A Potential of New Untreated Bio-Reinforcement from Caesalpinia sappan L. Wood Fiber for Polybutylene Succinate Composite Film

Abstract

:1. Introduction

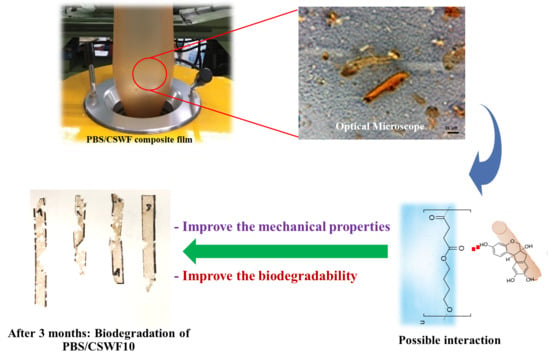

2. Materials and Methods

2.1. Materials

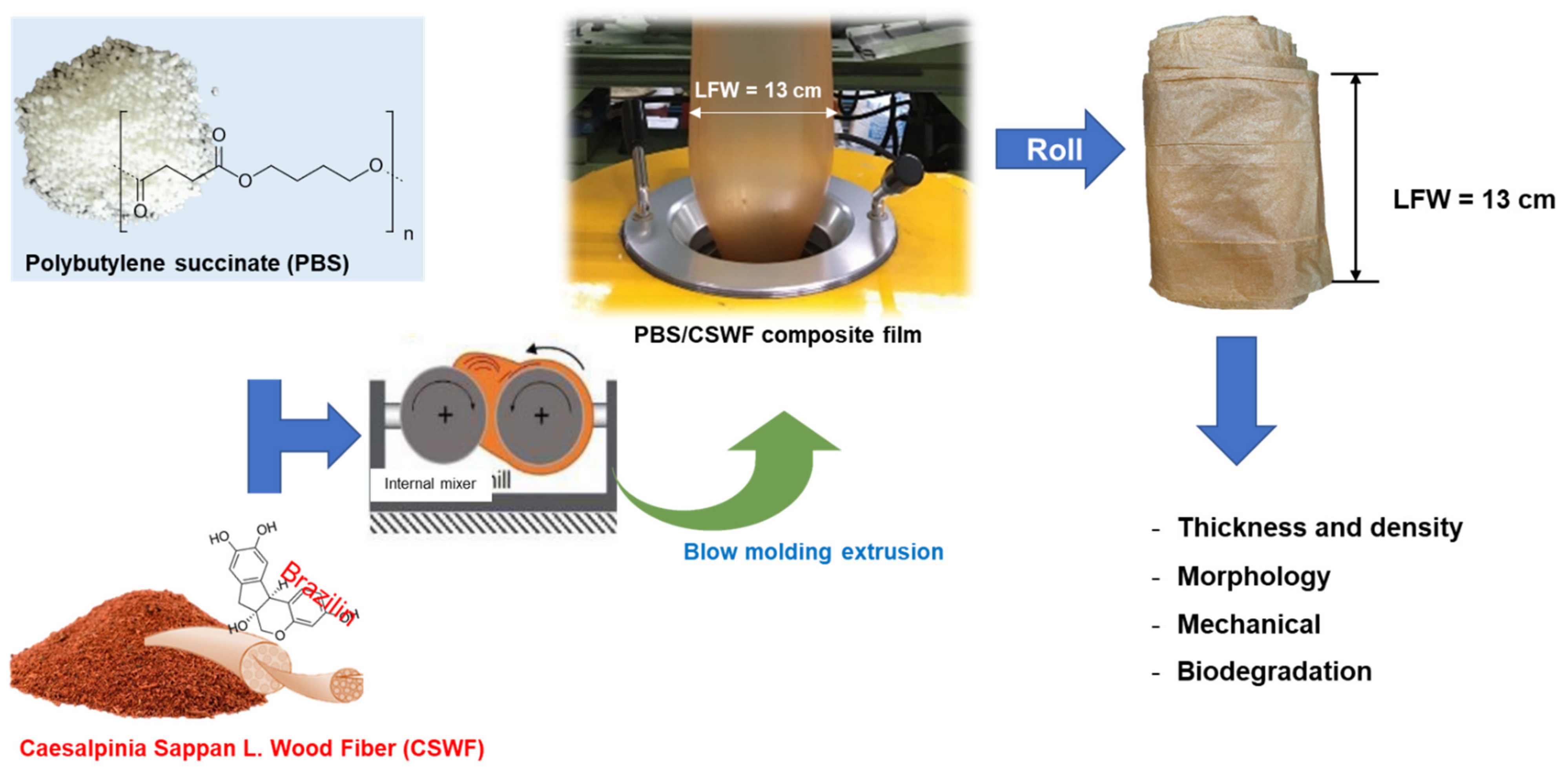

2.2. Method

2.2.1. Preparation of PBS/CSWF Composite Films

2.2.2. Characterization

3. Results and Discussion

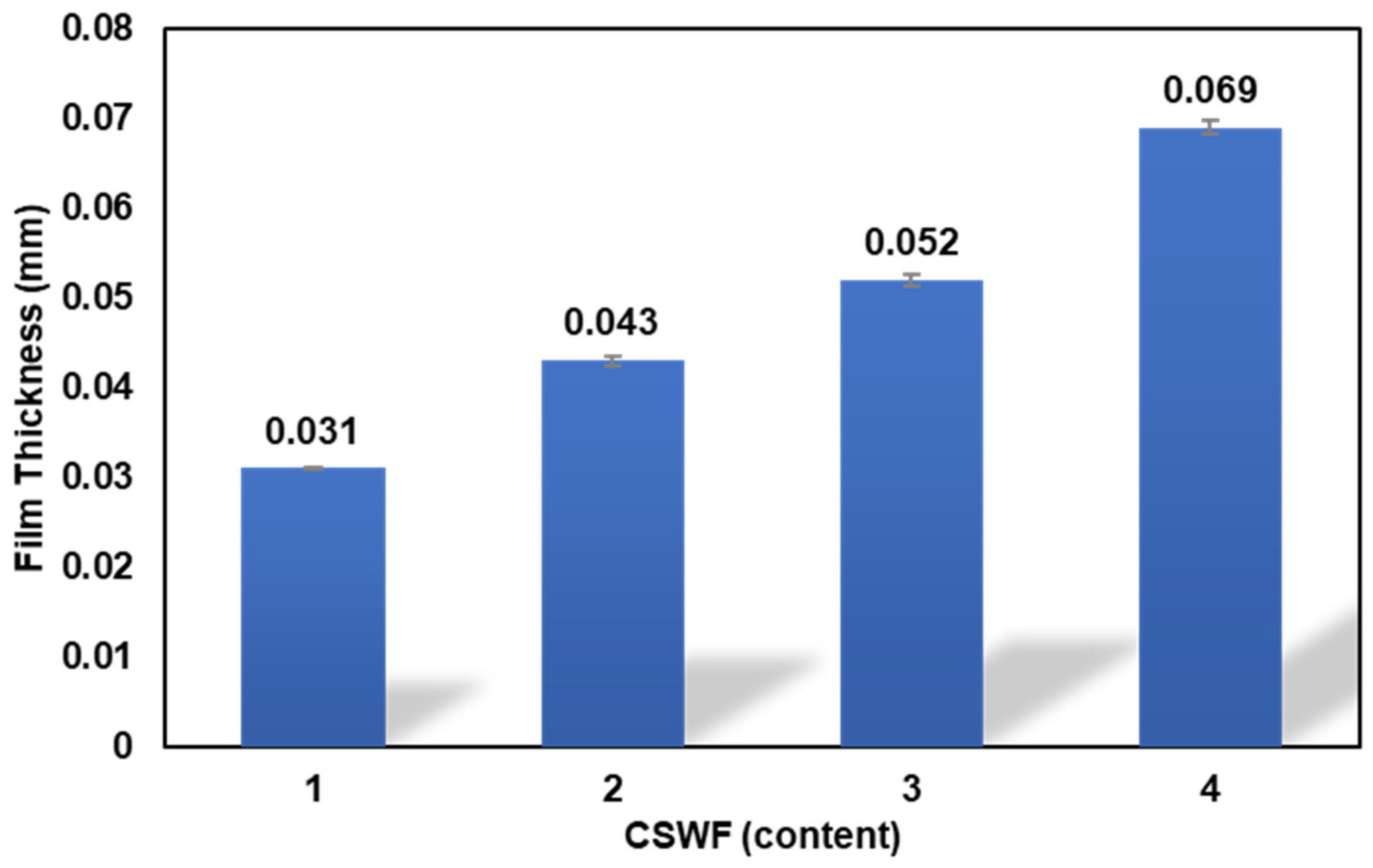

