New Synthesis Routes toward Improvement of Natural Filler/Synthetic Polymer Interfacial Crosslinking

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Chemicals and Modifiers

2.1.2. Filler and Polymer

2.2. Chemical Functionalization

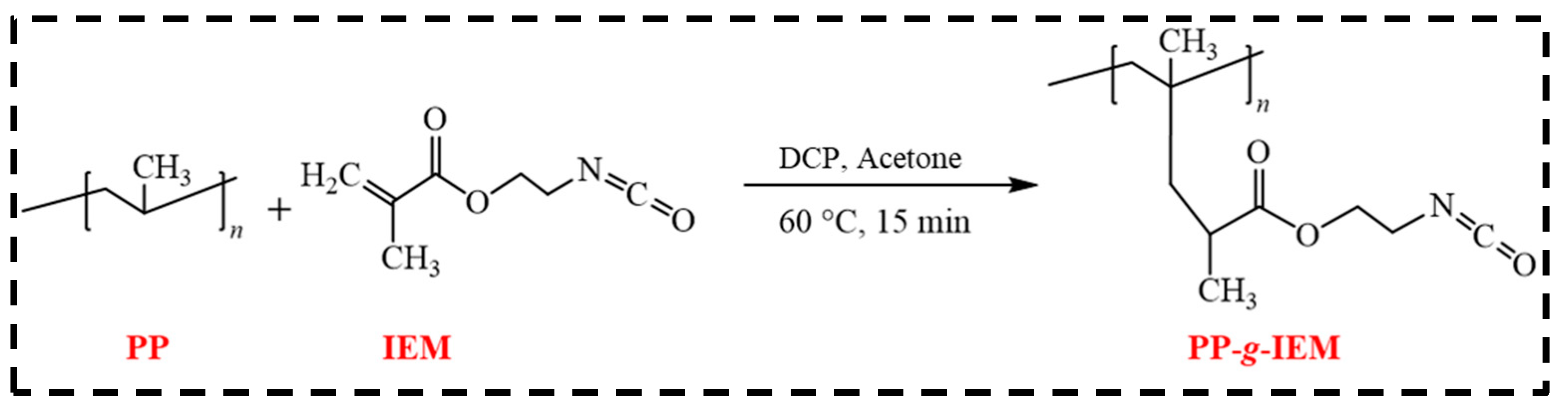

2.2.1. PP-g-IEM

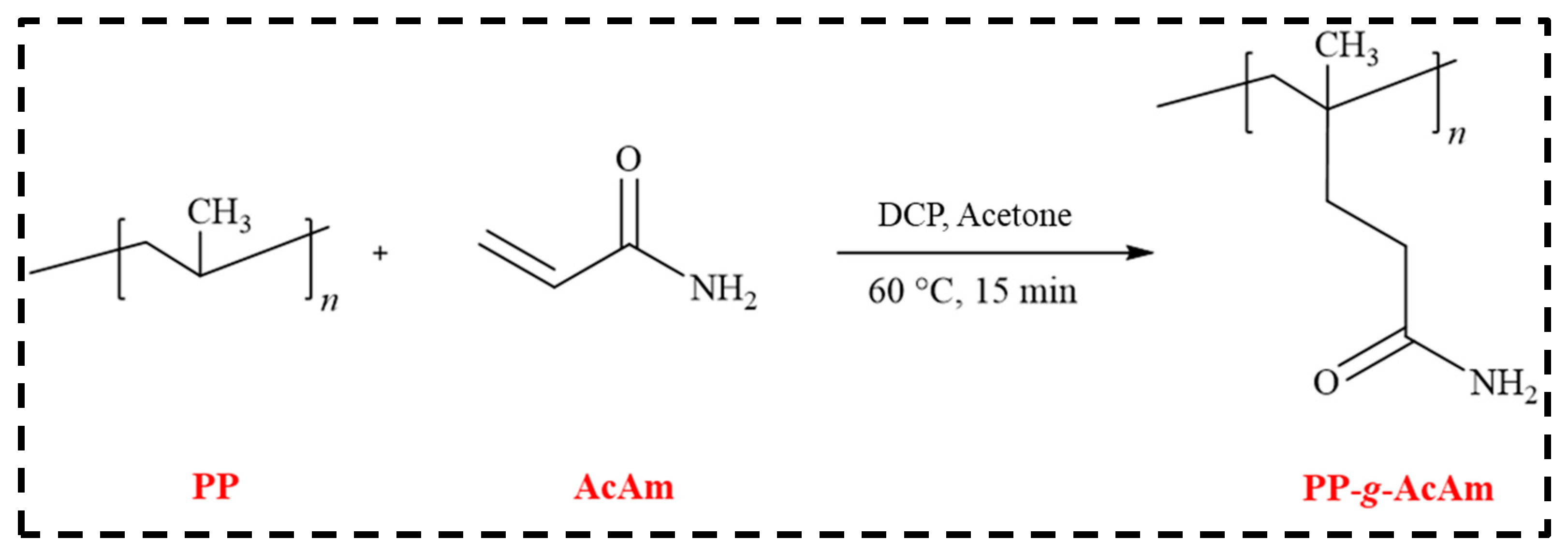

2.2.2. PP-g-AcAm

2.2.3. (DPP-T)-g-TsCl

2.3. Bio-Composite Fabrication

2.4. Bio-Composite Characterization

3. Results and Discussion

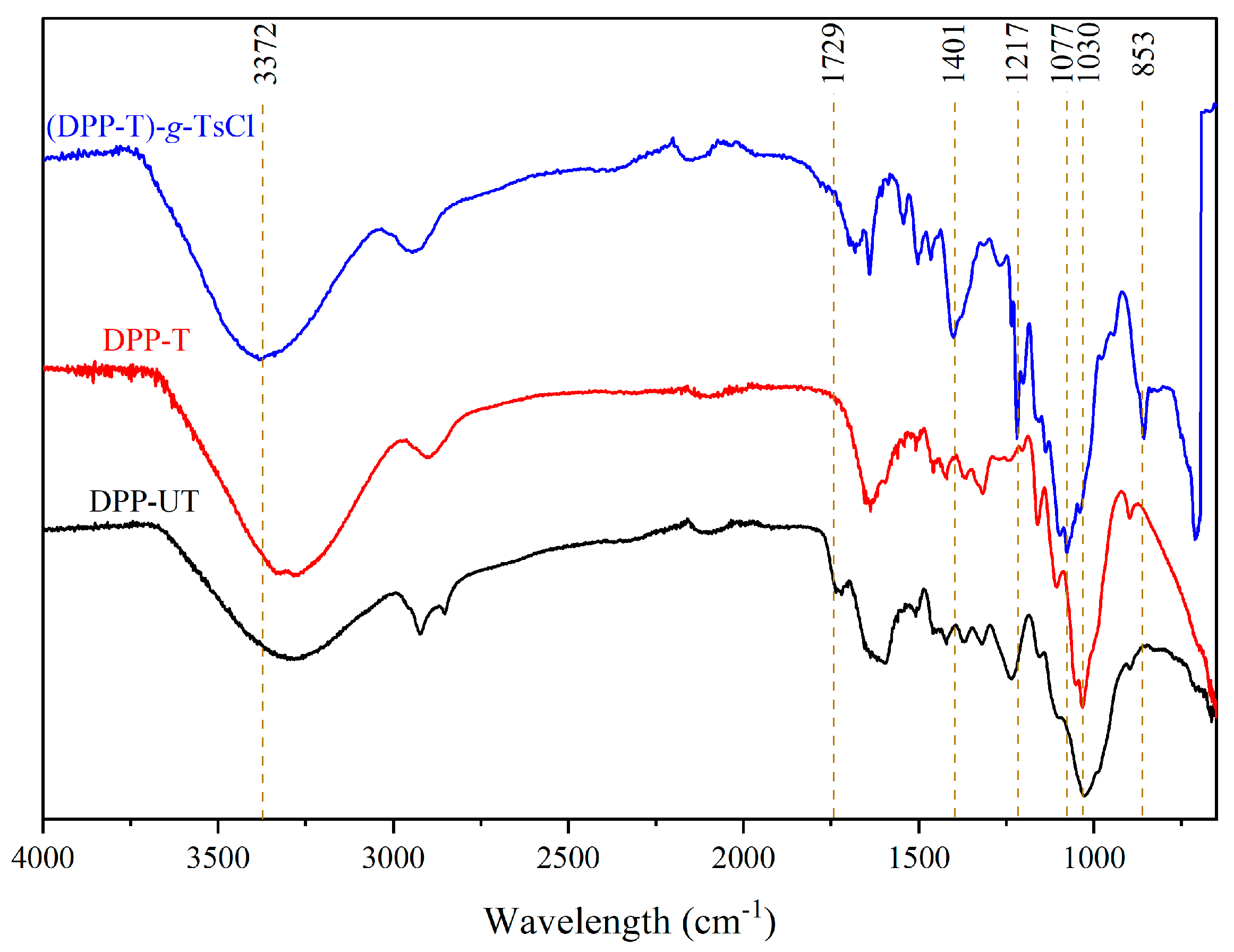

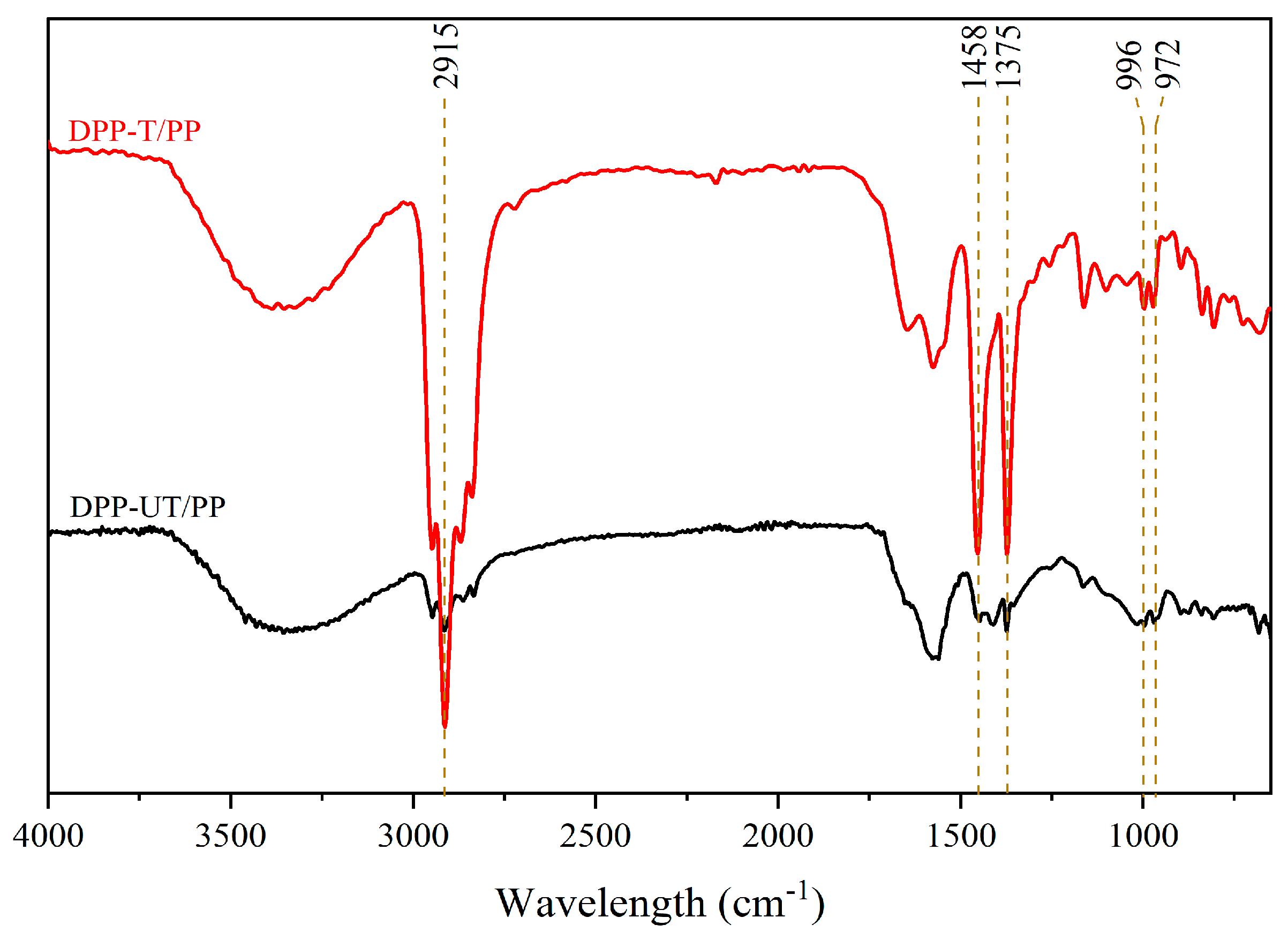

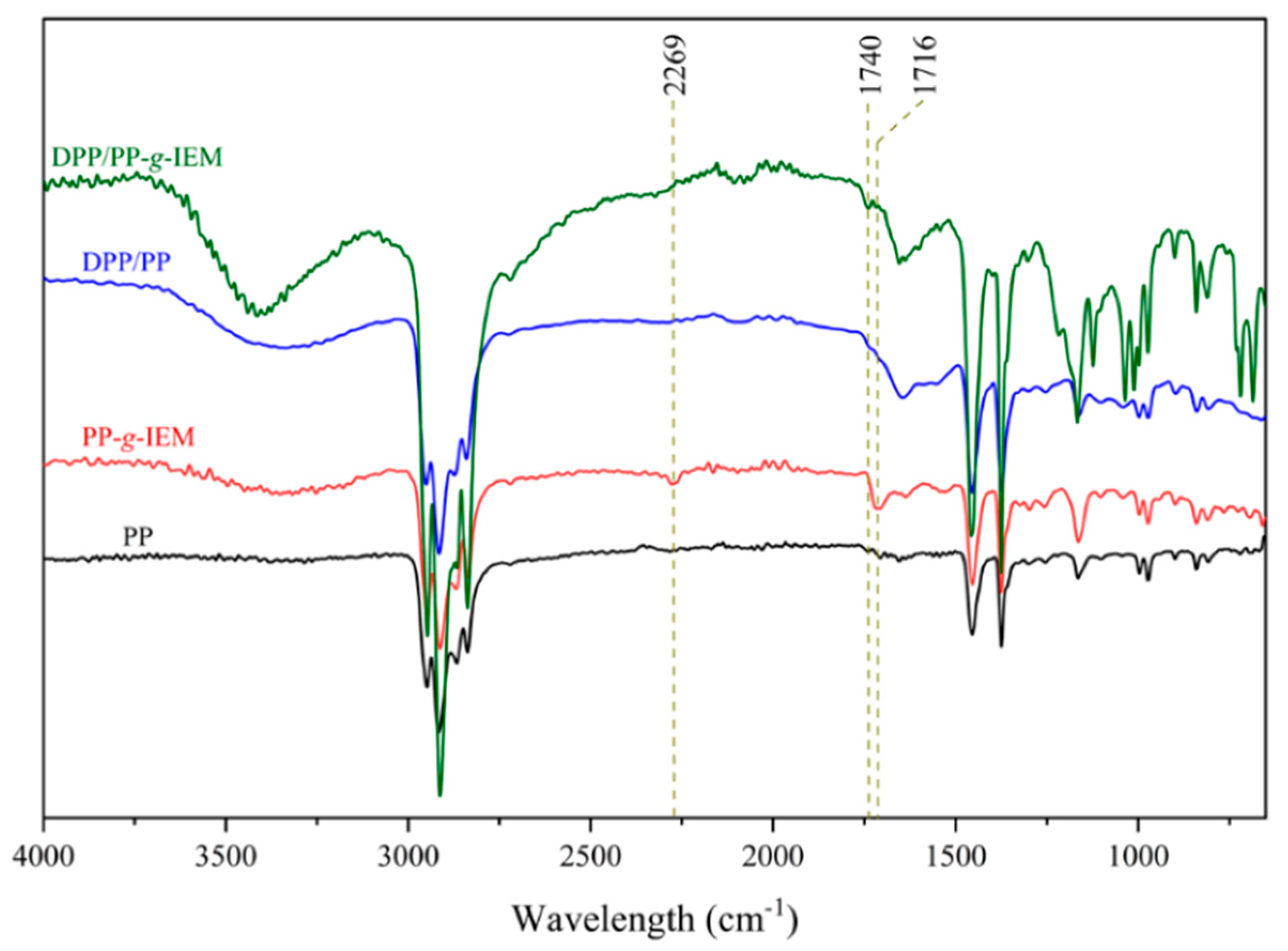

3.1. Chemical Characteristics

3.2. Morphology

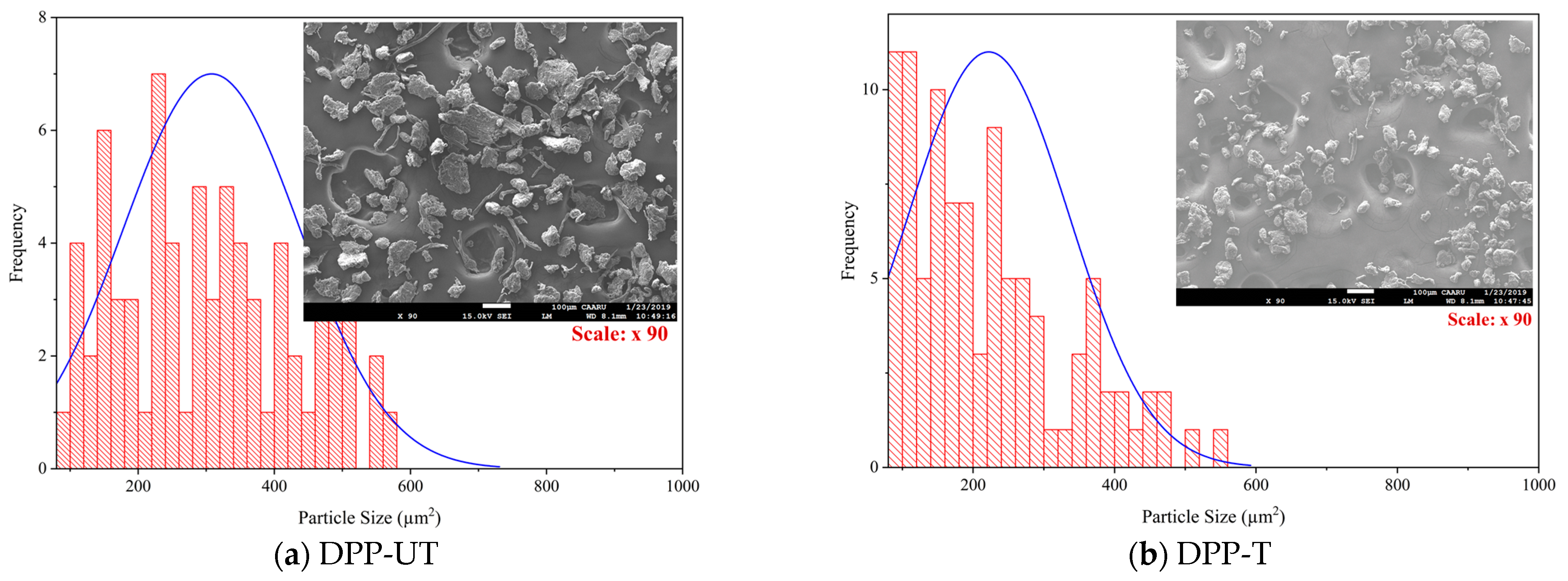

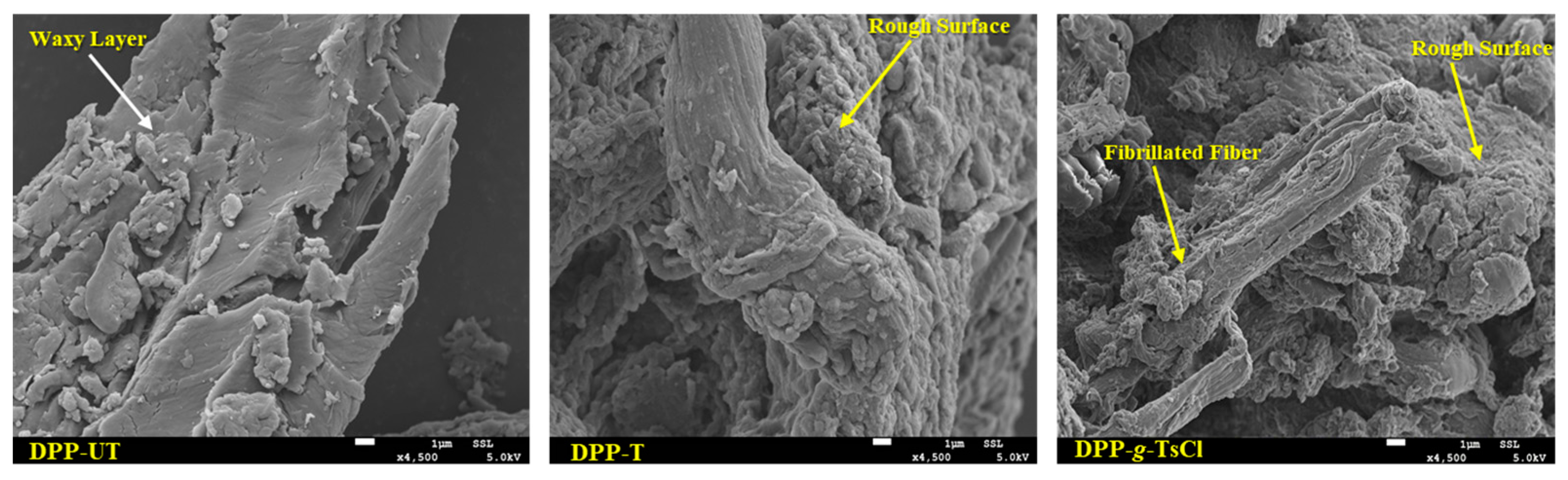

3.2.1. Filler Surface

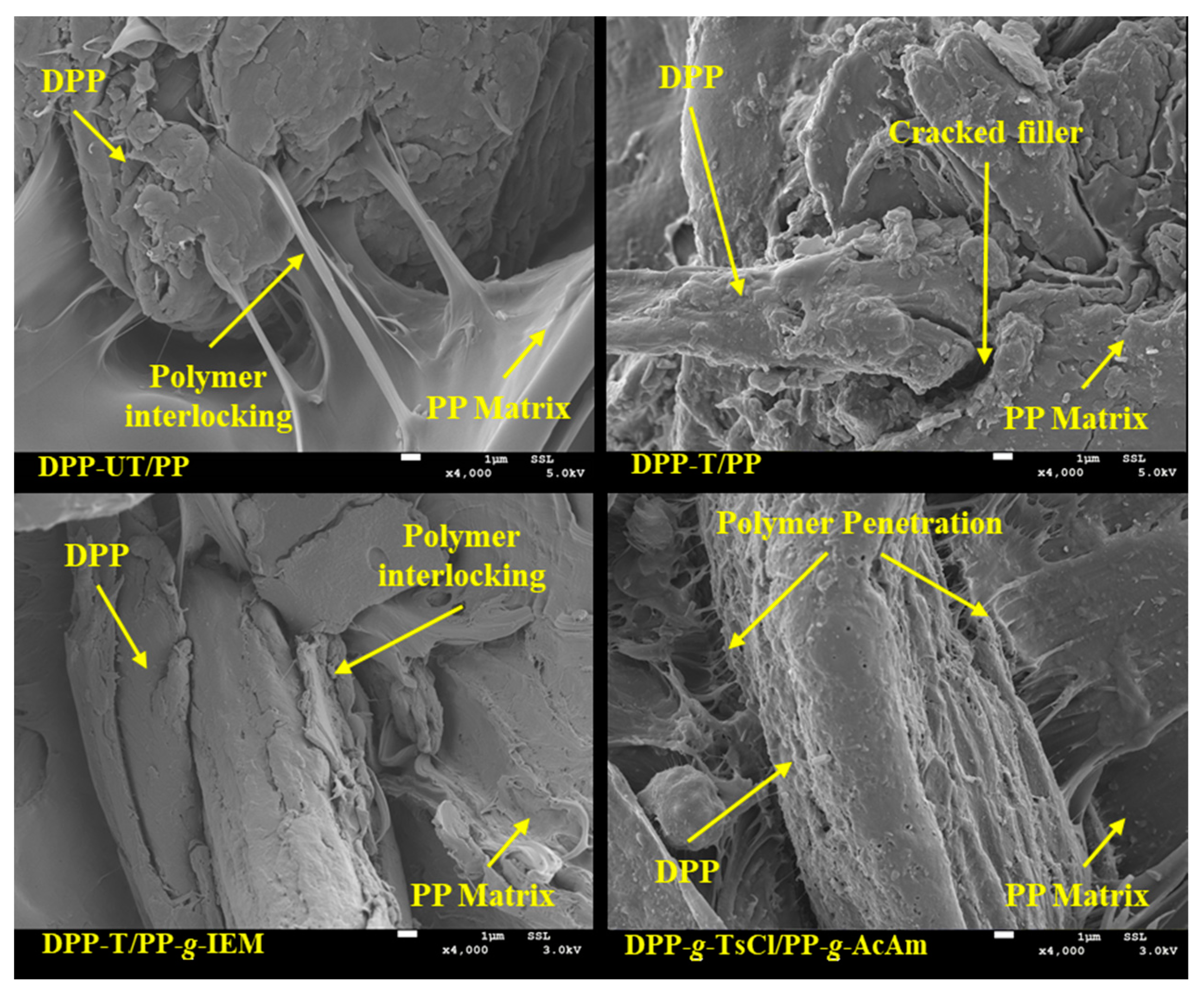

3.2.2. Fractography

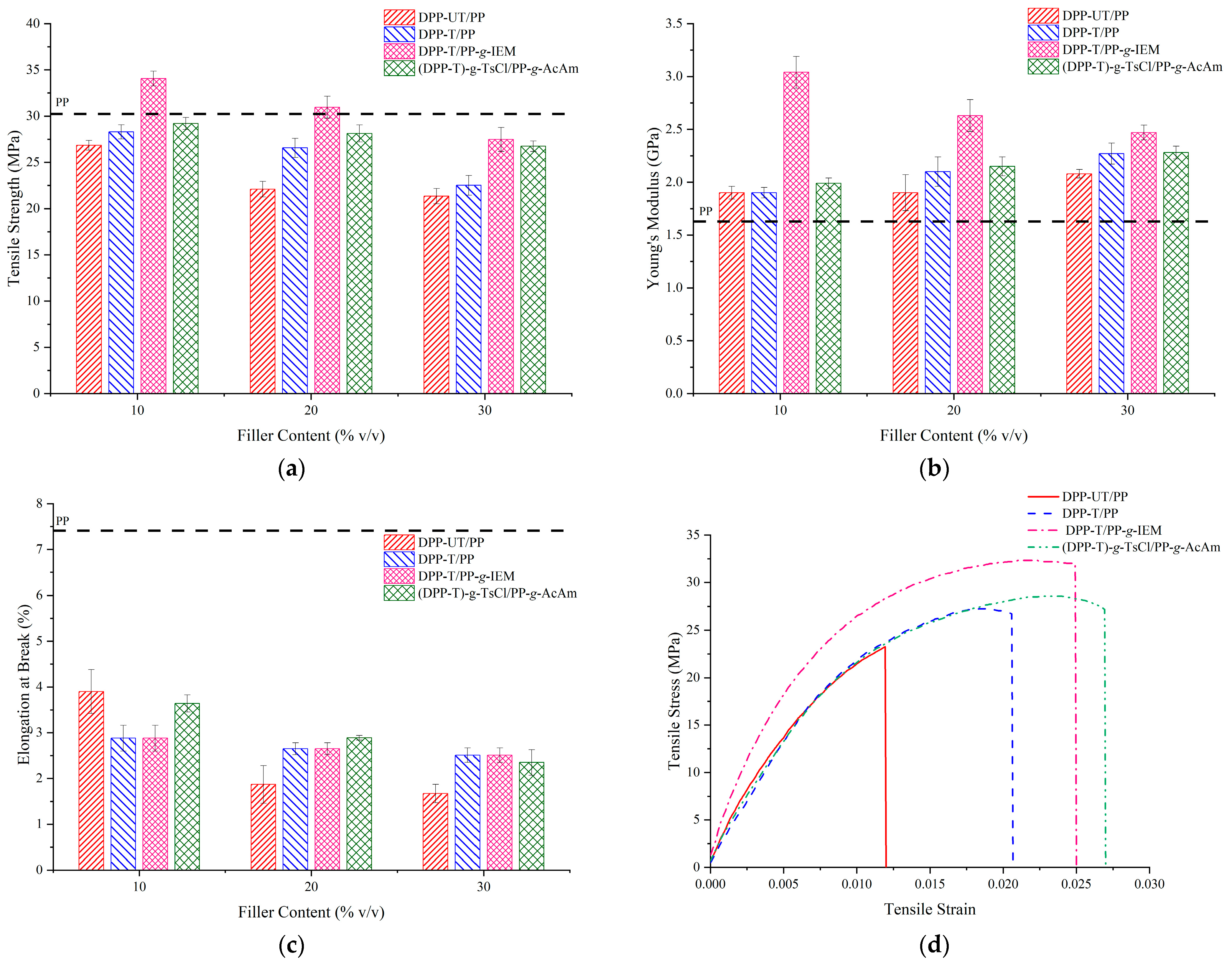

3.3. Mechanical Properties

3.3.1. Tensile Strength

