Effect of Graphene Oxide on the Low-Temperature Crack Resistance of Polyurethane–SBS-Modified Asphalt and Asphalt Mixtures

Abstract

1. Introduction

2. Materials and Methods

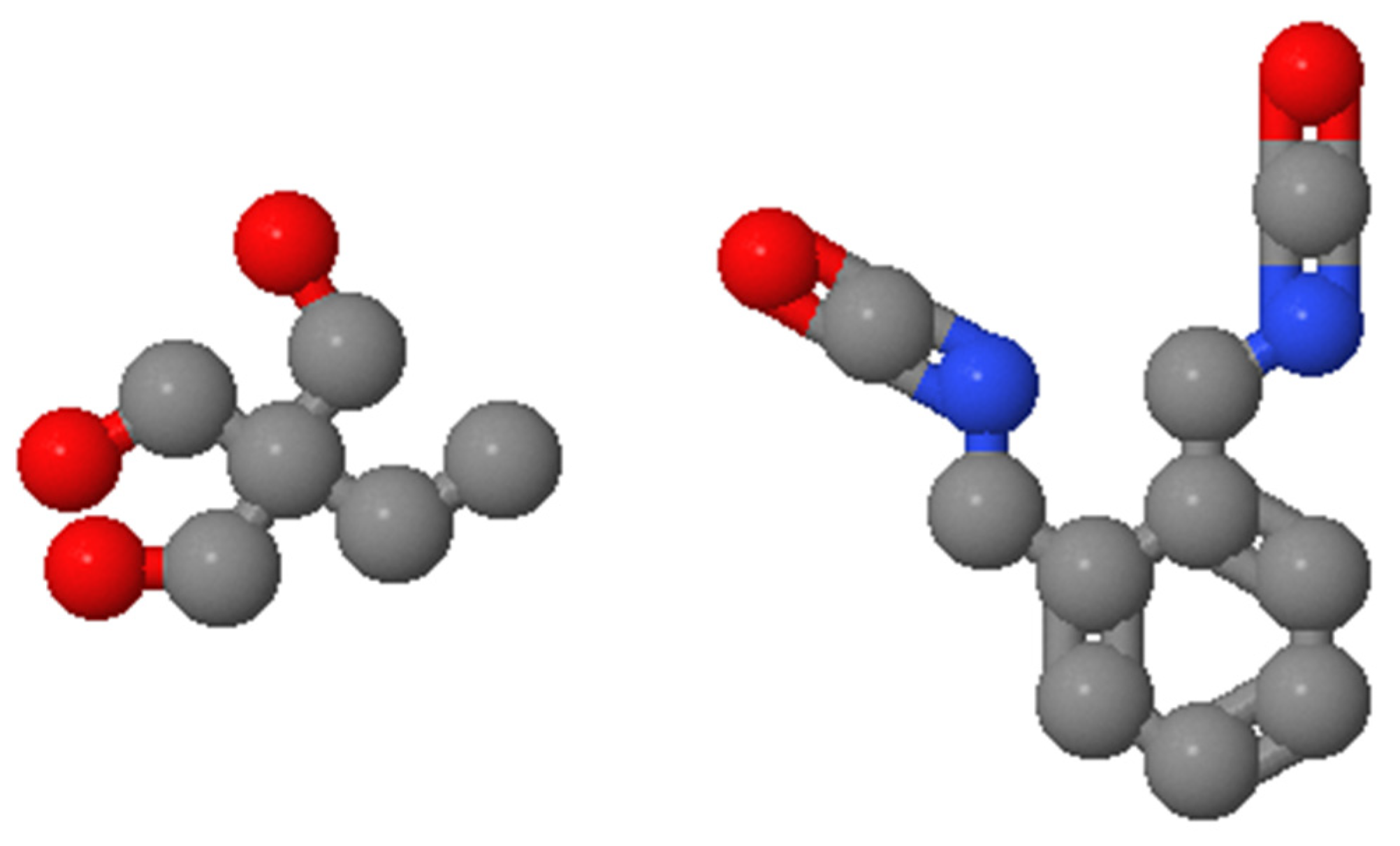

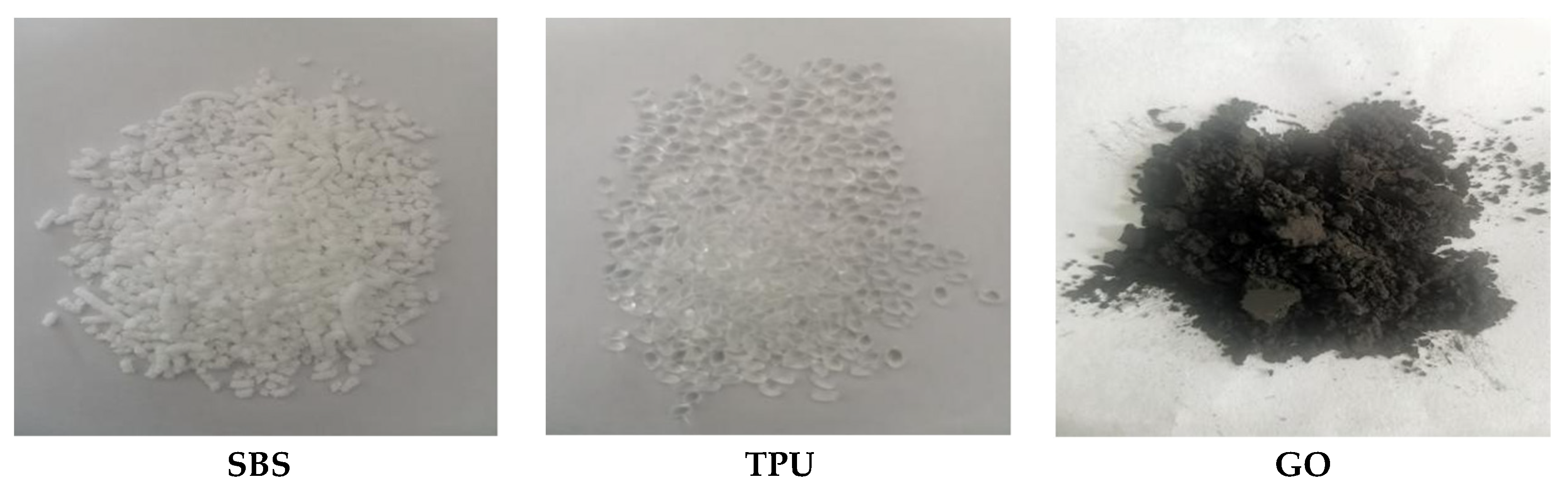

2.1. Raw Materials and Preparation of Samples

2.1.1. Asphalt Raw Materials

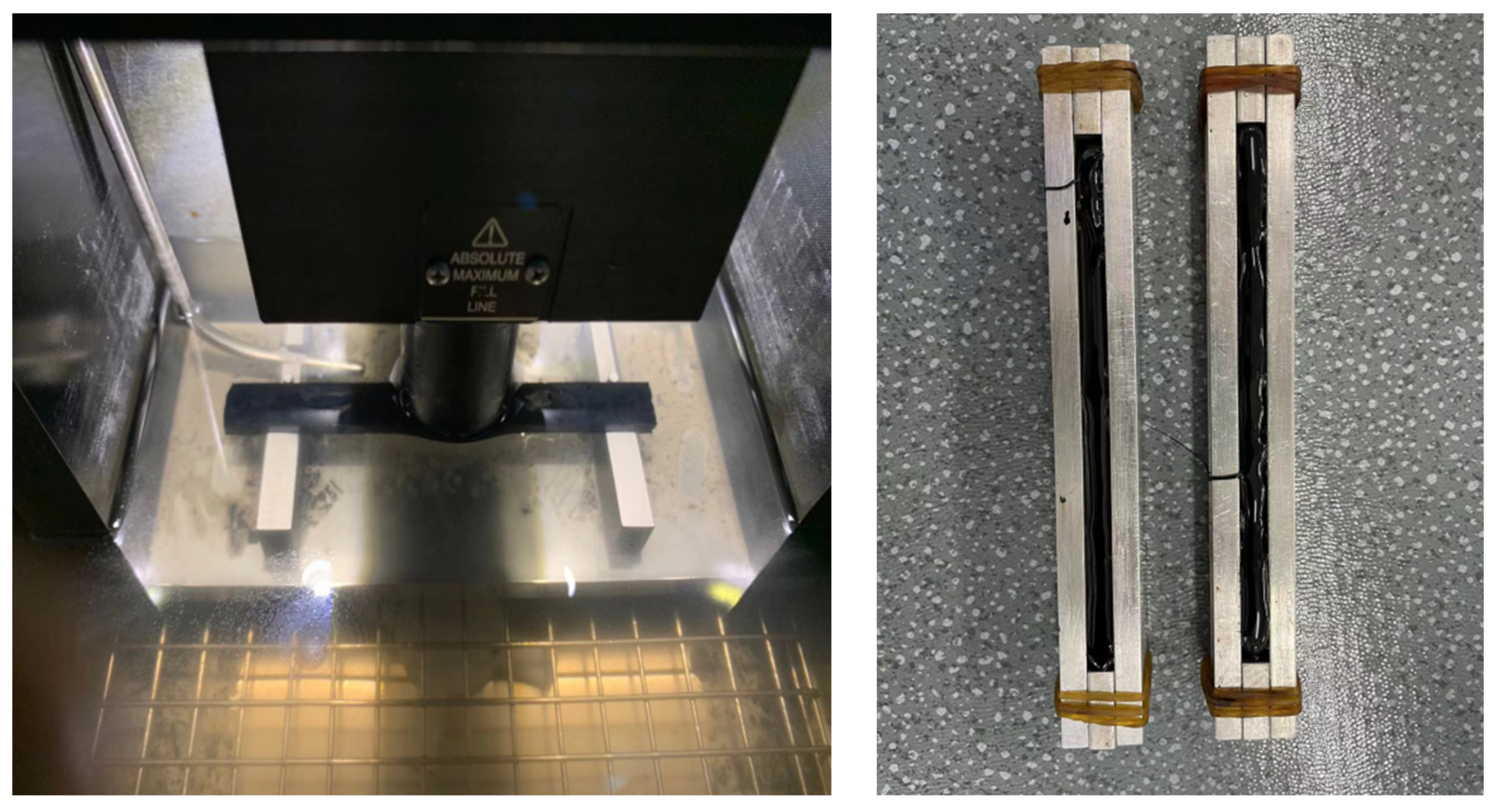