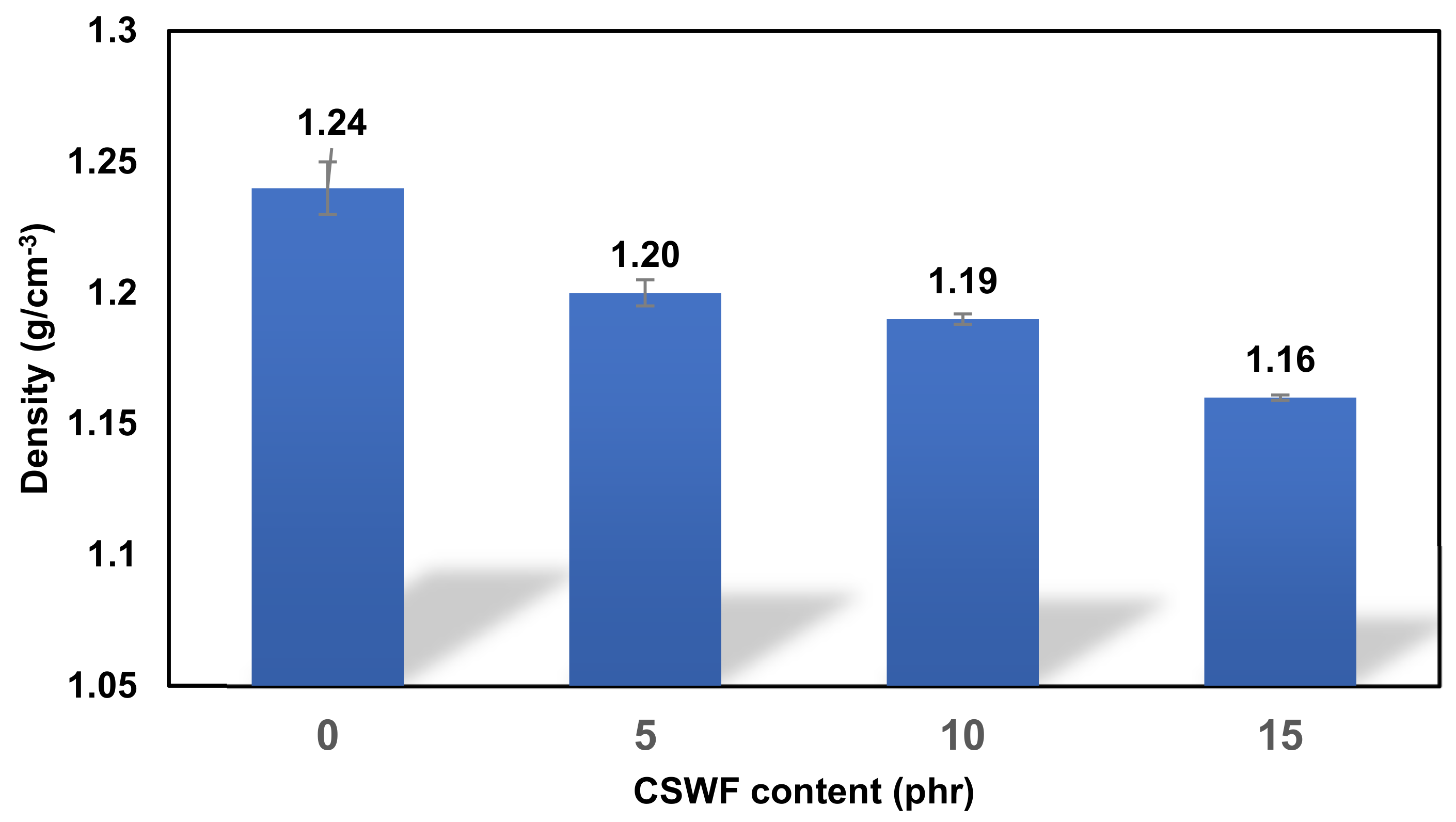

3.1. Properties of PBS/CSWF Composite Films

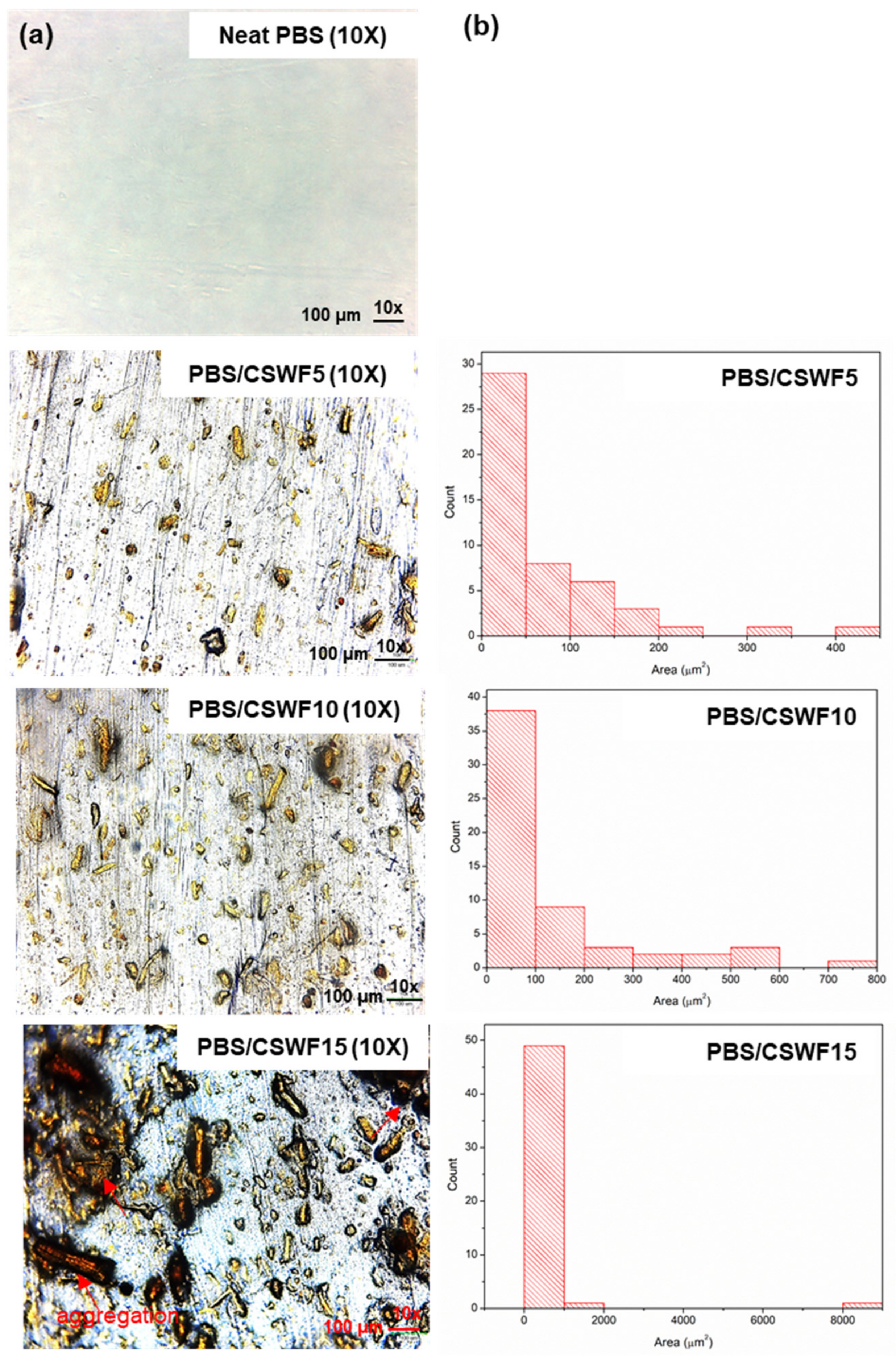

3.2. Morphology of PBS/CSWF Composite Films

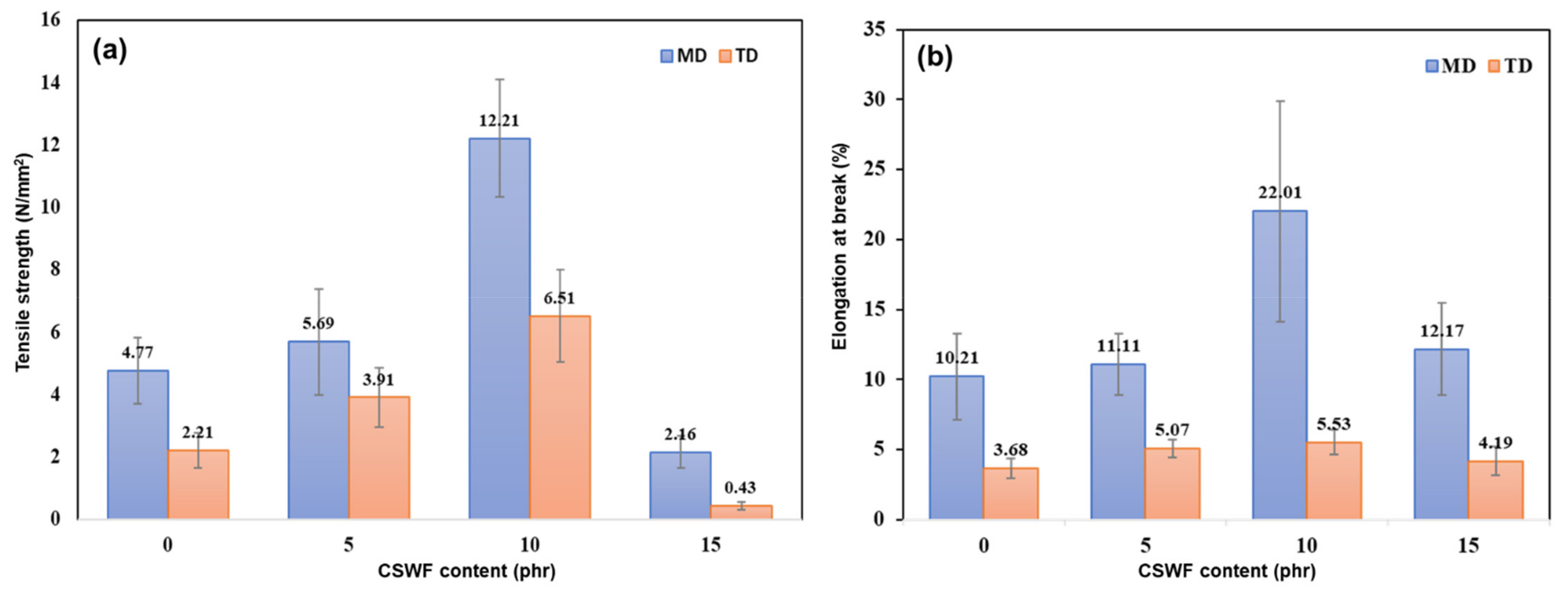

3.3. Mechanical Properties of PBS/CSWF Composite Films

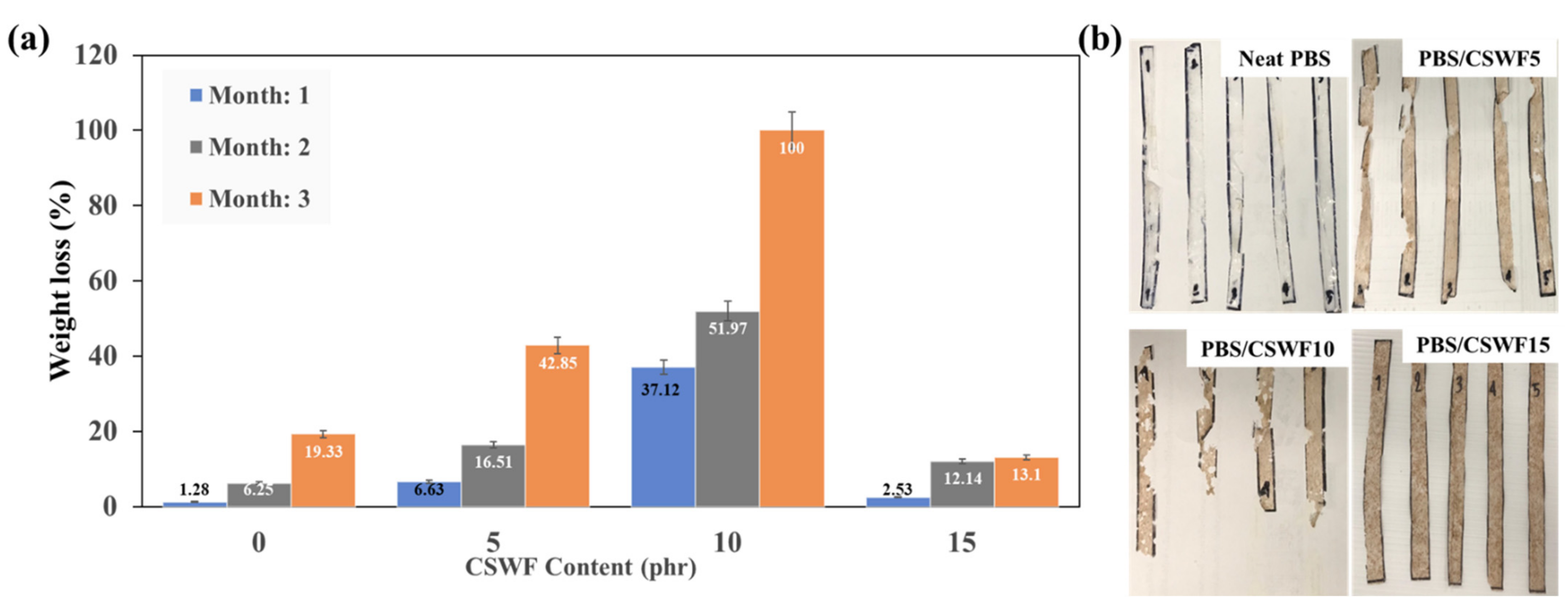

3.4. Biodegradation Properties of PBS/CSWF Composite Films

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Patil, S.S.; Jena, H.M. Performance