ synthesis of silver-nanoparticles/bacterial cellulose composites for slow-released antimicrobial wound dressing. Carbohydr. Polym. 2014, 102, 762–771. [Google Scholar] [CrossRef]

- Jonoobi, M.; Oladi, R.; Davoudpour, Y.; Oksman, K.; Dufresne, A.; Hamzeh, Y.; Davoodi, R. Different preparation methods and properties of nanostructured cellulose from various natural resources and residues: A review. Cellulose 2015, 22, 935–969. [Google Scholar] [CrossRef]

- Kafle, K.; Shin, H.; Lee, C.M.; Park, S.; Kim, S.H. Progressive structural changes of Avicel, bleached softwood and bacterial cellulose during enzymatic hydrolysis. Sci. Rep. 2015, 5, 15102. [Google Scholar] [CrossRef] [Green Version]

- Pal, S.; Nisi, R.; Stoppa, M.; Licciulli, A. Silver-Functionalized Bacterial Cellulose as Antibacterial Membrane for Wound-Healing Applications. ACS Omega 2017, 2, 3632–3639. [Google Scholar] [CrossRef] [Green Version]

- Zheng, L.; Li, S.; Luo, J.; Wang, X. Latest Advances on Bacterial Cellulose-Based Antibacterial Materials as Wound Dressings. Front. Bioeng. Biotechnol. 2020, 8, 1334. [Google Scholar] [CrossRef] [PubMed]

- Bano, S.; Negi, Y.S. Studies on cellulose nanocrystals isolated from groundnut shells. Carbohydr. Polym. 2017, 157, 1041–1049. [Google Scholar] [CrossRef] [PubMed]

- Habibi, Y.; Lucia, L.A.; Rojas, O.J. Cellulose Nanocrystals: Chemistry, Self-Assembly, and Applications. Chem. Rev. 2010, 110, 3479–3500. [Google Scholar] [CrossRef] [PubMed]

- George, J.; Sabapathi, S.N. Cellulose nanocrystals: Synthesis, functional properties, and applications. Nanotechnol. Sci. Appl. 2015, 8, 45. [Google Scholar] [CrossRef] [Green Version]

- Wang, S.; Lu, A.; Zhang, L. Recent advances in regenerated cellulose materials. Prog. Polym. Sci. 2016, 53, 169–206. [Google Scholar] [CrossRef]

- Siqueira, G.; Bras, J.; Dufresne, A. Cellulosic Bionanocomposites: A Review of Preparation, Properties and Applications. Polymers 2010, 2, 728. [Google Scholar] [CrossRef] [Green Version]

- Bruel, C.; Tavares, J.R.; Carreau, P.J.; Heuzey, M.-C. The structural amphiphilicity of cellulose nanocrystals characterized from their cohesion parameters. Carbohydr. Polym. 2019, 205, 184–191. [Google Scholar] [CrossRef] [Green Version]

- Sperandeo, P.; Bosco, F.; Clerici, F.; Polissi, A.; Gelmi, M.L.; Romanelli, A. Covalent Grafting of Antimicrobial Peptides onto Microcrystalline Cellulose. ACS Appl. Bio Mater. 2020, 3, 4895–4901. [Google Scholar] [CrossRef]

- Baghaei, B.; Skrifvars, M. All-Cellulose Composites: A Review of Recent Studies on Structure, Properties and Applications. Molecules 2020, 25, 2836. [Google Scholar] [CrossRef]

- Coma, V.; Freire, V.; Silvestre, A. Recent Advances on the Development of Antibacterial Polysaccharide-Based Materials; Springer: Cham, Switzerland, 2015; pp. 1751–1803. [Google Scholar] [CrossRef]

- Kar, M.; Chourasiya, Y.; Maheshwari, R.; Tekade, R.K. Chapter 2—Current Developments in Excipient Science: Implication of Quantitative Selection of Each Excipient in Product Development. In Basic Fundamentals of Drug Delivery; Tekade, R.K., Ed.; Academic Press: Cambridge, MA, USA, 2019; pp. 29–83. [Google Scholar]

- Klemm, D.; Heublein, B.; Fink, H.-P.; Bohn, A. Cellulose: Fascinating Biopolymer and Sustainable Raw Material. Angew. Chem. Int. Ed. 2005, 44, 3358–3393. [Google Scholar] [CrossRef]