2.1.2. Preparation of TPU–SBS-Modified Asphalt

2.1.3. Preparation of GO–TPU–SBS-Modified Asphalt

2.1.4. Raw Materials for Asphalt Mixes

2.2. Test Methods

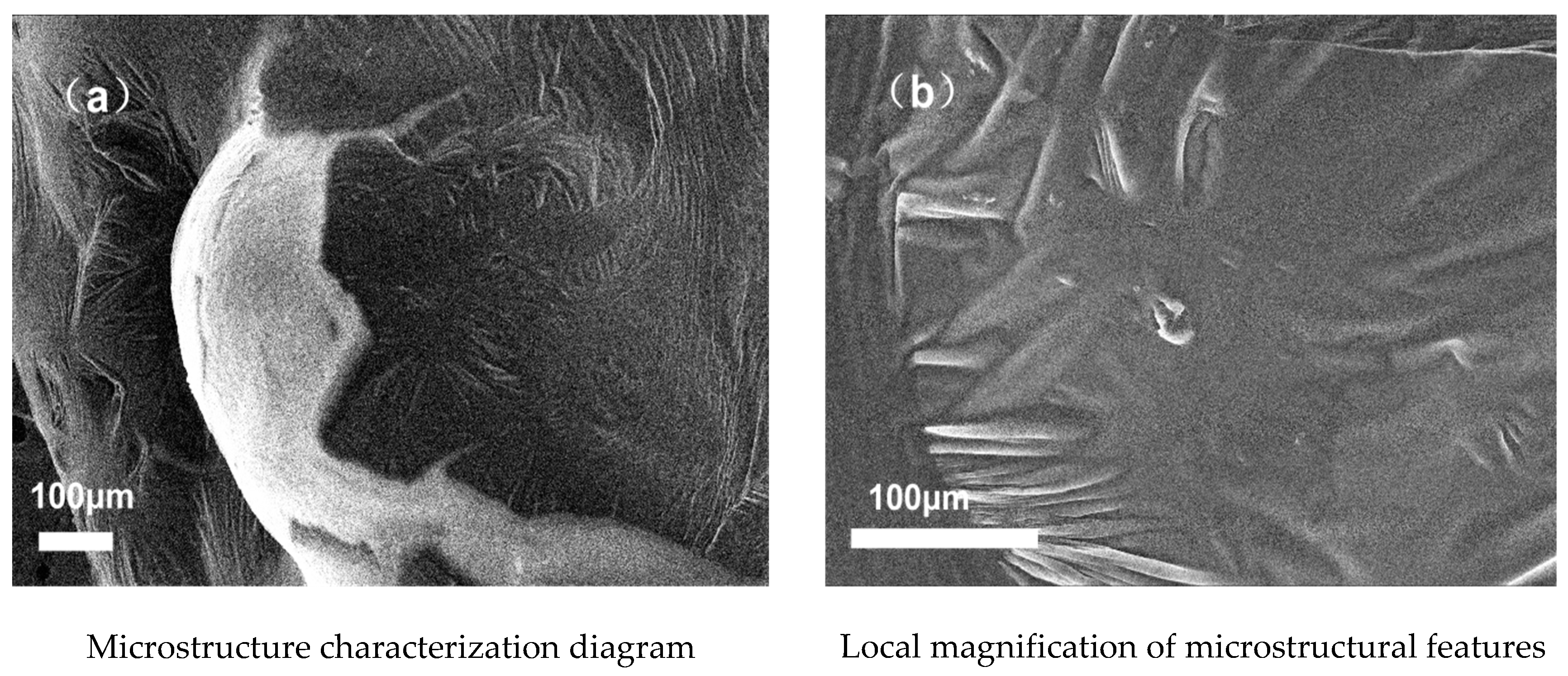

2.2.1. SEM Tests

2.2.2. BBR Test

2.2.3. Low-Temperature Bending Test for Small Beams

2.2.4. OpenCV Image Processing

3. Results and Discussion

3.1. Apparent Morphology

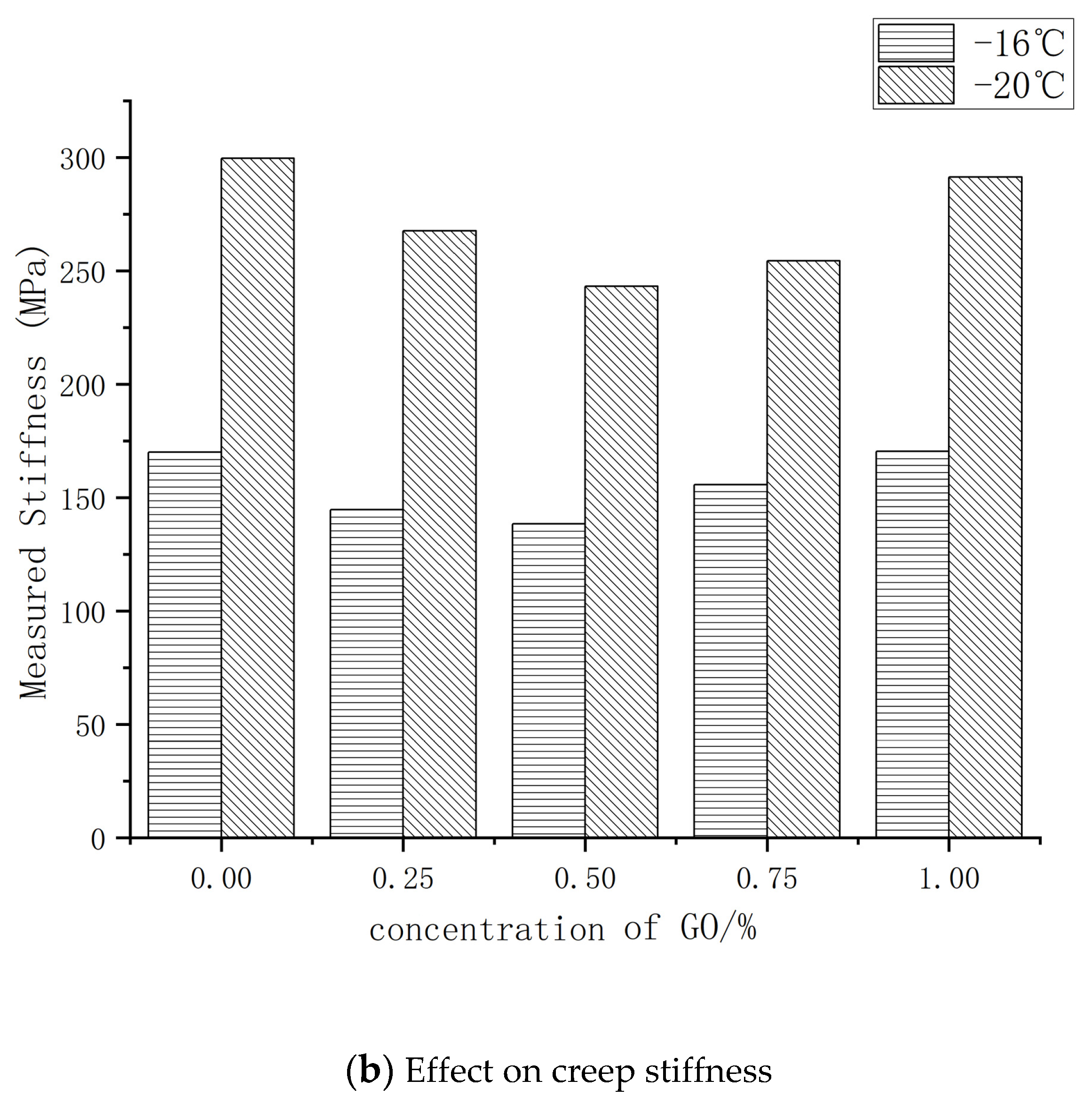