assessment of polyvinyl chloride films plasticized with Citrullus lanatus seed oil based novel plasticizer. Polym. Test. 2021, 101, 107271. [Google Scholar] [CrossRef]

- Sundar, N.; Kumar, S.A.; Keerthana, P.; Stanley, S.J.; Kumar, G.A. Schiff’s base (SB) modified zirconium dioxide reinforced PLA bio-composite film for industrial packaging applications. Compos. Commun. 2021, 25, 100750. [Google Scholar] [CrossRef]

- Kalogerakis, N.; Karkanorachaki, K.; Kalogerakis, G.C.; Triantafyllidi, E.I.; Gotsis, A.D.; Partsinevelos, P.; Fava, F. Microplastics Generation: Onset of Fragmentation of Polyethylene Films in Marine Environment Mesocosms. Front. Mar. Sci. 2017, 4, 84. [Google Scholar] [CrossRef]

- Rafiqah, S.A.; Khalina, A.; Harmaen, A.S.; Tawakkal, I.A.; Zaman, K.; Asim, M.; Nurrazi, M.N.; Lee, C.H. A Review on Properties and Application of Bio-Based Poly(Butylene Succinate). Polymers 2021, 13, 1436. [Google Scholar] [CrossRef] [PubMed]

- Jost, V. Packaging related properties of commercially available biopolymers—An overview of the status quo. Express Polym. Lett. 2018, 12, 429–435. [Google Scholar] [CrossRef]

- Grigoriadou, I.; Nianias, N.; Hoppe, A.; Terzopoulou, Z.; Bikiaris, D.; Will, J.; Hum, J.; Roether, J.A.; Detsch, R.; Boccaccini, A.R. Evaluation of silica-nanotubes and strontium hydroxyapatite nanorods as appropriate nanoadditives for poly(butylene succinate) biodegradable polyester for biomedical applications. Compos. Part B Eng. 2014, 60, 49–59. [Google Scholar] [CrossRef]

- Goutianos, S.; Arévalo, R.; Sørensen, B.F.; Peijs, T. Effect of Processing Conditions on Fracture Resistance and Cohesive Laws of Binderfree All-Cellulose Composites. Appl. Compos. Mater. 2014, 21, 805–825. [Google Scholar] [CrossRef]