- Li, Q.; Wang, Y.; Wu, Y.; He, K.; Li, Y.; Luo, X.; Li, B.; Wang, C.; Liu, S. Flexible cellulose nanofibrils as novel pickering stabilizers: The emulsifying property and packing behavior. Food Hydrocoll. 2019, 88, 180–189. [Google Scholar] [CrossRef]

- Huang, S.; Liu, X.; Chang, C.; Wang, Y. Recent developments and prospective food-related applications of cellulose nanocrystals: A review. Cellulose 2020, 27, 2991–3011. [Google Scholar] [CrossRef]

- Tamilselvi, A.; Jayakumar, G.C.; Sri Charan, K.; Sahu, B.; Deepa, P.R.; Kanth, S.V.; Kanagaraj, J. Extraction of cellulose from renewable resources and its application in leather finishing. J. Clean. Prod. 2019, 230, 694–699. [Google Scholar] [CrossRef]

- Salmeia, K.; Jovic, M.; Ragaišienė, A.; Rukuižienė, Ž.; Milašius, R.; Mikučionienė, D.; Gaan, S. Flammability of Cellulose-Based Fibers and the Effect of Structure of Phosphorus Compounds on Their Flame Retardancy. Polymers 2016, 8, 293. [Google Scholar] [CrossRef] [Green Version]

- Ullah, H.; Wahid, F.; Santos, H.A.; Khan, T. Advances in biomedical and pharmaceutical applications of functional bacterial cellulose-based nanocomposites. Carbohydr. Polym. 2016, 150, 330–352. [Google Scholar] [CrossRef]

- Ayala Valencia, G.; Cristina de Oliveira Vercik, L.; Ferrari, R.; Vercik, A. Synthesis and characterization of silver nanoparticles using water-soluble starch and its antibacterial activity on Staphylococcus aureus. Starch—Stärke 2013, 65, 931–937. [Google Scholar] [CrossRef]

- Kalwar, K.; Bhutto, M.A.; Li, D.L.; Shan, D. Cellulose based nanofabrication; immobilization of silver nanoparticales and its size effect against Escherichia coli. Mater. Res. Express 2017, 4, 6. [Google Scholar] [CrossRef]

- Wang, J.; Liu, W.; Li, H.; Huili, W.; Wang, Z.; Zhou, W.; Liu, H. Preparation of cellulose fiber–TiO2 nanobelt–silver nanoparticle hierarchically structured hybrid paper and its photocatalytic and antibacterial properties. Chem. Eng. J. 2013, 228, 272–280. [Google Scholar] [CrossRef]

- Bolhuis, G.K.; Armstrong, N.A. Excipients for direct compaction—An update. Pharm. Dev. Technol. 2006, 11, 111–124. [Google Scholar] [CrossRef]

- Liu, S.; Zeng, J.; Tao, D.; Na, N. Microfiltration performance of regenerated cellulose membrane prepared at low temperature for wastewater treatment. Cellulose 2010, 17, 1159–1169. [Google Scholar] [CrossRef]

- Fauzani, D.; Notodarmojo, S.; Handajani, M.; Helmy, Q.; Kardiansyah, T. Cellulose in natural flocculant applications: A review. J. Phys. Conf. Ser. 2021, 2047, 012030. [Google Scholar] [CrossRef]

- Suopajärvi, T.; Liimatainen, H.; Hormi, O.; Niinimäki, J. Coagulation–flocculation treatment of municipal wastewater based on anionized nanocelluloses. Chem. Eng. J. 2013, 231, 59–67. [Google Scholar] [CrossRef]

- Khiari, R.; Dridi-Dhaouadi, S.; Aguir, C.; Mhenni, M.F. Experimental evaluation of eco-friendly flocculants prepared from date palm rachis. J. Environ. Sci. 2010, 22, 1539–1543. [Google Scholar] [CrossRef]

- Onwukamike, K.N.; Grelier, S.; Grau, E.; Cramail, H.; Meier, M.A.R. Critical Review on Sustainable Homogeneous Cellulose Modification: Why Renewability Is Not Enough. ACS Sustain. Chem. Eng. 2019, 7, 1826–1840. [Google Scholar] [CrossRef] [Green Version]