3.2. Effect of Graphene Oxide (GO) on the Low-Temperature Performance of TPU–SBS Asphalt

3.3. Effect of Graphene Oxide (GO) on the Low-Temperature Performance of TPU–SBS Asphalt Mixtures

3.4. OpenCV Image Characterization of the Effect of Graphene Oxide (GO) on the Low-Temperature Cracking of the TPU–SBS Asphalt Mixes

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lin, M.; Wang, Z.L.; Yang, P.W.; Li, P. Micro- structure and rheological properties of graphene oxide rubber asphalt. Nanotechnol. Rev. 2019, 8, 227–235. [Google Scholar] [CrossRef]

- Cong, P.; Liu, N.; Tian, Y.; Zhang, Y. Effects of long-term aging on the properties of asphalt binder containing diatoms. Constr. Build. Mater. 2016, 123, 534–540. [Google Scholar] [CrossRef]

- Chen, B.; Dong, F.; Yu, X.; Zheng, C. Evaluation of Properties and Micro-Characteristics of Waste Polyurethane/Styrene-Butadiene-Styrene Composite Modified Asphalt. Polymers 2021, 13, 2249. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.-S.; Wang, T.J.; Lee, C.-T. Evaluation of a highly-modified asphalt binder for field performance. Constr. Build. Mater. 2018, 171, 539–545. [Google Scholar] [CrossRef]