3.3.2. Flexural Strength

3.4. Physical Properties

3.4.1. Density

3.4.2. Water Absorption

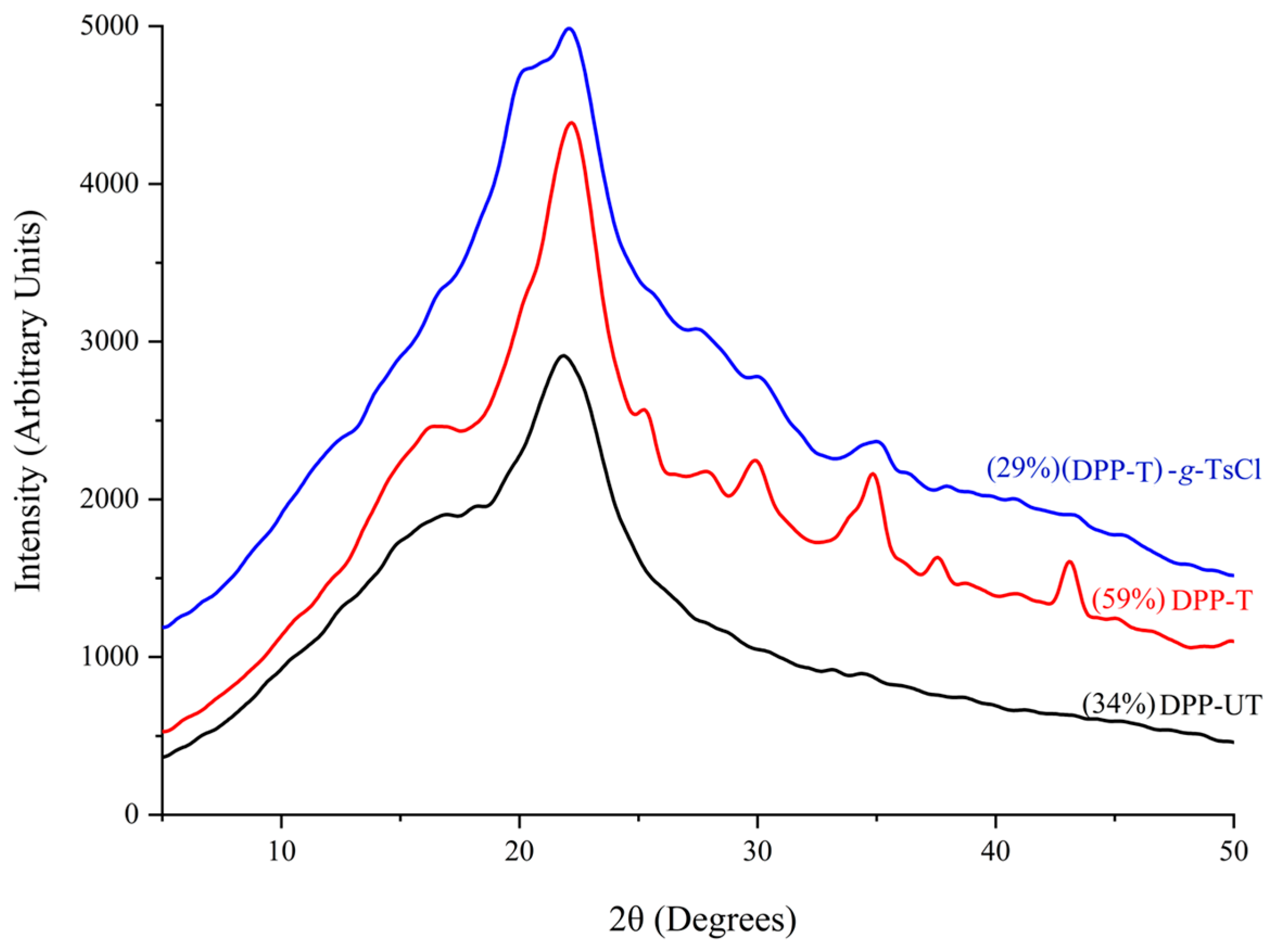

3.4.3. XRD

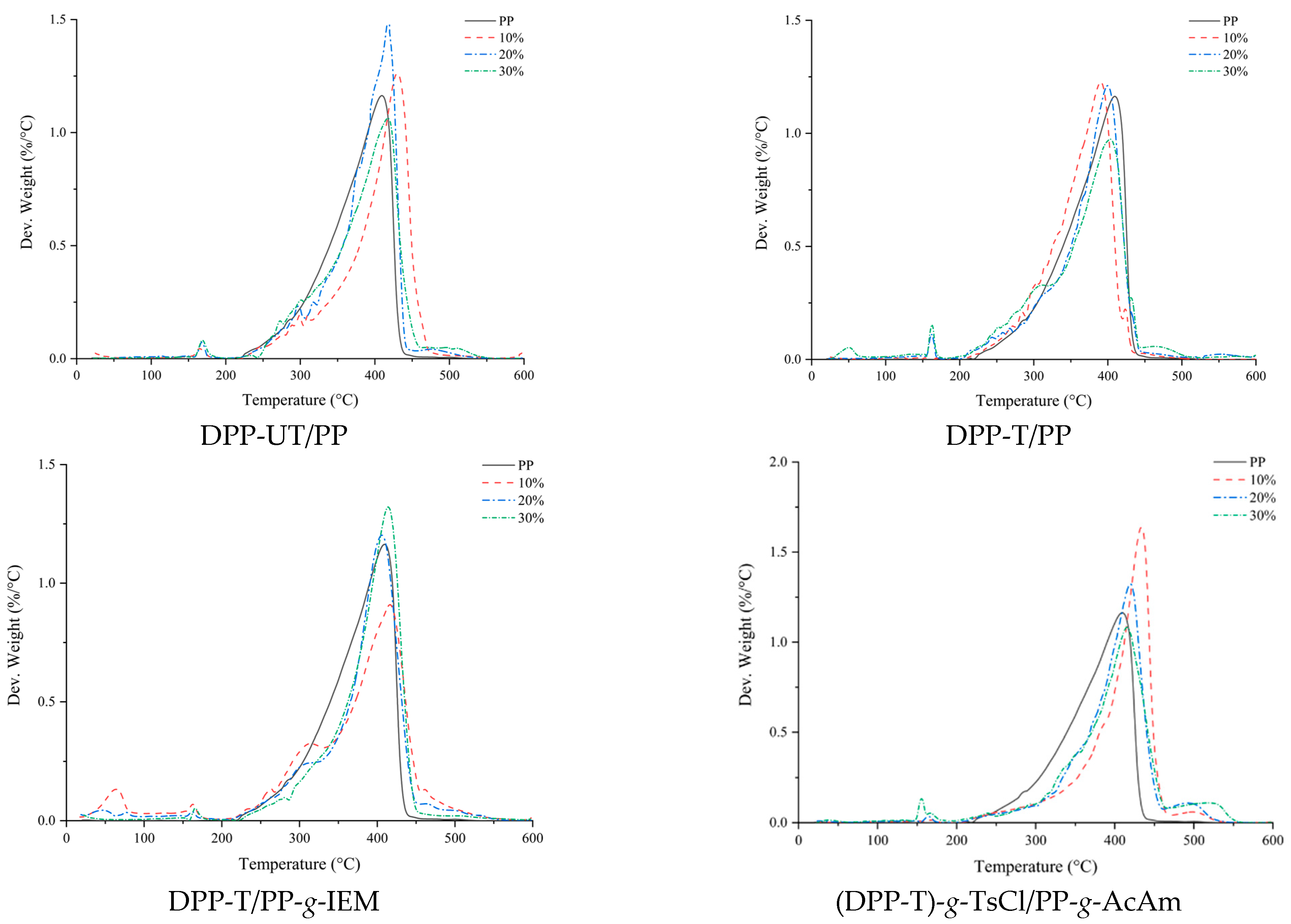

3.5. Thermal Degradation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Khalid, M.Y.; Al Rashid, A.; Arif, Z.U.; Ahmed, W.; Arshad, H.; Zaidi, A.A. Natural Fiber Reinforced Composites: Sustainable Materials for Emerging Applications. Results Eng. 2021, 11, 100263. [Google Scholar] [CrossRef]

- Sadik, T.; Muthuraman, S.; Sivaraj, M.; Negash, K.; Balamurugan, R.; Bakthavatsalam, S. Mechanical Behavior of Polymer Composites Reinforced with Coir and Date Palm Frond Fibers. Adv. Mater. Sci. Eng. 2022, 2022, 9882769. [Google Scholar] [CrossRef]

- Barton-Pudlik, J.; Czaja, K. Fast-Growing Willow (Salix Viminalis) As A Filler in Polyethylene Composites. Compos. Part B Eng. 2018, 143, 68–74. [Google Scholar] [CrossRef]