- Ardean, C.; Davidescu, C.M.; Nemeş, N.S.; Negrea, A.; Ciopec, M.; Duteanu, N.; Negrea, P.; Duda-Seiman, D.; Muntean, D. Antimicrobial Activities of Chitosan Derivatives. Pharmaceutics 2021, 13, 1639. [Google Scholar] [CrossRef]

- Cortina, J.L.; Miralles, N.; Sastre, A.; Aguilar, M.; Profumo, A.; Pesavento, M. Solvent-impregnated resins containing di-(2,4,4-trimethylpentyl) phosphonic acid I. Comparative study of di-(2,4,4-trimethylpentyl)phosphinic acid adsorbed into Amberlite XAD-2 and dissolved in toluene. React. Polym. 1993, 21, 89–101. [Google Scholar] [CrossRef]

- Cortina, J.L.; Miralles, N.; Sastre, A.M.; Aguilar, M.; Profumo, A.; Pesavento, M. Solvent-impregnated resins containing di-(2,4,4-trimethylpentyl) phosphinic acid II. Study of the distribution equilibria of Zn(II), Cu(II) and Cd(II). React. Polym. 1993, 21, 103–116. [Google Scholar] [CrossRef]

- Cortina, J.L.; Miralles, N.; Aguilar, M.; Sastre, M. Solvent impregnated resins containing di(2-ethylhexyl)phosphoric acid. I. Preparation and study of the retention and distribution of the extractant on the resin. Solvent Extr. Ion Exch. 1994, 12, 349–369. [Google Scholar] [CrossRef]

- Warshawsky, A. Extraction with Solvent-Impregnated Resins. In Ion Exchange and Solvent Extraction; Marinsky, J.A., Marcus, Y., Eds.; Marcel Dekker: New York, NY, USA, 1981; Volume 8, pp. 229–310. [Google Scholar]

- Csóka, L.; Božanić, D.K.; Božanić, D.K.; Nagy, V.; Dimitrijević-Branković, S.; Luyt, A.S.; Grozdits, G.; Djoković, V. Viscoelastic properties and antimicrobial activity of cellulose fiber sheets impregnated with Ag nanoparticles. Carbohydr. Polym. 2012, 90, 1139–1146. [Google Scholar] [CrossRef]

- Luan, F.; Wei, L.; Zhang, J.; Mi, Y.; Dong, F.; Li, Q.; Guo, Z. Antioxidant Activity and Antifungal Activity of Chitosan Derivatives with Propane Sulfonate Groups. Polymers 2018, 10, 395. [Google Scholar] [CrossRef] [Green Version]

- Belbekhouche, S.; Bousserrhine, N.; Alphonse, V.; Le Floch, F.; Mechiche, Y.C.; Menidjel, I.; Carbonnier, B. Chitosan based self-assembled nanocapsules as antibacterial agent. Colloids Surf. B Biointerfaces 2019, 181, 158–165. [Google Scholar] [CrossRef] [PubMed]

- Syamani, F.A.; Suryani, A. Changes in Oil Palm Frond Fiber Morphology, Cellulose Crystallinity and Chemical Functional Groups during Cellulose Extraction Phases. Chem. Mater. Res. 2015, 7, 113–121. [Google Scholar]

- Nazir, F.; Iqbal, M. Synthesis, Characterization and Cytotoxicity Studies of Aminated Microcrystalline Cellulose Derivatives against Melanoma and Breast Cancer Cell Lines. Polymers 2020, 12, 2634. [Google Scholar] [CrossRef] [PubMed]

- Tarchoun, A.F.; Trache, D.; Klapötke, T.M.; Derradji, M.; Bessa, W. Ecofriendly isolation and characterization of microcrystalline cellulose from giant reed using various acidic media. Cellulose 2019, 26, 7635–7651. [Google Scholar] [CrossRef]

- Negrea, A.; Gabor, A.; Davidescu, C.M.; Ciopec, M.; Negrea, P.; Duteanu, N.; Barbulescu, A. Rare Earth Elements Removal from Water Using Natural Polymers. Sci. Rep. 2018, 8, 316. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hospodarova, V.; Singovszka, E.; Stevulova, N. Characterization of Cellulosic Fibers by FTIR Spectroscopy for Their Further Implementation to Building Materials. Am. J. Anal. Chem. 2018, 09, 303–310. [Google Scholar] [CrossRef] [Green Version]