- Ren, Z.; Zhu, Y.; Wu, Q.; Zhu, M.; Guo, F.; Yu, H.; Yu, J. Enhanced Storage Stability of Different Polymer Modified Asphalt Binders through Nano-Montmorillonite Modification. Nanomaterials 2020, 10, 641. [Google Scholar] [CrossRef]

- Wu, S.; Zhao, Z.; Li, Y.; Pang, L.; Amirkhanian, S.; Riara, M. Evaluation of Aging Resistance of Graphene Oxide Modified Asphalt. Appl. Sci. 2017, 7, 702. [Google Scholar] [CrossRef]

- Singh, B.B.; Mohanty, F.; Das, S.S.; Swain, S.K. Graphene sandwiched crumb rubber dispersed hot mix asphalt. J. Traffic Transp. Eng. 2020, 7, 652–667. [Google Scholar] [CrossRef]

- Hu, K.; Yu, C.; Yang, Q.; Chen, Y.; Chen, G.; Ma, R. Multi–scale enhancement mechanisms of graphene oxide on styrene–butadiene–styrene modified asphalt: An exploration from molecular dynamics simulations. Mater. Des. 2021, 208, 109901. [Google Scholar] [CrossRef]

- Fakhri, M.; Shahryari, E. The effects of nano zinc oxide (ZnO) and nano reduced graphene oxide (RGO) on moisture susceptibility property of stone mastic asphalt (SMA). Case Stud. Constr. Mater. 2021, 15, e00655. [Google Scholar] [CrossRef]

- Ma, Y.-W.; Zhao, H.-Y.; Li, G.; Wang, Z.-J.; Tang, H.; Wang, A.-Q. Property Improvement of Cement Emulsified Asphalt Paste Modified by Graphene Oxide. Adv. Mater. Sci. Eng. 2020, 2020, 3462342. [Google Scholar] [CrossRef]

- Van der Merwe, W.J. Research and Application of Nanotechnology in Transportation. 2008. Available online: https://repository.up.ac.za/bitstream/handle/2263/6352/Steyn.pdf (accessed on 18 December 2021).

- Zhang, C.; Wang, H.; You, Z.; Gao, J.; Irfan, M. Performance Test on Styrene-Butadiene-Styrene (SBS) Modified Asphalt Based on the Different Evaluation Methods. Appl. Sci. 2019, 9, 467. [Google Scholar] [CrossRef]

- Yu, R.; Zhu, X.; Zhang, M.; Fang, C. Investigation on the Short-Term Aging-Resistance of Thermoplastic Polyurethane-Modified Asphalt Binders. Polymers 2018, 10, 1189. [Google Scholar] [CrossRef] [PubMed]

- Yu, R.; Wang, Q.; Wang, W.; Xiao, Y.; Wang, Z.; Zhou, X.; Zhang, X.; Zhu, X.; Fang, C. Polyurethane/graphene oxide nanocomposite and its modified asphalt binder: Preparation, properties and molecular dynamics simulation. Mater. Des. 2021, 209, 109994. [Google Scholar] [CrossRef]

- Li, X.; Wang, Y.-M.; Wu, Y.-L.; Wang, H.-R.; Chen, M.; Sun, H.-D.; Fan, L. Properties and modification mechanism of asphalt with graphene as modifier. Constr. Build. Mater. 2021, 272, 121919. [Google Scholar] [CrossRef]

- Liu, J.; Hao, P.; Jiang, W.; Sun, B. Rheological properties of SBS modified asphalt incorporated polyvinylpyrrolidone stabilized graphene nanoplatelets. Constr. Build. Mater. 2021, 298, 123850. [Google Scholar] [CrossRef]

- Le, J.-L.; Marasteanu, M.O.; Turos, M. Mechanical and compaction properties of graphite nanoplatelet-modified asphalt binders and mixtures. Road Mater. Pavement Des. 2020, 21, 1799–1814. [Google Scholar] [CrossRef]