- Saba, N.; Jawaid, M. A Review on Thermomechanical Properties of Polymers and Fibers Reinforced Polymer Composites. J. Ind. Eng. Chem. 2018, 67, 1–11. [Google Scholar] [CrossRef]

- Alzebdeh, K.I.; Nassar, M.M.A.; Al-Hadhrami, M.A.; Al-Aamri, O.; Al-Defaai, S.; Al-Shuaily, S. Characterization of Mechanical Properties of Aligned Date Palm Frond Fiber-Reinforced Low-Density Polyethylene. J. Eng. Res. 2017, 14, 115–123. [Google Scholar] [CrossRef] [Green Version]

- Ashori, A.; Nourbakhsh, A. Reinforced Polypropylene Composites: Effects of Chemical Compositions and Particle Size. Bioresour. Technol. 2010, 101, 2515–2519. [Google Scholar] [CrossRef]

- Nassar, M.M.A.; Alzebdeh, K.I.; Pervez, T.; Al-Hinai, N.; Munam, A. Progress and Challenges in Sustainability, Compatibility, and Production of Eco-Composites: A State-Of-Art Review. J. Appl. Polym. Sci. 2021, 138, 51284. [Google Scholar] [CrossRef]

- Fiore, V.; Badagliacco, D.; Sanfilippo, C.; Miranda, R.; Valenza, A. An Innovative Treatment Based on Sodium Citrate for Improving the Mechanical Performances of Flax Fiber Reinforced Composites. Polymers 2021, 13, 559. [Google Scholar] [CrossRef]

- Keskisaari, A.; Kärki, T. The Use of Waste Materials in Wood-Plastic Composites and their Impact on the Profitability of the Product. Resour. Conserv. Recycl. 2018, 134, 257–261. [Google Scholar] [CrossRef]

- Yang, G.; Park, M.; Park, S.J. Recent Progresses of Fabrication and Characterization of Fibers-Reinforced Composites: A Review. Compos. Commun. 2019, 14, 34–42. [Google Scholar] [CrossRef]

- Lassoued, M.; Mnasri, T.; Hidouri, A.; Ben Younes, R. Thermomechanical Behavior of Tunisian Palm Fibers Before and After Alkalization. Constr. Build. Mater. 2018, 170, 121–128. [Google Scholar] [CrossRef]