- Brown, L.; Wolf, J.M.; Prados-Rosales, R.; Casadevall, A. Through the wall: Extracellular vesicles in Gram-positive bacteria, mycobacteria and fungi. Nat. Rev. Microbiol. 2015, 13, 620–630. [Google Scholar] [CrossRef] [Green Version]

- Carolus, H.; Van Dyck, K.; Van Dijck, P. Candida albicans and Staphylococcus Species: A Threatening Twosome. Front. Microbiol. 2019, 10, 2162. [Google Scholar] [CrossRef]

- Kumariya, R.; Sood, S.K.; Rajput, Y.S.; Saini, N.; Garsa, A.K. Increased membrane surface positive charge and altered membrane fluidity leads to cationic antimicrobial peptide resistance in Enterococcus faecalis. Biochim. Biophys. Acta (BBA)—Biomembr. 2015, 1848, 1367–1375. [Google Scholar] [CrossRef] [Green Version]

- Russell, A.D. Similarities and differences in the responses of microorganisms to biocides. J. Antimicrob. Chemother. 2003, 52, 750–763. [Google Scholar] [CrossRef] [Green Version]

- Krasowska, A.; Sigler, K. How microorganisms use hydrophobicity and what does this mean for human needs? Front. Cell. Infect. Microbiol. 2014, 4, 112. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Palmer, J.; Flint, S.; Brooks, J. Bacterial cell attachment, the beginning of a biofilm. J. Ind. Microbiol. Biotechnol. 2007, 34, 577–588. [Google Scholar] [CrossRef] [PubMed]

- Bassetti, M.; Baguneid, M.; Bouza, E.; Dryden, M.; Nathwani, D.; Wilcox, M. European perspective and update on the management of complicated skin and soft tissue infections due to methicillin-resistant Staphylococcus aureus after more than 10 years of experience with linezolid. Clin. Microbiol. Infect. Off. Publ. Eur. Soc. Clin. Microbiol. Infect. Dis. 2014, 20 (Suppl. S4), 3–18. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ciofu, O.; Tolker-Nielsen, T. Tolerance and Resistance of Pseudomonas aeruginosa Biofilms to Antimicrobial Agents-How P. aeruginosa Can Escape Antibiotics. Front. Microbiol. 2019, 10, 913. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Koshani, R.; Tavakolian, M.; van de Ven, T.G.M. Cellulose-based dispersants and flocculants. J. Mater. Chem. B 2020, 8, 10502–10526. [Google Scholar] [CrossRef] [PubMed]

- Song, Y.; Zhang, J.; Gan, W.; Zhou, J.; Zhang, L. Flocculation Properties and Antimicrobial Activities of Quaternized Celluloses Synthesized in NaOH/Urea Aqueous Solution. Ind. Eng. Chem. Res. 2010, 49, 1242–1246. [Google Scholar] [CrossRef]

- Thewes, N.; Loskill, P.; Jung, P.; Peisker, H.; Bischoff, M.; Herrmann, M.; Jacobs, K. Hydrophobic interaction governs unspecific adhesion of staphylococci: A single cell force spectroscopy study. Beilstein J. Nanotechnol. 2014, 5, 1501–1512. [Google Scholar] [CrossRef] [Green Version]

- Chen, C.; Petterson, T.; Illergård, J.; Ek, M.; Wågberg, L. Influence of Cellulose Charge on Bacteria Adhesion and Viability to PVAm/CNF/PVAm-Modified Cellulose Model Surfaces. Biomacromolecules 2019, 20, 2075–2083. [Google Scholar] [CrossRef]