- Tarchoun, A.F.; Trache, D.; Klapötke, T.M.; Abdelaziz, A.; Derradji, M.; Bekhouche, S. Chemical design and characterization of cellulosic derivatives containing high-nitrogen functional groups: Towards the next generation of energetic biopolymers. Def. Technol. 2021. [Google Scholar] [CrossRef]

- Mohammed, A.A.; Bachtiar, D.; Rejab, M.R.M.; Siregar, J.P. Effect of microwave treatment on tensile properties of sugar palm fibre reinforced thermoplastic polyurethane composites. Def. Technol. 2018, 14, 287–290. [Google Scholar] [CrossRef]

- Baley, C.; Kervoëlen, A.; Le Duigou, A.; Goudenhooft, C.; Bourmaud, A. Is the low shear modulus of flax fibres an advantage for polymer reinforcement? Mater. Lett. 2016, 185, 534–536. [Google Scholar] [CrossRef]

- Sun, M.; Wang, H.; Li, X. Modification of cellulose microfibers by polyglutamic acid and mesoporous silica nanoparticles for Enterovirus 71 adsorption. Mater. Lett. 2020, 277, 128320. [Google Scholar] [CrossRef] [PubMed]

- Xu, H.-X.; Lee, S.F. The antibacterial principle of Caesalpina sappan. Phyther. Res. 2004, 18, 647–651. [Google Scholar] [CrossRef] [PubMed]

- Tewtrakul, S.; Tungcharoen, P.; Sudsai, T.; Karalai, C.; Ponglimanont, C.; Yodsaoue, O. Antiinflammatory and Wound Healing Effects of Caesalpinia sappan L. Phyther. Res. 2015, 29, 850–856. [Google Scholar] [CrossRef] [PubMed]

- Ye, M.; Xie, W.D.; Lei, F.; Meng, Z.; Zhao, Y.N.; Su, H.; Du, L.J. Important immunosuppressive component from Caesalpinia sappan L. Int. Immunopharmacol. 2006, 6, 426–432. [Google Scholar] [CrossRef] [PubMed]

| Sample Name | PBS (phr) | CSWF (phr) |

|---|---|---|

| Neat film | 100 | 0 |

| PBS/CSWF5 | 100 | 5 |

| PBS/CSWF10 | 100 | 10 |

| PBS/CSWF15 | 100 | 15 |

| Sample Name | Average Size (μm2) | Total Area (μm2) | Area (%) |

|---|---|---|---|

| PBS/CSWF5 | 74.37 ± 79.91 | 3644 | 10.17 |

| PBS/CSWF10 | 126.26 ± 163.40 | 7323 | 20.22 |

| PBS/CSWF15 | 279.86 ± 1145.97 | 14,273 | 40.03 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martwong, E.; Tran, Y.; Natsrita, N.; Kaewpang, C.; Kongsuk, K.; Nakaramontri, Y.; Sukhawipat, N. A Potential of New Untreated Bio-Reinforcement from Caesalpinia sappan L. Wood Fiber for Polybutylene Succinate Composite Film. Polymers 2022, 14, 499. https://doi.org/10.3390/polym14030499

Martwong E, Tran Y, Natsrita N, Kaewpang C, Kongsuk K, Nakaramontri Y, Sukhawipat N. A Potential of New Untreated Bio-Reinforcement from Caesalpinia sappan L. Wood Fiber for Polybutylene Succinate Composite Film. Polymers. 2022; 14(3):499. https://doi.org/10.3390/polym14030499

Chicago/Turabian StyleMartwong, Ekkachai, Yvette Tran, Nattawadee Natsrita, Chaithip Kaewpang, Kittisak Kongsuk, Yeampon Nakaramontri, and Nathapong Sukhawipat. 2022. "A Potential of New Untreated Bio-Reinforcement from Caesalpinia sappan L. Wood Fiber for Polybutylene Succinate Composite Film" Polymers 14, no. 3: 499. https://doi.org/10.3390/polym14030499

APA StyleMartwong, E., Tran, Y., Natsrita, N., Kaewpang, C., Kongsuk, K., Nakaramontri, Y., & Sukhawipat, N. (2022). A Potential of New Untreated Bio-Reinforcement from Caesalpinia sappan L. Wood Fiber for Polybutylene Succinate Composite Film. Polymers, 14(3), 499. https://doi.org/10.3390/polym14030499