- Zegaoui, A.; Derradji, M.; Ma, R.; Cai, W.A.; Liu, W.-B.; Wang, J.; Dayo, A.Q.; Song, S.; Zhang, L.L. High-Performance Polymeric Materials with Greatly Improved Mechanical and Thermal Properties from Cyanate Ester/Benzoxazine Resin Reinforced by Silane-Treated Basalt Fibers. J. Appl. Polym. Sci. 2018, 135, 46283. [Google Scholar] [CrossRef]

- Balla, V.K.; Kate, K.H.; Satyavolu, J.; Singh, P.; Tadimeti, J.G.D. Additive Manufacturing of Natural Fiber Reinforced Polymer Composites: Processing and Prospects. Compos. Part B Eng. 2019, 174, 106956. [Google Scholar] [CrossRef]

- Khieng, T.K.; Debnath, S.; Ting Chaw Liang, E.; Anwar, M.; Pramanik, A.; Basak, A.K. A Review on Mechanical Properties of Natural Fibre Reinforced Polymer Composites Under Various Strain Rates. J. Compos. Sci. 2021, 5, 130. [Google Scholar] [CrossRef]

- Carbonell-Verdú, A.; García-García, D.; Jordá, A.; Samper, M.D.; Balart, R. Development of Slate Fiber Reinforced High Density Polyethylene Composites for Injection Molding. Compos. Part B Eng. 2015, 69, 460–466. [Google Scholar] [CrossRef]

- Alzebdeh, K.I.; Nassar, M.M.A. Polymer Blend Natural Fiber Based Composites. In Fiber Reinforced Composites Constituents, Compatibility, Perspectives, and Applications; Woodhead Publishing Series in Composites Science and Engineering: Sawston, UK, 2021; pp. 214–238. ISBN 9780128210901. [Google Scholar]

- Liao, J.; Brosse, N.; Pizzi, A.; Hoppe, S.; Xi, X.; Zhou, X. Polypropylene Blend with Polyphenols through Dynamic Vulcanization: Mechanical, Rheological, Crystalline, Thermal, and UV Protective Property. Polymers 2019, 11, 1108. [Google Scholar] [CrossRef] [Green Version]

- Sider, I.; Nassar, M.M.A. Chemical Treatment of Bio-Derived Industrial Waste Filled Recycled Low-Density Polyethylene: A Comparative Evaluation. Polymers 2021, 13, 2682. [Google Scholar] [CrossRef]