- Andresen, M.; Stenstad, P.; Møretrø, T.; Langsrud, S.; Syverud, K.; Johansson, L.S.; Stenius, P. Nonleaching antimicrobial films prepared from surface-modified microfibrillated cellulose. Biomacromolecules 2007, 8, 2149–2155. [Google Scholar] [CrossRef]

| Group | FT-IR Bands (cm−1) | Observations |

|---|---|---|

| Cellulose (Cel) | ||

| O-H C-H CH2 C-O O-C-O OH2 | 3660 2893  | Large band Small plateau; stretching vibrations in polysaccharides Vibrations specific to the crystalline structure of cellulose Amorphous region in cellulose Water molecules vibrations |

| Cel-DDTMABr | ||

| >N-CH2 | 2700–2800 | specific link e− nonparticipants from N |

| Cel-TDTMABr | ||

| >N-CH2 | 2700–2800 | specific link e− nonparticipants from N |

| Cel-HDTMACl | ||

| >N-CH2 | 2700–2800 | specific link e− nonparticipants from N |

| Cel-DDTPPBr | ||

| P-O-Aril C-O (fenil) O-H | 1190–1240 1200 3500–3200 | |

| Cel-HDTBPBr | ||

| P-O-Alchil | 1150–1180; 1080 | |

| Cel-MBT | ||

| S-C-S C-N C-H; N-H | 568–600 1030–1074 1250–1320 750 | Aromatic ring -torsion Stretching vibration |

| Cel-THIO | ||

| -NH2 N-H C=S | 3395  | Asymmetric vibration; symmetric vibration Elongation vibration Vibrations strongly influenced by intramolecular effects |

| Material | Cel:Extractant Ratio | Inhibition Rate (%) | OBSERVATIONS | |||

|---|---|---|---|---|---|---|

| Staphylococcus aureus ATCC 25923 | Pseudomonas aeruginosa ATCC 27853 | Escherichia coli ATCC 25922 | Candida albicans ATCC 10231 | |||

| Cellulose (Cel) | - | 2.8 | 7.7 | 20 | 12.2 | Slightly better bactericidal effect on Gram-negative bacteria and C. albicans strain |

| Cel:DDTMABr | 1:0.012 | 100.0 | 40.8 | 100.0 | 100.0 | Maximum bactericidal effect on Gram-positive bacteria and C. albicans strain |

| 1:0.1 | 100.0 | 52.8 | 100.0 | 100.0 | ||

| Cel:TDTMABr | 1:0.012 | 100.0 | 49.9 | 100.0 | 100.0 | |

| 1:0.1 | 100.0 | 54.8 | 100.0 | 100.0 | ||

| Cel:HDTMACl | 1:0.012 | 100.0 | 17.0 | 53.4 | 100.0 | |

| 1:0.05 | 100.0 | 34.3 | 58.1 | 100.0 | ||

| 1:0.1 | 100.0 | 40.8 | 67.5 | 100.0 | ||

| Material | Cel:Extractant Ratio | Inhibition Rate (%) | |||

|---|---|---|---|---|---|

| Staphylococcus aureus ATCC 25923 | Pseudomonas aeruginosa ATCC 27853 | Escherichia coli ATCC 25922 | Candida albicans ATCC 10231 | ||

| Cel:DDTPPBr | 1:0.012 | 100.0 | 32.0 | 100.0 | 100.0 |

| 1:0.1 | 100.0 | 39.8 | 100.0 | 100.0 | |

| Cel:HDTPPBr | 1:0.012 | 30.7 | 8.4 | 42.7 | 65.3 |

| 1:0.05 | 58.7 | 20.7 | 44.9 | 67.0 | |

| 1:0.1 | 69.7 | 21.6 | 52.6 | 77.9 | |

| 1:0.3 | 100.0 | 26.6 | 87.3 | 100.0 | |

| 1:0.5 | 100.0 | 42.6 | 89.1 | 100.0 | |

| Material | Cel:Extractant Ratio | Inhibition Rate (%) | |||

|---|---|---|---|---|---|

| Staphylococcus aureus ATCC 25923 | Pseudomonas aeruginosa ATCC 27853 | Escherichia coli ATCC 25922 | Candida albicans ATCC 10231 | ||