- Wang, R.; Yue, M.; Xiong, Y.; Yue, J. Experimental study on mechanism, aging, rheology and fatigue performance of carbon nanomaterial/SBS-modified asphalt binders. Constr. Build. Mater. 2021, 268, 121189. [Google Scholar] [CrossRef]

- Li, J.; Duan, S.; Muhammad, Y.; Yang, J.; Meng, F.; Zhu, Z.; Liu, Y. Microwave assisted fabrication of polymethyl methacrylate-graphene composite nanoparticles applied for the preparation of SBS modified asphalt with enhanced high temperature performance. Polym. Test. 2020, 85, 106388. [Google Scholar] [CrossRef]

- Wei, H.; Bai, X.; Qian, G.; Wang, F.; Li, Z.; Jin, J.; Zhang, Y. Aging Mechanism and Properties of SBS Modified Bitumen under Complex Environmental Conditions. Materials 2019, 12, 1189. [Google Scholar] [CrossRef]

- Hong, W.; Li, Q.; Guan, G.; Di, Y.; Sun, J.; Jiao, T.; Xing, G. Research on the Microstructure and Property of an Anion Rubber Modified Asphalt. J. Nanomater. 2013, 2013, 30. [Google Scholar] [CrossRef]

- Alghrafy, Y.M.; Alla, E.-S.M.A.; El-Badawy, S.M. Rheological properties and aging performance of sulfur extended asphalt modified with recycled polyethylene waste. Constr. Build. Mater. 2021, 273, 121771. [Google Scholar] [CrossRef]

- Ren, S.; Liu, X.; Wang, H.; Fan, W.; Erkens, S. Evaluation of rheological behaviors and anti-aging properties of recycled asphalts using low-viscosity asphalt and polymers. J. Clean. Prod. 2020, 253, 120048. [Google Scholar] [CrossRef]

- Wu, J.; Hong, R.; Gu, C. Influence of Fiber Type on Low-Temperature Fracture Performance of Presawed Asphalt Mixture Beams. Adv. Mater. Sci. Eng. 2018, 2018, 5087395. [Google Scholar] [CrossRef]

- Yu, Q.; Cheng, H.H.; Cheng, W.W.; Zhou, X. Ch OpenCV for interactive open architecture computer vision. Adv. Eng. Softw. 2004, 35, 527–536. [Google Scholar] [CrossRef][Green Version]

- Dai, J.; Lang, M. Preparation and Mechanical Properties of Graphene Oxide/PMMA and Surface-functionalized Graphene/PMMA Composites. Acta Chim. Sin. 2012, 70, 1237–1244. [Google Scholar] [CrossRef][Green Version]

- Pszczola, M.; Jaczewski, M.; Rys, D.; Jaskula, P.; Szydlowski, C. Evaluation of Asphalt Mixture Low-Temperature Performance in Bending Beam Creep Test. Materials 2018, 11, 100. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.-R.; Li, F.; Ma, Q.-Y. Effect of Polyester Fiber on Air Voids and Low-Temperature Crack Resistance of Permeable Asphalt Mixture. Adv. Civ. Eng. 2020, 2020, 2381504. [Google Scholar] [CrossRef]

- Zhang, P.; Ouyang, L.; Yang, L.; Yang, Y.; Lu, G.; Huang, T. Laboratory Investigation of Carbon Black/Bio-Oil Composite Modified Asphalt. Materials 2021, 14, 4910. [Google Scholar] [CrossRef]