- Zhang, H. Effect of A Novel Coupling Agent, Alkyl Ketene Dimer, on the Mechanical Properties of Wood-Plastic Composites. Mater. Des. 2014, 59, 130–134. [Google Scholar] [CrossRef]

- Panaitescu, D.M.; Nicolae, C.A.; Vuluga, Z.; Vitelaru, C.; Sanporean, C.G.; Zaharia, C.; Florea, D.; Vasilievici, G. Influence of Hemp Fibers with Modified Surface on Polypropylene Composites. J. Ind. Eng. Chem. 2016, 37, 137–146. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Asyraf, M.R.M.; Rayung, M.; Norrrahim, M.N.F.; Shazleen, S.S.; Rani, M.S.A.; Shafi, A.R.; Aisyah, H.A.; Radzi, M.H.M.; Sabaruddin, F.A.; et al. Thermogravimetric Analysis Properties of Cellulosic Natural Fiber Polymer Composites: A Review on Influence of Chemical Treatments. Polymers 2021, 13, 2710. [Google Scholar] [CrossRef]

- Mulenga, T.K.; Ude, A.U.; Vivekanandhan, C. Techniques for Modelling and Optimizing the Mechanical Properties of Natural Fiber Composites: A Review. Fibers 2021, 9, 6. [Google Scholar] [CrossRef]

- Li, M.; Pu, Y.; Thomas, V.M.; Yoo, C.G.; Ozcan, S.; Deng, Y.; Nelson, K.; Ragauskas, A.J. Recent Advancements of Plant-Based Natural Fiber–Reinforced Composites and their Applications. Compos. Part B Eng. 2020, 200, 108254. [Google Scholar] [CrossRef]

- Guo, C.G.; Wang, Q.W. Influence of m-Isopropenyl-α, α-Dimethylbenzyl Isocyanate Grafted Polypropylene on The Interfacial Interaction of Wood-Flour/Polypropylene Composites. J. Appl. Polym. Sci. 2008, 109, 3080–3086. [Google Scholar] [CrossRef]

- Oladele, I.O.; Ibrahim, I.O.; Akinwekomi, A.D.; Talabi, S.I. Effect of Mercerization on the Mechanical and Thermal Response of Hybrid Bagasse Fiber/CaCO3 Reinforced Polypropylene Composites. Polym. Test. 2019, 76, 192–198. [Google Scholar] [CrossRef]

- Aggarwal, P.K.; Raghu, N.; Karmarkar, A.; Chuahan, S. Jute-Polypropylene Composites Using m-TMI-Grafted-Polypropylene as A Coupling Agent. Mater. Des. 2013, 43, 112–117. [Google Scholar] [CrossRef]

- Sohail, M.; Ashfaq, B.; Azeem, I.; Faisal, A.; Doğan, S.Y.; Wang, J.; Duran, H.; Yameen, B. A Facile and Versatile Route to Functional Poly(Propylene) Surfaces Via UV-Curable Coatings. React. Funct. Polym. 2019, 144, 104366. [Google Scholar] [CrossRef]

- Gironès, J.; Lopez, J.P.; Vilaseca, F.; Bayer, R.; Herrera-Franco, P.J.; Mutjé, P. Biocomposites from Musa Textilis and Polypropylene: Evaluation of Flexural Properties and Impact Strength. Compos. Sci. Technol. 2011, 71, 122–128. [Google Scholar] [CrossRef]

- Kaewkuk, S.; Sutapun, W.; Jarukumjorn, K. Effects of Interfacial Modification and Fiber Content on Physical Properties of Sisal Fiber/Polypropylene Composites. Compos. Part B Eng. 2013, 45, 544–549. [Google Scholar] [CrossRef]

- Lee, H.J.; Lee, H.K.; Lim, E.; Song, Y.S. Synergistic Effect of Lignin/Polypropylene as A Compatibilizer in Multiphase Eco-Composites. Compos. Sci. Technol. 2015, 118, 193–197. [Google Scholar] [CrossRef]

- Dayo, A.Q.; Zegaoui, A.; Nizamani, A.A.; Kiran, S.; Wang, J.; Derradji, M.; Cai, W.-A.; bin Liu, W. The Influence of Different Chemical Treatments on the Hemp Fiber/Polybenzoxazine Based Green Composites: Mechanical, Thermal and Water Absorption Properties. Mater. Chem. Phys. 2018, 217, 270–277. [Google Scholar] [CrossRef]

- Mulinari, D.R.; Cipriano, J.D.P.; Capri, M.R.; Brandão, A.T. Influence of Surgarcane Bagasse Fibers with Modified Surface on Polypropylene Composites Influence of Surgarcane Bagasse Fibers with Modified Surface on Polypropylene Composites. J. Nat. Fibers 2017, 15, 174–182. [Google Scholar] [CrossRef]

- El-Sabbagh, A. Effect of Coupling Agent on Natural Fibre in Natural Fibre/Polypropylene Composites on Mechanical and Thermal Behavior. Compos. Part B Eng. 2014, 57, 126–135. [Google Scholar] [CrossRef]

- Karmarkar, A.; Chauhan, S.S.; Modak, J.M.; Chanda, M. Mechanical Properties of Wood-Fiber Reinforced Polypropylene Composites: Effect of A Novel Compatibilizer with Isocyanate Functional Group. Compos. Part A 2007, 38, 227–233. [Google Scholar] [CrossRef]

- Liu, W.; Chen, T.; Wen, X.; Qiu, R.; Zhang, X. Enhanced Mechanical Properties and Water Resistance of Bamboo Fiber–Unsaturated Polyester Composites Coupled by Isocyanatoethyl Methacrylate. Wood Sci. Technol. 2014, 48, 1241–1255. [Google Scholar] [CrossRef]

- Chauhan, S.; Aggarwal, P.; Karmarkar, A. The Effectiveness of m-TMI-Grafted-PP as a Coupling Agent for Wood Polymer Composites. J. Compos. Mater. 2016, 50, 3515–3524. [Google Scholar] [CrossRef]

- Nassar, M.M.A.; Munam, A.; Alzebdeh, K.I.; Al Fahdi, R.; Abu Tarboush, B.J. Efficient Methods of Surface Functionalization of Lignocellulosic Waste Toward Surface Clickability Enhancement. Compos. Interfaces 2021, 29, 79–95. [Google Scholar] [CrossRef]

- Sun, M.; Zhang, X.; Chen, W.; Feng, L. Surface Functionalization of Polypropylene-Bearing Isocyanate Groups in Solid State and their Cyclotrimerization with Diisocyanates. J. Appl. Polym. Sci. 2015, 132, 42186. [Google Scholar] [CrossRef]

- Nassar, M.M.A.; Alzebdeh, K.I.; Al-Hinai, N.; Pervez, T. A New Treatment Method for Cellulose-Rich Fibers Toward High Performance Bio-composite Applications. PPU Res. Repos. 2021. Available online: https://scholar.ppu.edu/handle/123456789/2711 (accessed on 1 December 2021).