| Cel:MBT | 1:0.012 | 25.6 | 10.0 | 20.5 | 54.0 |

| 1:0.05 | 62.9 | 13.7 | 22.1 | 63.2 | |

| 1:0.1 | 100.0 | 19.5 | 50.4 | 100.0 | |

| 1:0.3 | 100.0 | 36.2 | 65.4 | 100.0 | |

| 1:0.5 | 100.0 | 41.0 | 100.0 | 100.0 | |

| Cel:THIO | 1:0.012 | 20.7 | 12.9 | 28.9 | 52.5 |

| 1:0.05 | 27.7 | 20.7 | 49.6 | 55.8 | |

| 1:0.1 | 39.3 | 39.6 | 51.0 | 54.5 | |

| 1:0.3 | 75.3 | 44.5 | 52.4 | 60.1 | |

| 1:0.5 | 76.0 | 45.1 | 55.5 | 60.9 | |

| Material | Antimicrobial Effect (Inhibition Rate %) upon Microbial Strain | References |

|---|---|---|

| Cellulose with octadecyldimethyl(3-trimethoxysilylpropyl) ammonium chloride | 96–99% on E. coli >99% on S. aureus | [63] |

| Silver–cellulose fiber sheets | 91.58–99.46% on S. aureus 93.6–99.78% on E. coli 97.5–100% on C. albicans | [43] |

| Propane sulfonated chitosan | 78.8% on Phomopsis asparagi 80.2% on Fusarium oxysporum | [44] |

| Dipropane sulfonated chitosan | 82.2% on Phomopsis asparagi 94% on Fusarium oxysporum | [44] |

| Gold nanoparticles | 5.4–20.0% on E. coli 4.6–16.3% on S. aureus | [45] |

| Gold nanocapsules | 23.7–40.0% on E. coli 18.6–34.9% on S. aureus | [45] |

| Chitosan derivatives based upon quaternary ammonium salt | 100% on S. aureus * 13.1–60.3% on P. aeruginosa * 25.8–100.0% on E. coli * 76.0–100.0% on C. parapsilosis * | [38] |

| Chitosan derivatives based upon phosphonium salt | 100% on S. aureus * 28.2–48.6% on P. aeruginosa * 20.2–100.0 on E. coli * 100.0% on C. parapsilosis * | [38] |

| Chitosan derivatives based upon sulfur compound | 38.6–100% on S. aureus * 22.8–46.7% on P. aeruginosa * 25.8–72.3% on E. coli * 80.6–100.0% on C. parapsilosis * | [38] |

| Cellulose derivatives based upon quaternary ammonium salt | 100.0% on S. aureus * 17.0–54.8% on P. aeruginosa * 53.4–100.0% on E. coli * 100% on C. albicans * | present study |

| Cellulose derivatives based upon phosphonium salt | 30.7–100.0% on S. aureus * 8.4–42.6% on P. aeruginosa * 42.7–100.0% on E. coli * 65.3–100.0% on C. albicans * | present study |

| Cellulose derivatives based upon sulfur compound | 20.7–100.0% on S. aureus * 10.0–45.1% on P. aeruginosa * 20.5–100.0% on E. coli * 52.5–100.0% on C. albicans * | present study |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nemeş, N.S.; Ardean, C.; Davidescu, C.M.; Negrea, A.; Ciopec, M.; Duţeanu, N.; Negrea, P.; Paul, C.; Duda-Seiman, D.; Muntean, D. Antimicrobial Activity of Cellulose Based Materials. Polymers 2022, 14, 735. https://doi.org/10.3390/polym14040735

Nemeş NS, Ardean C, Davidescu CM, Negrea A, Ciopec M, Duţeanu N, Negrea P, Paul C, Duda-Seiman D, Muntean D. Antimicrobial Activity of Cellulose Based Materials. Polymers. 2022; 14(4):735. https://doi.org/10.3390/polym14040735

Chicago/Turabian StyleNemeş, Nicoleta Sorina, Cristina Ardean, Corneliu Mircea Davidescu, Adina Negrea, Mihaela Ciopec, Narcis Duţeanu, Petru Negrea, Cristina Paul, Daniel Duda-Seiman, and Delia Muntean. 2022. "Antimicrobial Activity of Cellulose Based Materials" Polymers 14, no. 4: 735. https://doi.org/10.3390/polym14040735

APA StyleNemeş, N. S., Ardean, C., Davidescu, C. M., Negrea, A., Ciopec, M., Duţeanu, N., Negrea, P., Paul, C., Duda-Seiman, D., & Muntean, D. (2022). Antimicrobial Activity of Cellulose Based Materials. Polymers, 14(4), 735. https://doi.org/10.3390/polym14040735