- Chong, Z.Z.; Tor, S.B.; Ganan-Calvo, A.; Loh, N.H.; Nguyen, N.-T.; Tan, S.H. Automated droplet measurement (ADM): An enhanced video processing software for rapid droplet measurements. Microfluid. Nanofluid. 2016, 20, 66. [Google Scholar] [CrossRef]

| Test Results | Technical Requirements (Reference GTGF40-2004) | |

|---|---|---|

| Penetration (0.1 mm) | 87.7 | 80–100 |

| Softening point (Global Method) (°C) | 47.2 | ≥45 |

| Ductility (cm) | 46.5 | ≥45 |

| Solubility (%) | 102.3 | ≥99.9 |

| Dynamic viscosity at 60 °C (Pa∙s) | 177.7 | ≥160 |

| Type | S/B Ratio | Oil Filling Rate (%) | Volatile Components (≤%) | Ash (≤%) | 300% Tensile Stress (≥MPa) | Tensile Strength (≥MPa) | Elongation at Tear (≥%) | Tear off Permanent (≤%) | Shore Hardness (A) | Melt Flow Rate (g/10 min) |

|---|---|---|---|---|---|---|---|---|---|---|

| SBSYH-792E | 40/60 | 0 | 0.7 | 0.2 | 3.5 | 24 | 730 | 55 | ≥85 | 0.10–5.00 |

| Symbol | Detection of Typical Values | |

|---|---|---|

| Place of Origin | Qitaihe City, Heilongjiang Province, China | |

| Place of Origin | Black powder | |

| Oxygen level | % | 44.88 |

| Particle size | D50 (μ) | 30.22 |

| Thickness | (μh) | <5 |

| Specific surface area | m2·g−1 | >500 |

| Particle Size | 10–20 mm | 5–10 mm | 3–5 mm | 0–3 mm | Mineral Powder | Upper Grading Limit | Lower Grading Limit | Median Gradation | Composite Gradation |

|---|---|---|---|---|---|---|---|---|---|

| 19 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| 16 | 86.1 | 100 | 100 | 100 | 100 | 100 | 90 | 95 | 97.1 |

| 13.2 | 45.8 | 100 | 100 | 100 | 100 | 92 | 76 | 84 | 88.6 |

| 9.5 | 0.74 | 94.2 | 100 | 100 | 100 | 80 | 60 | 70 | 76.9 |

| 4.75 | 0.5 | 8.5 | 92.1 | 100 | 100 | 62 | 34 | 48 | 42.9 |

| 2.36 | 0 | 0.5 | 11.1 | 89.4 | 100 | 48 | 20 | 34 | 30.6 |

| 1.18 | 0 | 0 | 3.5 | 68.2 | 100 | 36 | 13 | 24.5 | 23.1 |

| 0.6 | 0 | 0 | 1.6 | 51.7 | 100 | 26 | 9 | 17.5 | 17.7 |

| 0.3 | 0 | 0 | 0 | 36.1 | 99 | 18 | 7 | 12.5 | 12.7 |

| 0.15 | 0 | 0 | 0 | 27.1 | 94.4 | 14 | 5 | 9.5 | 9.7 |

| 0.075 | 0 | 0 | 0 | 16.8 | 75.7 | 8 | 4 | 6 | 6.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Xu, W.; Zhang, F.; Wu, H.; Zhao, P. Effect of Graphene Oxide on the Low-Temperature Crack Resistance of Polyurethane–SBS-Modified Asphalt and Asphalt Mixtures. Polymers 2022, 14, 453. https://doi.org/10.3390/polym14030453

Li S, Xu W, Zhang F, Wu H, Zhao P. Effect of Graphene Oxide on the Low-Temperature Crack Resistance of Polyurethane–SBS-Modified Asphalt and Asphalt Mixtures. Polymers. 2022; 14(3):453. https://doi.org/10.3390/polym14030453

Chicago/Turabian StyleLi, Shuai, Wenyuan Xu, Fengfa Zhang, He Wu, and Pengchao Zhao. 2022. "Effect of Graphene Oxide on the Low-Temperature Crack Resistance of Polyurethane–SBS-Modified Asphalt and Asphalt Mixtures" Polymers 14, no. 3: 453. https://doi.org/10.3390/polym14030453

APA StyleLi, S., Xu, W., Zhang, F., Wu, H., & Zhao, P. (2022). Effect of Graphene Oxide on the Low-Temperature Crack Resistance of Polyurethane–SBS-Modified Asphalt and Asphalt Mixtures. Polymers, 14(3), 453. https://doi.org/10.3390/polym14030453