- Nassar, M.M.A.; Alzebdeh, K.; Munam, A.; Al-Hinai, N.; Pervez, T.; Al-Jahwari, F. Preparation of High-Performance Fiber from Natural Fiber (Date Palm). World Intellectual Property Organization (WIPO) WO2020139088A1, 2020. [Google Scholar]

- Jiang, W.; Han, G.; Zhang, Y.; Wang, M. Fast Compositional Analysis of Ramie Using Near-Infrared Spectroscopy. Carbohydr. Polym. 2010, 81, 937–941. [Google Scholar] [CrossRef]

- Wang, H.; Yao, X.; Sui, G.; Yin, L.; Wang, L. Properties of Xanthoceras Sorbifolia Husk Fibers with Chemical Treatment for Applications in Polymer Composites. J. Mater. Sci. Technol. 2015, 31, 164–170. [Google Scholar] [CrossRef]

- Yin, Z.; Zhang, X.; Yin, J.; Zhang, Y. Synthesis and Characterization of Polypropylene Grafted by Acrylamide. Polym. Plast. Technol. Eng. 1996, 35, 905–915. [Google Scholar] [CrossRef]

- Rahman, N.S.A.; Azahari, B.; Yhaya, M.F.; Ismail, W.R. Crosslinking of Kapok Cellulose Fiber Via Azide Alkyne Click Chemistry as A New Material for Filtering System: A Preliminary Study. Int. J. Adv. Sci. Eng. Inf. Technol. 2016, 6, 16–19. [Google Scholar] [CrossRef] [Green Version]

- Gericke, M.; Schaller, J.; Liebert, T.; Fardim, P.; Meister, F.; Heinze, T. Studies on the Tosylation of Cellulose in Mixtures of Ionic Liquids and A Co-Solvent. Carbohydr. Polym. 2012, 89, 526–536. [Google Scholar] [CrossRef] [PubMed]

- Elchinger, P.H.; Faugeras, P.A.; Zerrouki, C.; Montplaisir, D.; Zerrouki, R.; Brouillette, F.; Zerrouki, R. Tosylcellulose Synthesis in Aqueous Medium. Green Chem. 2012, 14, 3126–3131. [Google Scholar] [CrossRef]

- Krylova, V.; Dukštienė, N. Synthesis and Characterization of Ag2S Layers Formed on Polypropylene. J. Chem. 2013, 2013, 987879. [Google Scholar] [CrossRef] [Green Version]

- Gopanna, A.; Mandapati, R.N.; Thomas, S.P.; Rajan, K.; Chavali, M. Fourier Transform Infrared Spectroscopy (FTIR), Raman Spectroscopy and Wide-Angle X-Ray Scattering (WAXS) of Polypropylene (PP)/Cyclic Olefin Copolymer (COC) Blends for Qualitative and Quantitative Analysis. Polym. Bull. 2019, 76, 4259–4274. [Google Scholar] [CrossRef]

- Shi, J.; Xing, D.; Li, J. FTIR Studies of the Changes in Wood Chemistry from Wood Forming Tissue under Inclined Treatment. Energy Procedia 2012, 16, 758–762. [Google Scholar] [CrossRef] [Green Version]

- Yeo, J.; Seong, D.; Hwang, S. Chemical Surface Modification of Lignin Particle and Its Application as Filler in the Polypropylene Composites. J. Ind. Eng. Chem. 2015, 31, 80–85. [Google Scholar] [CrossRef]

- Tran, L.Q.N.; Fuentes, C.A.; Dupont-gillain, C.; van Vuure, A.W.; Verpoest, I. Understanding the Interfacial Compatibility and Adhesion of Natural Coir Fibre Thermoplastic Composites. Compos. Sci. Technol. 2013, 80, 23–30. [Google Scholar] [CrossRef]

- Mustafa, Z.; Taufiq, M.J.; Mansor, M.R. Influence of Water Absorptivity on Kenaf Fibre Reinforced Recycled-Polymer Composite Properties. Prog. Ind. Ecol. Int. J. 2018, 12, 220–233. [Google Scholar] [CrossRef]

- Amarasekara, A.S.; Ebede, C.C. Bioresource Technology Zinc Chloride Mediated Degradation of Cellulose At 200 °C and Identification of the Products. Bioresour. Technol. 2009, 100, 5301–5304. [Google Scholar] [CrossRef] [Green Version]

- Sun, G.; Kong, X.; Wang, Z.; Luo, Q.; Li, Q. Experimental Investigation into Stamping of Woven CF/PP Laminates: Influences of Molding Temperature on Thermal, Mesoscopic and Macroscopic Properties. Compos. Struct. 2021, 263, 113507. [Google Scholar] [CrossRef]

| Fillers | DPP-UT | DPP-T |

|---|---|---|

| Particle Size (µm2) | 303.8 ± 120.0 | 221.9 ± 104.7 |

| Hemicellulose | 16.57 ± 0.4 | 10.77 ± 0.4 |

| Lignin | 25.02 ± 0.6 | 24.34 ± 1.4 |

| Cellulose | 45.79 ± 0.9 | 64.89 ± 1.3 |

| Pectin | 4.95 ± 0.69 | NA |

| Wax | 5.40 ± 0.28 | NA |

| Water-Soluble Matter | 2.27 ± 0.02 | NA |

| Filler Content (%) | Density (g/cm3) | Water Absorption (%) | Crystallinity Degree (%) | |

|---|---|---|---|---|

| PP | - | 0.902 | 0.016 | 44.8 |

| DPP-UT/PP | 10 | 0.875 | 0.352 | 43.2 |

| 20 | 0.877 | 0.577 | 41.0 | |

| 30 | 0.859 | 0.683 | 41.5 | |

| DPP-T/PP | 10 | 0.883 | 0.286 | 44.5 |

| 20 | 0.879 | 0.459 | 42.5 | |

| 30 | 0.876 | 0.664 | 41.2 | |

| DPP-T/PP-g-IEM | 10 | 0.905 | 0.293 | 45.4 |

| 20 | 0.895 | 0.447 | 46.4 | |

| 30 | 0.883 | 0.595 | 54.2 | |

| (DPP-T)-g-TsCl/PP-g-AcAm | 10 | 0.894 | 0.247 | 33.7 |

| 20 | 0.88 | 0.354 | 36.1 | |

| 30 | 0.881 | 0.413 | 41.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nassar, M.M.A.; Tarboush, B.J.A.; Alzebdeh, K.I.; Al-Hinai, N.; Pervez, T. New Synthesis Routes toward Improvement of Natural Filler/Synthetic Polymer Interfacial Crosslinking. Polymers 2022, 14, 629. https://doi.org/10.3390/polym14030629

Nassar MMA, Tarboush BJA, Alzebdeh KI, Al-Hinai N, Pervez T. New Synthesis Routes toward Improvement of Natural Filler/Synthetic Polymer Interfacial Crosslinking. Polymers. 2022; 14(3):629. https://doi.org/10.3390/polym14030629

Chicago/Turabian StyleNassar, Mahmoud M. A., Belal J. Abu Tarboush, Khalid I. Alzebdeh, Nasr Al-Hinai, and Tasneem Pervez. 2022. "New Synthesis Routes toward Improvement of Natural Filler/Synthetic Polymer Interfacial Crosslinking" Polymers 14, no. 3: 629. https://doi.org/10.3390/polym14030629

APA StyleNassar, M. M. A., Tarboush, B. J. A., Alzebdeh, K. I., Al-Hinai, N., & Pervez, T. (2022). New Synthesis Routes toward Improvement of Natural Filler/Synthetic Polymer Interfacial Crosslinking. Polymers, 14(3), 629. https://doi.org/10.3390/polym14030629